Gas guiding unit, gas guiding device, pulverized coal pyrolysis device and method

A technology of gas guiding unit and gas guiding device, which is applied in the field of gas guiding unit, gas guiding device, and pulverized coal pyrolysis device, and can solve the problems of low thermal efficiency of heating and cooling cycle gas, low comprehensive energy consumption of vertical furnace, and difficult gas discharge, etc. problems, to achieve the effects of low overflow speed, low ash content of coke powder, and slow pyrolysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

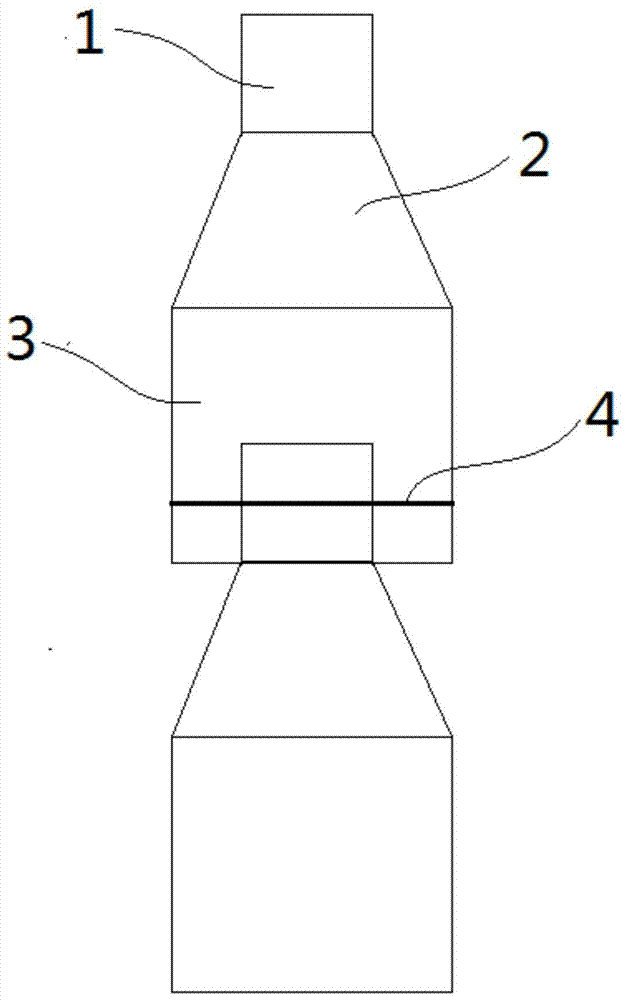

[0042] refer to figure 1 , the air guide device of this embodiment includes a plurality of air guide units, each air guide unit includes an upper vent 1, a lower vent 3 and a vent pipe 2, wherein the upper and lower vents are circular tube structures, and the vent pipe 2 is a conical tube.

[0043] Suspension connection is adopted between the connected air guide units, that is, a suspension rod 4 is installed in the lower air vent of the upper air guide unit, and a through hole is opened on the side wall of the upper air vent of the lower air guide unit, and through the air guide unit The holes are suspended from the suspension rod such that adjacent lower vents form side air intakes between lower vents. Adjacent air guide units are connected by suspension, with a certain degree of deflection between them, which is beneficial to avoid blockage of the air guide pipe when the coal material goes down.

[0044] In this embodiment, the height of the upper air vent is 40 mm, and t...

Embodiment 2

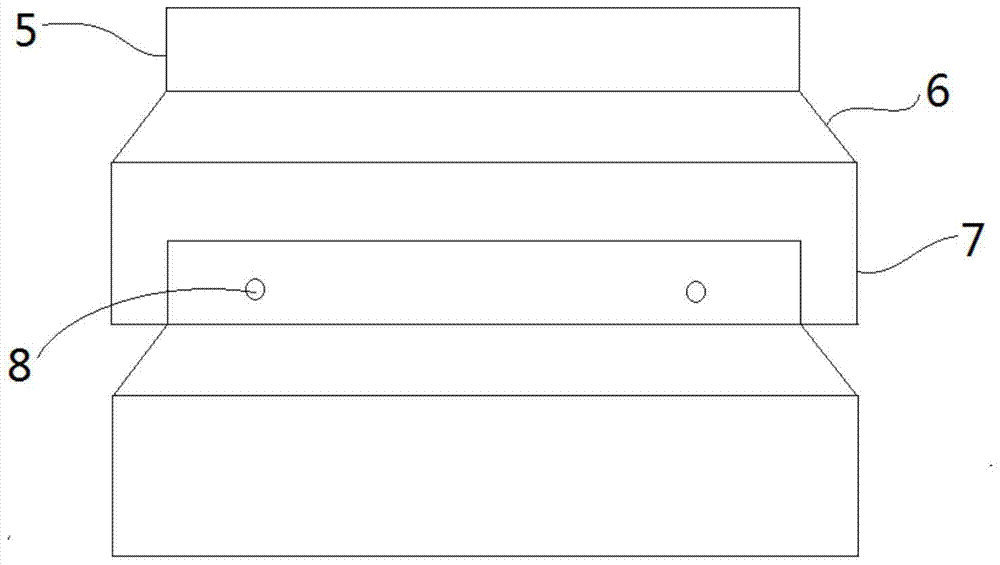

[0046] Such as figure 2 As shown, the air guide device of this embodiment includes a plurality of air guide units, and each air guide unit includes an upper vent 5, a lower vent 7 and a vent pipe 6, wherein the upper and lower vents are box-type structures, and The trachea 6 is in the shape of a truncated cone. The same connection between the connected air guide units adopts suspension rods 8 to connect.

[0047] The size of the upper vent in this embodiment is 60X1400mm; the height of the vent pipe is 100mm; the size of the lower vent is 120X1500mm.

Embodiment 3

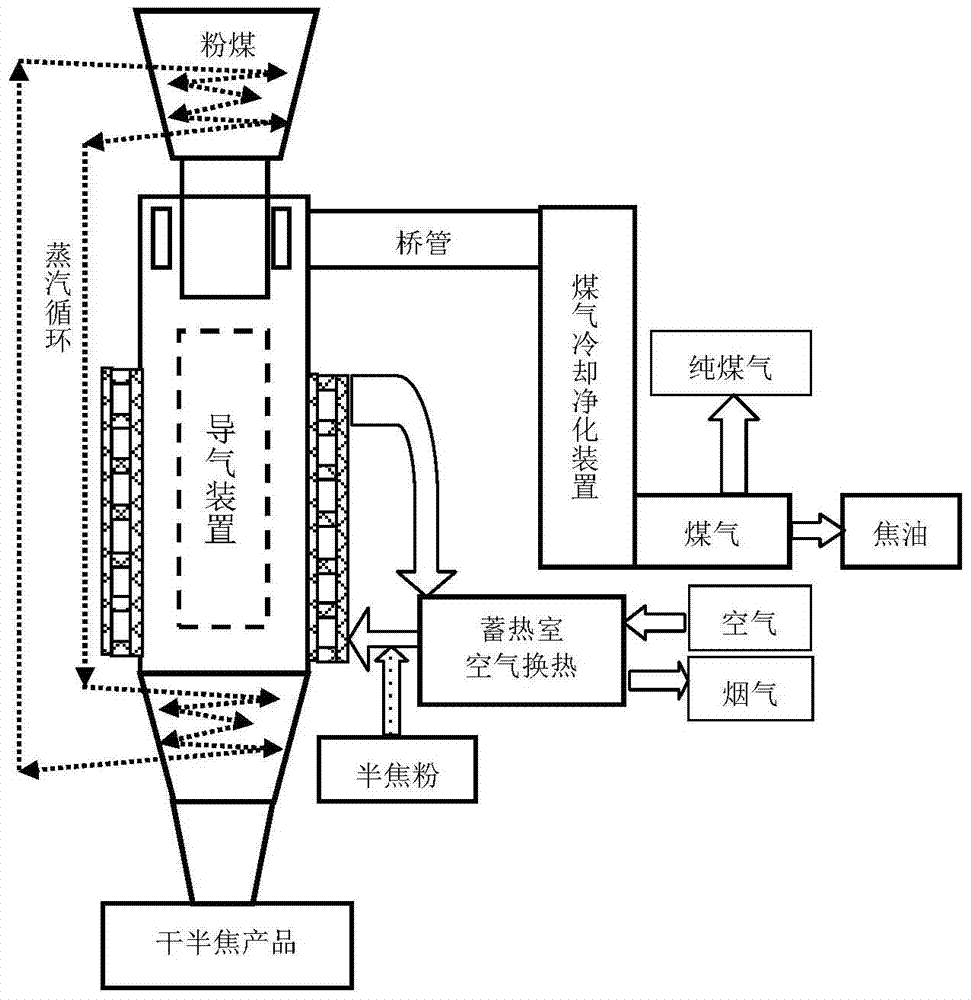

[0049] refer to image 3 , the pulverized coal pyrolysis device of this embodiment includes a raw coal preheating device, a pulverized coal pyrolysis furnace, a semi-coke product cooling device and a semi-coke powder combustion furnace, such as Figure 4 As shown, in the pulverized coal pyrolysis furnace 9, a gas guiding device 10 described in Embodiment 1 is set every 0.5-1 meter along the width, and the taper of the conical section of the gas guiding device ensures that the pulverized coal falls naturally, and the side of the gas The inlet is not blocked by the descending coal material, which is conducive to the introduction of raw gas, and also prevents the coal material in the carbonization chamber from entering the gas guide pipe through the gas introduction hole 4 .

[0050] The steam generated when the raw coal is cooled in the raw coal preheating device is indirectly heated;

[0051]In the pyrolysis furnace, the high-temperature flue gas generated by the combustion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com