Patents

Literature

41results about How to "Reduce blowby" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

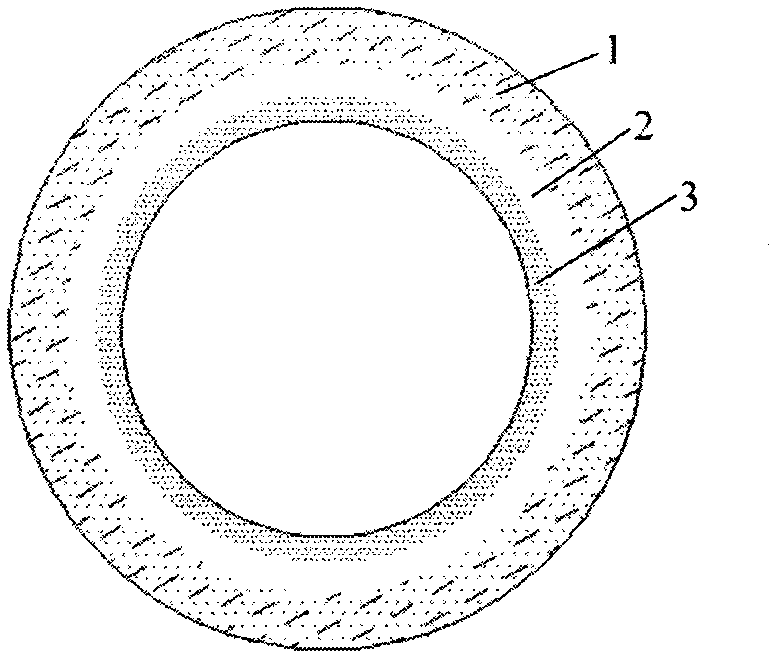

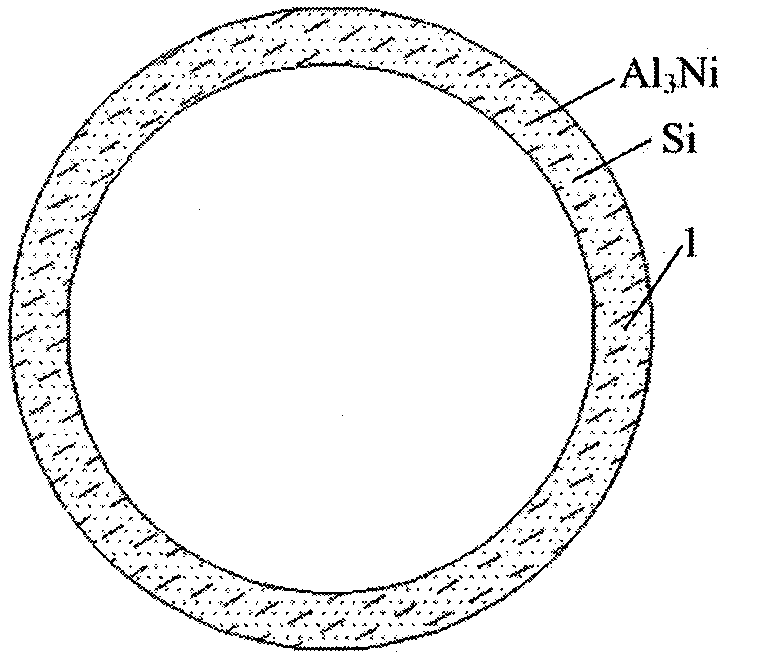

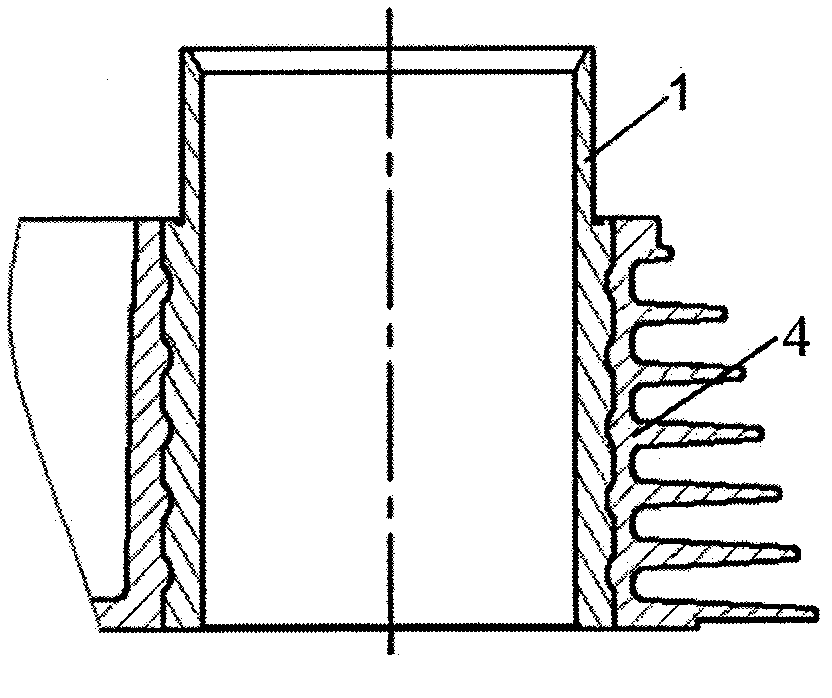

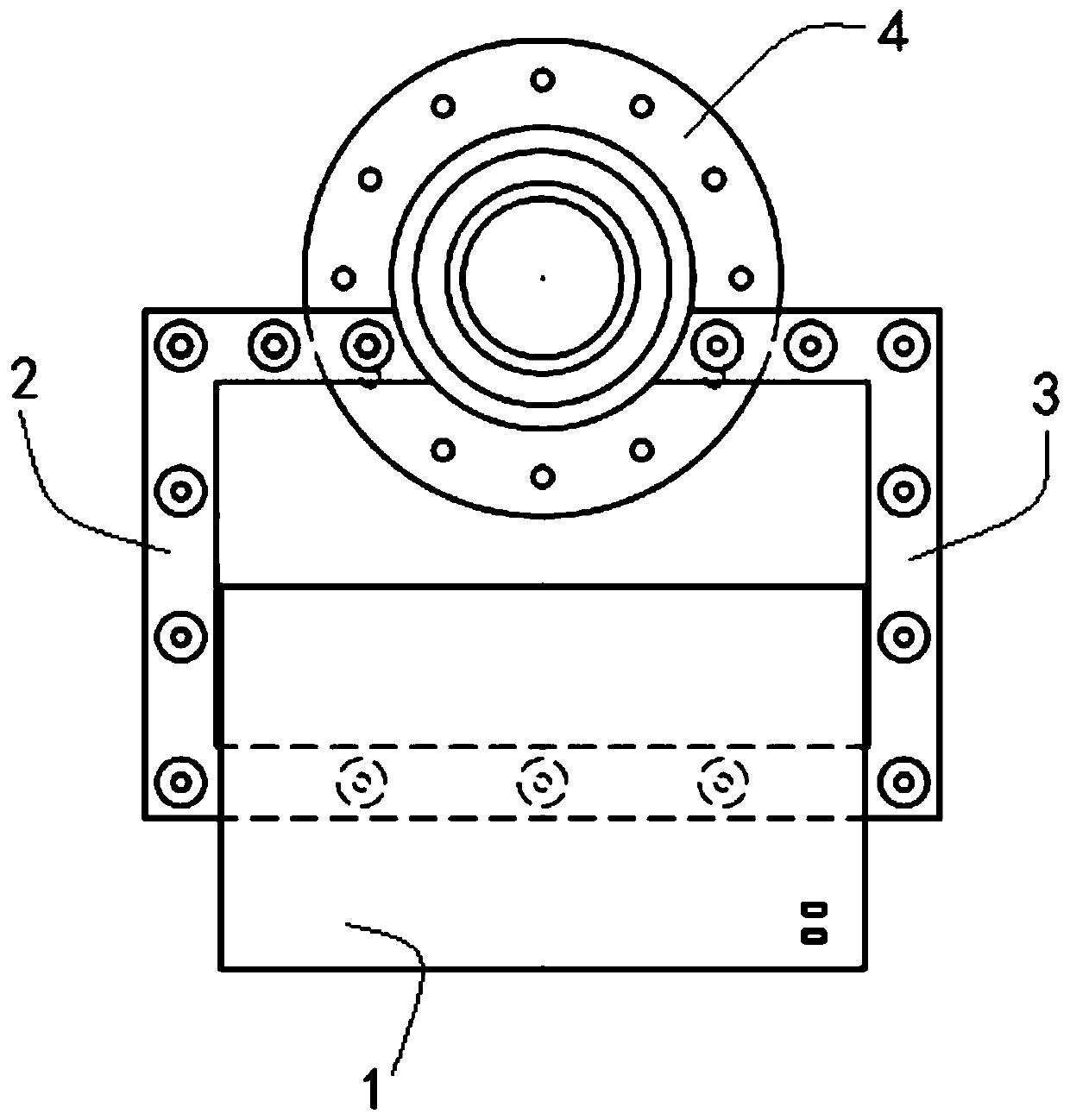

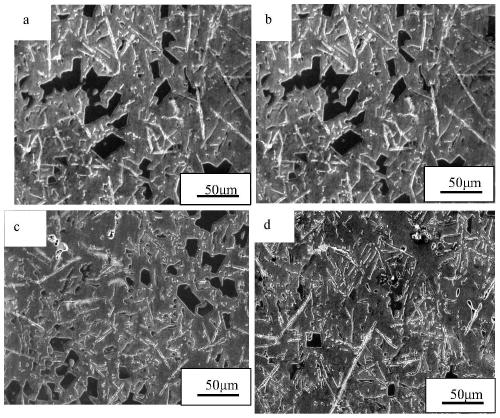

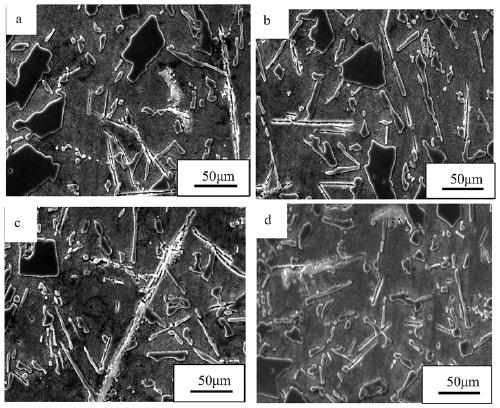

Self-generated mixed particle-reinforced aluminum alloy cylinder sleeve and preparation method thereof

InactiveCN102358928AExtended service lifeImprove bindingCylinder headsCylindersTemperature resistanceInternal combustion engine

The invention discloses a self-generated mixed particle-reinforced aluminum alloy cylinder sleeve and a preparation method thereof. The self-generated mixed particle-reinforced aluminum alloy cylinder sleeve comprises an aluminum alloy and certain amounts of Ni and Si. The preparation method of the self-generated mixed particle-reinforced aluminum alloy cylinder sleeve comprises the following steps that in alloy solidification, Al3Ni particles first separated out from melt can push a part of Si primary crystal particles to move outward with the Al3Ni particles under the action of a centrifugal force; a cannular blank casting is obtained, wherein the cannular blank casting has an outer segregation layer containing a mass of primary Al3Ni and Si primary crystal mixed particles, an inner segregation layer containing Si primary crystal particles, and a middle base layer; and the inner segregation layer and the middle base layer of the cannular blank casting are removed by turning and the outer segregation layer having a high volume fraction is left so that the self-generated mixed particle-reinforced aluminum alloy cylinder sleeve is obtained. The self-generated mixed particle-reinforced aluminum alloy cylinder sleeve and an aluminum cylinder can be subjected to compression casting assembly molding and then are processed into an all-aluminum internal-combustion engine through machining and assembling. The self-generated mixed particle-reinforced aluminum alloy cylinder sleeve has light weight, high particle volume percentage content and excellent wear resistance and high-temperature resistance, and can improve engine work efficiency.

Owner:CHONGQING UNIV

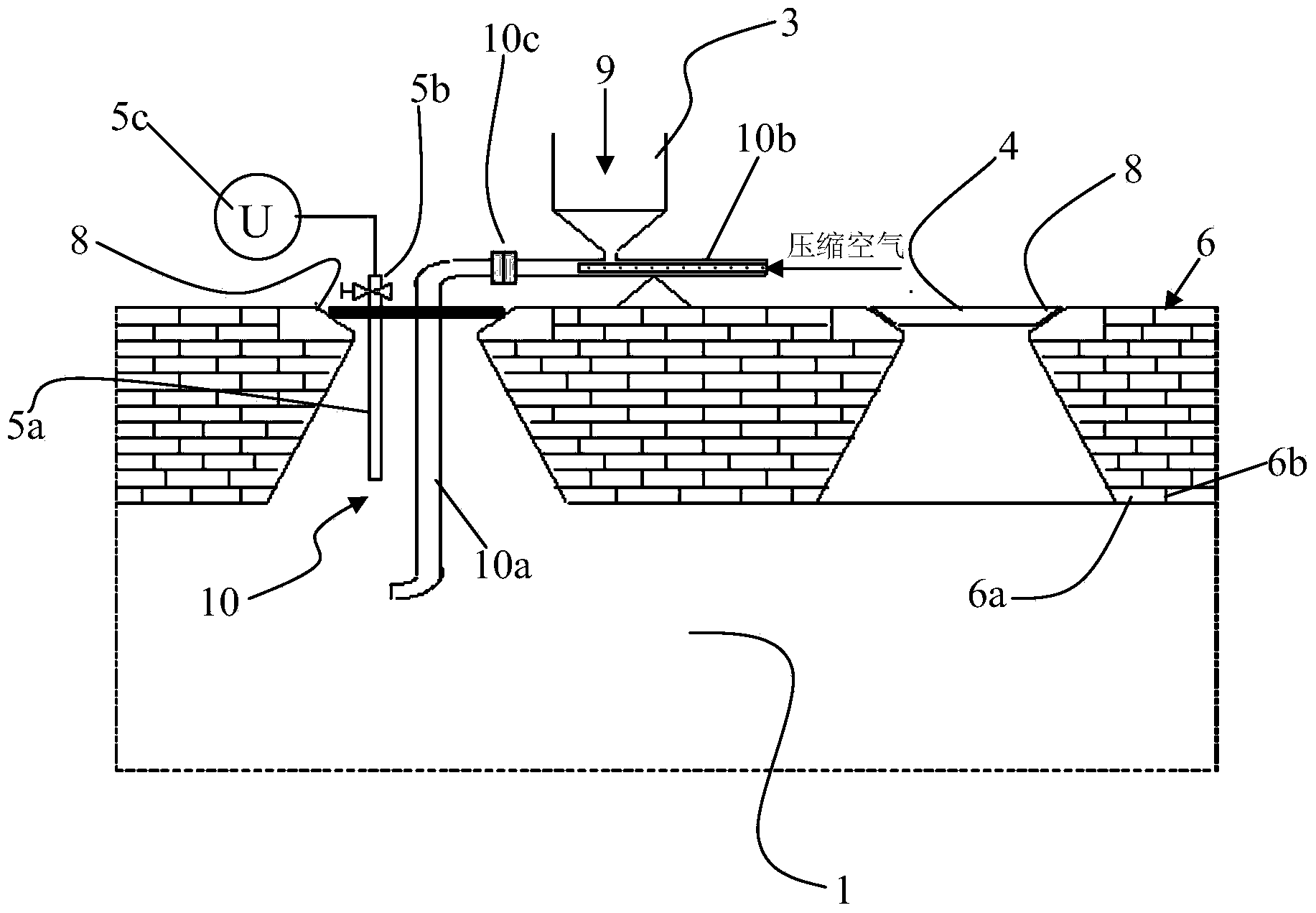

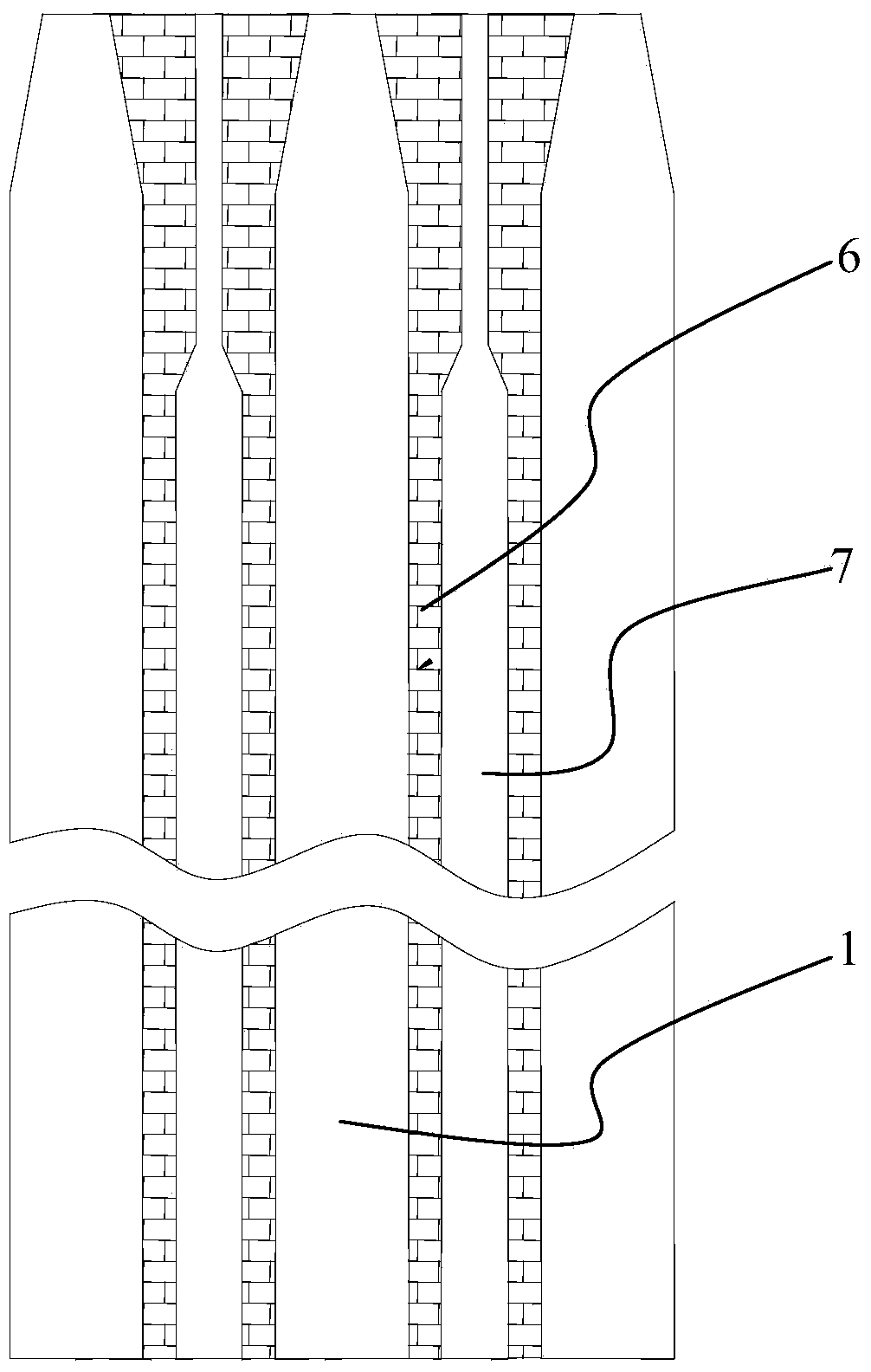

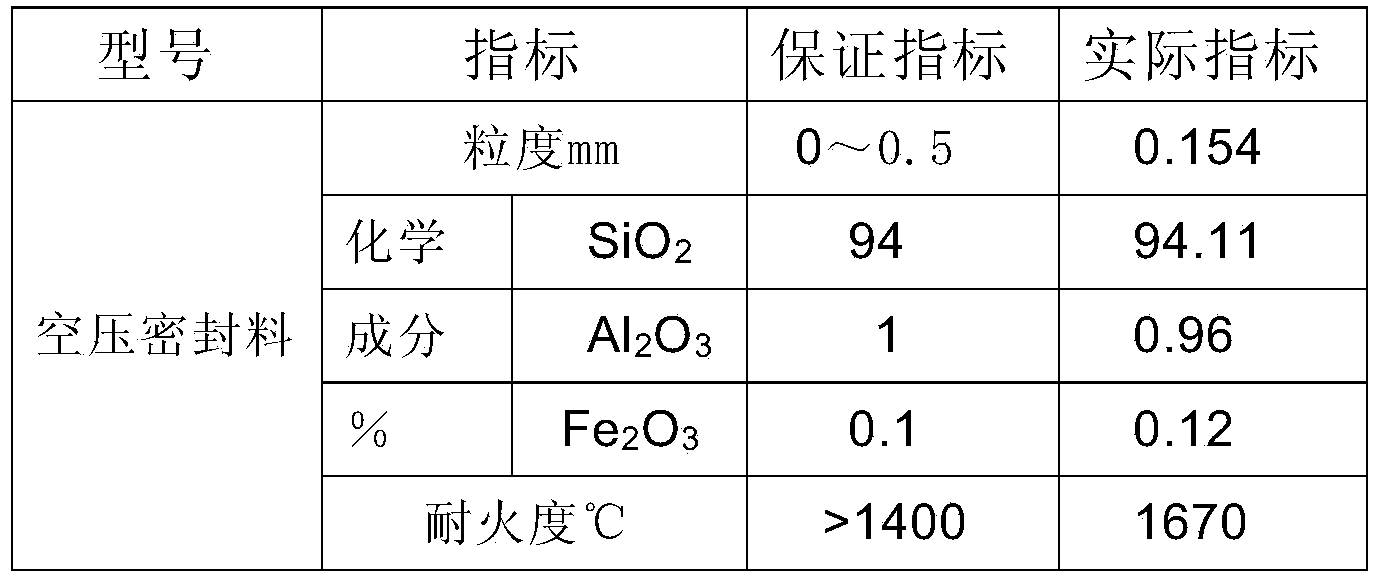

Sealing method of furnace body before primary coal charging of newly built coke furnace

InactiveCN104232110AReduce blowbyNo yellow smoke phenomenonCoke oven doors/closuresAir compressionBrick

The invention relates to a sealing method of a furnace body before the primary coal charging of a newly built coke furnace. The coke furnace comprises a plurality of carbonization chambers and a plurality of combustion chambers which are separated by furnace walls. The sealing method comprises the following steps: closing the carbonization chambers; inserting air compression sealing equipment from a coal charging hole into each carbonization chamber; starting pressure measuring equipment; charging sealing materials by virtue of a charging hopper, and opening air valves to input compressed air into the carbonization chambers through the air compression sealing equipment; after materials are completely sprayed each time, closing the air valves, and standing for a period of time so that the sealing materials enter gaps among wall bricks of the furnace walls and then are thermally expanded and sintered; and checking the situation of pressure inside the coke furnace by virtue of a fire hole and a pressure gauge, and judging whether to continue to carry out air compression sealing operation or not. The sealing method disclosed by the invention can be used for sealing the brick joints of the furnace walls of the carbonization chambers in thermal engineer operation before the primary coal charging, thereby mending the leaks among the brick joints, checking the sealing property of each carbonization chamber and preventing the phenomenon of smoking of the chimney of the coke furnace from being generated during the primary coal charging.

Owner:BAOSHAN IRON & STEEL CO LTD

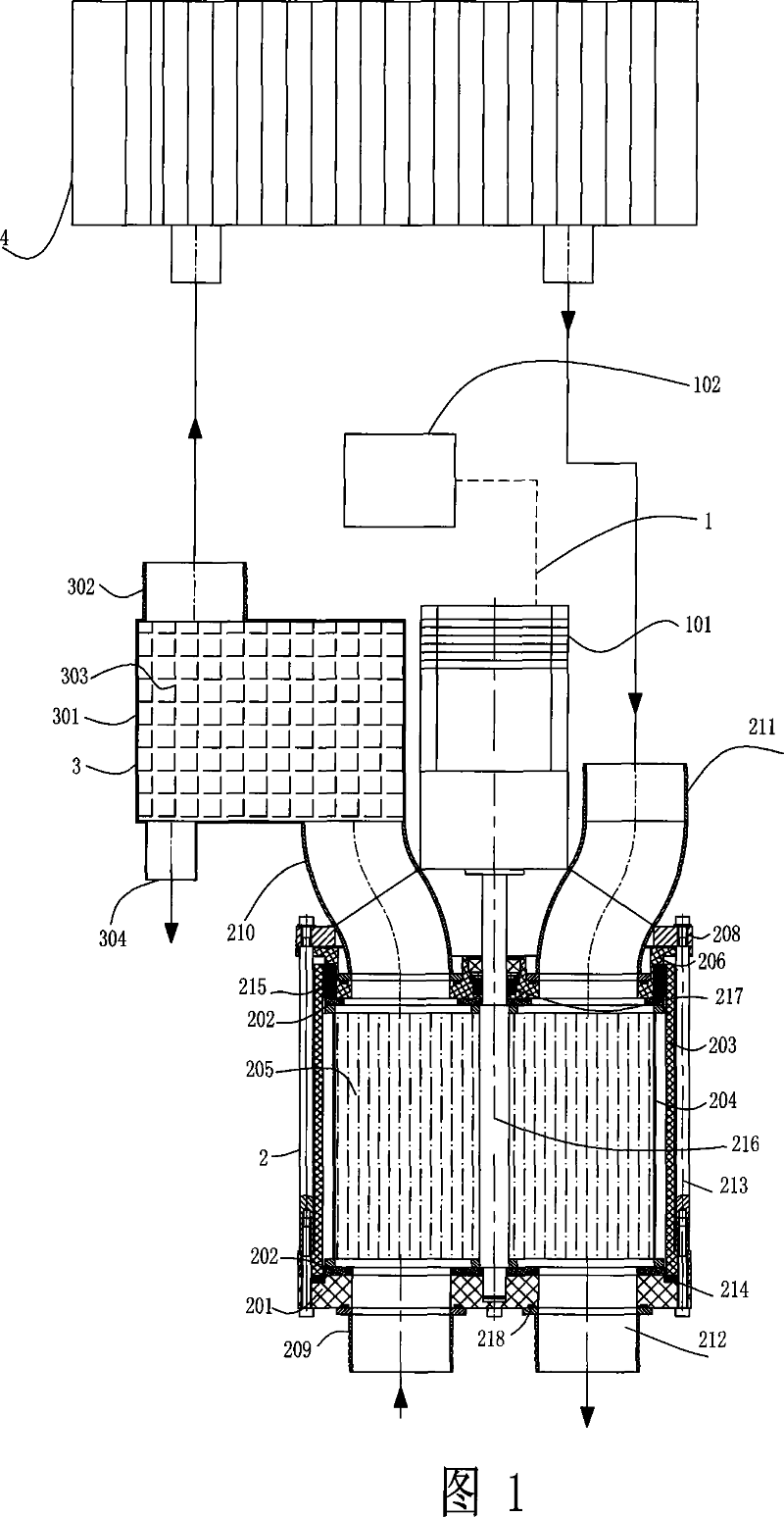

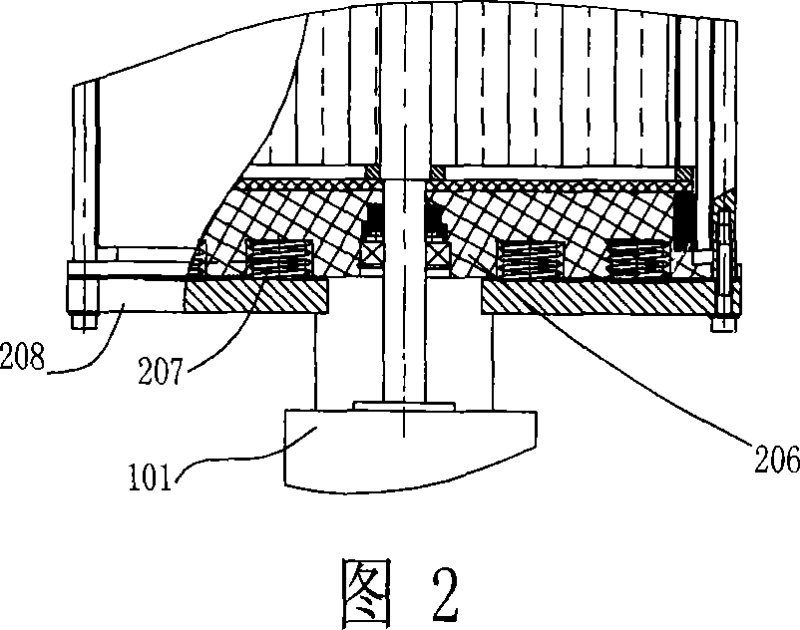

Air humid enthalpyconverting device used for fuel batter with proton exchange film

ActiveCN101043081AGuaranteed service lifeGuaranteed power generation efficiencyFuel cell auxillariesElectricityProton

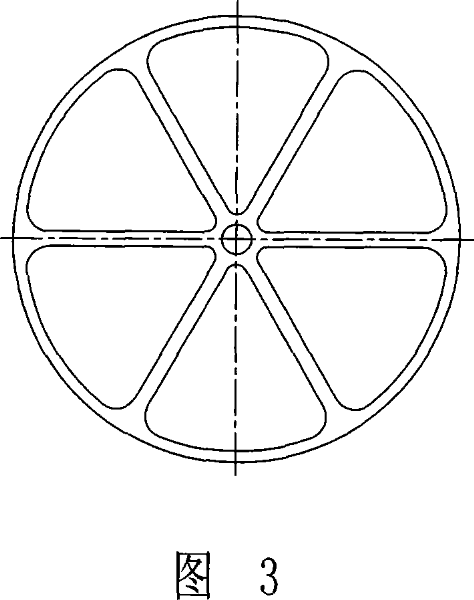

A air moisture transform device which is used in proton exchanging film fuel cell includes power part, moisture transform part, it characterized in that: said air moisture transform device also includes diversion part; the power part includes timing motor and motor controller, the moisture transform part comprises fixed end plate(201) equipped with supporting seat, floating end plate, moisture transform tubular with multi cavity and sealing part, the diversion part(3) comprises shell(301) and screen mesh(303) which is set in the shell(301), the advantages of the invention are: The application range of device is wide, the service life and generate electricity efficiency of proton exchanging film fuel cell can be guaranteed, the cost of maintaining is low.

Owner:SUNRISE POWER CO LTD

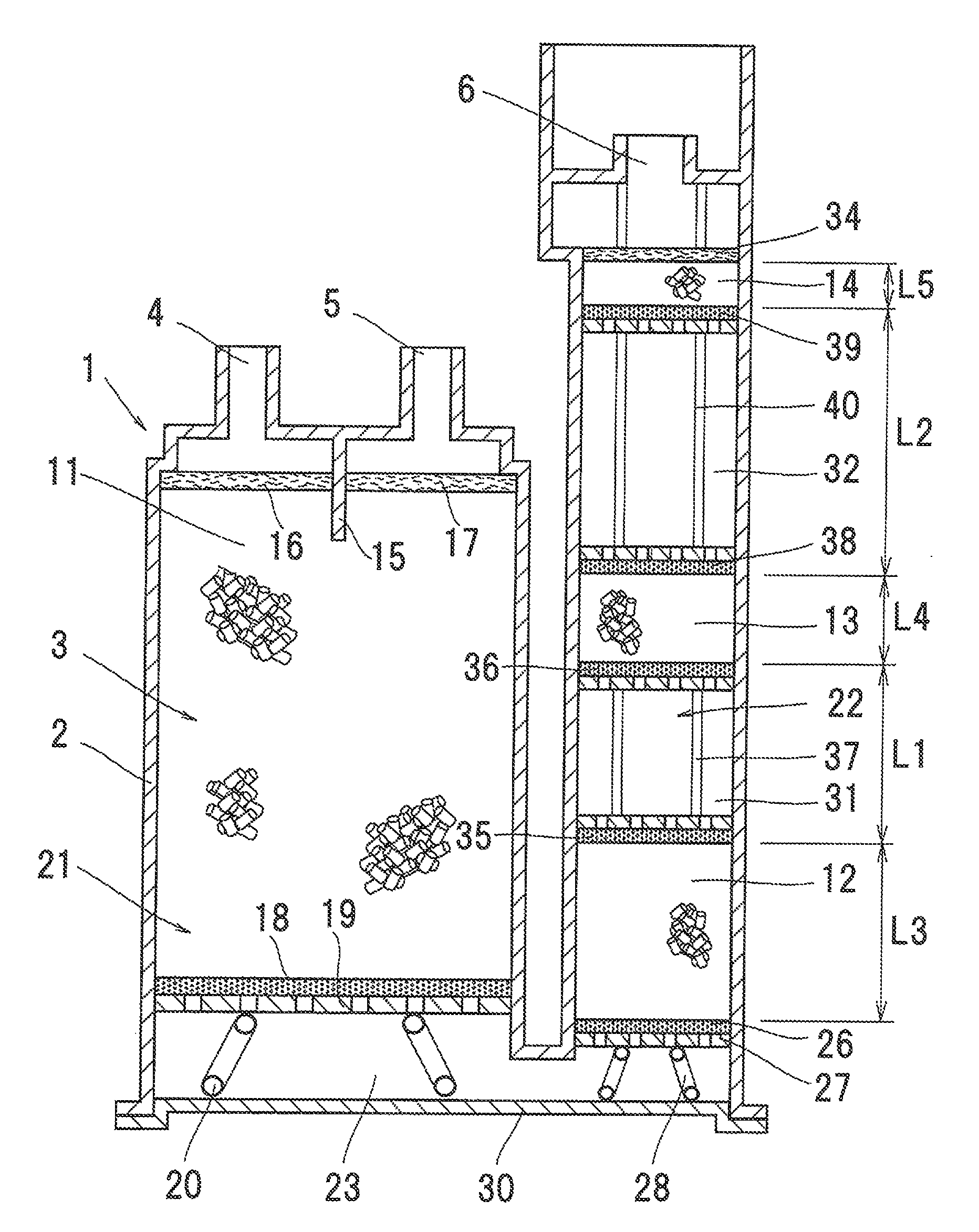

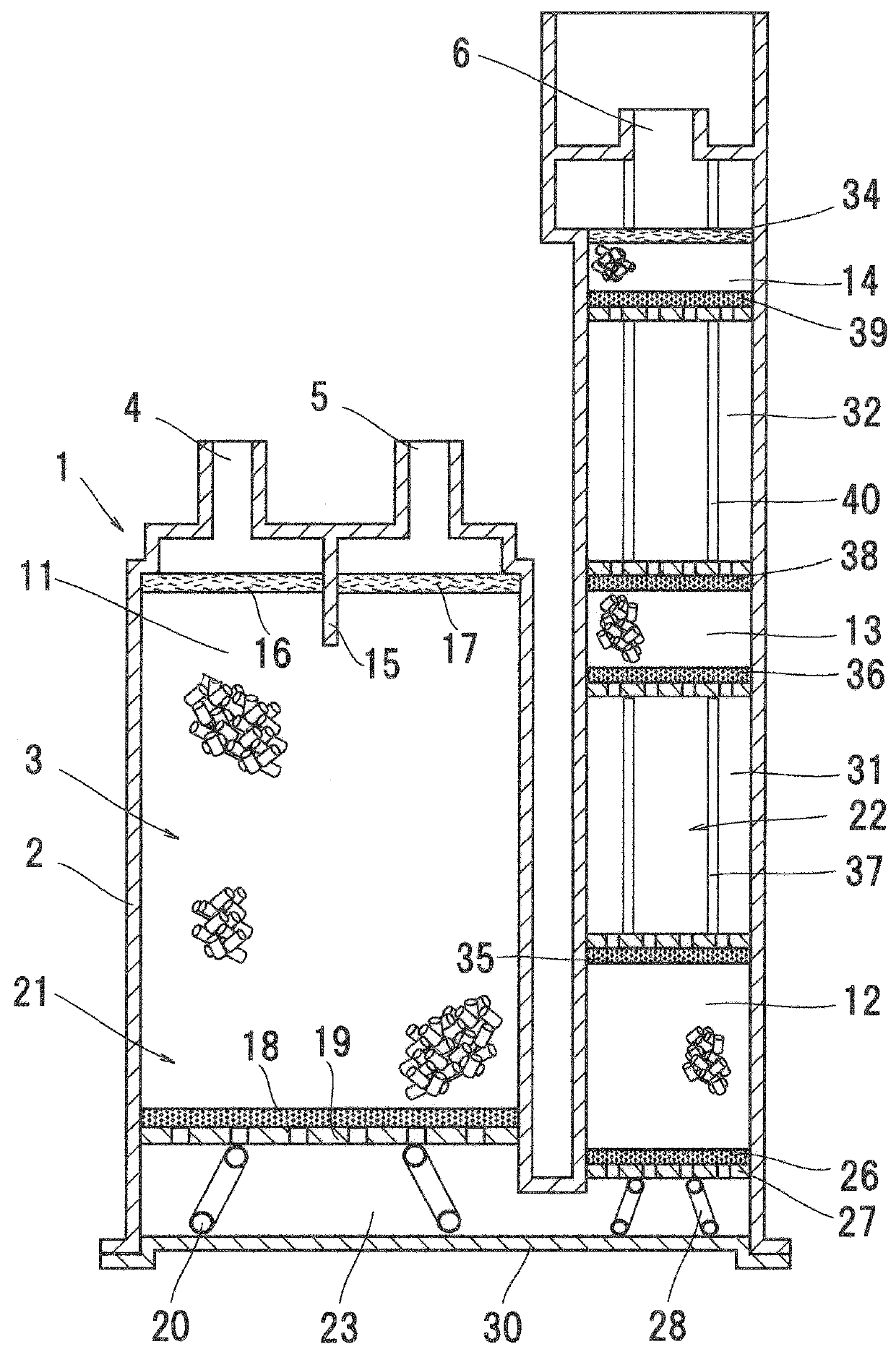

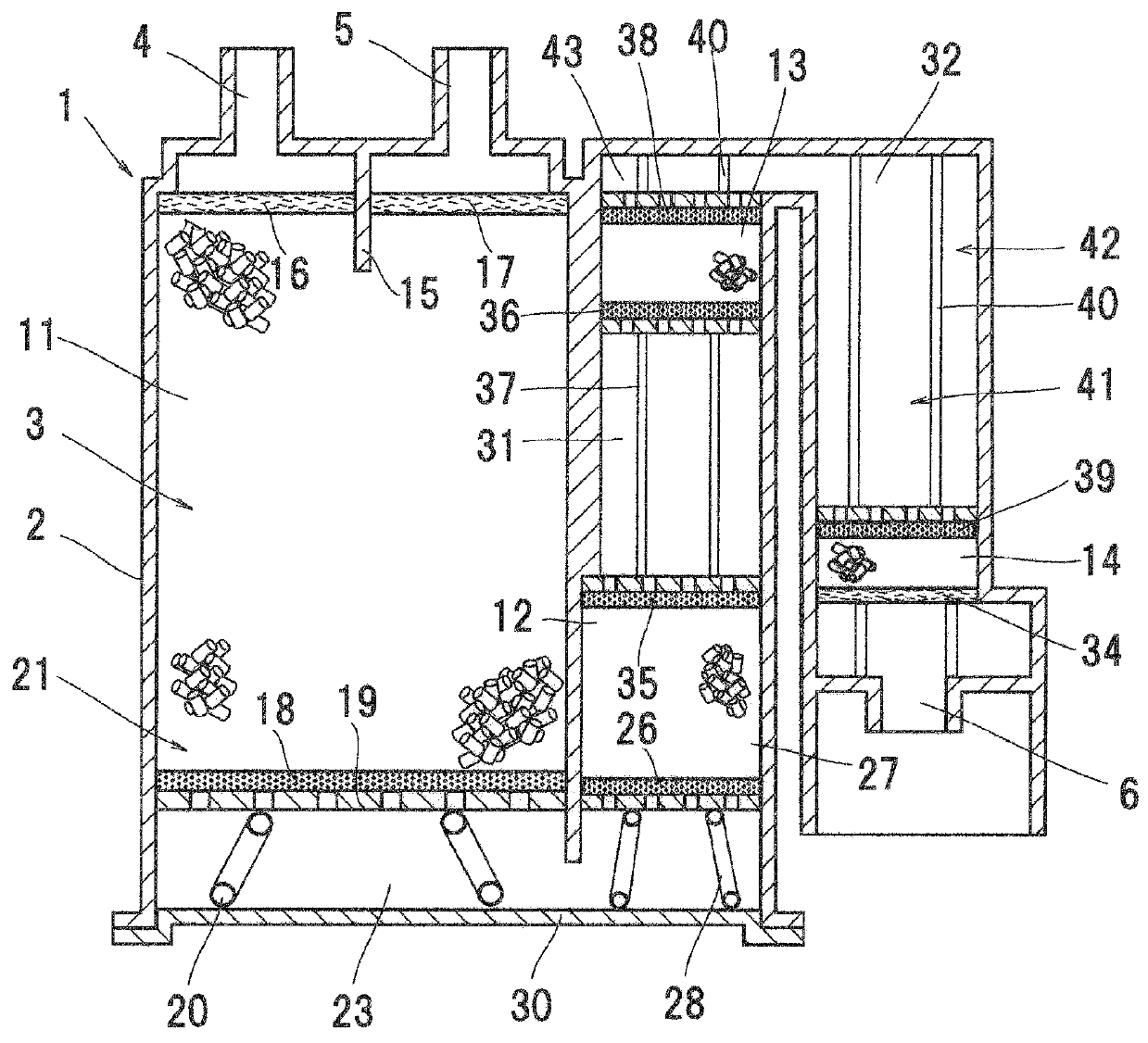

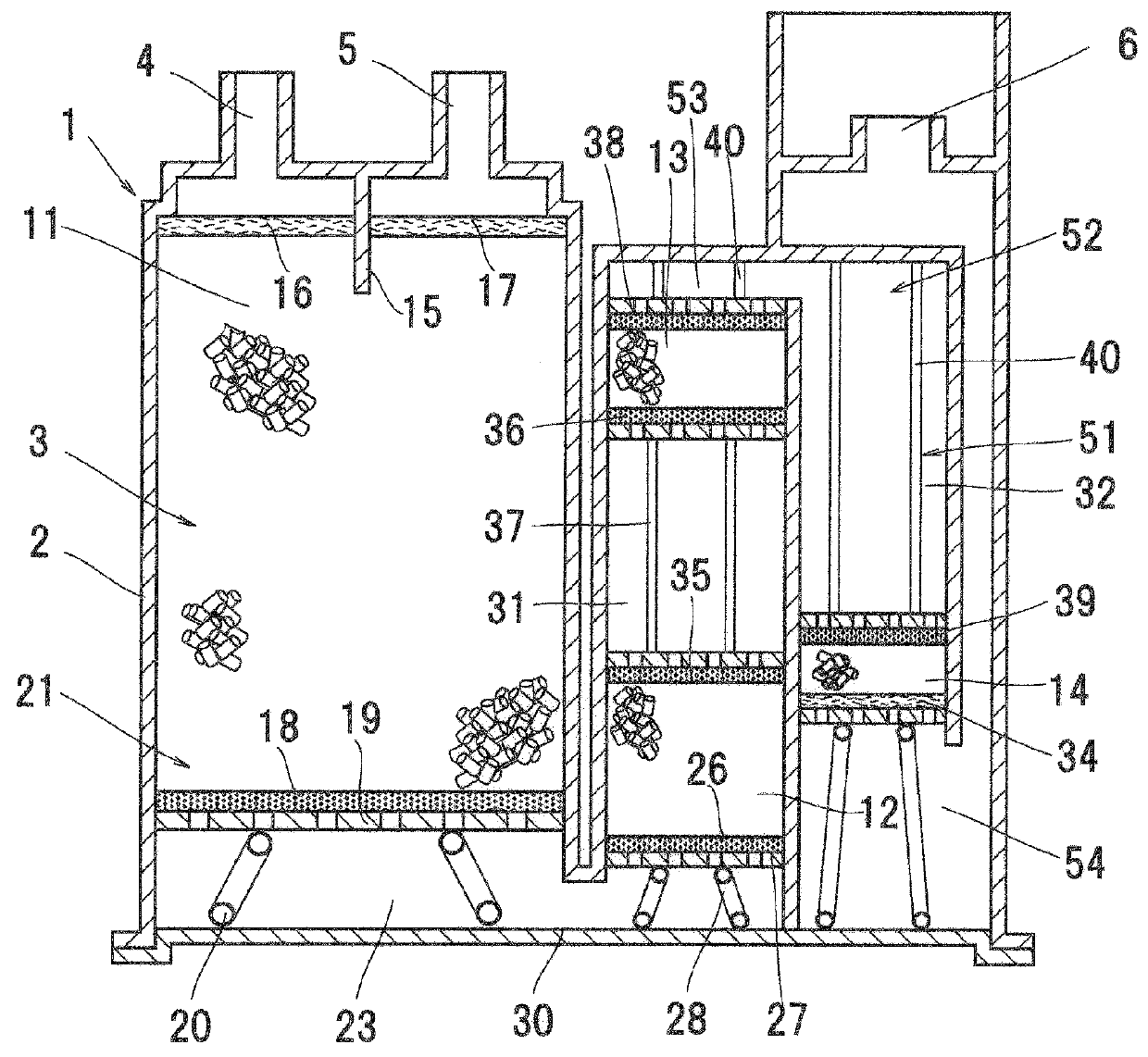

Evaporation fuel processing device

ActiveUS20140060497A1Improve performanceReduce performanceNon-fuel substance addition to fuelMachines/enginesFuel tankEngineering

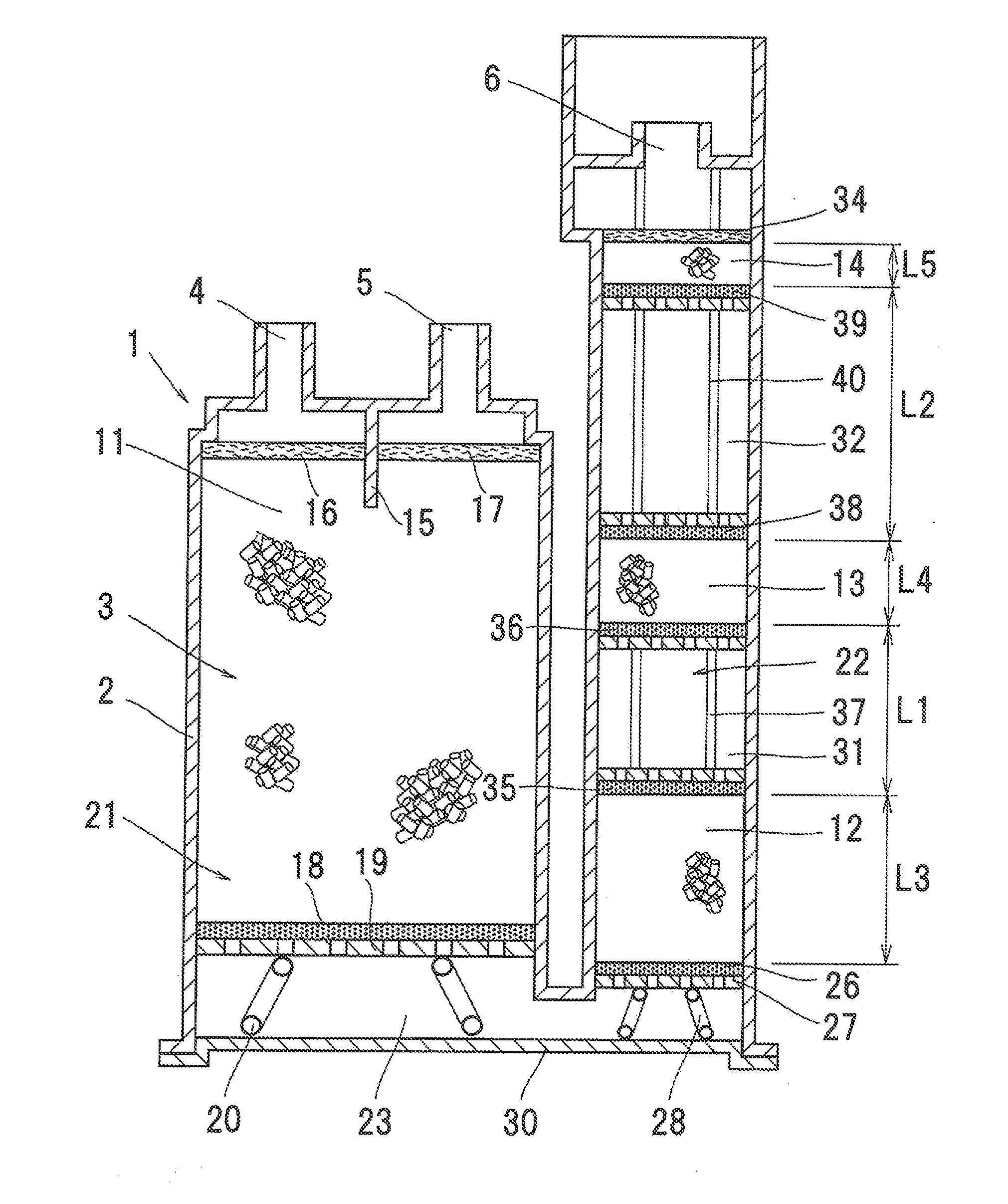

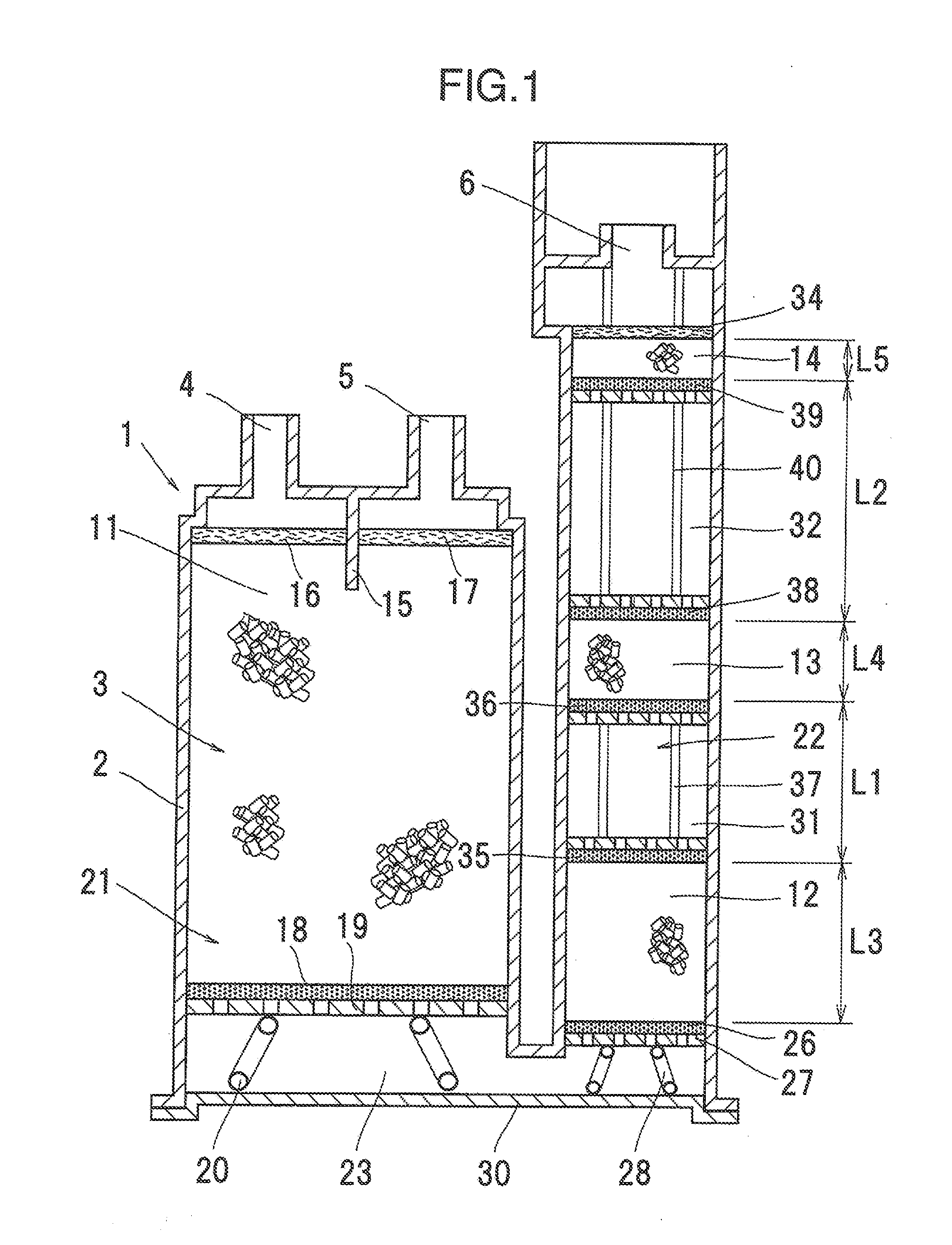

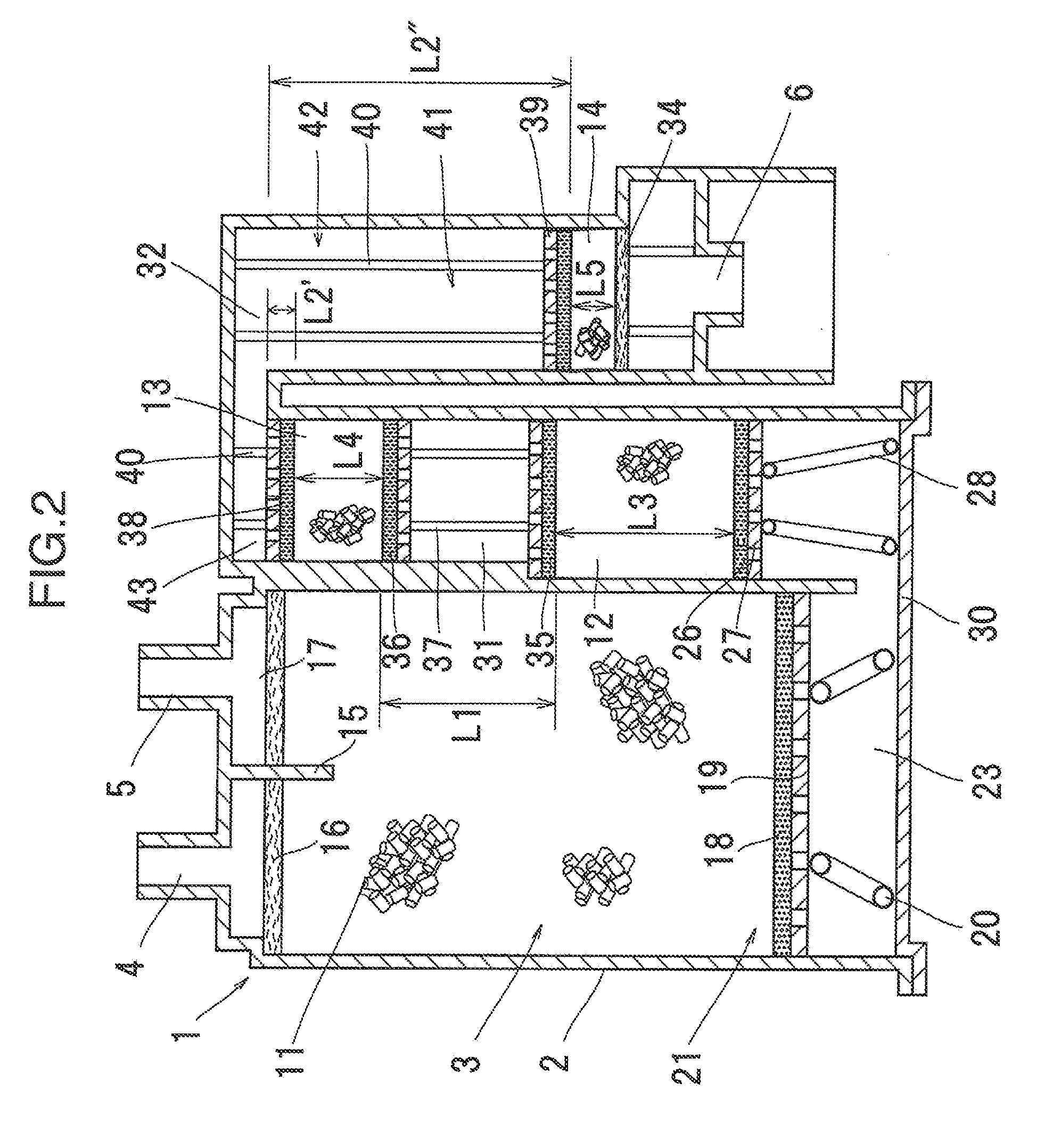

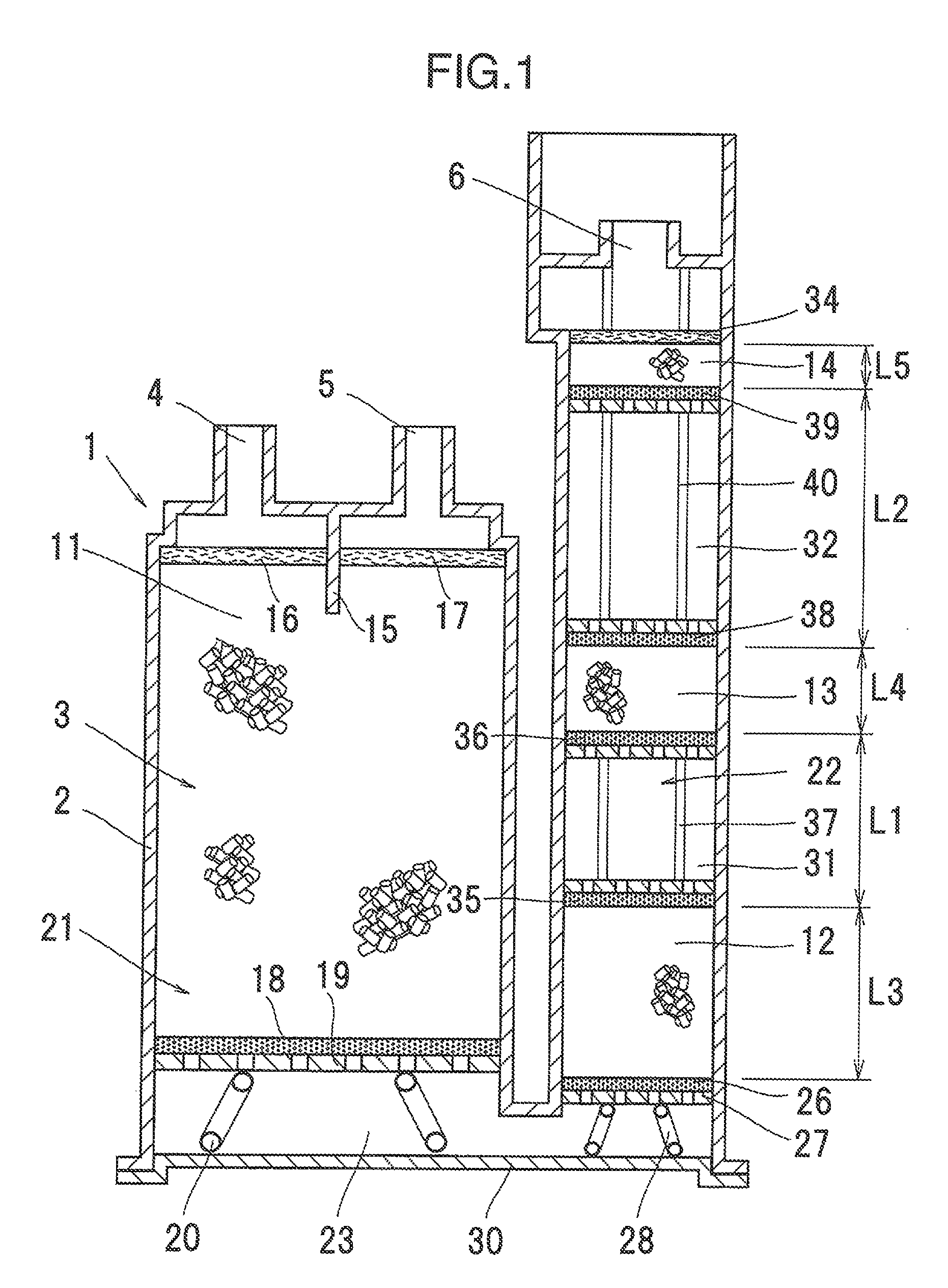

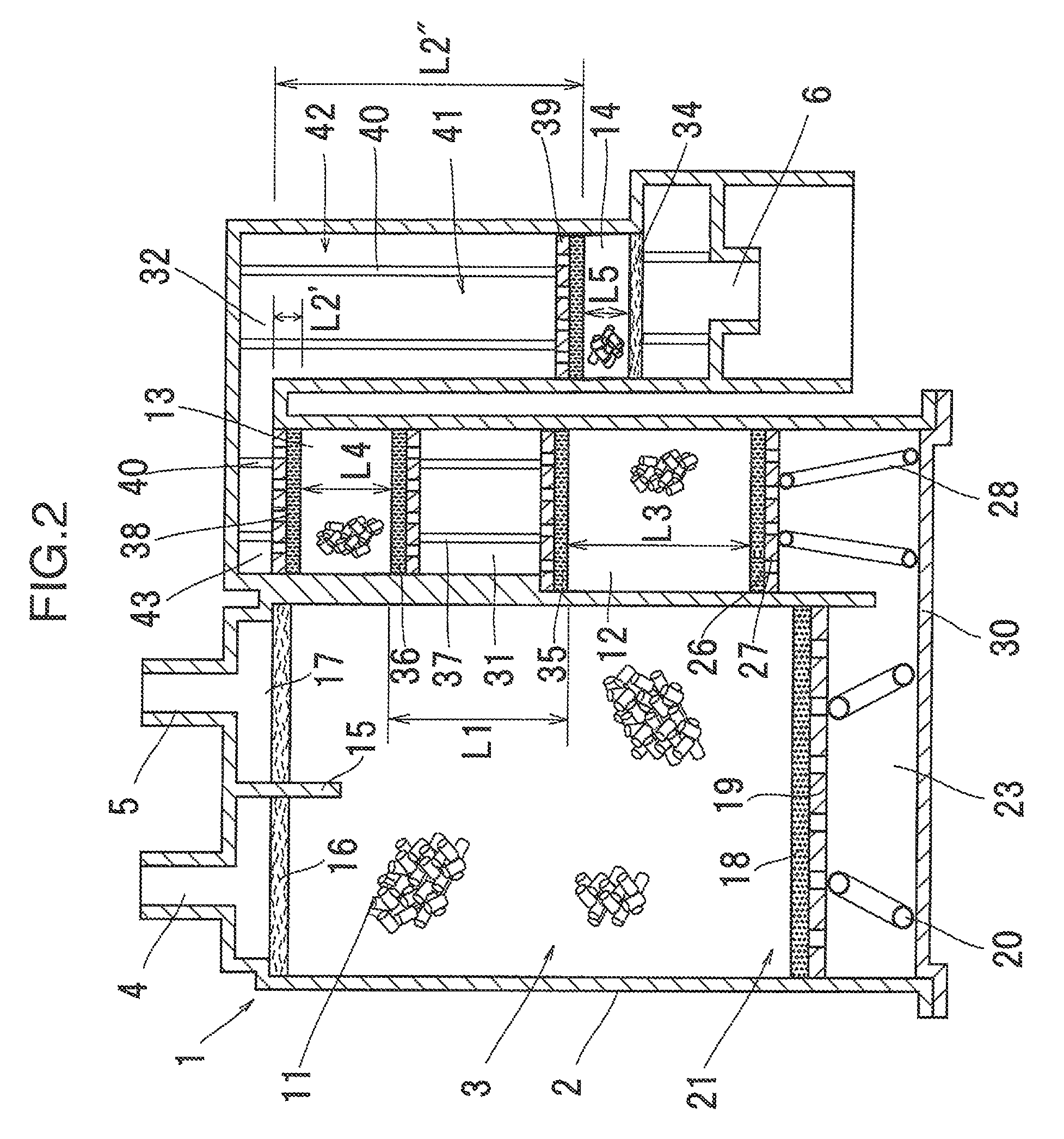

An evaporation fuel processing device is provide including: a passage; a tank port and a purge port on one end side of the passage; an atmospheric air port on the other end side of the passage; and adsorbent layers filled with adsorbent for evaporation fuel components, provided in the passage; a region provided on an atmospheric air port side of the passage, being constituted of three or more adsorbent layers and separating parts for separating the adjacent adsorbent layers, in which a volume of the adsorbent layer is smaller in the adsorbent layer closer to the atmospheric air port, a volume of the separating part is larger closer to the atmospheric air port, and the volume of the separating part located farthest on a tank port side is larger than that of the adsorbent layer located farthest on the atmospheric air port side.

Owner:AISAN IND CO LTD

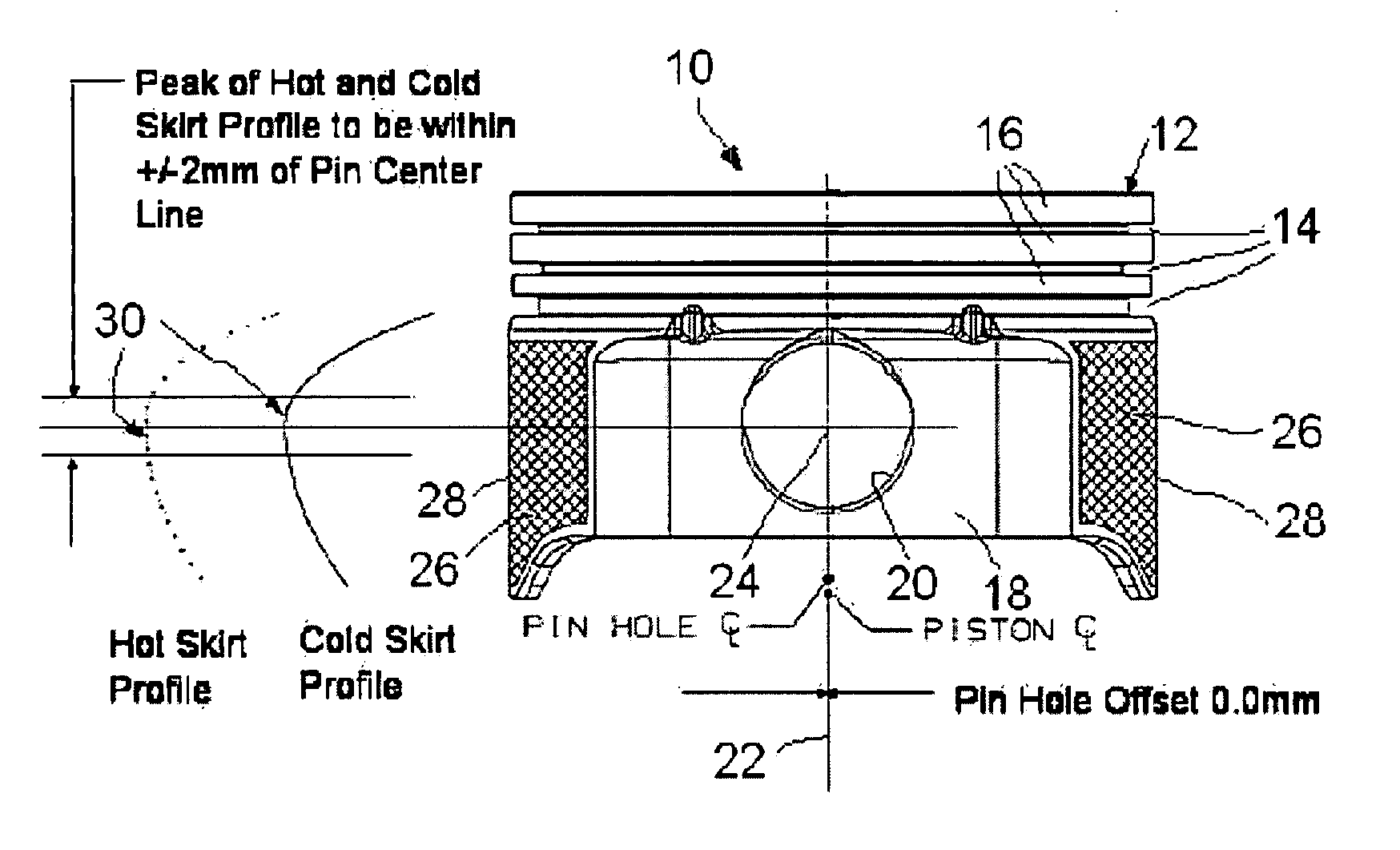

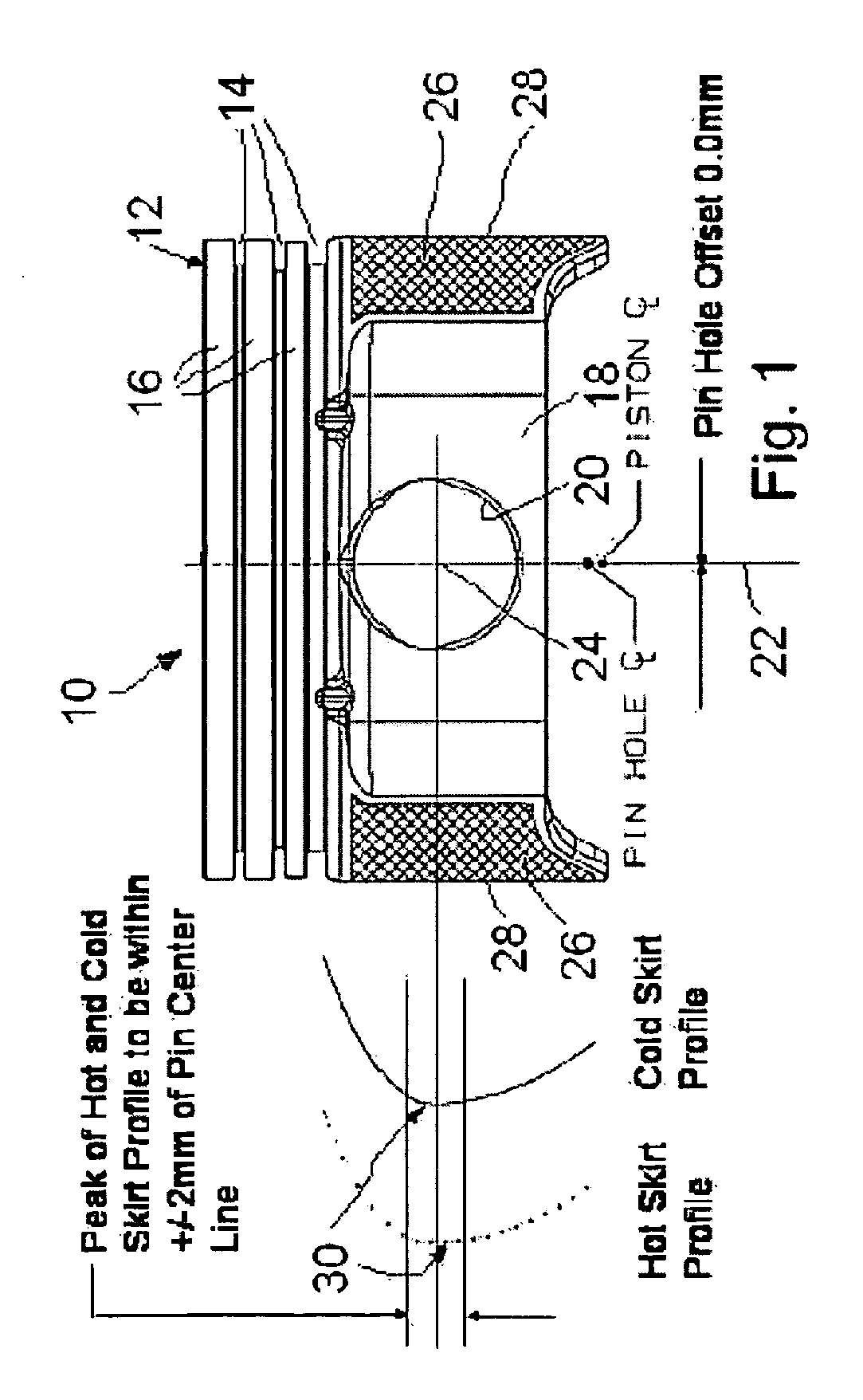

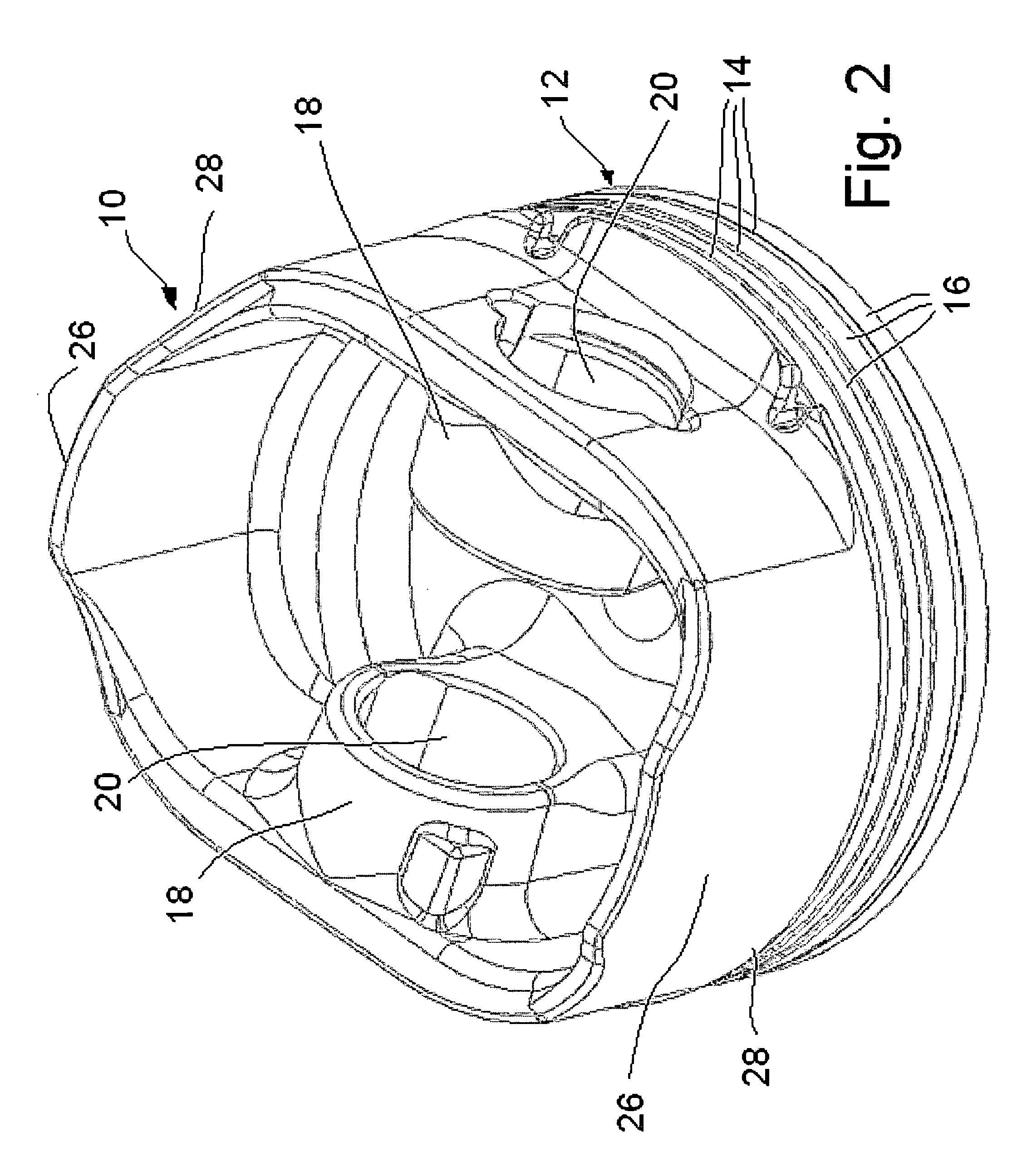

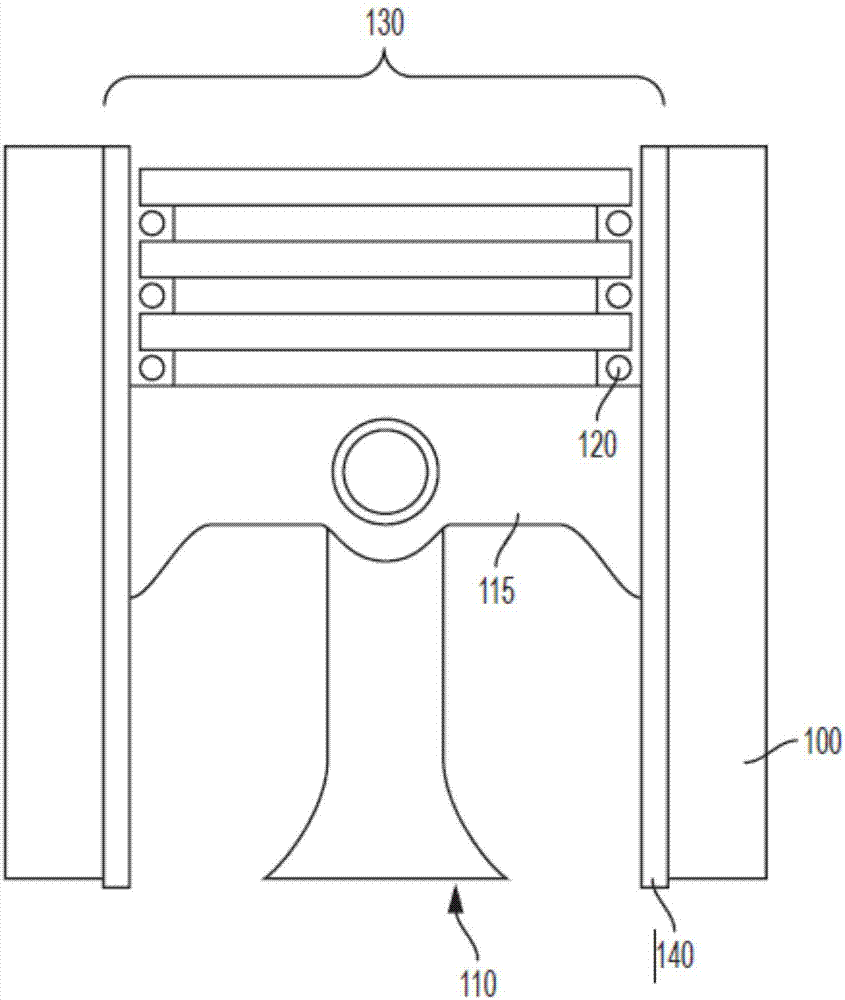

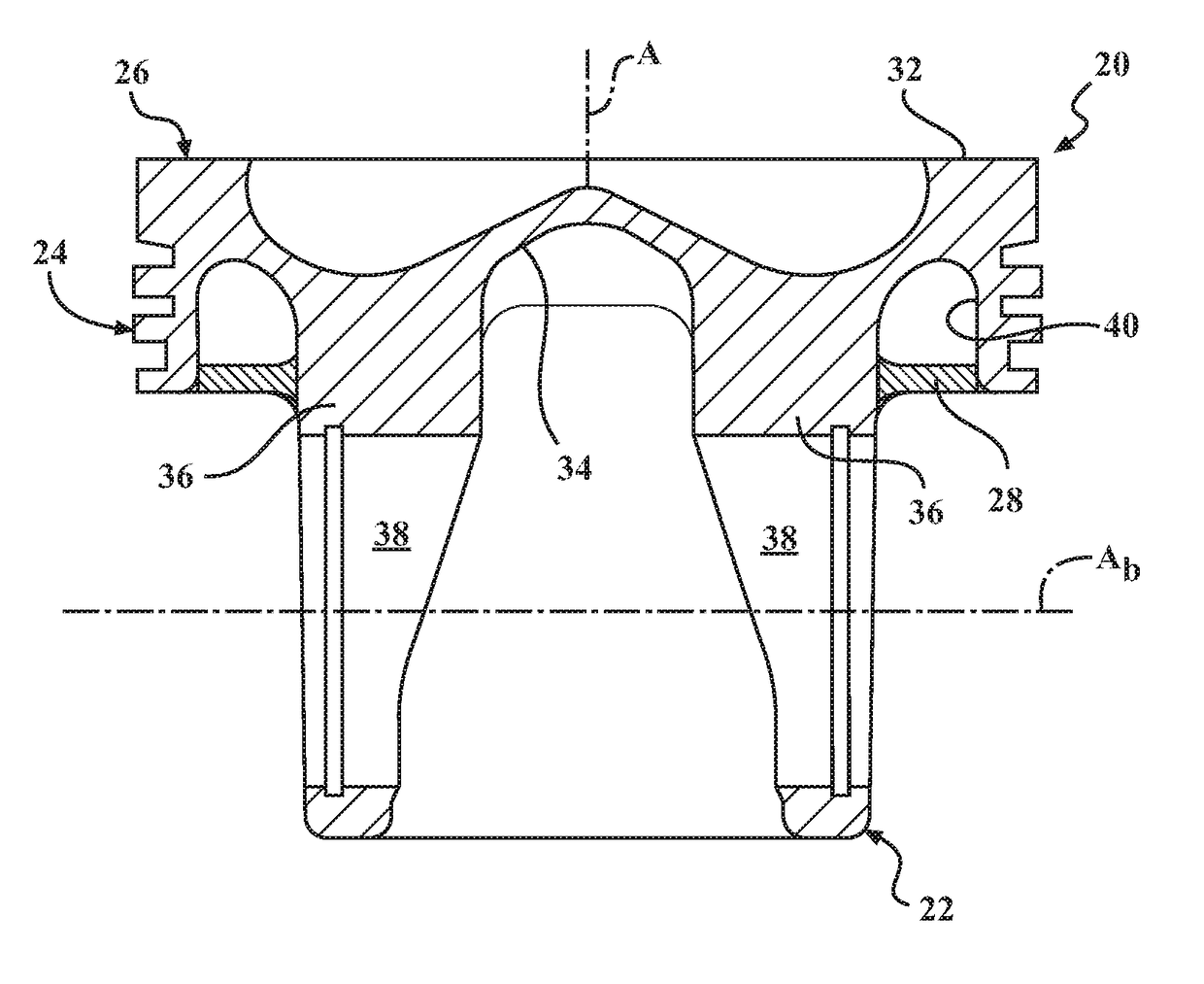

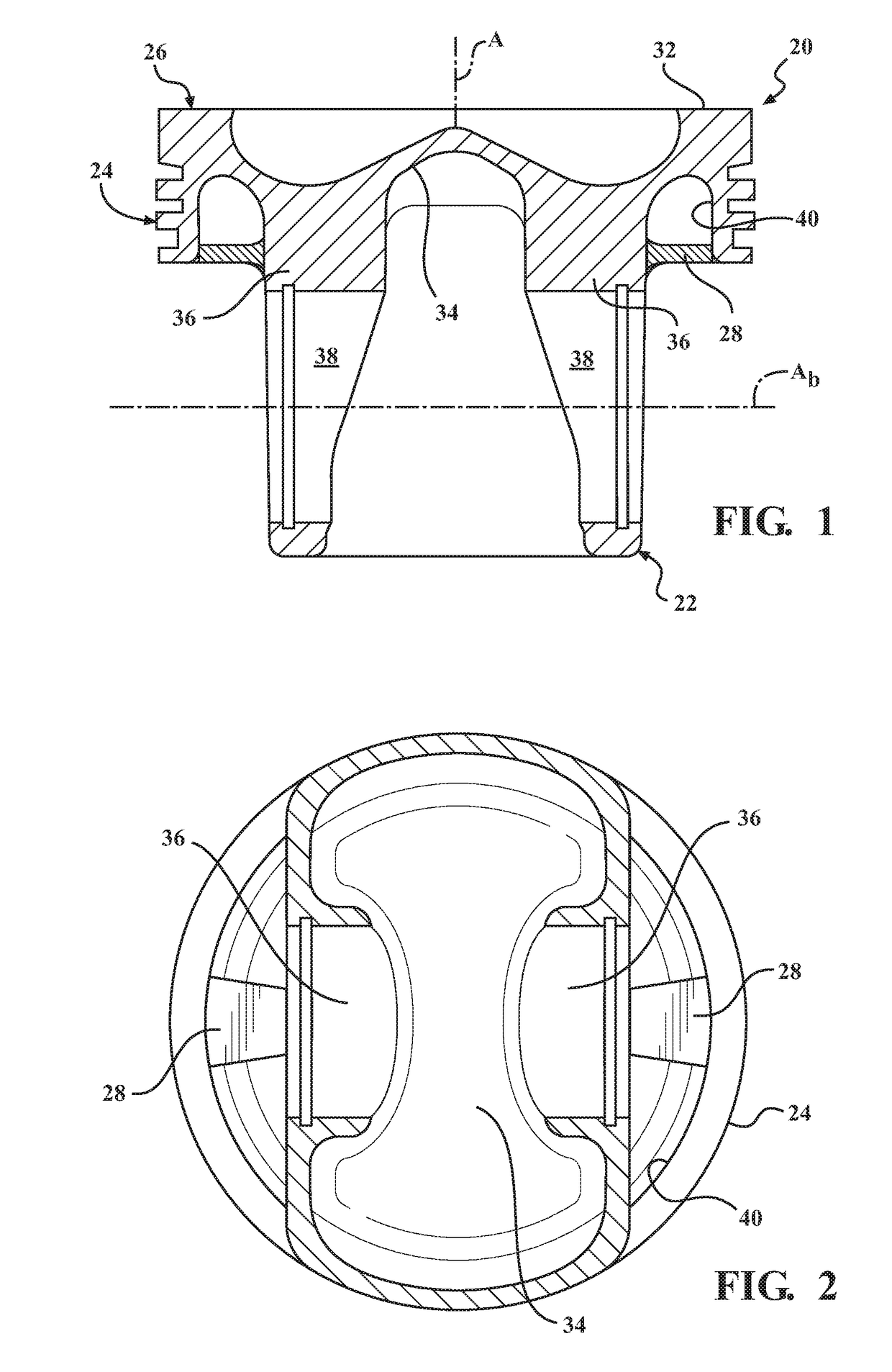

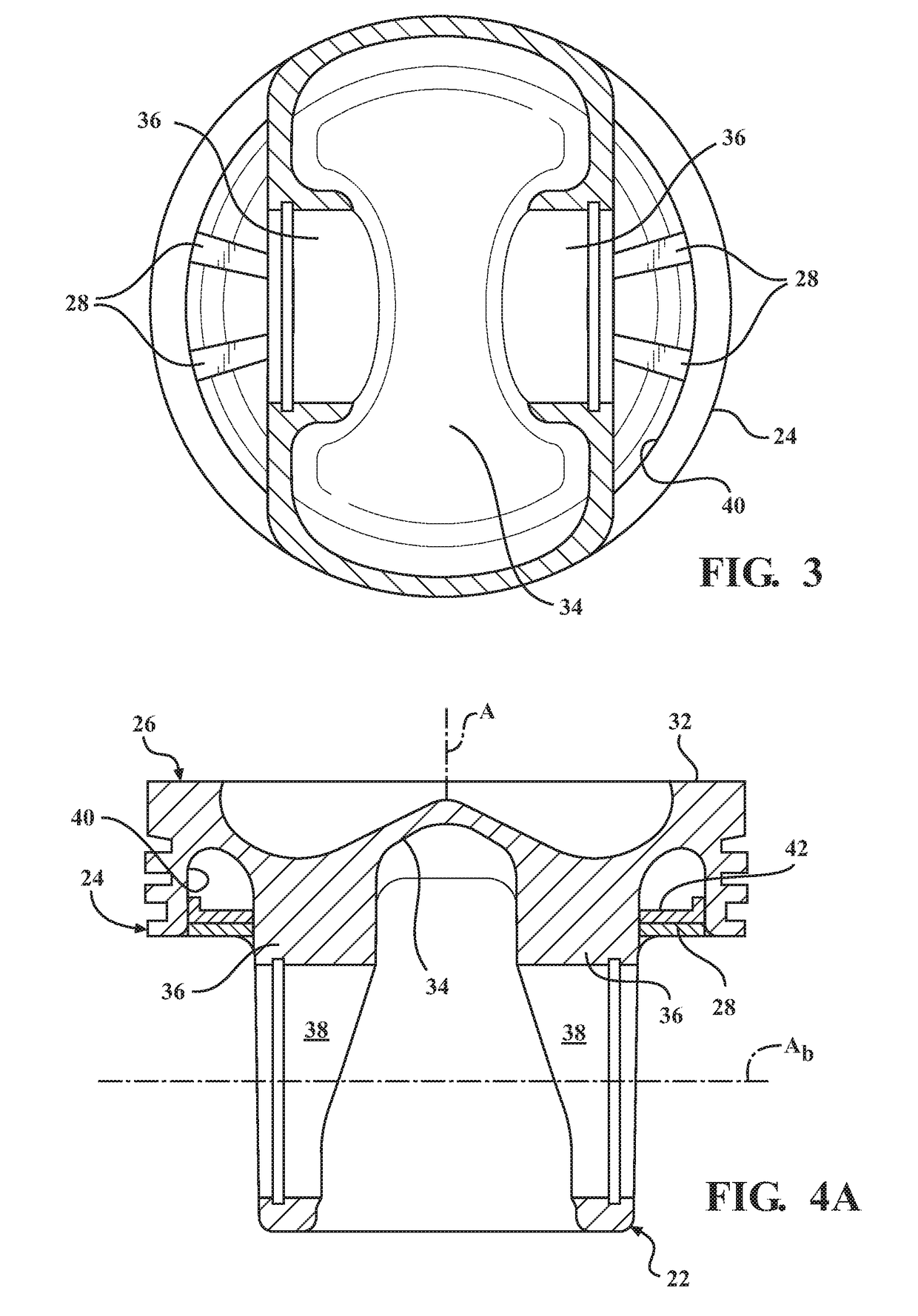

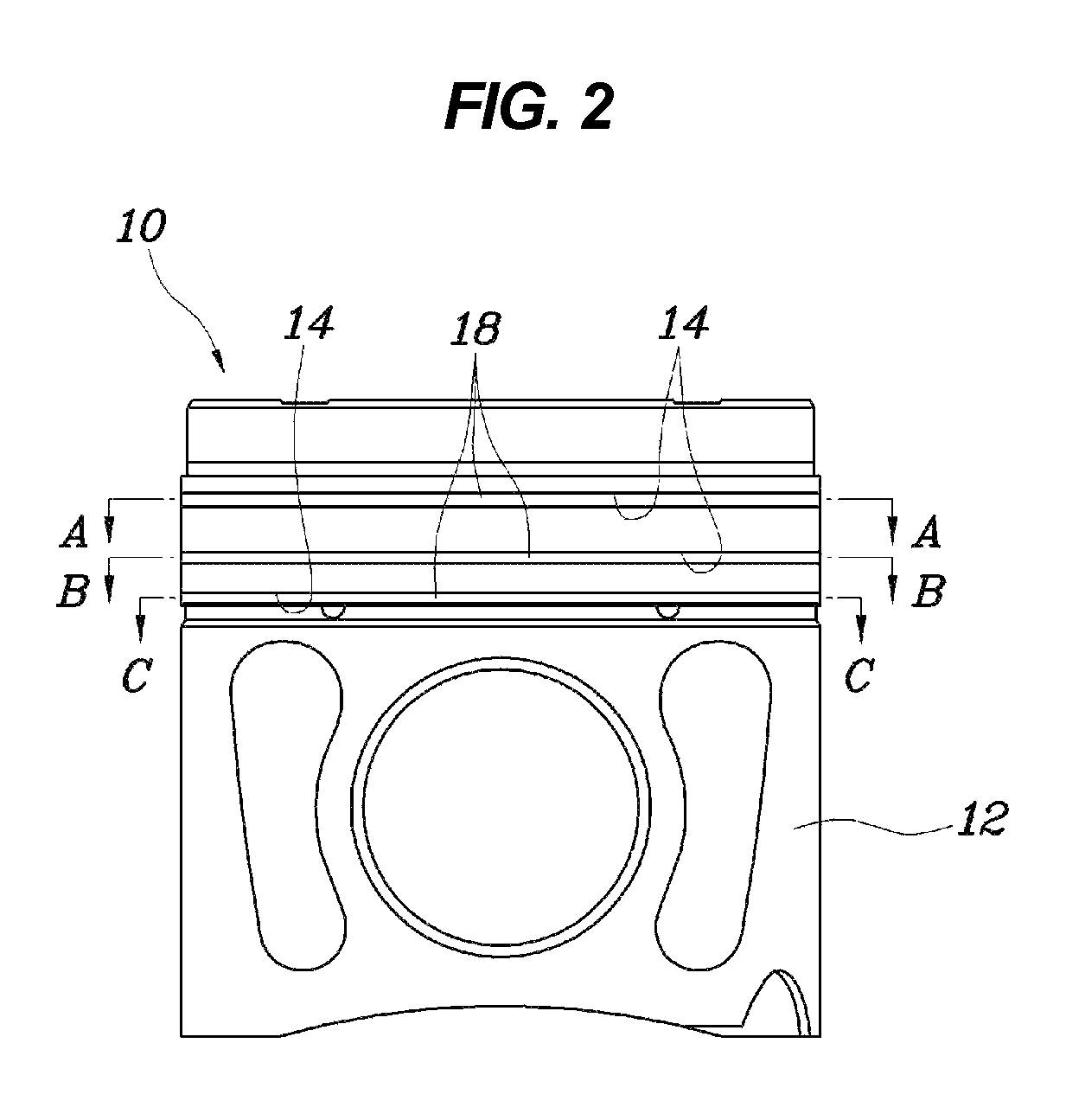

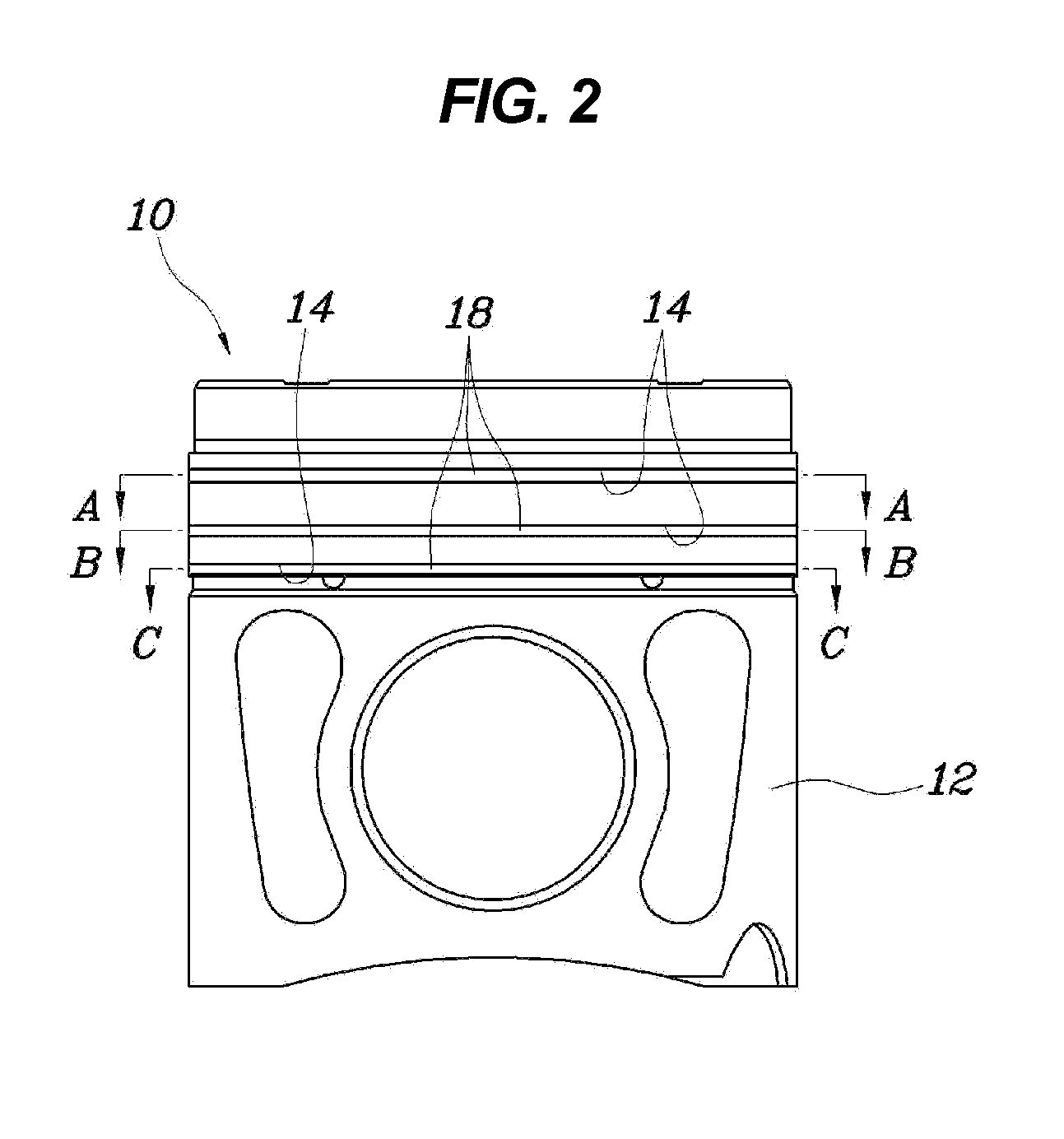

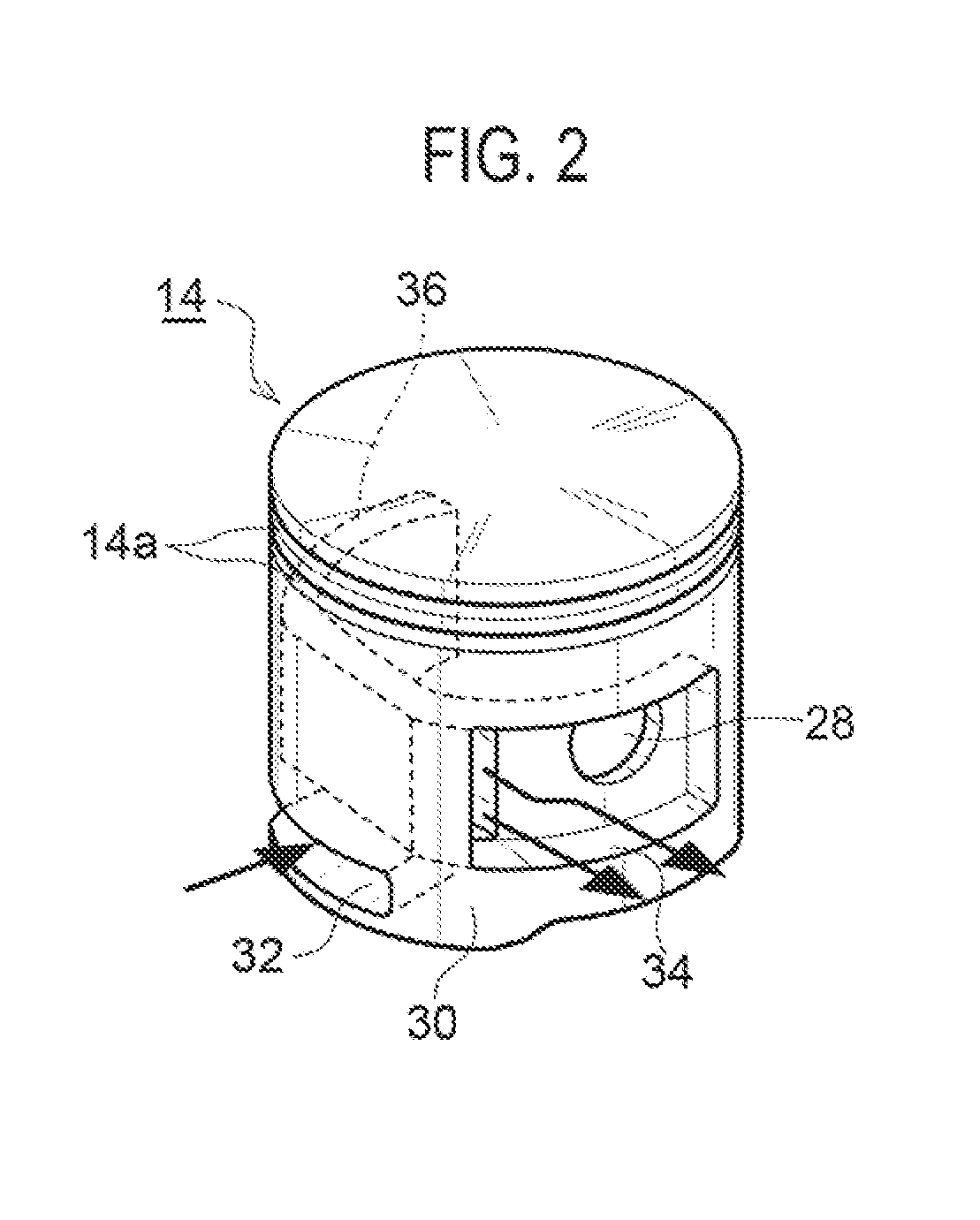

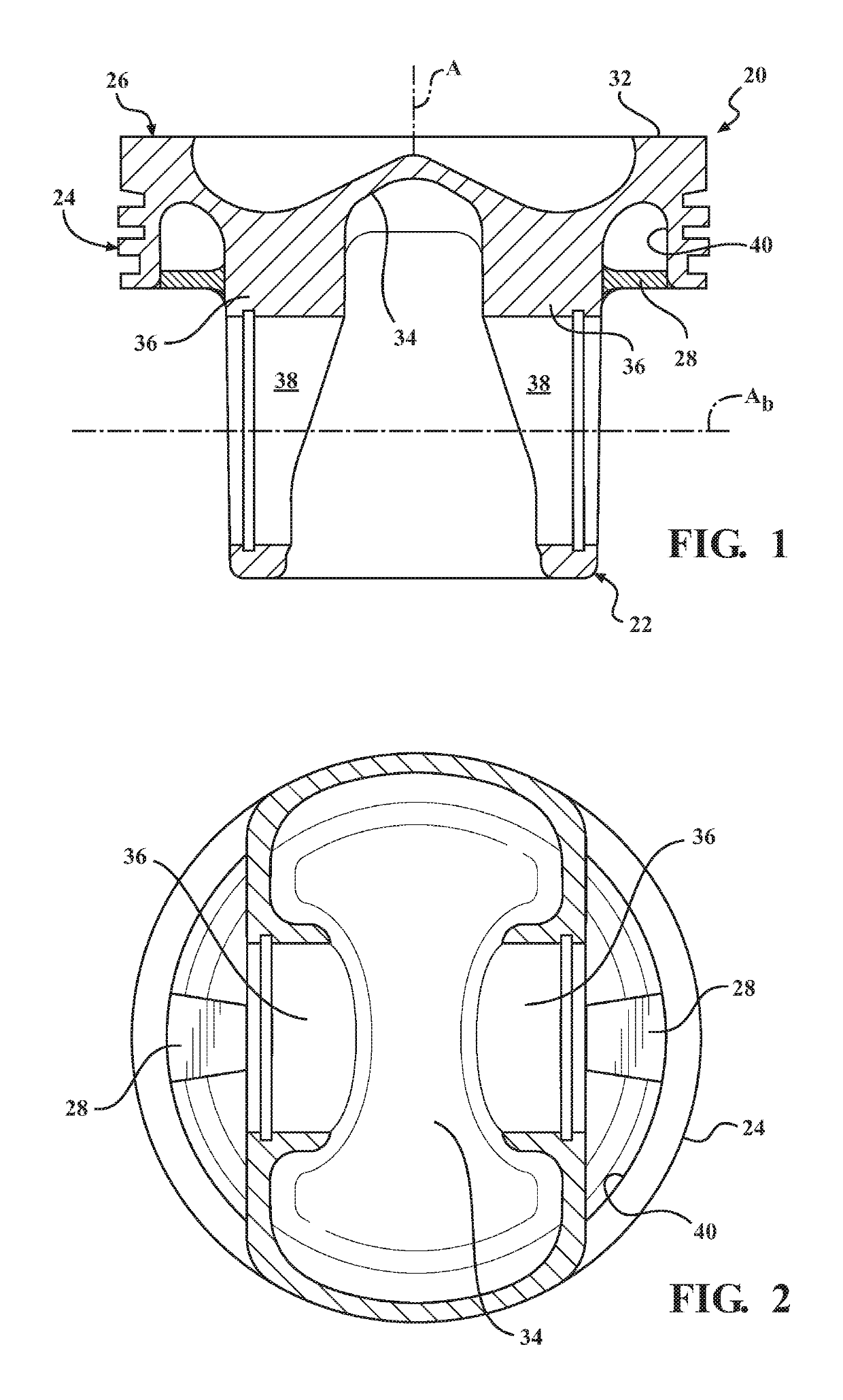

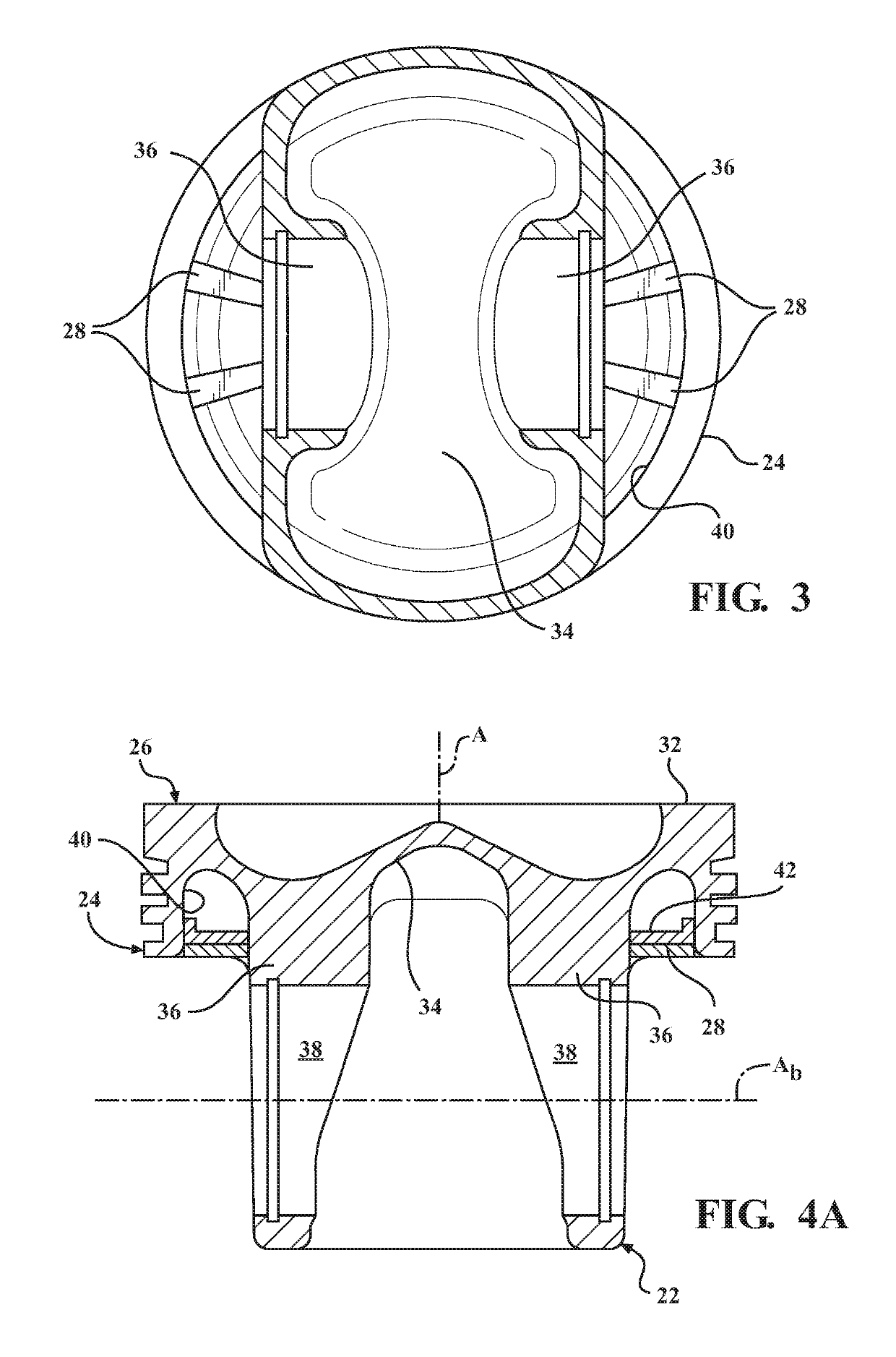

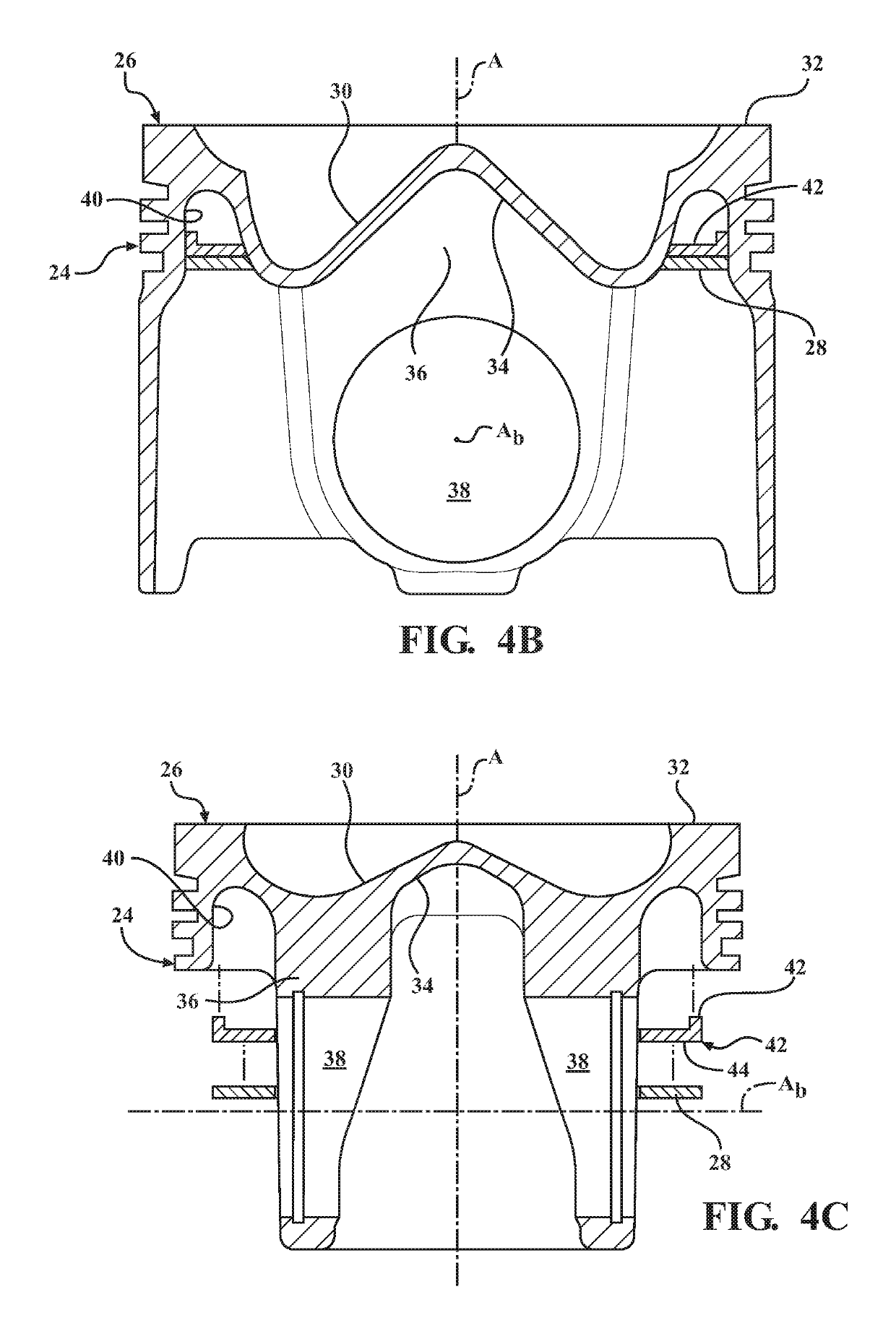

Piston having centered pin hole and skirt profile

InactiveUS20060027095A1Relieve pressureReduce the total massPlungersMachines/enginesEngineeringMechanical engineering

A piston includes a piston body having a longitudinal central axis. A piston head is formed with a plurality of ring grooves and a pair of pin bosses depend from the head and are formed with a pair of pin bores that are centered on a common pin bore axis that intersects the longitudinal axis of the piston. Skirt Portions have outer surfaces with a longitudinal profile that is convexly shaped. A major diameter of the profile lies within ±2 mm of the pin bore axis in both a cold and hot condition.

Owner:FEDERAL MOGUL WORLD WIDE

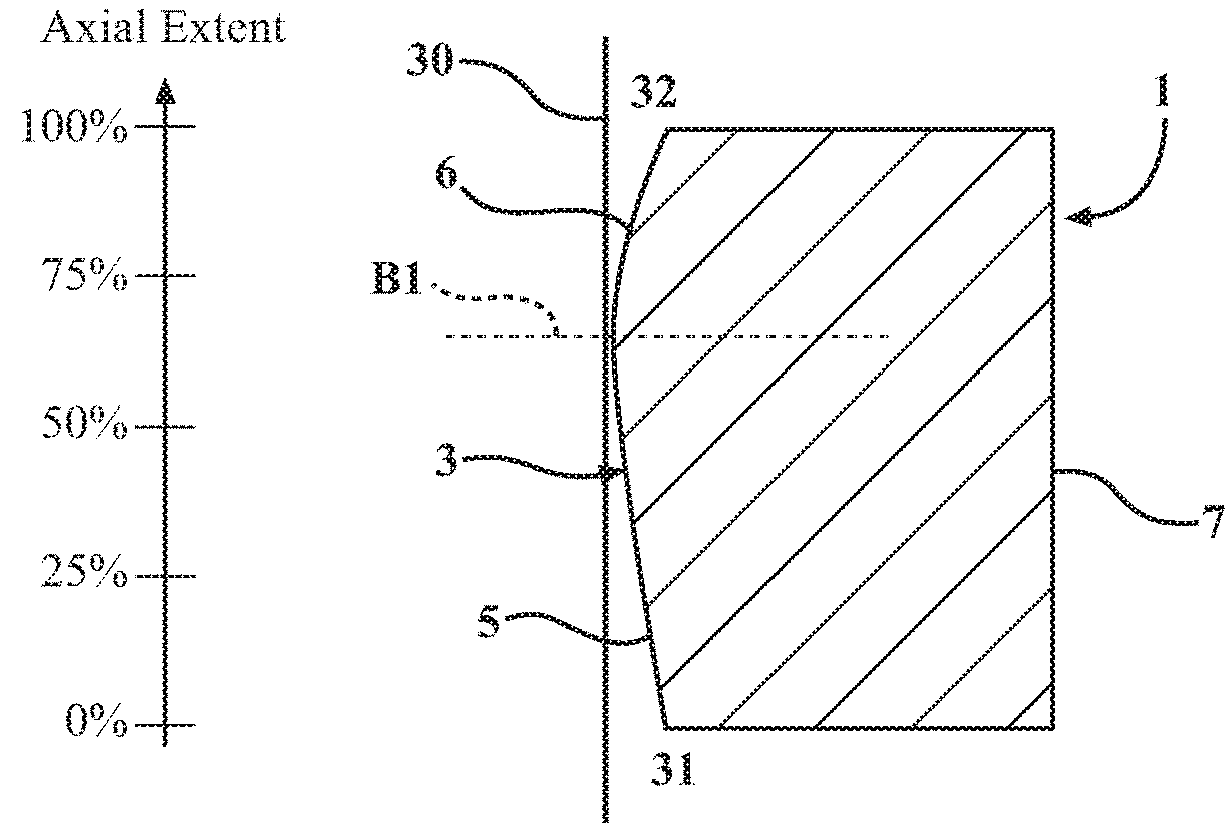

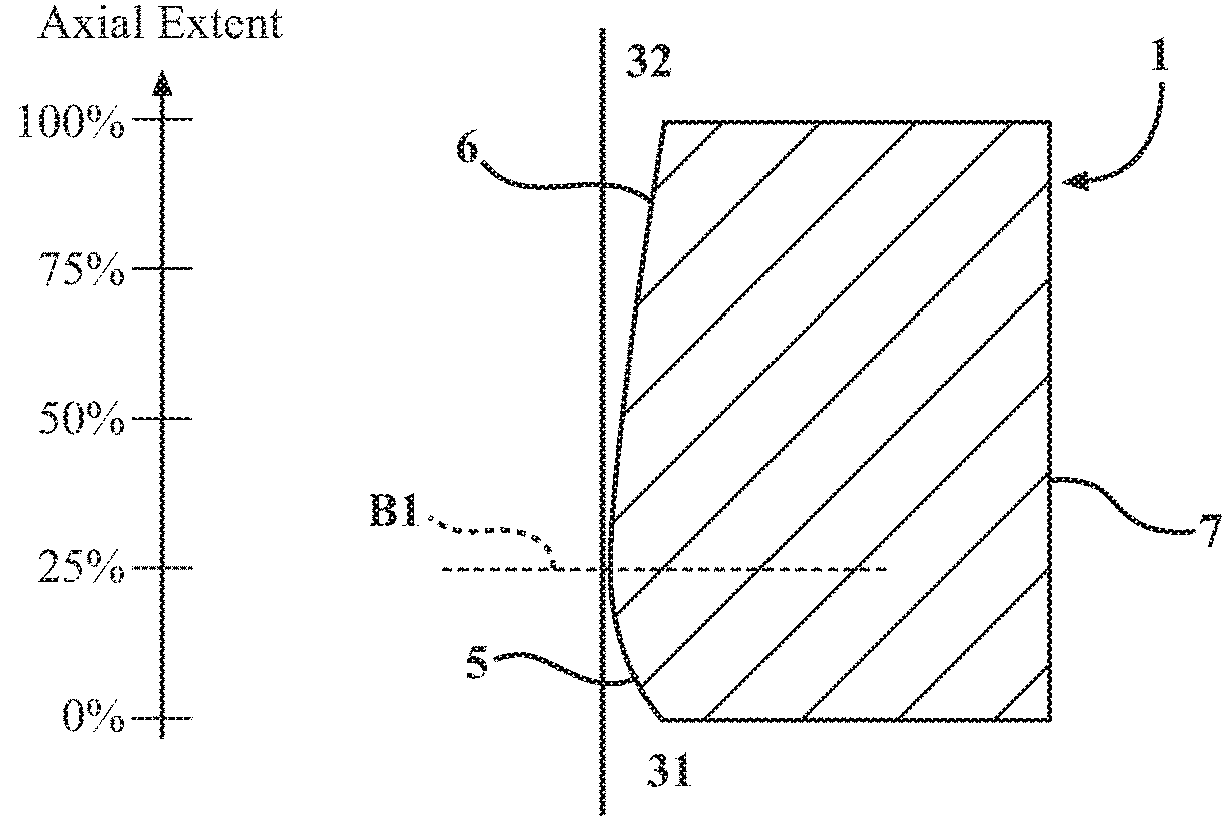

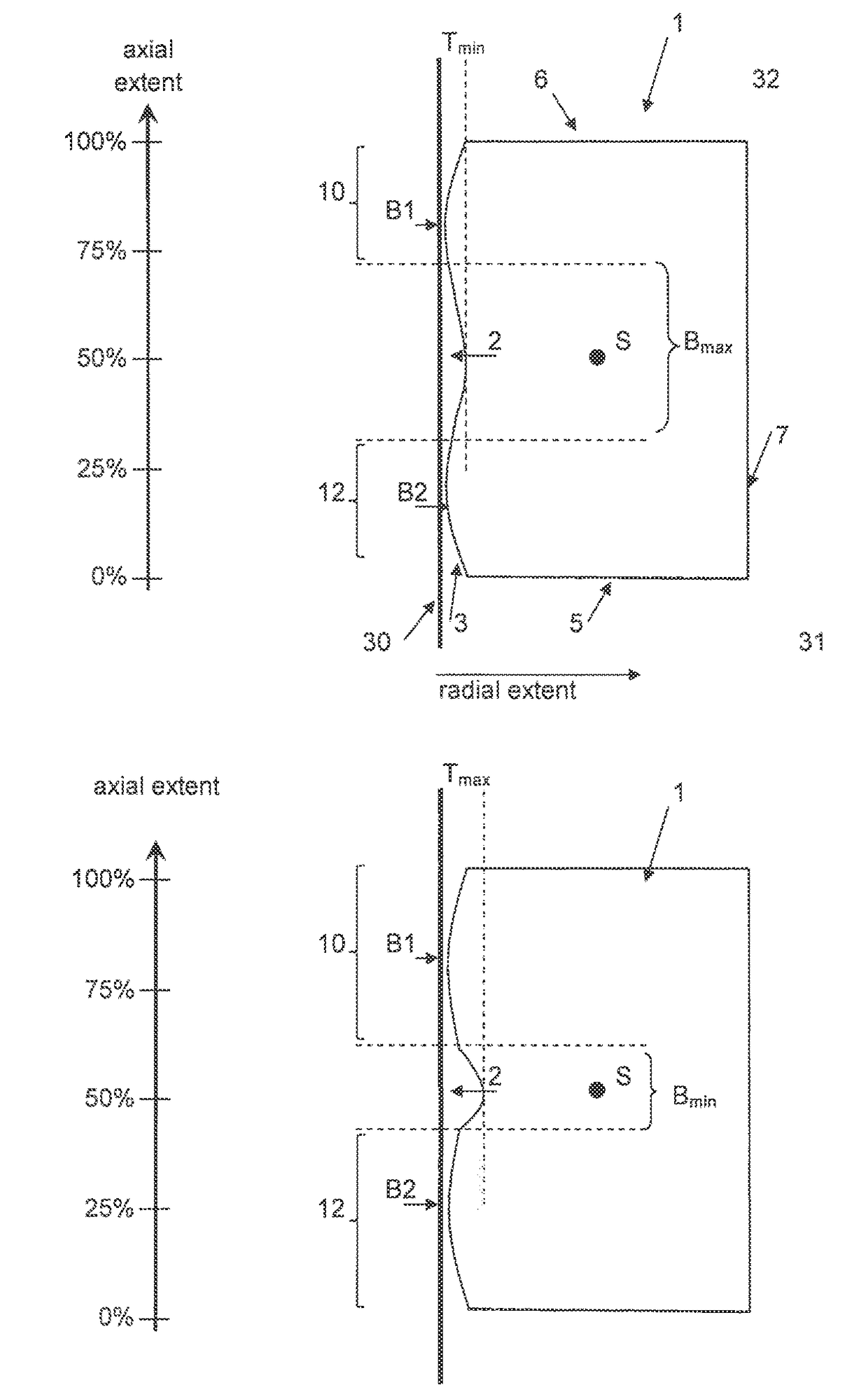

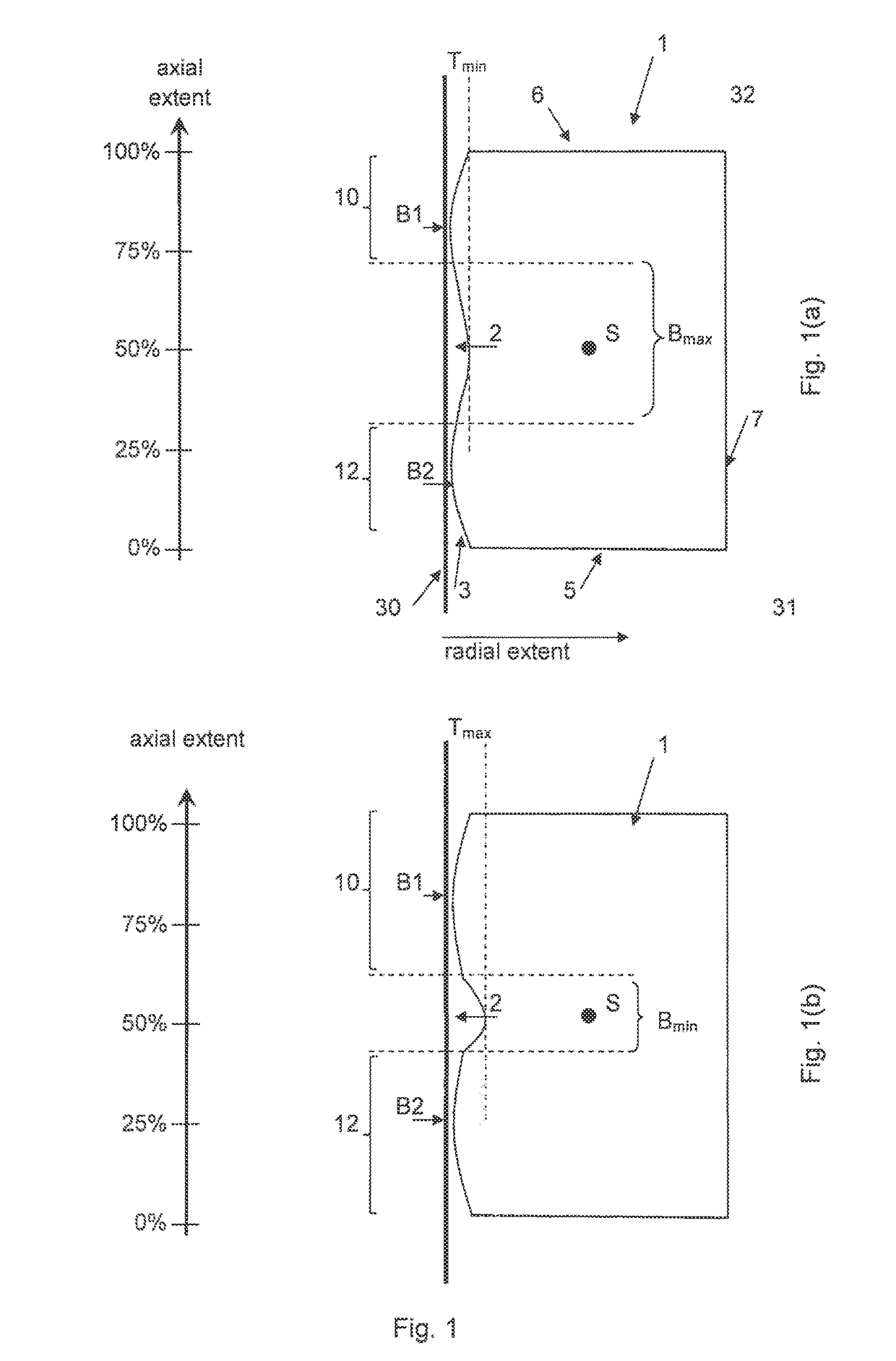

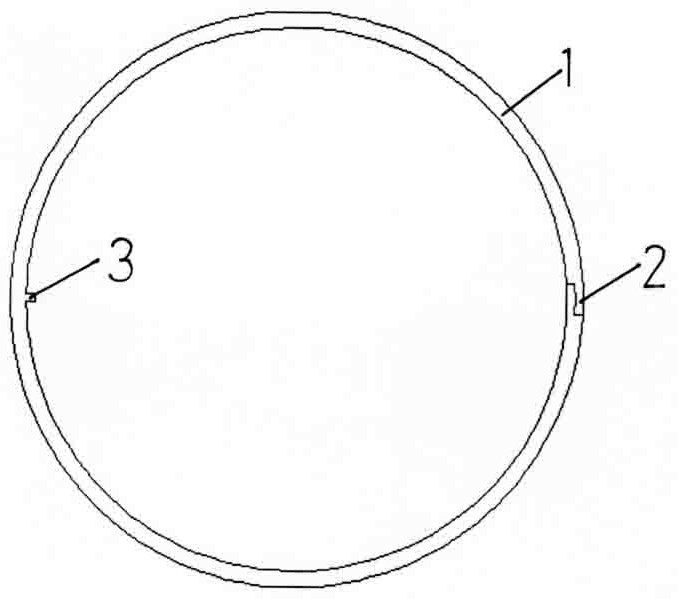

Piston ring with varying apex lines

InactiveUS20180274675A1Reduce in quantityEvenly distributedEngine sealsPiston ringsPiston ringEngineering

A piston ring having an outer running face, two flanks and an inner circumferential face is provided. The running face has profiling. The profile of the running face is substantially convexly curved and has an apex. The axial position of the apex varies periodically in the circumferential direction.

Owner:FEDERAL MOGUL BURSCHEID

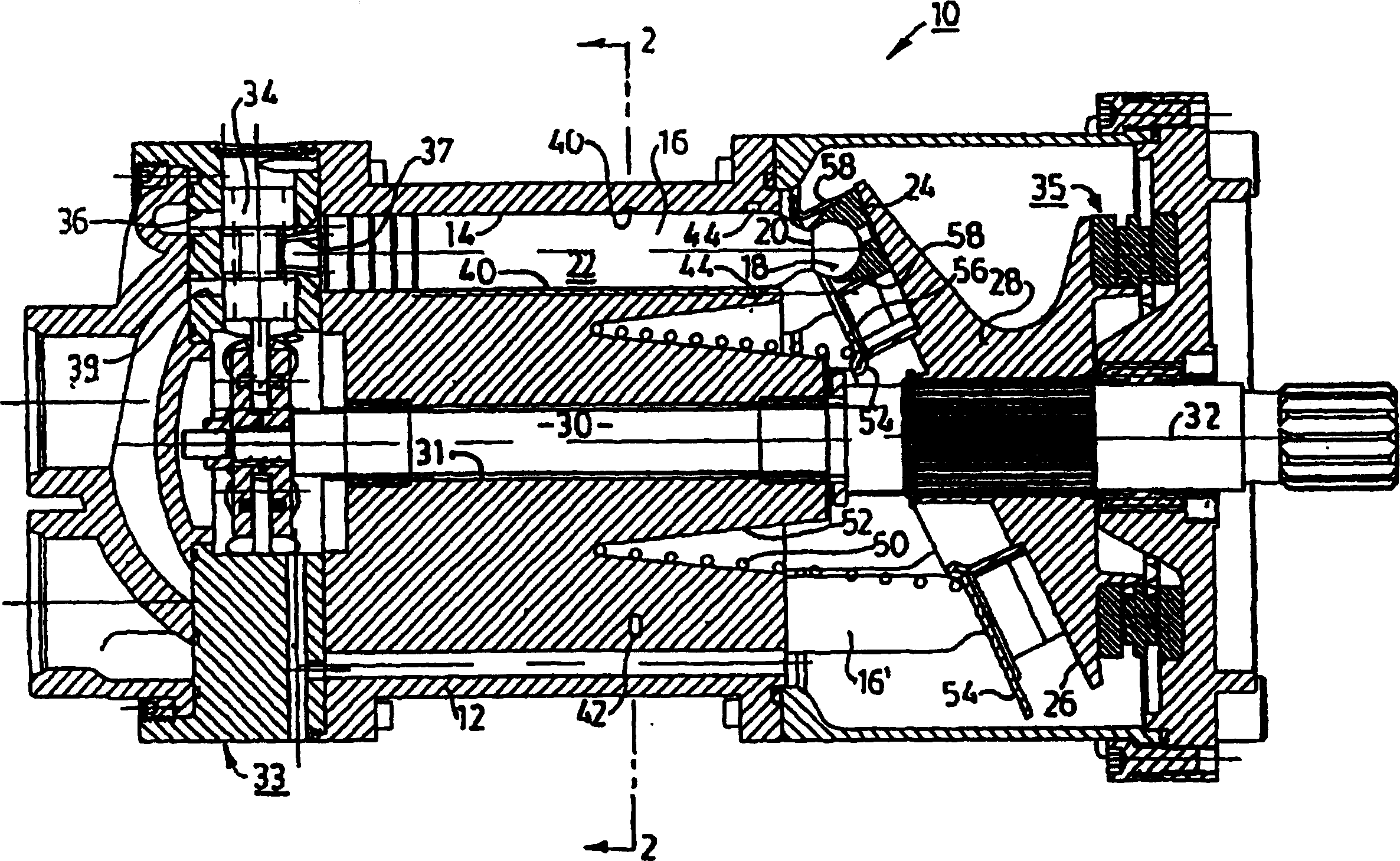

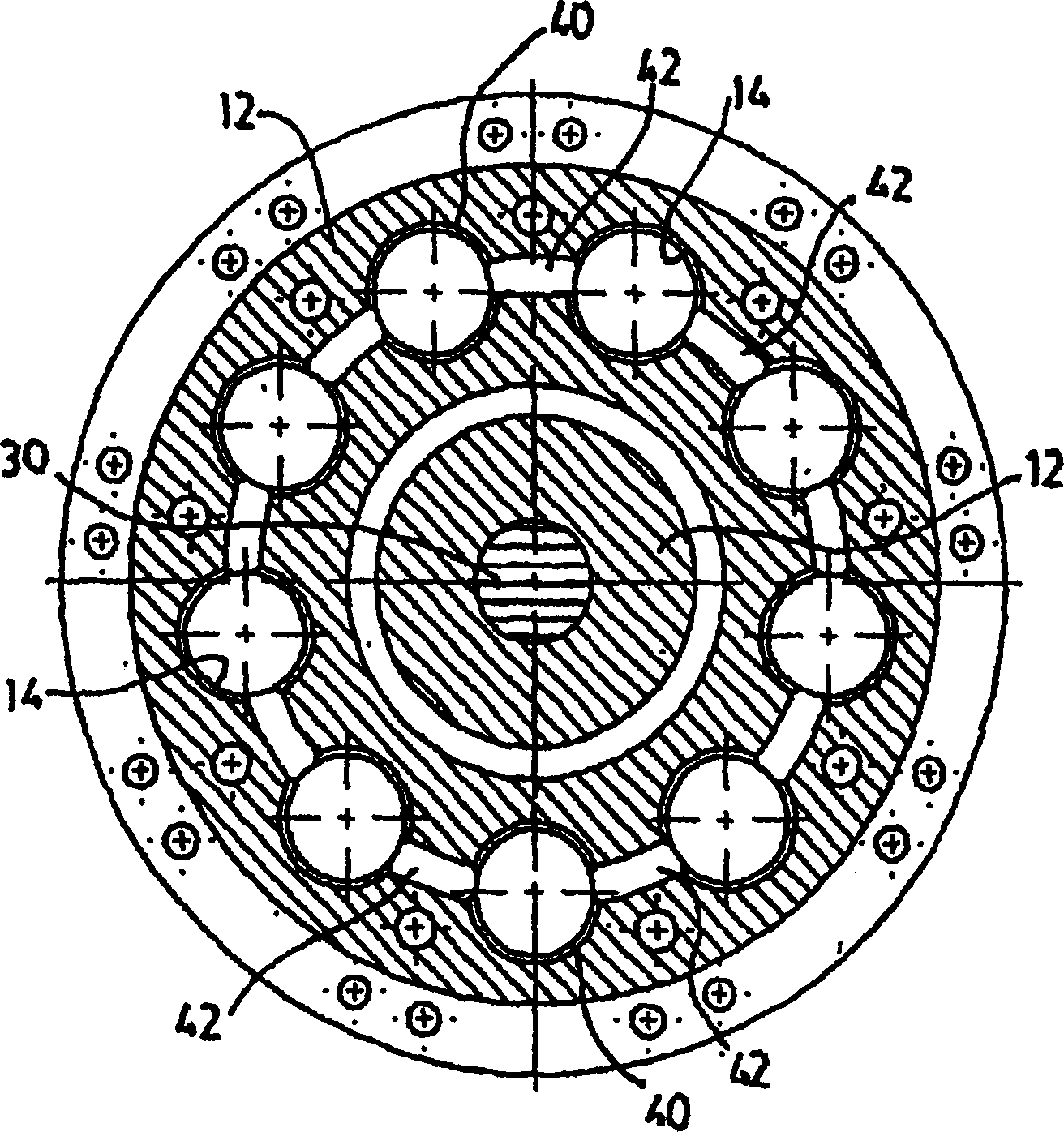

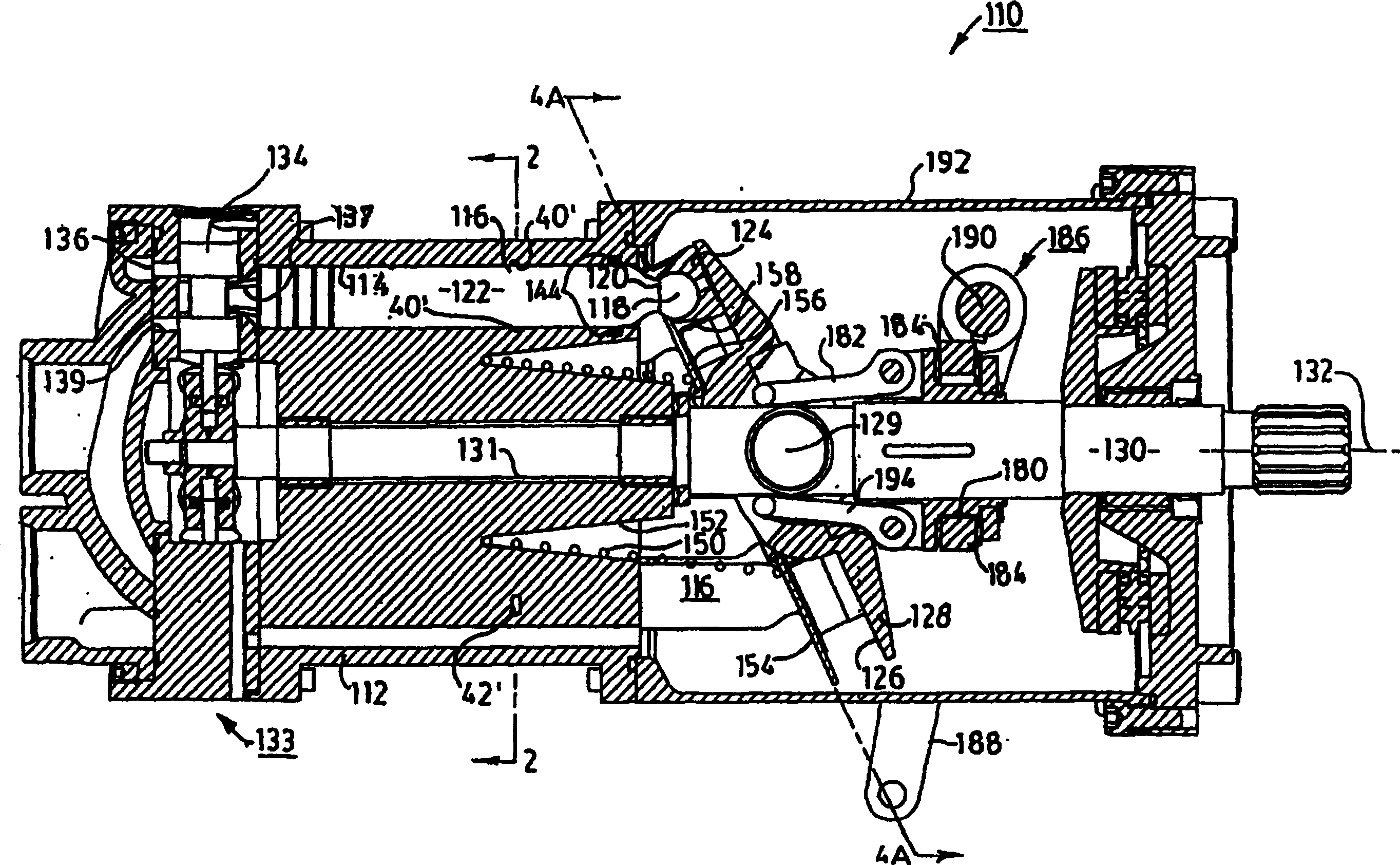

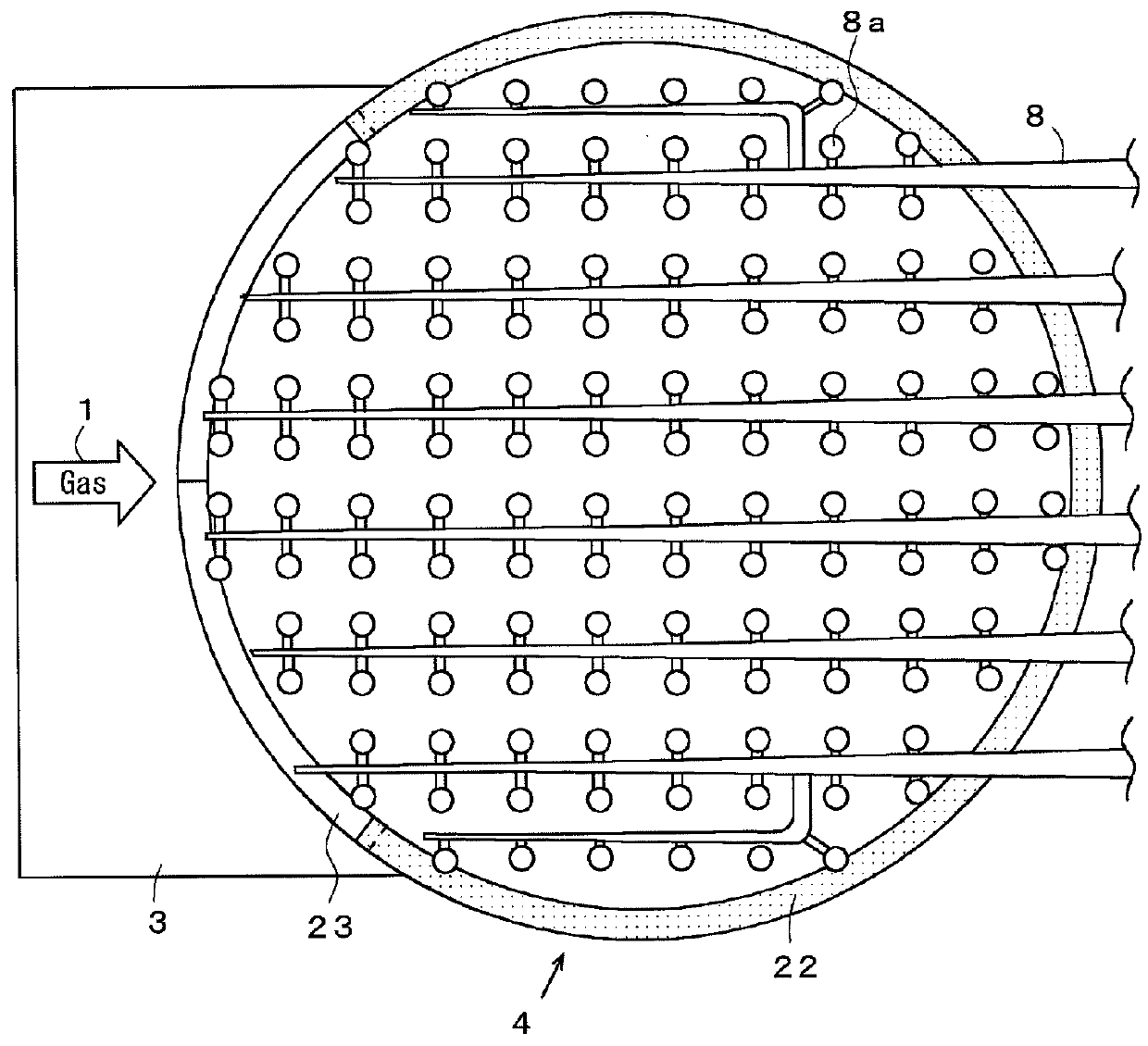

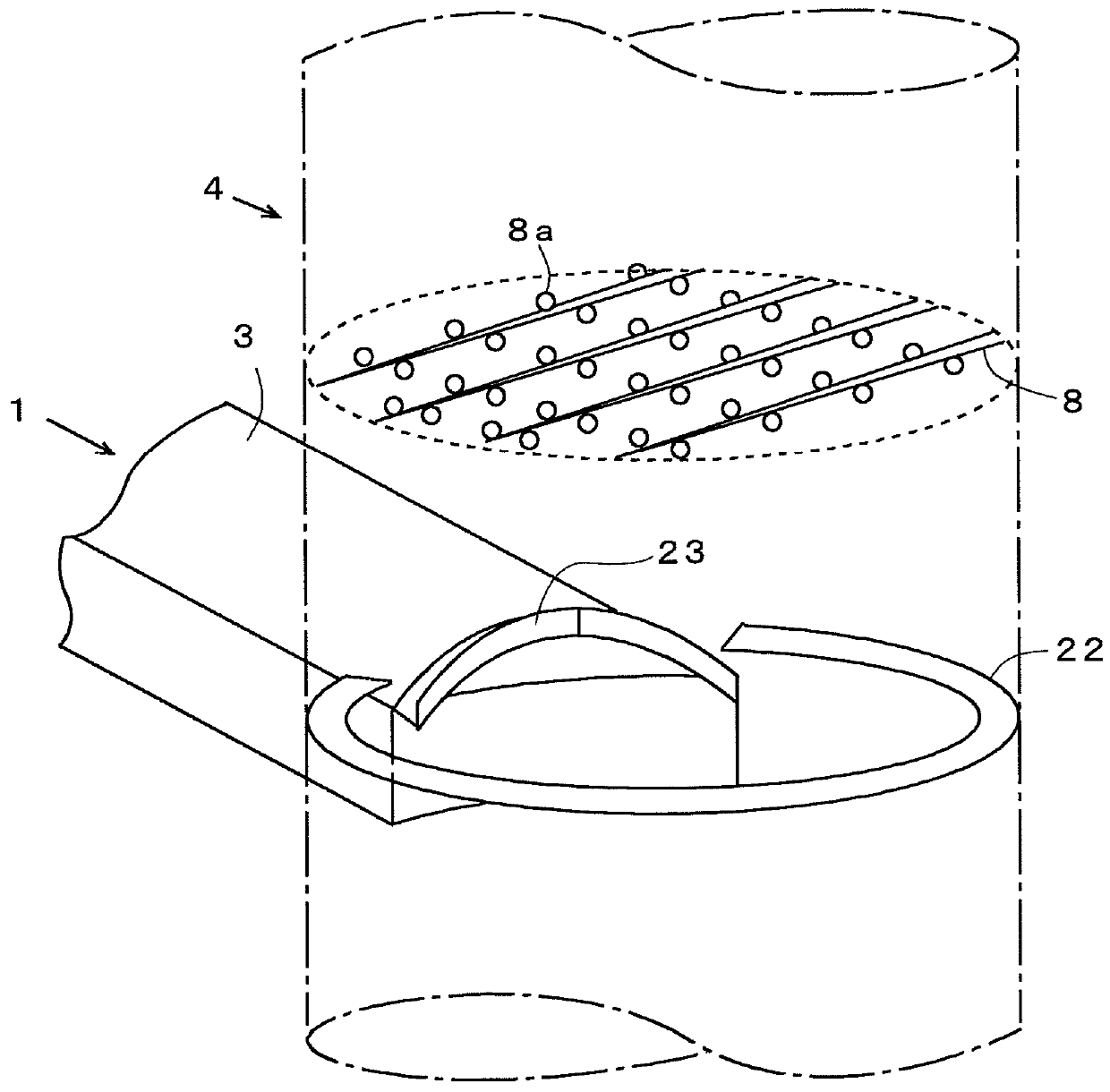

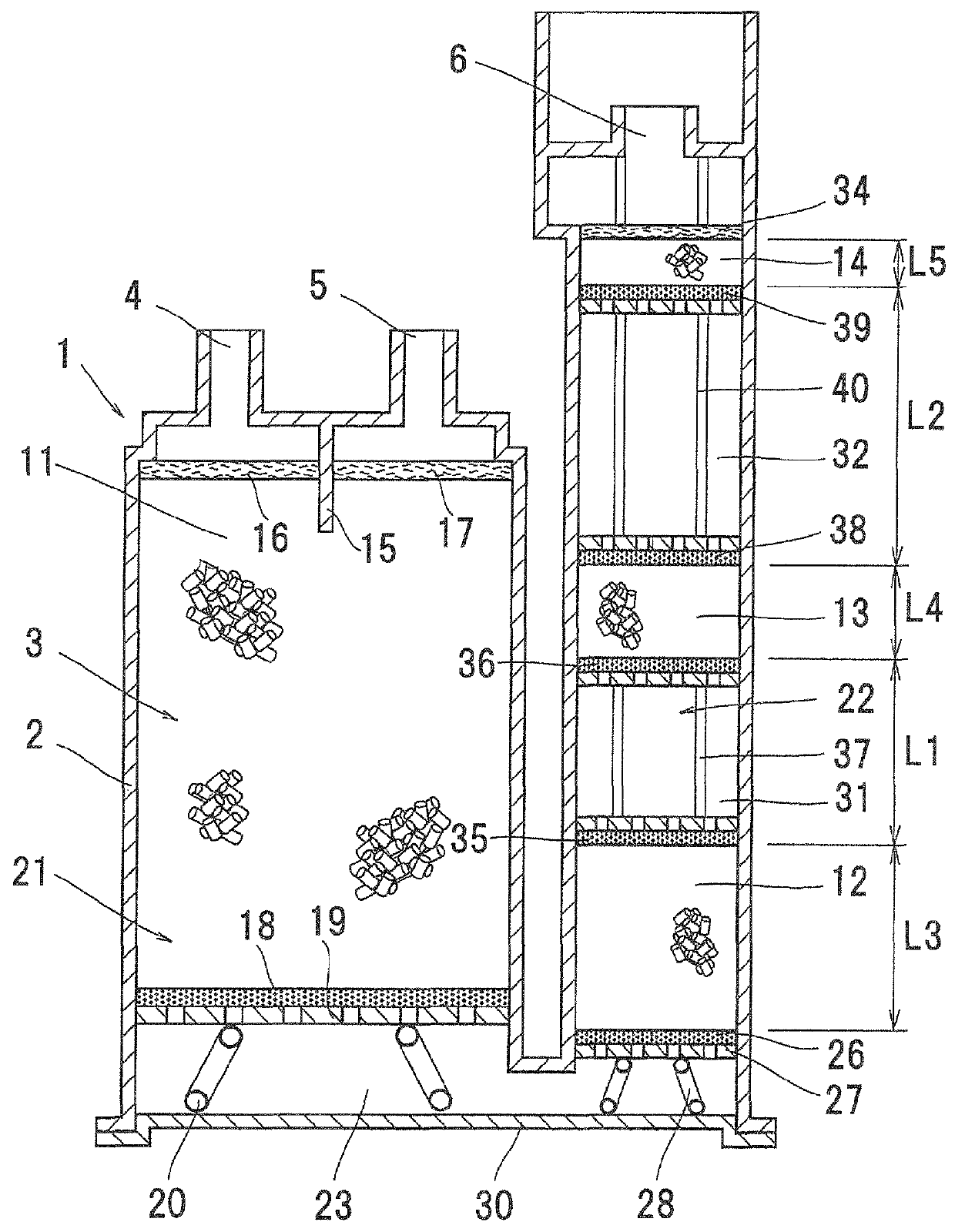

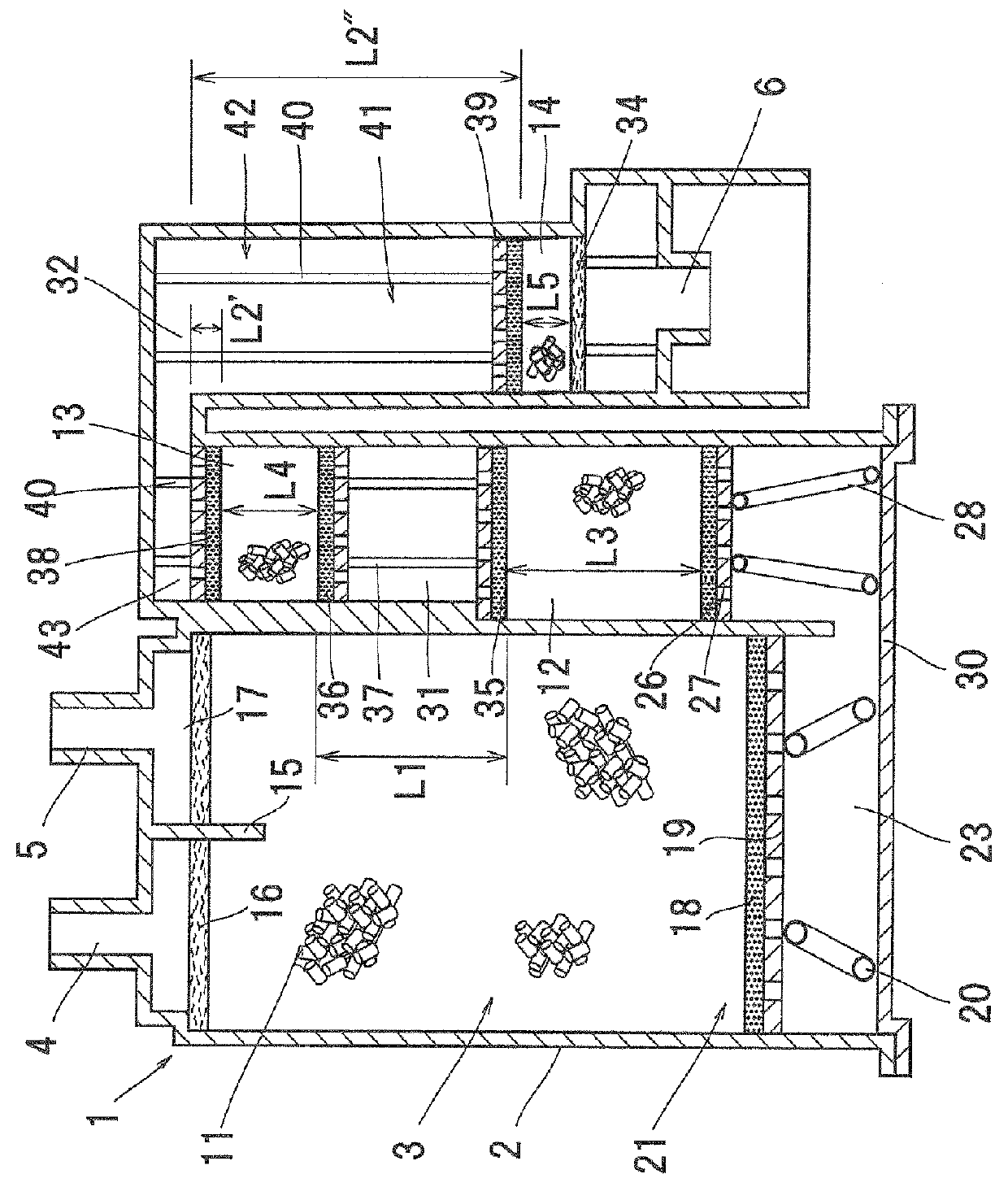

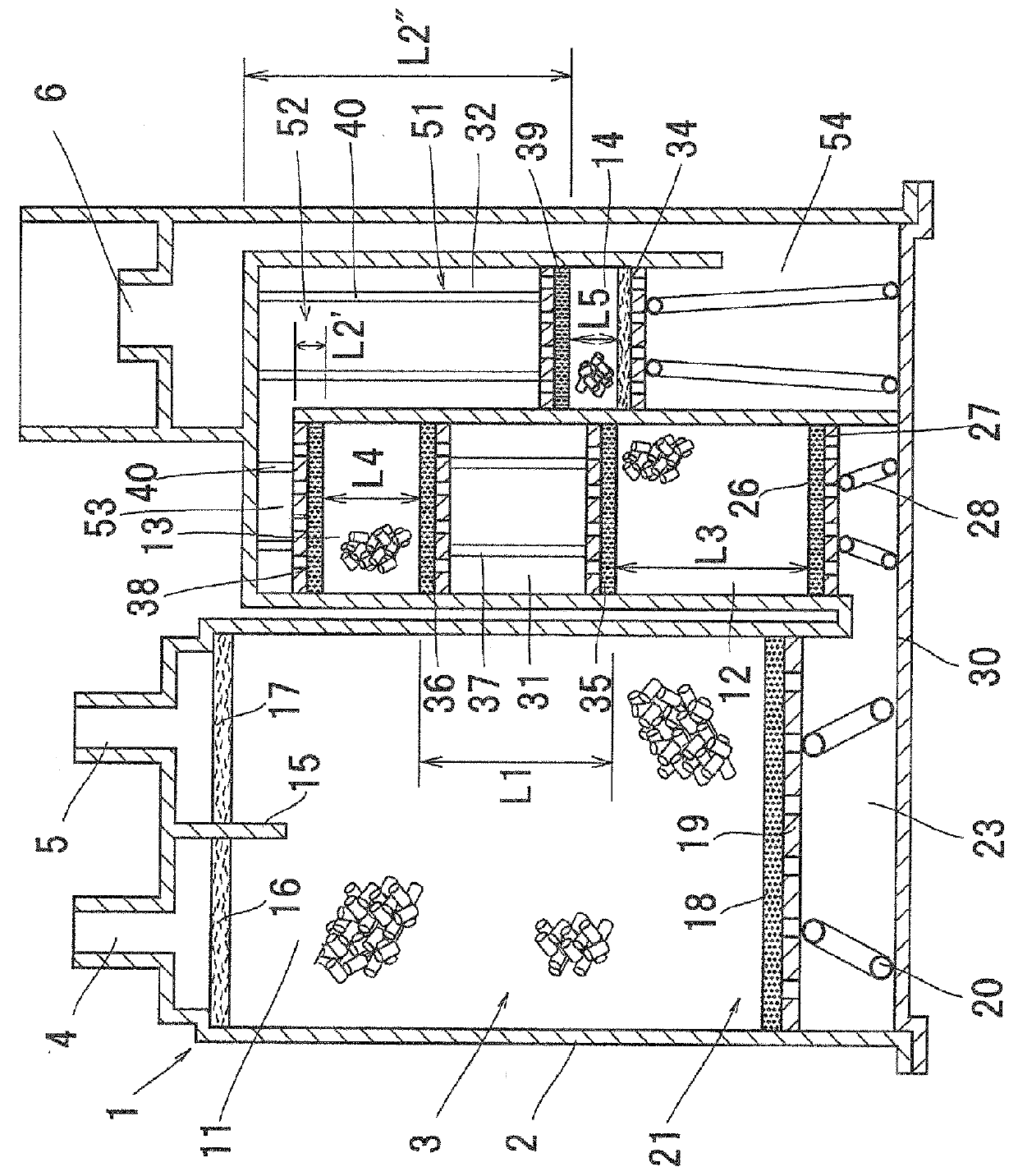

Long-piston hydraulic machines

InactiveCN1688812AReduce lateral displacementEffective sliding contactMulti-stage pumpsPositive-displacement liquid enginesReciprocating motionHydraulic pump

A smaller, lighter hydraulic pump or motor is provided with pistons, each of which has a body with a length approximately equal to the axial length of a corresponding cylinder in which the piston to-and-froly moves. A plurality of corresponding lubricating grooves which are circumferentially formed and radially traverse the wall of each cylinder are respectively positioned at positions which are always closed by the axial cylindrical body of each corresponding piston during the whole travel. The lubricating grooves are connected with one another to form a continuous lubricating channel totally positioned in the cylinder, and not connected by the input or output channels of fluid but supplemented by the blowby entering from the valve end of each cylinder. A plurality of sealing parts respectively positioned near the opening of each cylinder provide strong sealing and nearly eliminate the blowby coming from the lubricating channel, thus notably increasing the volumetric efficiency. The formed improved lubrication, combined with the only spring biasing holddown component, can use a variable-angle swash cam arrangement, which does not need not only a dogbone part on the outer end of the piston but also an ordinary swinger which can only nutate.

Owner:TORVEC INC

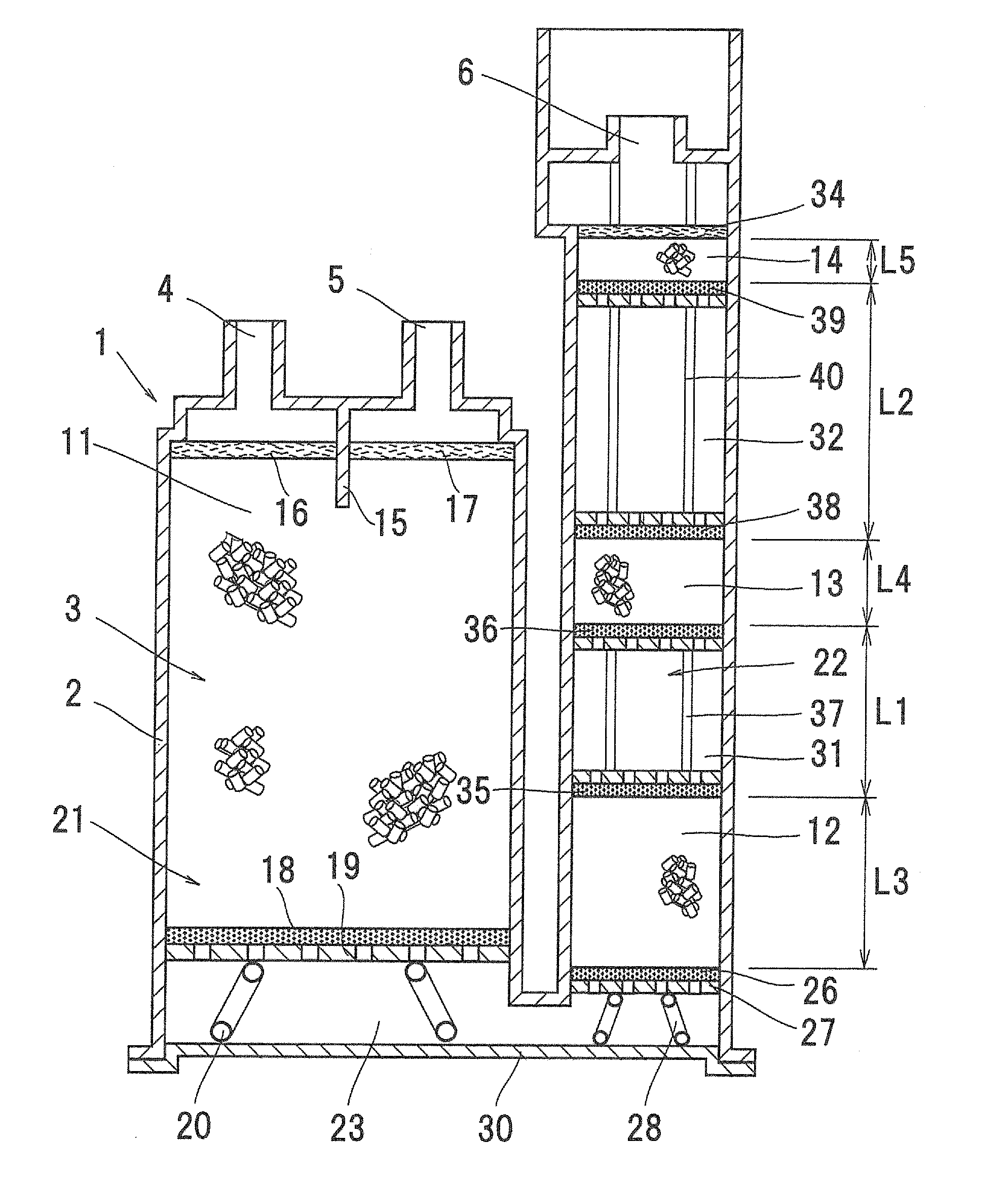

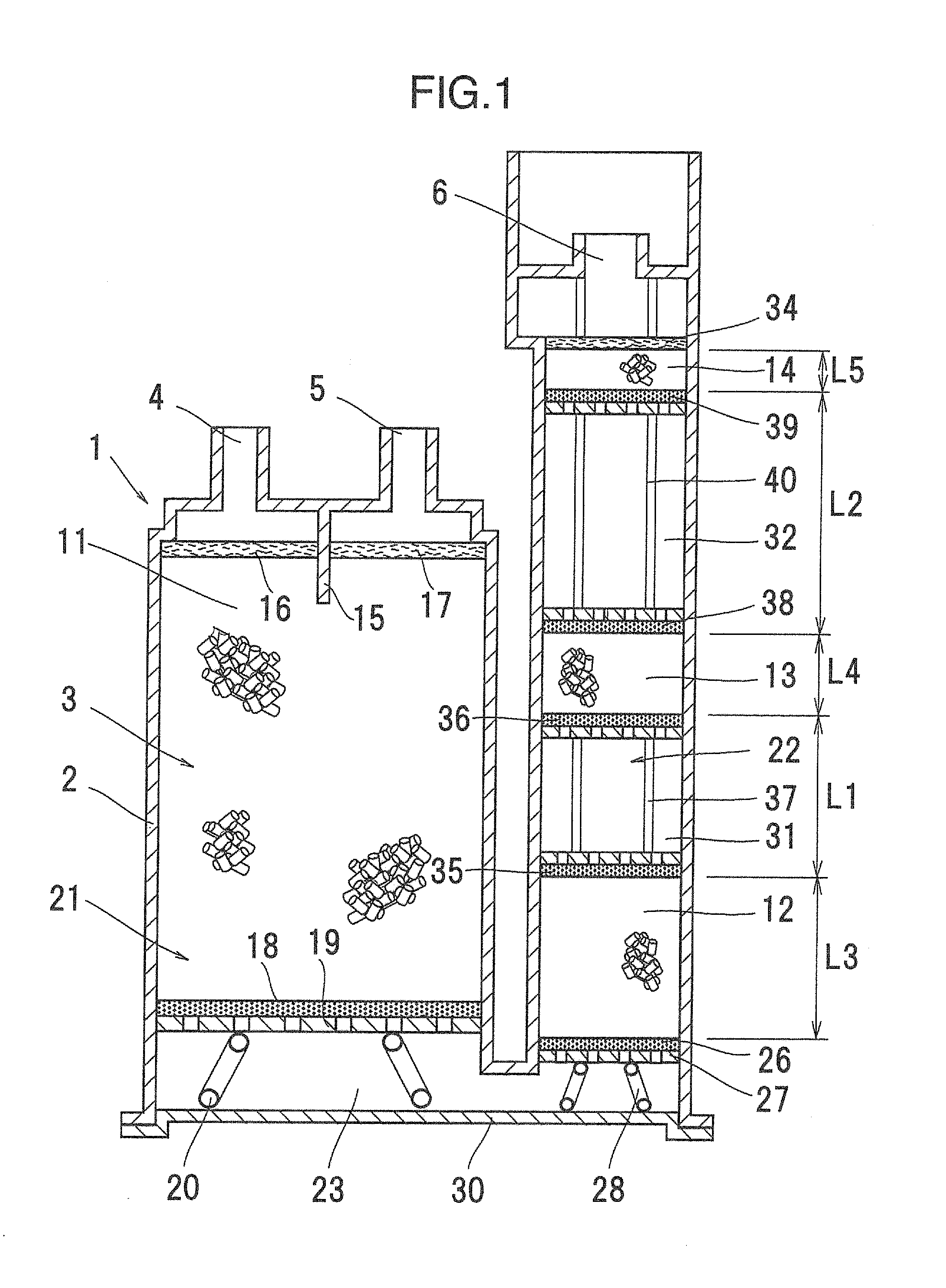

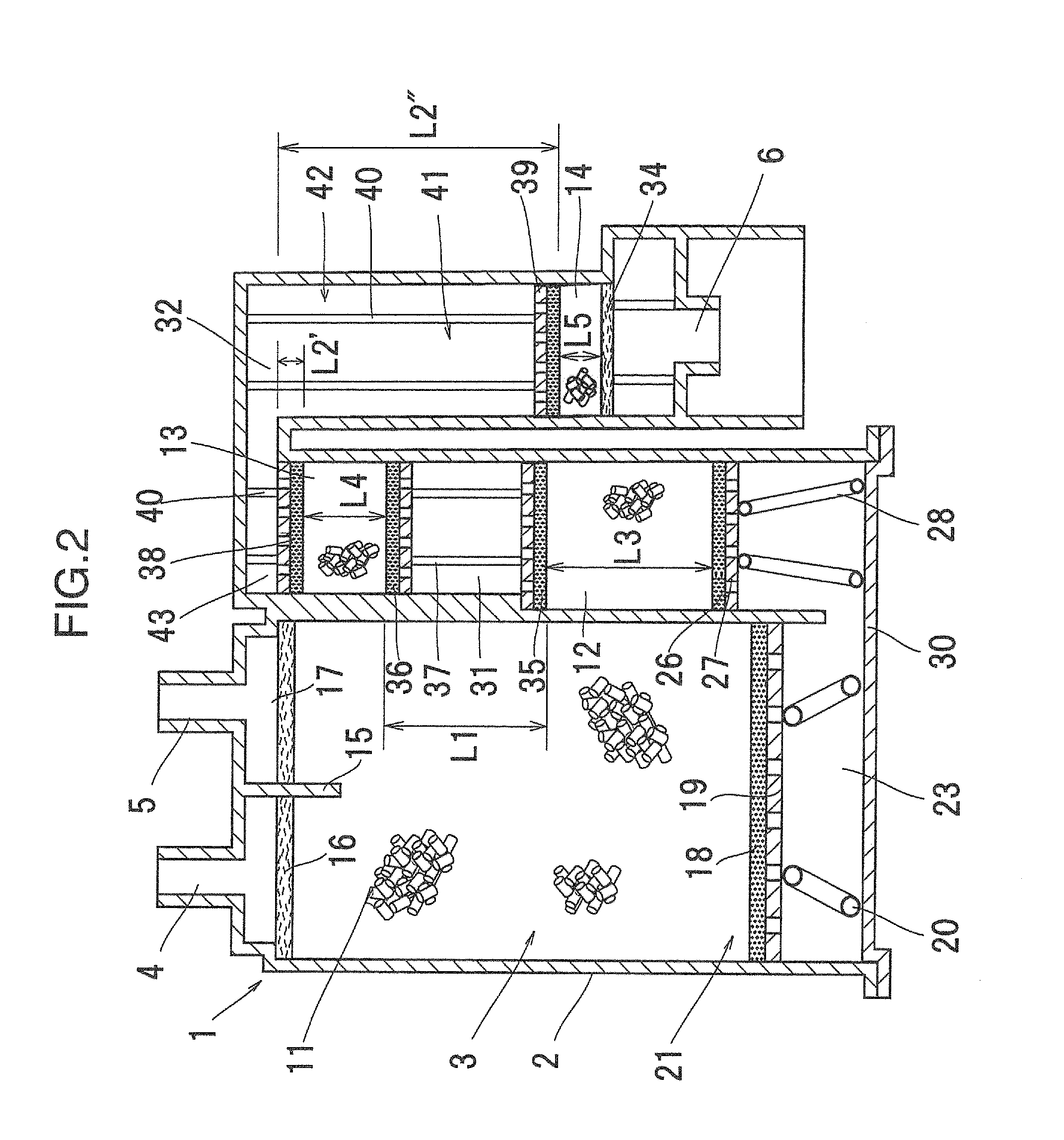

Evaporation fuel processing device

ActiveUS20140060499A1Reduce componentsReduce blowbyGas treatmentNon-fuel substance addition to fuelAtmospheric airSorbent

The present invention provides an evaporation fuel processing device including: a passage formed inside so as to allow a fluid to flow through the passage; a tank port and a purge port formed on one end side of the passage; an atmospheric air port formed on the other end side of the passage; and adsorbent layers filled with adsorbent which can adsorb evaporation fuel components, the adsorbent layers being provided in the passage, wherein a region which is constituted of three or more adsorbent layers and separating parts for separating the adjacent adsorbent layers, and in which a total volume of the adsorbent layers is set smaller than a total volume of the separating parts, is provided on an atmospheric air port side of the passage.

Owner:AISAN IND CO LTD

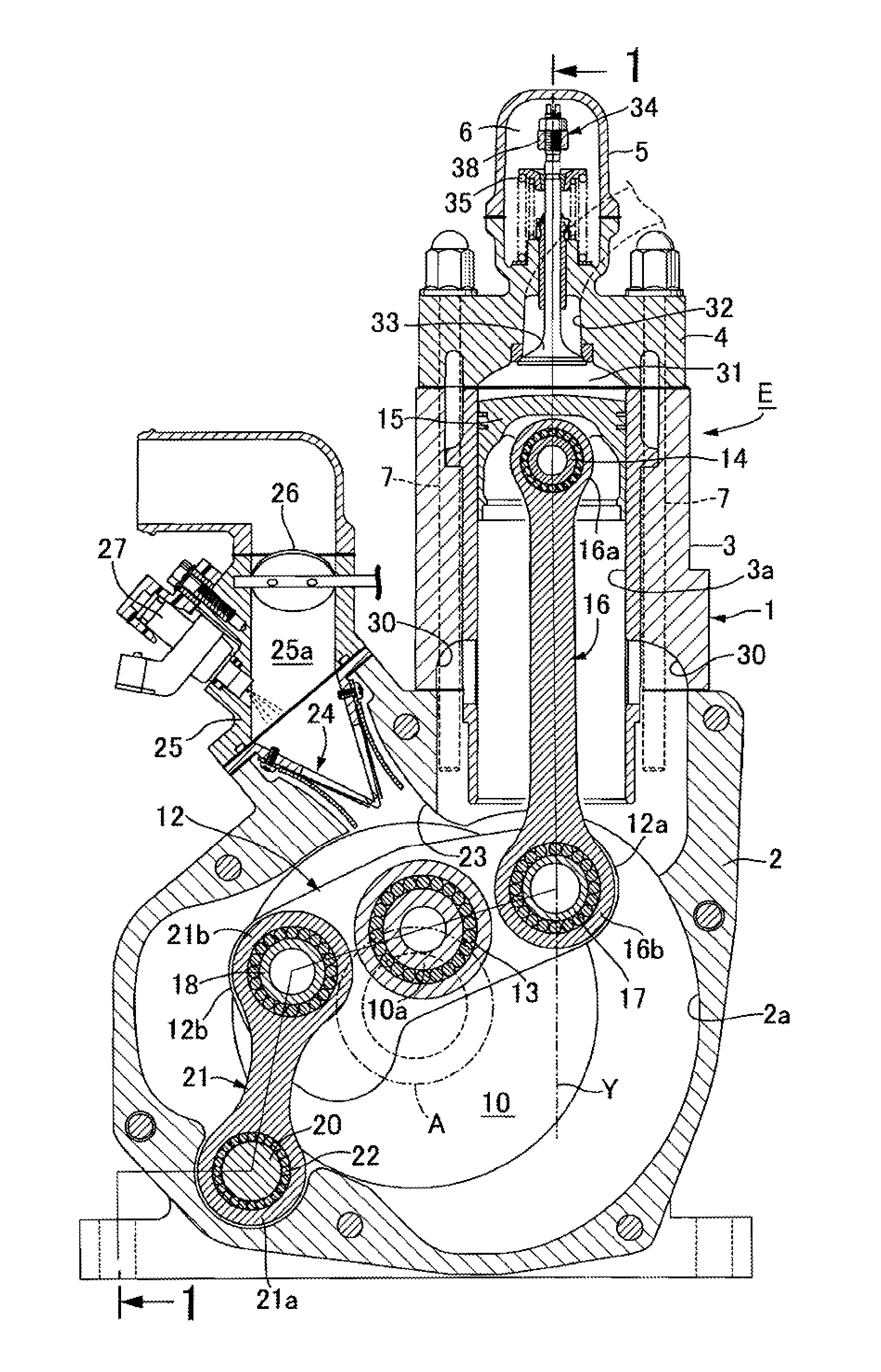

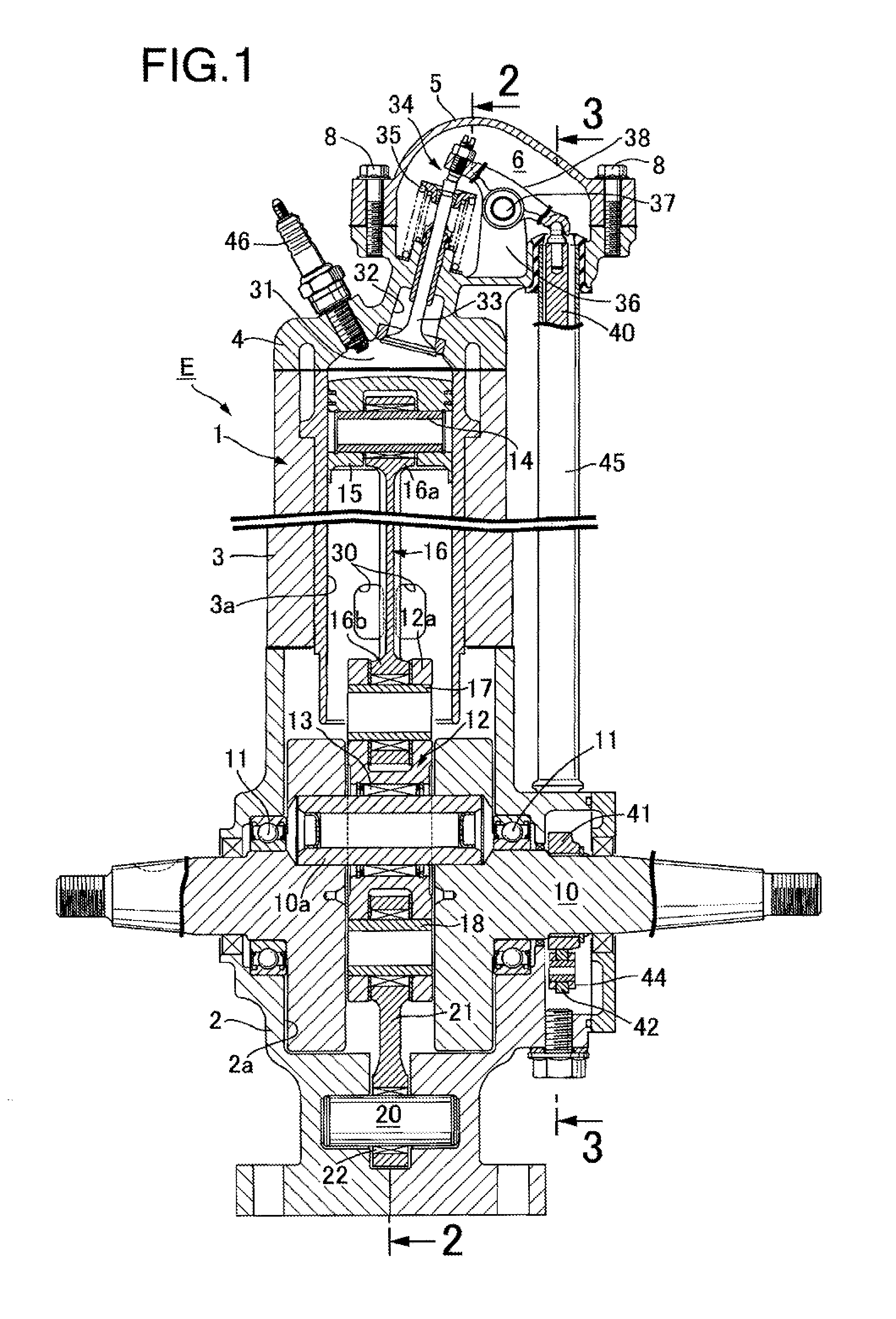

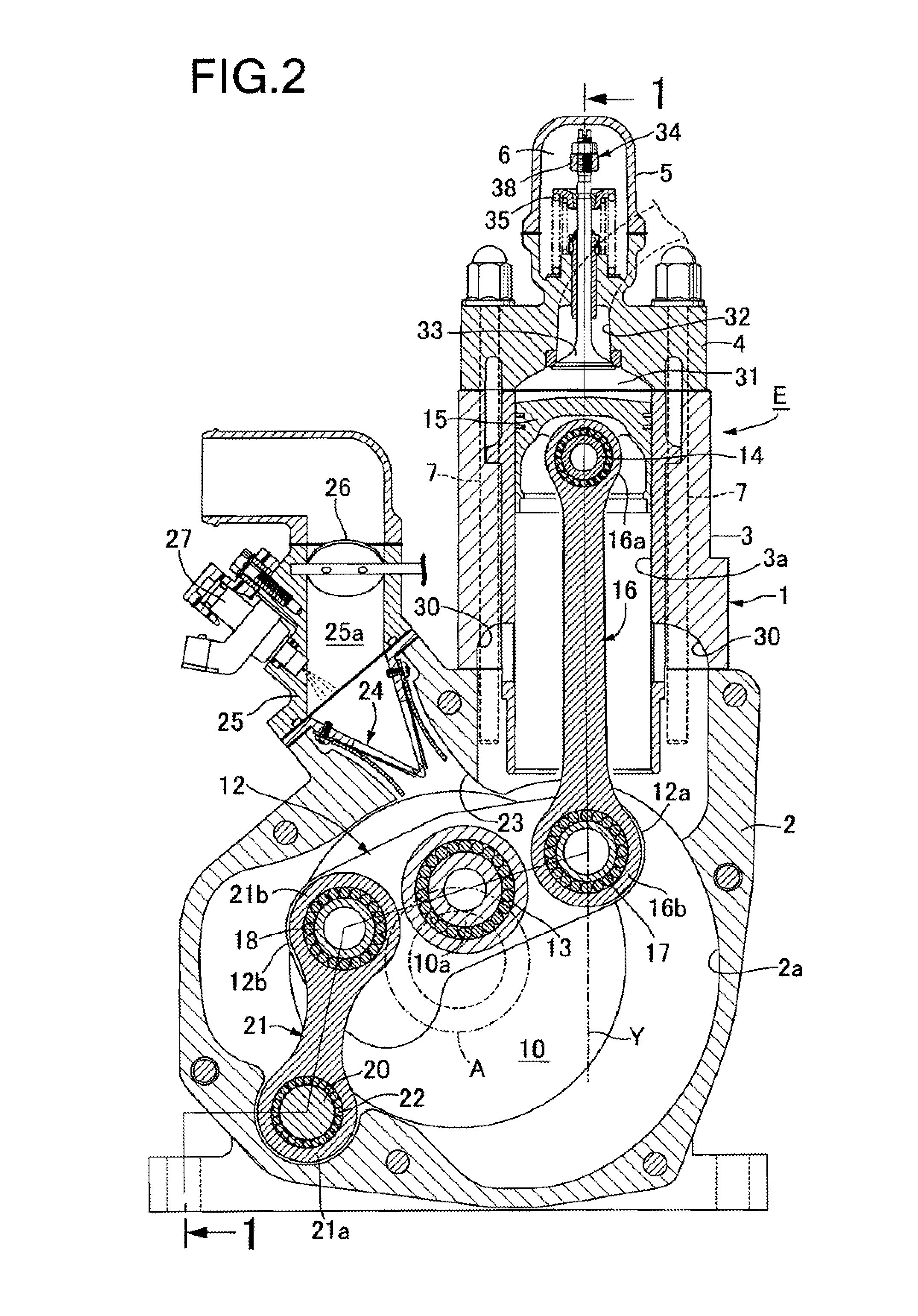

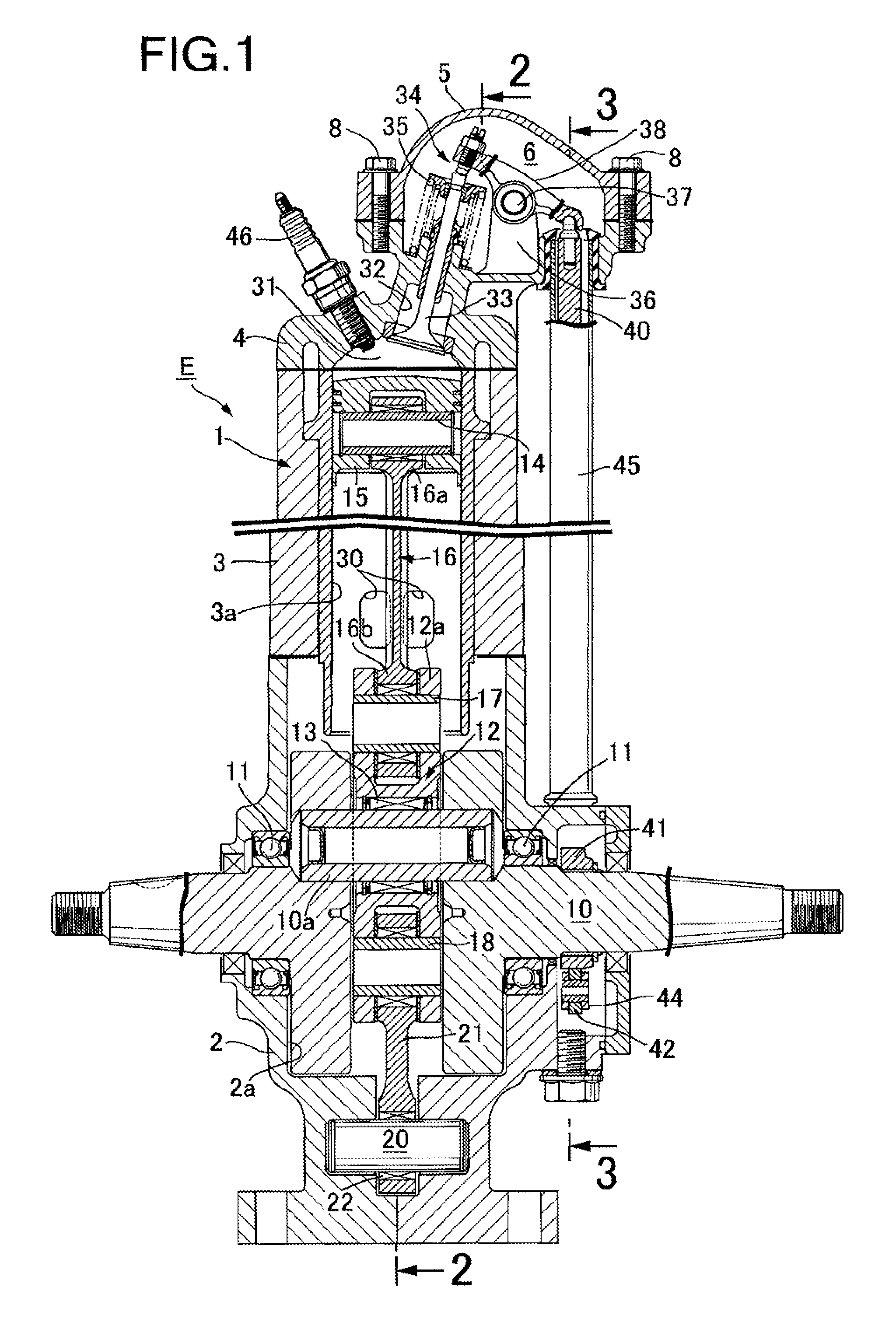

Premixed compression self-ignition engine

InactiveUS20140209054A1Increase the compression ratioHigh thermal efficiencyConnecting rodsCrankshaft bearingsExhaust valveCylinder head

In a premixed compression self-ignition engine which is compact but capable of exerting a high output, an intermediate portion of a trigonal link is rotatably supported on a crankpin, a large end portion of a connecting rod is connected to one end portion of the trigonal link, and a swing link swingably supported on a fulcrum shaft is connected to another end portion of the trigonal link. The engine includes: an intake port open to a crank chamber; a reed valve mounted in the intake port; a scavenging port configured to guide fresh air from the crank chamber into a cylinder bore in a downward stroke of a piston; an exhaust port provided in a cylinder head and open to a top portion of the cylinder bore; and an exhaust valve configured to be opened before the piston opens the scavenging port in the downward stroke of the piston.

Owner:HONDA MOTOR CO LTD

Evaporation fuel processing device

ActiveUS9422894B2Reduce componentsReduce blowbyNon-fuel substance addition to fuelMachines/enginesAtmospheric airEvaporation

An evaporation fuel processing device is provide including: a passage; a tank port and a purge port on one end side of the passage; an atmospheric air port on the other end side of the passage; and adsorbent layers filled with adsorbent for evaporation fuel components, provided in the passage; a region provided on an atmospheric air port side of the passage, being constituted of three or more adsorbent layers and separating parts for separating the adjacent adsorbent layers, in which a volume of the adsorbent layer is smaller in the adsorbent layer closer to the atmospheric air port, a volume of the separating part is larger closer to the atmospheric air port, and the volume of the separating part located farthest on a tank port side is larger than that of the adsorbent layer located farthest on the atmospheric air port side.

Owner:AISAN IND CO LTD

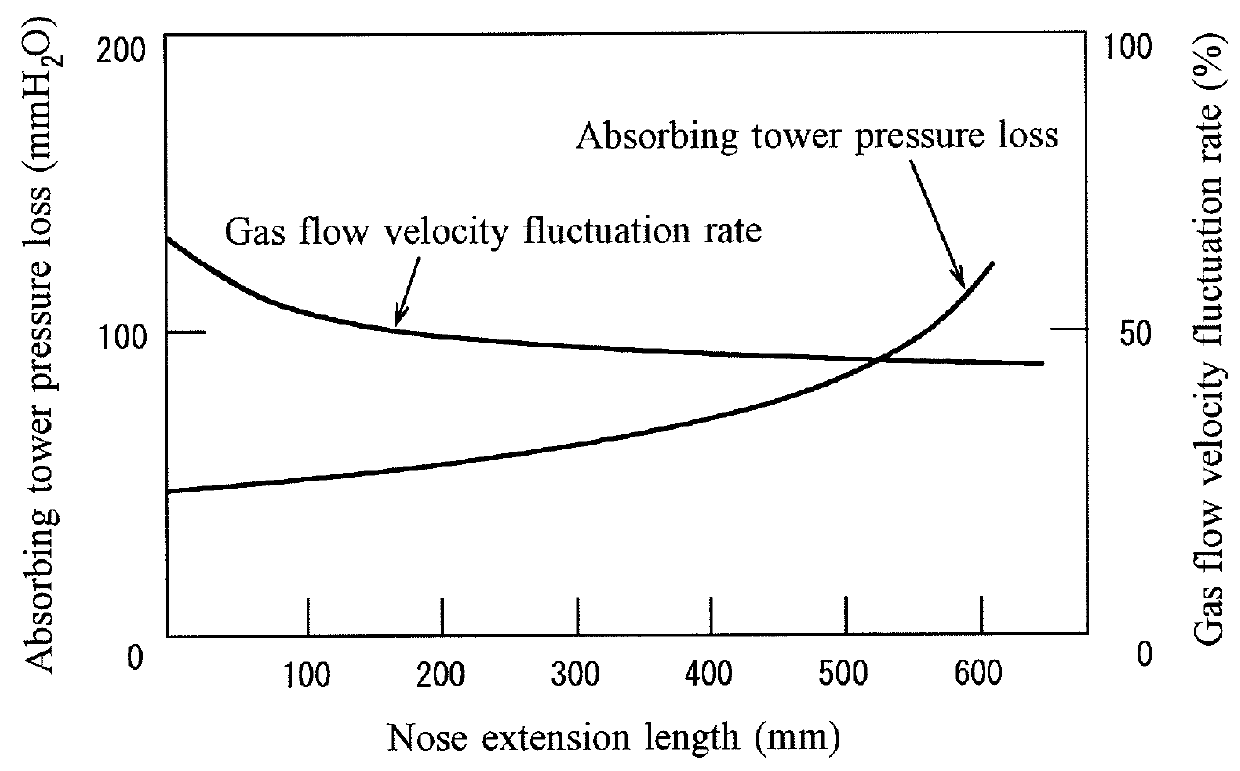

Wet-type exhaust desulfurizing apparatus

ActiveUS8172931B2Reduce the required powerReduce total powerGas treatmentMixing methodsCombustionExhaust fumes

Owner:MITSUBISHI POWER LTD

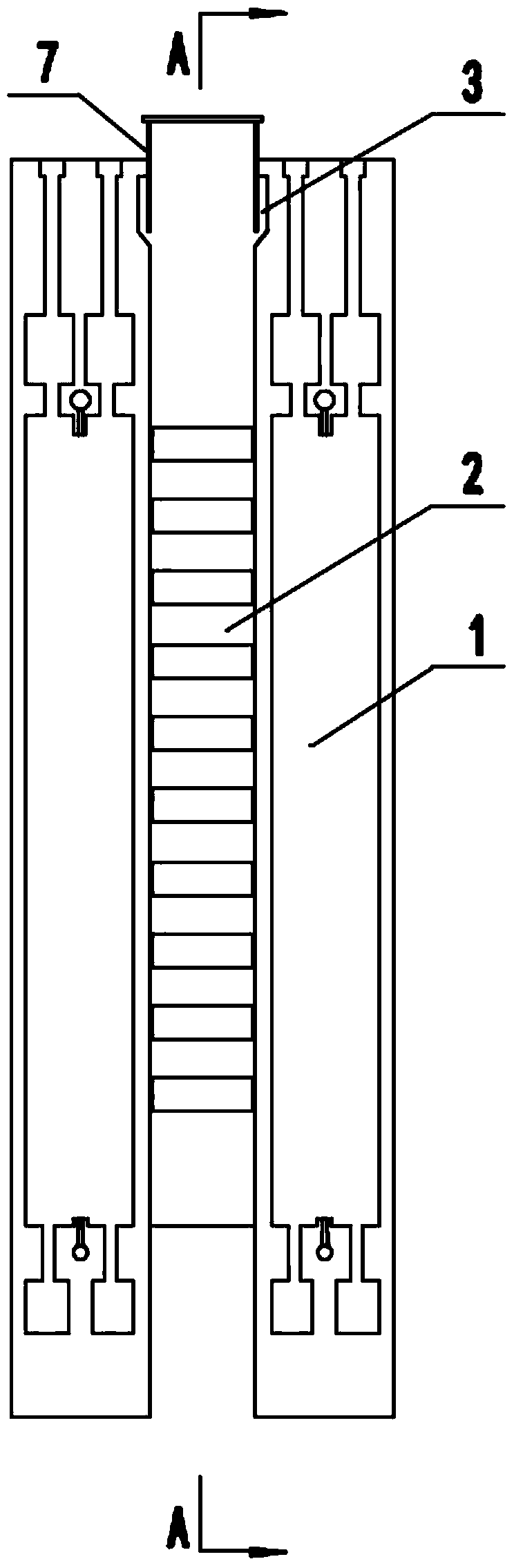

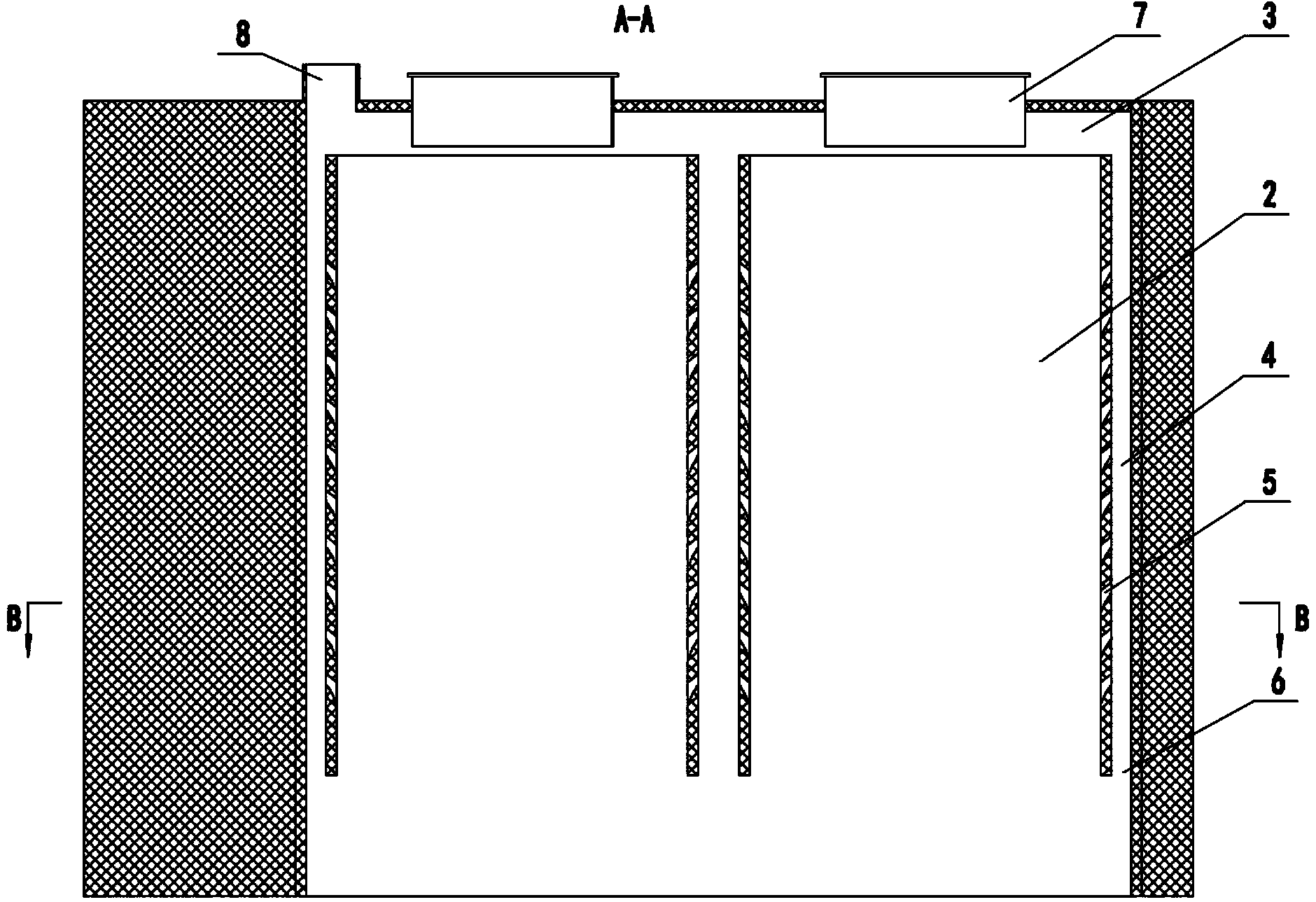

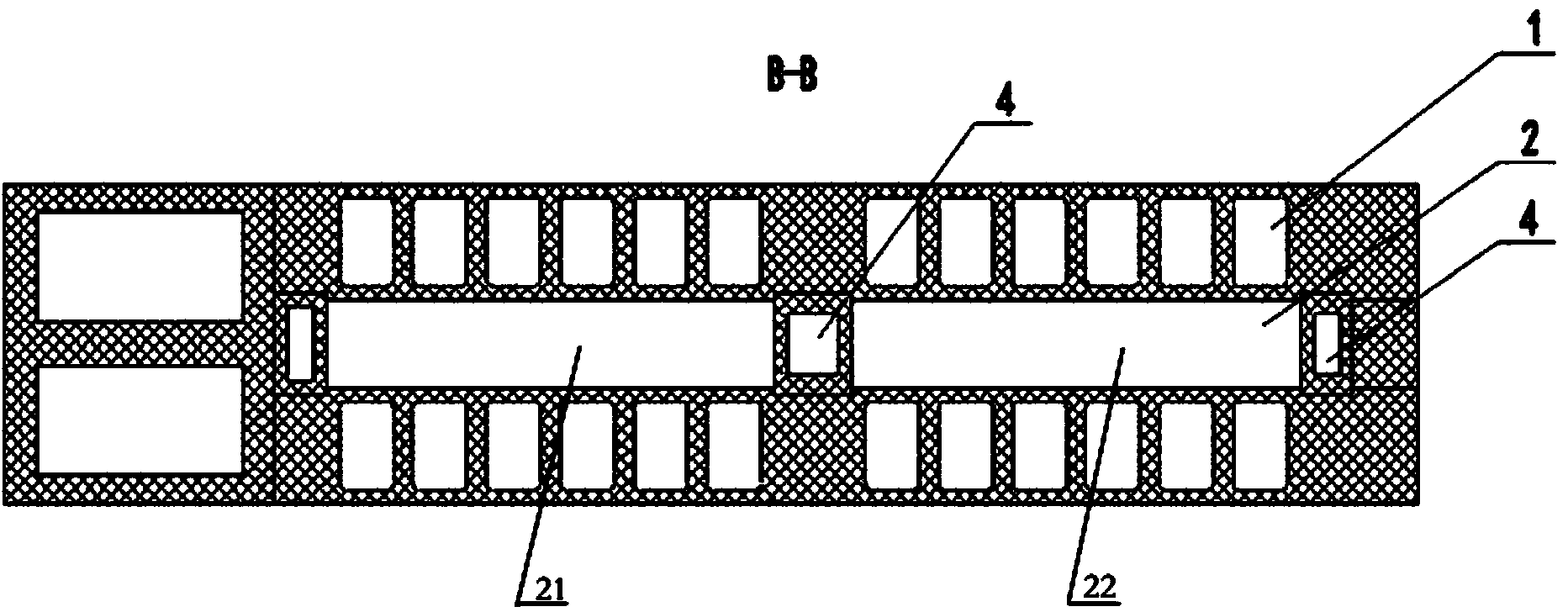

Vertical furnace carbonization chamber with internal gas collection cavities

ActiveCN103897710AImprove gas recovery rateReduce furnace pressureSpecial form destructive distillationStationary retortsTarSteel plates

The invention relates to a vertical furnace carbonization chamber with internal gas collection cavities. The vertical furnace carbonization chamber comprises a carbonization chamber, wherein gas collection cavities are arranged at the two ends and / or in the middle of the carbonization chamber along the height direction of the carbonization chamber; coal gas export holes are formed between the carbonization chamber and the gas collection cavities; a convergence gas channel is arranged at the top of the carbonization chamber, is communicated with each gas collection cavity and leads to an ascending pipe; the gas collection cavities, the coal gas export holes and the convergence gas channel can be formed by refractory bricks and can be also formed by welding heat-resisting steel plates. Compared with the prior art, the vertical furnace carbonization chamber has the beneficial effects that 1) the vertical furnace carbonization chamber can be widely used for preparing tar, coal gases and semi-coke through dry distillation of various low-rank coal, is not limited by feed coal granularity requirements, is suitable for lump coal raw materials and is also suitable for pulverized coal raw materials; 2) the pressure in the furnace can be reduced, furnace body blowby can be reduced, the coal gas recovery rate can be increased, the production safety can be improved, and the furnace body life can be prolonged; 3) the amount of coke powder entrained by raw gas produced by the device is smaller, and coal tar and coal gases with higher quality can be produced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for metallurgically bonding a cylinder liner into a bore in an engine block

InactiveCN107971623ALow ductilityImprove ductilityCylinder headsWelding/cutting auxillary devicesCylinder blockMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

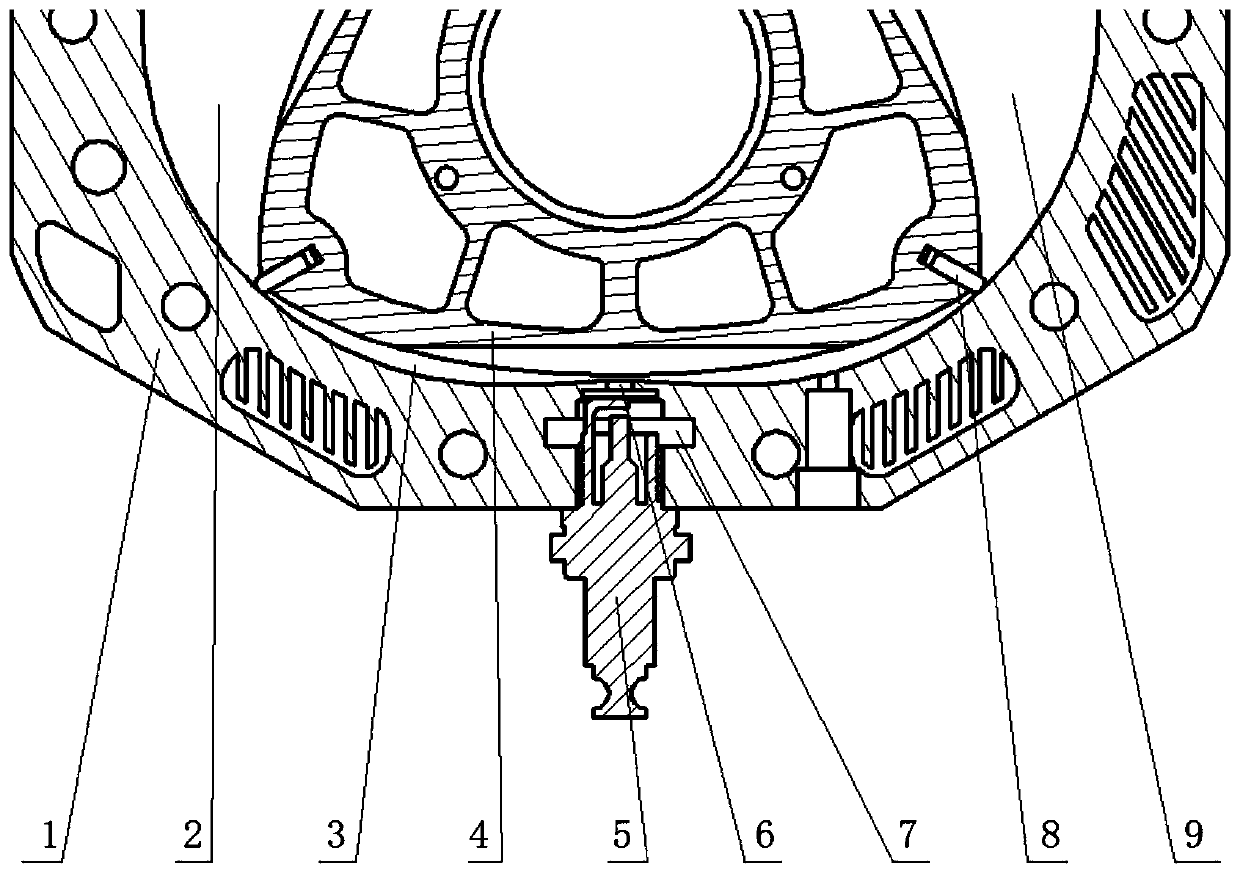

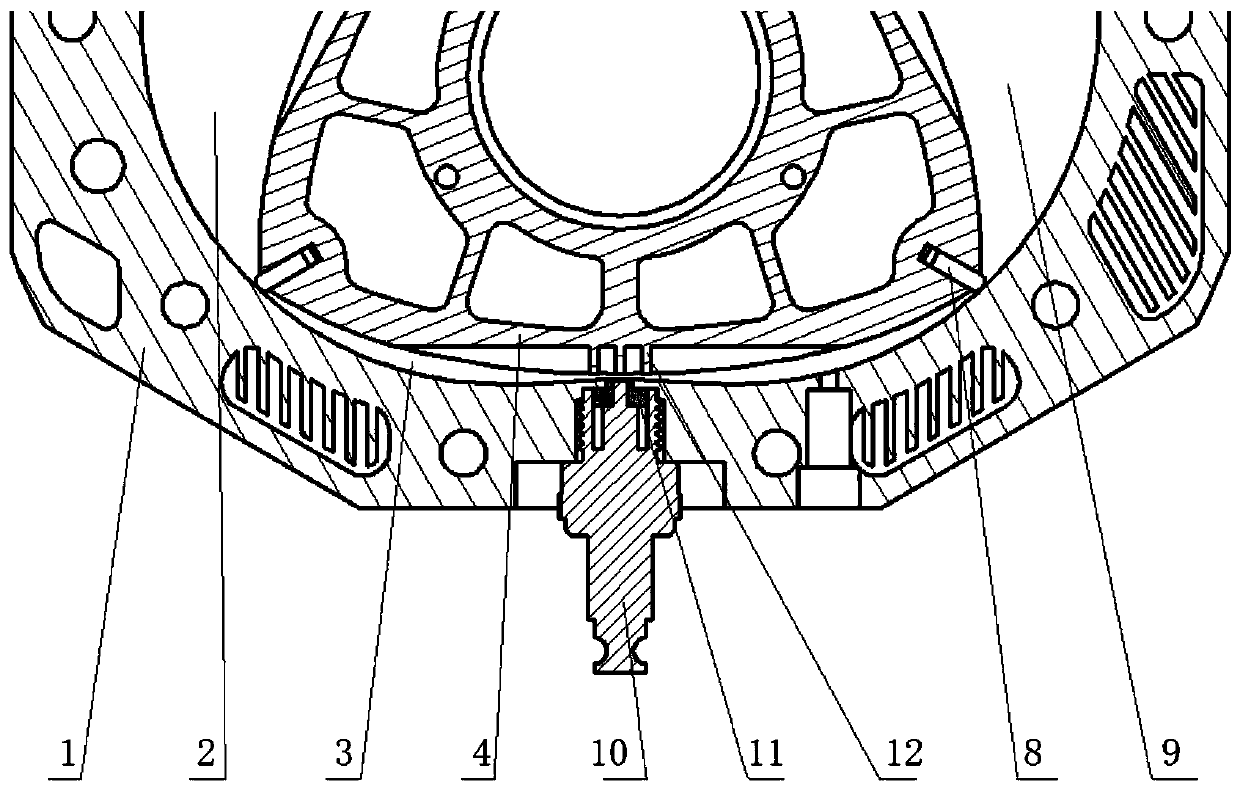

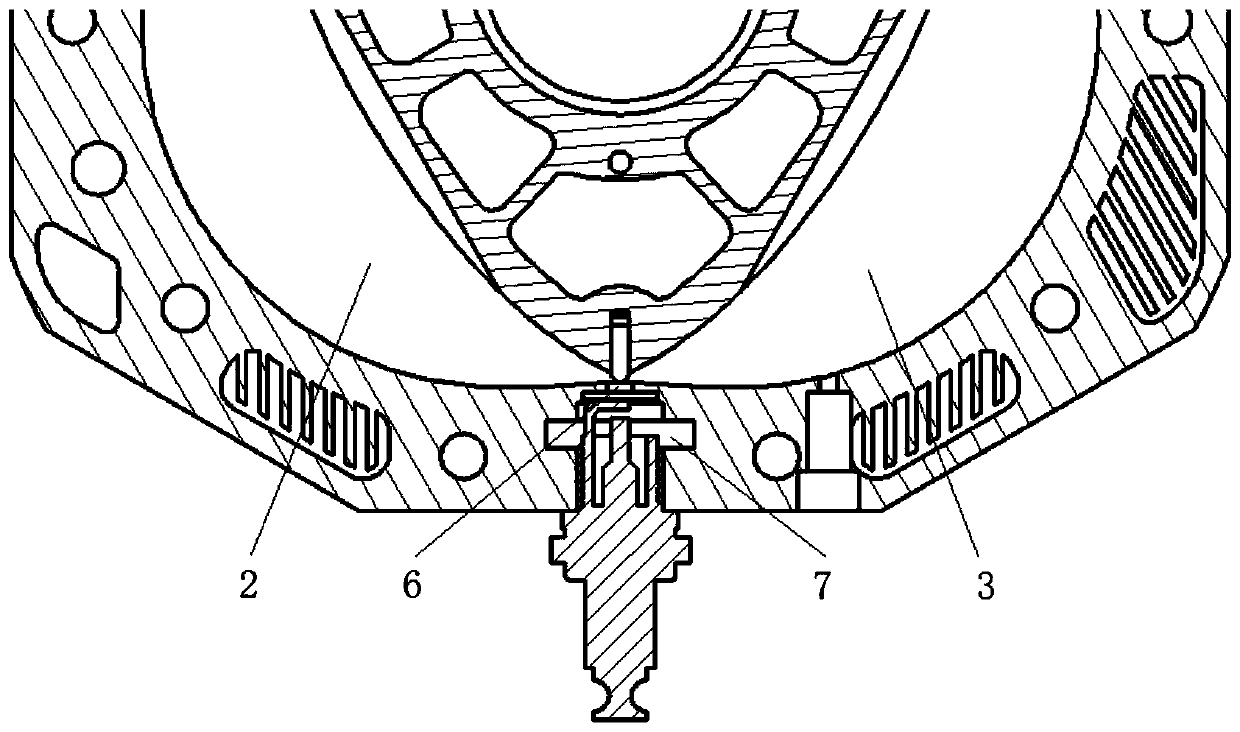

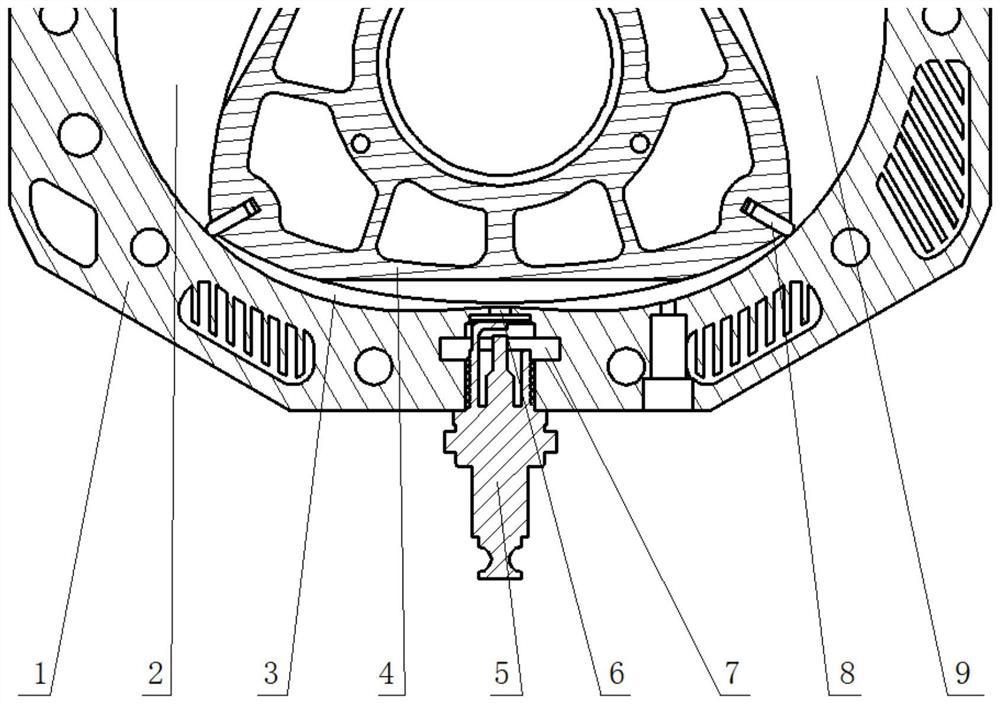

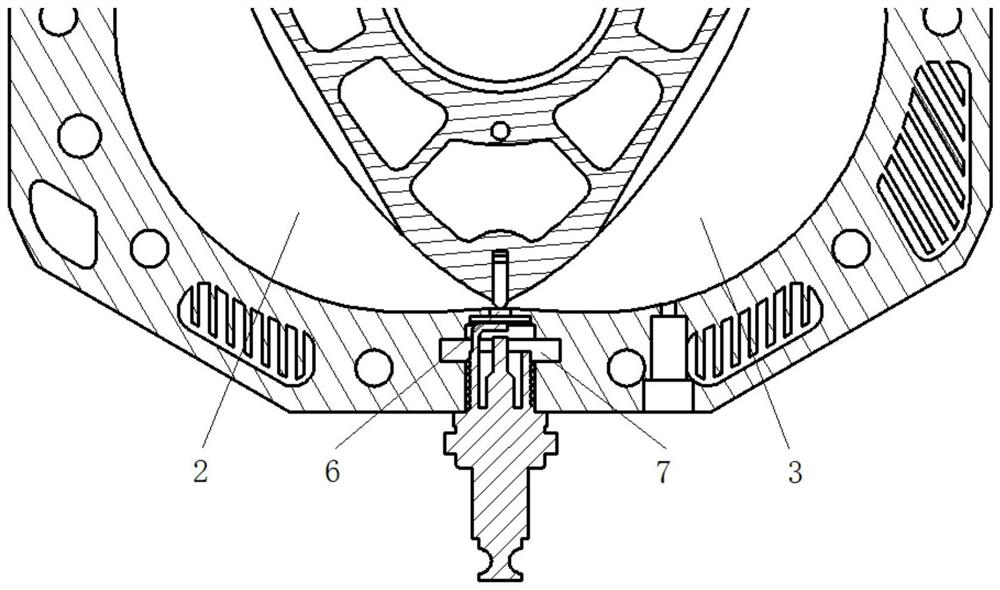

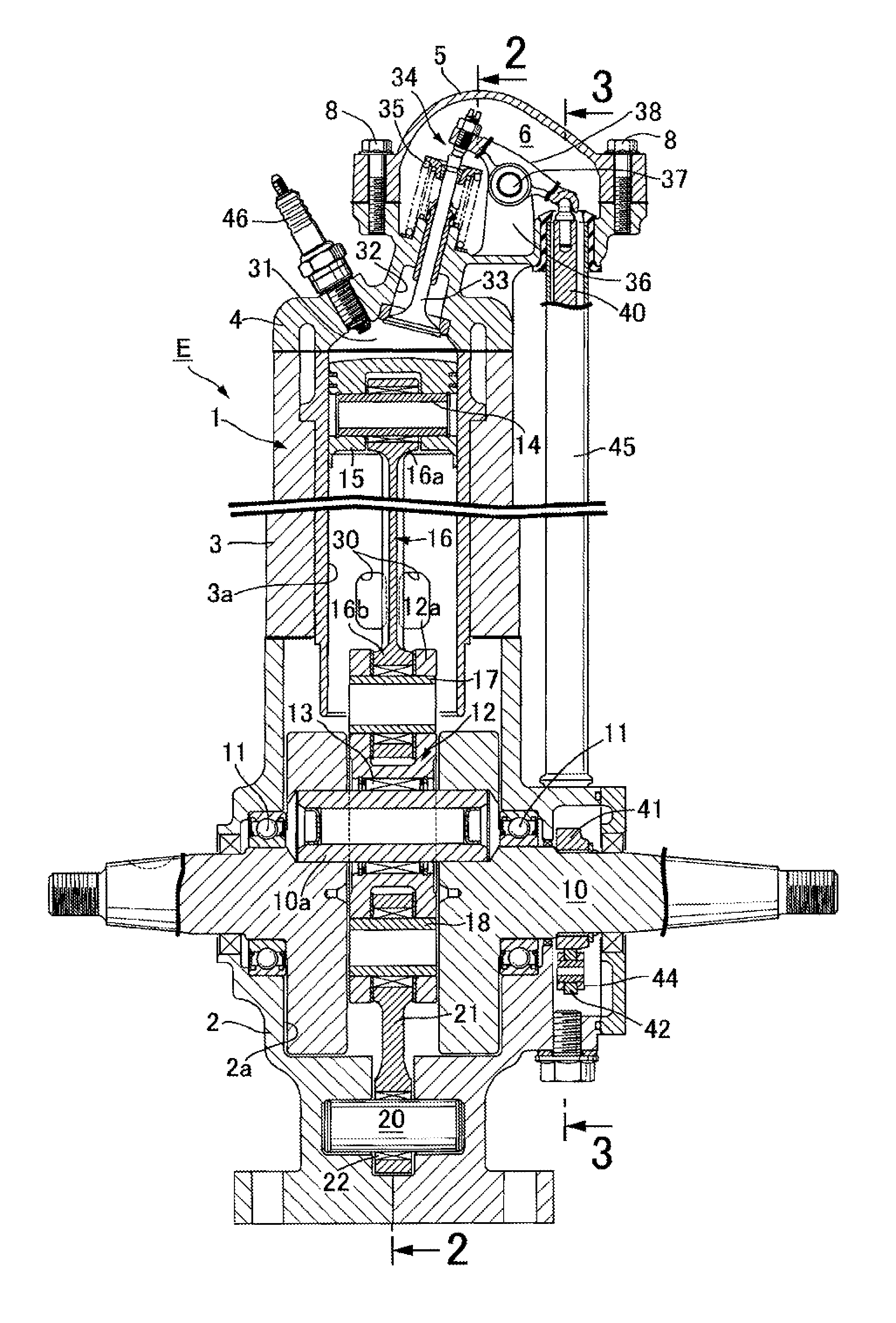

Sparking plug ignition device in combustion chamber of small rotary engine and method

ActiveCN110541757AImprove performanceExtended propagation distanceInternal combustion piston enginesOther installationsFlame propagationCombustion chamber

The invention discloses a sparking plug ignition device in a combustion chamber of a small rotary engine and a method, and belongs to the field of small rotary engines. The device provided by the invention comprises a first working chamber, a second working chamber, an ordinary sparking plug, a sparking plug channel, an ignition chamber, sealing sheets and a third working chamber, and further comprises an engine cylinder, a modified sparking plug, a modified sparking plug anode, bushings, a cathode and a triangle rotor. The sparking plug ignition device provided by the invention has the following advantages by removing the ignition chamber and the sparking plug channel: (1) energy loss is reduced and the probability of blow-by of gas between two adjacent cylinders is lowered; and (2) the compression ratio can also be improved without changing the rest of the structure, and the smaller the size of an engine, the greater the increase in the compression ratio. By improving the ignition position from the interior of the ignition chamber to the interior of the combustion chamber, the following advantages are achieved: (1) the flame propagation distance is greatly reduced, and the possibility of knocking and flame quenching of the small rotary engine is reduced; and (2) the direct contact of spark with compressed fresh gas mixture reduces the difficulty in ignition.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

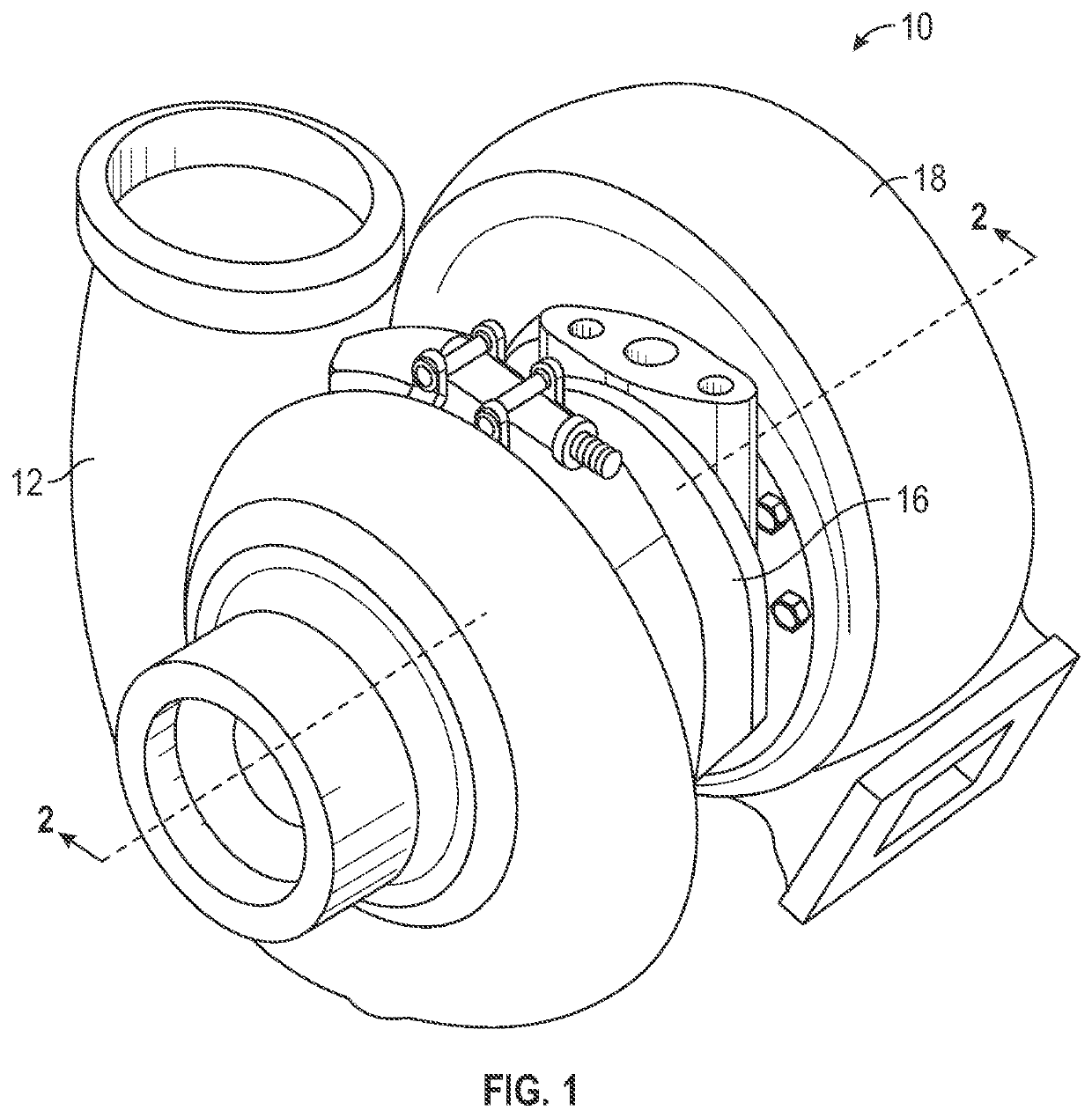

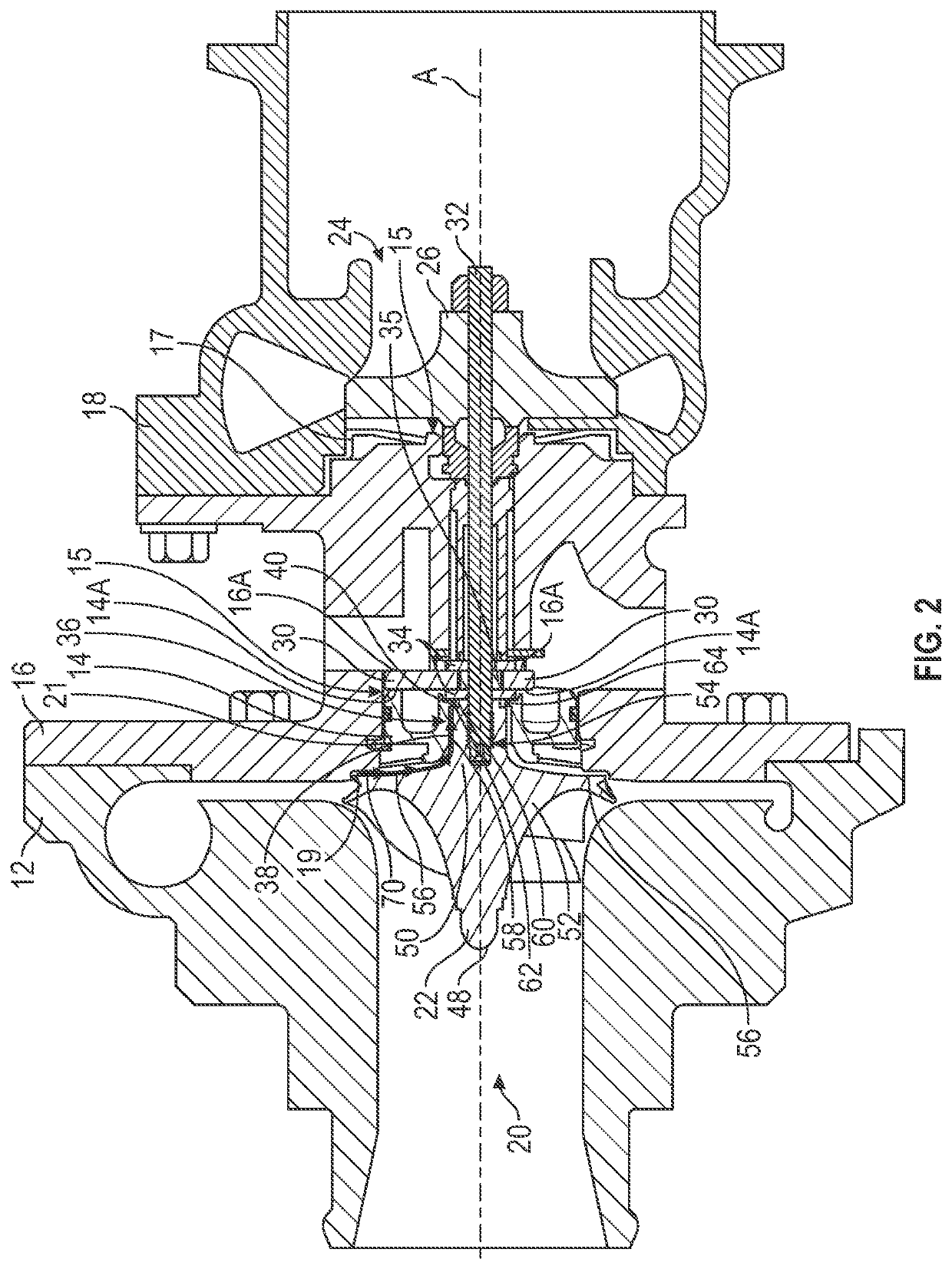

Multi-step bore turbocharger

A turbocharger includes a compressor housing, turbine housing, and center housing between the compressor and turbine housings. A turbine wheel is disposed in the turbine housing on a turbine shaft. A compressor wheel having a shank is disposed in the compressor housing on the turbine shaft. The shank has outer and reduced portions. The reduced portion has a smaller diameter than the outer portion. A backplate is mounted to the compressor housing adjacent the compressor wheel and defines a stepped cylindrical bore with a maximum diameter portion and a minimum diameter portion having a smaller diameter than the maximum portion. The outer portion is disposed in the maximum portion. The reduced portion is disposed in the minimum portion. The outer diameter of the shank is greater than or equal to the minimum diameter of the backplate, and the stepped cylindrical bore and the shank define a variable width gap.

Owner:GM GLOBAL TECH OPERATIONS LLC

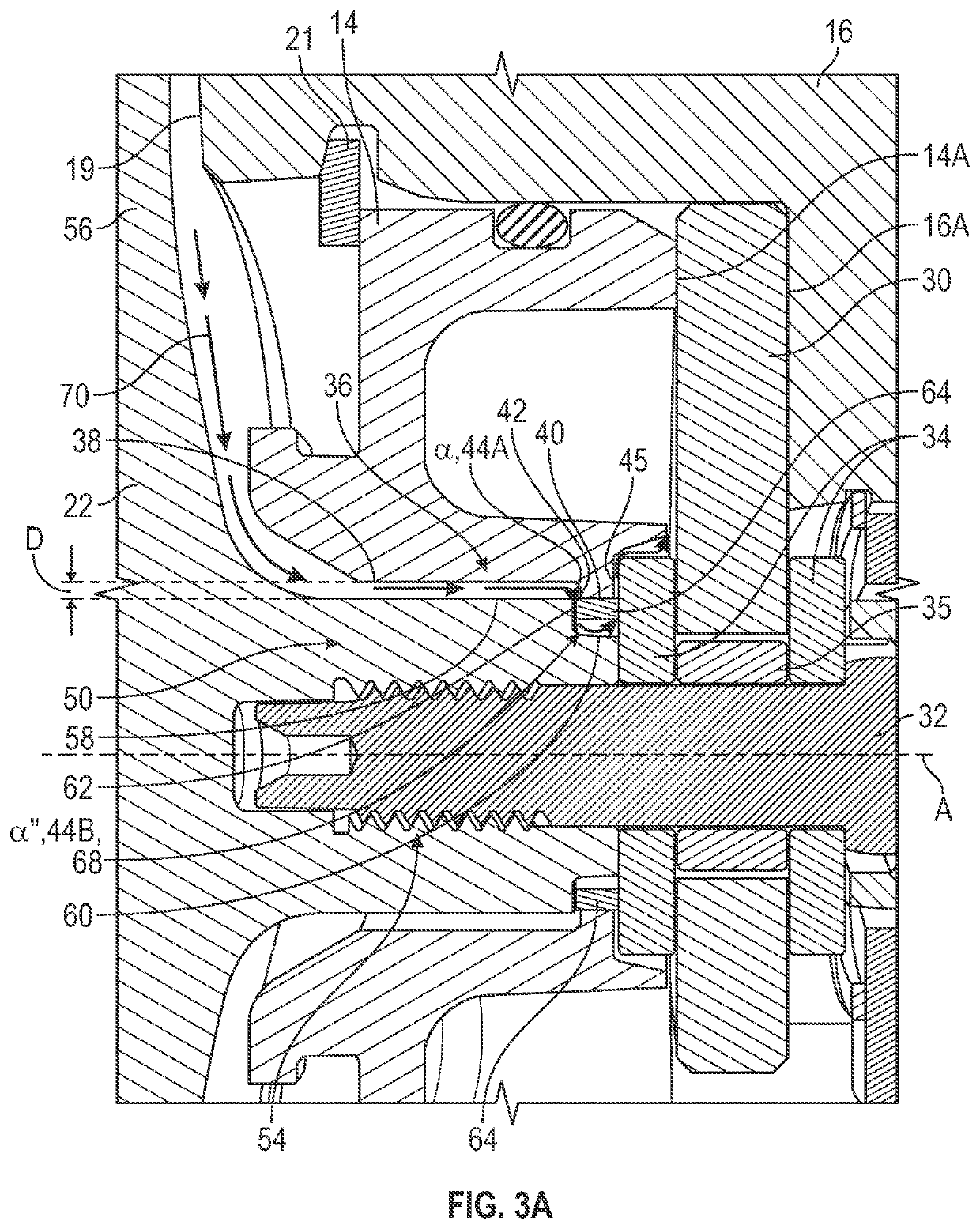

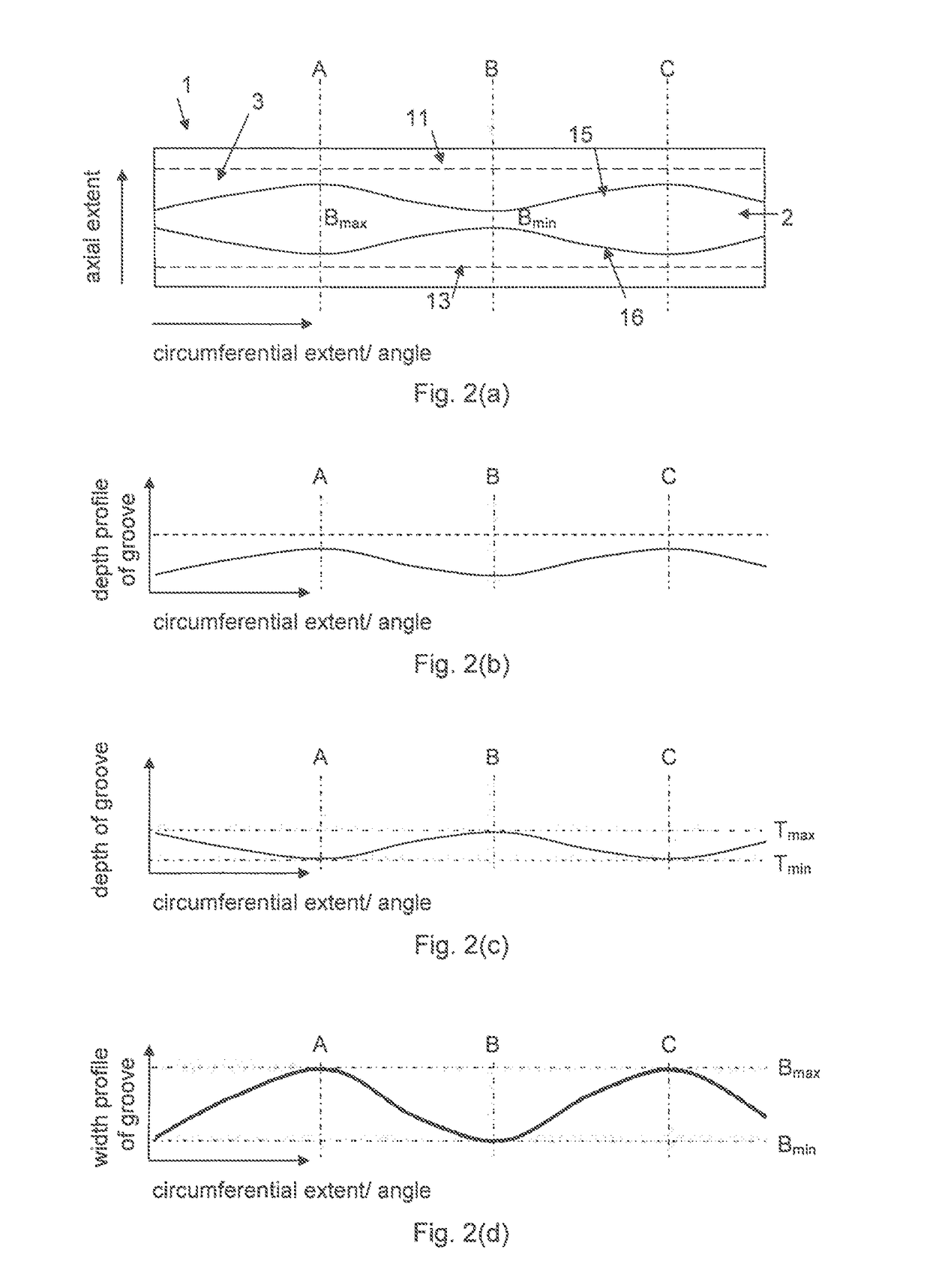

Piston ring-belt structural reinforcement via additive machining

ActiveUS20180087470A1Reduce thermal and mechanical distortionIncrease piston ring performanceAdditive manufacturing apparatusMolten spray coatingDistortionMachining process

A piston including at least one insert disposed between an inner surface of a ring belt and undercrown surface, and / or between the inner surface of the ring belt and a pin boss, to provide reinforcement to the ring belt is provided. The insert reduces thermal and mechanical distortion of the ring belt, and thus increases the piston ring performance, reduces blow-by, and ultimately improves engine emissions. The insert is formed by an additive machining process, such as direct depositing, laser cladding, laser sintering, arc welding, additive welding, plasma transferred arc spraying, plasma welding, arc welding, selective laser sintering, and high velocity oxygen fuel spraying, plasma spraying. According to one embodiment, an intermediate piece is mechanically attached to the piston, and the insert is applied to the intermediate piece, to provide additional reinforcement.

Owner:TENNECO

Evaporation fuel processing device

ActiveUS9334836B2Reduce componentsReduce blowbyGas treatmentNon-fuel substance addition to fuelAtmospheric airSorbent

The present invention provides an evaporation fuel processing device including: a passage formed inside so as to allow a fluid to flow through the passage; a tank port and a purge port formed on one end side of the passage; an atmospheric air port formed on the other end side of the passage; and adsorbent layers filled with adsorbent which can adsorb evaporation fuel components, the adsorbent layers being provided in the passage, wherein a region which is constituted of three or more adsorbent layers and separating parts for separating the adjacent adsorbent layers, and in which a total volume of the adsorbent layers is set smaller than a total volume of the separating parts, is provided on an atmospheric air port side of the passage.

Owner:AISAN IND CO LTD

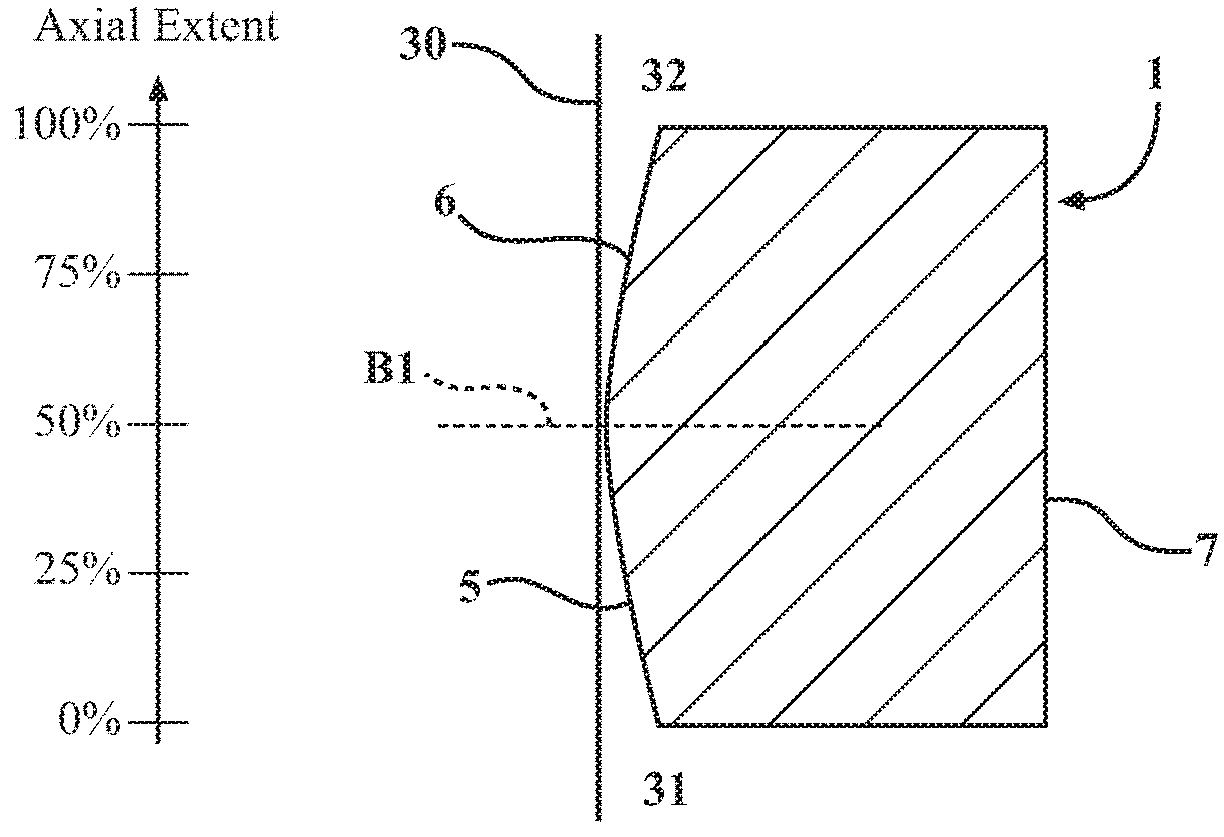

Piston ring with a periodically varying groove

A piston ring having an outer running face, two flanks and an inner circumferential face is provided, the running face of which has profiling with a groove. The groove is arranged between two running face sections in relation to the cross section of the piston ring. The two running face sections are spaced apart from each other and substantially convexly curved and each have an apex. The groove has a periodically varying depth and a periodically varying width, and the number of periods of the course of the depth and the number of periods of the course of the width are equal.

Owner:FEDERAL MOGUL BURSCHEID

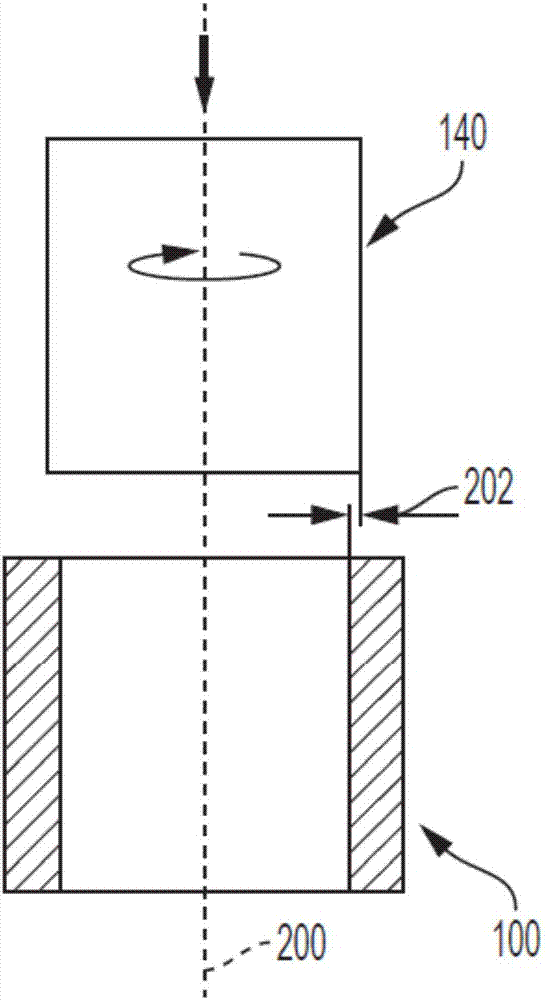

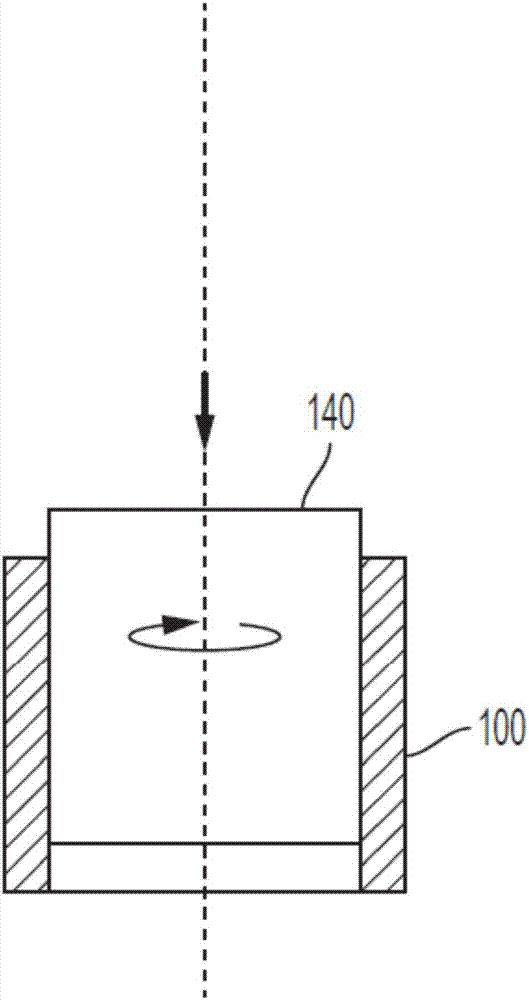

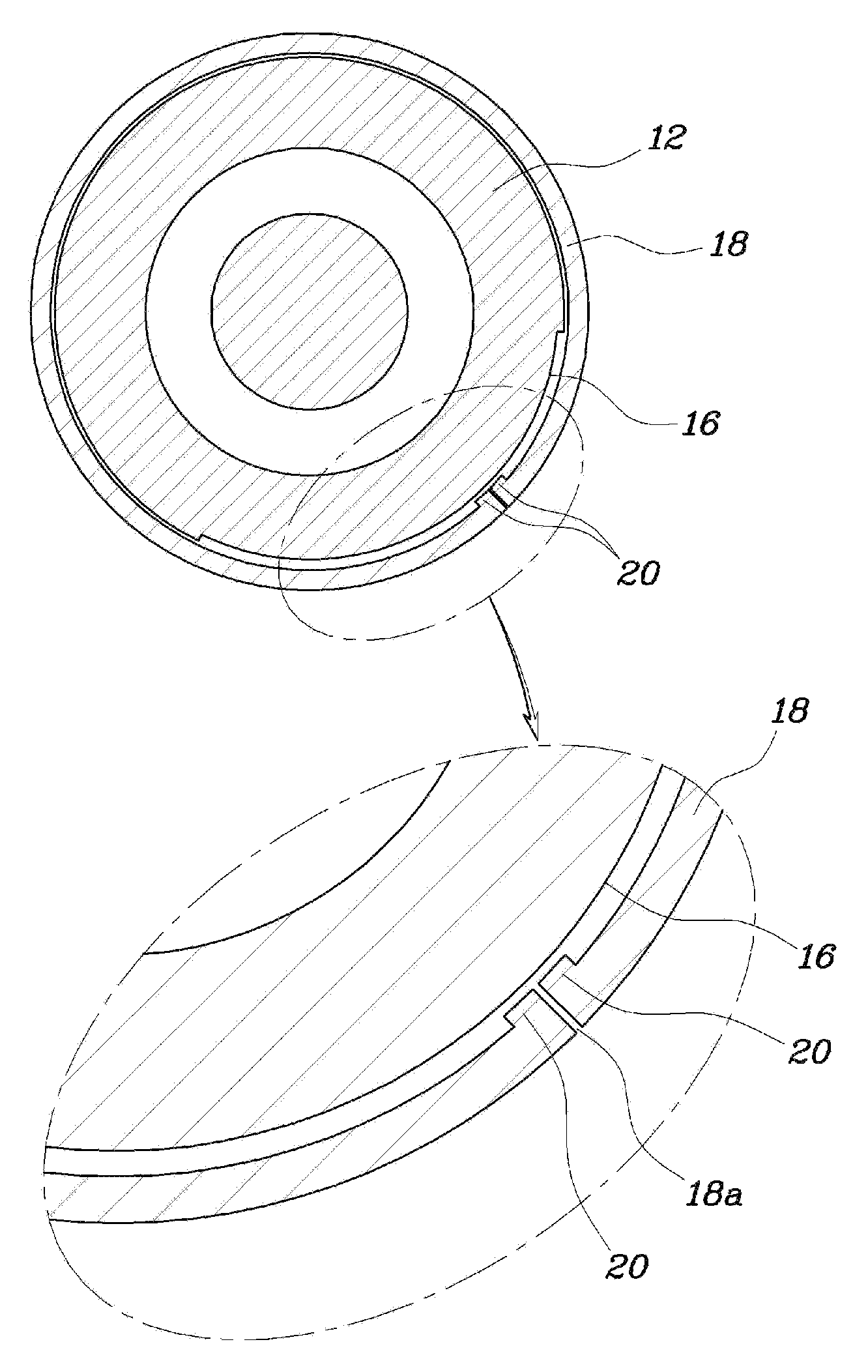

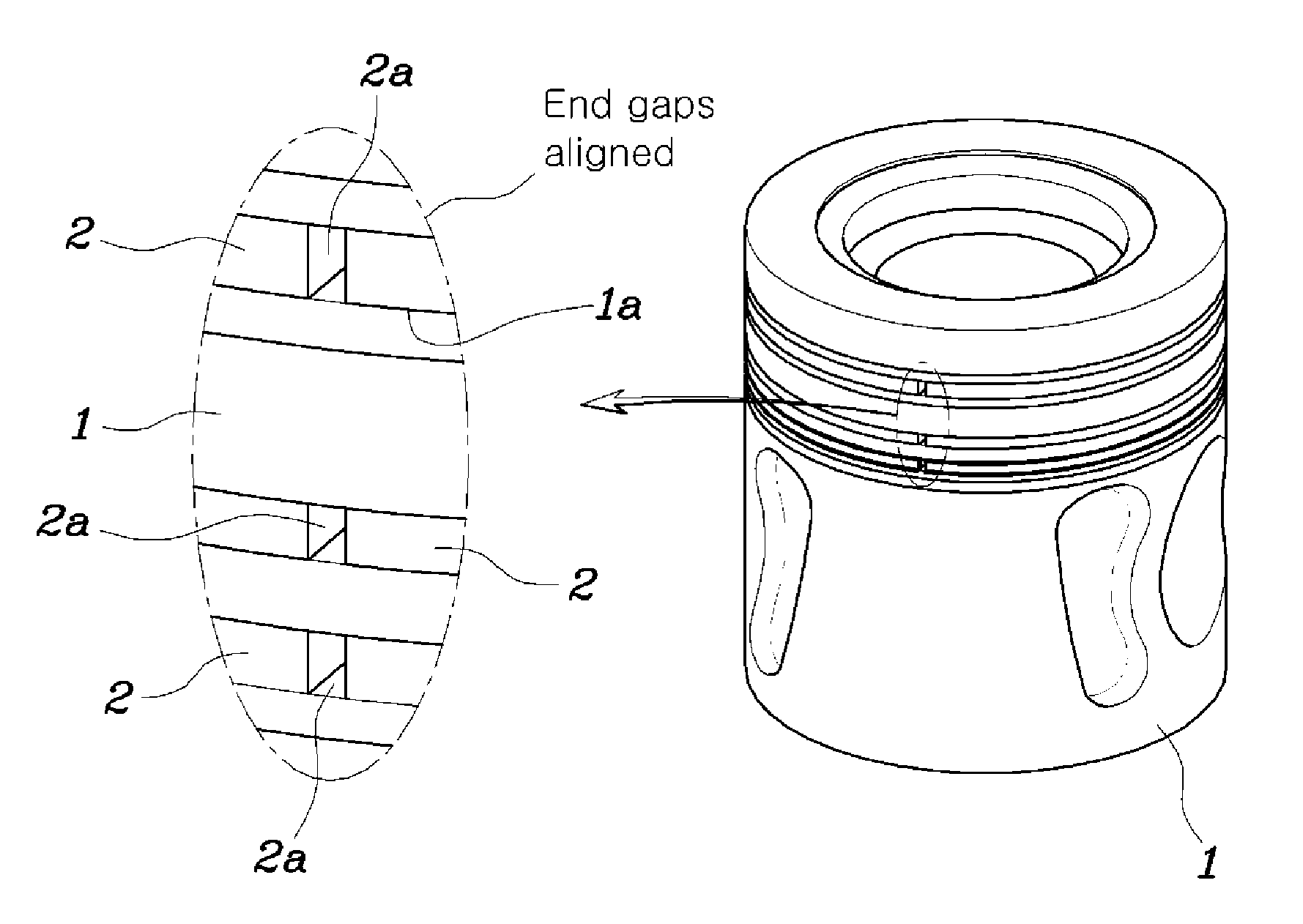

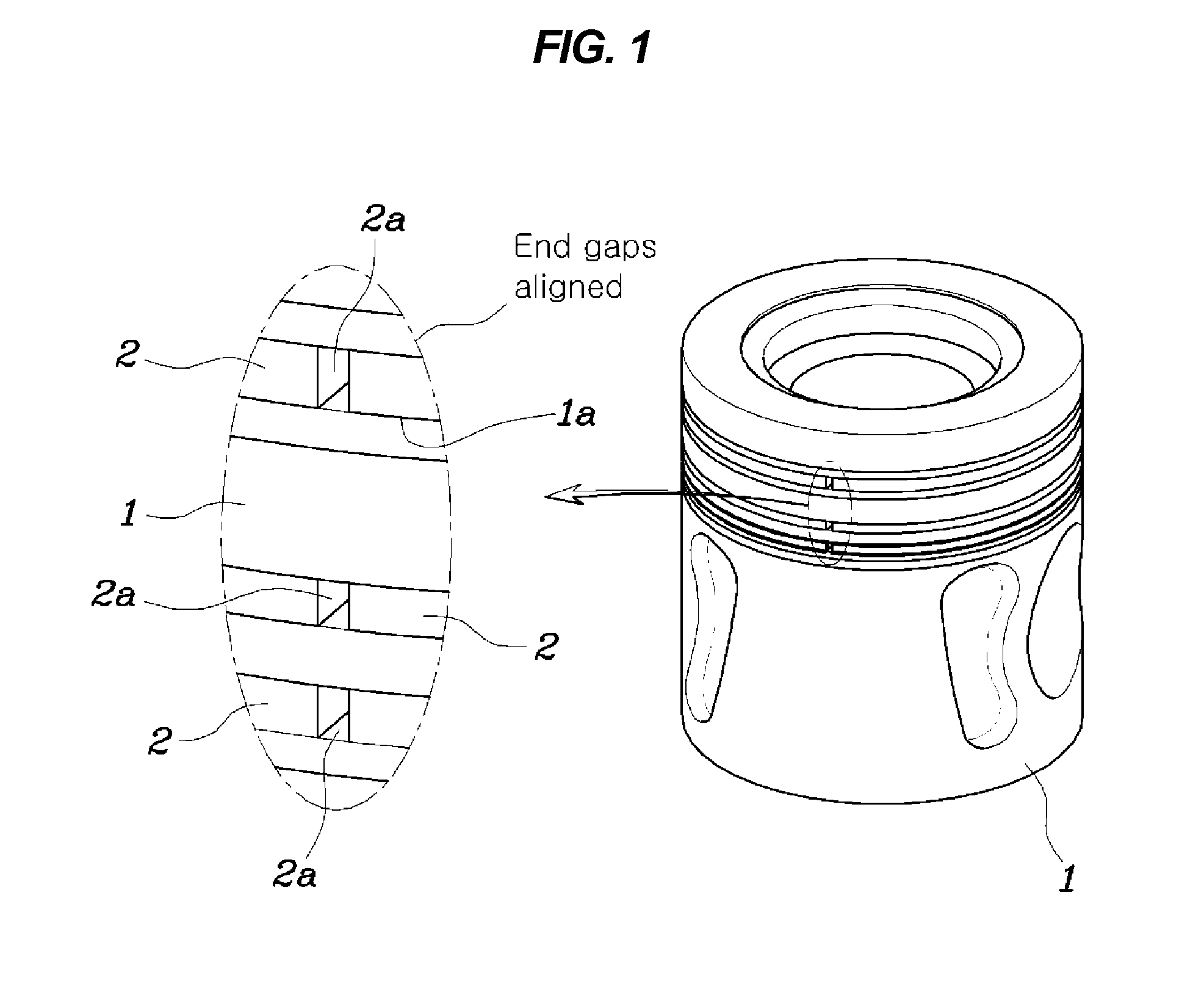

Structure for mounting piston ring

A structure for mounting a piston ring mounted around a piston head of a piston is provided. The structure includes a ring groove formed along the piston head with a guide recess circumferentially formed in the ring groove in a certain section. The piston ring is rotatably fitted into the ring groove. A guide protrusion is formed on the piston ring and is provided in the section of the guide recess such that the guide protrusion is rotated within the section. The structure is configured such that when a plurality of piston rings is mounted around the piston head, rotation sections of the end gaps of the piston rings are not aligned with each other.

Owner:HYUNDAI MOTOR CO LTD

Structure for mounting piston ring

ActiveUS20140109764A1Reduce blowbyAvoid alignmentPiston ringsPlungersPiston ringMechanical engineering

A structure for mounting a piston ring mounted around a piston head of a piston is provided. The structure includes a ring groove formed along the piston head with a guide recess circumferentially formed in the ring groove in a certain section. The piston ring is rotatably fitted into the ring groove. A guide protrusion is formed on the piston ring and is provided in the section of the guide recess such that the guide protrusion is rotated within the section. The structure is configured such that when a plurality of piston rings is mounted around the piston head, rotation sections of the end gaps of the piston rings are not aligned with each other.

Owner:HYUNDAI MOTOR CO LTD

Evaporated fuel treatment apparatus

ActiveUS9376990B2Reduce blowbyReduce the amount requiredGas treatmentNon-fuel substance addition to fuelFuel treatmentEnvironmental engineering

An evaporated fuel treatment apparatus includes a passage circulating fluid being formed therein, a tank port and a purge port being formed at one end side of the passage, and an atmosphere port being formed at another end side of the passage. At least four adsorbent layers in which adsorbent adsorbing fuel components is filled are provided in the passage. The evaporated fuel treatment apparatus has a main adsorbent layer and a region provided on an atmosphere port side of the main adsorbent layer. At least three adsorbent layers that are different from the main adsorbent layer, and separating portions that separate the adsorbent layers which are adjacent to each other are provided in the region. The volume of at least one separating portion in the region is made larger than a total of the volumes of adsorbent layers that sandwich the separating portion therebetween.

Owner:AISAN IND CO LTD

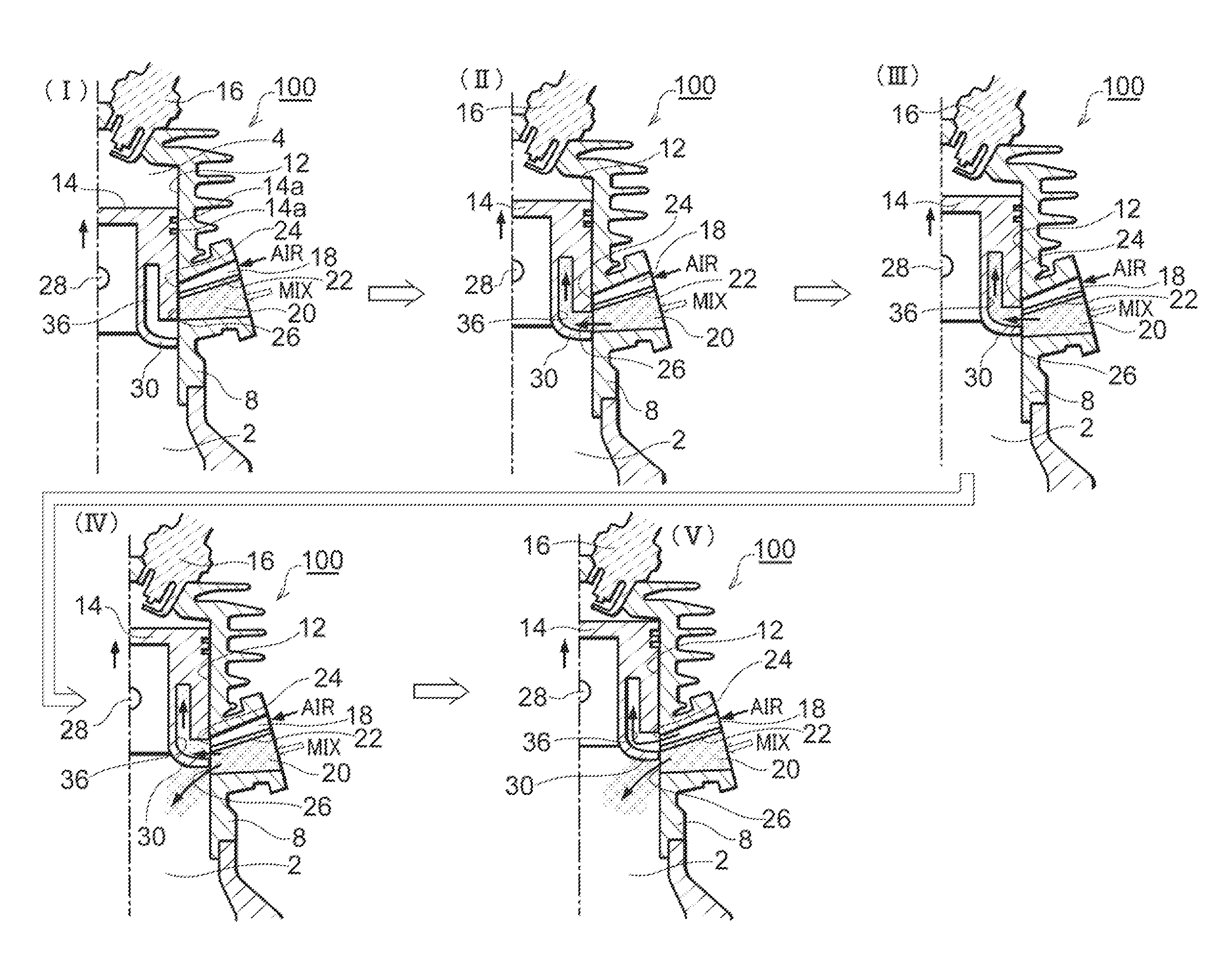

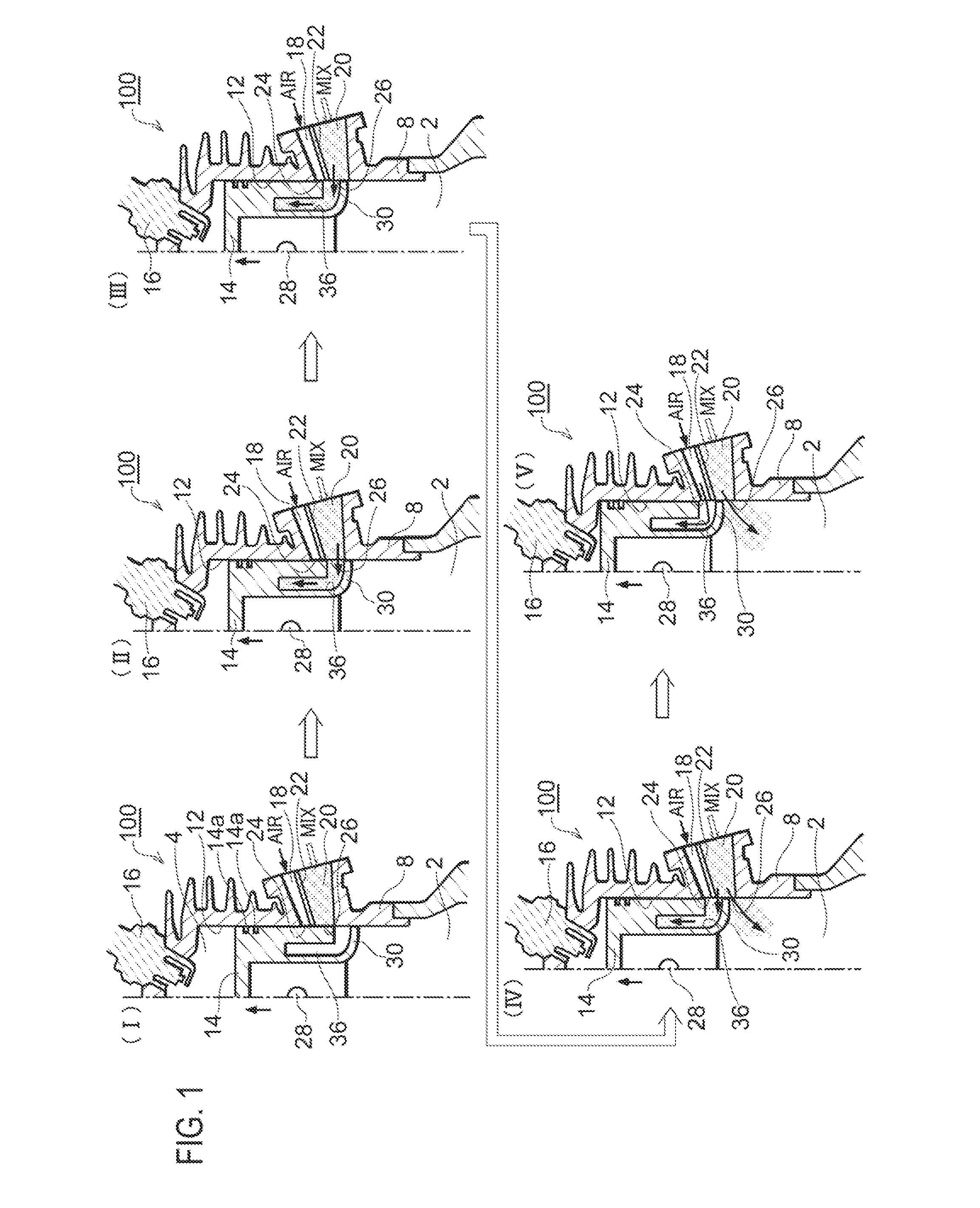

Two-Stroke Internal Combustion Engine and Its Scavenging Method

InactiveUS20110180054A1Reducing acceleration failureReducing engine stopCombustion enginesPistonsCombustion chamberCrankcase

In a two-stroke internal combustion engine using air for scavenging its combustion chamber (4), a scavenging passage (6) communicating with a crankcase (2) and a combustion chamber (4) is charged first with rich air-fuel mixture generated by a carburetor, next with lean air-fuel mixture, and next with air through an in-piston passage (36). The lean air-fuel mixture is generated in the in-piston passage 36 by diluting the air-fuel mixture with the air. In each scavenging stroke to scavenge the combustion chamber (4), the combustion chamber (4) is supplied first with the air (40) and next with the lean air-fuel mixture (42) from the scavenging passage (6). The use of the lean-air-fuel mixture (42) next to the air (40) contributes to reduce acceleration failure or engine stop caused by sudden acceleration.

Owner:YAMABIKO CORP

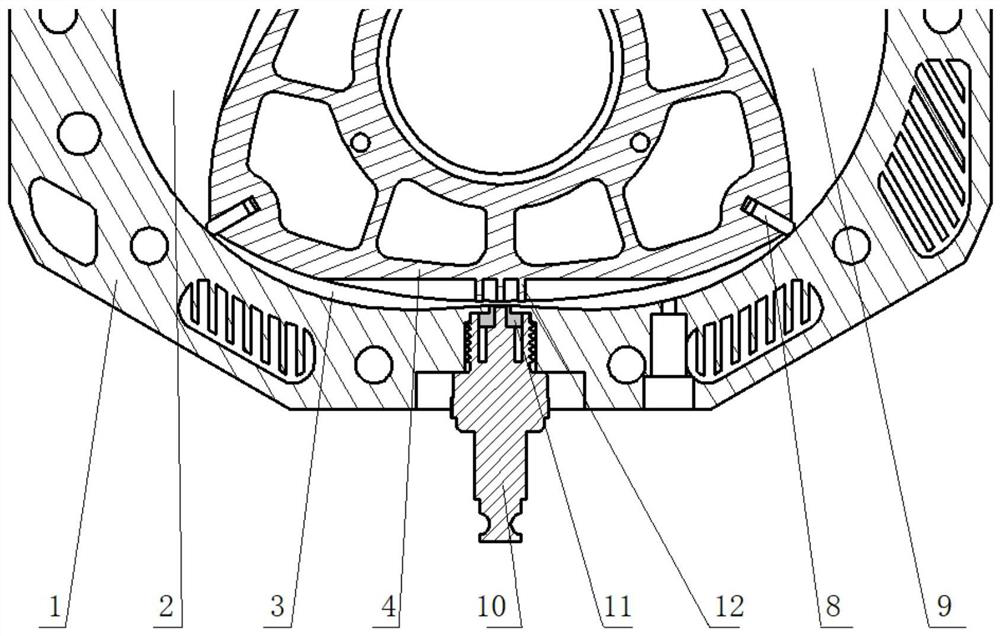

Spark plug ignition device and method in combustion chamber of small rotary engine

ActiveCN110541757BSmall structureImprove performanceInternal combustion piston enginesOther installationsCombustion chamberFlame propagation

The invention discloses a sparking plug ignition device in a combustion chamber of a small rotary engine and a method, and belongs to the field of small rotary engines. The device provided by the invention comprises a first working chamber, a second working chamber, an ordinary sparking plug, a sparking plug channel, an ignition chamber, sealing sheets and a third working chamber, and further comprises an engine cylinder, a modified sparking plug, a modified sparking plug anode, bushings, a cathode and a triangle rotor. The sparking plug ignition device provided by the invention has the following advantages by removing the ignition chamber and the sparking plug channel: (1) energy loss is reduced and the probability of blow-by of gas between two adjacent cylinders is lowered; and (2) the compression ratio can also be improved without changing the rest of the structure, and the smaller the size of an engine, the greater the increase in the compression ratio. By improving the ignition position from the interior of the ignition chamber to the interior of the combustion chamber, the following advantages are achieved: (1) the flame propagation distance is greatly reduced, and the possibility of knocking and flame quenching of the small rotary engine is reduced; and (2) the direct contact of spark with compressed fresh gas mixture reduces the difficulty in ignition.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

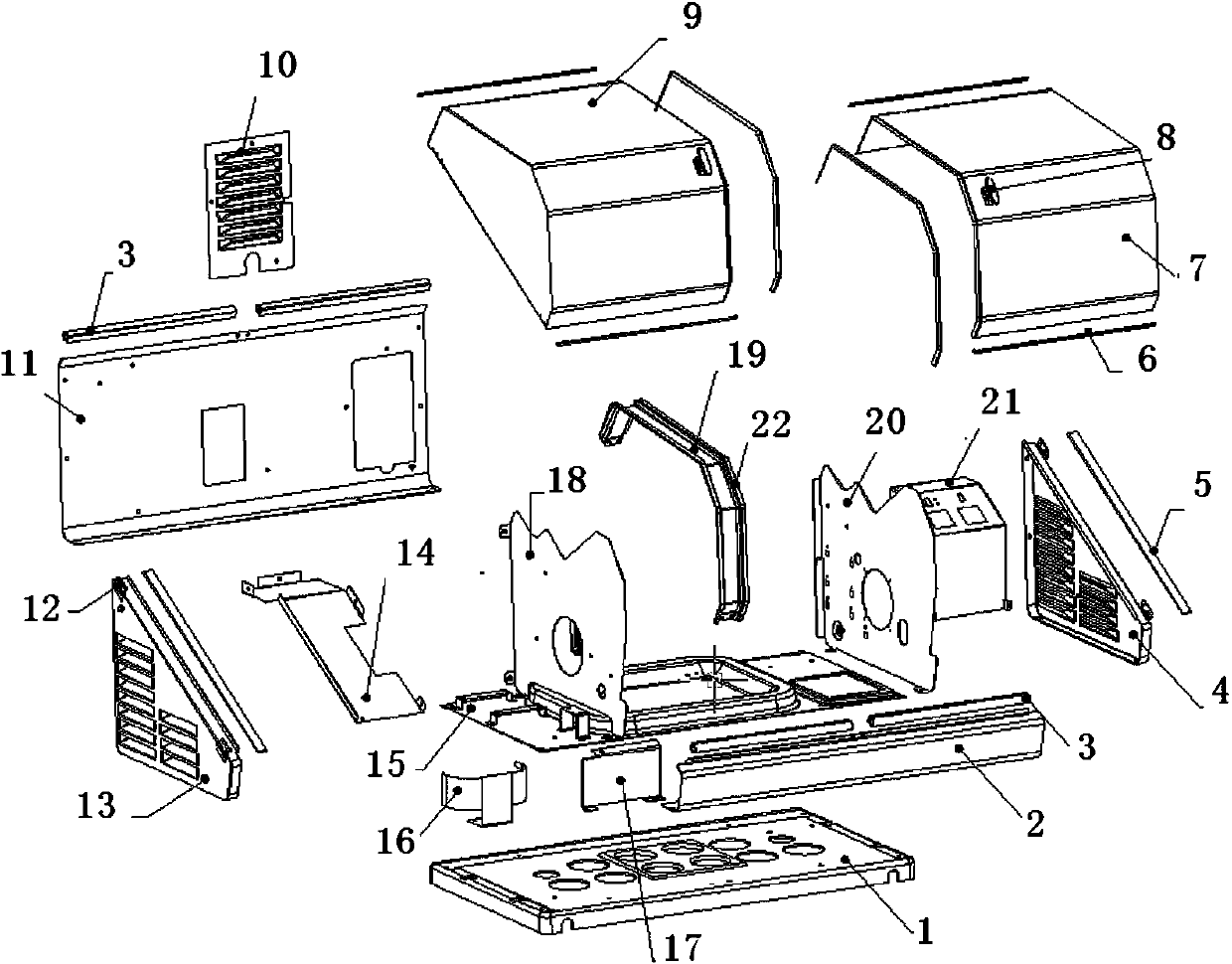

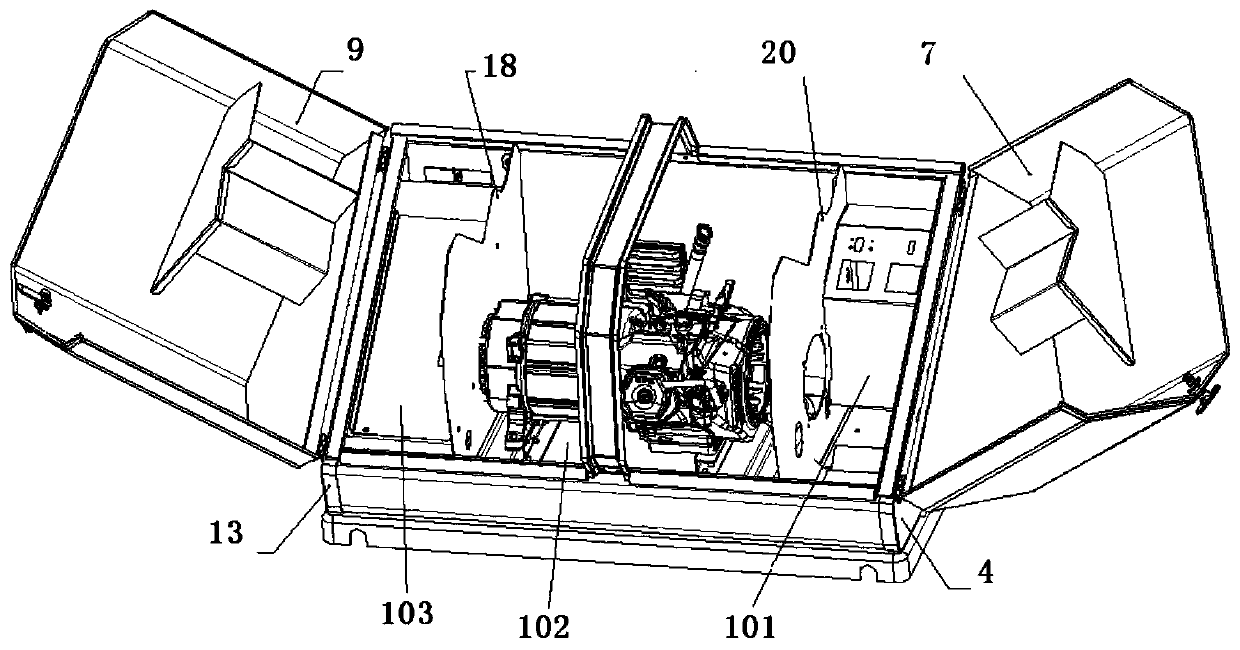

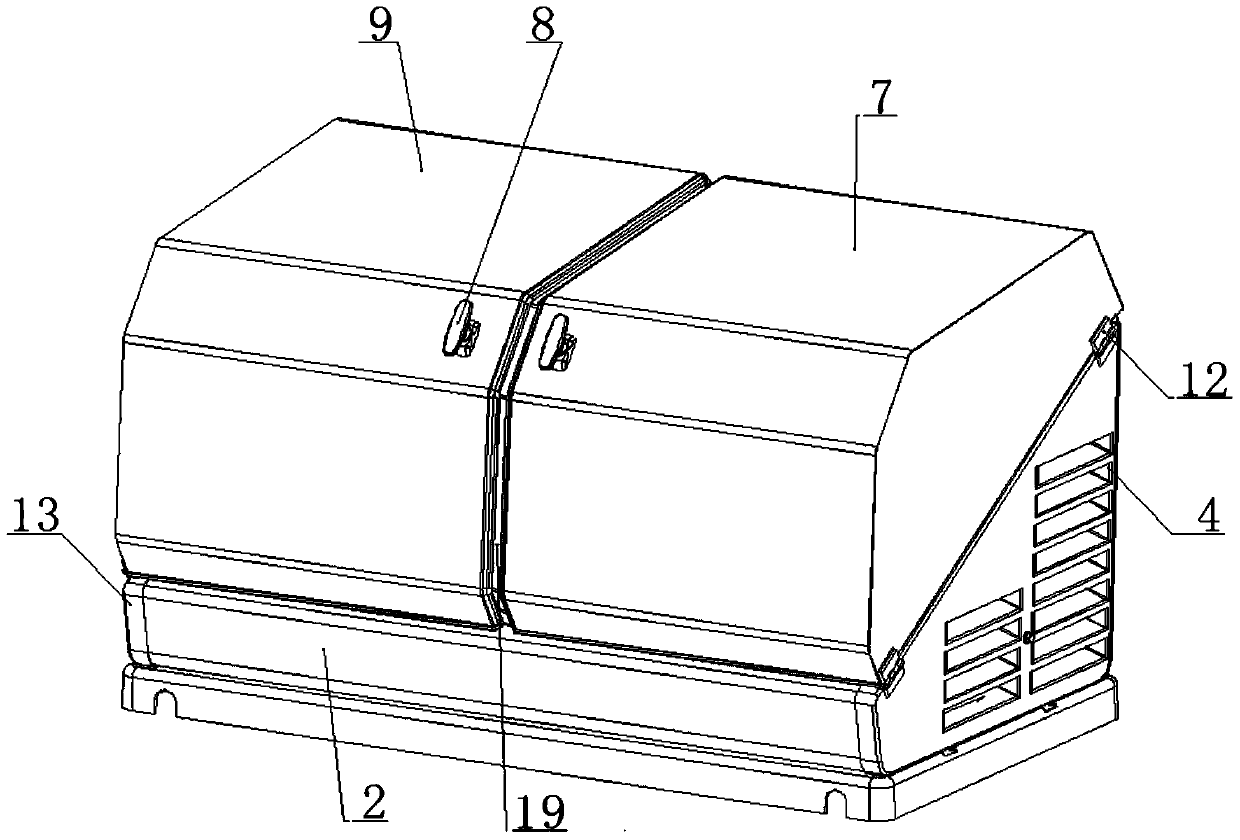

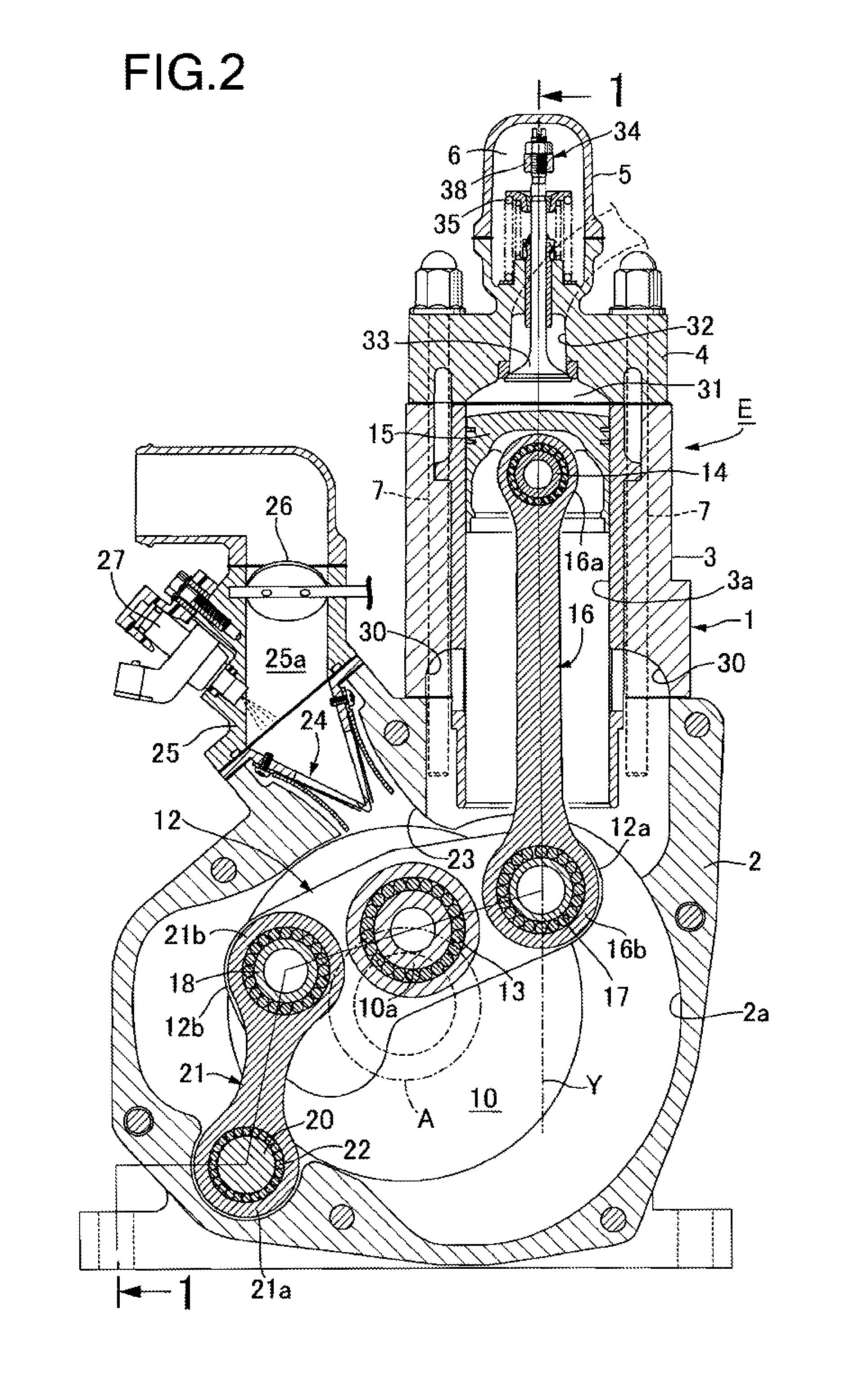

The overall structure of the silent generator set

ActiveCN104314676BAvoid damageReasonable space layoutMachines/enginesEngine componentsNacelleElectronic component

The invention relates to a complete structure of a silent generating set, which includes a nacelle body. The accommodation space in the nacelle body is formed with three chambers: an air inlet chamber, an engine chamber and a heat exhaust chamber arranged in sequence, wherein the air inlet chamber It is separated from the engine chamber, the engine chamber and the heat exhaust chamber by a first partition and a second partition respectively, and an exhaust hole is arranged on the second partition; the engine room body has four sides, of which The three sides are provided with ventilating parts; one of the ventilating parts communicates with the air inlet chamber, the other ventilating part communicates with the engine chamber, and the other ventilating part communicates with the heat exhaust chamber. The beneficial effects of the invention are: the interior space layout of the generator set is more reasonable, the heat removal efficiency is high, and the damage caused by the high temperature of electronic parts, power spark plug gaskets and engine oil is avoided.

Owner:HANGZHOU POWER YOUNG TECH CO LTD +1

Piston ring-belt structural reinforcement via additive machining

ActiveUS10316790B2Reduce distortionImprove performanceAdditive manufacturing apparatusMolten spray coatingSelective laser sinteringAs Directed

A piston including at least one insert disposed between an inner surface of a ring belt and undercrown surface, and / or between the inner surface of the ring belt and a pin boss, to provide reinforcement to the ring belt is provided. The insert reduces thermal and mechanical distortion of the ring belt, and thus increases the piston ring performance, reduces blow-by, and ultimately improves engine emissions. The insert is formed by an additive machining process, such as direct depositing, laser cladding, laser sintering, arc welding, additive welding, plasma transferred arc spraying, plasma welding, arc welding, selective laser sintering, and high velocity oxygen fuel spraying, plasma spraying. According to one embodiment, an intermediate piece is mechanically attached to the piston, and the insert is applied to the intermediate piece, to provide additional reinforcement.

Owner:TENNECO INC

Piston ring for internal combustion engine

InactiveCN113685286AImprove sealing performanceReduce blowbyPiston ringsMachines/enginesInternal combustion engineDiesel engine

The invention discloses a piston ring for an internal combustion engine. The piston ring comprises a piston ring body and is characterized in that the open end of the piston ring body is provided with an airflow sealing structure for sealing the gap of the open end, the airflow sealing structure comprises a protrusion integrated with one end part of the open end of the piston ring body, and the other end part of the open end of the piston ring body is provided with a clamping groove into which the protrusion is clamped. Through the design of the airflow sealing structure at the open end, the sealing performance of the piston ring is greatly improved, the blow-by amount is reduced, the diesel engine efficiency is improved, the engine oil consumption is reduced, and the engine life is prolonged.

Owner:南通四维动力机械科技有限责任公司

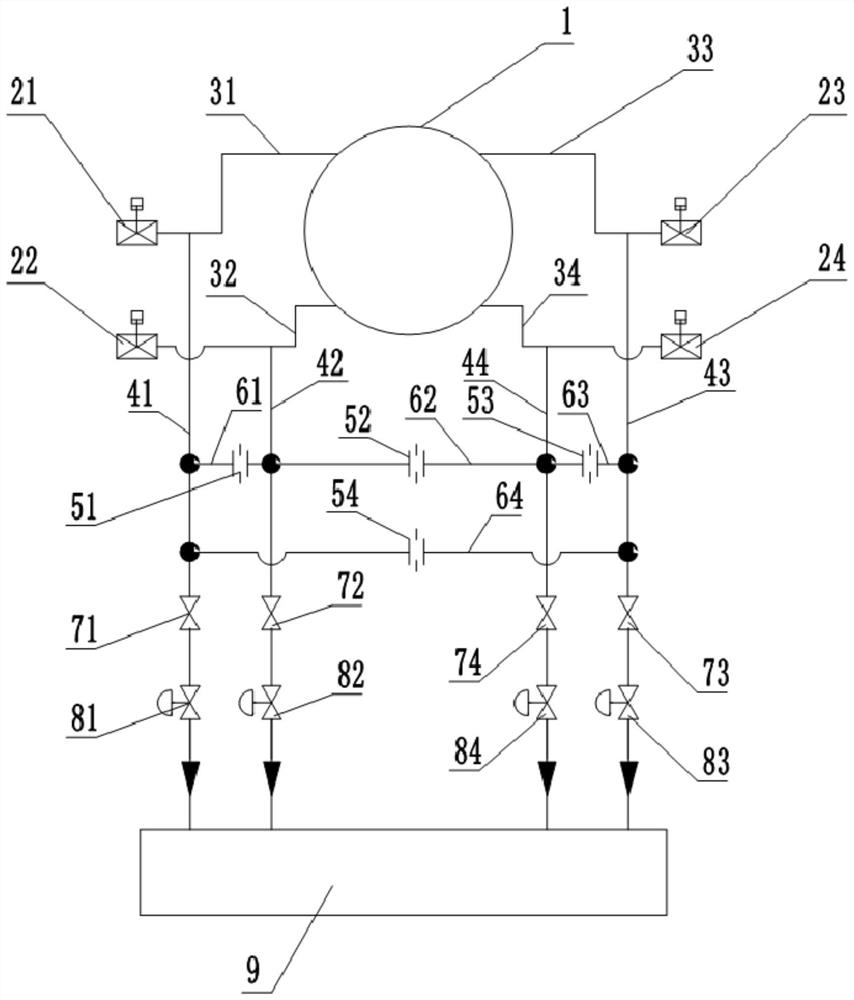

Steam turbine high-pressure steam guide pipe drainage system and drainage method

ActiveCN114370307AEliminate riskImprove securityMachines/enginesEngine componentsWater pipePetroleum engineering

The invention discloses a steam turbine high-pressure steam guide pipe drainage system and method, and belongs to the technical field of thermal power generation devices. The system comprises a high-pressure cylinder applied to the field of steam turbines, four steam guide pipes are arranged on the high-pressure cylinder, each steam guide pipe is provided with a main steam adjusting valve and further communicated with a drain pipe, and the drain pipe is communicated with a drain flash tank through a valve assembly; warm pipe pipelines are arranged between the drain pipes, the drain pipes are communicated in series through the warm pipe pipelines, or the drain pipes are communicated in pairs through the warm pipe pipelines; according to the invention, the structural design breaks through the design of a traditional structure, especially the design of utilizing a heating pipeline, and the mutual communication effect is realized, so that the steam guide pipe behind the opened high-pressure main steam regulating valve heats the steam guide pipe behind the closed high-pressure main steam regulating valve, the risk that water or cold steam enters a high-pressure cylinder is eliminated, and the service life of the high-pressure cylinder is prolonged. And the safety of the unit is improved.

Owner:DONGFANG TURBINE CO LTD

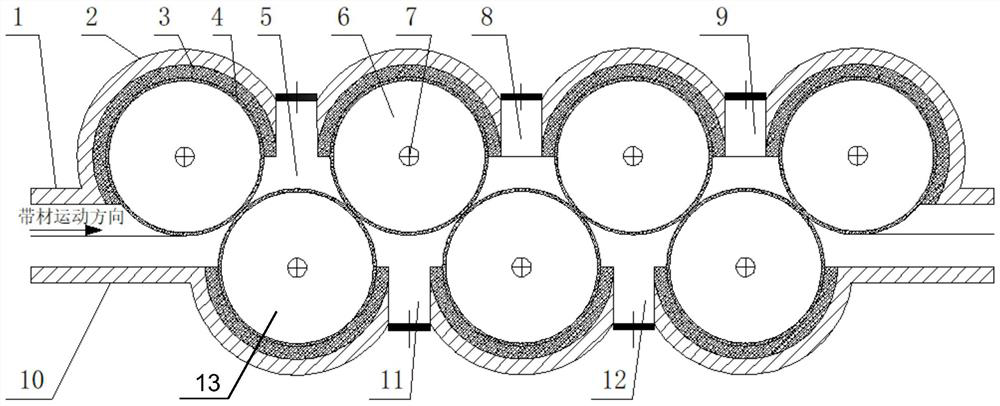

Continuous vacuum coating sealing lock for metal strip

PendingCN113737149AReduce blowbyReduce consumptionVacuum evaporation coatingSputtering coatingMetal stripsEngineering

The invention discloses a continuous vacuum coating sealing lock for a metal strip. The continuous vacuum coating sealing lock comprises an upper sealing cover, a lower sealing cover and sealing rollers, wherein the upper sealing cover and the lower sealing cover are detachable, the sealing rollers are arranged between the upper sealing cover and the lower sealing cover, and shaft shells adapted to the sealing roller are arranged on the upper sealing cover and the lower sealing cover respectively; a shaft shell flexible layer is arranged on the inner surface of each shaft shell; the sealing rollers comprise a plurality of upper sealing rollers and a plurality of lower sealing rollers, the upper sealing rollers and the lower sealing rollers are arranged in a staggered mode, sealing roller flexible layers are arranged on the upper sealing rollers and the lower sealing rollers respectively, and the surfaces of the sealing roller flexible layers of the upper sealing rollers make contact with the surfaces of the sealing roller flexible layers of the lower sealing rollers respectively; a sub-chamber is formed among every three adjacent sealing rollers; each sub-chamber is connected with a vacuum pump; and the metal strip passes through the space between the upper sealing rollers and the lower sealing rollers. For the continuous vacuum coating sealing lock for the metal strip of the invention, an inlet cavity is divided into a plurality of sub-chambers, and the shaft shell form, the shaft shell flexible layers and the sealing roller flexible layers are adopted for sealing, so that the vacuumizing efficiency is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Premixed compression self-ignition engine

InactiveUS9074618B2Increase the compression ratioHigh thermal efficiencyConnecting rodsCrankshaft bearingsExhaust valveCylinder head

Owner:HONDA MOTOR CO LTD

A multi-element alloyed aluminum alloy material, cylinder liner and preparation method thereof

ActiveCN107779696BHigh tensile strengthHigh strengthCylinder headsCylindersTitaniumMechanical property

The invention relate to a multi-component alloying aluminum alloy material, an air cylinder sleeve and a preparation method thereof. The multi-component alloying aluminum alloy air cylinder sleeve isprepared from the following components in percentage by weight: 20-30% of silicon, 5-10% of magnesium, 0.1-1% of titanium, 0.1-1.5% of zirconium and the balance of aluminum. The multi-component alloying aluminum alloy air cylinder sleeve provided by the invention is based on a lattice matching principle. By adding a proper amount of Ti and Zr, an Al-Si-Mg matrix tissue is refined effectively, wherein the element Ti can refine the aluminum alloy matrix, the element Zr can refine the grain size of MG, and more MgSi2 second phase particles can be formed favorably. The formula of the multi-component alloying aluminum alloy air cylinder sleeve is simple in component, and does not contain noble elements such as Ni, so that the production cost is relatively low; and the elements are proportionedreasonably and have a synergistic action, so that the aluminum alloy matrix tissue is fined favorably, and the mechanical properties such as tensile strength of the air cylinder sleeve are improved.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com