Piston ring for internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

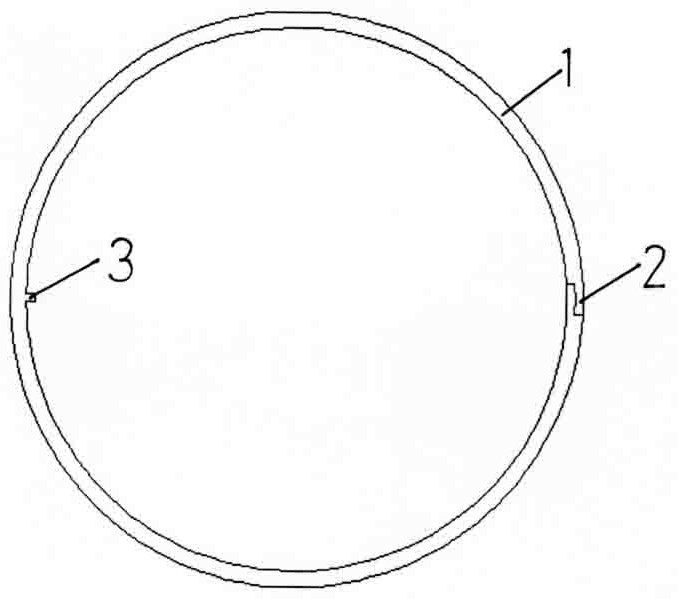

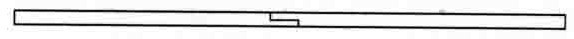

[0013] A piston ring for an internal combustion engine, comprising a piston ring body 1, at the open end of the piston ring body, an air flow sealing structure for sealing the gap at the open end is provided; the air flow sealing structure includes a protrusion integrated with one of the open ends of the piston ring body Body 2, the other end of the open end of the piston ring body is provided with a slot engaging with the protrusion.

[0014] The protrusion fits with the slot in a Z-shape (viewed along the radial direction), or an N-shape, a W-shape, and the like.

[0015] On the piston ring body, a positioning structure cooperating with the groove wall of the piston ring is arranged. On the piston ring body, set 1-multiple cylindrical positioning blocks 3 that are positioned in cooperation with the grooves on the piston ring groove wall, or set grooves on the piston ring body, and set on the piston ring groove wall to match the grooves Fittingly positioned tabs.

[0016] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com