Self-generated mixed particle-reinforced aluminum alloy cylinder sleeve and preparation method thereof

A particle-reinforced aluminum and particle-reinforced technology, which is applied to cylinders, cylinder heads, mechanical equipment, etc., can solve the problem that there are no reports of graded functional materials in centrifugal casting of Al-Ni-Si ternary alloys, and the hardness and wear resistance are not high. , Difficulties in practical application, etc., to achieve the effect of light weight, low production cost, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

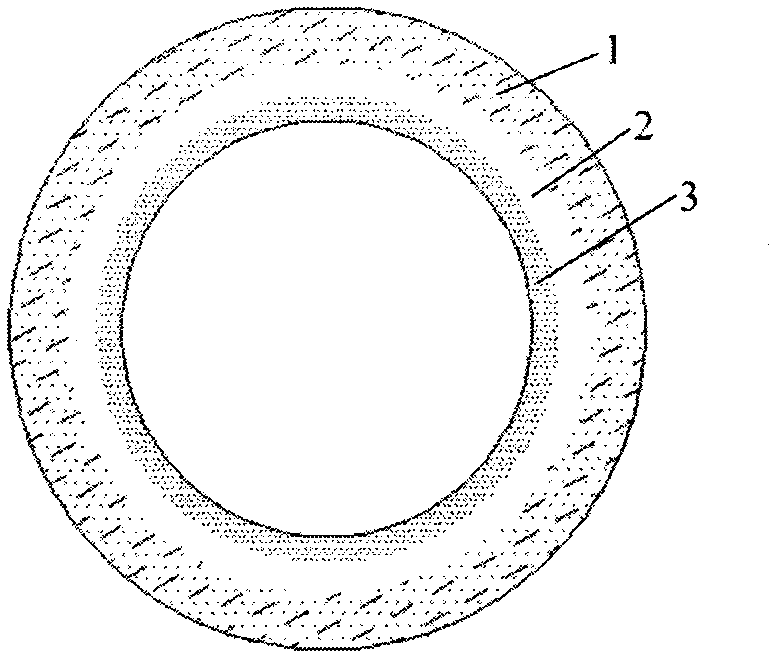

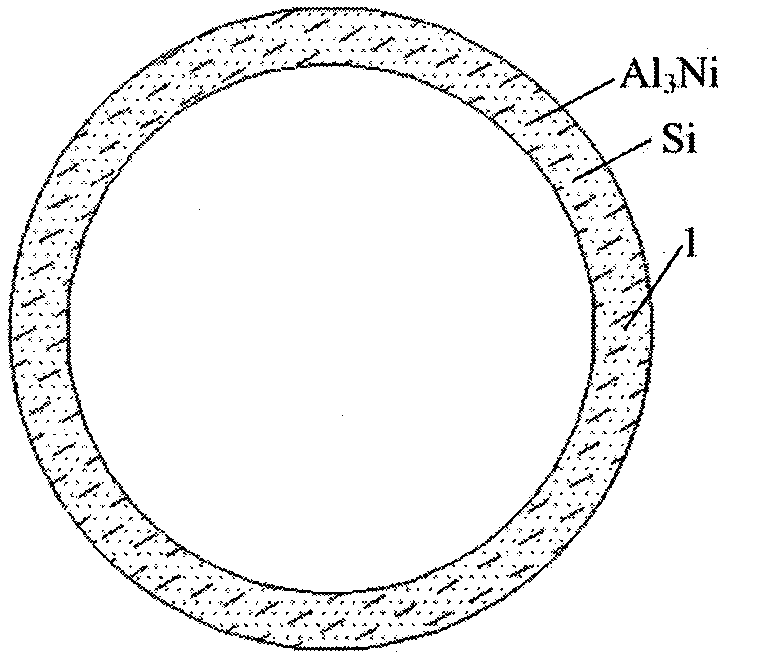

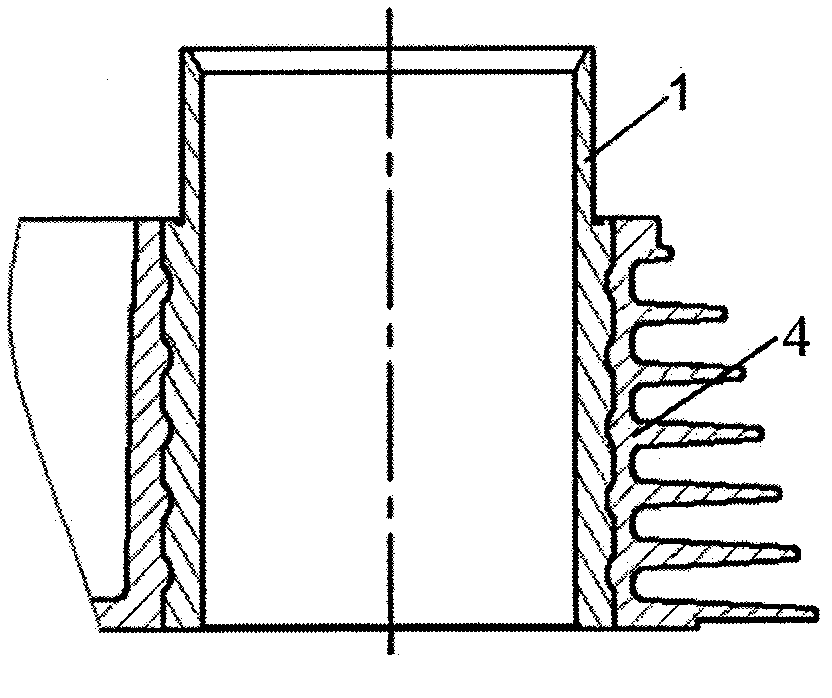

[0040] The reinforcement layer forms the wall thickness of the cylinder liner, and the primary Al on the inner surface of the cylinder liner 3 The total volume percentage of Ni and primary Si reinforcing particles is 15%. In nascent Al 3 In the mixed reinforced particles of Ni and primary Si, the primary Al 3 Ni particles account for 70% by relative volume percentage.

Embodiment 2

[0042] The reinforcement layer forms the wall thickness of the cylinder liner, and the primary Al on the inner surface of the cylinder liner 3 The total volume percentage of Ni and primary Si reinforced particles is 30%, and the primary Al 3 In the mixed reinforced particles of Ni and primary Si, the primary Al 3 Ni particles account for 70% by relative volume percentage. In this embodiment, the percentage content of reinforcing particles makes the heat resistance and wear resistance of the cylinder liner better than that of Embodiment 1.

Embodiment 3

[0044] The reinforcement layer forms the wall thickness of the cylinder liner, and the primary Al on the inner surface of the cylinder liner 3 The total volume percentage of Ni and primary Si reinforced particles is 40%, and the primary Al 3 In the mixed reinforced particles of Ni and primary Si, the primary Al 3 Ni particles account for 70% by relative volume percentage. This embodiment strengthens the primary Al in the particles 3 The volume percentage of Ni particles makes the heat resistance and wear resistance of the cylinder liner better than that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com