Spark plug ignition device and method in combustion chamber of small rotary engine

A technology of rotary engine and ignition device, applied in engine ignition, spark ignition controller, combustion engine, etc., can solve the problems of difficult ignition and long flame propagation distance, so as to reduce the flame propagation distance, improve overall performance, reduce Effects of Airflow Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

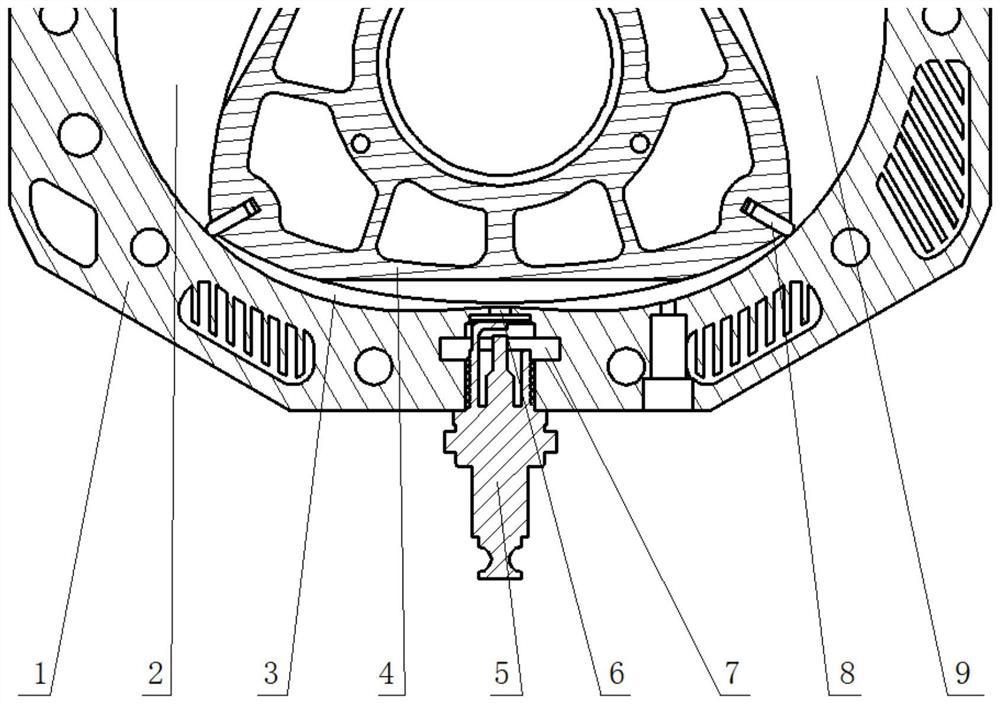

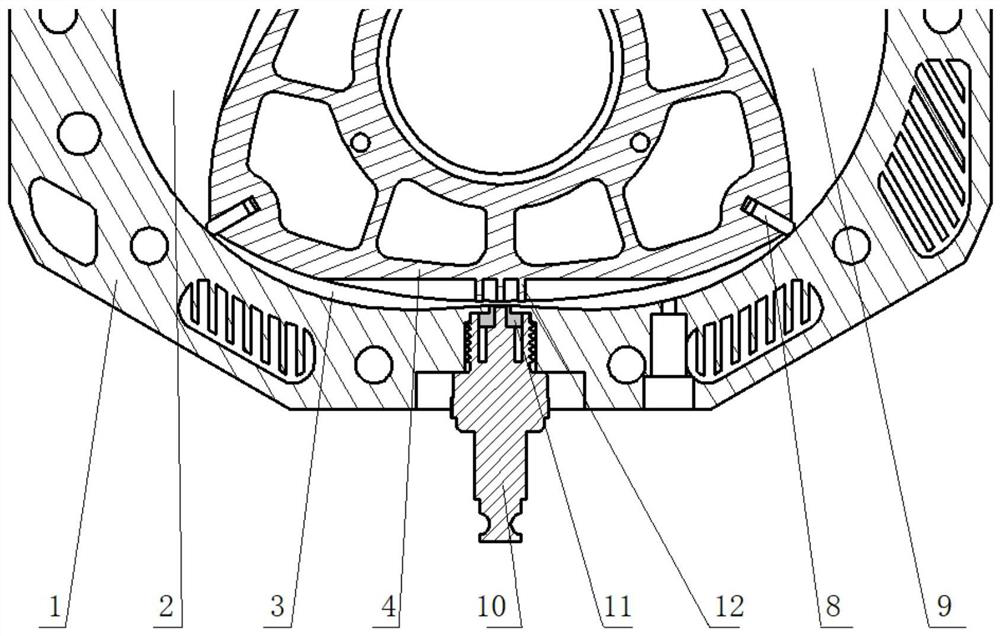

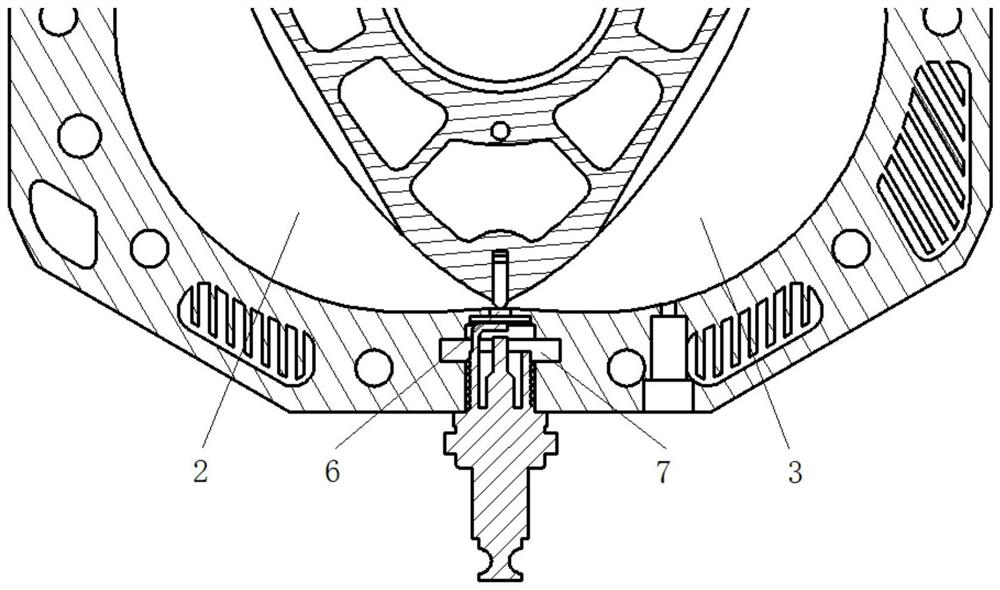

[0035] figure 1 The traditional small rotary engine spark plug ignition device shown with figure 2 The comparison of the spark plug ignition device and method in the combustion chamber of a small rotary engine shown shows that the spark plug ignition devices of the two devices have the same structure: engine cylinder 1, first working chamber 2, second working chamber ( figure 1 , 2 Moment is combustion chamber) 3, triangular rotor 4, sealing plate 8, the 3rd working chamber 9, these structures are the basic structure of small-sized rotor engine. and figure 1 The ordinary spark plug 5, the spark plug channel 6 and the ignition chamber 7 are the unique structures of the spark plug ignition device of the traditional small rotary engine; figure 2 The modified spark plug 10, bushing 11 and cathode 12 are the unique structures of the spark plug ignition device and method in the combustion chamber of a small rotary engine disclosed in this embodiment.

[0036] The modified spar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com