Long-piston hydraulic machines

A technology of hydraulic presses and pistons, applied in the field of hydraulic pump/motor machines, can solve problems such as limitations and achieve the effect of cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The operation of hydraulic machines of the type that can be augmented by the present invention is known. Therefore, this operation will not be described in detail.

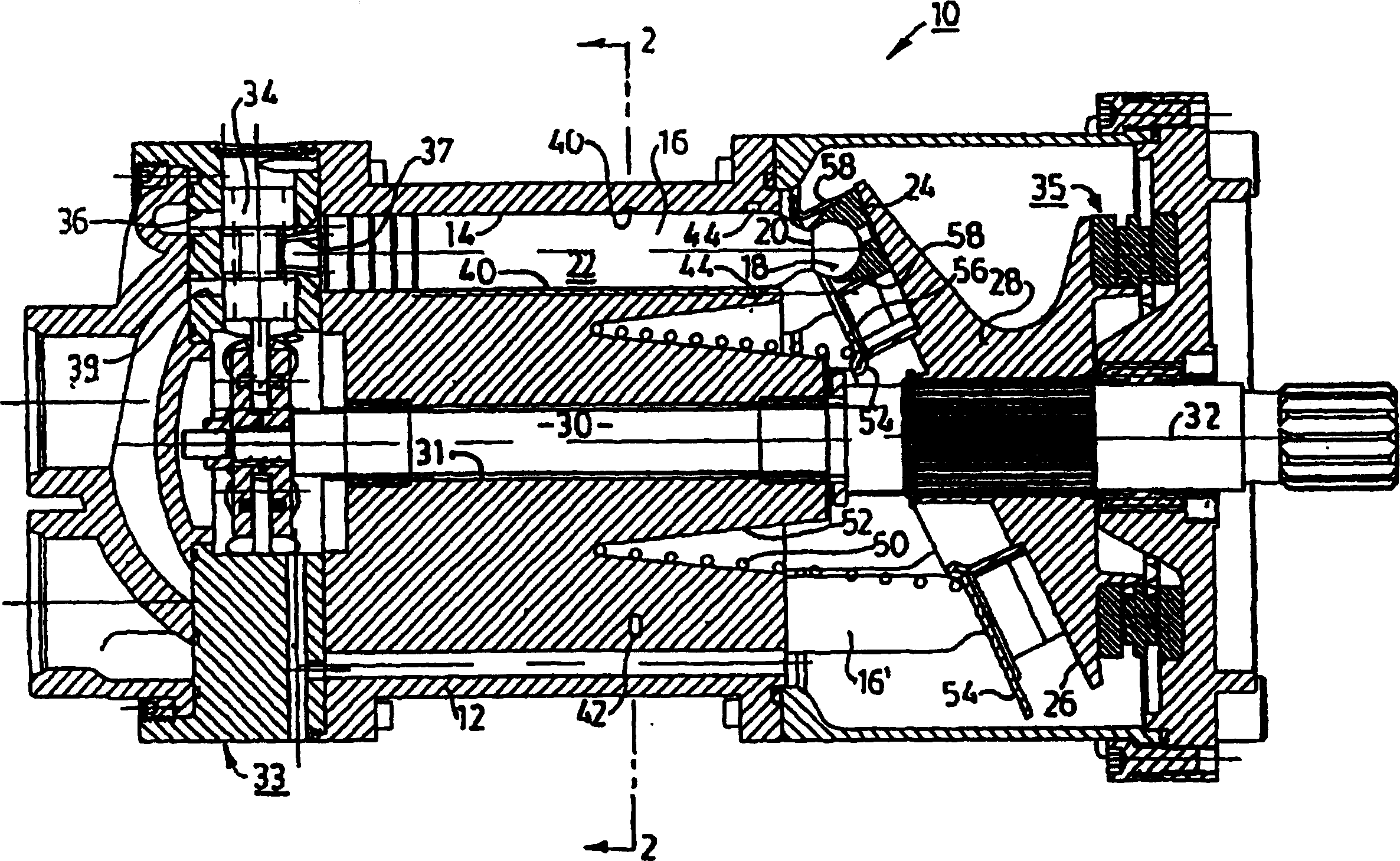

[0025] hydraulic motor

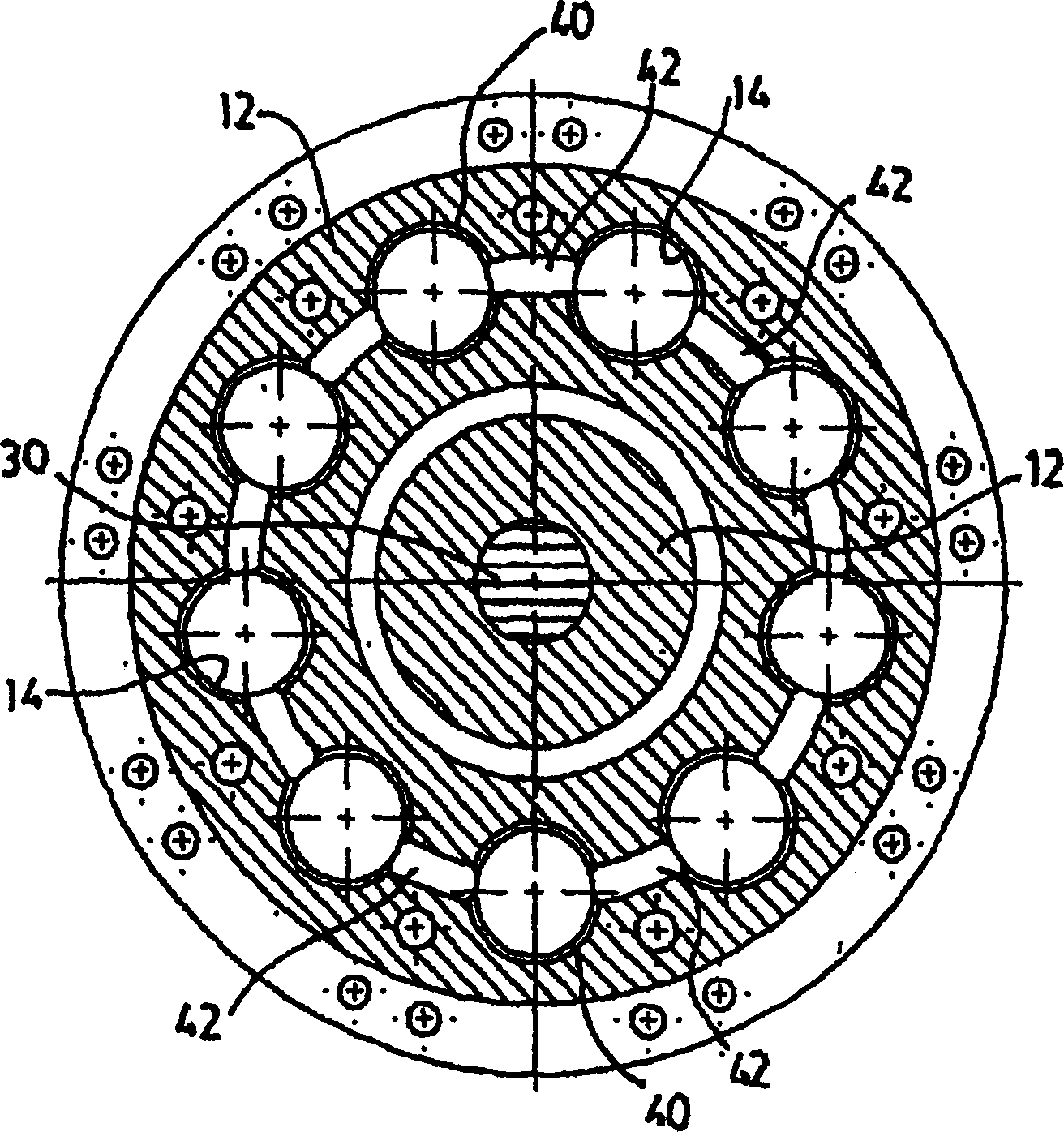

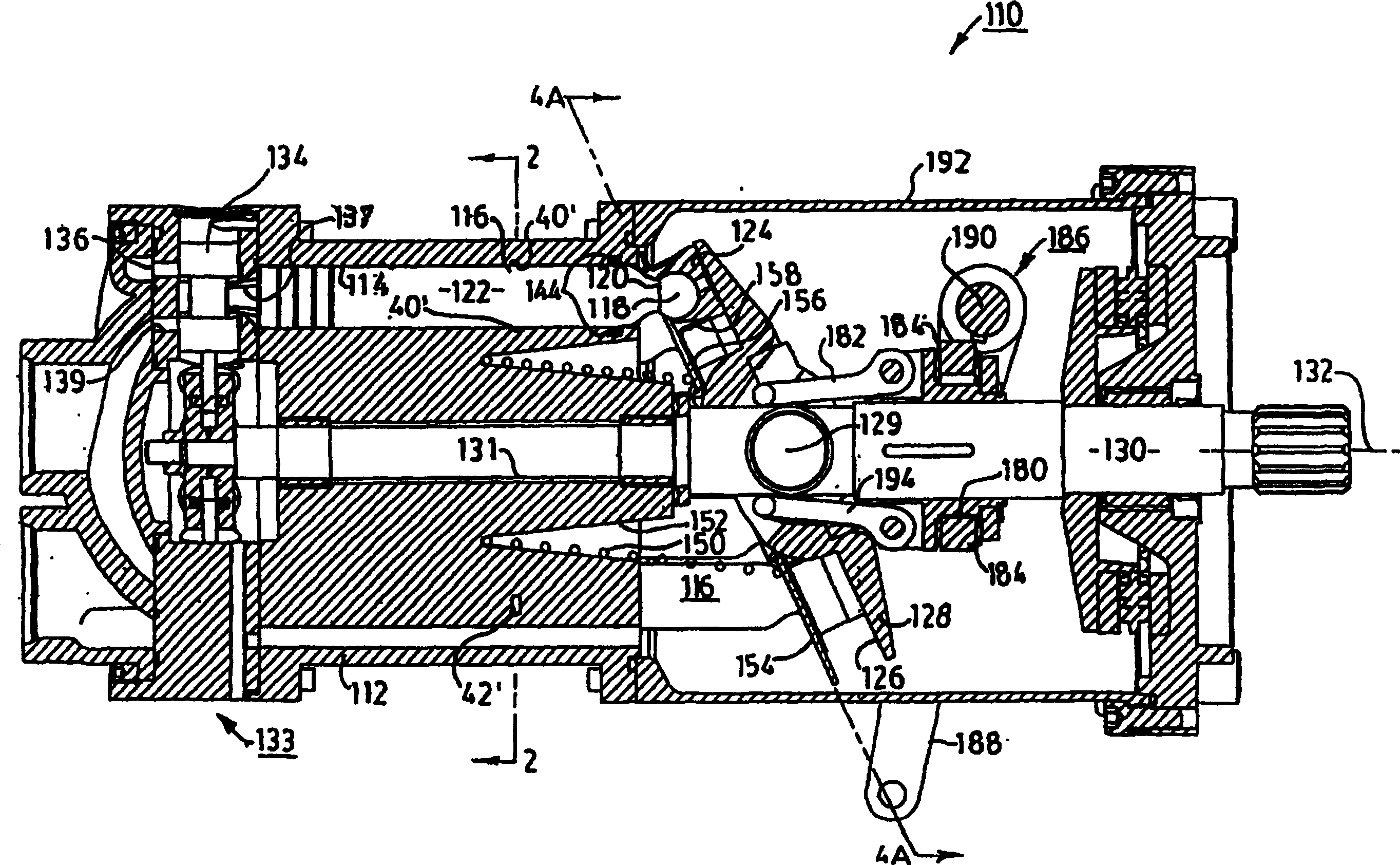

[0026] refer to figure 1 , the hydraulic motor 10 includes a stationary cylinder 12 having a plurality of cylinders 14 (only one shown), wherein a corresponding plurality of mating pistons 16 reciprocates between a retracted position of the piston 16 and an extended position of the piston 16'. Each piston has a spherical head 18 mounted on a neck 20 at one end of an elongated axially cylindrical body portion 22 which, in the preferred embodiment shown, is substantially aligned with each respective cylinder. 14 is the same length.

[0027] Each spherical end 18 fits in a respective shoe sliding on a plane 26 formed on the surface of a rotor 28 co-fixed on the drive element, ie the shaft 30 of the machine. The shaft 30 is supported on bearings in a bore 31 at the center of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com