Patents

Literature

118 results about "Rc frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

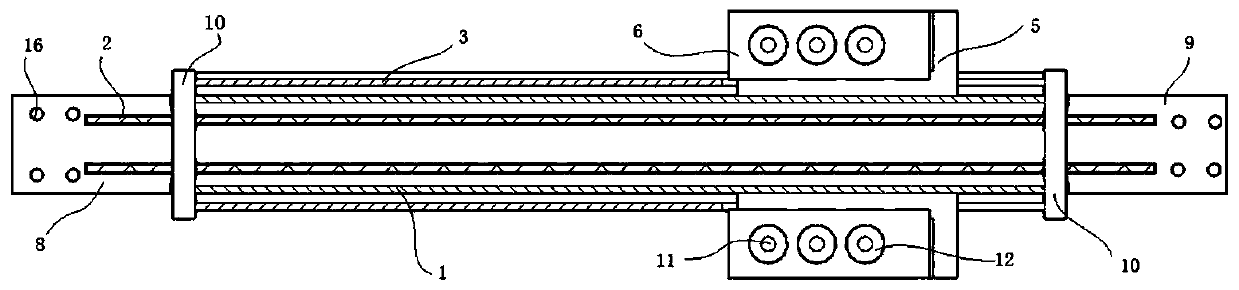

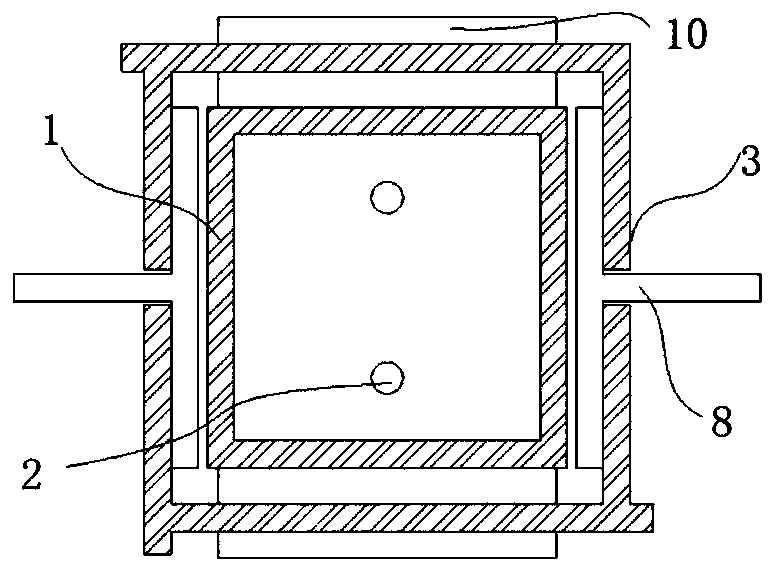

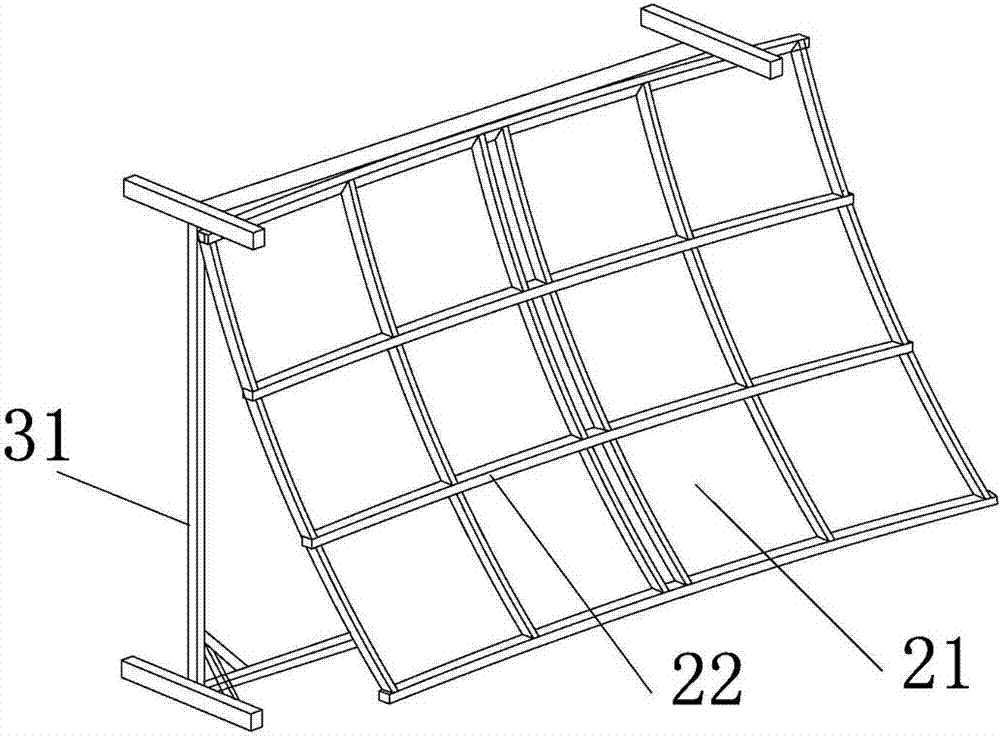

Assemble type multifunctional outer wall body and production and installation method thereof

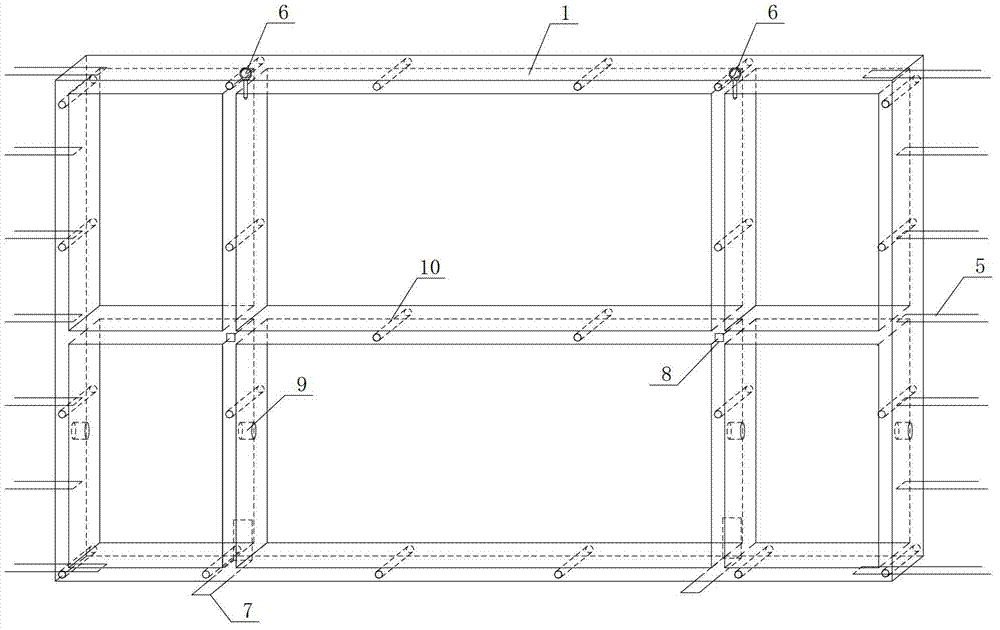

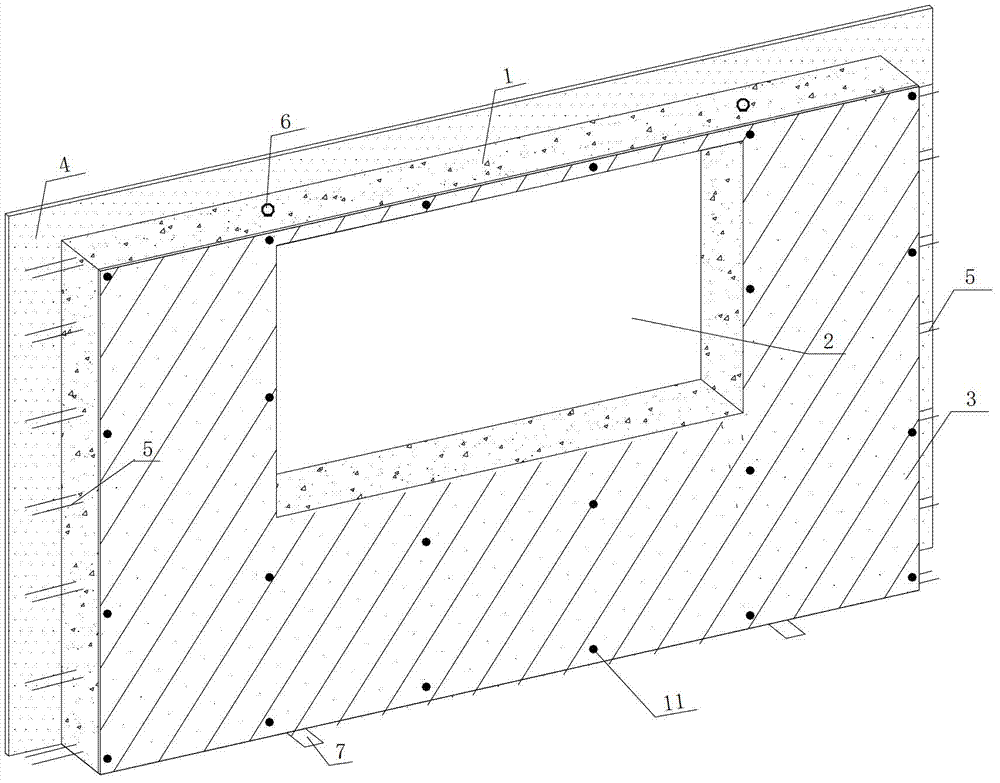

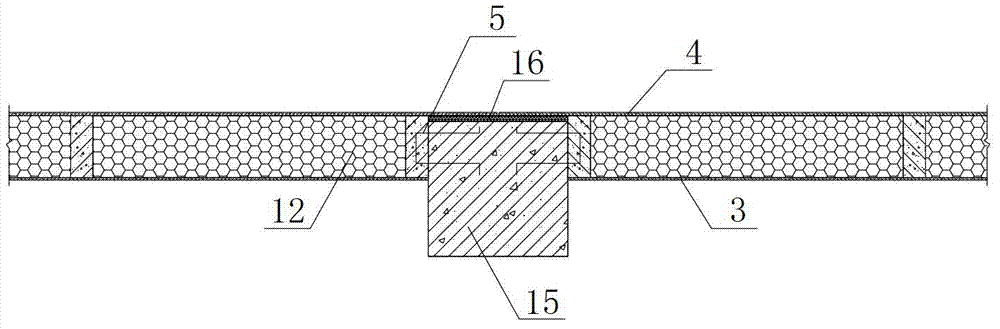

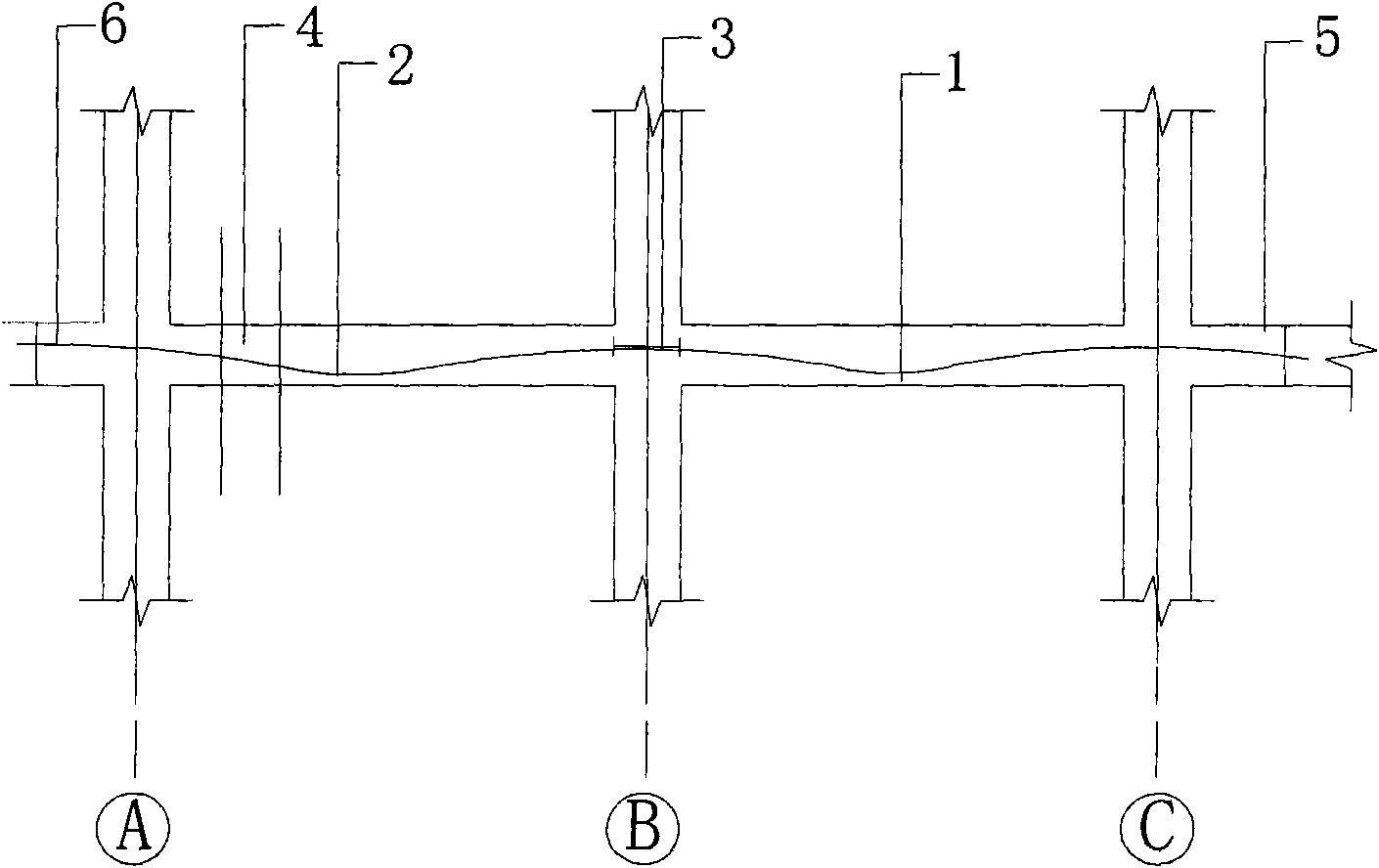

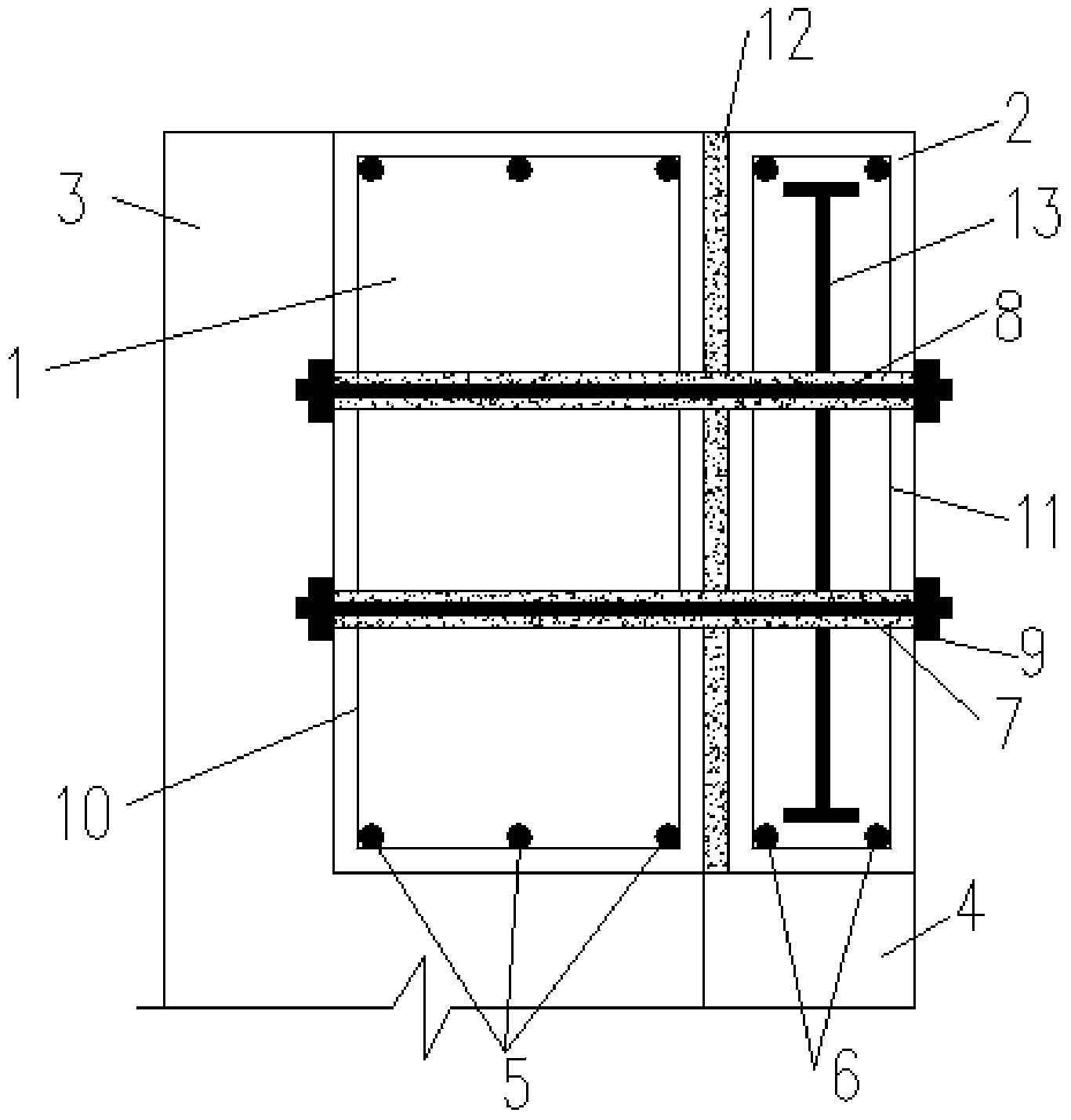

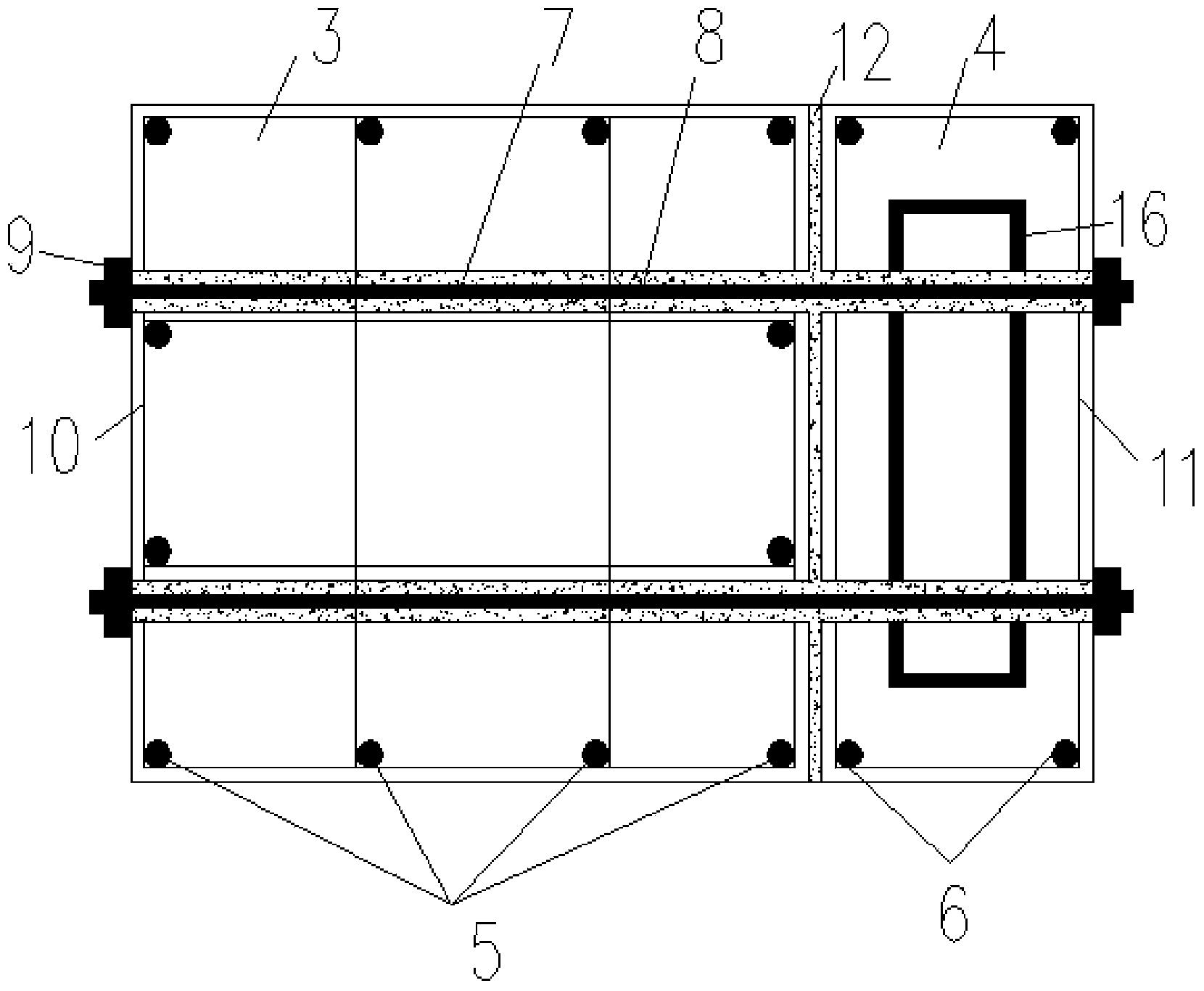

The invention discloses an assemble type multifunctional outer wall body and a production and installation method thereof. An assemble type outer wall body mainly takes lightweight section as a keel, takes expanded polystyrene (EPS) thermal mortar as a heat preservation interlayer and is mainly applied to steel structure construction at present. The existing assemble type outer wall body has the problems that durability is bad, thermal bridge effect is notable, manufacturing cost is high, adaptability with a reinforced concrete structure is bad and the like. The assemble type multifunctional outer wall body is a frame interlayer composite structure and takes a fine stone reinforced concrete frame as the keel. Cellular concrete is filled in bars of the frame, and a window opening is reserved in the frame. Cement fiber panels are respectively fixedly installed on the inner side and the outer side of the fine stone reinforced concrete frame, and decorating layers are arranged on the cement fiber panels. The assemble type multifunctional outer wall body is suitable for assembling an integrated type structure building or a cast-in-place concrete building, split joint of the assemble type multifunctional outer wall body and a building main body structure is firm, and thus integrity is good. The assemble type multifunctional outer wall body has the integrated functions of protection, heat preservation, decoration, water proofing and the like, all working procedures are settled in one step, an outer scaffold does not need to be arranged in the process of installation, and thus construction speed is fast.

Owner:浙江省建筑科学设计研究院建筑设计所

Construction method for pouring after settlement of reinforced concrete continuous beam with cohesive pre-stress

InactiveCN101775903AReduce construction costsSimple construction processBuilding material handlingForm treatmentFalseworkFloor slab

The invention relates to a construction method for pouring after the settlement of reinforced concrete continuous beam with cohesive pre-stress, which belongs to the technical field of reinforced concrete construction. The template construction of a primary beam, a secondary beam and a floor slab of a reinforced concrete frame structure adopts an early dismantling system framework; the pre-stressed reinforced concrete of the main beam is erected on two spans of brackets, and respectively meets the erection requirements; the tension ends on both sides of the two spans are respectively provided with beam haunches on both sides of the brackets; the beam haunches are respectively designed into the tension ends; pres-stressed reinforced concrete and cast concrete are paved according to the design requirements; after the concrete of the main beam reaches 14 days and 80percent of design strength, the pre-stressed beam on the right side is tensioned; after tensioning, the template early dismantling supporting scaffold of the span is dismantled; the early dismantling system supporting scaffold at the bottom of the pre-stressed beam on the left side is not dismantled, and the concrete at the settled pouring part after settlement is poured after structural settlement, and micro expansion concrete is used to cast the settled poured belt; and after the poured belt concrete after the main beam reaches 14 days and 80percent of design strength, the pre-stressed beam of the span on the left side is tensioned. And the construction method has the advantages of lower construction cost and simple process.

Owner:BEIJING SHOUGANG CONSTR GROUP

Prefabricated assembled box culvert and construction method thereof

InactiveCN102418319AImprove construction progressQuality assuranceGround-workRc framesArchitectural engineering

The invention discloses a prefabricated assembled box culvert and a construction method thereof. The box culvert is in an assembled structure and consists of a reinforced concrete culvert body, wing walls, a foundation and deformation joints, wherein the culvert body of the box culvert is in an integral closed-type reinforced concrete framework structure formed by combining transition culvert joints, non-standard culvert joints and standard culvert joints. The culvert body and the wing walls adopt assembly and construction. By utilizing the prefabricated assembled box culvert, batch production can be performed in a factory, field assembly is realized, the construction progress of the culvert is accelerated, the construction period is shortened and the quality of the culvert is ensured. Therefore, the problems of long culvert construction period and difficult control on the quality during the current road construction can be solved.

Owner:新疆交通科学研究院有限责任公司

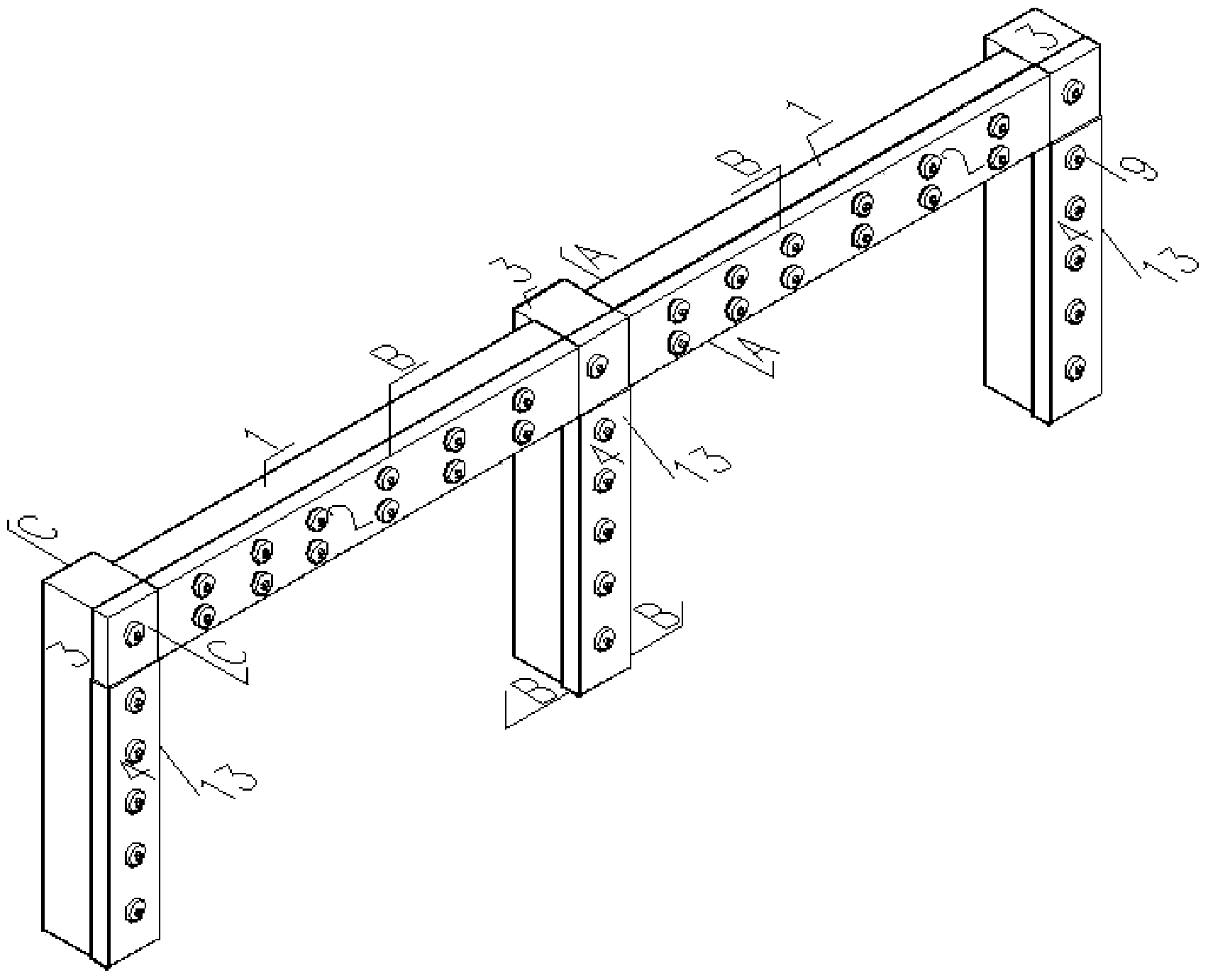

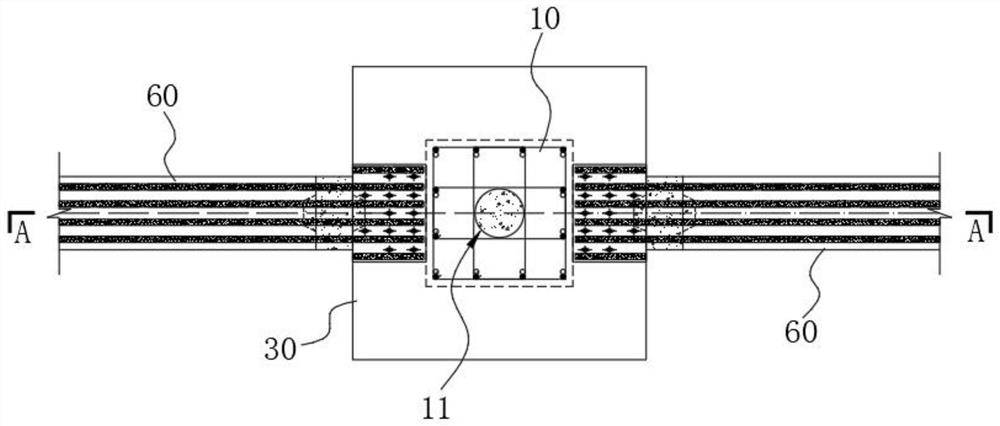

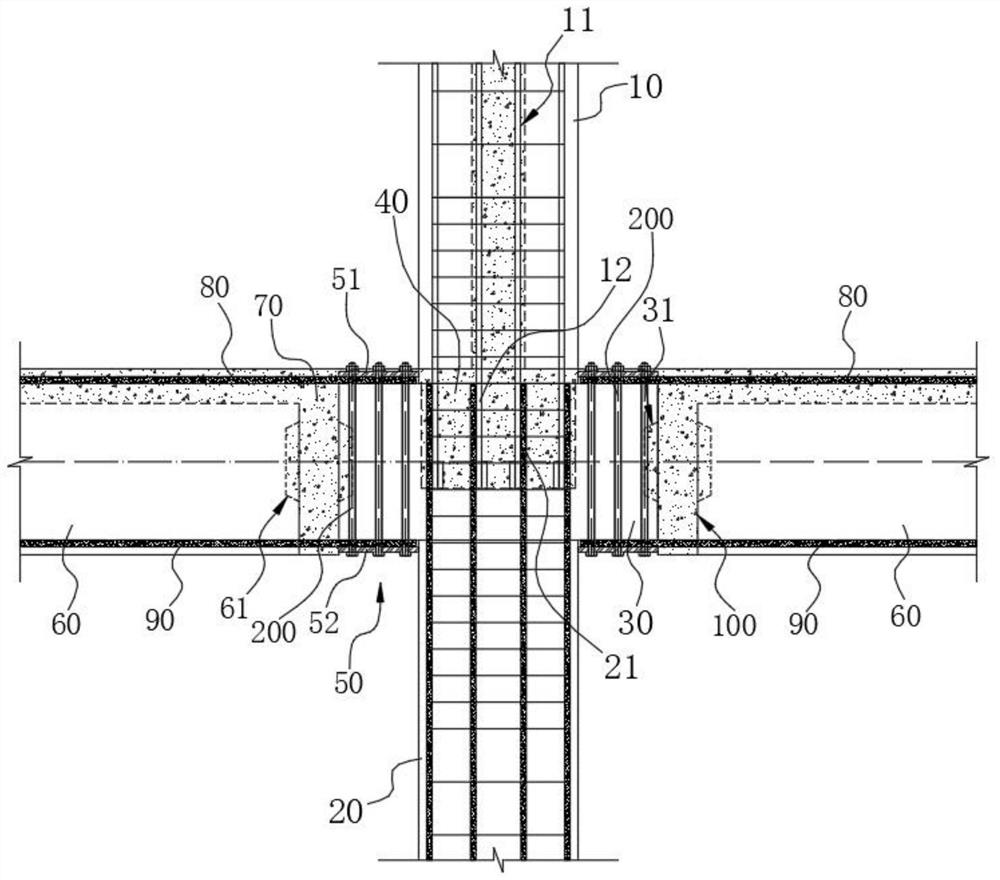

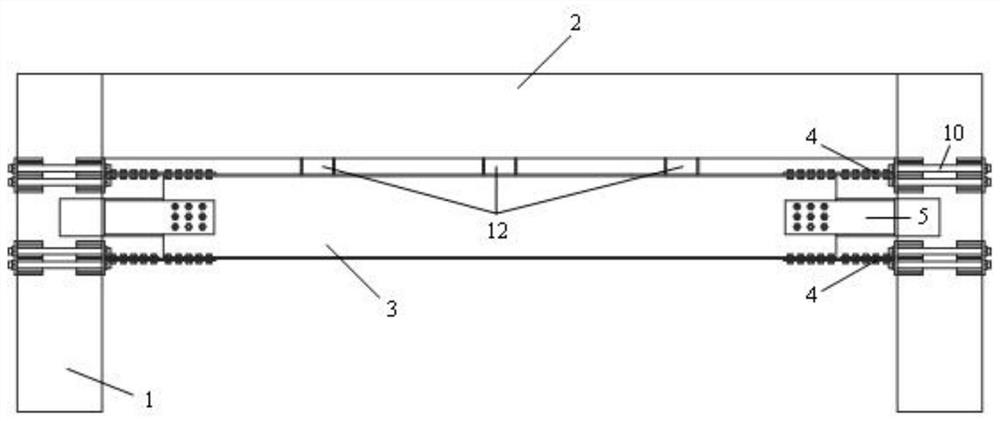

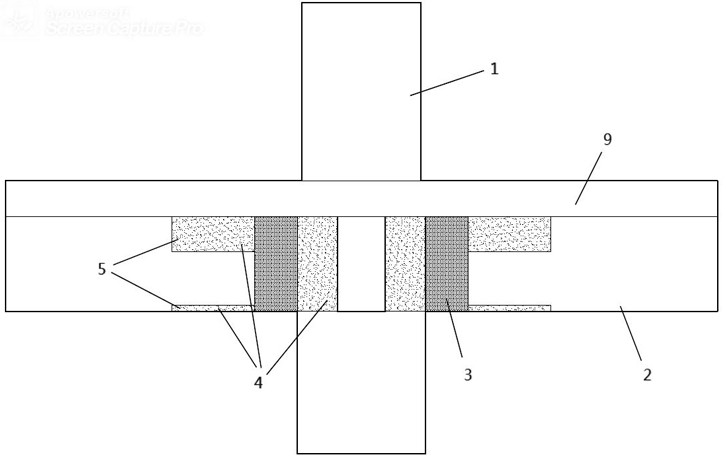

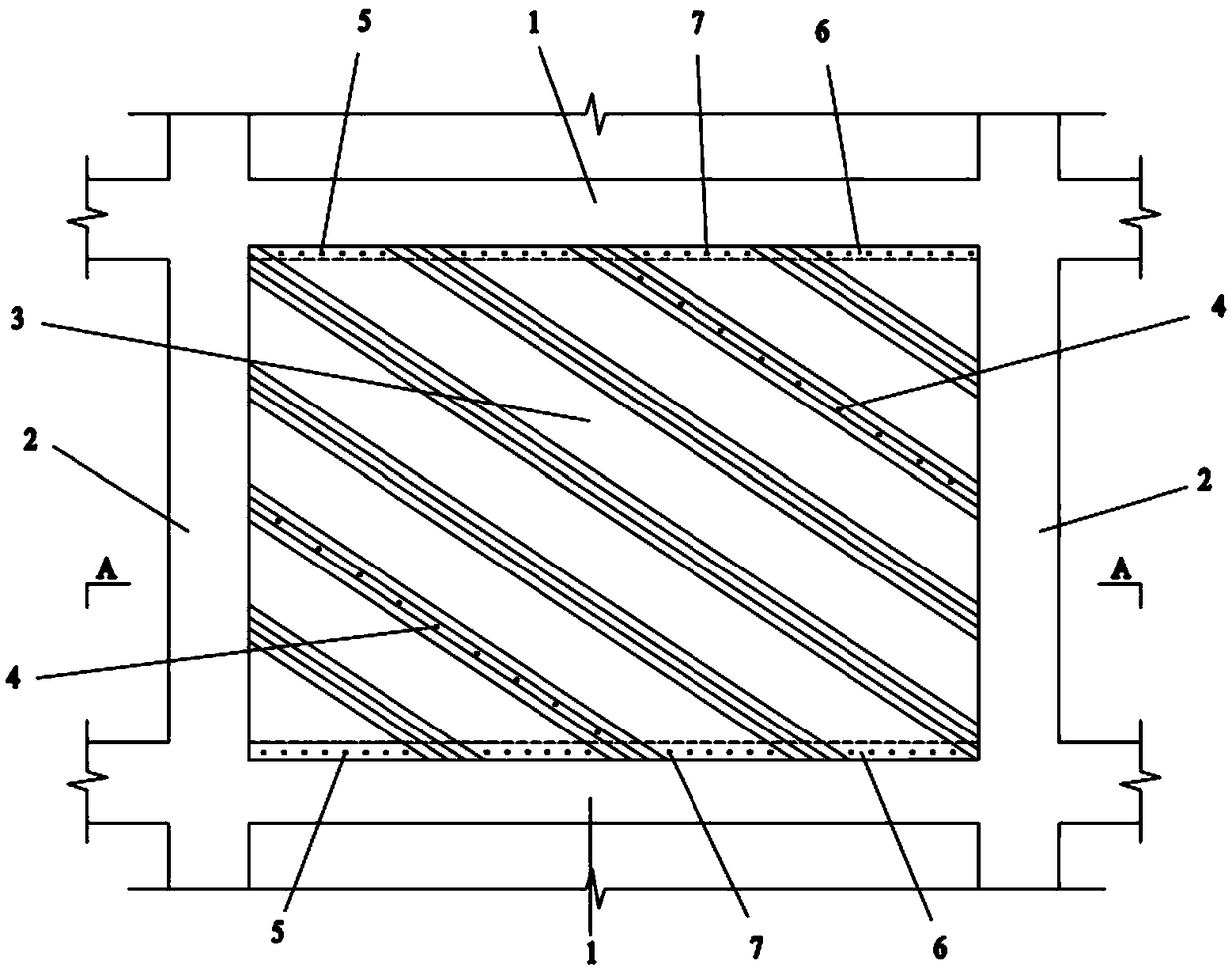

Low-damage self-resetting fabricated concrete two-way frame beam-column joint

ActiveCN107237402AImprove seismic performanceReduce earthquake damageClimate change adaptationBuilding constructionsEarthquake resistanceRc frames

The invention relates to a prefabricated reinforced concrete two-way frame beam-column joint. The prefabricated reinforced concrete two-way frame beam-column joint is characterized in that a prefabricated frame column is uninterrupted in the joint area, a prefabricated frame beam is interrupted in the joint area, and a contact surface is formed by the beam end and the column side. Hole channels are reserved in the elevation positions of an upper reinforcing steel bar and a lower reinforcing steel bar of a corresponding beam in the frame column and penetrate into the reinforcing steel bars, the two ends of each reinforcing steel bar are fixed on a pre-buried steel part of the frame beam side, the seismic energy can be consumed under the earthquake effect, and replacement is easy to conduct after the earthquake. Hole channels are reserved in the position, close to the neutral axis, of the inner portion of the two-way frame beam and the corresponding position of the frame column, no-bonding prestressed tendons are arranged in the hole channels, and the prefabricated frame beam and the column are connected by applying prestress along the two-way frame beam. According to the prefabricated reinforced concrete two-way frame beam-column joint, the anti-seismic performance of the fabricated frame structure can be obviously improved. The structure system connected through the joint can achieve the purposes that zero damage or slight damage is achieved under a rare occurrence earthquake, and autonomous resetting is achieved after the earthquake. The joint is simple and convenient to construct and low in construction cost, and the novel prefabricated concrete frame joint connecting technology is worth being promoted vigorously.

Owner:BEIJING ACAD OF BUILDING ENG

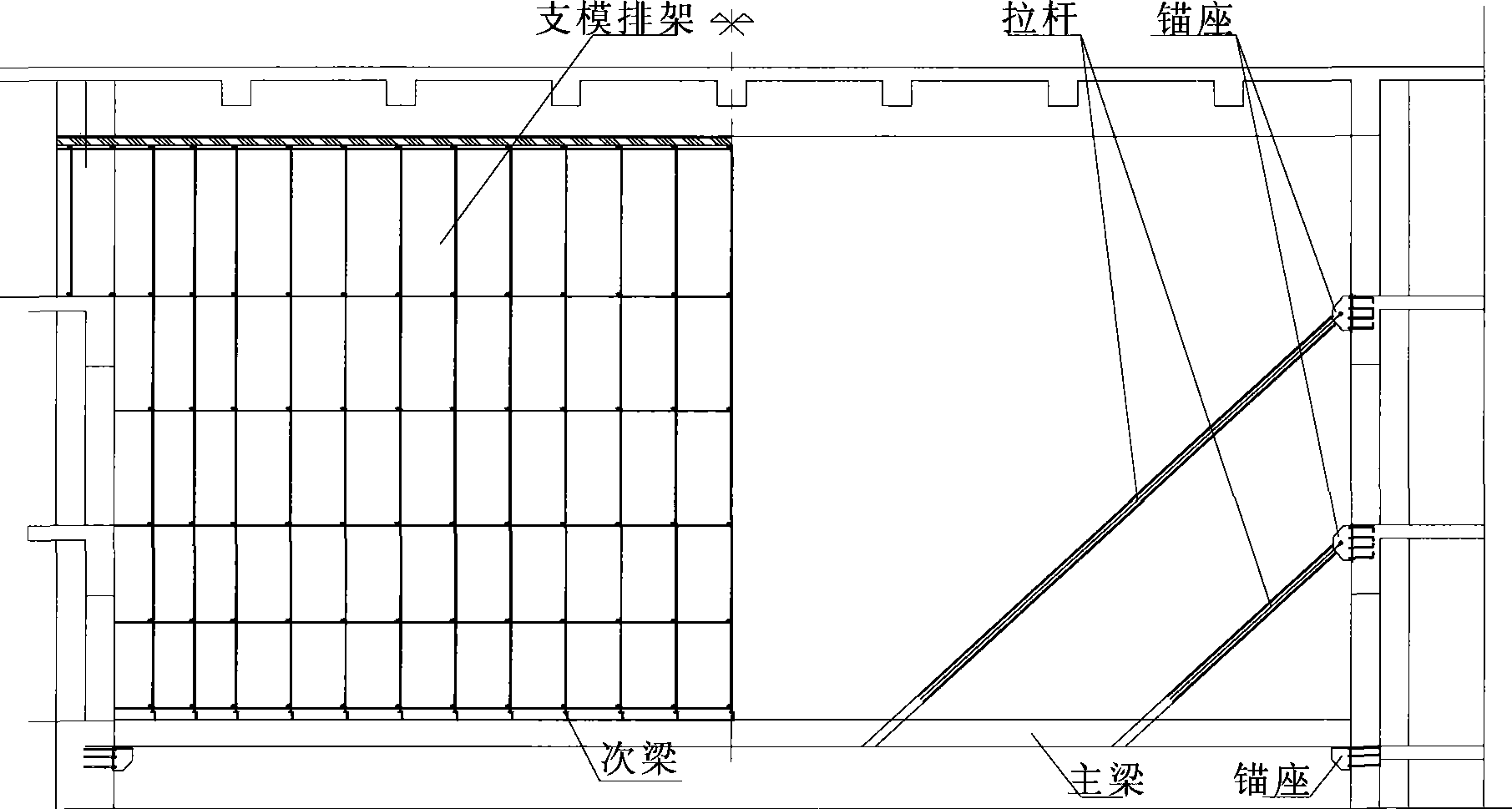

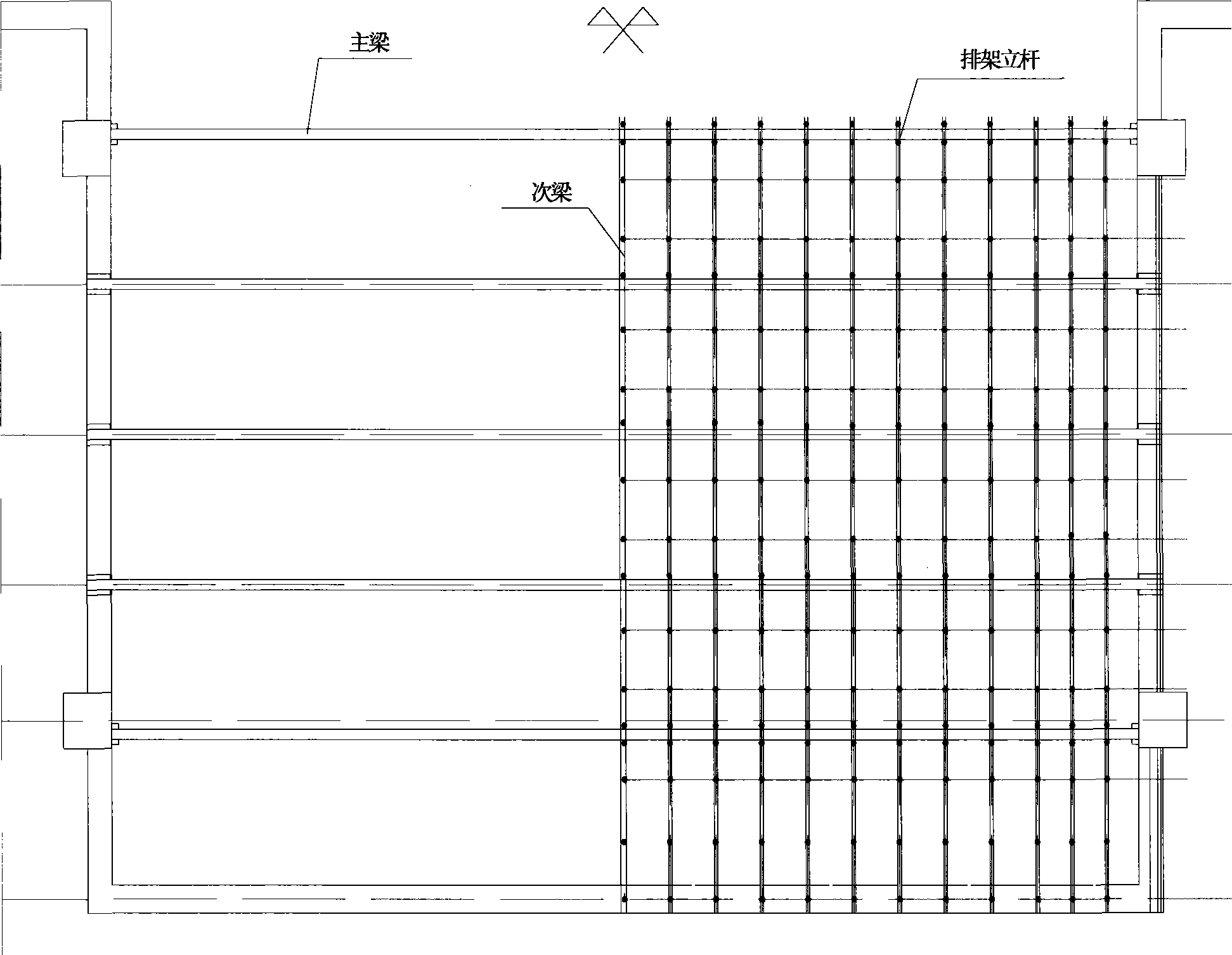

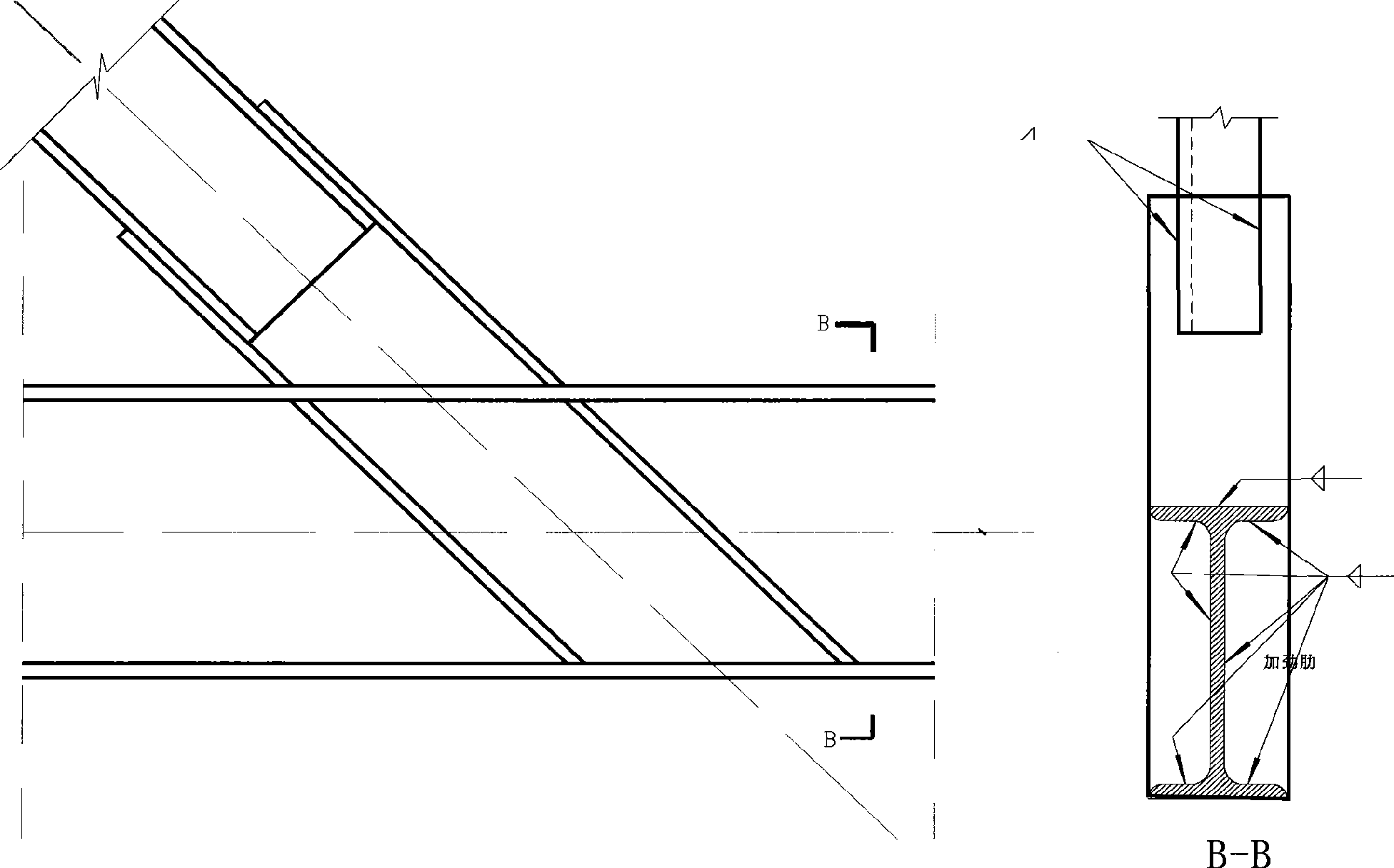

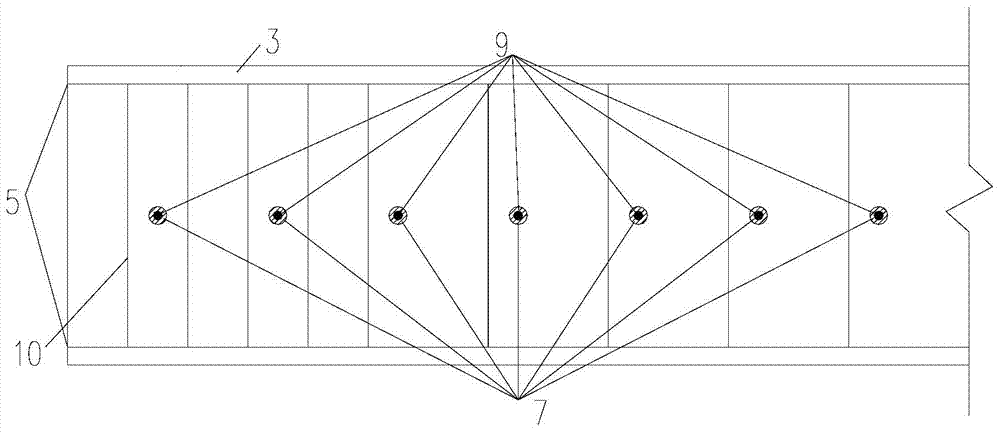

Stay suspender multispan beam structure highly hollow-out formwork system and construction method

InactiveCN101372865ASafe and reliable structureSafe and practical structureAuxillary members of forms/shuttering/falseworksBuilding support scaffoldsReinforced concreteContinuous beam

The invention relates to an inclined pulling type suspender multi-span continuous beam structure high hollowed-out formwork system and a construction method. The system is a structure support system loaded on a support bent frame of a concrete die plate for supporting the upper floor, and the system is formed through adopting section steel to form a primary and secondary beam steel platform structure and pulling the reinforced concrete framework of the surrounding major structure through a steel pulling rod. Formwork steel platform formed by the inclined structure changes the high hollowed-out structure formwork into a general formwork board which is supported and established on the supporting platform of the inclined pulling type suspender multi-span continuous beam structure.

Owner:ZHEJIANG ZHONGCHENG CONSTR GRP

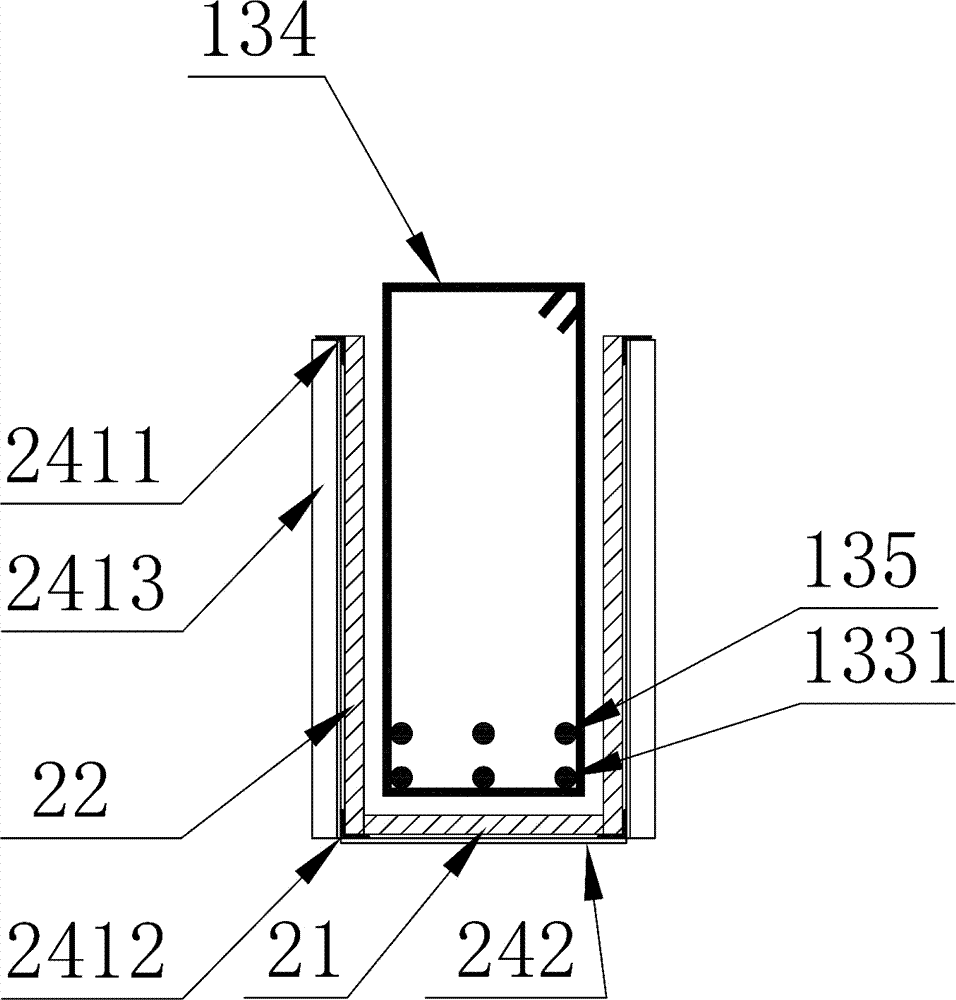

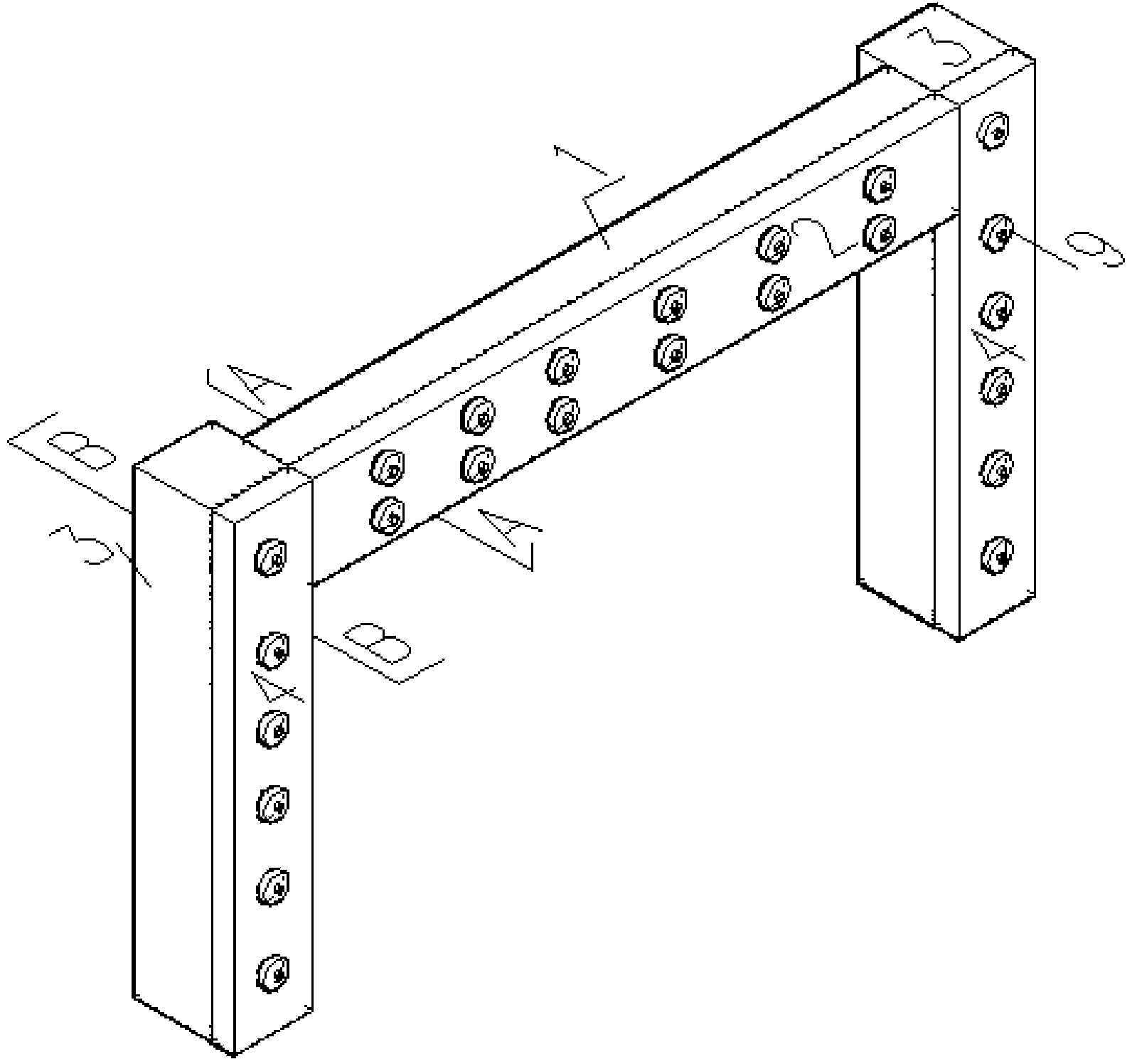

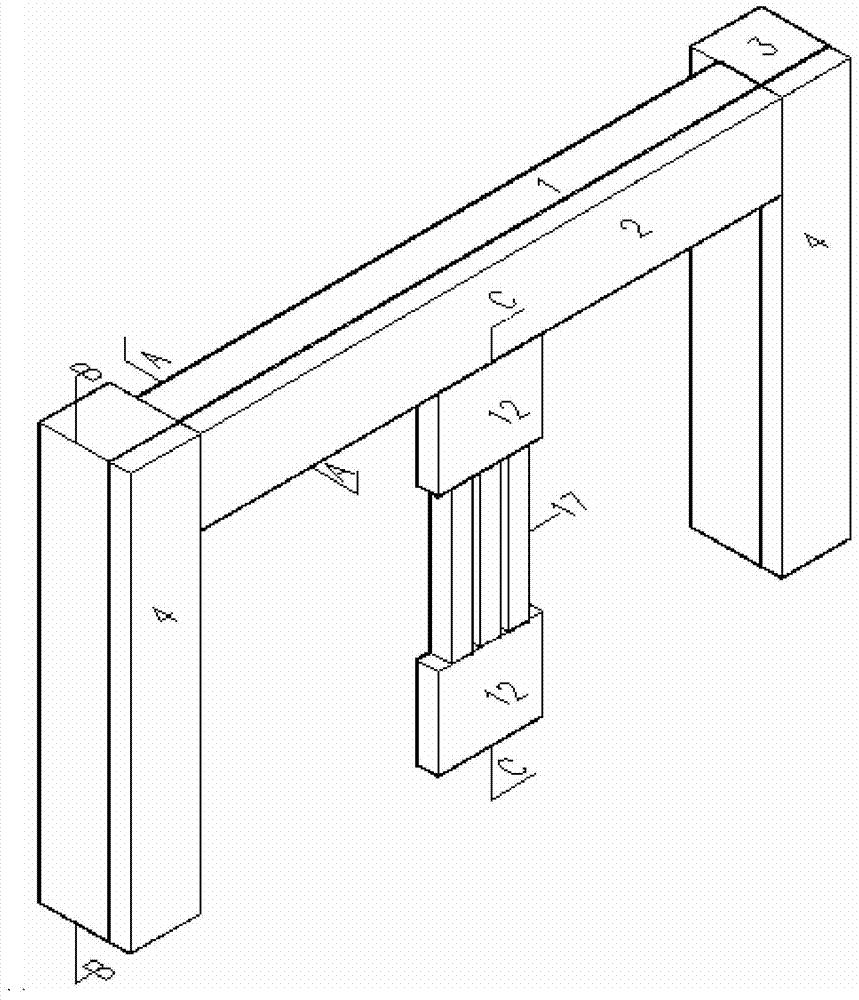

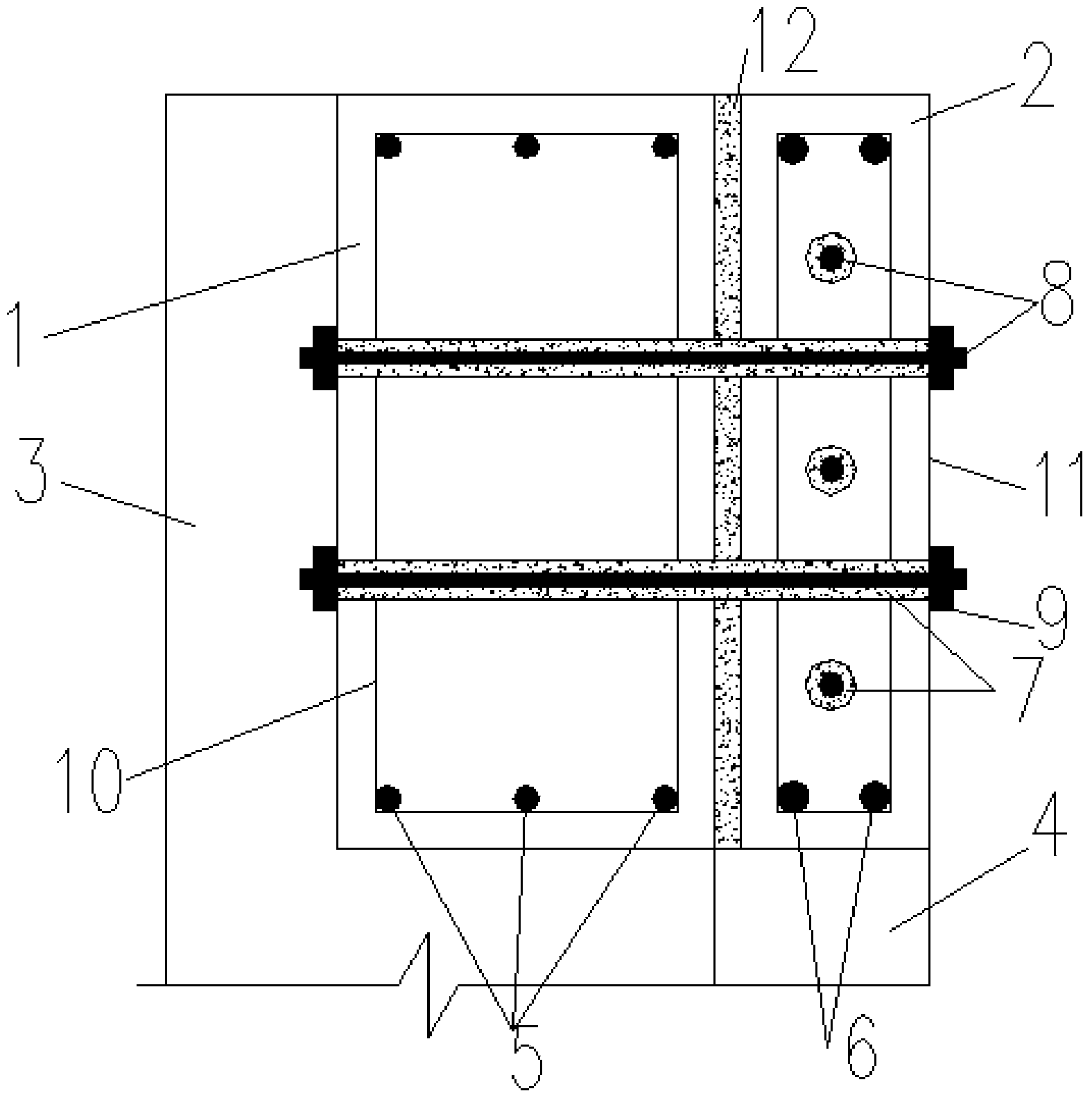

Assembled reinforced concrete framework structure beam-column joint and manufacturing method thereof

ActiveCN107288218ALength is not affectedImprove the anchoring effectForms/shuttering/falseworksRc framesClassical mechanics

The invention relates to an assembled reinforced concrete framework structure beam-column joint and a manufacturing method thereof, and belongs to the technical field of building materials and building construction. The assembled reinforced concrete framework structure beam-column joint is composed of a splicing joint (13) of a prefabricated framework column (11) and a prefabricated framework beam (12), and cast-in-place concrete (14). Column longitudinal ribs (131) in the prefabricated framework column (11) extend out of the top of the column to form column top reserved longitudinal ribs (1311). A plurality of joint column hoops (132) are arranged around the column top reserved longitudinal ribs (1311) and bound to the column top reserved longitudinal ribs (1311). The prefabricated framework beam (12) is spliced to the top of the prefabricated framework column (11). A beam bottom longitudinal rib (133) in the prefabricated framework beam (12) extends out towards the splicing head of the prefabricated framework beam (12), and penetrates through the splicing joint (13) to be linearly anchored. According to the assembled reinforced concrete framework structure beam-column joint and the manufacturing method thereof, the design of connection of a framework joint and a framework beam column around the framework joint is modified, linear anchoring of the framework beam bottom longitudinal rib and continuous through anchoring of a framework beam top longitudinal rib are achieved, connection integrity of an assembled reinforced concrete framework structure is enhanced, and the assembled reinforced concrete framework structure can possess better earthquake-resistant ductility.

Owner:姚伟华 +1

Method for reinforcing structure by means of method of externally attaching steel-reinforced concrete framework

InactiveCN103711329AImprove carrying capacityImprove ductilityBuilding repairsReinforced concreteEngineering

The invention discloses a method for reinforcing a structure by means of the method of externally attaching a steel-reinforced concrete framework, and belongs to the field of concrete structure reinforcing. The steel-reinforced concrete framework is externally attached to the outer side of an existing reinforced concrete framework structure. A newly-added reinforced concrete beam and column are prefabricated in a whole-casting integrated mode and are connected with an existing reinforced concrete beam and column respectively in a post-tensioning method anchoring prestressed tendon mode. Steel ribs in the newly-added reinforced concrete beam and column are connected together through bolts and angle iron. A gap with the width of 5-10mm is reserved between the newly-added steel-reinforced concrete framework and the existing reinforced concrete framework structure and is sealed by mortar. Ducts need to be reserved in the newly-added reinforced concrete beam and column and the steel ribs in the newly-added steel-reinforced concrete beam and column, so that prestressed tendons penetrate through the steel ribs conveniently. Unbounded prestressed tendons are anchored through an anchorage device. According to the method, the bearing capacity, rigidity, ductility and the like of the structure can be effectively improved, a worker does not need to enter a house in the construction process without removal, the efficient, economical and practical effects can be achieved, and the reinforcing effect is facilitated.

Owner:BEIJING UNIV OF TECH

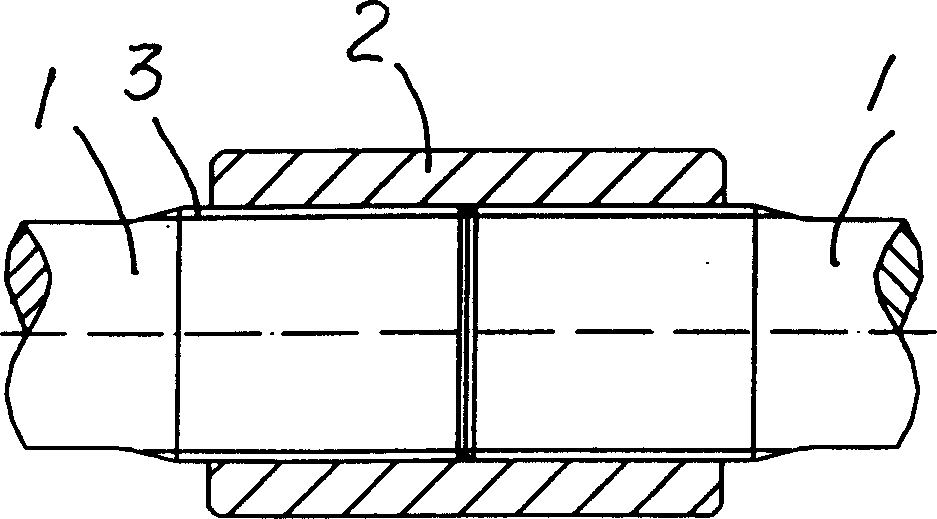

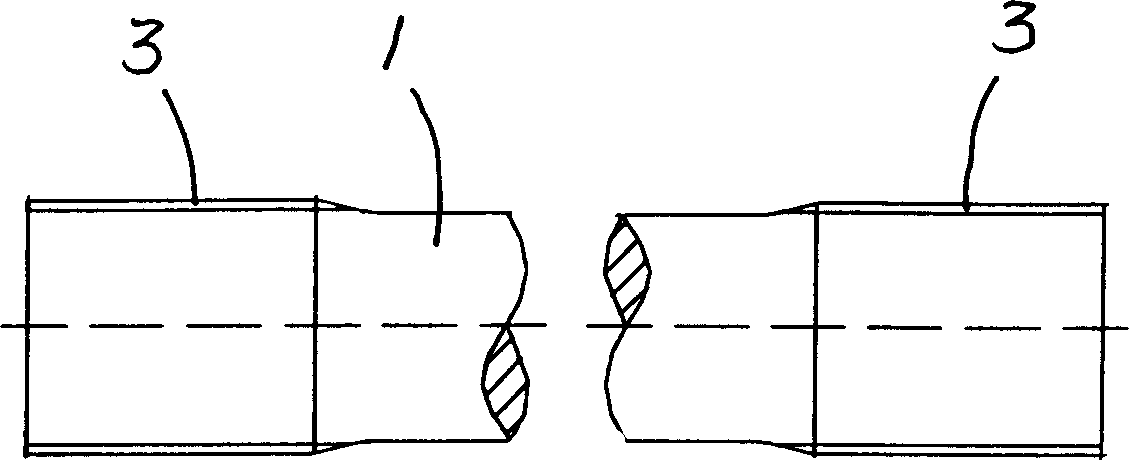

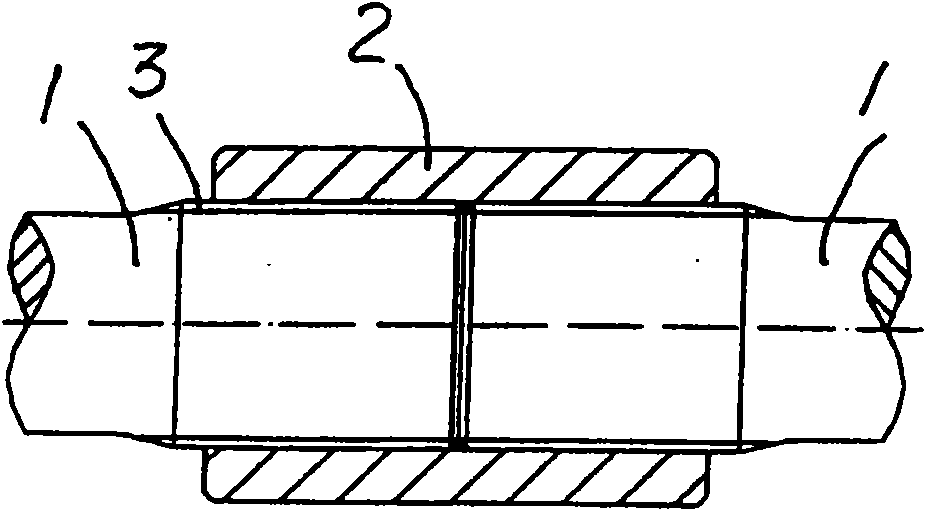

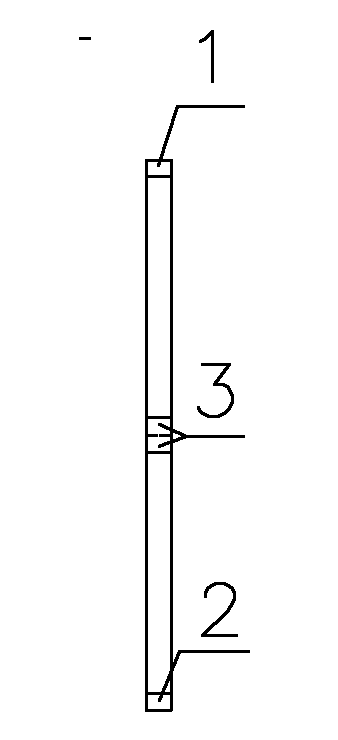

Straight thread connector with steel reinforced end and connection thereof

InactiveCN1746452AReduce labor intensityHigh strengthBuilding reinforcementsBuilding material handlingRebarReinforced concrete

A strength straight thread connecting piece of concrete iron ends and connecting method are disclosed. Two ends of screw stem have outer straight thread. Coat has inner straight thread that matches with outer straight thread. The invention decreases the work force and improves the efficiency.

Owner:上海建研钢筋连接技术有限公司

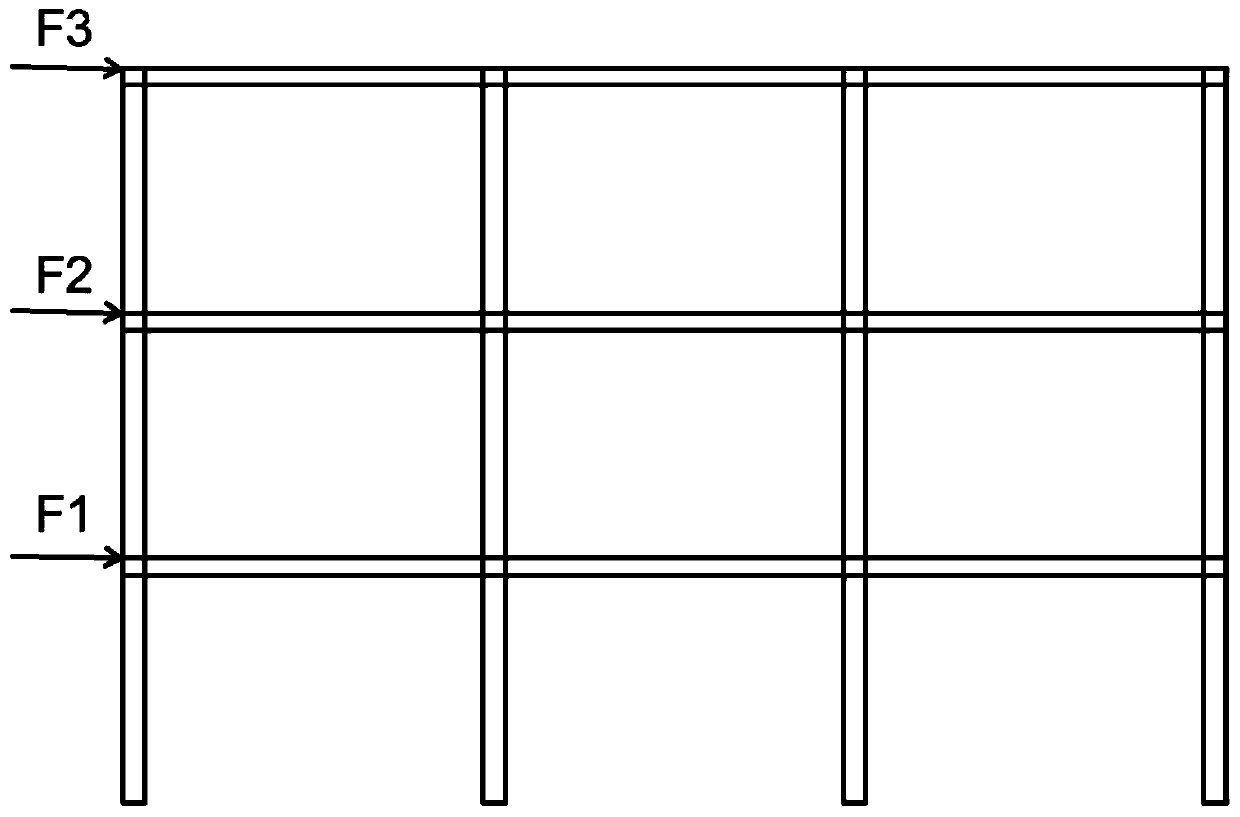

Fabricated RC frame structure for arranging buckling-restrained braces (BRB) based on interlayer stiffness demands

InactiveCN109868897AControl developmentAvoid damageProtective buildings/sheltersShock proofingBuckling-restrained braceRc frames

The invention relates to the field of structural engineering, in particular to a fabricated RC frame structure system for arranging buckling-restrained braces (BRB) based on interlayer stiffness demands. The fabricated RC frame structure system comprises a main body structure of a fabricated RC frame, a variable-section BRB structure, and an SMA vibration isolator, wherein the variable-section BRBstructure is the BRB structure, and the section size of a BRB inner core unit is determined according to the set target interlayer stiffness; the SMA vibration isolator comprises SMA intelligent concrete and an SMA bar fabricated self-reset damper adopted by a column base, wherein the SMA intelligent concrete is located in a beam and the column. According to the method for optimizing the interlayer stiffness, the interlayer stiffness of each layer is consistent by changing the size of the inner core section of the BRB; in addition, an SMA material is adopted in the area where the structure isprone to being damaged, thus the structure can self-reset and self-repair when being suffered from seismic action, and the damage forms of the 'strong beam and weak column' and 'the weak layer, especially the bottom layer becoming the weak layer' of the structure are avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

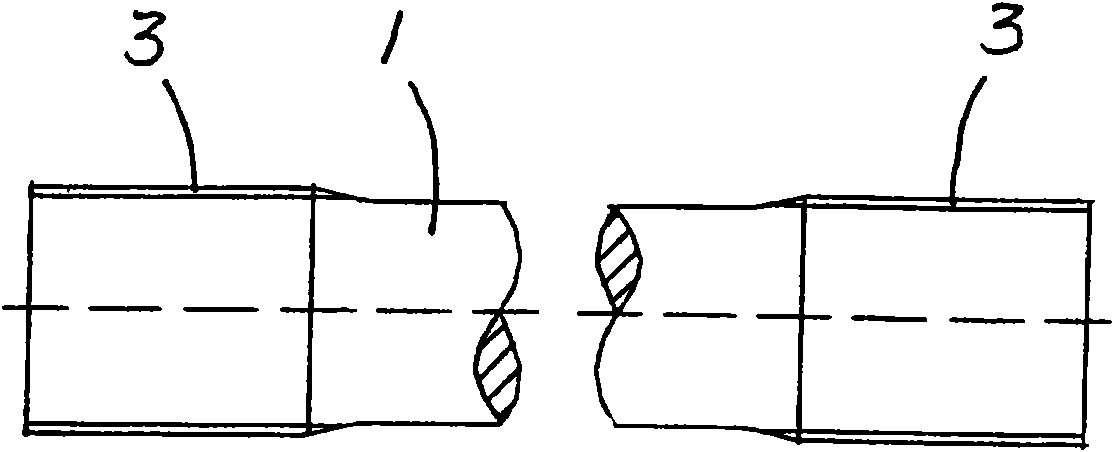

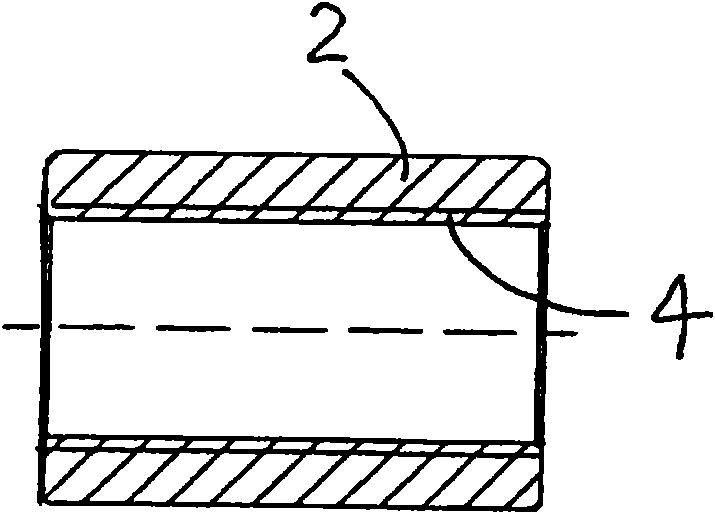

Reinforcement end reinforced large-diameter straight thread connector and connecting method thereof

InactiveCN101624854AMeet design and construction requirementsHigh tensile strengthBuilding reinforcementsReinforced concreteEconomic benefits

The invention relates to the technical field of building construction, in particular to a reinforcement end reinforced large-diameter straight thread connector for a reinforced concrete frame structure of a building and a connecting method thereof. The reinforcement end reinforced large-diameter straight thread connector comprises a screw and a screw sleeve; two ends of the screw are provided with an external straight thread respectively; an internal straight thread matched with the external straight threads on the screw is formed in the screw sleeve; the external straight threads of the screw are screwed with the internal straight thread of the screw sleeve; and the diameters of the internal straight thread and the external straight threads which are matched are 30 to 40 millimeters. The connecting method for the reinforcement end reinforced large-diameter straight thread connector alternately screws the screw and the screw sleeve with the same diameter and the same screwing direction in turn to make the screwing lengths of the screw and the screw sleeve meet the requirements of design and construction. The connector and the connecting method improve the tensile strength of reinforcement, reduce the potential safety hazard, greatly lighten the labor intensity of building constructors, improve the building construction efficiency, and have the advantages of convenient construction, stable quality, obvious economic benefit, convenience for field management, safe production and the like.

Owner:上海建研钢筋连接技术有限公司 +1

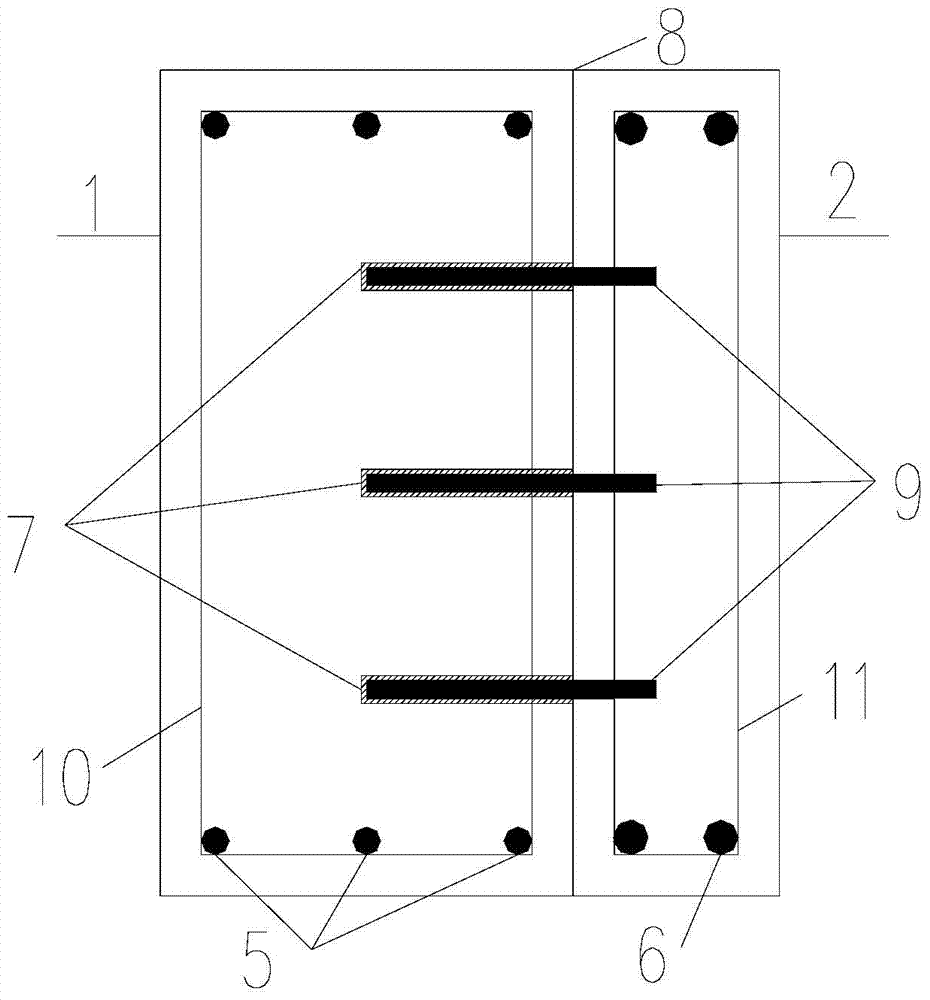

Non-prestress self-resetting energy dissipation supporting device provided with variable friction damper

InactiveCN111425038AEliminate residual deformationIncrease displacement reserveProtective buildings/sheltersShock proofingRc framesPre stress

The invention discloses a non-prestress self-resetting energy dissipation supporting device provided with a variable friction damper. The non-prestress self-resetting energy dissipation supporting device comprises the variable friction damper, an inner sleeve pipe, a plurality of pre-pull rods arranged in the inner sleeve pipe and an outer sleeve pipe arranged outside the inner sleeve pipe, wherein the variable friction damper comprises an upper friction plate, a middle friction plate and a lower friction plate which are sequentially connected, the contact surface of the upper friction plate and the middle friction plate is an embedded zigzag undulating slope surface, the middle friction plate is connected with the inner sleeve pipe, and the lower friction plate is connected with the outersleeve pipe. The energy dissipation device can dissipate energy under the earthquake action, reduce the interlayer displacement angle and acceleration of a building structure, eliminate or reduce residual deformation and damage of a reinforced concrete frame structure under the earthquake action, effectively avoid obvious plastic deformation of a main body structural member, and meanwhile, due tothe fact that the energy dissipation device is convenient to disassemble and assemble, friction energy consumption devices playing a role in dissipating energy are all in an elastic stage, and the repair cost and difficulty of the structure after an earthquake can be obviously reduced.

Owner:SOUTHEAST UNIV

Three-dimensional distorted rotating inclined reinforced concrete frame structure template and construction method thereof

ActiveCN104775612AGuaranteed space to reverse the mobile formLow production costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksRc framesRebar

The invention discloses a three-dimensional distorted rotating inclined reinforced concrete frame structure template and a construction method thereof. The three-dimensional distorted rotating inclined reinforced concrete frame structure template comprises a skirt column template, a skirt plate template and a template support frame. The construction method of the template comprises the following steps: (1) a three-dimensional model graph is built; and a skirt plate structure is known; (2) the positioning paying-off is performed; (3) a skirt column template inner tube mold and a skirt plate jig frame are manufactured; (4) the skirt column template is manufactured; (5) the skirt plate template is manufactured; (6) the skirt column template 1 and the skirt plate template 2 are tried to be spliced; (7) the skirt column template 1 is mounted and reinforced; and (8) the skirt plate template 2 is mounted and reinforced. Skirt column and skirt plate modules are divided in an elevation and segmentation manner through the built three-dimensional graph; the skirt column and skirt plate templates are manufactured through the skirt column inner tube mold and the skirt plate jig frame by the multilayer plate flexibility and square steel two-surface bending performance; and the technical difficulty of the skirt column and skirt plate templates is successfully solved through such methods as external angle subassembly and trial splicing of angle steel bolts.

Owner:BEIJING FOURTH CONSTR & ENG

Novel buckling-restrained brace-RC frame replaceable connecting joint

PendingCN110468987ASolve complexitySolving problems such as uncertain failure modesProtective buildings/sheltersShock proofingReinforced concrete columnPull force

The invention discloses a novel buckling-restrained brace-RC frame replaceable connecting joint. The connecting joint comprises a reinforced concrete column, a reinforced concrete beam, a gusset plateand a buckling-restrained brace. The gusset plate connected with the buckling-restrained brace is installed at the end of the reinforced concrete beam, and it is ensured that the gusset plate is notin contact with the reinforced concrete column. The reinforced concrete beam is provided with a yield section with relatively strong deformability. During an earthquake, the buckling-restrained bracetransmits tensile force or pressure to the reinforced concrete beam, and the yield section dissipates earthquake energy through plastic deformation, so that the elastic working state of the reinforcedconcrete beam is ensured. The novel buckling-restrained brace-RC frame replaceable connecting joint is clear in force transferring route and controllable in failure mode, solves the problems that anexisting BRB-RC framework joint is complex in stress, uncertain in failure mode and the like, and further enlarges the application range of a BRB-RC framework structure.

Owner:CHONGQING UNIV

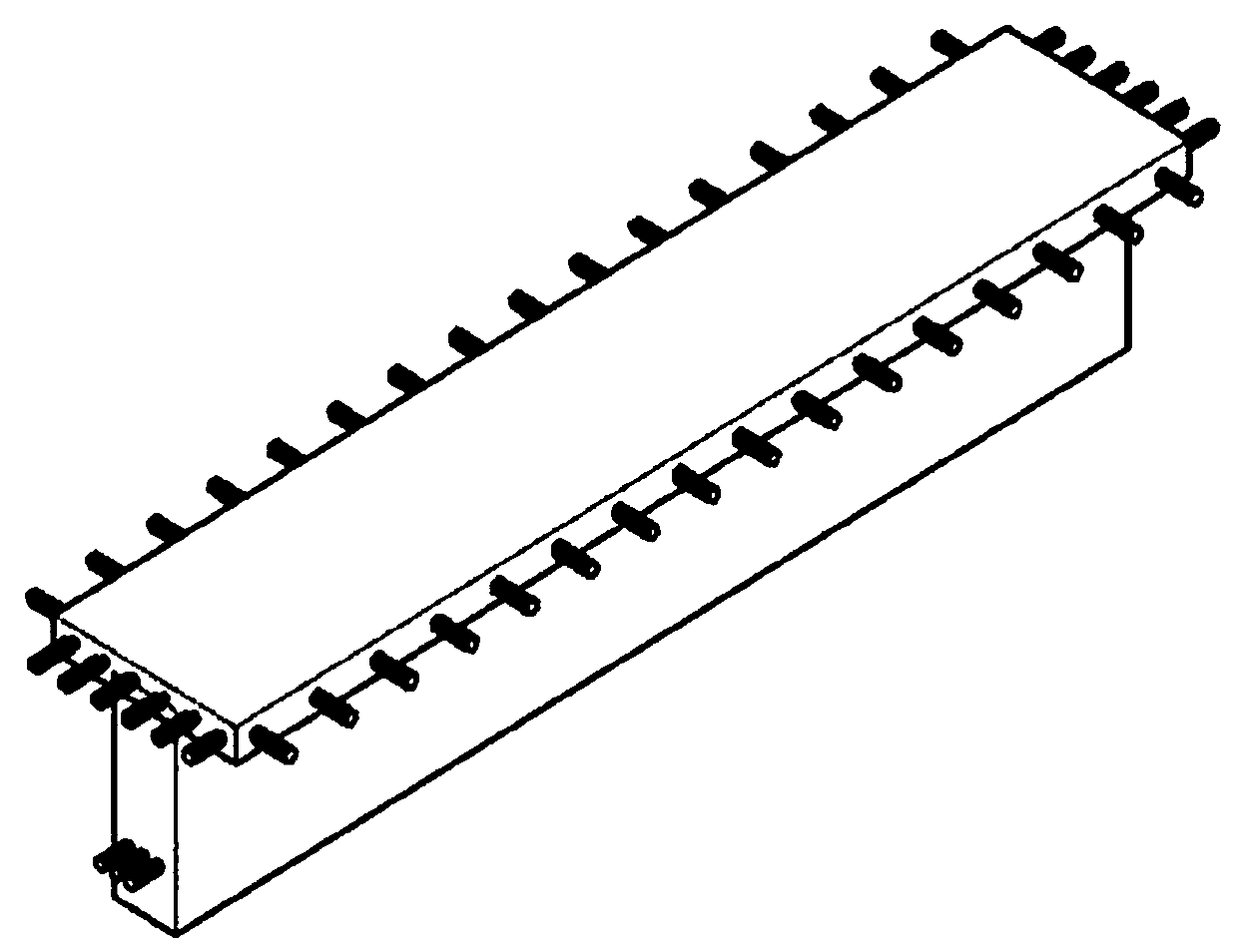

Fabricated floor panel and manufacture method

PendingCN107119839AReduce labor intensityEasy to assembleFloorsCeramic shaping plantsThermal insulationRc frames

The invention relates to a fabricated floor panel and a manufacturing method thereof. According to the floor panel, a beam needing to be built is a flower basket type beam provided with horizontal steps on the single side or the two sides in the length direction of the flower basket type beam, the beam uses the horizontal steps as a boundary and is divided into an upper beam body and a lower beam body; the floor panel is a fabricated board having light thermal insulation board core, the floor panel is internally provided with a rebar in the length direction of the floor panel, and the two ends of the rebar stretch out of the floor panel and serve as connecting bars; the two ends of the floor panel are installed on the horizontal steps of the beam, the connecting bars, opposite to each other and on the two sides of a middle beam, of the floor panel are connected in a welded mode and formed into a whole with the upper beam body through pouring, and the connecting bar, on one side of an edge beam, of the floor panel is connected with a carrying bar in an upper beam body of the edge beam and formed into a whole with the upper beam body through pouring. Prefabricated building materials can be adopted and connected with the beam to form a whole, the strength of the whole structure of high-rise construction of a rebar concrete frame structure can be improved, and meanwhile the advantages that the assembly type construction efficiency is high and the construction period is short are kept.

Owner:唐元元

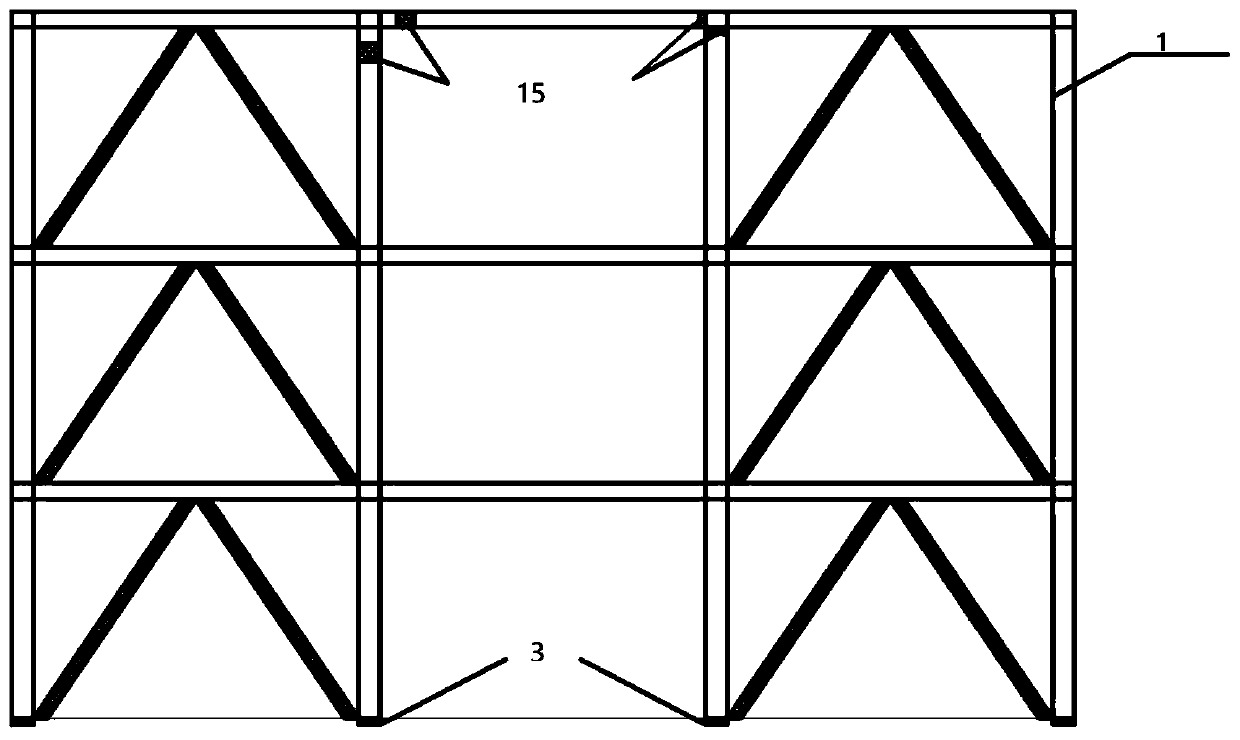

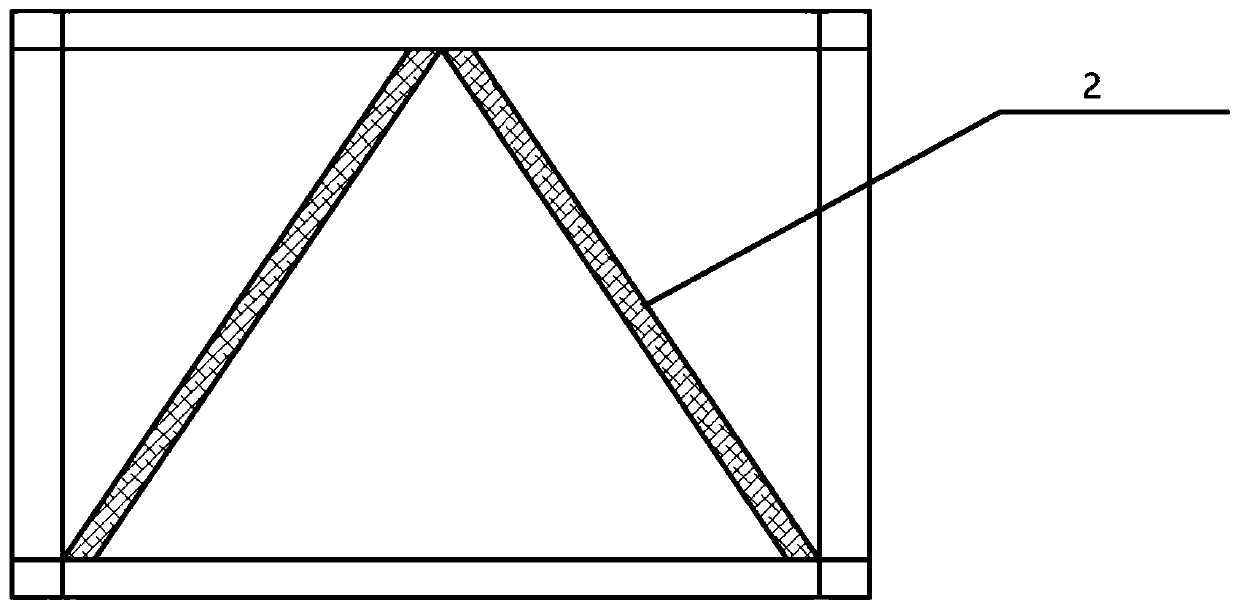

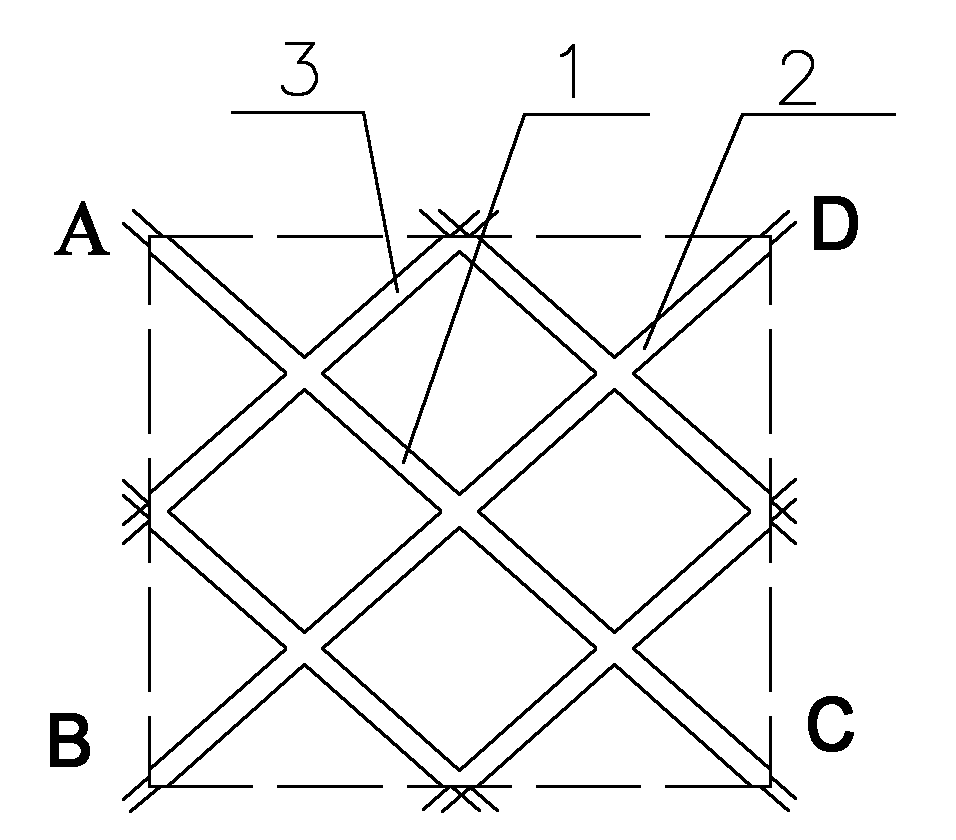

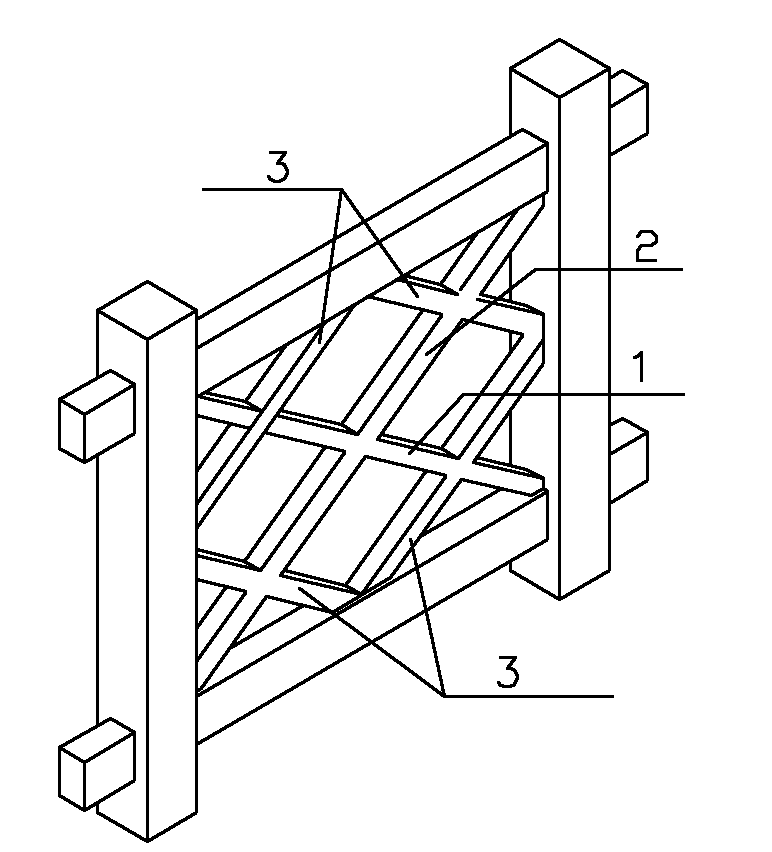

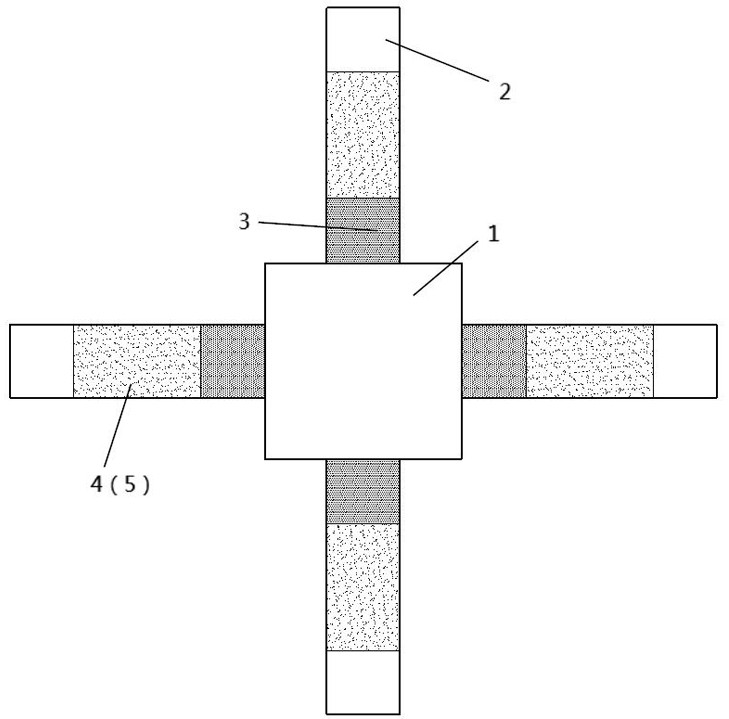

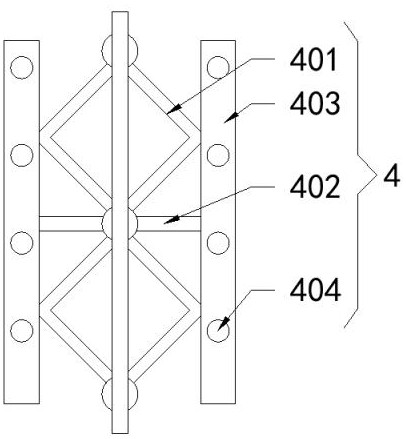

Cross bracing type reinforced concrete energy consuming device

InactiveCN101956434AReduce lateral displacementLight in massShock proofingRc framesArchitectural engineering

The invention relates to a cross bracing type reinforced concrete energy consuming device, which belongs to the field of resistance and absorption of earthquake for construction structures, and overcomes the defects that the framework structure of reinforced concrete is small in lateral rigidity and easy to laterally sway under the action of the earthquake, and a traditional energy consuming device has the defects of high construction cost and large construction difficulty. The energy consuming device comprises a first and a second main bracings as well as a first and a second assistant bracings in a rectangular area ABCD, wherein the first main bracing is arranged on the diagonal AC of the rectangle ABCD; the second main bracing is arranged on the diagonal BD of the rectangle ABCD; or the first main bracing is arranged in the position deviating from a first vertex and a third vertex in a distance of 1 to 1.5 times the height of a framework beam, and is crossed with the upper edge and the lower edge of the rectangle ABCD; the second main bracing is arranged in the position deviating from a second vertex and a fourth vertex in a distance of 1 to 1.5 times the height of the framework beam, and is crossed with the upper edge and the lower edge of the rectangle ABCD; the assistant bracings are arranged on connecting lines of bisection points of four edges of the rectangle ABCD; the first and the second main bracings as well as the first and the second assistant bracings form a hollow grid; and when used as a filling wall, the hollow grid is filled with energy absorbing materials.

Owner:BEIJING JIAOTONG UNIV

Method for reinforcing structures through method of externally pasting reinforced concrete frame with ductility column energy dissipators

InactiveCN103669896AImprove energy consumptionAvoid damageBuilding repairsShock proofingReinforced concreteRebar

The invention discloses a method for reinforcing structures through a method of externally pasting a reinforced concrete frame with ductility column energy dissipators, and belongs to the field of reinforcement of concrete structures. The reinforced concrete frame with the ductility column energy dissipators is externally pasted on the outer side of an original reinforced concrete frame structure. The intensity grade of the concrete and the intensity grade of the reinforcing steel bars of a newly added frame beam and those of a newly added frame column are higher than those of an original frame beam and those of an original frame column, and the intensity grade difference should not exceed two. The newly added frame beam and the newly added frame column are connected with the original frame beam and the original frame column respectively through an adhesively bonded anchorage mode. The adhesively bonded anchorage mode is achieved through the fact that embedded steel bar glue is implanted by drilling anchor bars to be fixedly connected with original frame concrete. The anchor bars and the newly added frame structure are cast in situ. Each reinforced concrete ductility column energy dissipator comprises a reinforced concrete ductility column and rigid supports at the two ends of the corresponding reinforced concrete ductility column. The intensity grade of the concrete and the intensity grade of the reinforcing steel bars of the reinforced concrete ductility column energy dissipators are identical to those of the newly added frame. The reinforced concrete ductility column energy dissipators and the newly added reinforced concrete beam are integrally cast in situ. The method is quite beneficial to reinforcement effects.

Owner:BEIJING UNIV OF TECH

Assembled type anchor rod frame beam structure containing EPS elastic cushion layer and suitable for expansive soil slope

ActiveCN112411579AReduce manufacturing difficultyClosely connectedExcavationsBulkheads/pilesRc framesArchitectural engineering

The invention discloses an assembled type anchor rod frame beam structure containing an elastic cushion layer and suitable for an expansive soil slope and a construction method thereof. The construction efficiency and quality of an anchor rod frame beam are effectively improved, the material cost of the frame beam is saved, and the comprehensive supporting effect of the anchor rod frame beam structure is improved. The structure comprises a reinforced concrete concave beam prefabricating unit, EPS (polystyrene) elastic cushion layers arranged on two sides of the reinforced concrete concave beamprefabricating unit, and an anchor rod arranged at a joint of a reinforced concrete frame beam. The reinforced concrete frame beam is formed by connecting the reinforced concrete concave beam prefabricated unit, cast-in-place concrete at the joint and bolts. The EPS elastic cushion layers are arranged on two sides of the frame beam. According to the assembled type anchor rod frame beam structure,the construction efficiency and quality of slope supporting engineering are effectively improved, the material cost of the frame beam is reduced, and the supporting effect of the anchor rod frame beam structure and the economic benefit of the construction project are improved.

Owner:SHANGHAI UNIV

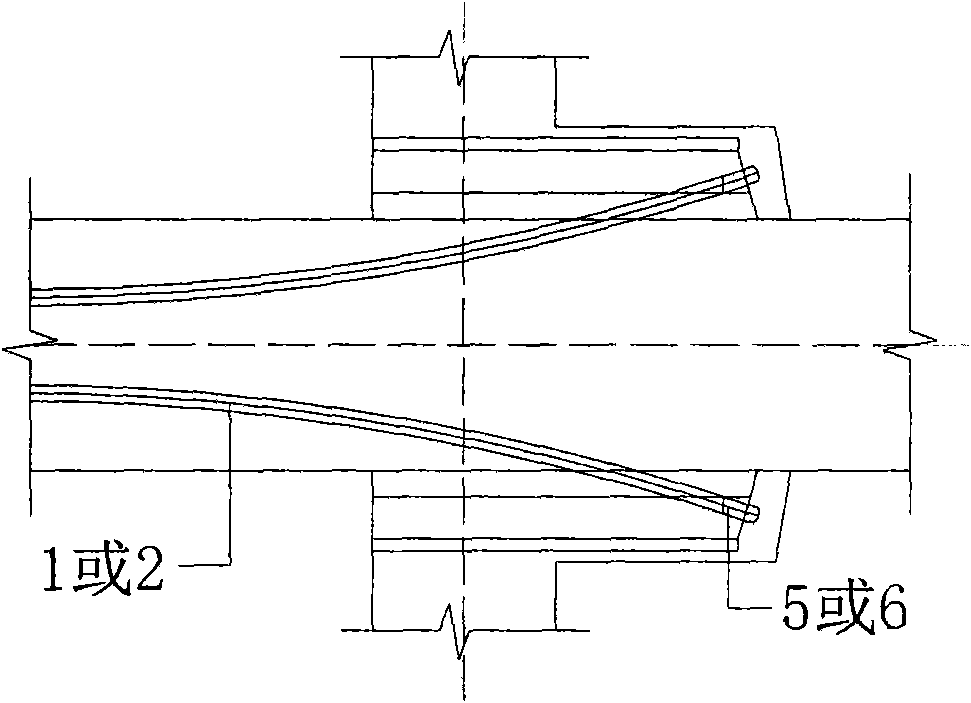

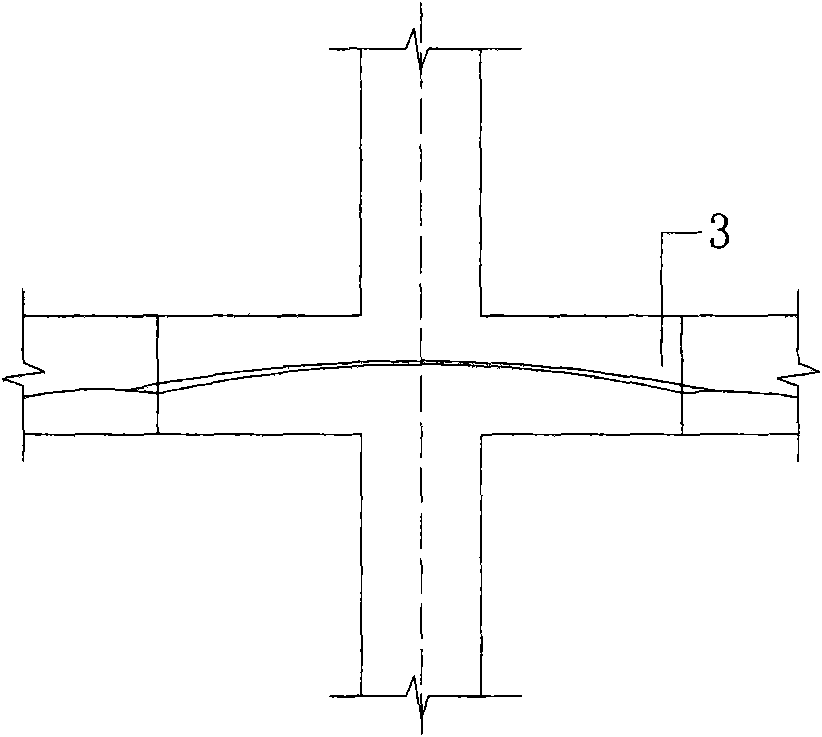

Structure reinforcing method in externally-attached steel-encased assembly type PC frame mode

InactiveCN103726668AImprove recovery effectGuaranteed deformation coordinationBuilding repairsRebarSteel plates

The invention belongs to the concrete structure reinforcing field and provides a structure reinforcing method in an externally-attached steel-encased assembly type PC frame mode. A steel-encased assembly type PC frame is externally attached to the outside of an original reinforced concrete frame structure, steel plates of steel-encased prefabricated reinforced concrete frame columns wrap columns below lower sections of beams, and holes of pre-stressed tendons are reserved in the steel plates. Beams and columns of a newly-added prefabricated frame are connected through the unbonded pre-stressed tendons and are connected with beams and columns of the original frame respectively in an unbonded pre-stressed tendon mode. The original frame structure is connected with the new frame structure through the unbonded pre-stressed tendons, and by means of the pre-stressing force of the unbonded pre-stressed tendons, pressure and friction generate on the contact portion between the original frame and the new frame, so that the original frame and the new frame are tightly connected together, and bearing capacity, rigidity, ductility and the like of the reinforced concrete structure are effectively improved; workers do not need to enter a house, and relocation is not needed in the construction process, efficient, economical and practical effects are achieved, and the structure reinforcing method is quite beneficial to the reinforcing effect.

Owner:BEIJING UNIV OF TECH

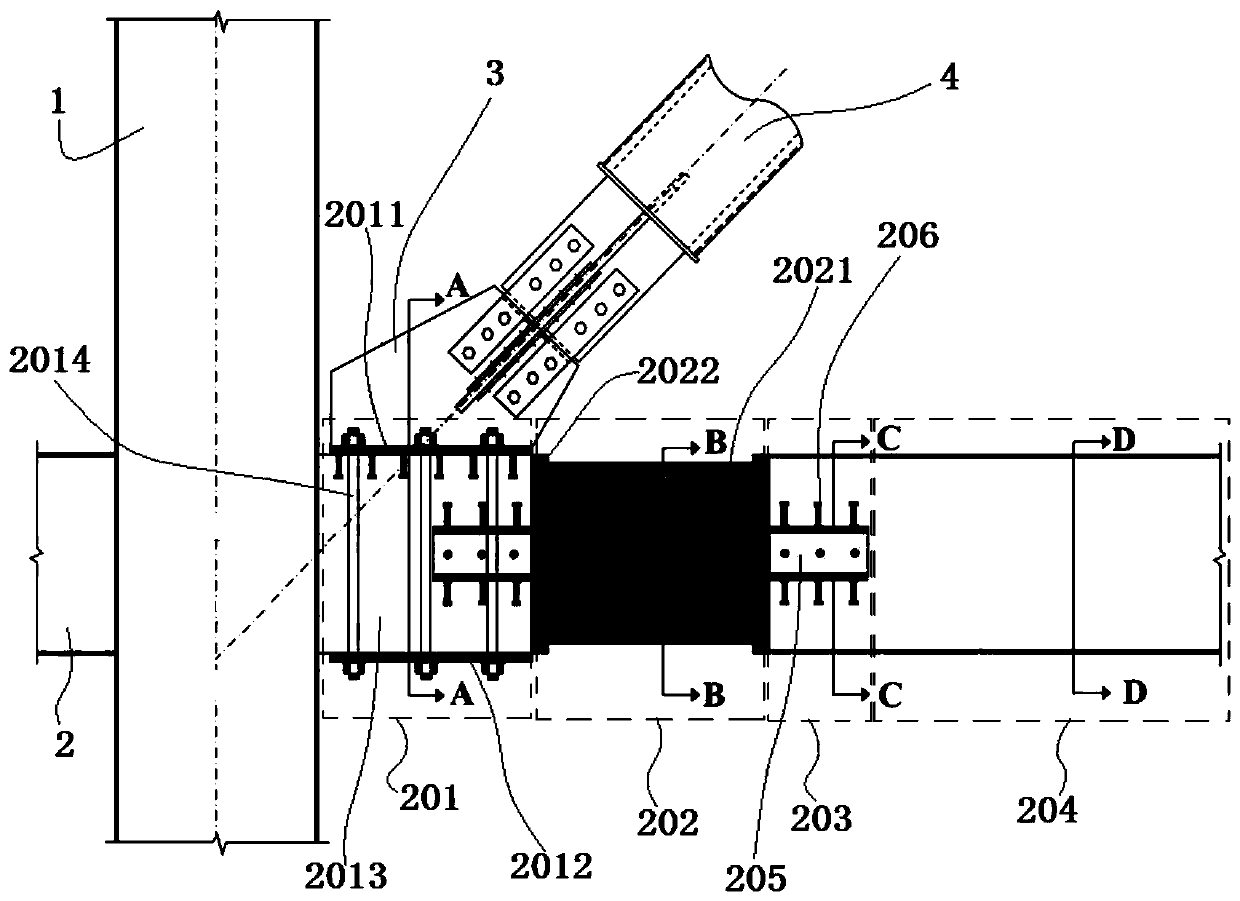

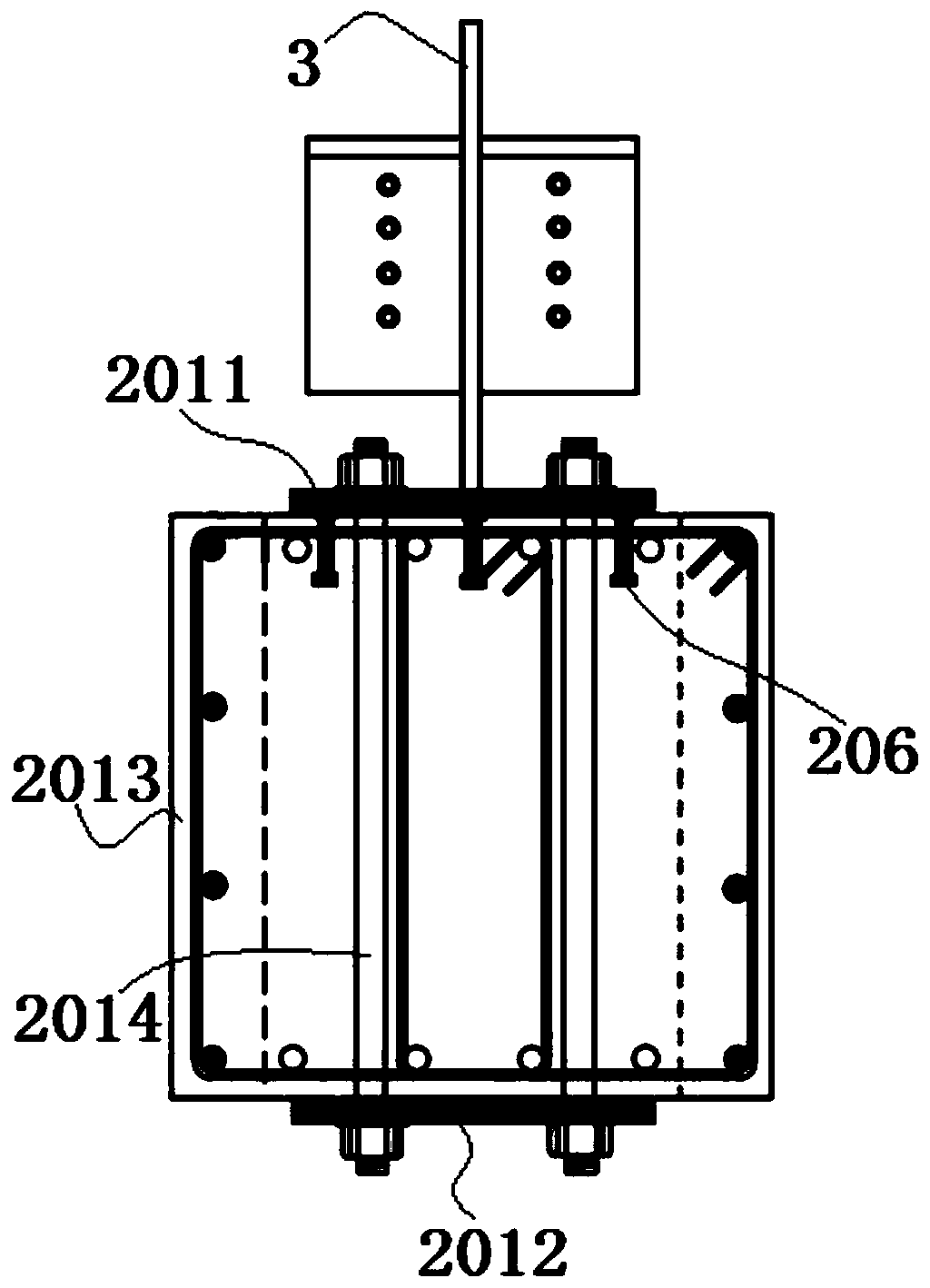

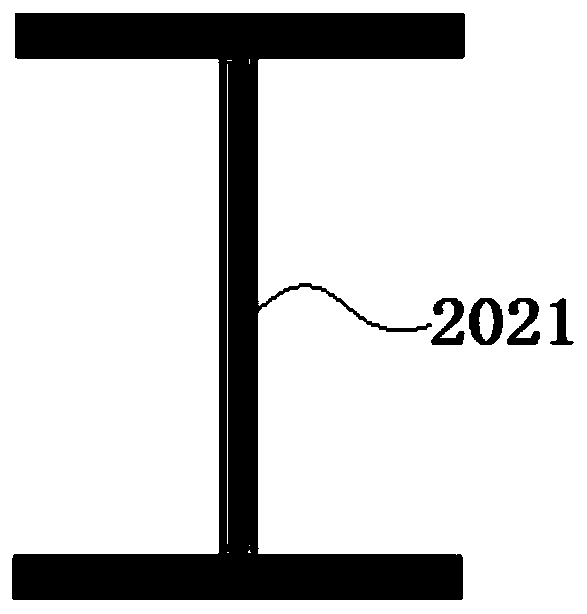

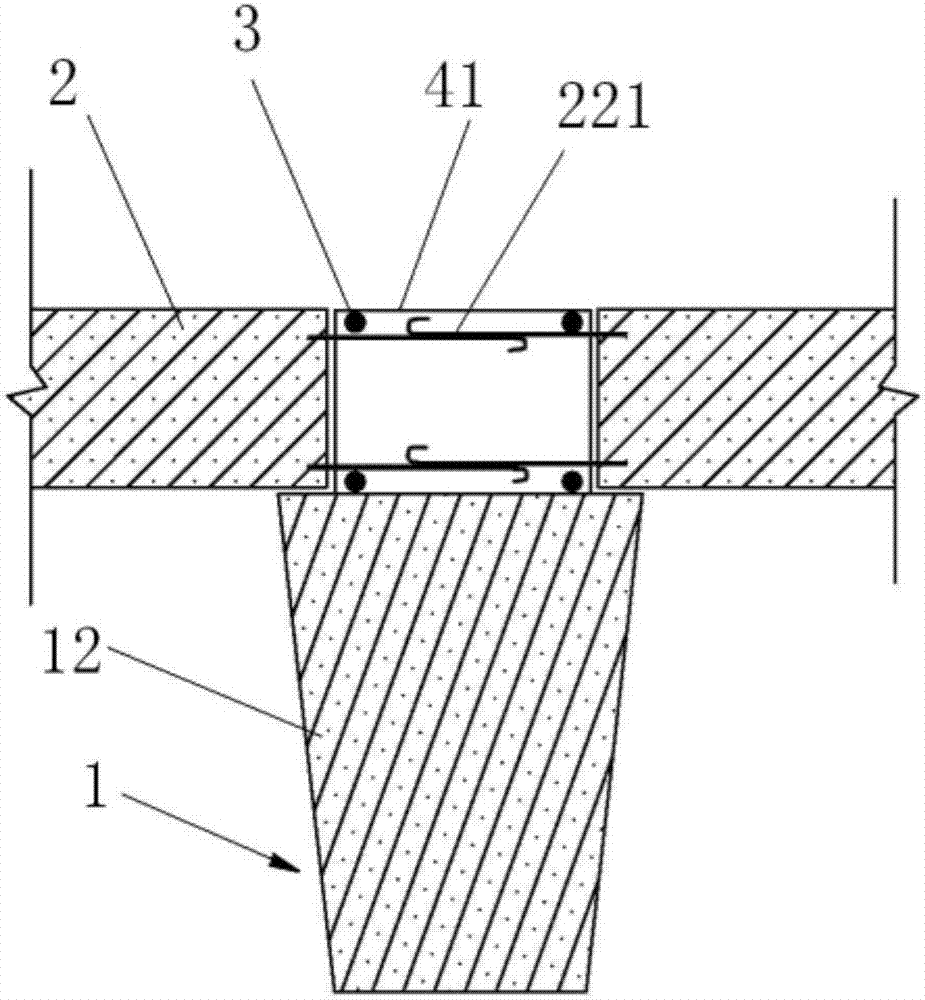

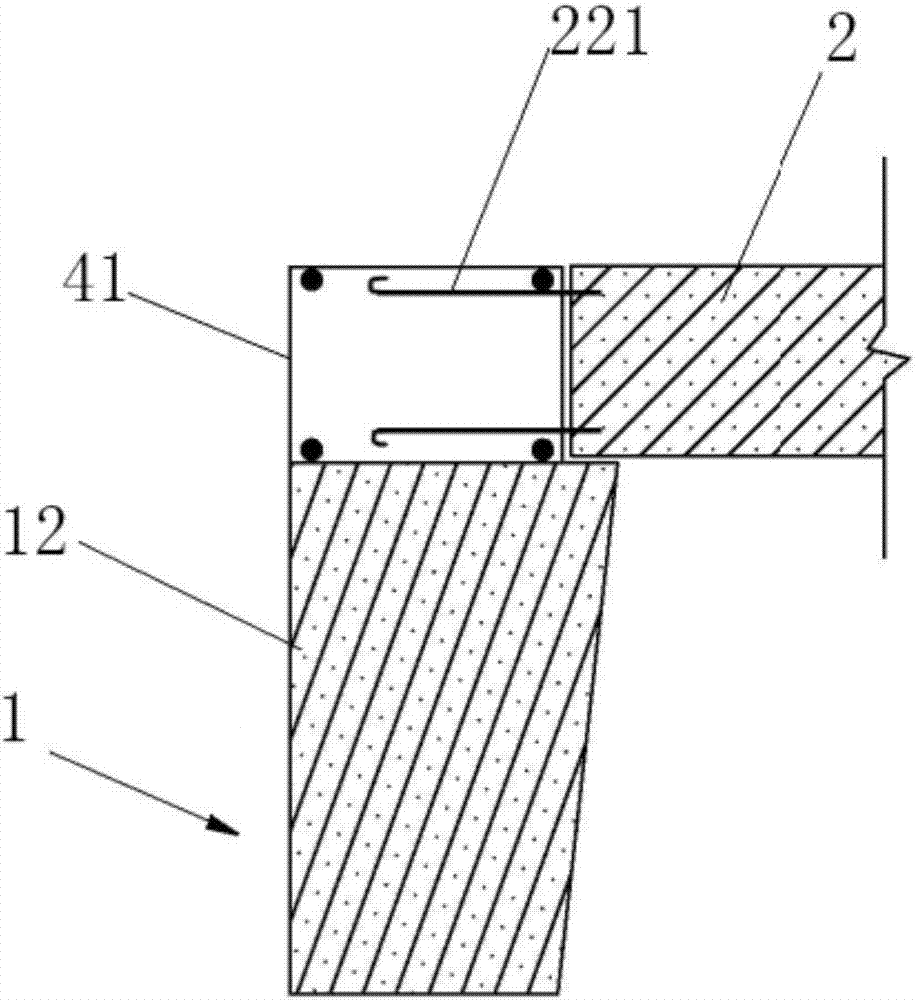

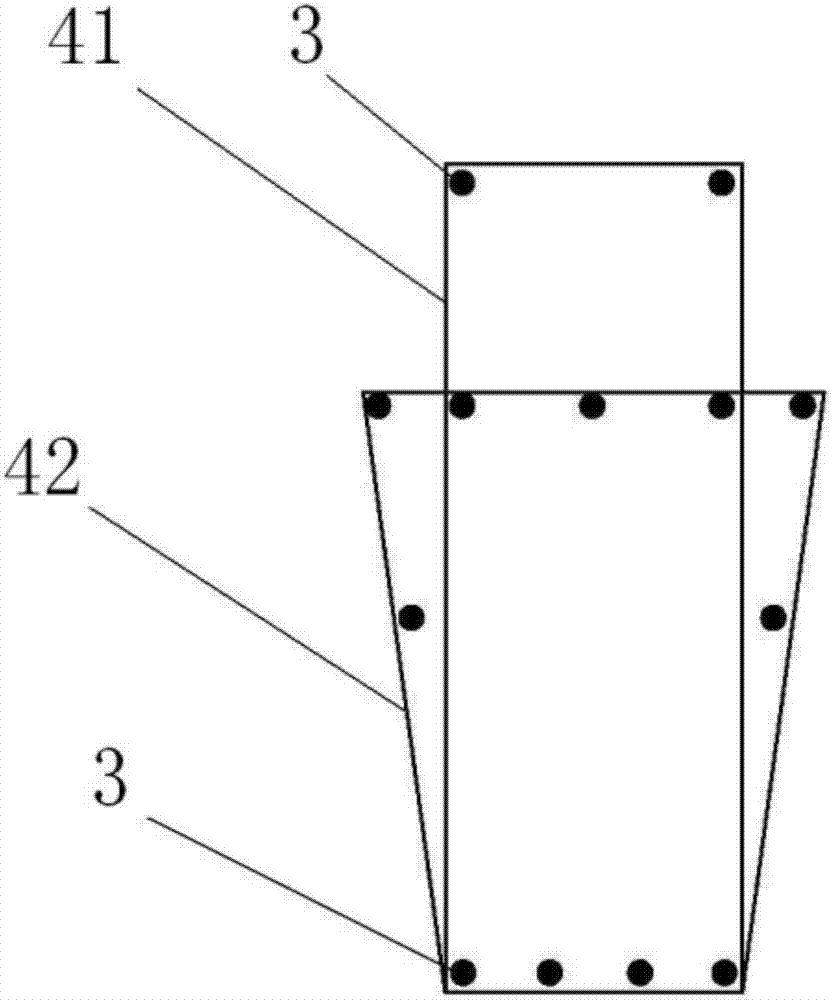

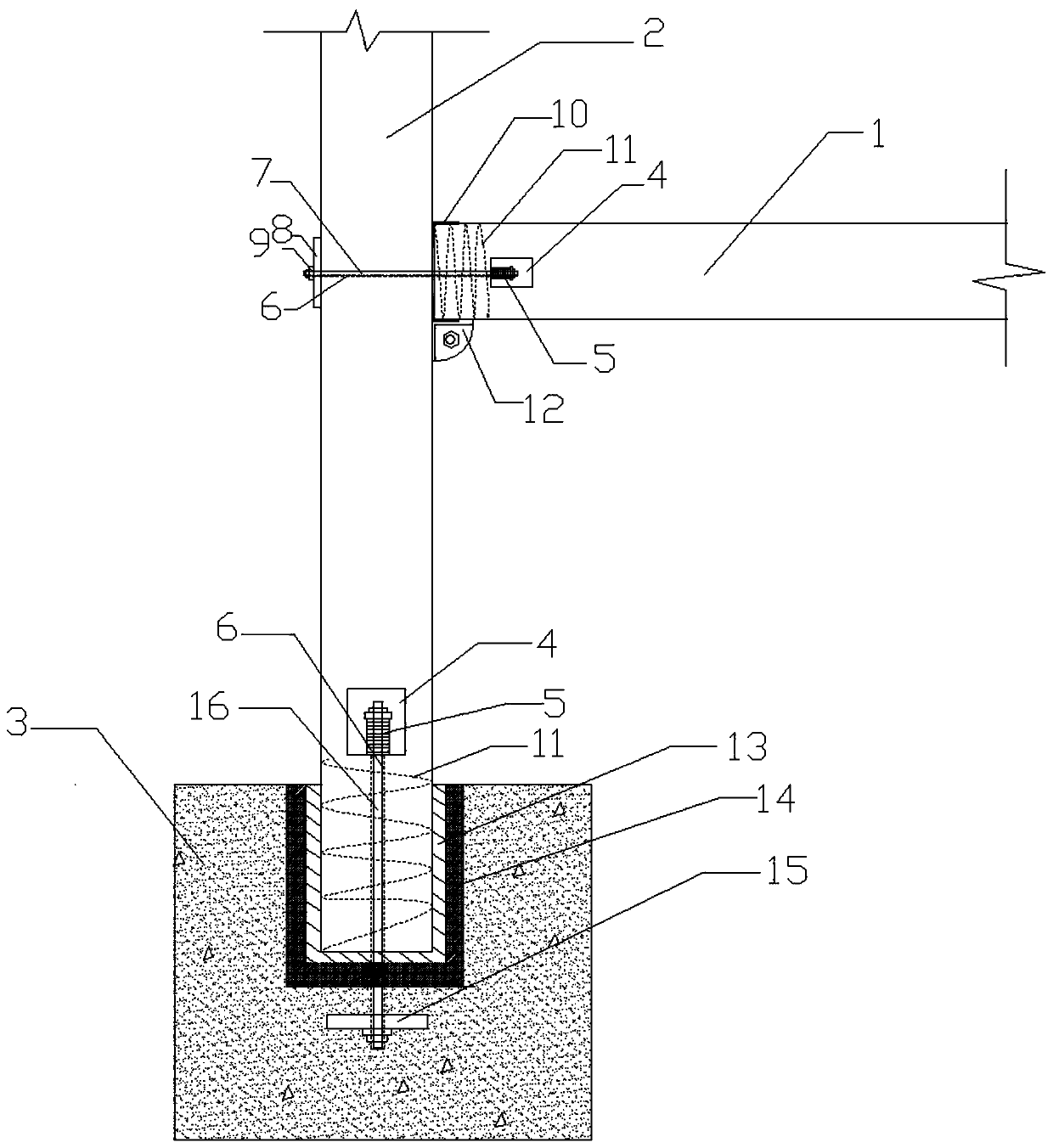

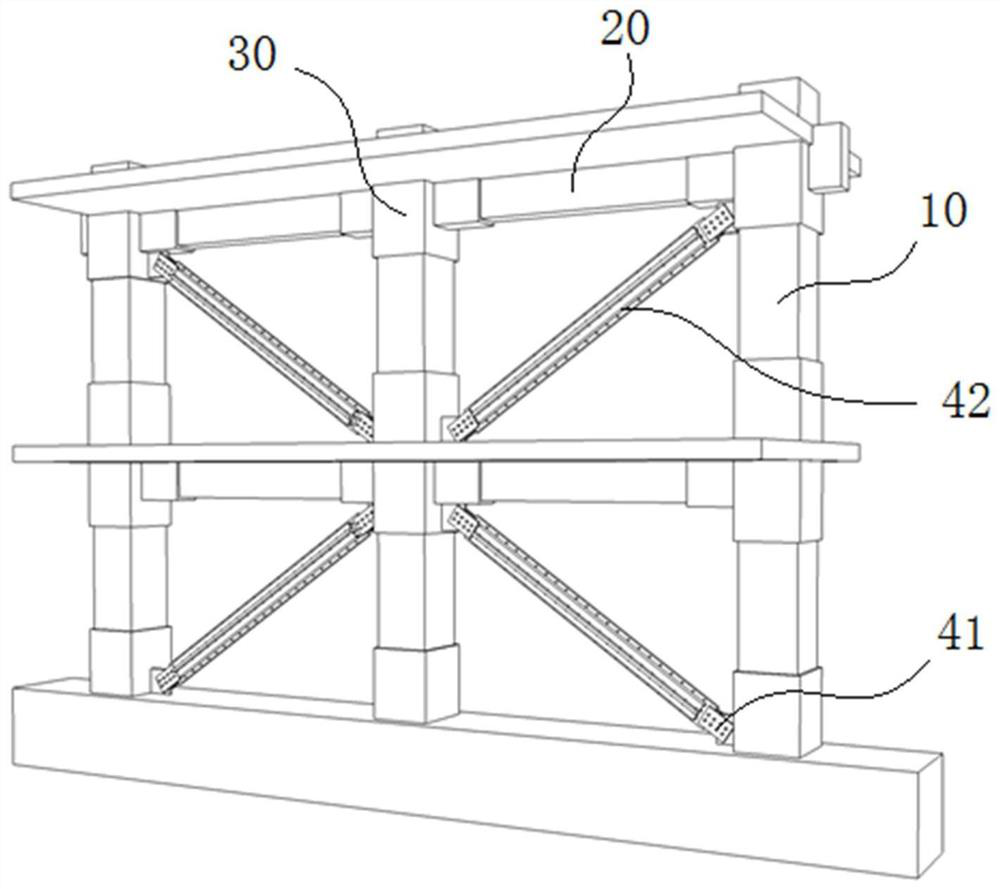

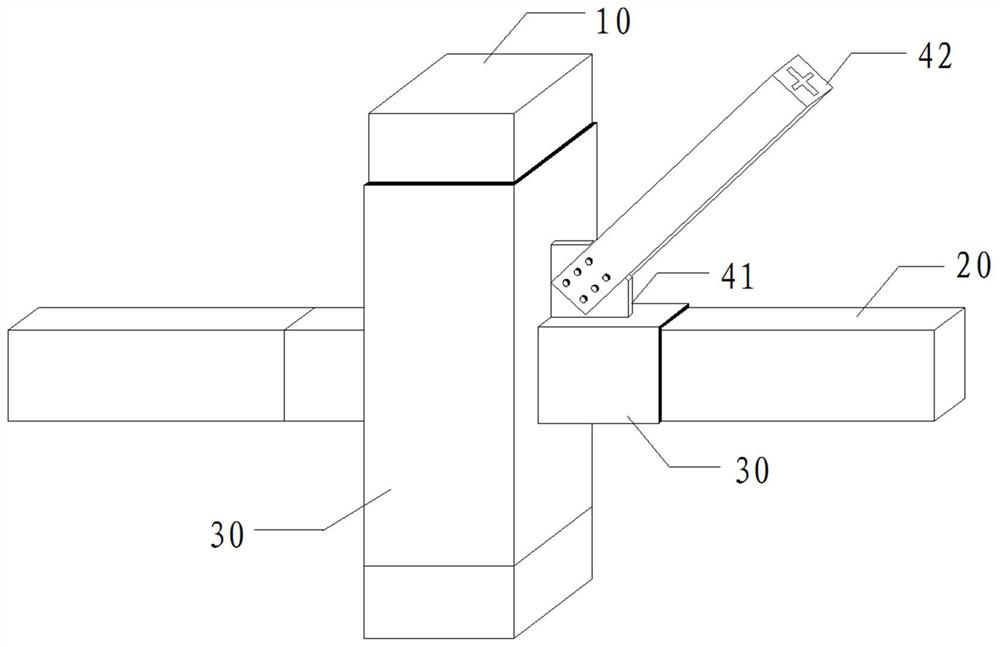

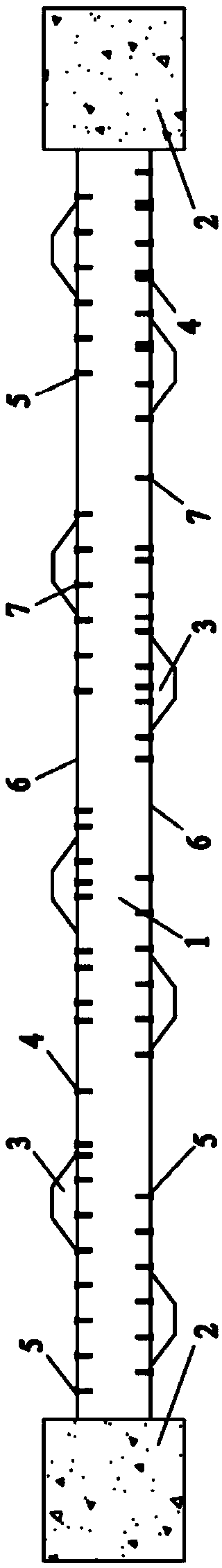

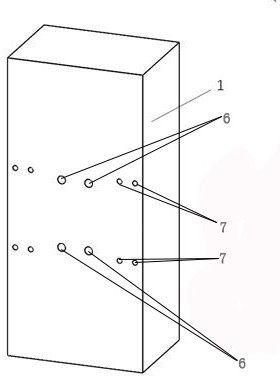

Prefabricated assembly-type seismic toughness reinforced concrete frame structure and construction method

ActiveCN110952825AImprove ductilitySmall residual displacement after earthquakeProtective buildings/sheltersShock proofingReinforced concrete columnRc frames

The invention discloses a prefabricated assembly-type seismic toughness reinforced concrete frame structure and a construction method. The frame structure is constructed on the basis of concrete and comprises a reinforced concrete column, an anchor rod, a reinforced concrete beam, a pull rod and a damper. According to the prefabricated assembly-type seismic toughness reinforced concrete frame structure, a hole is formed in each of the reinforced concrete column and the reinforced concrete beam, a disc spring group is installed in each hole, the disc spring groups are fixedly connected with beam and column joints through the pull rod and fixedly connected with column and foundation joints through the anchor bolt, densified stirrups or spiral stirrups or exterior steel plates are arranged atthe ends of the reinforced concrete beam and the reinforced concrete column correspondingly, the damper is arranged on the lower side of the beam end, the periphery of the gaps of reserved grooves ofthe reinforced concrete column and a concrete foundation is filled with an elastic scalable material, the ductility of the seismic toughness frame structure is high, the aftershock residual displacement is low, an aftershock main structure basically keeps elastic, and the prefabricated assembly-type seismic toughness reinforced concrete frame structure can be widely used in building structures.

Owner:HAINAN UNIVERSITY

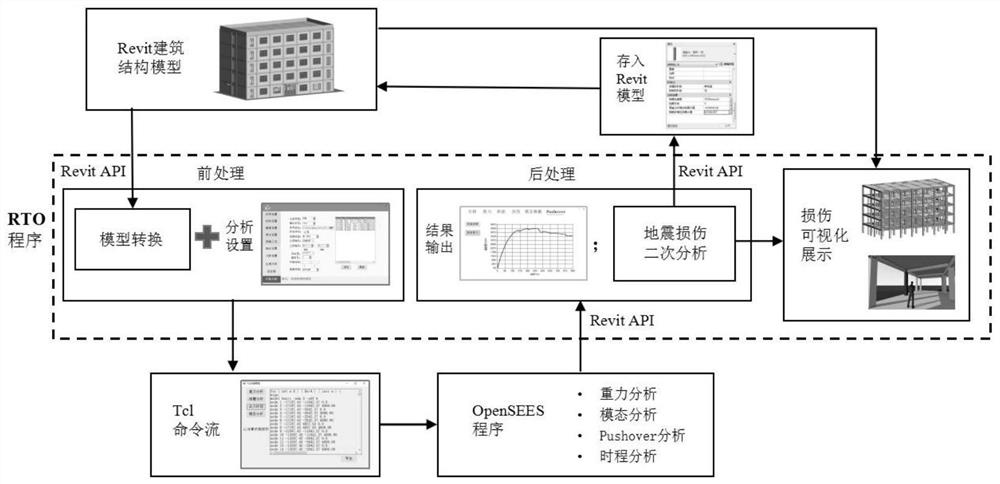

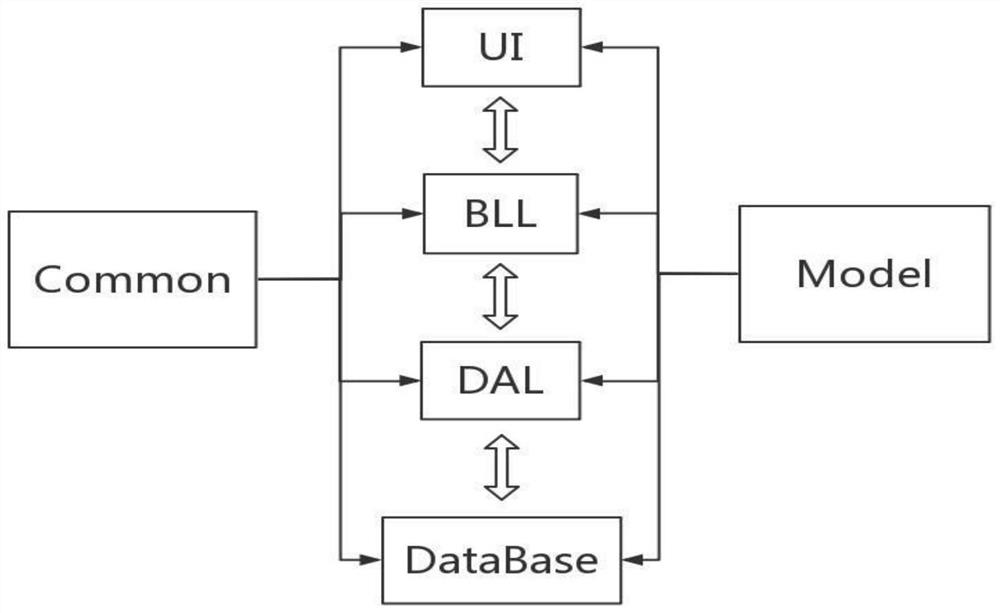

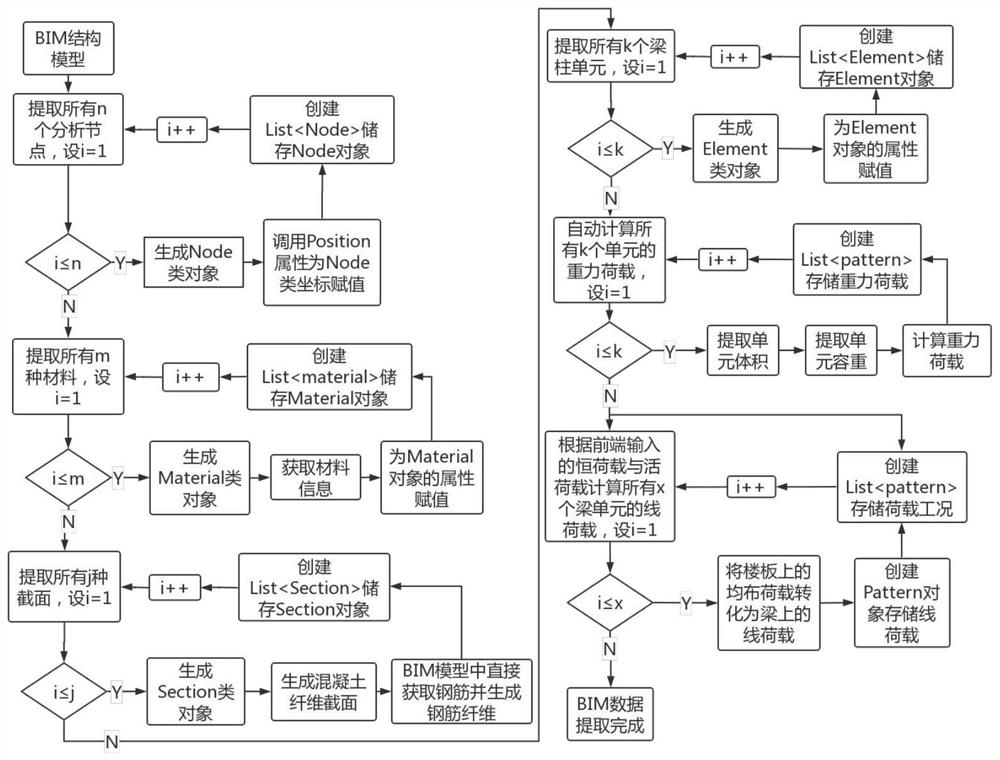

Reinforced concrete frame structure anti-seismic analysis method based on Revit-OpenSEES

PendingCN114707377ARealize visual displayAchieve integrationGeometric CADDesign optimisation/simulationElement modelAnalysis data

The invention discloses a reinforced concrete frame structure anti-seismic analysis method based on Revit-OpenSEES, and belongs to the technical field of civil engineering. According to the technical scheme, finite element model conversion is carried out from a BIM model of Revit to OpenSEES, and anti-seismic analysis setting and output setting are carried out; the analysis data output by the OpenSEES are grouped, sorted and extracted, and are displayed and output in the form of a graph, a table or a document and the like; according to the concrete and steel bar strain data output by the OpenSEES, earthquake damage secondary analysis is carried out on the structure; key structure earthquake damage information is automatically stored in a Revit structure model; the earthquake damage state is displayed through a three-dimensional view, or virtual roaming is carried out through VR software. The method has the beneficial effects that the integration of common BIM software and a finite element analysis program is realized, the anti-seismic analysis and damage evaluation of the reinforced concrete frame structure directly based on the BIM model are realized, and a solution is provided for the structural anti-seismic analysis to participate in the cooperative work of the BIM.

Owner:DALIAN NATIONALITIES UNIVERSITY

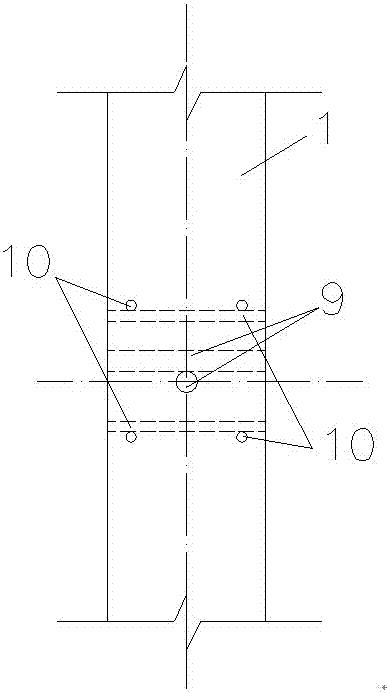

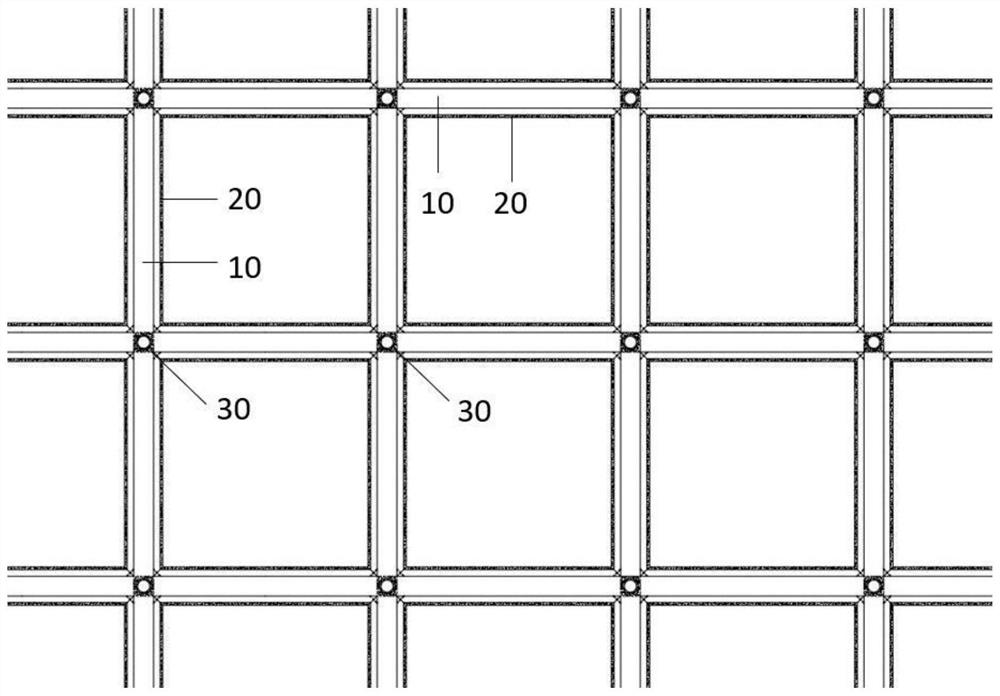

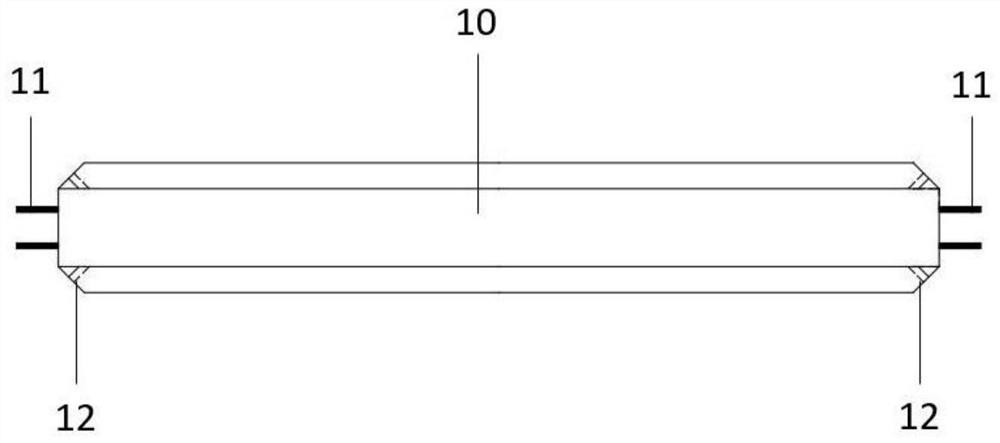

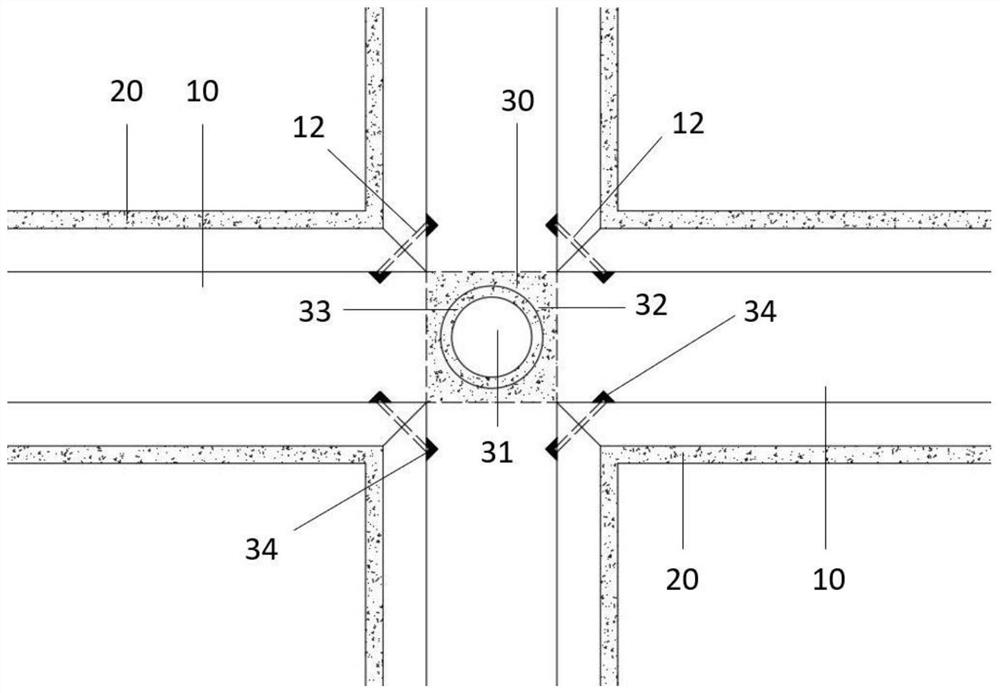

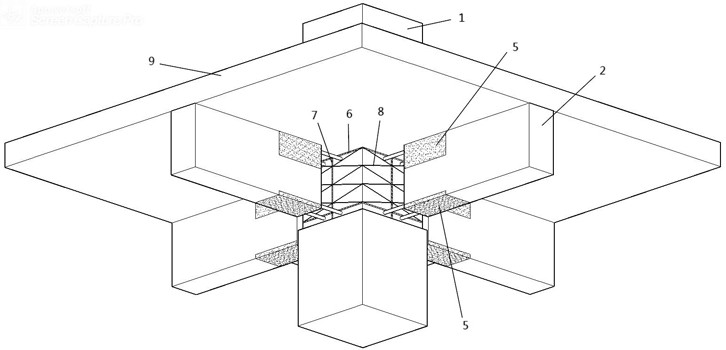

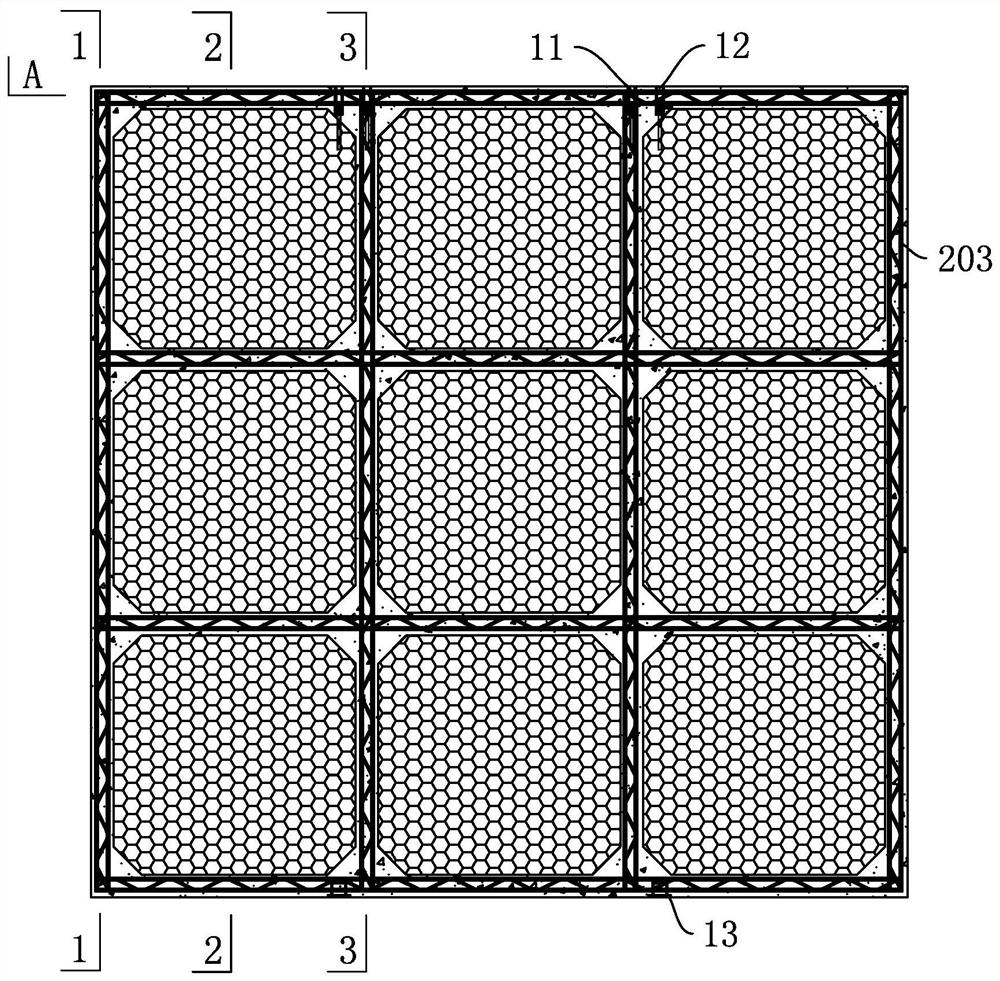

Assembly type reinforced concrete frame beam-column joint connecting structure

PendingCN113123524ASolve stitching problemsResolve connectionStrutsGirdersRc framesArchitectural engineering

The invention provides an assembly type reinforced concrete frame beam-column joint connecting structure. The assembly type reinforced concrete frame beam-column joint connecting structure comprises a prefabricated column, a connecting steel plate set and prefabricated beams, the prefabricated column comprises a prefabricated upper column, a prefabricated lower column, a prefabricated column cap and a first post-pouring section, the prefabricated column cap is formed at the upper end of the prefabricated lower column, the first post-pouring section is formed inside the prefabricated column cap, and the prefabricated upper column is fixedly connected with the prefabricated lower column through the first post-pouring section; the connecting steel plate set is arranged on the outer side of the prefabricated column cap; and the prefabricated beams are arranged on one side of the prefabricated column cap in parallel at intervals, the prefabricated beams and the prefabricated column cap are connected through a second post-pouring section, a beam longitudinal bar set extends out of the end, facing the prefabricated column cap, of each prefabricated beam, and the beam longitudinal bar sets are locked and fixed to the connecting steel plate set through bolt assemblies. Splicing of the prefabricated column is achieved through lap joint of the prefabricated upper column and the prefabricated lower column and the first post-pouring section formed in the prefabricated column cap, and connection between the prefabricated beams and the prefabricated column achieves anchoring of the beam longitudinal bar sets through friction force formed by the beam longitudinal bar sets and the connecting steel plate set under the pretension action of high-strength bolt assemblies.

Owner:CCCC FHDI ENG

Damage-free steel beam reinforced concrete frame and construction method thereof

The invention discloses a damage-free steel beam reinforced concrete frame and a construction method thereof. The damage-free steel beam reinforced concrete frame comprises steel clamping plates, thesteel clamping plates comprise an upper steel clamping plate, a middle steel clamping plate and a lower steel clamping plate, the upper steel clamping plate and the lower steel clamping plate are thesame in structure and correspondingly correspond to a flange connecting area of a steel beam, and the middle steel clamping plate corresponds to a web of the steel beam; the upper steel clamping platecomprises two steel plates, and the two steel plates are fixed to reinforced concrete columns through long screws on the two sides. The U-shaped middle steel clamping plates are fixed to the reinforced concrete columns through adhesives, outward-extending steel plates are arranged on the sides, close to the steel beam, of the upper steel clamping plates, the middle steel clamping plates and the lower steel clamping plates, and the outward-extending steel plates of the upper steel clamping plate and the lower steel clamping plate are connected with upper and lower flanges of the steel beam through connecting steel plates. The outwards-extending steel plate of the middle steel clamping plate is directly connected with the web of the steel beam. According to the damage-free steel beam reinforced concrete frame and the construction method thereof, the integrity of the columns during reinforcing of the reinforced concrete frame is enhanced, and the damage-free steel beam reinforced concrete frame has wide application prospects in reinforced concrete structure buildings.

Owner:HUAQIAO UNIVERSITY

Method for dismantling and splicing cast-in-place reinforced concrete frame structure building components

ActiveCN109797971AAchieve recyclingAvoid wastingBuilding repairsBuilding material handlingReinforced concreteEngineering

The invention discloses a method for dismantling and splicing cast-in-place reinforced concrete frame structure building components. The method includes dismantling a frame structure into floor slabs, secondary beams, longitudinal struts and horizontal frames in a main stress direction sequentially from top to bottom; dismantling the floor slabs by marking out dismantling strips along the peripheries of the floor slabs, crushing and removing concrete within the range of the dismantling strips, and cutting off reinforcing steel bars from the middles of the dismantling strips while leaving butts of the reinforcing steel bars on the peripheries of the floor slabs and peripheral beams so as to facilitate connection during splicing; dismantling the secondary beams and the longitudinal struts sequentially in the same way; last, dismantling beams and columns of the horizontal frames along the middle disconnection positions into +-shaped, T-shaped and L-shaped joint units. The components andthe joint units can be obtained by dismantling according to the method and can be spliced into a building frame like modular furniture, and accordingly relocation of buildings is realized.

Owner:CHINA UNIV OF MINING & TECH

Reinforced concrete frame joint HDC wire winding reinforcing device and construction method thereof

PendingCN112144910AIncrease redundancyImprove protectionBuilding repairsRc framesArchitectural engineering

The invention relates to a reinforced concrete frame joint HDC wire winding reinforcing device and a construction method thereof. The reinforced concrete frame joint HDC wire winding reinforcing device comprises a vertical frame column and a frame beam extending horizontally on the peripheral side of the vertical frame column. A reinforcing area of the reinforcing device comprises a full-height replacement area and a partial replacement area which communicate with each other, and the full-height replacement area is formed by chiseling and penetrating the contact end of the frame beam and the frame column. The partial replacement area is formed by chiseling inwards from the peripheral surface of the frame column to a joint core area in the frame column, vertical steel bars are fixedly connected to connecting lines of midpoints of exposed stirrups of the joint core area, the steel bars are connected into a whole in a winding mode through cold-drawn steel wires, and the full-height replacement area and the partial replacement area are reinforced through HDC spraying, smearing, filling and reinforcing. By arranging the multiple sections of replacement areas, weakening beam ends are reinforced, the number of plastic hinges of the beam end under the action of an earthquake is increased, the redundancy of joint damage is improved, concrete in the core area can be restrained more efficiently by adopting the cold-drawn steel wires and steel bars for wire winding, the hooping effect of the core area is improved, and the restraining effect on the concrete is improved.

Owner:FUZHOU UNIV

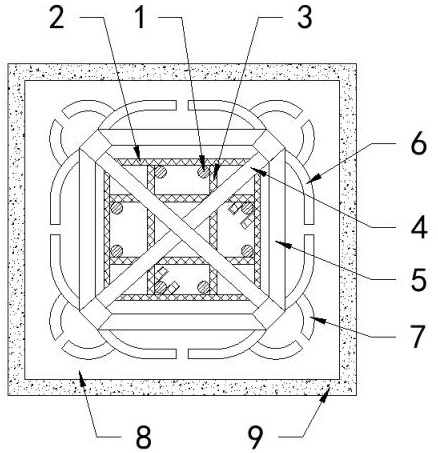

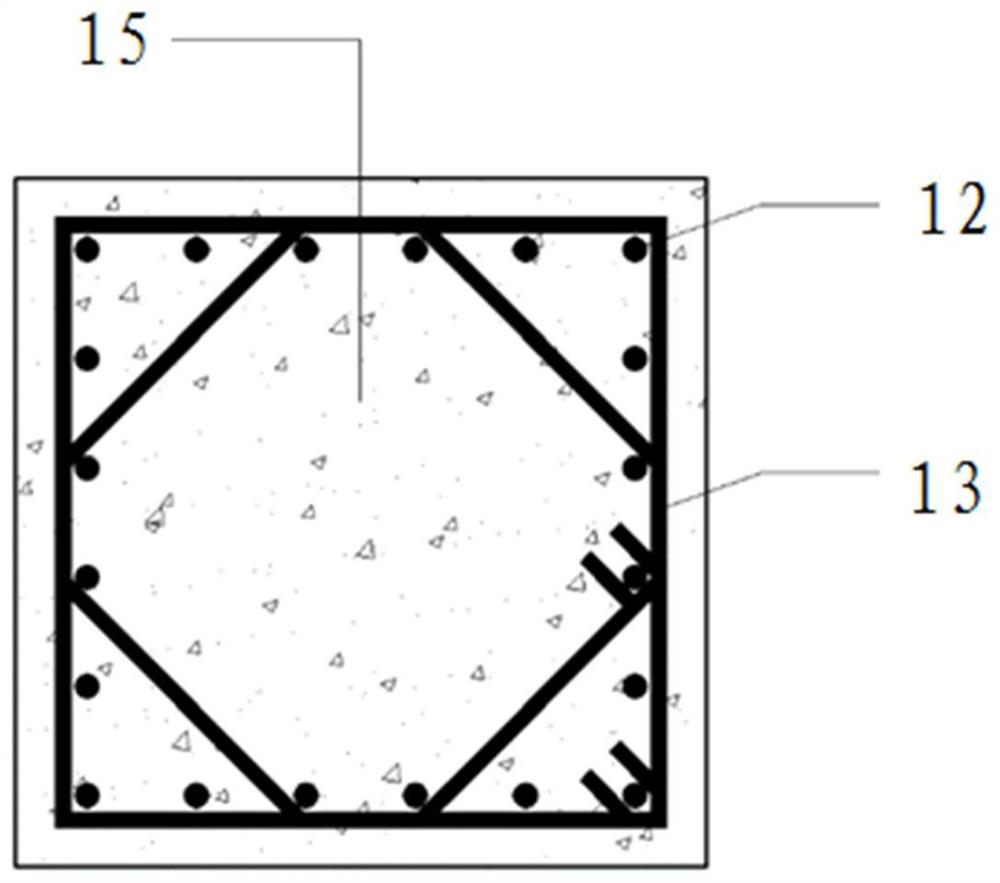

Reinforced concrete frame column reinforcing structure and method

ActiveCN112064788AStable supportImprove bending abilityStrutsProtective buildings/sheltersRc framesArchitectural engineering

The invention relates to a reinforced concrete frame column reinforcing structure and method. The problem that in the prior art, a frame column serving as a main bearing component of a house is low instability and shock resistance is solved. According to the reinforced concrete frame column reinforcing structure and method, the reinforced concrete frame column reinforcing structure comprises longitudinal bars penetrating through a frame column, inner stirrups, outer stirrups, a concrete filling area poured in the frame column and an outer wall plate attached to the outer portion of the concrete filling area, wherein the inner stirrups and the outer stirrups are connected to the outer portions of the longitudinal bars in a winding mode. The reinforced concrete frame column reinforcing structure further comprises a built-in bailey frame. According to the reinforced concrete frame column reinforcing structure and method, the frame column integrally uses the X-shaped crossed built-in bailey frame as a core shaft, the longitudinal bars penetrate through the frame column along the axis of the frame column, the inner stirrups and the outer stirrups are connected to the longitudinal barsand the X-shaped crossed built-in bailey frame in a winding mode, the built-in bailey frame is wrapped by the outer bailey frame, and therefore the two bailey frames form a stable triangular structure; and in addition, concrete pouring is conducted, and therefore the supporting force, the bending resistance and the pressure resistance of the frame column are all greatly improved.

Owner:江苏苏建路桥机械有限公司

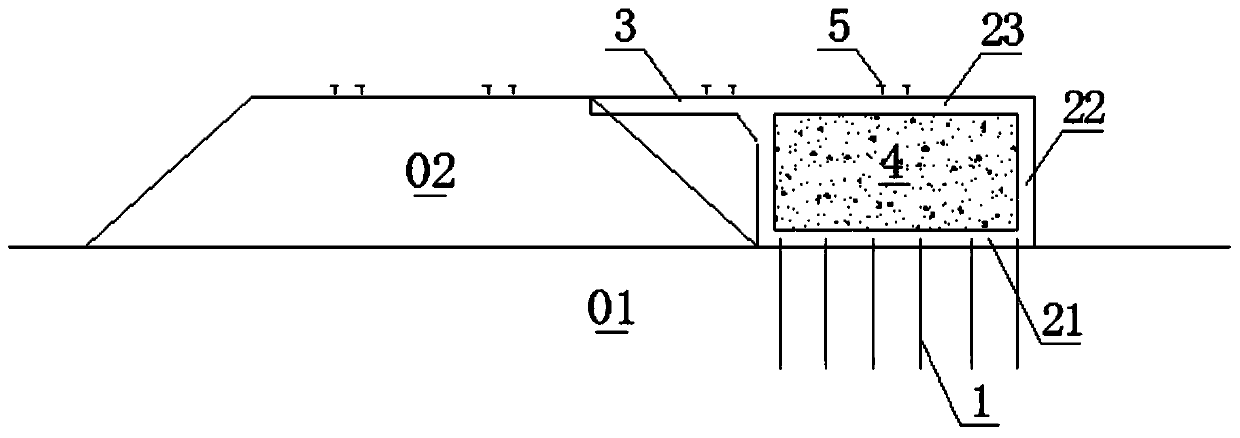

Rock foundation existing high-speed railway embankment force balance assisting widening structure and construction method

PendingCN110761127AAvoid Vertical DistortionAvoid disadvantagesRailway tracksRailway embankmentRc frames

The invention discloses a rock foundation existing high-speed railway embankment force balance assisting widening structure and a construction method. The assisting widening structure comprises a plurality of grouting anchor rods, a reinforced concrete frame structure, a reinforced concrete cantilever plate and a filling body, wherein the plurality of grouting anchor rods are used for being arranged in a rock foundation outside a slope foot of an existing embankment at intervals, the reinforced concrete frame structure is used for being arranged on the rock foundation outside the slope foot ofthe existing embankment, all the grouting anchor rods are connected to the bottom of the frame structure, one end of the reinforced concrete cantilever plate is connected to the top of the frame structure, the other end of the reinforced concrete cantilever plate is arranged on an existing embankment road shoulder structure, the top surface of the frame structure, the top surface of the cantilever plate and the top surface of the existing embankment are flush, and the filling body fills a cavity in the frame structure. By using the assisting widening structure, the high bearing capacity and anchoring force of the rock foundation are fully utilized, the weight of the frame structure and the internal filling body of the frame structure are utilized, pulling force generated by the grouting anchor rods is combined, and load acting on the cantilever plate by a train is resisted, so that adverse vertical deformation generated when the train passes through the cantilever plate can be avoided, and an existing high-speed railway is not influenced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Reinforced concrete frame structure

PendingCN113898232AAvoid damageDamage controllableProtective buildings/sheltersBuilding reinforcementsRc framesArchitectural engineering

The invention relates to the technical field of reinforced concrete frames, and provides a reinforced concrete frame structure which comprises a plurality of frame columns and a plurality of frame beams, wherein the frame columns and the frame beams are perpendicularly arranged and connected; a frame unit is formed between every two adjacent frame columns and between every two adjacent frame beams; the frame columns are formed by pouring first concrete; the frame beams are formed by pouring second concrete; the grade of the first concrete is C50 to C70; the grade of the second concrete is C40 to C60; the yield strength of first steel bars of the frame columns is larger than or equal to 1280 MPa; the yield strength of second steel bars of the frame beams is larger than or equal to 500 MPa; and the surface of the first steel bars is provided with an anti-rust corrosion-resistant coating. The reinforced concrete frame structure has good recoverability, and reasonable weakening control on the bonding strength of the first steel bars and the first concrete is achieved, so that the performance goals that the reinforced concrete frame structure achieves small post-earthquake damage and is easy to repair rapidly are achieved.

Owner:BEIJING UNIV OF TECH

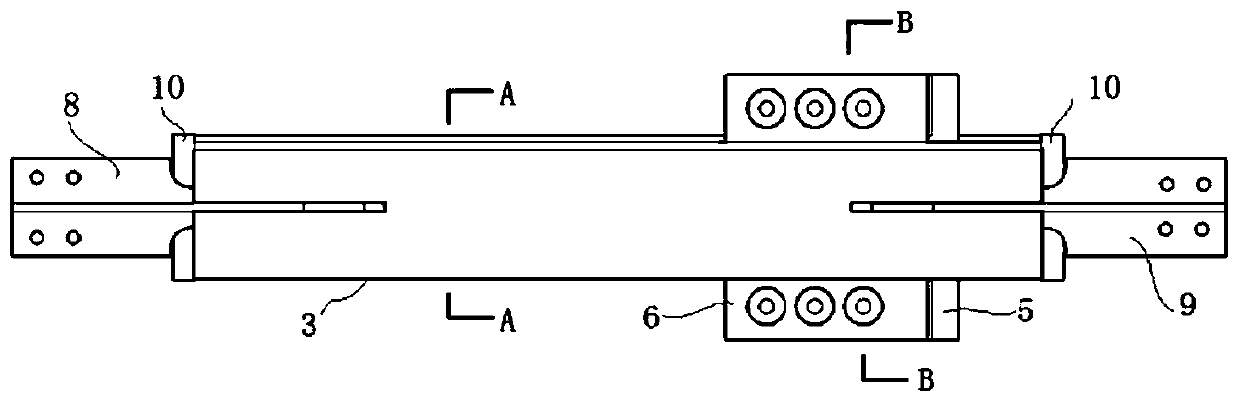

Connection structure and construction method of profiled steel plate shear wall and rc frame beam

ActiveCN106499212BEasy to transportShorten the reinforcement timeBuilding repairsSheet steelRc frames

Owner:NANJING AMEBA ENG STRUCTURE OPTIMIZATION RES INST CO LTD

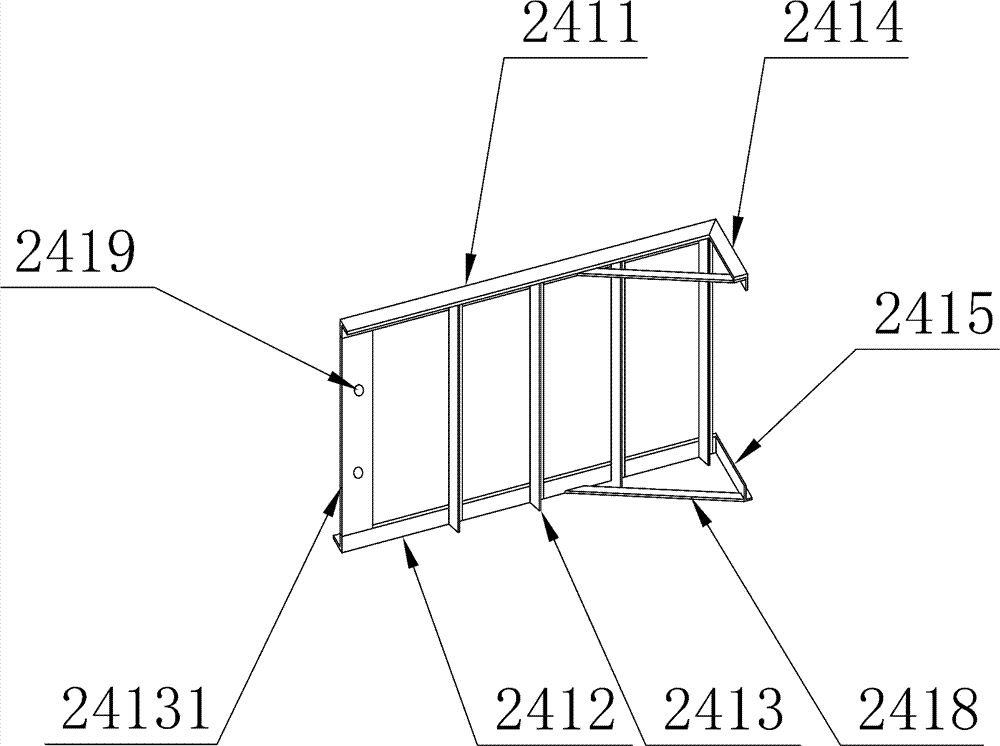

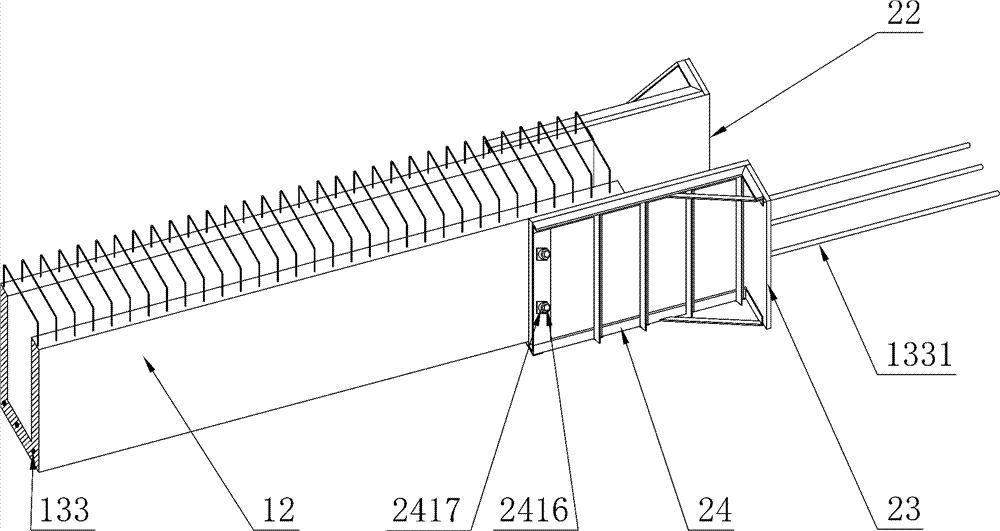

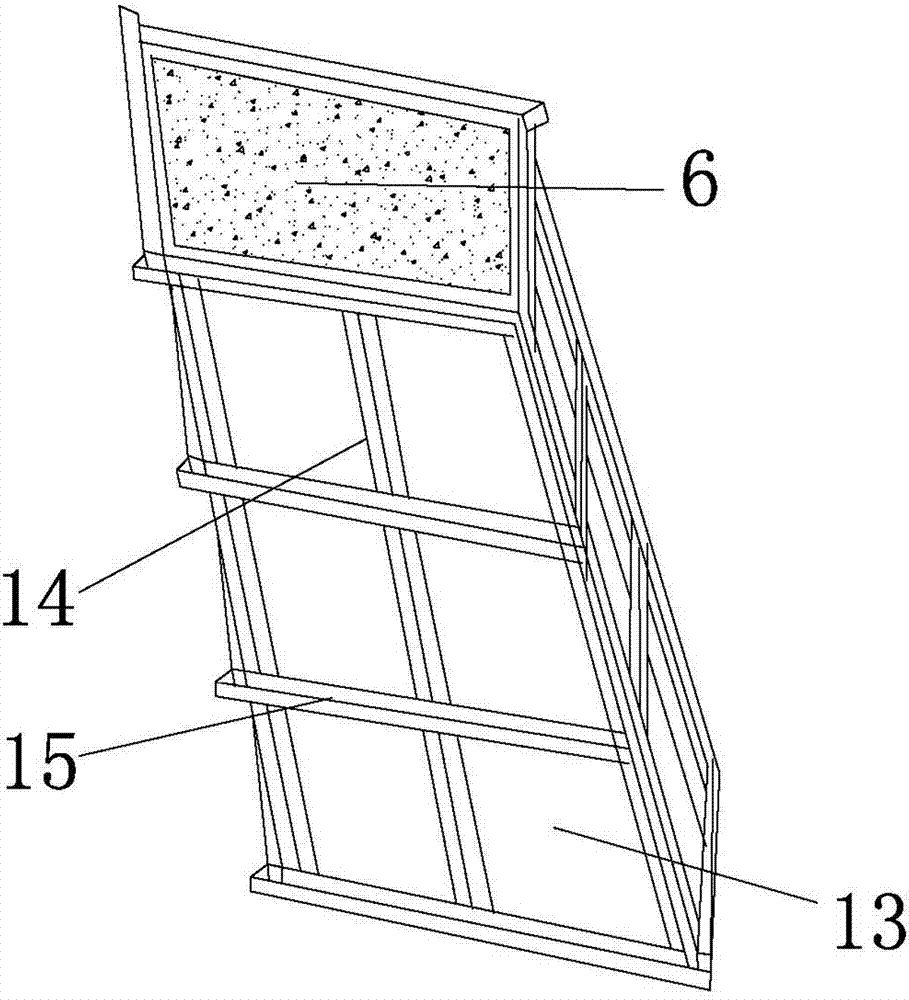

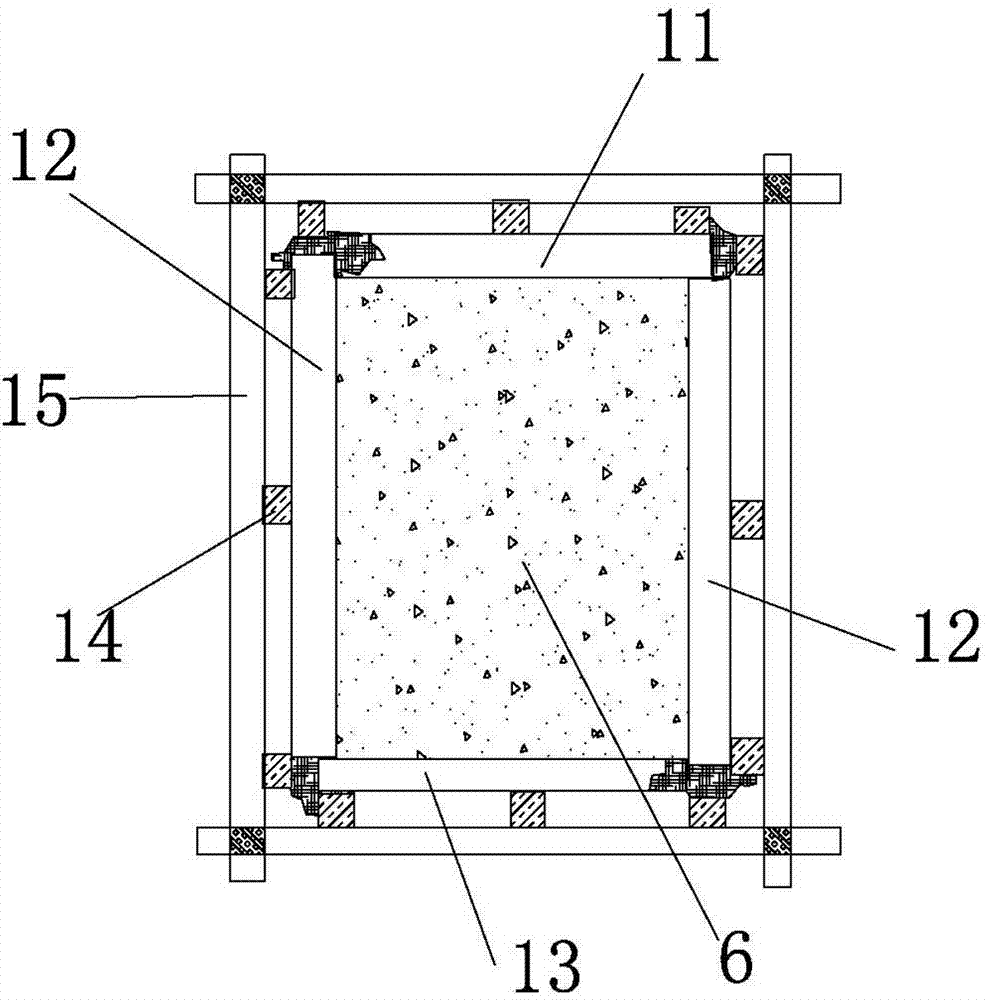

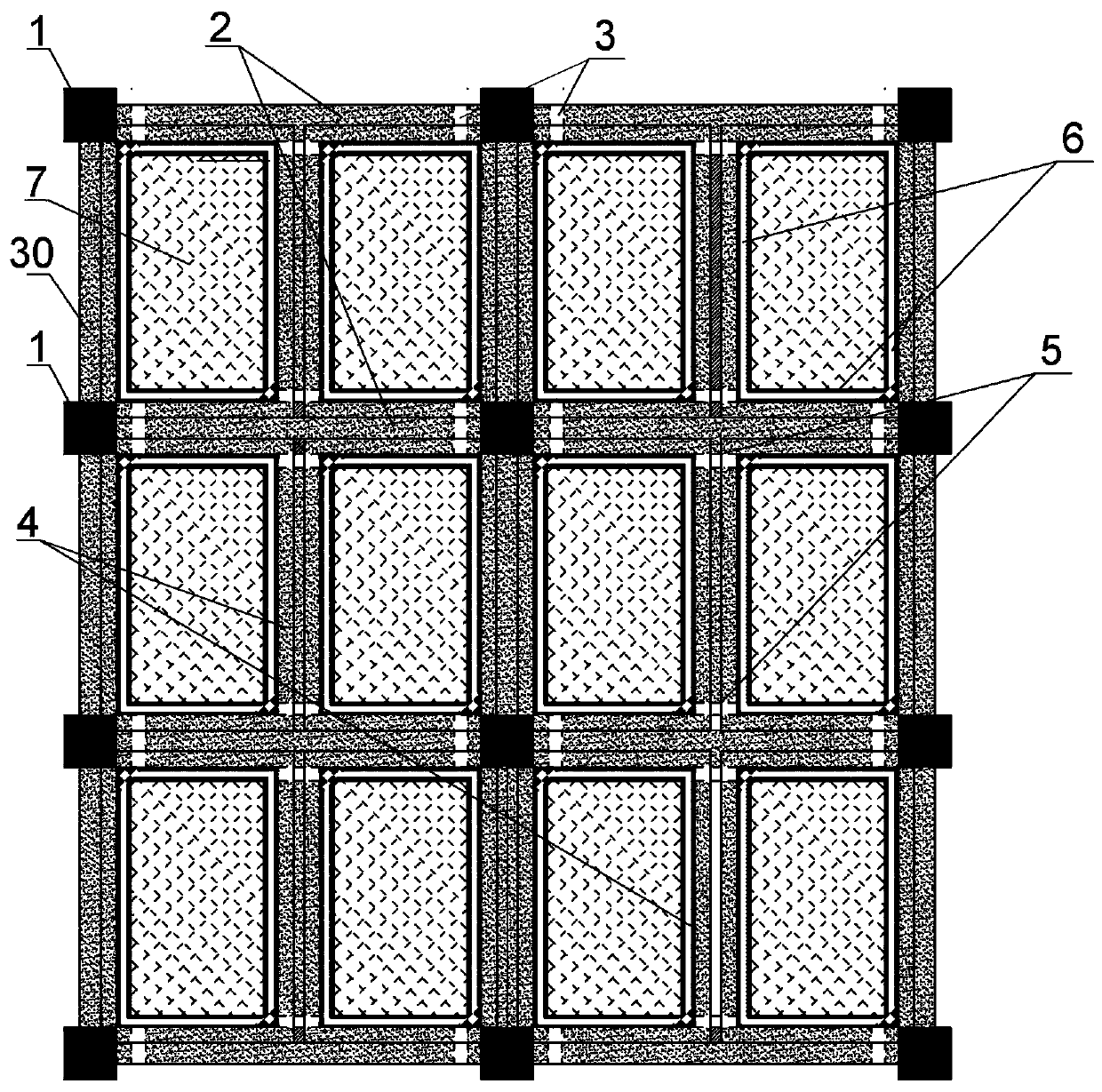

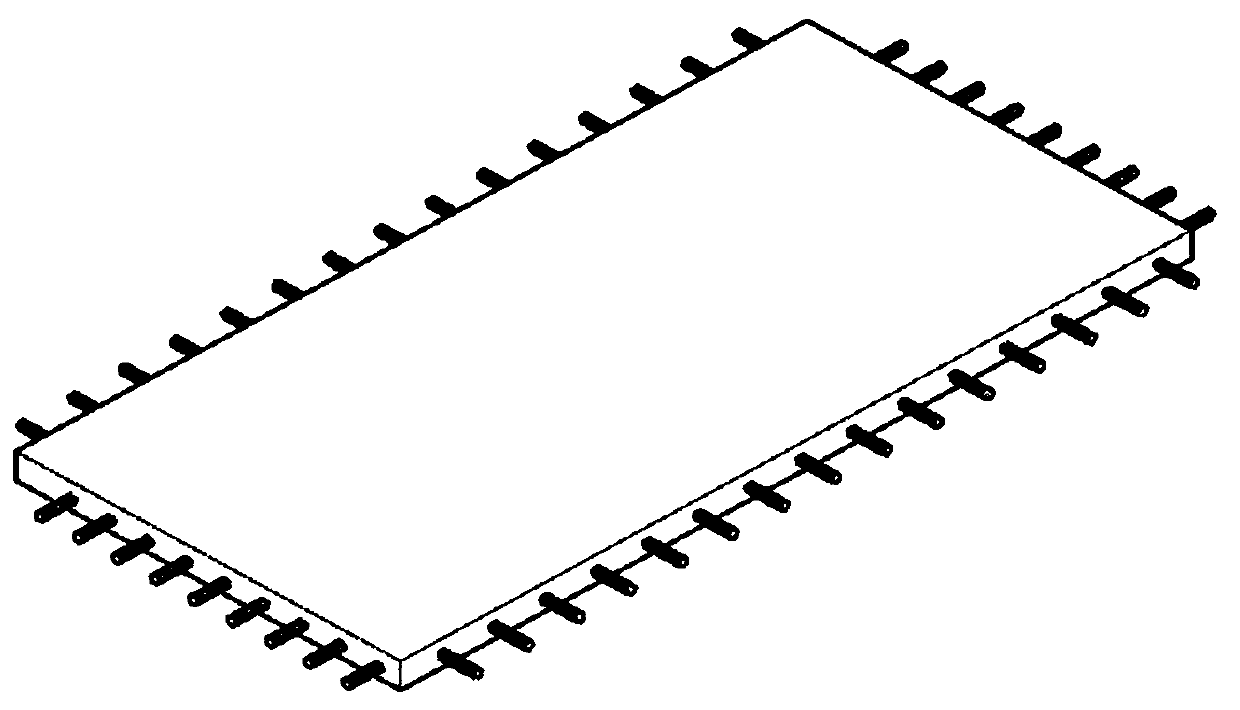

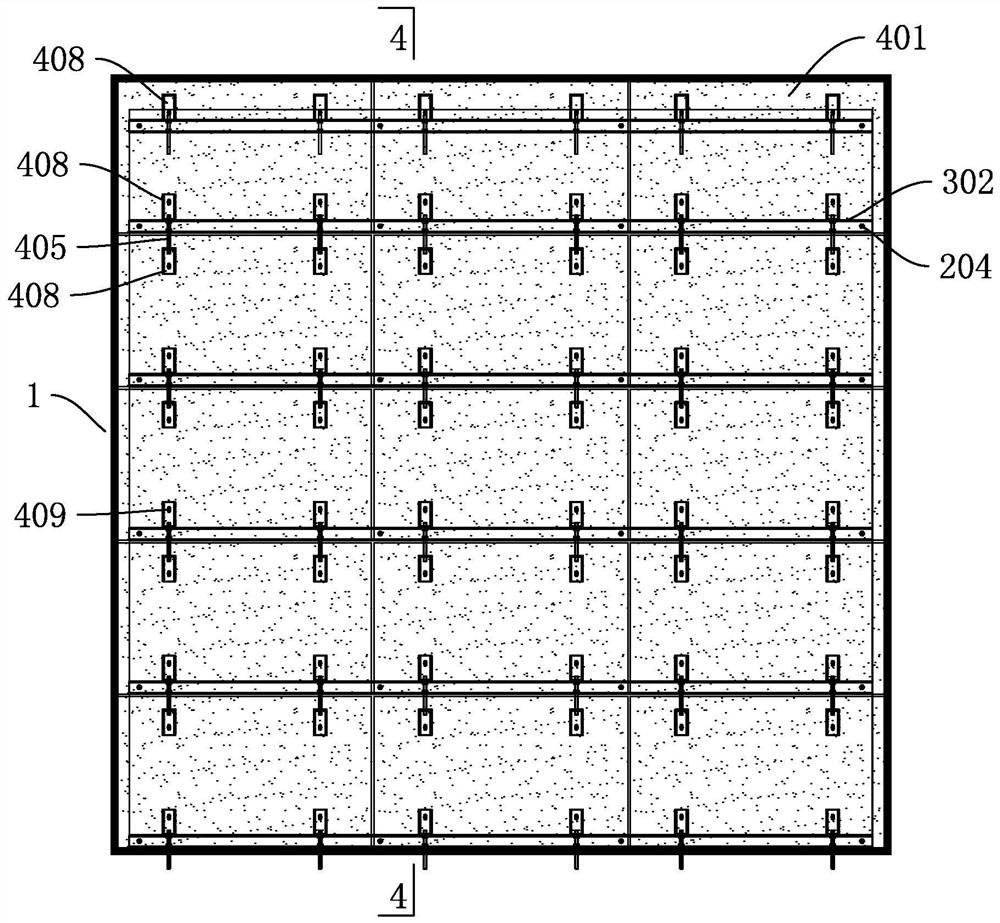

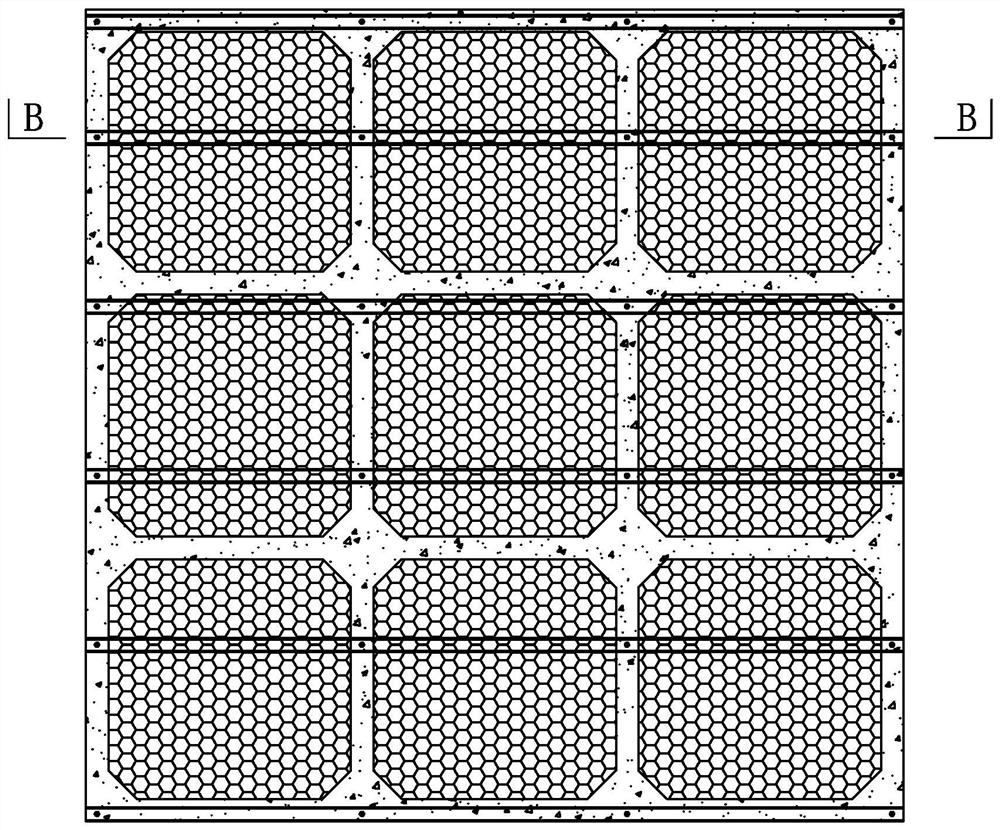

Building unit combined type heat preservation and decoration integrated outer wall hanging plate and mounting method

PendingCN112144791AImprove securityExtended service lifeCovering/liningsComposite constructionInsulation layer

The invention discloses a building unit combined type heat preservation and decoration integrated outer wall hanging plate and a mounting method. The outer wall hanging plate is of a layered compositestructure and sequentially comprises an inner side heat preservation layer, a reinforced concrete frame, a fireproof heat preservation layer and a decoration plate layer from inside to outside, the reinforced concrete frame is formed by connecting reinforced concrete frame ribs which are located on the four sides and inside the reinforced concrete frame and distributed in the longitudinal direction and the transverse direction, a heat preservation filling layer is embedded in the reinforced concrete frame, rectangular truss reinforcement cages are arranged in the reinforced concrete frame ribs, a plurality of dry hanging keels which are arranged in the longitudinal direction and are horizontally arranged are arranged in the fireproof heat preservation layer, each dry hanging keel is fixedto the outer side of the reinforced concrete frame through embedded bolts embedded in longitudinal reinforced concrete frame ribs, the space between every two adjacent dry hanging keels is filled with a fireproof heat preservation material, the decoration plate layer is formed by splicing a plurality of decoration plates, and the decoration plates are connected with the dry hanging keels adjacentto the inner side of the decoration plates together in a dry hanging mode through dry hanging connecting pieces.

Owner:BEIJING EVEREST GREEN BUILDING TECH

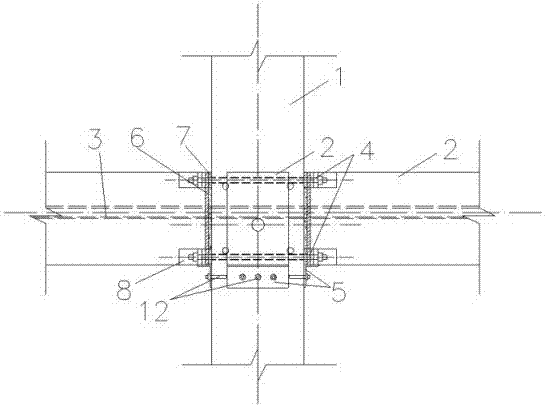

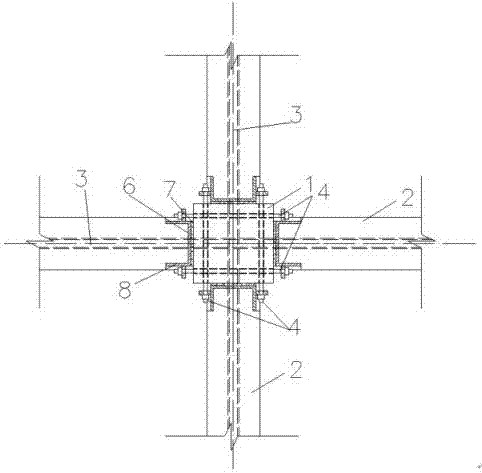

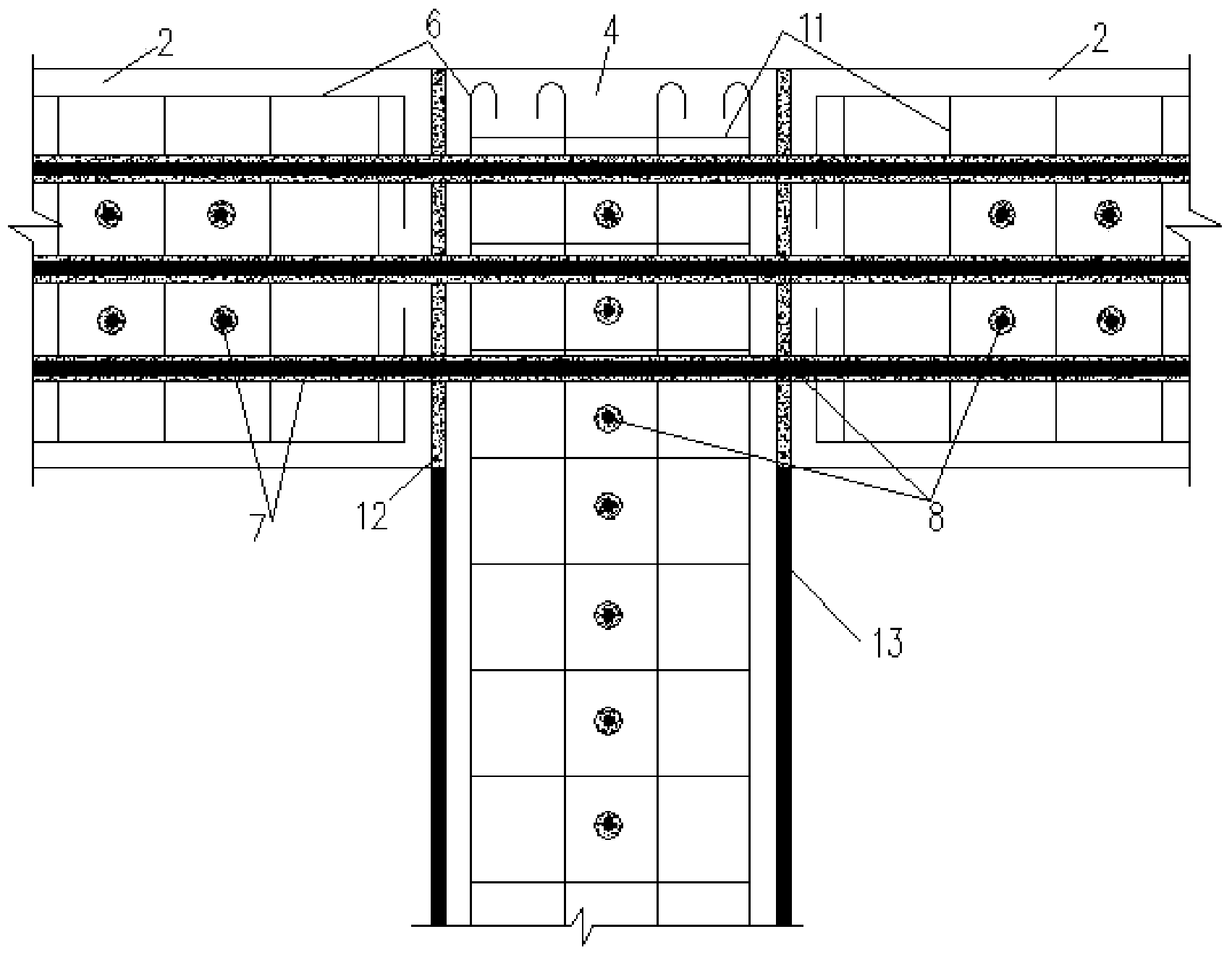

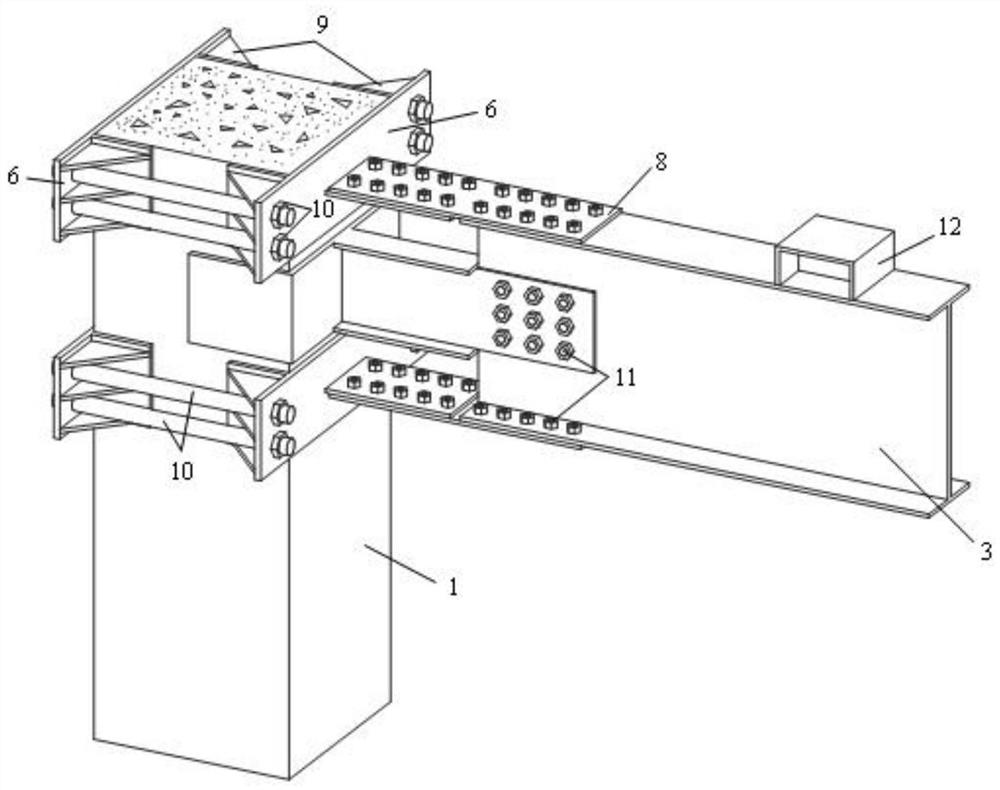

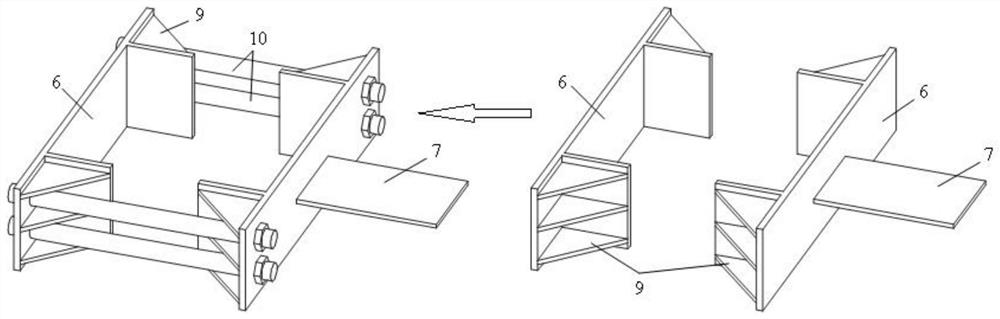

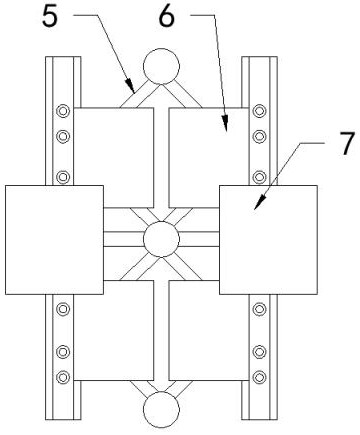

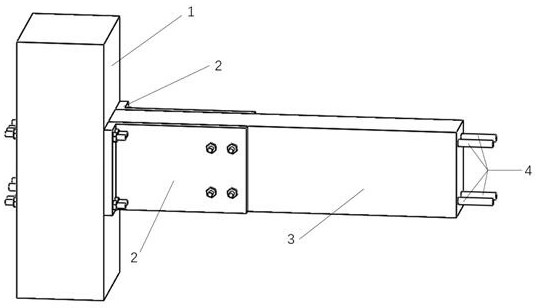

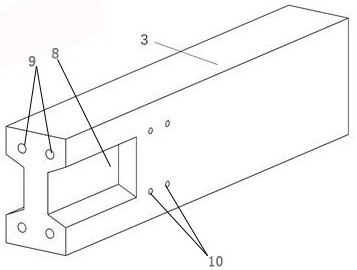

Beam-column joint connection device of fabricated reinforced concrete frame

ActiveCN110952657BReduce residual deformationAvoid damageBuilding constructionsReinforced concrete columnConcrete beams

The invention relates to a beam-column joint connection device of a prefabricated reinforced concrete frame, which includes a prefabricated reinforced concrete column and a prefabricated reinforced concrete beam connected by multiple prestressed tendons, and connecting metal components arranged on both sides of the joint between the column and the beam . One end of the connecting metal member is fixedly connected to the side of the prefabricated reinforced concrete column, and the other end is fixedly connected to the side of the prefabricated reinforced concrete beam; both sides of one end of the prefabricated reinforced concrete beam are provided with concrete beam side grooves; the contact between the connecting metal member and the prefabricated reinforced concrete beam Protrusions are arranged on the surface, and the protrusions are embedded in the side grooves of the concrete beams; high damping material plates are filled between the protrusions and the walls of the side grooves of the concrete beams. This kind of connection device can ensure that when the beam-column joint is prone to corner misalignment, in addition to relying on the prestressed tendons to improve the self-resetting ability of the joint, it can also use the frictional energy dissipation and cyclic compression buffer of the high-damping material plate performance, improving the energy dissipation and bending resistance of the node.

Owner:NANJING INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com