Reinforced concrete frame column reinforcing structure and method

A technology of reinforced concrete and reinforced structure, applied in the direction of columns, piers, pillars, etc., can solve the problems of low stability and seismic resistance, and achieve the effects of high stability, improved seismic grade, and good shock absorption and buffer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

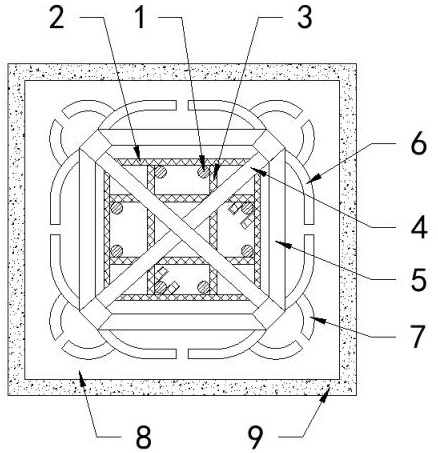

[0032] refer to Figure 1-3 , the reinforced structure of the reinforced concrete frame column, including the longitudinal bar 1 running through the frame column, the inner stirrup 2 and the outer stirrup 3 wrapped around the longitudinal bar 1, and the concrete filling area 8 and poured in the frame column The external wall panels 9 outside the concrete filling area 8 also include:

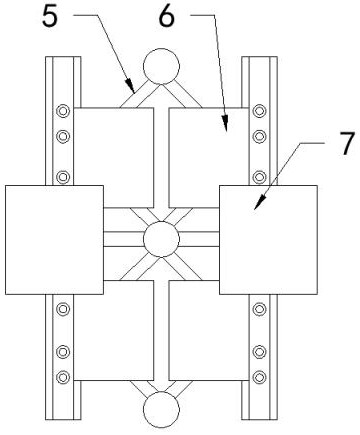

[0033] The built-in Bailey frame 4 is provided with two groups. The two groups of built-in Bailey frames 4 are crossed and fixed in an X shape along the diagonal of the frame column. The group is built into the Bailey frame 4;

[0034] The external Bailey frame 5 is provided with four groups, and the four groups of external Bailey frames 5 are fixedly connected in pairs to form a square structure, and the two ends of the two sets of built-in Bailey frames 4 are fixedly connected in a square structure on the diagonal; the built-in Bailey frame 4, the external Bailey frame 5, the side spring boar...

Embodiment 2

[0038] refer to Figure 1-3 , the reinforcing method of reinforced concrete frame column, comprises the following steps:

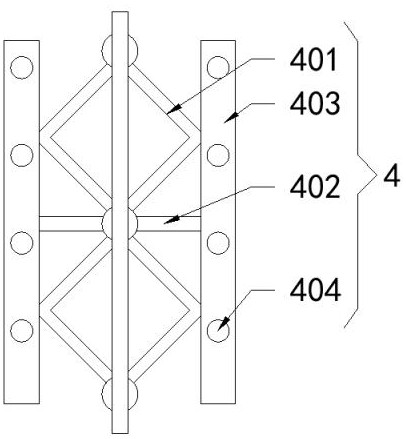

[0039] Step 1: After the two built-in Bailey frames 4 are arranged in an X-shaped cross, the square frames 401 of the two built-in Bailey frames 4 are welded, and then multiple groups of two built-in frames welded along the axis line of the frame column are welded. The Bailey frame 4 is inserted into the preset hole of the frame column, and the intersection point of the two built-in Bailey frames 4 is on the axis line of the frame column;

[0040] Step 2: Arrange the longitudinal reinforcement 1 in the preset hole of the frame column, and then connect the inner stirrup 2 and the outer stirrup 3 sequentially from the bottom to the top of the frame column, and the inner stirrup 2 runs through the two built-in Bailey frames 4 The square frame 401, the outer stirrups 3 run through the through holes 404 of the vertical frames 403 of the two built-in Bailey fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com