Reinforcement end reinforced large-diameter straight thread connector and connecting method thereof

A reinforced, large-diameter technology, applied in building reinforcements, building components, structural elements, etc., can solve problems such as low efficiency, high labor intensity, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

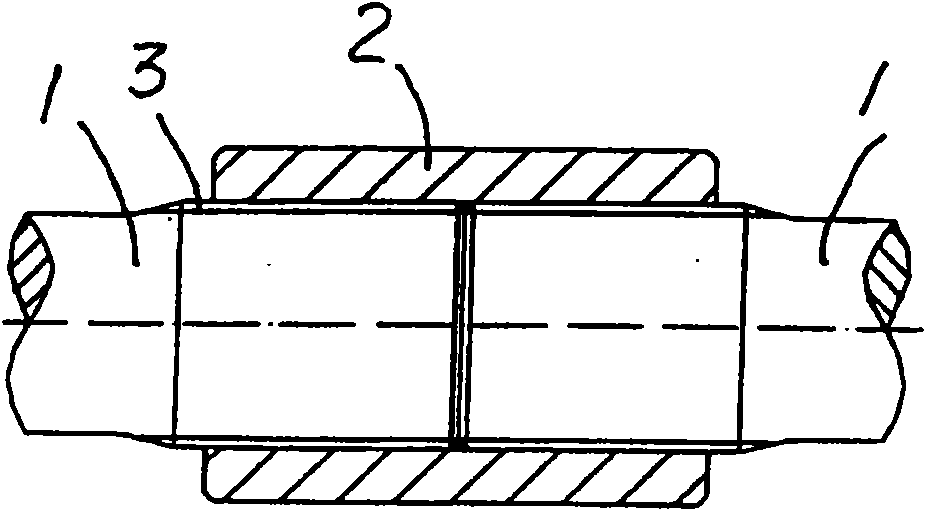

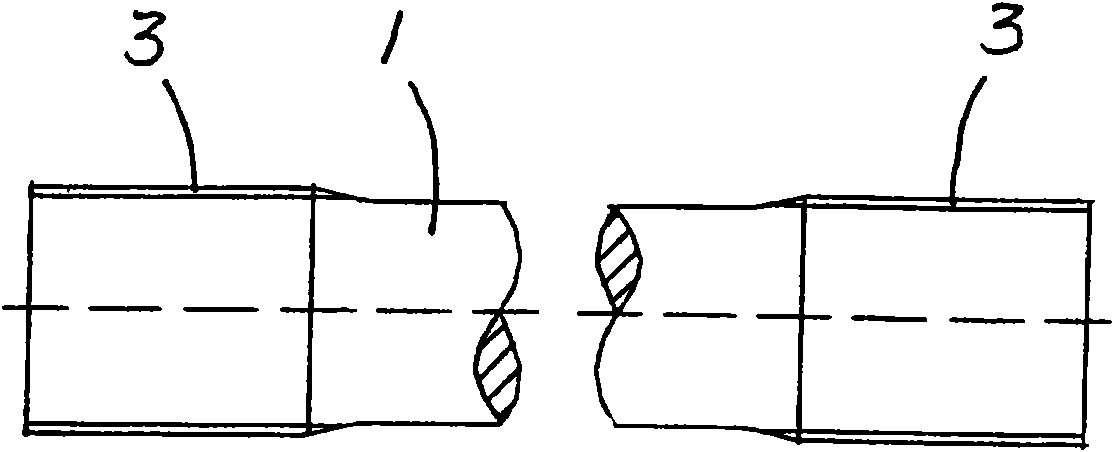

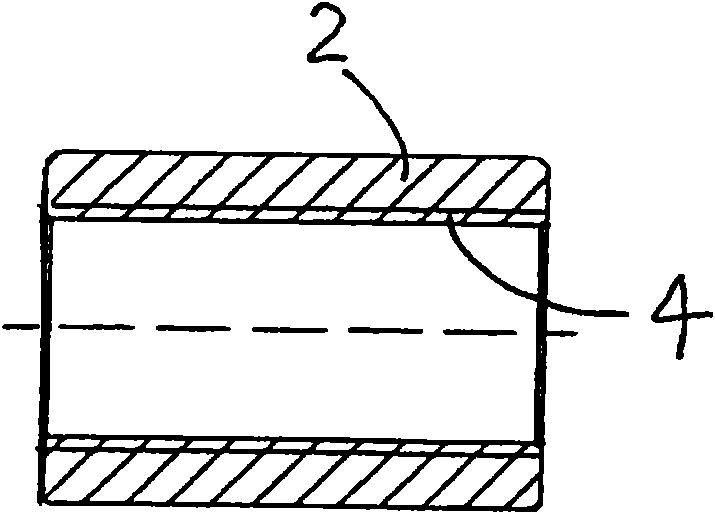

[0009] Embodiment 1: refer to figure 1 , figure 2 , image 3 , the two ends of the screw rod of this embodiment have external straight threads respectively, and there are internal straight threads matching the external straight threads on the screw in the screw sleeve, and the external straight threads of the screw rod are screwed into the internal straight threads of the screw sleeve, and the matching The diameter of the internal straight thread and the external straight thread is 30mm-40mm. In this embodiment, the diameters of the two ends of the screw and the screw sleeve are the same and the direction of rotation is the same (see image 3 ). first to figure 2 The two ends of the shown screw are covered with external straight threads, and then the image 3 The screw sleeve shown is tapped with internal straight thread, and finally pressed at the construction site figure 1 The structure shown is alternately screwed to the screw and the screw sleeve with the same diam...

Embodiment 2

[0010] Embodiment 2: refer to figure 1 , figure 2 , Figure 4 , the two ends of the screw rod of the present embodiment have external straight threads respectively, and there are internal straight threads matched with the external straight threads on the screw rod in the screw sleeve, the external straight threads of the screw rod are screwed with the internal straight threads of the screw sleeve, and the two ends of the screw rod The direction of rotation of the outer straight thread is opposite, the inner straight thread of the screw sleeve is divided into two sections, and the direction of rotation of the two sections of the inner straight thread of the screw sleeve is opposite. The matching inner straight thread and outer straight thread have a diameter of 30mm-40mm. In this embodiment, the diameters at the two ends of the screw and the screw sleeve are the same and the direction of rotation is opposite (see Figure 4 ). This embodiment is suitable for occasions where...

Embodiment 3

[0011] Embodiment 3: refer to figure 1 , figure 2 , Figure 5 , in this embodiment, the diameters of the two ends of the screw and the screw sleeve are different and the direction of rotation is the same. The two ends of the screw rod of this embodiment have outer straight threads respectively, and there are inner straight threads matched with the outer straight threads on the screw in the screw sleeve, the outer straight threads at one end of the screw rod are larger than the outer straight threads at the other end of the screw rod, The inner straight thread of the screw is larger than the inner straight thread at the other end of the screw sleeve, the outer straight thread of the screw is screwed into the inner straight thread of the screw sleeve, and the diameter of the matching inner straight thread and outer straight thread is 30mm to 40mm. Compared with embodiment 1, this embodiment only has the outer straight thread of the screw rod at one end and the inner straight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com