Connection joint of box-shaped steel beam and concrete filled steel tubular column and construction method of connection joint

A technology of concrete-filled steel tubular columns and box-shaped steel beams, which is applied in the direction of buildings, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

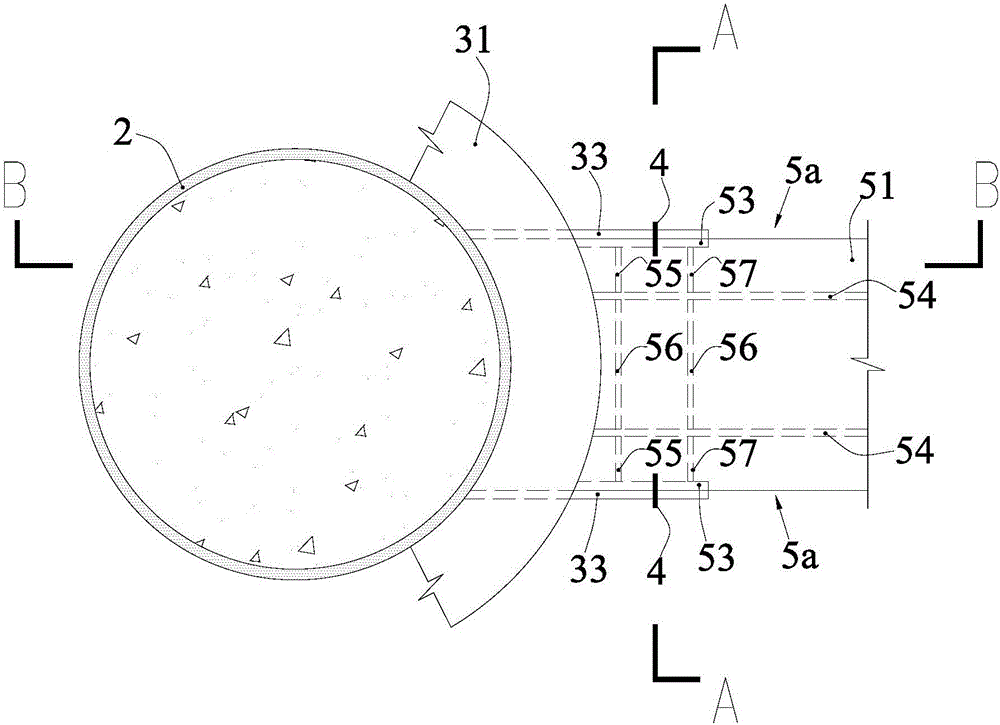

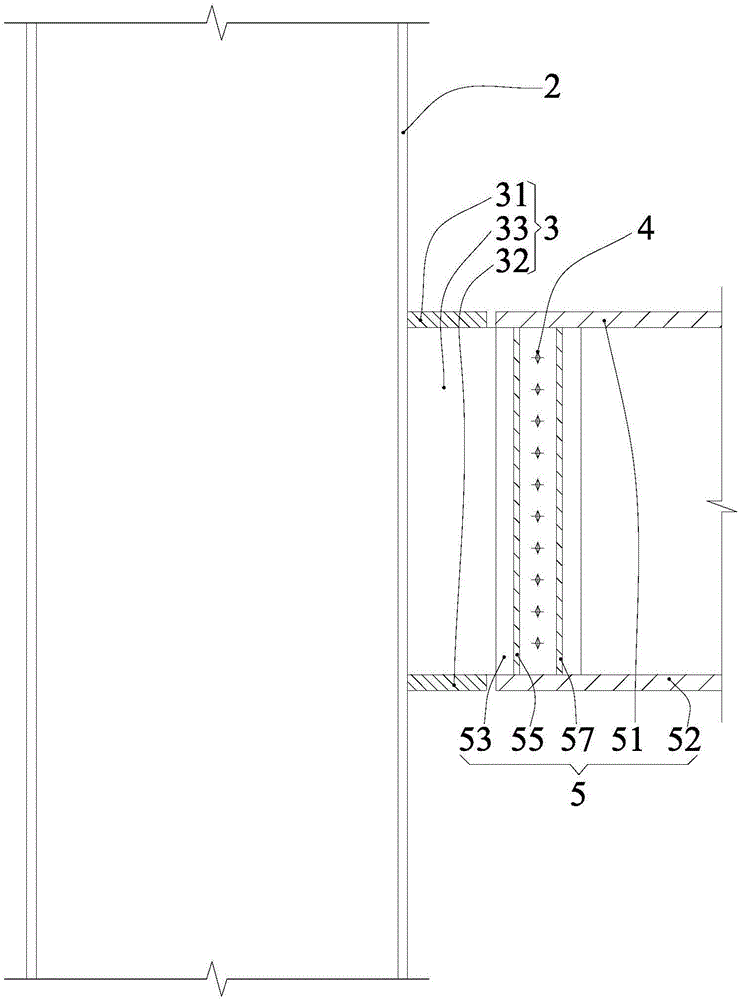

[0084] Such as Figure 6 to Figure 9 As shown, Embodiment 1 of the present invention is based on the above-mentioned general inventive concept, and adopts the following specific schemes for the manner of forming the shear force transfer structure 5:

[0085] The box-shaped steel girder 1 is a first-form box-shaped steel girder 1A, and the two beam webs 13A of the first-form box-shaped steel girder 1A are connected to the middle of the bottom surface of the beam upper flange 11A and the top of the beam lower flange 12A. Between the middle of the surface, that is, the two side edges 111A of the beam upper flange 11A of the first form of box-shaped steel girder 1A and the two side edges 121A of the beam lower flange 12A respectively extend to the two sides of the first form of box-shaped steel girder 1A. outside of the block beam web 13A.

[0086] The beam force transmission member 6 is an outsourcing beam force transmission component, which is composed of two outer force transm...

Embodiment 2

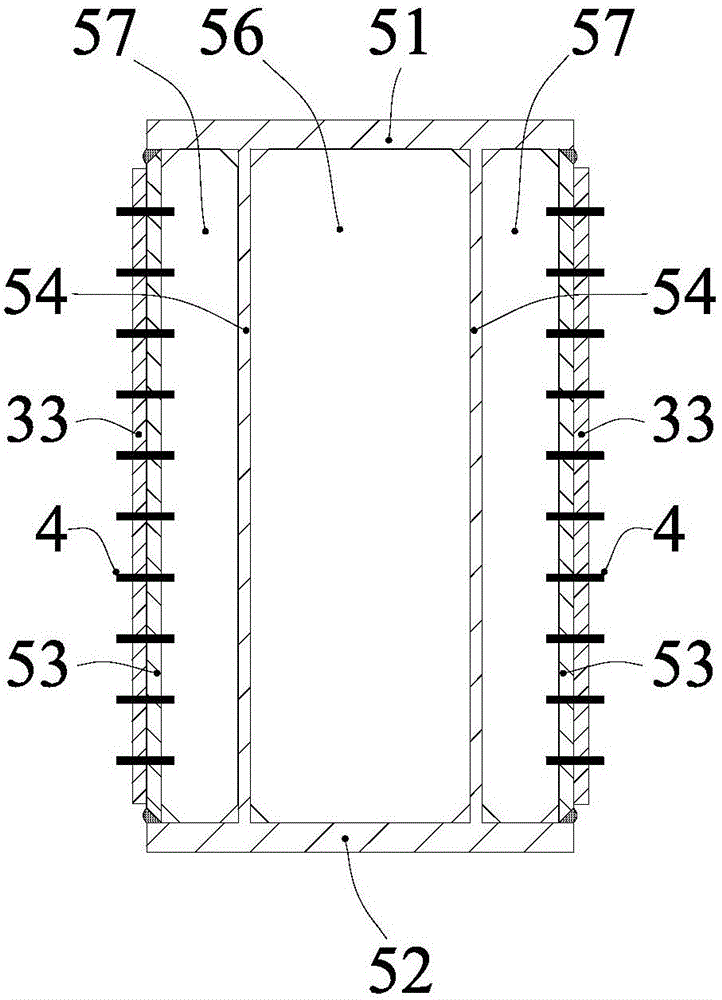

[0090] Such as Figure 10 to Figure 13 As shown, the second embodiment of the present invention is based on the above-mentioned general inventive concept, and adopts the following specific schemes for forming the shear force transfer structure 5:

[0091] The box-shaped steel girder 1 is a second-form box-shaped steel girder 1B, and the edges of the beam upper flange 11B, the beam lower flange 12B and the two beam webs 13B of the second-form box-shaped steel girder 1B are flush, that is, the second The box-shaped steel girder 1B of the first form has a "mouth" cross-section; and the beam web 13B of the second-form box-shaped steel beam 1B is provided with an installation through hole 13a close to the end of the second-form box-shaped steel beam 1B.

[0092] Beam force transmission member 6 is an embedded beam force transmission member, which is composed of two inner force transmission webs 61B, two front front force transmission transverse ribs 62B, two front middle force tran...

Embodiment 3

[0098] Such as Figure 14 As shown, the third embodiment of the present invention is based on the above-mentioned general inventive concept, and adopts the following specific scheme to realize the simultaneous connection of the steel-filled steel tube column 2 with multiple box-shaped steel beams 1 and improve the connection strength between the box-shaped steel beam 1 and the steel-filled steel tube column 2 :

[0099] The connection node of the third embodiment of the present invention is provided with at least two box-shaped steel beams 1, and the upper column force transmission flange 31 and the lower column force transmission flange 32 of the column force transmission member 3 are ring plates, and the ring plates pass through their The central through hole is set outside the steel tube concrete column 2 and connected with the steel tube concrete column 2 by surrounding welding. The column force transmission member 3 is equipped with two column force transmission webs 33 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com