A sleeve for mechanical connection of low-temperature-resistant steel bars for LNG storage tanks and its manufacturing method

A technology of mechanical connection and low temperature resistance, which is applied in the direction of manufacturing tools, building structures, furnaces, etc., can solve the problems of high cost, low tensile strength, elongation, corrosion resistance, etc. Low, good anti-rust and anti-corrosion performance, good tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

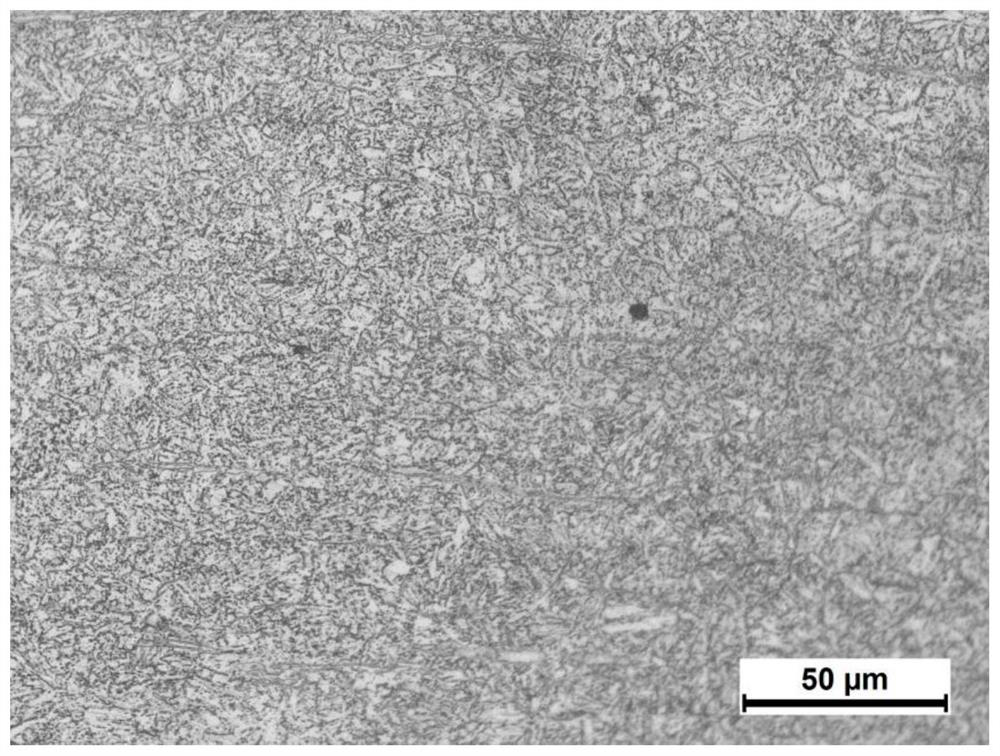

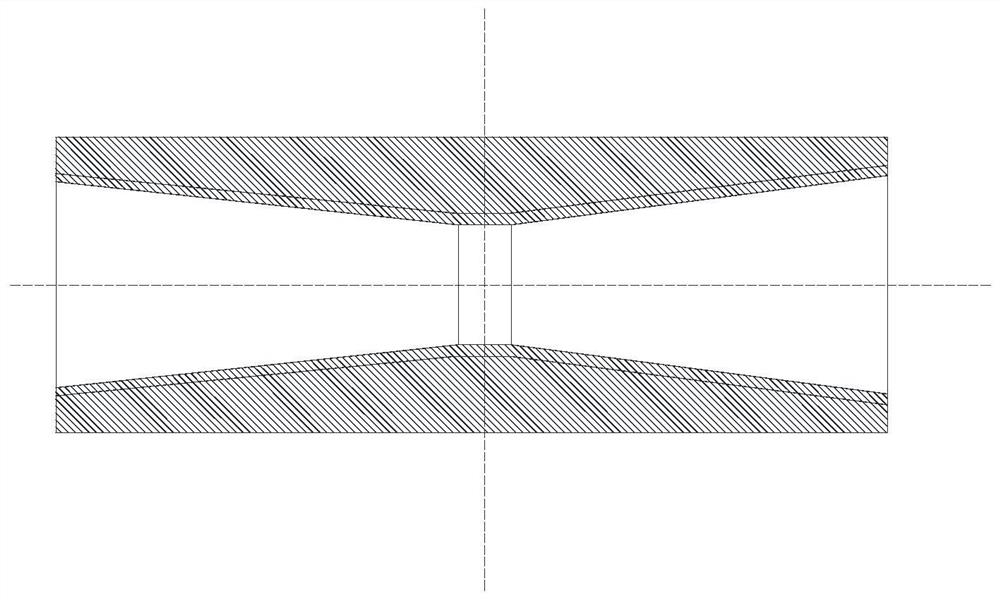

[0077] Each embodiment provides a sleeve respectively, which is one of the three specifications of sleeves suitable for low-temperature steel bars, respectively 12mm, 16mm, and 25mm. Each embodiment adopts the sleeve described above in the embodiment of the present application. The manufacturing method of the cylinder is obtained, but the chemical composition of the copper sleeve and / or the process parameters of the quenching and tempering heat treatment are different among the various embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com