Epoxy glass flake heavy-duty coating and preparation method thereof

A technology of epoxy glass and glass flakes, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of inability to carry out mechanical treatment, manpower and material resources, and high maintenance costs, and achieve good anti-rust and anti-corrosion performance, Energy saving and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

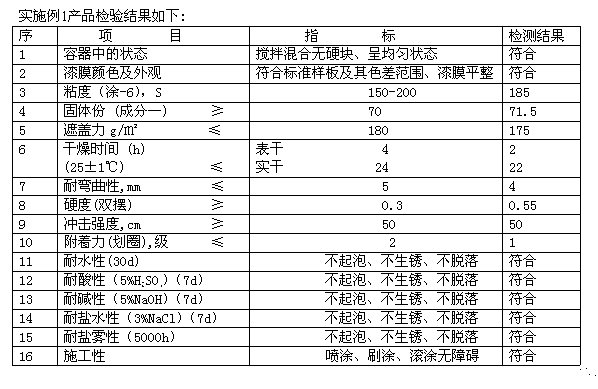

Embodiment 1

[0027] An epoxy glass flake heavy-duty anti-corrosion coating, which is obtained by mixing and aging components A and B, and is specifically prepared according to the following steps:

[0028] 1. Preparation of materials:

[0029] The raw material weight percent of A component is as follows:

[0030] 42% epoxy resin, 26% glass flakes, 18% pigments, 6.5% fillers, 3% nanomaterials, 1.5% additives, 3% solvents;

[0031] The raw material weight percent of B component is as follows:

[0032] 8235 cashew nut oil modified epoxy curing agent 10%, 650 polyamide epoxy curing agent 40%, mixed solvent 50%.

[0033] The weight ratio of the described component A and component B is 10:1.2.

[0034] The auxiliary agent is a mixture of 904S wetting and dispersing agent, 606 anti-settling agent and CIMA240 anti-settling agent; 904S wetting and dispersing agent: 606 anti-settling agent: CIMA240 anti-settling agent The weight ratio=0.5:0.4:0.6; The mixed solvent described ab...

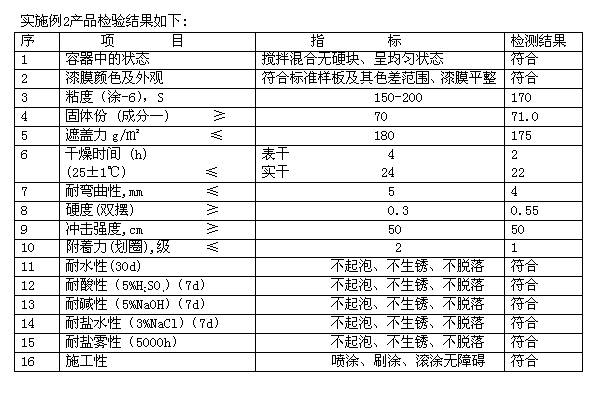

Embodiment 2

[0044] An epoxy glass flake heavy-duty anti-corrosion coating, which is obtained by mixing and aging components A and B, and is specifically prepared according to the following steps:

[0045] 1. Preparation of materials:

[0046] The weight percent of A component is as follows:

[0047] 44% epoxy resin, 25% glass flakes, 15% pigments, 7% fillers, 3% nanomaterials, 2% additives, 4% solvents;

[0048] The weight percent of B component is as follows:

[0049] 8235 cashew nut oil modified epoxy curing agent 14%, 650 polyamide epoxy curing agent 42%, mixed solvent 44%.

[0050] The weight ratio of the described component A and component B is 10:1.2.

[0051] The auxiliary agent is a mixture of 904S wetting and dispersing agent, 606 anti-settling agent and CIMA240 anti-settling agent; 904S wetting and dispersing agent: 606 anti-settling agent: CIMA240 anti-settling agent The weight ratio=0.5:0.4:0.6; The mixed solvent described above is composed of xylene an...

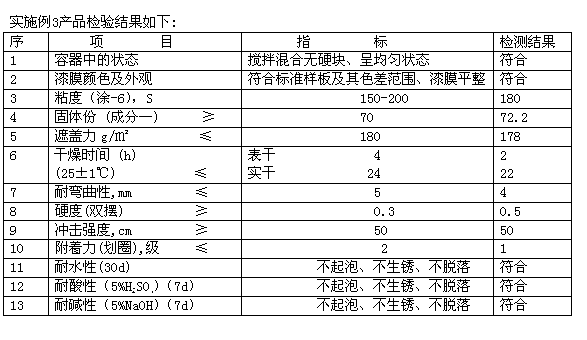

Embodiment 3

[0061] An epoxy glass flake heavy-duty anti-corrosion coating, which is obtained by mixing and aging components A and B, and is specifically prepared according to the following steps:

[0062] 1. Preparation of materials:

[0063] The weight percent of A component is as follows:

[0064] 44% epoxy resin, 25.5% glass flakes, 15% pigments, 8% fillers, 3% nanomaterials, 1.5% additives, 3% solvents;

[0065] The weight percent of B component is as follows:

[0066] 8235 cashew nut oil modified epoxy curing agent 15%, 650 polyamide epoxy curing agent 45%, mixed solvent 40%.

[0067] The weight ratio of the described component A and component B is 10:1.2.

[0068] The auxiliary agent is a mixture of 904S wetting and dispersing agent, 606 anti-settling agent and CIMA240 anti-settling agent; 904S wetting and dispersing agent: 606 anti-settling agent: CIMA240 anti-settling agent The weight ratio=0.5:0.4:0.6; The mixed solvent described above is composed of xylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com