Patents

Literature

49results about How to "Good anti-rust and anti-corrosion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly semisynthetic cutting fluid for titanium alloys as well as preparation method and application of cutting fluid

InactiveCN105176656AImprove processing efficiencyExtend your lifeLubricant compositionMetalworking fluidActive agent

The invention belongs to the field of metal processing fluids and discloses an environment-friendly semisynthetic cutting fluid for titanium alloys as well as a preparation method and an application of the cutting fluid. The cutting fluid comprises components in percentage by mass as follows: 20%-30% of base oil, 4%-6% of a lubricant, 6%-10% of an extreme pressure agent, 10%-15% of mixed alcohol amine, 4%-8% of an anti-rusting agent, 2%-4% of a pH (potential of hydrogen) stabilizer, 15%-25% of a surfactant, 1%-2% of a hard water stabilizer, 1%-3% of a coupling agent, 2%-4% of a sterilizing mildew preventive and the balance of water. The cutting fluid doesn't contain mineral oil, sulfur, phosphorus, chlorine, boron, phenol, formaldehyde, secondary amine, heavy metals, sodium nitrite and other poisonous and harmful substances and is environment-friendly. The cutting fluid has excellent extreme pressure performance for lubrication, rust prevention and corrosion prevention performance and hard water stability and long service life, and can meet requirements of cutting processing including turning, milling, boring, drilling, tapping and the like of various titanium alloys, the titanium alloy processing efficiency can be improved by 40%, and the service life of a cutting is prolonged by 30%.

Owner:GUANGZHOU MECHANICAL ENG RES INST +1

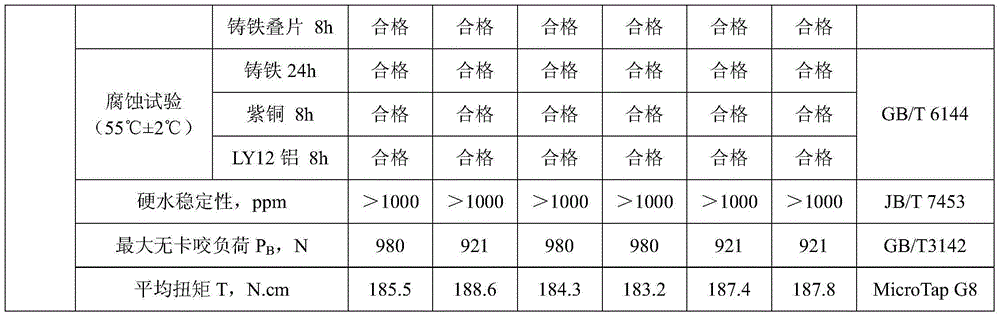

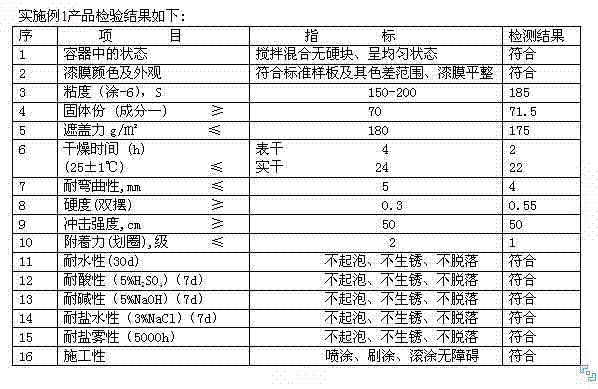

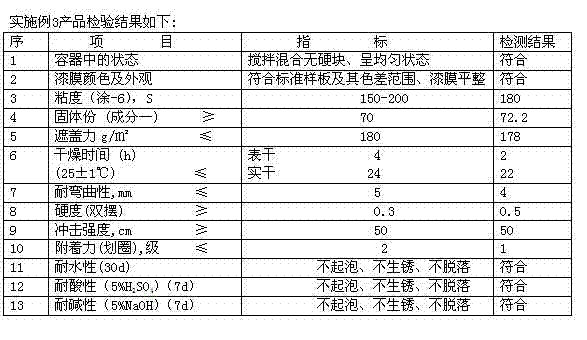

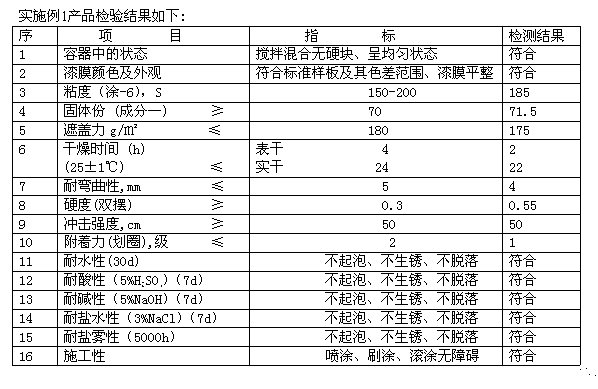

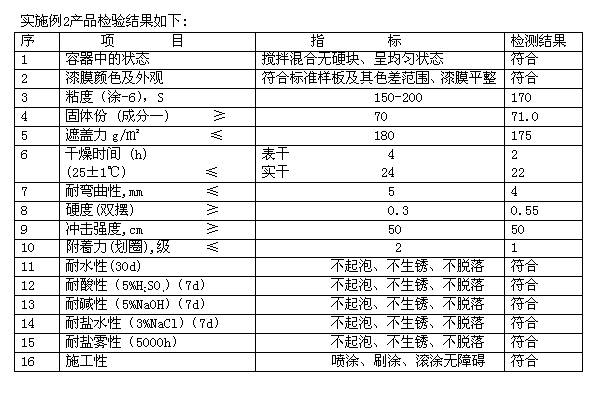

Epoxy glass flake heavy-duty coating and preparation method thereof

ActiveCN102344739AGood weather resistanceGood anti-rust and anti-corrosion effectAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

The invention relates to an anti-corrosion coating, in particular to an epoxy glass flake heavy-duty coating and a preparation method thereof. The epoxy glass flake heavy-duty coating is prepared by mixing and curing a component A and a component B. The epoxy glass flake heavy-duty coating can be coated on the surface of a steel structure, and can be taken as a primer together with an epoxy zinc-rich primer. When taken as a finish coat, the anti-corrosion coating has high antirust and anti-corrosion performance. As proved by detection, a paint film does not become foamed or rusty when the salt spray resistance reaches 5,000 hours and has high weather resistance, and the coating and maintaining costs of a steel structure can be lowered. The production method of the epoxy glass flake heavy-duty coating does not need post-treatment, so that the process method is simple, energy is saved, and the cost is low. The component A and the component B can be automatically dried into a film at normal temperature after being uniformly mixed, so that high film forming performance is realized, and the product has high storing stability.

Owner:浙江钱浪涂料科技有限公司

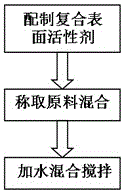

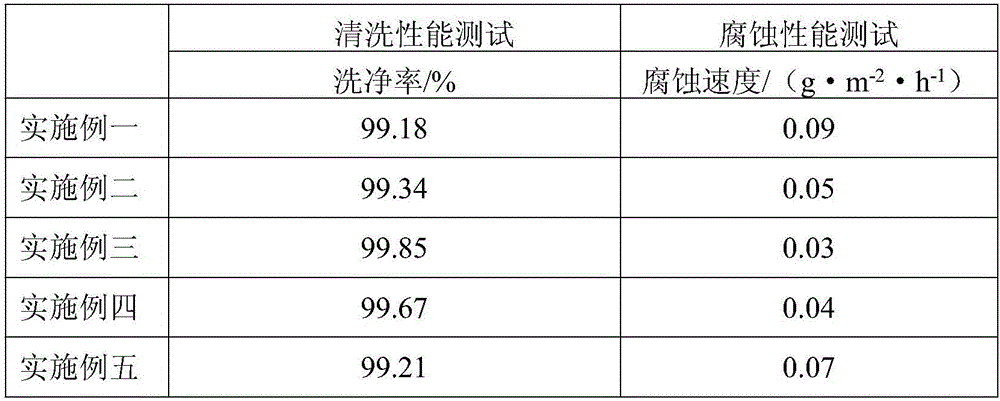

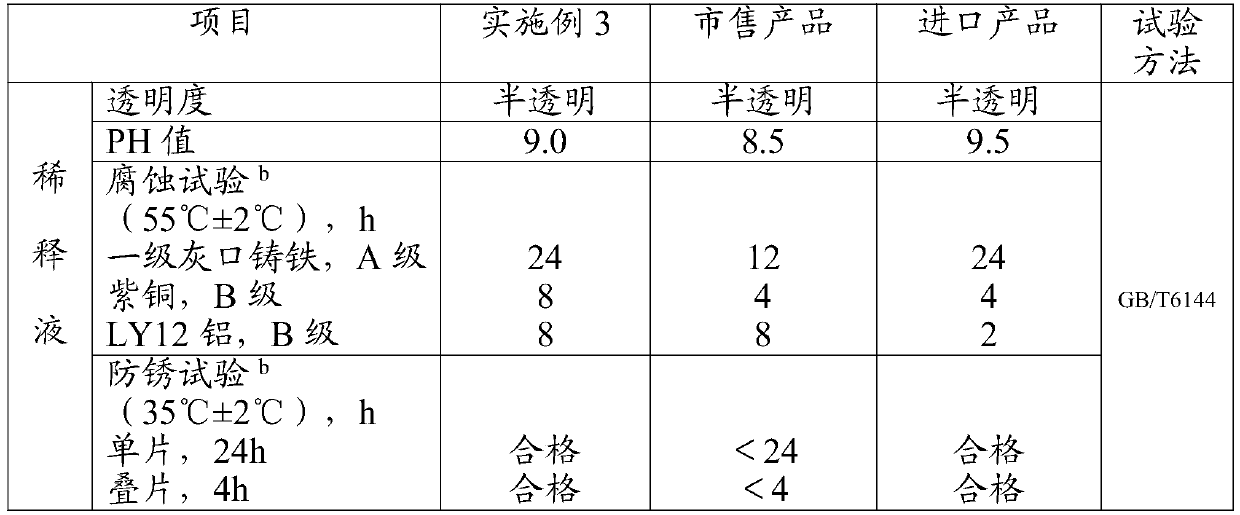

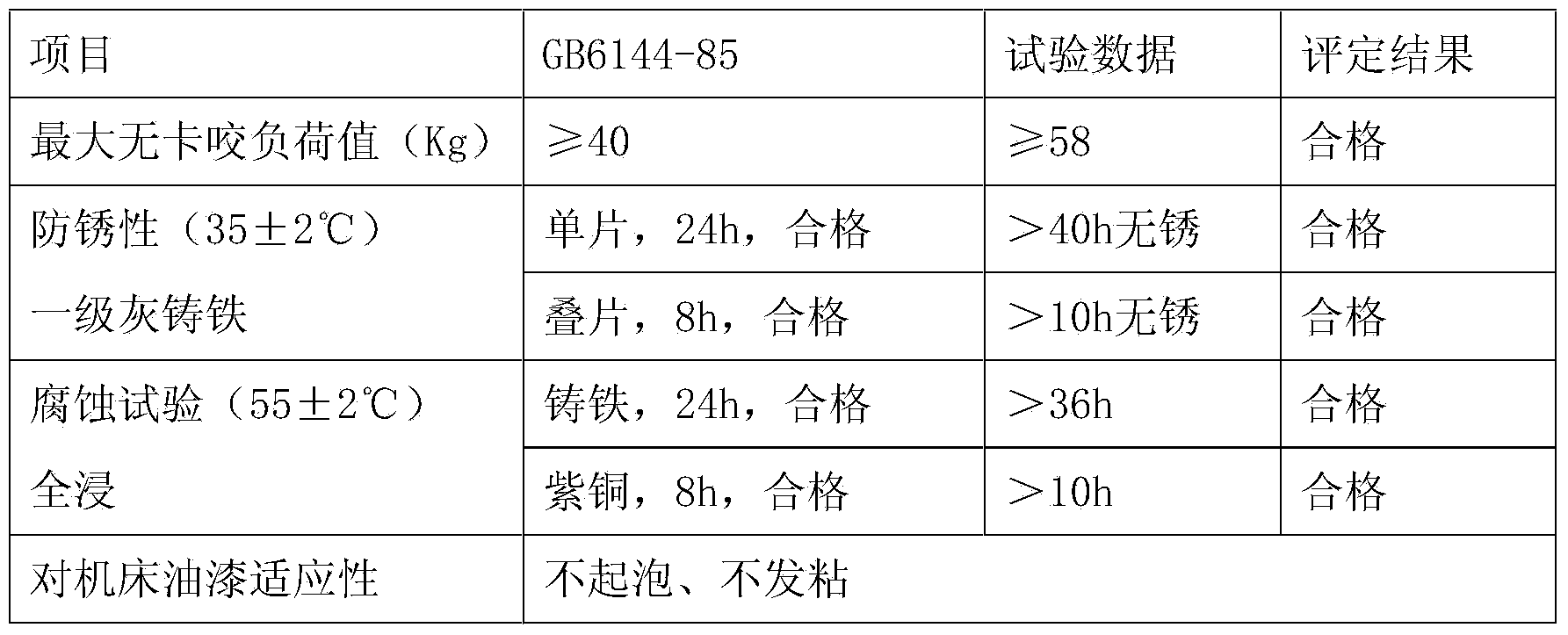

Water-based cleaning agents for automobile parts and preparation method for water-based cleaning agents

The invention provides water-based cleaning agents for automobile parts and a preparation method for the water-based cleaning agents. The water-based cleaning agents include, by weight, 8.5-12% of composite surfactants, 6-10% of compound additives, 5-8% of mixed inorganic salt, 8-10% of solubilizers of diethylene glycol diethylether, 0.25-0.4% of inhibiters of benzotriazole, 0.05-0.1% of organic silicon defoamers and 59.5-72.2% of deionized water. The preparation method includes the following steps of (a) preparation of the composite surfactants, (b) weighing and mixing of raw materials and (c) water addition, mixing and stirring. The water-based cleaning agents are low in cleaning temperature, long in service life and free of toxin and pollution and have high cleaning efficiency and good anti-rust and anti-corrosion capacity, and the cleaning efficiency for automobile parts can be more than 99%.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

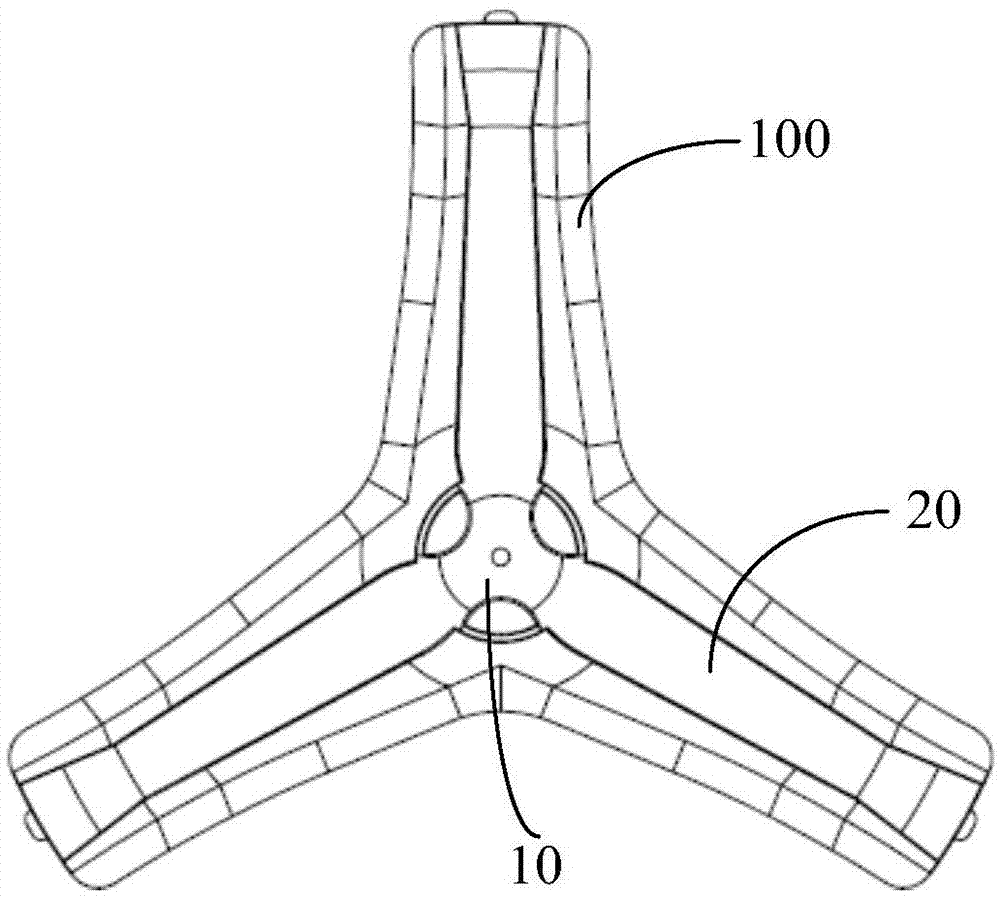

Inner barrel rack of washing machine

InactiveCN104711813AGood anti-rust and anti-corrosion propertiesSimple molding processOther washing machinesTextiles and paperCorrosionEngineering

The invention discloses an inner barrel rack of a washing machine. The inner barrel rack is fixedly arranged at the bottom of a washing machine inner barrel, and comprises a mounting portion and an extending portion extending outwards from the mounting portion, and the mounting portion and the extending portion are formed in an integrated injection molding mode through plastic particles. The inner barrel rack of the washing machine has the good rust and corrosion preventing performance, and is simple in forming technology and high in production efficiency. Material deformation is small, and meanwhile good coaxiality can be guaranteed.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

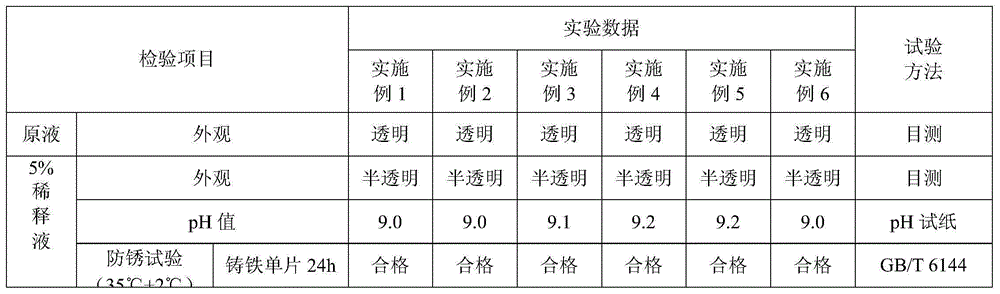

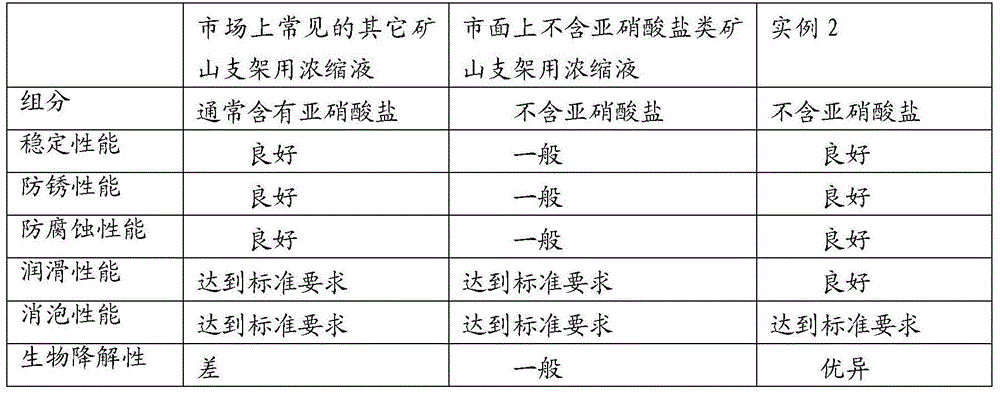

Nitrite-free concentrated solution for rapidly biodegrading mine prop and preparation method

The invention discloses a nitrite-free concentrated solution for rapidly biodegrading a mine prop and belongs to the field of mine machine application and maintenance. The concentrated solution comprises, by mass, 21% to 25% of an antirust agent packet obtained through an amidation reaction of an organic acidic compound and an alcohol amine compound, 0.5% to 0.7% of benzotriazole, 0.5% to 0.6% of an ionic surfactant, 0.8% to 0.9% of nonionic surfactant, 3% to 5% of a lubricant agent, 0.1% to 0.12% of a defoaming agent, and the balance soft water. According to the antirust agent packet, the organic acidic compound is the composition of three or more of C8-C12 monobasic saturated fatty acids, C10-C12 binary saturated fatty acids, C12-C18 unsaturated fatty acids and C18-C22 dimer acids and must contain the C18-C22 dimer acids, and the alcohol amine compound is the composition of three or more of monoethanolamine, diethanol amine, monoisopropanolamine and diglycolamine; the alcohol amine compound is excessive in the antirust agent packet.

Owner:QUAKER CHEM CHINA

Preparation method of epoxy resin long-acting anticorrosive coating

InactiveCN105440890AGood weather resistanceGood anti-rust and anti-corrosion effectAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

The invention provides a preparation method of an epoxy resin long-acting anticorrosive coating. An epoxy glass flakeheavy anticorrosive coating is obtained by mixing and curing a component A and a component B; when the epoxy glass flakeheavy anticorrosive coating provided by the invention is used for coating, the coating can be coated on the surface of a steel structure and also can be matched with epoxy zinc-enriching priming paint to be used as priming paint; when the product is used as finishingpaint to be matched, the product has good rustproof and anticorrosive performances; a detection shows that the salt mist resistance reaches 5000 hours and a paint film is not bubbled and rusted and has good weather resistance; the coating maintaining cost of the steel structure can be reduced; the production method of the epoxy glass flakeheavy anticorrosive coating, provided by the invention, does not need post-treatment, so that the process method is simple, energy sources are saved and the cost is relatively low; after the component A and the component B are uniformly mixed, the mixture can be automatically dried to form the film at a room temperature; and the product has a good film forming performance and good storage stability.

Owner:QUANZHOU NAISI MATERIAL TECH

Aluminum cleaning agent and preparation method thereof

The invention discloses an aluminum cleaning agent. The aluminum cleaning agent consists of the following raw materials in percentage by weight: 2-6% of potassium hydroxide, 2-10% of propanediol butyl ether, 1-5% of sodium metasilicate, 1-5% of boric acid, 1-7% of sodium polyacrylate, 1-5% of d-sorbitol solution, 0.4-1.2% of sodium chloride, 0.1-0.5% of dimethyl siloxane, 1-8% of anion surface active agent, 1-8% of nonion surface active agent, and the balance of water. The aluminum cleaning agent contains no such substances as phosphate and heavy metals harmful to human bodies and environments, is free of environmental pollution, is safe and reliable in use, is higher in cleaning efficiency, reaches the cleaning efficiency of 99%, meanwhile, is better in rust and corrosion resistance, is bright and smooth in cleaned aluminum workpieces, and is free of damaging the workpieces.

Owner:宁波际超新材料科技有限公司

Cutting fluid for processing cast iron and aluminum alloy mixture and preparation method thereof

InactiveCN111423928AGood anti-rust and anti-corrosion effectGood biostable formulaLubricant compositionActive agentManufactured material

The invention discloses a cutting fluid for processing a cast iron and aluminum alloy mixture and a preparation method of the cutting fluid. The product is characterized by comprising the following components in percentage by weight: 5-15% of a composite antirust preservative, 5-15% of a composite lubricant, 3-10% of organic amine, 5-15% of a surfactant, 1-3% of a hard water resistant agent, 1-5.0% of a bactericide, 20-50% of base oil, 0.1-0.5% of a defoaming agent and the balance of deionized water. After the raw materials are added according to a certain sequence and proportion, the cuttingfluid for processing the cast iron and aluminum alloy mixture can be obtained. Compared with a traditional cutting fluid system in the prior art, the cast iron and aluminum alloy mixture cutting fluidhas the characteristics of long cast iron rust prevention time, outstanding aluminum alloy discoloration prevention performance, good stability, high cost performance, easily available raw materials,no need of adding intermediates subjected to chemical reaction, simple production and preparation process, controllable production amplification process and the like.

Owner:中山仝垚润滑科技有限公司

Self-emulsified cutting fluid and preparation method thereof

InactiveCN103666719AImprove the lubrication effectGood anti-rust and anti-corrosion effectLubricant compositionButanedioic acidTrimethylolpropane

A self-emulsified cutting fluid is prepared from the following raw materials in parts by weight: 3-4 parts of sodium molybdate, 2-3 parts of disodium ethylenediamine tetraacetate, 2-3 parts of sodium silicate, 3-4 parts of linoleic acid, 1-2 parts of alkenyl butanedioic acid, 20-23 parts of soybean oil, 20-24 parts of propylene glycol, 1-2 parts of trimethylolpropane, 3-4 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ammonium persulfate, 6-8 parts of an auxiliary agent and 200 parts of water. The cutting fluid provided by the invention has excellent lubricity by employing soybean oil and has excellent antirust anti-corrosion property by employing sodium molybdate, disodium ethylenediamine tetraacetate, linoleic acid and alkenyl butanedioic acid; and the cutting fluid has no peculiar smell, no toxicity and no pollution, good stability and extremely high hard-water resistance, and is suitable for cutting processing of various aluminium, magnesium alloy, cast iron and stainless steel.

Owner:MAANSHAN HENGYI MACHINERY MFG

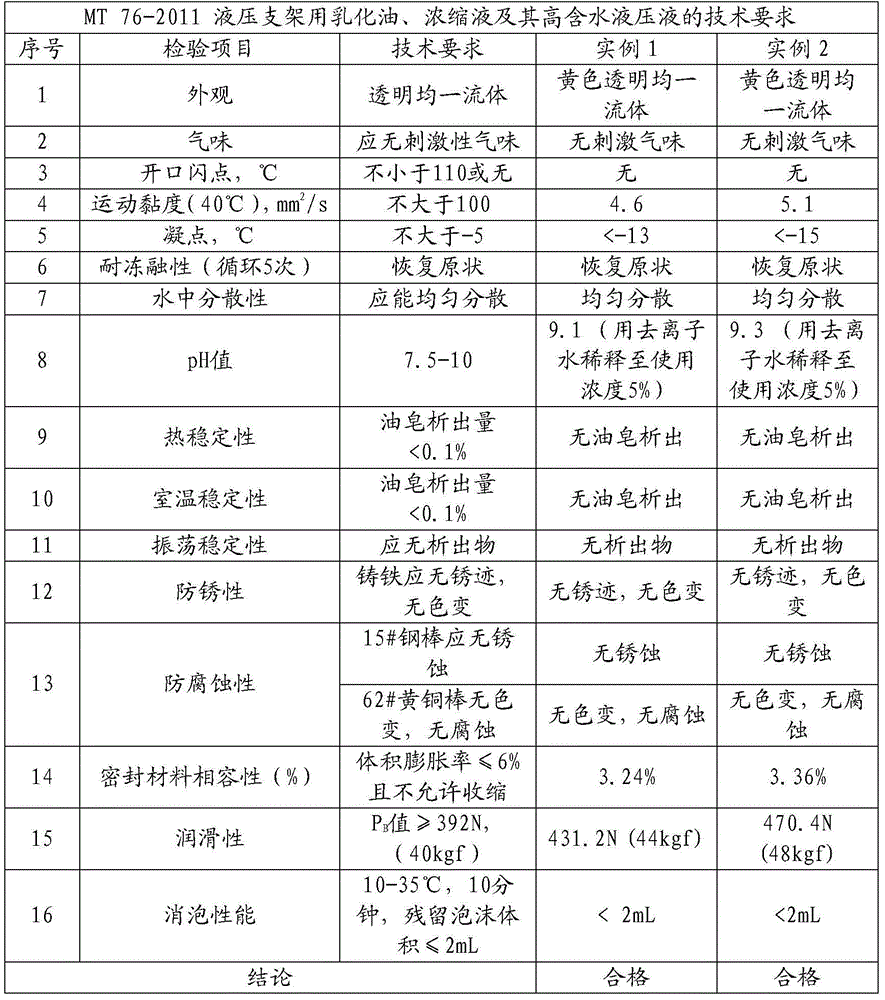

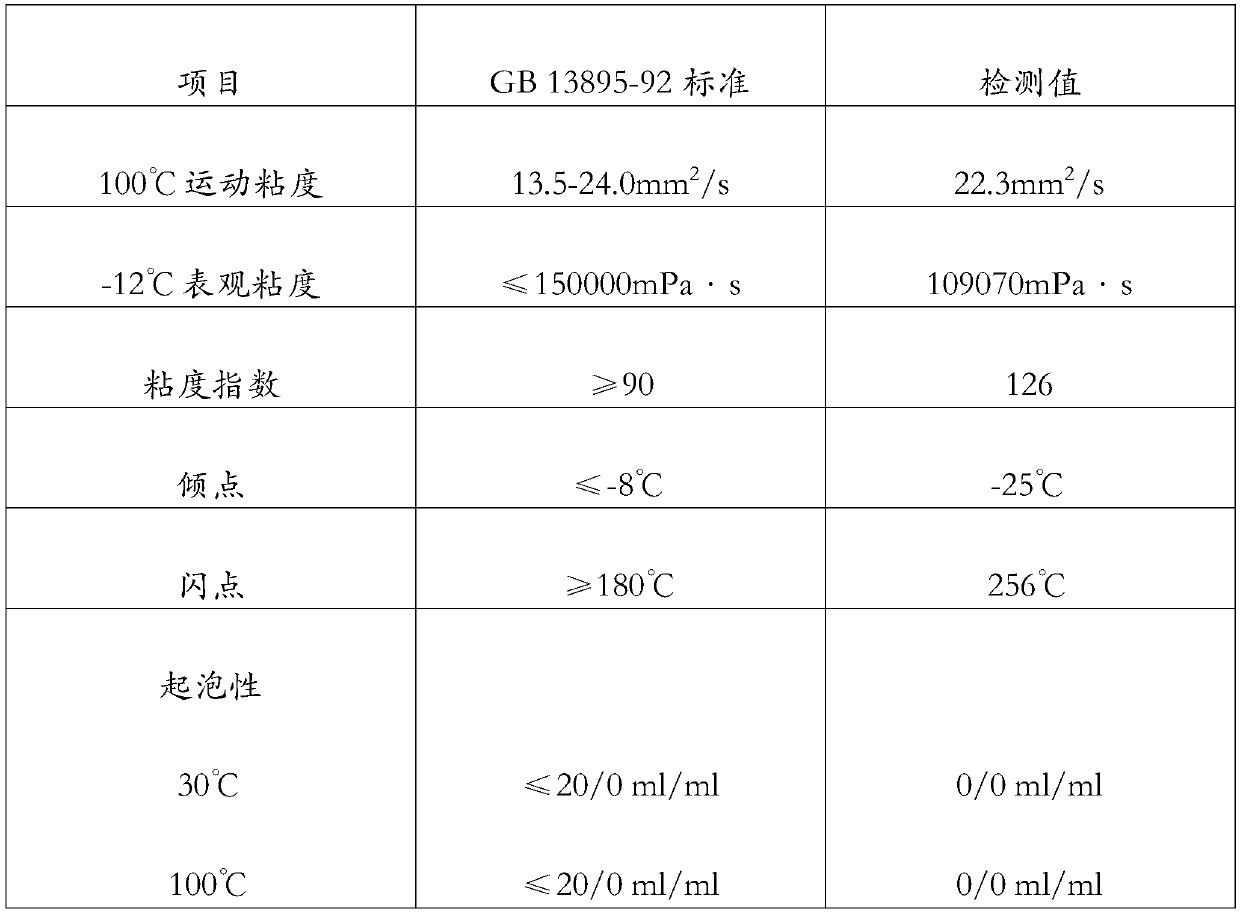

Emulsified oil for hydraulic bracket and production technology of emulsified oil

InactiveCN107287009AImprove performanceGood emulsifying effectLubricant compositionFreeze thawingOleic Acid Triglyceride

The invention discloses emulsified oil for a hydraulic bracket and a production technology of the emulsified oil. The emulsified oil for the hydraulic bracket is prepared from the following substances: mineral base oil, oleic acid, triethanolamine, petroleum sodium sulfonate, benzotriazole, glycerin, S-80, Op-10, urea, EDTA, sodium hydroxide and the balance of water. The emulsified oil is stable in performance, good in emulsifying effect, free of separation of dirts, such as oil and soap and longer in service time, has good freeze-thaw stability, anti-wear and anti-extreme pressure properties and anti-rust and anti-corrosive properties and can meet the requirements of use of the hydraulic bracket under a harsh work condition, a long-term use system is clean, the whole system normally runs, the hydraulic bracket does not have the phenomenon of slow action, operation is safe and accurate and the production efficiency is improved.

Owner:山东天力润滑油有限公司

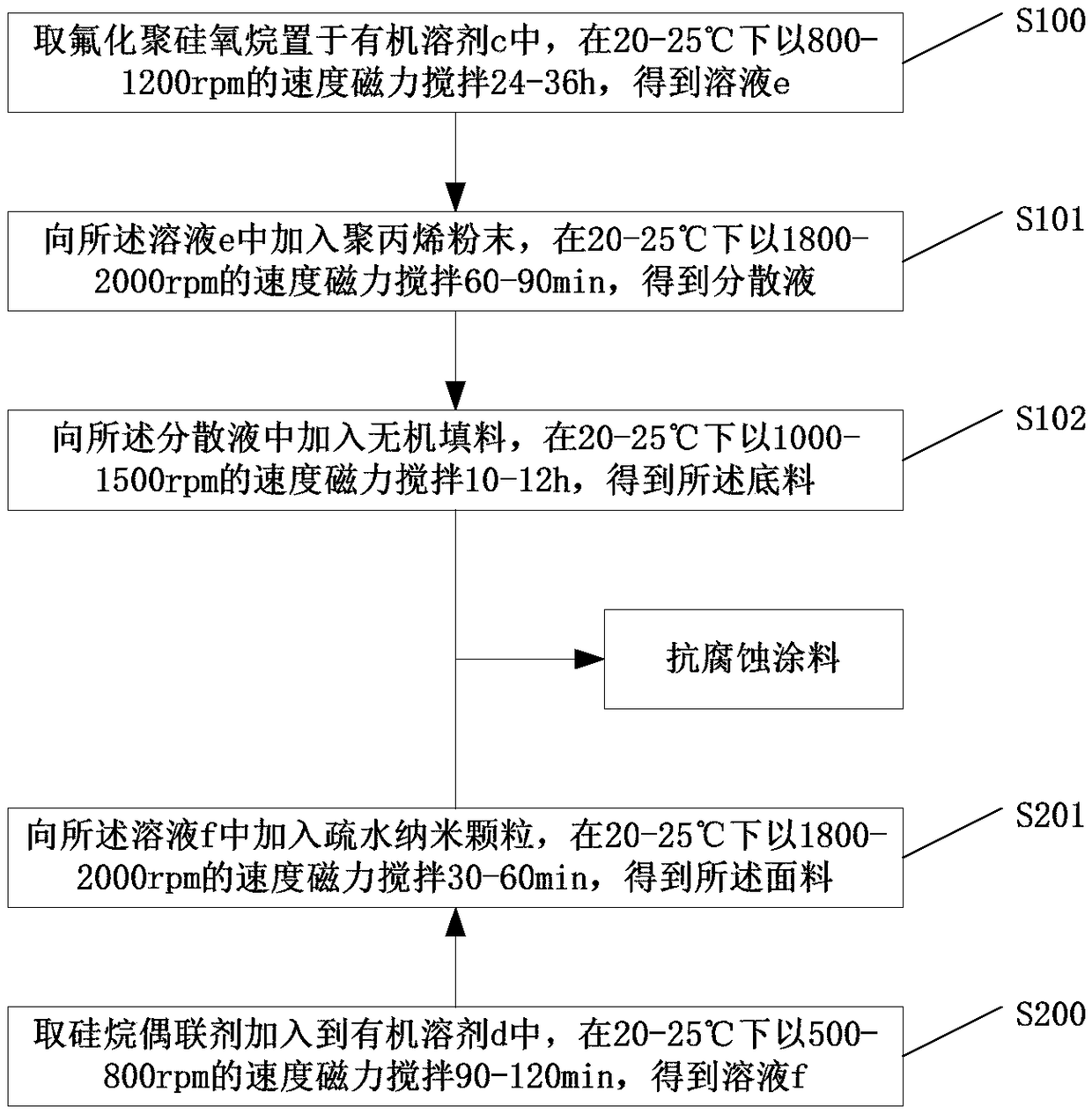

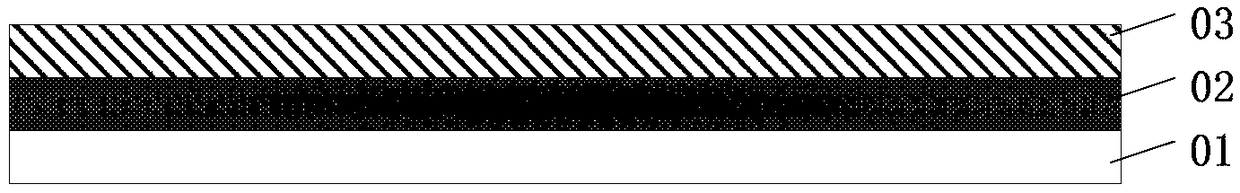

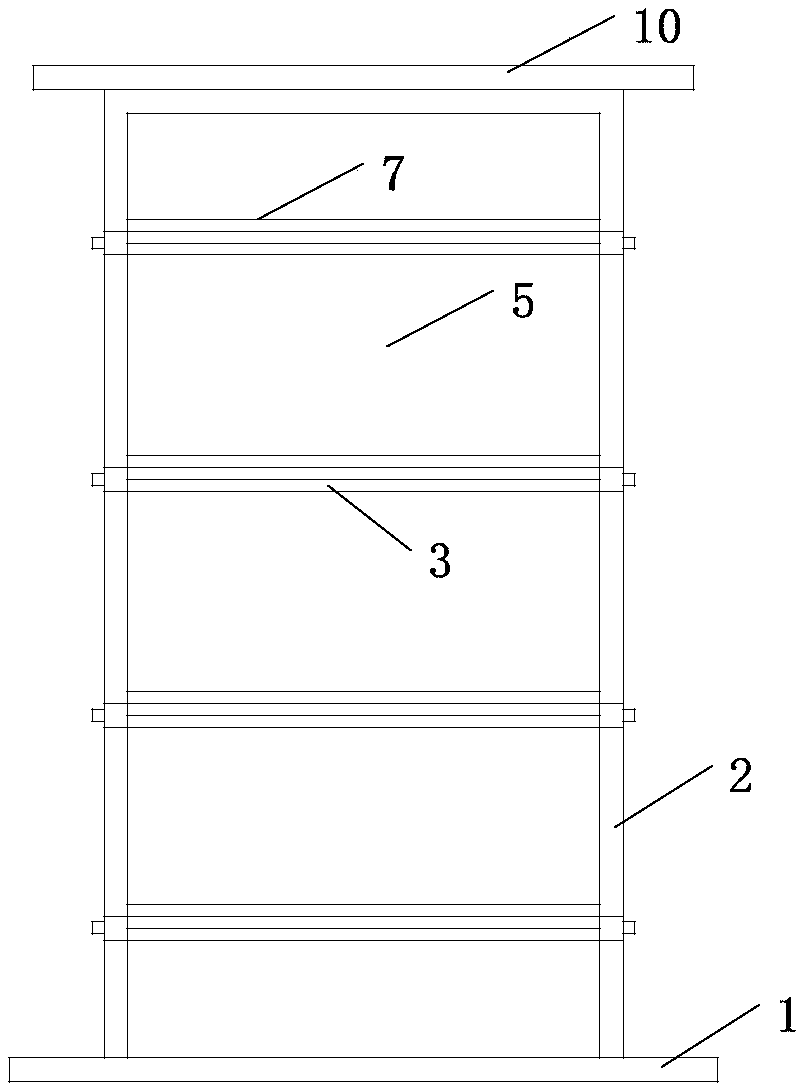

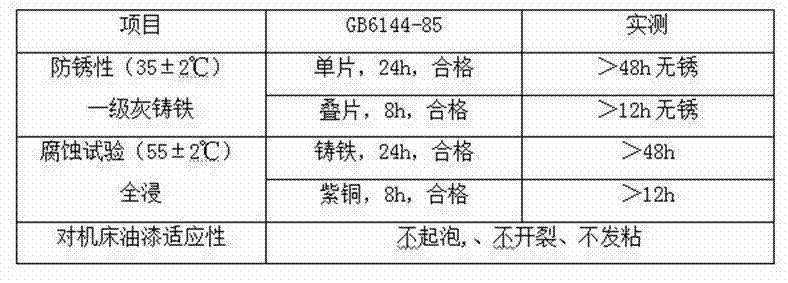

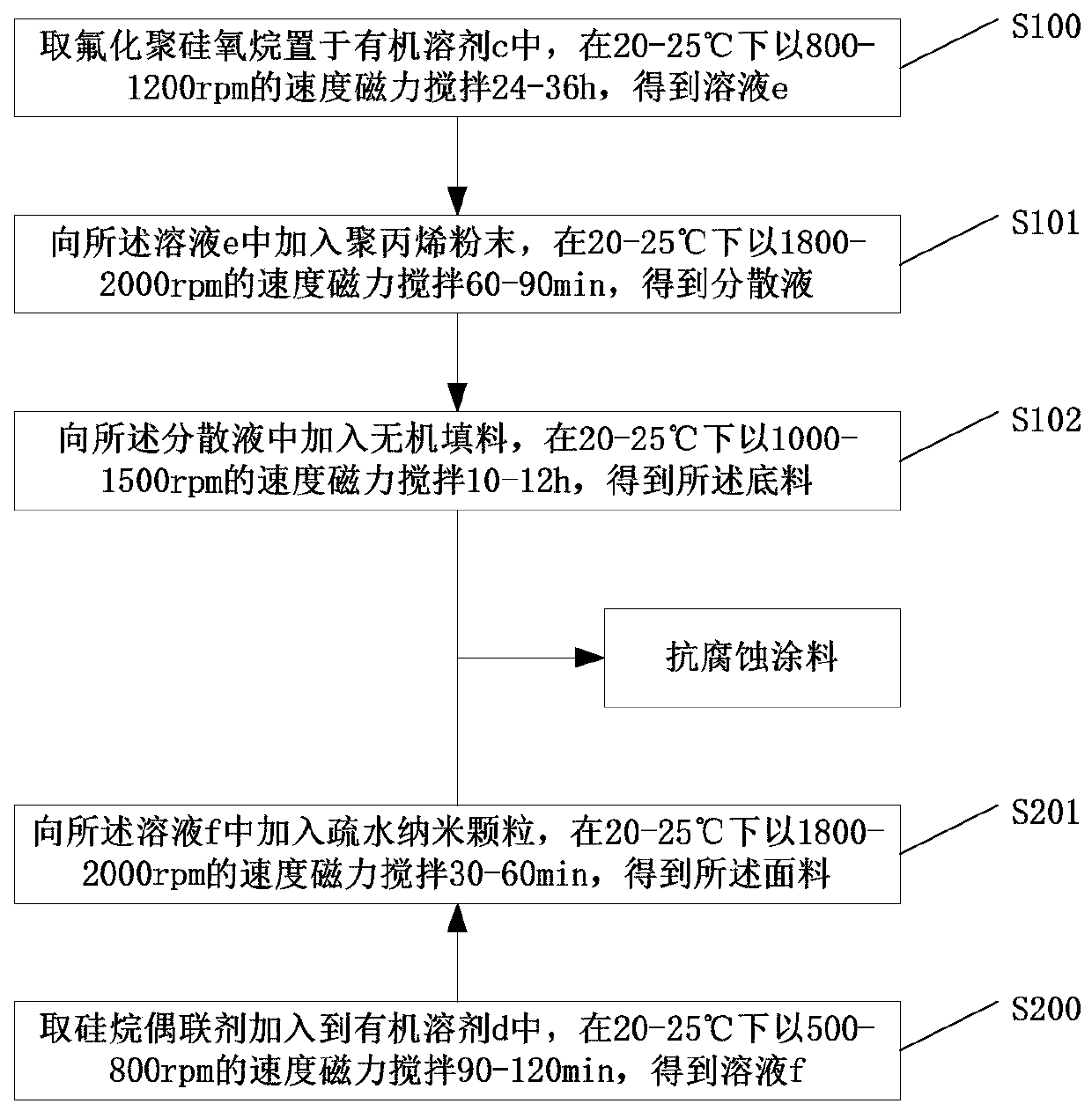

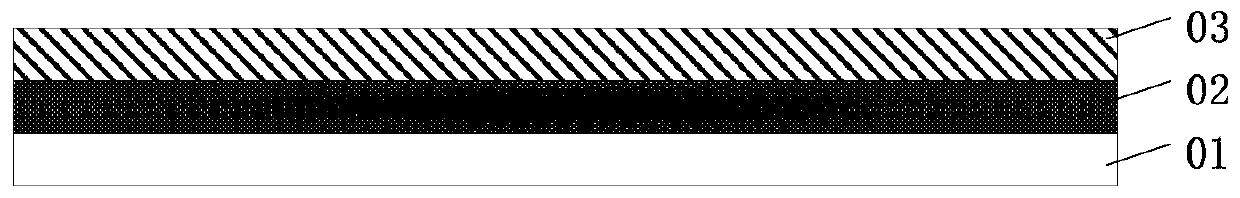

Preparation method, coating construction method and use of anti-corrosion coating and display frame

ActiveCN108997931AImprove wear resistanceImprove hydrophobicityAnti-corrosive paintsSilane couplingMicron scale

The invention provides a preparation method of an anti-corrosion coating. Through fluorinated polysiloxane in the primer, the anti-corrosion coating has good adhesion to a base and has good hydrophobicity. An inorganic filler can enhance the corrosion resistance of the anti-corrosion coating and provide a micron-scale surface. Nanometer hydrophobic particles in a fabric can enhance the hydrophobicity of the anti-corrosion coating. The nanometer particles interpenetrate with the micron-scale surface in the primer so that an uneven microscopic hydrophobic structure is formed and the hydrophobicity is further improved. The silane coupling agent can enhance the identity of the nanometer hydrophobic particles and the system so that dispersion is more uniform. The invention also provides a multifunctional anti-corrosion display frame. The interiors of mounting holes and through holes of the display frame are spray-coated with anti-corrosion coatings for preventing rust corrosion caused by long-term retention of water and prolonging the service life of the display frame.

Owner:常州市筑友展示科技股份有限公司

Rust-proof and corrosion-resistant paint for steel

InactiveCN109971301AGood anti-rust and anti-corrosion effectImprove antioxidant capacityAnti-corrosive paintsEpoxy resin coatingsFiberEpoxy

The invention discloses a rust-proof and corrosion-resistant paint for steel. The paint is a composite paint prepared from multiple raw materials, and the paint is composed of, by weight, 20%-30% of epoxy resin, 10%-12% of a waterborne epoxy curing agent, 10%-20% of polystyrene and 5%-9% of ethylene glycol monomethyl ether, 4%-6% of calcium stearate, 2%-8% of lanolin magnesium soap, 5%-8% of polyacrylonitrile fiber, 7%-9% of an antioxidant, 4%-6% of aluminum tripolyphosphate, 5%-7% of zinc phosphate, 1%-3% of an additive, and the balance water. The invention has the beneficial effects that: the paint can endow steel with better rust resistance and corrosion resistance and stronger oxidation resistance after coating on the steel, can greatly enhance the service life of steel, has good market prospects, and is easy to popularize.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD

Easy-clean cutting fluid with uniformly dispersed grinding material and preparation method thereof

The invention discloses an easy-clean cutting fluid with a uniformly dispersed grinding material. The invention is characterized in that the cutting fluid is prepared from the following raw materials in parts by weight: 2-3 parts of citric acid, 4-6 parts of fatty alcohol polyethenoxy ether, 2-3 parts of benzotriazole, 1.5-2.5 parts of ethylene glycol monobutyl ether, 3-5 parts of oleic acid, 3.5-4.5 parts of polyvinyl alcohol, 1-2 parts of oleamide, 9-12 parts of nano silicon dioxide, 2-3 parts of diethanolamine oleate, 5-7 parts of assistant and 200 parts of deionized water. The nano silicon dioxide and surfactant are uniformly mixed by grinding, so that the grinding material is dispersed uniformly and has stable and uniform quality; the assistant enhances the wear resistance, dispersity, lubricating property and film formation property, so that the processed workpiece has smooth surface and no damage; and the cutting fluid has the advantages of excellent lubricating property, excellent cleaning property and excellent rust and corrosion resistance, and is suitable for processing silicon chips.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Bad-flavor-free multifunctional electric power equipment casing rust-resisting paint preparation method thereof

InactiveCN104513587AImprove adhesionGood film formingAnti-corrosive paintsPolyether coatingsPolymer scienceAluminum silicate

The invention discloses a bad-flavor-free multifunctional electric power equipment casing rust-resisting paint characterized by comprising the following components by weight: 2-3 parts of polycaprolactone, 1-2 parts of sodium benzoate, 2-4 parts of iron carbonate, 0.2-0.3 part of vanillin, 6-9 parts of silicone acrylic emulsion, 4-6 parts of precipitated barium sulfate, 4-6 parts of mica iron oxide, 0.4-0.6 part of polyoxyethylated castor oil, 1-2 parts of zinc stearate, 1-2 parts of dibutyl phthalate, 32-37 parts of epoxy resin, 3-5 parts of aluminium silicate, 1-2 parts of crosslinking agent TAIC (triallyl isocyanurate), 22-26 parts of diphenyl oxide resin, 0.5-1.0 part of dodecencylsuccinic acid, 10-14 parts of xylene, 5-7 parts of butyl acetate and 4-7 parts of an additive; the bad-flavor-free multifunctional electric power equipment casing rust-resisting paint has high adhesion and good film forming effect, the paint film is flexible and hard, the added vanillin and silicone acrylic emulsion can improve paint bad flavor to make the flavor pleasant and easy to accept, the bad-flavor-free multifunctional electric power equipment casing rust-resisting paint has good water, rust and corrosion resistance and high aging resistance, the added additive also has the noise reduction effect to improve impact of noise produced by the work of electric power equipment on the people's physical and mental health.

Owner:BENGBU NANZI INSTR

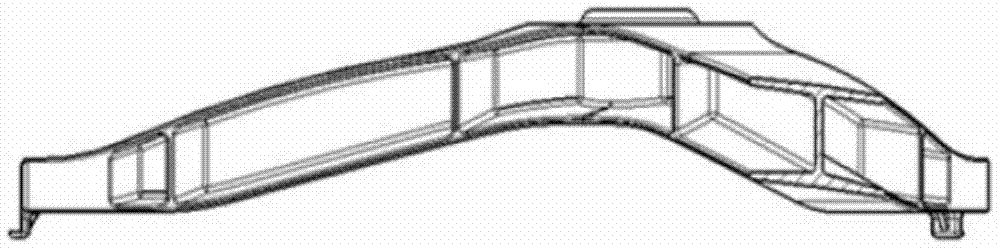

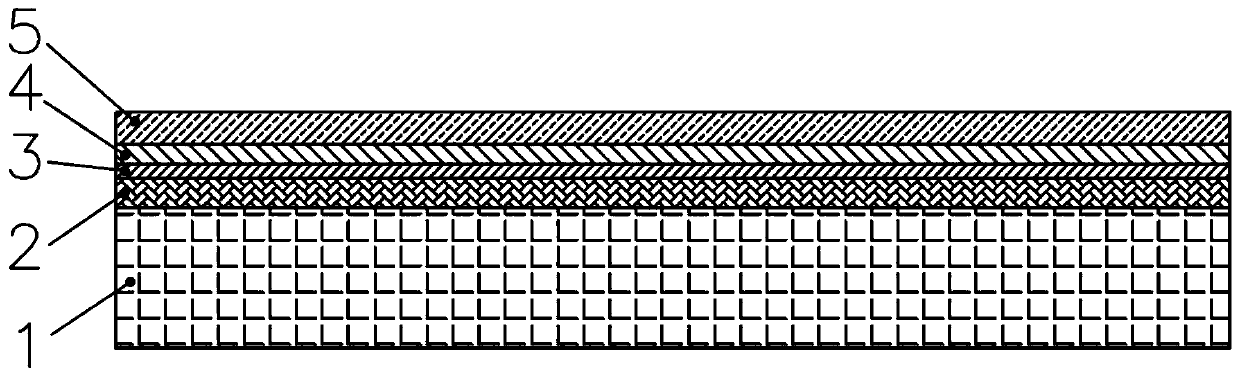

Efficient fireproof heat-insulating coating layer for special compartment or shelter

ActiveCN110746856AThe overall thickness is thinReduce weightFireproof paintsEpoxy resin coatingsFoaming agentCarbonization

The invention provides an efficient fireproof heat-insulating coating layer for a special compartment or shelter, wherein the coating layer is coated on the outer wall of a compartment or shelter steel plate (1), and an antirust matrix layer (2), a heat-insulating functional layer (3), an anti-burning functional layer (4) and a protective finish paint layer (5) are sequentially arranged on the outer wall of the compartment or shelter steel plate (1). The heat-insulating functional layer (3) is composed of a film forming matter a, a low-heat-conductivity-coefficient filler and a functional additive; the anti-burning functional layer (4) is composed of a film forming matter b, a dehydrating agent, a carbon forming agent and a foaming agent. Under the conventional working condition, the structure has the advantages of small thickness, light weight and no influence on the overall performance of an automobile; under flame burning, foaming and carbonization can be rapidly carried out, the foaming ratio is 40-50 times, and the coating layer is compact in structure, small in porosity, high in bonding strength, not prone to falling off, good in fireproof and heat-insulating effects and goodin rust-proof and corrosion-proof performance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

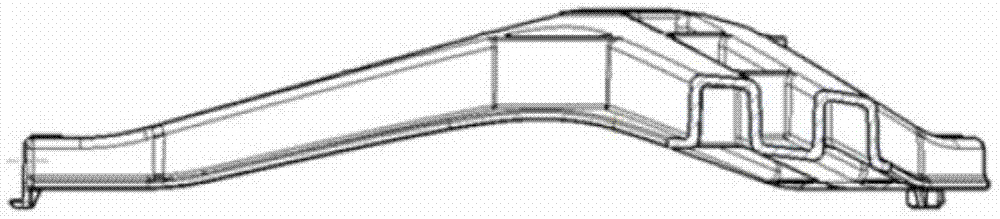

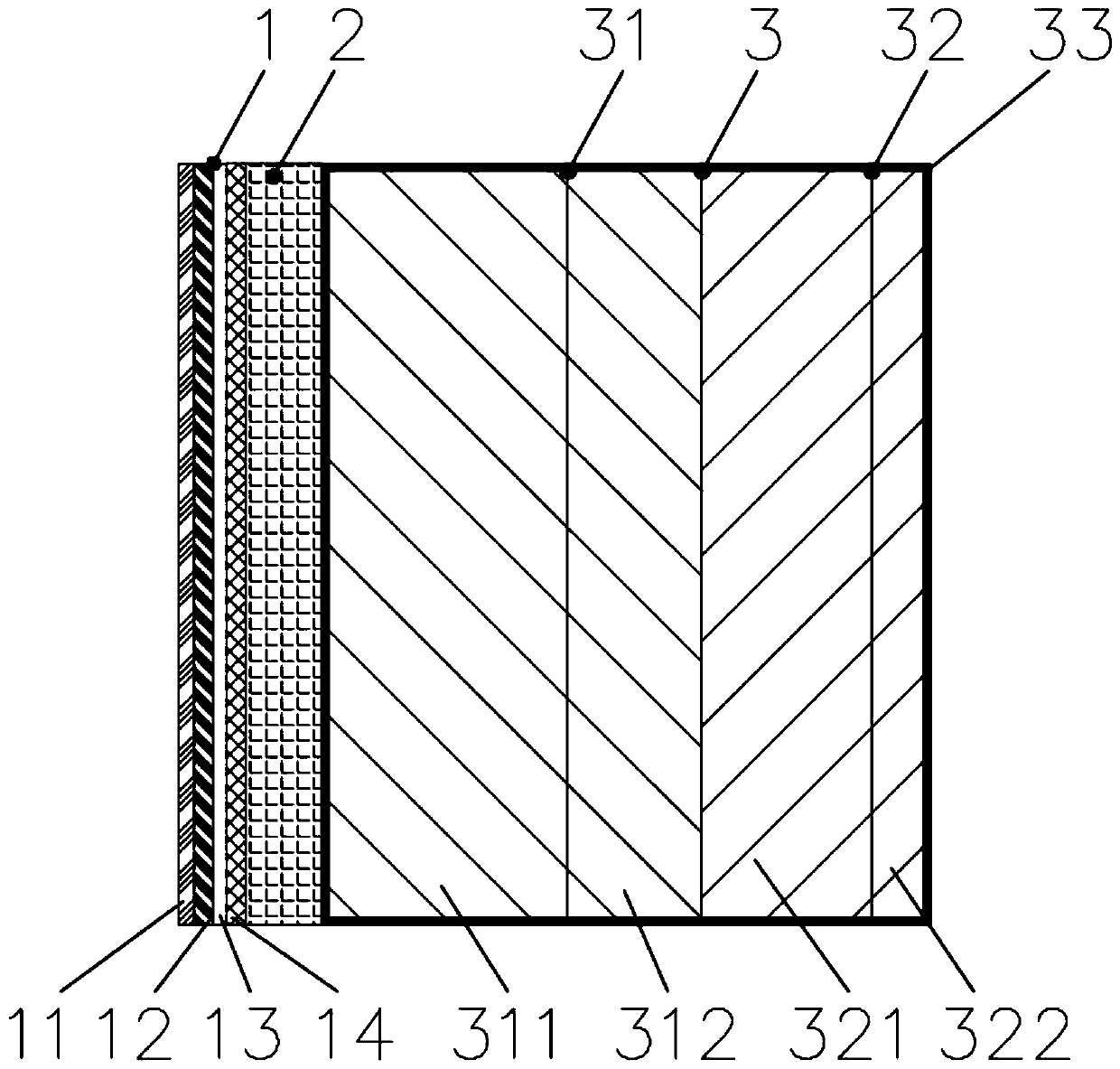

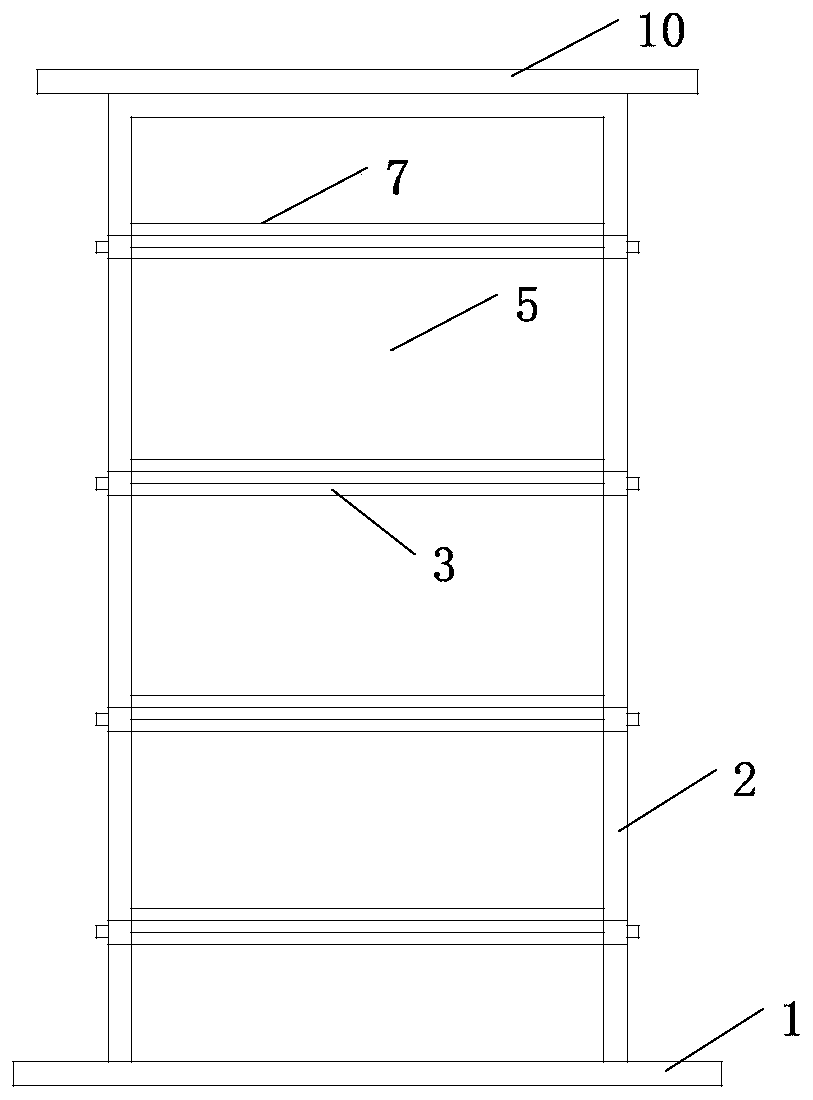

Fireproof thermal-insulation functional material and structure for special carriages

ActiveCN110843286AThe overall thickness is thinReduce weightAnti-corrosive paintsVehicle componentsFiberInsulation layer

The invention discloses a fireproof thermal-insulation functional material and a structure for special carriages. The fireproof thermal-insulation functional material sequentially comprises a fireproof thermal insulation layer (1), a carriage or shelter body steel plate (2) and a thermal insulation layer (3) from the outside of a carriage or a shelter to the inside of the carriage or the shelter,wherein the fireproof thermal insulation layer (1) is composed of a protective finish paint layer (11), an anti-burning functional layer (12), a heat insulation functional layer (13) and a rust-proofbase body layer (14); the thermal insulation layer (3) is composed of a high-temperature-resistant thermal-insulation layer (31) composed of a high-thermal-resistance layer (312), and a high-reflection layer a (311), and a low-heat-conduction thermal-insulation layer (32) composed of a high-heat-resistance layer a (322) and a high-reflection layer b (321); and the periphery of a multi-layer structure composed of the high-temperature-resistant thermal-insulation layer (31) and the low-heat-conduction thermal-insulation layer (32) is wrapped with fiber cloth (33). The structure is good in fireproof performance, good in heat insulation effect, high in efficiency, small in thick bottom, low in weight, tight in connection of all layers and not prone to falling off.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Emulsified oil for mining hydraulic support

ActiveCN103937592ANo pollution in the processReduce sluggishnessLubricant compositionGlycol synthesisPetroleum oil

The invention provides an emulsified oil for a mining hydraulic support. The emulsified oil is composed of the following substances in percentage by weight: 15.0%-20.0% of mineral base oil, 8.0%-10.0% of boric acid, 10.0%-12.0% of triethanolamine, 10.0%-11.0% of petroleum sodium sulfonate, 0.5%-0.8% of benzotriazole, 20.5%-22.5% of ethylene glycol, 13.5%-15.5% of urea, 6.0%-8.0% of EDTA (Ethylene Diamine Tetraacetic Acid)-tetra sodium, 1.0%-1.5% of sodium hydroxide and the balance of water. The emulsified oil has excellent freeze-thaw property, wear resistance, extreme pressure resistance, and rust and corrosion resistance, and thus is capable of satisfying the use of the hydraulic support under the conditions of an underground severe environment.

Owner:特浦朗克材料科技(营口)股份有限公司

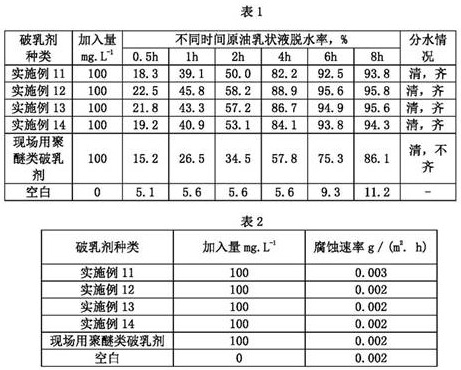

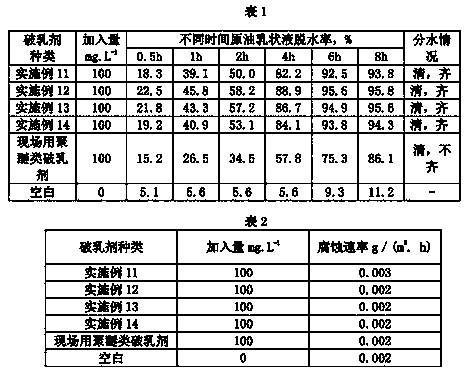

Demulsifier for treating heavy oil and preparation method thereof

ActiveCN109609178BFast demulsificationImprove water qualityDewatering/demulsification with chemical meansAlkaneDemulsifier

The invention relates to the technical field of petroleum demulsifiers and their preparation, and relates to a demulsifier for treating heavy oil and a preparation method thereof. The raw materials of the former include polyoxyethylene polyoxypropylene block copolymers, ketoacids, acetylenic alcohols and water. The oxyethylene polyoxypropylene block copolymer is mixed and dissolved with keto acid, acetylenic alcohol and water after being heated in a reactor to obtain a demulsifier for treating heavy oil. The demulsifier for treating heavy oil of the present invention has the characteristics of fast demulsification speed and good water quality after separation, especially can solve the corrosion problem of equipment containing acid demulsifier products, and has better antirust and anticorrosion effects. The preparation process of the present invention is simple, convenient for large-scale production, and the demulsifier for treating heavy oil has excellent demulsification effect and dehydration performance. At the same time, the raw materials do not contain sulfur, phosphorus, aromatic rings, chlorine and other substances harmful to human body and environment, which meet the requirements of The concept of safe and environmentally friendly production.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

Anti-rust anti-corrosion coating

InactiveCN108300113ALow viscosityReduce manufacturing costFireproof paintsAnti-corrosive paintsRustChemistry

The invention provides an anti-rust anti-corrosion coating. The anti-rust anti-corrosion coating comprises the following raw materials by weight: 10-19 parts of epoxy resin, 5-12 parts of polyurethaneresin, 2-8 parts of butylated amino resin, 5-9 parts of aliphatic glycidyl ether phenolic resin, 1-5 parts of polyamide resin, 2-7 parts of iron oxide, 1-2 parts of titanium dioxide, 5-8 parts of mica powder, 4-9 parts of lithium silicate, 2-7 parts of nanometer calcium carbonate and 2-5 parts of carboxymethyl cellulose. The coating of the invention has good high-temperature resistance, cold resistance, corrosion resistance, wear resistance, etc. and is applicable to harsh environments; and the coating has strong rust prevention ability, low production cost, good adhesion, toughness, wear resistance, and acid and alkaline resistance, a fast drying speed, effectively improved corrosion resistance.

Owner:丹阳市海信涂料化工厂

Preparation method of anti-corrosion coating, coating construction method and its application and display stand

ActiveCN108997931BImprove hydrophobicityImprove wear resistanceAnti-corrosive paintsMicron scaleSilanes

The invention provides a preparation method of an anti-corrosion coating. Through fluorinated polysiloxane in the primer, the anti-corrosion coating has good adhesion to a base and has good hydrophobicity. An inorganic filler can enhance the corrosion resistance of the anti-corrosion coating and provide a micron-scale surface. Nanometer hydrophobic particles in a fabric can enhance the hydrophobicity of the anti-corrosion coating. The nanometer particles interpenetrate with the micron-scale surface in the primer so that an uneven microscopic hydrophobic structure is formed and the hydrophobicity is further improved. The silane coupling agent can enhance the identity of the nanometer hydrophobic particles and the system so that dispersion is more uniform. The invention also provides a multifunctional anti-corrosion display frame. The interiors of mounting holes and through holes of the display frame are spray-coated with anti-corrosion coatings for preventing rust corrosion caused by long-term retention of water and prolonging the service life of the display frame.

Owner:常州市筑友展示科技股份有限公司

Anti-rust insect-repelling coating

InactiveCN108300116AEasy to filmStrong rust resistanceAntifouling/underwater paintsPaints with biocidesEpoxyPumpkin seed

The invention relates to an anti-rust insect-repelling coating. The anti-rust insect-repelling coating comprises the following raw materials by weight: 10-18 parts of epoxy resin, 1-5 parts of phenolic resin, 2-9 parts of alkyd resin, 4-8 parts of polyamide resin, 3-10 parts of iron oxide, 4-9 parts of titanium dioxide, 2-5 parts of mica powder, 1-6 parts of antimony trioxide, 1-8 parts of lithiumsilicate, 1-2 parts of lavender, 3-5 parts of lemon-scented gum, 2-4 parts of lemongrass, 5-9 parts of mint, 1-2 parts of tuberose, 1-2 parts of ephedra stem oil, 1-4 parts of gentian, 1-5 parts of sophora buds, 3-6 parts of toosendan fruit, 4-6 parts of Fructus Ulmi, 7-9 parts of mint, 6-8 parts of betel nuts, 2-5 parts of pumpkin seeds and 4-9 parts of gentian. The anti-rust insect-repelling coating of the invention is simple in composition and reasonable in proportion, and has good corrosion resistance, good anti-rust capability, no toxicity, no side effect, obvious use effect, and environmental protection performance.

Owner:丹阳市海信涂料化工厂

Modified gear oil and production method thereof

InactiveCN109679735AAdequate extreme pressure and wear resistanceGood demulsibilityLubricant compositionDemulsifierMethods of production

The invention discloses modified gear oil and a production method. The modified gear oil is prepared from the following raw materials: base oil, an oxidation and corrosion inhibitor, an antirusting agent, an extreme pressure antiwear additive, a metal passivator, a demulsifier, vegetable gum and a thickener. The modified gear oil disclosed by the invention has the beneficial effects that the modified gear oil is formed by compounding the high-quality base oil with a novel environment-friendly gear additive; all raw materials of the modified gear oil are organically combined together, so that the modified gear oil has enough extreme pressure antiwear property, good demulsibility and good rust and corrosion resistance. In addition, the modified gear oil disclosed by the invention has betterviscidity, improves the strength of an oil film and enhances the performance of gear oil; bearing capacity of the gear oil can be greatly improved, the influence of a traditional lead-containing formula on the health of an operation worker is avoided, the service life of an oil product can be greatly prolonged, the oil change frequency is reduced, and the cost of enterprises is reduced.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

Improved gear oil composition

InactiveCN104673450AThe formula is scientific and reasonableExtended service lifeLubricant compositionParaffin waxLubrication

The invention discloses an improved gear oil composition which is prepared from the following raw materials in parts by weight: 36-44 parts of 38# cylinder oil, 0.5-0.9 part of BHT (butylated hydroxytoluene) antioxidant, 3-6 parts of di-n-butyl phosphite, 2-8 parts of sulfur-phosphorous butyl octanol zinc salt, 0.6-0.9 part of sodium petroleum sulfonate, 3-8 parts of chlorinated paraffin wax, 9-15 parts of dithiodipropionate, 5-15 parts of p-phenylenediamine, 5-15 parts of dibenzyl disulfur, 4-12 parts of polydimethylsiloxane, 9-16 parts of benzotriazole, 15-25 parts of synthetic oil and 3-12 parts of graphite. The improved gear oil composition can achieve maximum nonseizure load for lubrication and reduce the sintering load and comprehensive abrasion by reducing the abrasion loss of the automobile gear, and has the advantages of excellent abrasion resistance, excellent corrosion resistance and excellent rust resistance.

Owner:QINGDAO KERUN PLASTIC MACHINERY

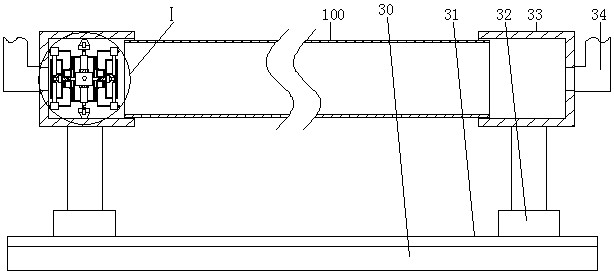

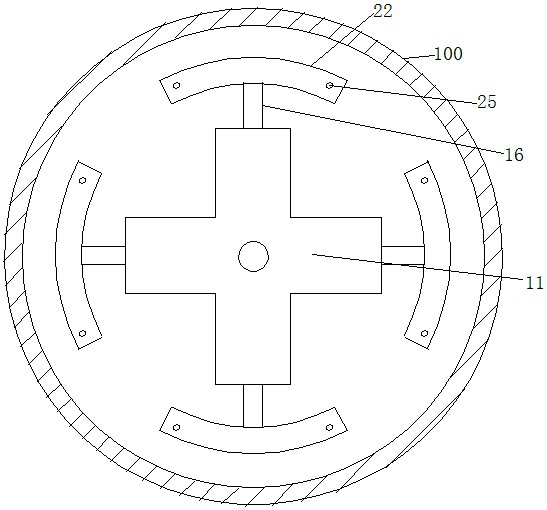

A semi-enclosed space coating equipment for building industrialization

ActiveCN113477447BSmooth painted surfaceNot easy to fall offGrinding carriagesRevolution surface grinding machinesArchitectural engineeringStructural engineering

A semi-enclosed space coating equipment for construction industrialization, including a pipe clamping device, a pipeline internal walking device and a pipe inner wall coating device, the pipe clamping device can clamp and loosen the pipe, and the pipe inner wall coating device includes pipe inner wall grinding Department, pipeline inner wall spraying department, while the pipeline internal walking device reciprocates inside the pipeline, the pipe inner wall coating device can sequentially polish and spray the inner wall of the pipeline. In the present invention, the pipe is clamped by the pipe clamping device. The internal walking device of the pipe and the pipe inner wall coating device are located on the inner side of the pipe. Through the use of the present invention, the steps of first polishing and then spraying make the painting surface of the pipe inner wall smoother. The coating layer is not easy to fall off, has a longer service life, better anti-rust and anti-corrosion effects, and does not need the internal running device of the pipeline to return to its original position before processing the replaced pipe, which improves the spraying processing efficiency.

Owner:浙江中垚建设有限公司

A kind of emulsified oil for mine hydraulic support

ActiveCN103937592BNo pollution in the processReduce sluggishnessLubricant compositionGlycol synthesisPetroleum oil

The invention provides an emulsified oil for mine hydraulic support, which is composed of the following substances according to the mass percentage: 15.0%-20.0% of mineral base oil, 8.0%-10.0% of boric acid, 10.0%-12.0% of triethanolamine, and 10.0% of sodium petroleum sulfonate %~11.0%, benzotriazole 0.5%~0.8%, ethylene glycol 20.5%~22.5%, urea 13.5%~15.5%, EDTA-tetrasodium 6.0%~8.0%, sodium hydroxide 1.0%~1.5% , The balance is water. The emulsified oil has good freeze-thaw properties, anti-wear, anti-extreme pressure, anti-rust and anti-corrosion properties, and can meet the conditions of the hydraulic support in the harsh environment of the underground.

Owner:特浦朗克材料科技(营口)股份有限公司

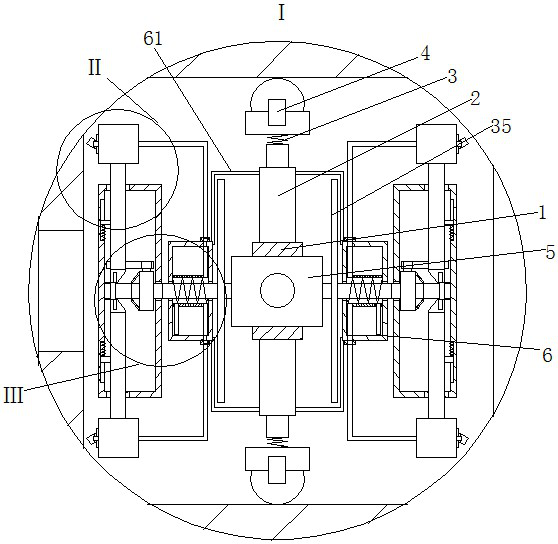

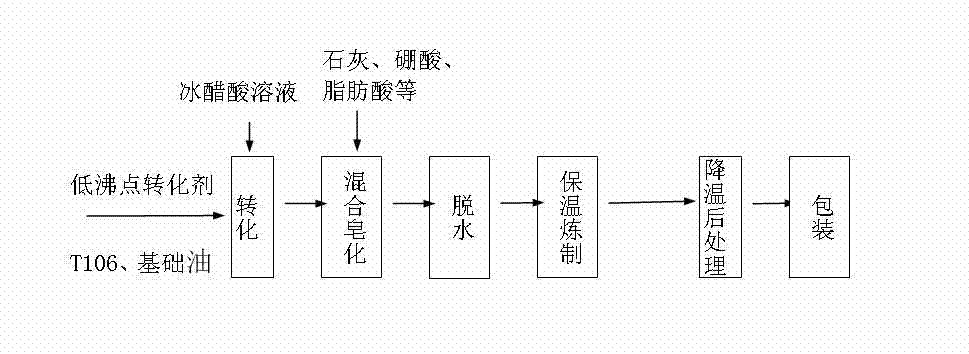

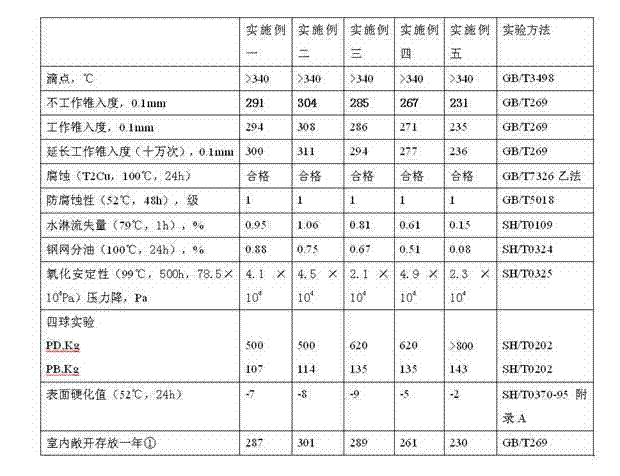

Calcium sulfonate complex grease and preparation method thereof

InactiveCN101935578BImprove Oxidation StabilityPrevent precipitationLubricant compositionFatty acidAlkylbenzenes

The invention discloses calcium sulfonate complex grease and a preparation method thereof. The calcium sulfonate complex grease comprises the following components in percentage by weight: 15 to 50% of high-alkalinity sulfonate, 21 to 83.7% of base oil, 1 to 5% of conversion accelerating agent, 0.1 to 4% of glacial acetic acid, 0 to 4% of alkyl benzene sulfonic acid calcium salt, 0.1 to 4% of lime, 0.1 to 4% of boric acid and 0 to 4% of fatty acid and 0 to 4% of aromatic acid. The alkyl benzene sulfonic acid or alkyl benzene sulfonate is seleceted from the group of one or more than one C6 to C16 alkyl benzene sulfonic acid calcium salt, or heavy alkyl benzene sulfonic acid calcium salt. The preparation method comprises the steps of: uniformly stirring the high-alkalinity sulfonate, the conversion accelerating agent and partial base oil by utilizing an ordinary pressure kettle; then adding a glacial acetic acid water solution at normal temperature, fast stirring, heating to 60 to 100DEG C and maintaining the reaction for 30 to 90min; adding a lime emulsion, a boric acid hydrothermal solution, the alkyl benzene sulfonic acid or alkyl benzene sulfonate, the fatty acid and / or aromatic acid and maintaining the temperature to 90 to 120 DEG C and the reaction for 30 to 90min; dewatering, heating to 130 to 160 DEG C, and keeping the reaction for 10 to 30min; and cooling and carrying out postprocessing. The invention can ensure that the products can be settled for a long term without hardening; the preparation technology is simple; and the preparation method has no special requirement on equipment.

Owner:长沙众城石油化工股份有限公司

Epoxy glass flake heavy-duty coating and preparation method thereof

ActiveCN102344739BGood weather resistanceGood anti-rust and anti-corrosion effectAnti-corrosive paintsEpoxy resin coatingsEpoxyWeather resistance

The invention relates to an anti-corrosion coating, in particular to an epoxy glass flake heavy-duty coating and a preparation method thereof. The epoxy glass flake heavy-duty coating is prepared by mixing and curing a component A and a component B. The epoxy glass flake heavy-duty coating can be coated on the surface of a steel structure, and can be taken as a primer together with an epoxy zinc-rich primer. When taken as a finish coat, the anti-corrosion coating has high antirust and anti-corrosion performance. As proved by detection, a paint film does not become foamed or rusty when the salt spray resistance reaches 5,000 hours and has high weather resistance, and the coating and maintaining costs of a steel structure can be lowered. The production method of the epoxy glass flake heavy-duty coating does not need post-treatment, so that the process method is simple, energy is saved, and the cost is low. The component A and the component B can be automatically dried into a film at normal temperature after being uniformly mixed, so that high film forming performance is realized, and the product has high storing stability.

Owner:浙江钱浪涂料科技有限公司

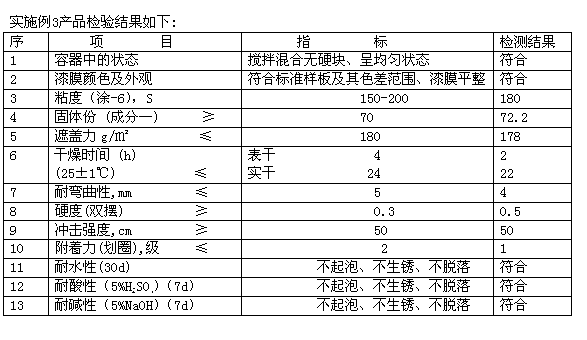

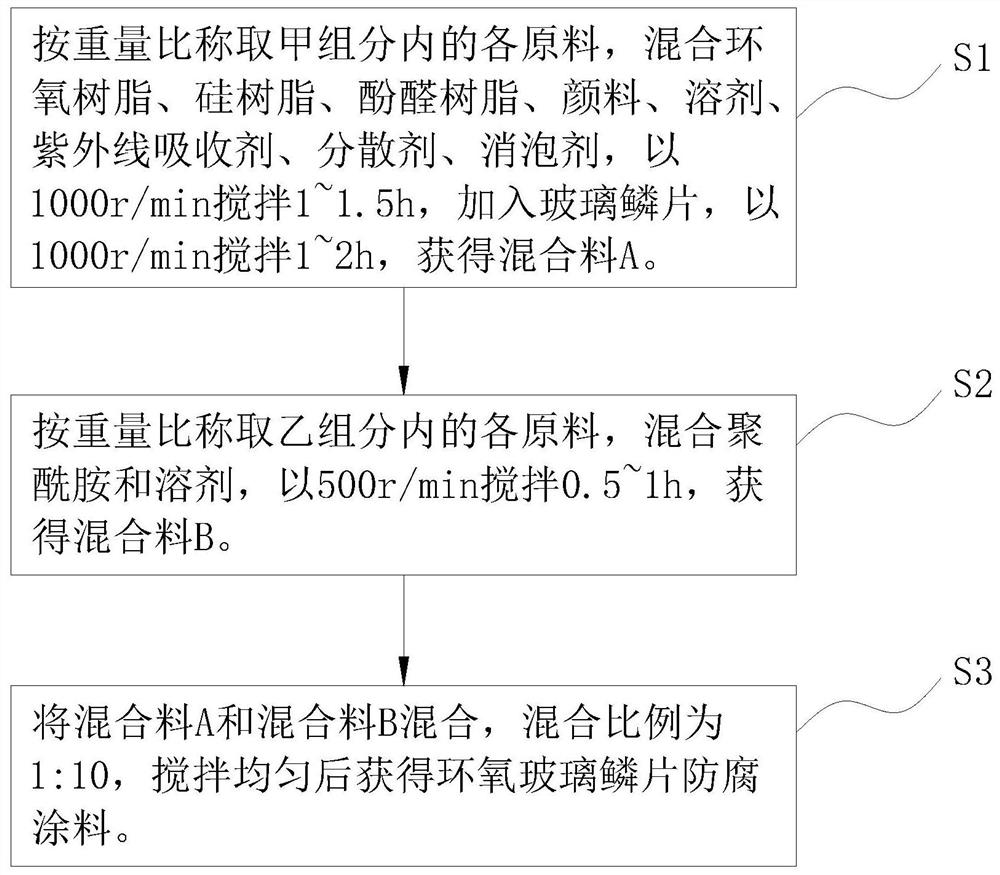

Epoxy glass flake anticorrosive paint and preparation method thereof

InactiveCN112266702AImprove heat resistanceImprove temperature resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention is applicable to the technical field of anticorrosive coatings, and provides an epoxy glass flake anticorrosive coating and a preparation method thereof.The anticorrosive coating comprises a component A and a component B. The component A comprises, by weight, 15-20 parts of epoxy resin, 5-10 parts of silicon resin, 5-10 parts of phenolic resin, 10-18 parts of glass flakes, 8-15 partsof pigment, 5-10 parts of solvent, 5-10 parts of ultraviolet absorber, 0.5-1 part of dispersant and 0.5-1 part of defoamer; the component B comprises the following components in parts by weight: 35-45 parts of polyamide and 15-25 parts of a solvent; wherein the weight ratio of the component A to the component B is 1: 10, the silicon resin and the phenolic resin are adopted as raw materials, the silicon resin can improve the heat resistance of the anticorrosive paint, and the phenolic resin can improve the temperature resistance and the corrosion resistance of the anticorrosive paint. The anticorrosive paint can be applied to the surface of the steel structure. The product disclosed by the invention is matched with finish paint and has good antirust and anticorrosive properties.

Owner:无锡福斯特涂料有限公司

Demulsifying agent for treating thick oil and preparation method of demulsifying agent

ActiveCN109609178AFast demulsificationImprove water qualityDewatering/demulsification with chemical meansKetonic acidsSulfur

The invention relates to the technical fields of petroleum demulsifying agents and preparation thereof, and relates to a demulsifying agent for treating thick oil and a preparation method of the demulsifying agent. Raw materials of the demulsifying agent comprise a polyoxyethylene polyoxypropylene block copolymer, ketonic acid, alkynol and water. The polyoxyethylene polyoxypropylene block copolymer is heated in a reactor, and then is mixed and dissolved with the ketonic acid, the alkynol and water, so that the demulsifying agent for treating thick oil is obtained. The demulsifying agent for treating the thick oil has the characteristics of high demulsification speed and good water quality after separation, can particularly being used to solve the problem that an acid-containing demulsifying agent product corrodes equipment, and has good anti-rust and anti-corrosion effects. According to the invention, the preparation process is simple, large-scale production is facilitated, and the obtained demulsifying effect for treating thick oil has excellent demulsifying effect and dewatering performance. Meanwhile, the raw materials do not contain sulfur, phosphorus, aromatic rings, chlorineand the like which are harmful to human bodies and to the environment, so that the demulsifying agent accords with the concept of safe and environment-friendly production.

Owner:克拉玛依新科澳石油天然气技术股份有限公司

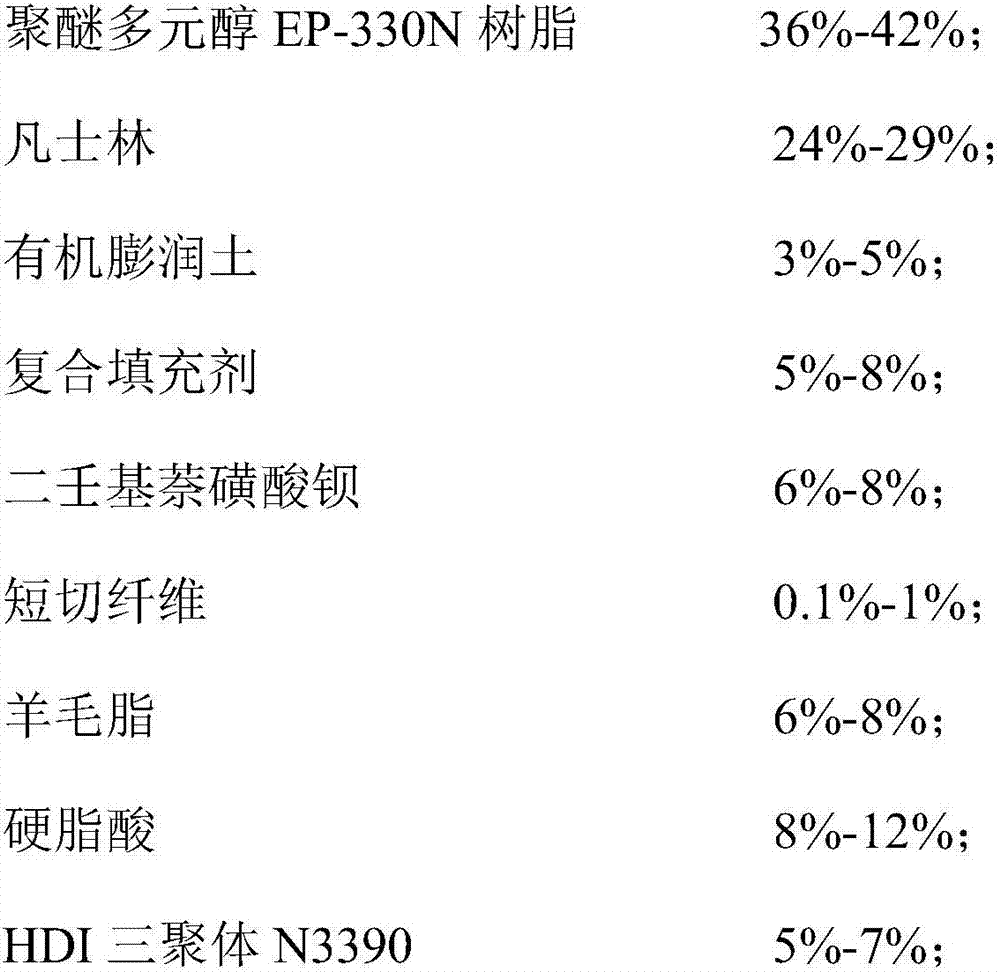

A non-sticky petrolatum anti-corrosion paste

ActiveCN105001775BGood anti-rust and anti-corrosion effectStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsCorrosion resistantStearic acid

The present invention provides a non-sticky petrolatum corrosion resistant paste, specifically a non-sticky petrolatum corrosion resistant paste for corrosion protection of tower bolt fasteners in electrical network power transmission line and the gaps between steel-frame structure and bolt fasteners. The non-sticky petrolatum corrosion resistant paste comprises by weight: 36%-42% of polyether polyol EP-330N resin, 24%-29% of vaseline, 3%-5% of organic bentonite, 5%-8% of a composite filler, 6%-8% of dinonyl barium naphthalene sulfonate, 0.1%-1% of chopped fiber, 6%-8% of lanolin, 8%-12% of stearic acid and 5%-7% of an HDI trimer (N3390). The non-sticky petrolatum corrosion resistant paste coats on the surface of a protected objective to form a flexible organic coating, and the coating layer is dense and has physical isolation protective effect; at the same time, non-sticky petrolatum corrosion resistant paste plays a good role in corrosion protection of the metals to be protected. The non-sticky petrolatum corrosion resistant paste effectively protects the bolt fasteners, and facilitates construction and post-maintenance and operation.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com