Aluminum cleaning agent and preparation method thereof

A technology of cleaning agent and active agent, which is applied in the field of aluminum cleaning agent and its preparation, can solve the problems of affecting the survival of aquatic organisms and animals, destroying ecological balance, and high corrosion of aluminum materials, so as to achieve easy wetting, lower surface tension, The effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

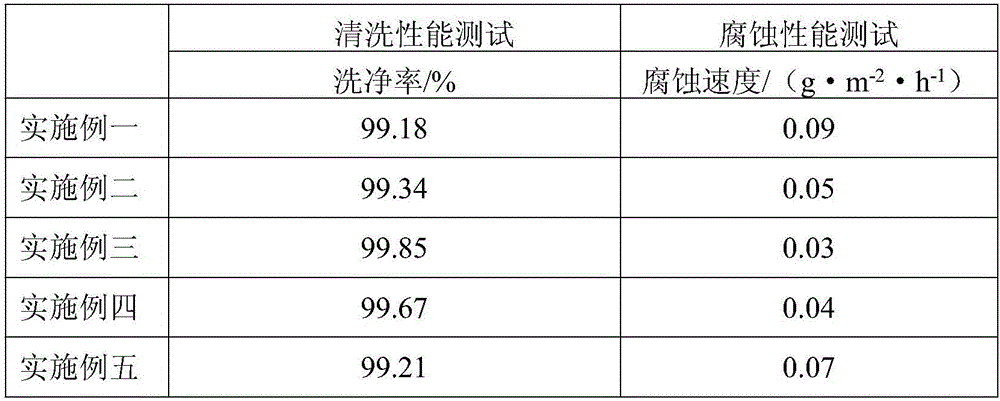

Examples

Embodiment 1

[0036] Take the raw materials of following weight for subsequent use:

[0037] Potassium hydroxide 2kg, propylene glycol butyl ether 2kg, sodium metasilicate pentahydrate 1kg, boric acid 1kg, sodium polyacrylate 1kg, sorbitol solution 1kg, sodium chloride 0.4kg, dimethylsiloxane 0.1kg, dodecane Sodium phenyl sulfonate 1kg, OP-102kg, water 88.5kg.

[0038] Its preparation method comprises the following steps:

[0039] (1) Add potassium hydroxide, sodium polyacrylate, sorbitol solution, sodium chloride, and dimethylsiloxane into water in sequence, and stir for 0.5-1 hour at 30-50°C until the mixture is uniform;

[0040] (2) Add sodium metasilicate pentahydrate and boric acid to the mixed solution obtained in step (1), and adjust the pH to 8-10;

[0041] (3) sodium dodecylbenzenesulfonate and OP-10 are mixed to obtain a compounded surfactant;

[0042] (4) Add the compounded surfactant obtained in step (3) into the mixed solution obtained in step (2), stir evenly, and let stand...

Embodiment 2

[0045] Take the raw materials of following weight for subsequent use:

[0046] Potassium hydroxide 3kg, propylene glycol butyl ether 4kg, sodium metasilicate pentahydrate 2kg, boric acid 2kg, sodium polyacrylate 2kg, sorbitol solution 2kg, sodium chloride 0.6kg, dimethylsiloxane 0.2kg, dodecane Sodium phenyl sulfonate 2kg, NP-103kg, water 79.2kg.

[0047] Its preparation method comprises the following steps:

[0048] (1) Add potassium hydroxide, sodium polyacrylate, sorbitol solution, sodium chloride, and dimethylsiloxane into water in sequence, and stir for 0.5-1 hour at 30-50°C until the mixture is uniform;

[0049] (2) Add sodium metasilicate pentahydrate and boric acid to the mixed solution obtained in step (1), and adjust the pH to 8-10;

[0050] (3) sodium dodecylbenzenesulfonate and NP-10 are mixed to obtain a compounded surfactant;

[0051] (4) Add the surfactant compounded in step (3) into the mixed solution obtained in step (2), stir evenly, and let stand for 1 to...

Embodiment 3

[0054] Take the raw materials of following weight for subsequent use:

[0055]Potassium hydroxide 4kg, propylene glycol butyl ether 6kg, sodium metasilicate pentahydrate 3kg, boric acid 3kg, sodium polyacrylate 4kg, sorbitol solution 3kg, sodium chloride 0.8kg, dimethylsiloxane 0.3kg, dodecane Sodium phenyl sulfonate 4kg, OP-106kg, water 65.9kg.

[0056] Its preparation method comprises the following steps:

[0057] (1) Add potassium hydroxide, sodium polyacrylate, sorbitol solution, sodium chloride, and dimethylsiloxane into water in sequence, and stir for 0.5-1 hour at 30-50°C until the mixture is uniform;

[0058] (2) Add sodium metasilicate pentahydrate and boric acid to the mixed solution obtained in step (1), and adjust the pH to 8-10;

[0059] (3) sodium dodecylbenzenesulfonate and OP-10 are mixed to obtain a compounded surfactant;

[0060] (4) Add the compounded surfactant obtained in step (3) into the mixed solution obtained in step (2), stir evenly, and let stand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com