Preparation method of anti-corrosion coating, coating construction method and its application and display stand

An anti-corrosion and coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor wear resistance, complex preparation methods, and single display method, and achieve improved wear resistance, improved homogeneity, and improved hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

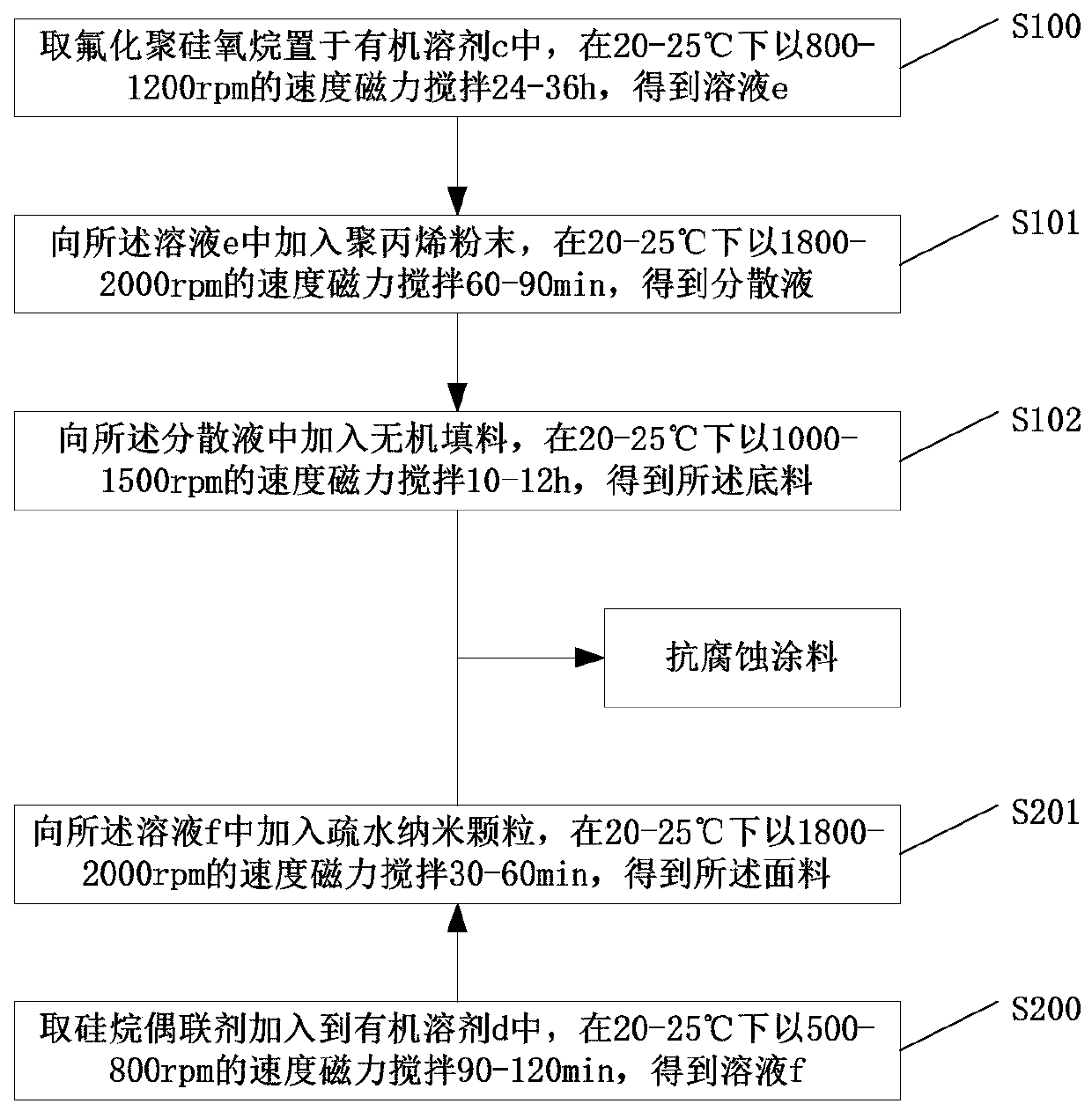

[0059] An embodiment of the present invention provides a method for preparing an anti-corrosion coating, the anti-corrosion coating includes a primer and a fabric,

[0060] The preparation method of described primer comprises:

[0061] Take the fluorinated polysiloxane in an organic solvent c, and magnetically stir at a speed of 800-1200rpm at 20-25°C for 24-36h to obtain a solution e, and the fluorinated polysiloxane is in the solution e The concentration is 1-10mg / mL.

[0062] The fluorinated polysiloxane contains the following structure:

[0063] Wherein, n is a positive integer, and the fluorinated polysiloxane containing the above structure has good thermal stability, and it is used in the anti-corrosion coating of the embodiment of the present invention, which can make it suffer from repeated mechanical friction and heat up, Remain stable without decomposition.

[0064] In the embodiment of the present invention, the fluorinated polysiloxane is polytrifluoropropylme...

Embodiment 1

[0089] A preparation method of an anti-corrosion coating, the anti-corrosion coating comprises a primer and a lining,

[0090] The preparation method of described primer comprises:

[0091] S100: 2.5 g of polytrifluoropropylmethylsiloxane was placed in 100 mL of tetrahydrofuran, and magnetically stirred at 800 rpm for 36 h at 25° C. to obtain a solution e.

[0092] S101: Add 0.25 g of polypropylene powder to the solution e, and magnetically stir at 25° C. at a speed of 1800 rpm for 90 min to obtain a dispersion liquid. The particle size of the polypropylene powder is 10 μm.

[0093] S102: Add 0.05 g of titanium dioxide to the dispersion, and magnetically stir at 1000 rpm for 12 hours at 25° C. to obtain the primer, and the particle size of the inorganic filler is 1 μm.

[0094] The preparation method of described lining comprises:

[0095] S200: Add 1.5 mL of 3-aminopropyltriethoxysilane into 100 mL of methanol, and magnetically stir at 500 rpm for 120 min at 25° C. to obtai...

Embodiment 2

[0098] A preparation method of an anti-corrosion coating, the anti-corrosion coating comprises a primer and a lining,

[0099] The preparation method of described primer comprises:

[0100] S100: 5 g of polymethylnonafluorohexylsiloxane was placed in 100 mL of ethyl acetate, and magnetically stirred at 25° C. at a speed of 1000 rpm for 36 h to obtain a solution e.

[0101] S101: Add 0.5 g of polypropylene powder to the solution e, and magnetically stir at 25° C. at a speed of 1800 rpm for 90 min to obtain a dispersion liquid. The particle size of the polypropylene powder is 10 μm.

[0102] S102: Add 0.1 g of silicon dioxide to the dispersion, and magnetically stir at 1200 rpm at 25° C. for 11 h to obtain the primer, and the particle size of the inorganic filler is 5 μm.

[0103] The preparation method of described lining comprises:

[0104] S200: Add 2 mL of 3-aminopropyltrimethoxysilane into 100 mL of ethanol, and magnetically stir at 500 rpm for 120 min at 25° C. to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com