Environment-friendly semisynthetic cutting fluid for titanium alloys as well as preparation method and application of cutting fluid

An environmentally friendly, titanium alloy technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of the surface quality of titanium alloy workpieces being difficult to meet process requirements, endangering environmental safety and human health, and short tool life, avoiding stress. Corrosion problems, reducing environmental and human hazards, and prolonging tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

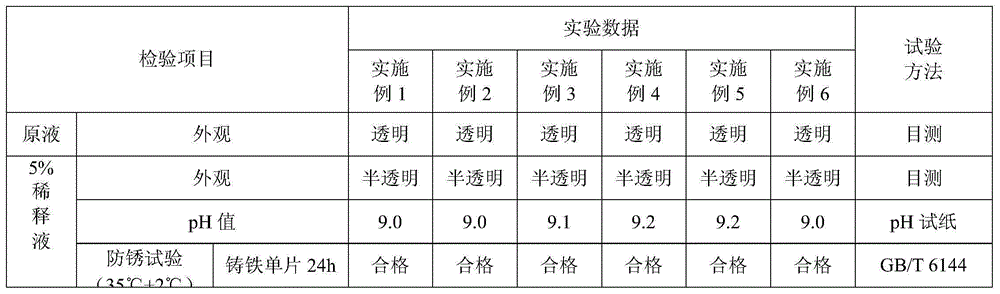

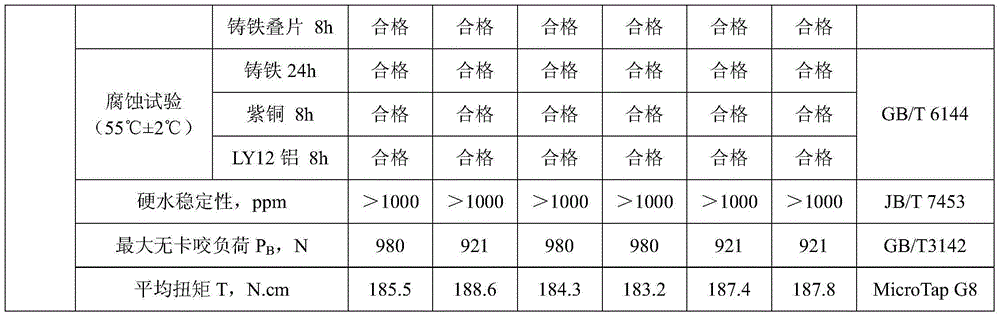

Examples

Embodiment 1

[0029] A kind of environment-friendly titanium alloy semi-synthetic cutting fluid, is made up of following components by mass percentage: fatty acid isopropyl ester 20%, isomeric stearic acid 6%, high molecular weight polyester (average relative molecular mass M a 700-7000 Daltons) 10%, monoethanolamine 5%, triethanolamine 5%, isooctanoic acid 1%, sebacic acid 1%, triazine triaminocaproic acid 1%, alkyl succinic anhydride 1%, 2- Amino-2-methyl-1-propanol 2%, castor oil polyoxyethylene ether dioleate 6%, oleyl alcohol polyoxyethylene ether 5%, polyisobutylene succinic anhydride derivative 4%, direct alkyl ether Carboxylic acid 1%, 2-butyl octanol 1%, 1,2-benzisothiazolin-3-one (BIT) 1.5%, n-butyl-1,2-benzisothiazolin-3- Ketone (BBIT) 0.5%, water balance.

[0030] Preparation method: first add water, monoethanolamine, triethanolamine, 2-amino-2-methyl-1-propanol, isooctanoic acid, sebacic acid, triazine triaminocaproic acid, and alkyl succinic anhydride into the reaction kettle...

Embodiment 2

[0033] A kind of environmentally friendly titanium alloy semi-synthetic cutting fluid, is made up of following components by mass percentage: fatty acid isobutyl ester 22%, dimer acid 6%, high molecular weight polyester (average relative molecular mass M a 700-7000 Daltons) 9%, monoethanolamine 5%, diethanol monoisopropanolamine 6%, isononanoic acid 1%, undecanedioic acid 1%, triazine triaminocaproic acid 1%, Alkyl succinic anhydride 2%, 3-amino-4-octanol 2.5%, castor oil polyoxyethylene ether dioleate 10%, fatty alcohol alkoxylate 4%, polymer surfactant 2%, branched chain Alkyl ether carboxylic acid 1.5%, 2-butyldecanol 1.5%, N-methyl-1,2-benzisothiazolin-3-one (MBIT) 2%, 3-iodo-2-propynyl Butyl carbamate (IPBC) 0.5%, water balance.

[0034]Preparation method: First add water, monoethanolamine, diethanolmonoisopropanolamine, 3-amino-4-octanol, isononanoic acid, undecanedioic acid, triazine triaminocaproic acid, and alkyl succinic anhydride Stir in the reaction kettle at roo...

Embodiment 3

[0037] A kind of environmentally friendly titanium alloy semi-synthetic cutting fluid, is made up of following components by mass percentage: fatty acid isooctyl ester 24%, trimer acid 4%, high molecular weight polyester (average relative molecular mass M a 700-7000 Daltons) 8%, one isopropanolamine 6%, triethanolamine 6%, neodecanoic acid 1%, lauric acid 1%, triazine triaminocaproic acid 2%, alkyl succinic anhydride 2 %, 2-amino-1-butanol 3%, oleyl alcohol polyoxyethylene ether 6%, castor oil ethoxylate 8%, polyisobutylene succinic anhydride derivatives 4%, aralkyl ether carboxylic acid 2%, 2 - Hexyl octanol 2%, n-butyl-1,2-benzisothiazolin-3-one (BBIT) 2.5%, sodium pyrithione (SPT) 0.5%, water balance.

[0038] Preparation method: first add water, monoisopropanolamine, triethanolamine, 2-amino-1-butanol, neodecanoic acid, lauric acid, triazine triaminocaproic acid, and alkyl succinic anhydride into the reaction kettle, Stir at room temperature for 60-90 minutes until unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com