Fireproof thermal-insulation functional material and structure for special carriages

A thermal insulation functional material, fire prevention and heat preservation technology, applied in anti-corrosion coatings, vehicle parts, epoxy resin coatings, etc. Safety performance and other issues, to achieve good anti-rust and anti-corrosion performance, heat insulation, good fire and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

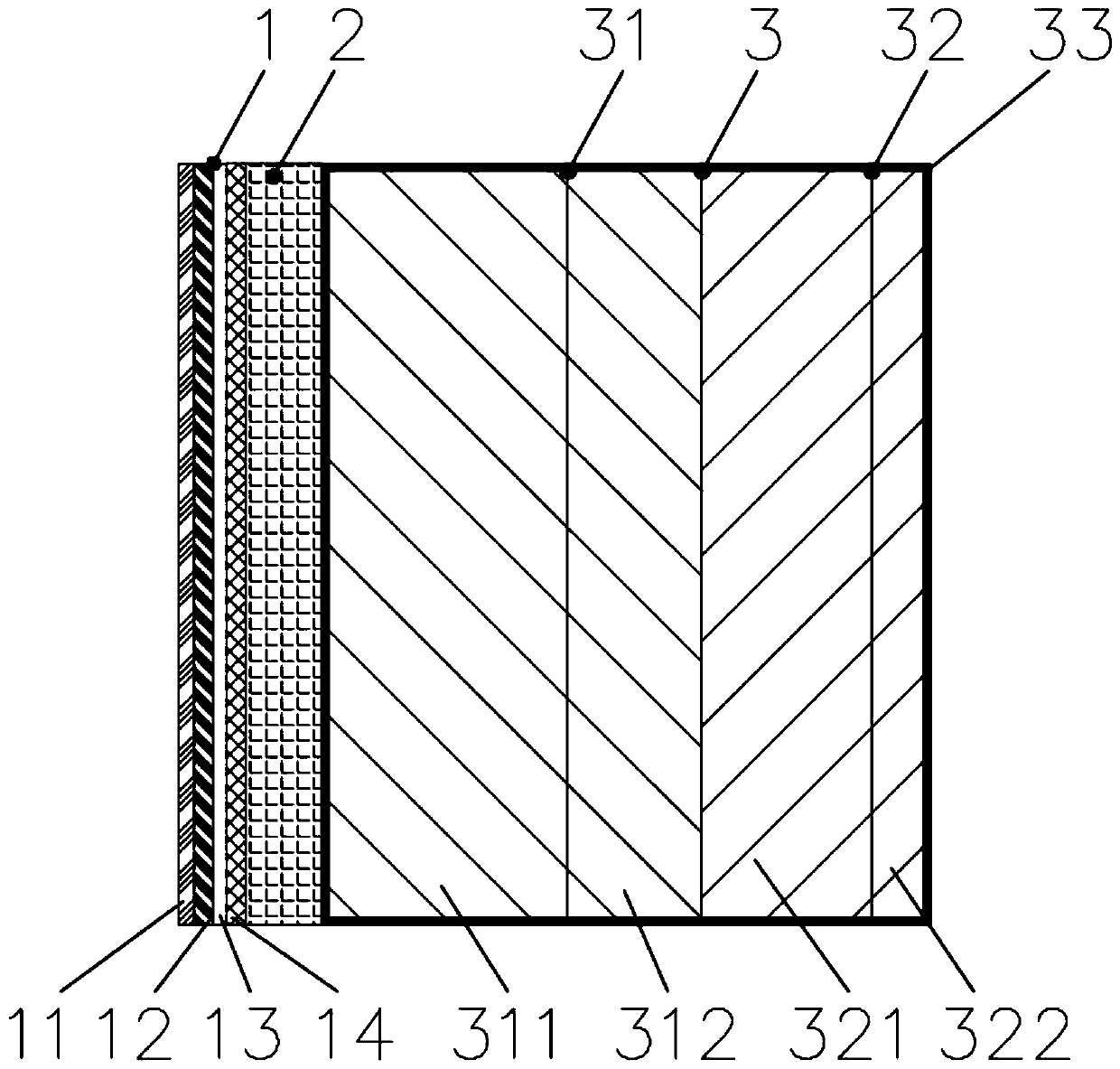

[0030] like figure 1 As shown, a fireproof heat insulation functional material and structure for a special carriage is characterized in that it consists of a fireproof heat insulation layer 1, a carriage or shelter body steel plate 2, Heat insulation layer 3; wherein, the anti-burning heat insulation layer 1 is made up of four-layer structure, and its structure is from the outside of the carriage or shelter to the outer wall surface of the body steel plate 2 of the carriage or shelter, followed by protective finish paint layer 11, anti-corrosion Burning functional layer 12, heat insulating functional layer 13, antirust matrix layer 14, described heat insulating functional layer 13 is made up of film former a, low thermal conductivity filler, functional auxiliary agent, and described anti-burning functional layer 12 is made of film forming b, a dehydrating agent, a carbon forming agent, and a foaming agent; the heat insulation layer 3 is a two-layer structure, and its structure...

Embodiment 2

[0035] like figure 1 As shown, a fireproof heat insulation functional material and structure for a special carriage is characterized in that it consists of a fireproof heat insulation layer 1, a carriage or shelter body steel plate 2, Heat insulation layer 3; wherein, the anti-burning heat insulation layer 1 is made up of four-layer structure, and its structure is from the outside of the carriage or shelter to the outer wall surface of the body steel plate 2 of the carriage or shelter, followed by protective finish paint layer 11, anti-corrosion Burning functional layer 12, heat insulating functional layer 13, antirust matrix layer 14, described heat insulating functional layer 13 is made up of film former a, low thermal conductivity filler, functional auxiliary agent, and described anti-burning functional layer 12 is made of film forming b, a dehydrating agent, a carbon forming agent, and a foaming agent; the heat insulation layer 3 is a two-layer structure, and its structure...

Embodiment 3

[0040] like figure 1 As shown, a fireproof heat insulation functional material and structure for a special carriage is characterized in that it consists of a fireproof heat insulation layer 1, a carriage or shelter body steel plate 2, Heat insulation layer 3; wherein, the anti-burning heat insulation layer 1 is made up of four-layer structure, and its structure is from the outside of the carriage or shelter to the outer wall surface of the body steel plate 2 of the carriage or shelter, followed by protective finish paint layer 11, anti-corrosion Burning functional layer 12, heat insulating functional layer 13, antirust matrix layer 14, described heat insulating functional layer 13 is made up of film former a, low thermal conductivity filler, functional auxiliary agent, and described anti-burning functional layer 12 is made of film forming b, a dehydrating agent, a carbon forming agent, and a foaming agent; the heat insulation layer 3 is a two-layer structure, and its structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com