Modified gear oil and production method thereof

A gear oil and modification technology, applied in the field of gear oil, can solve the problems of poor vehicle heat dissipation performance, reduced air flow, oil oxidation of gear oil and aging of seals, etc., to achieve good anti-rust and anti-corrosion performance, reduce The frequency of oil changes, the effect of eliminating health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

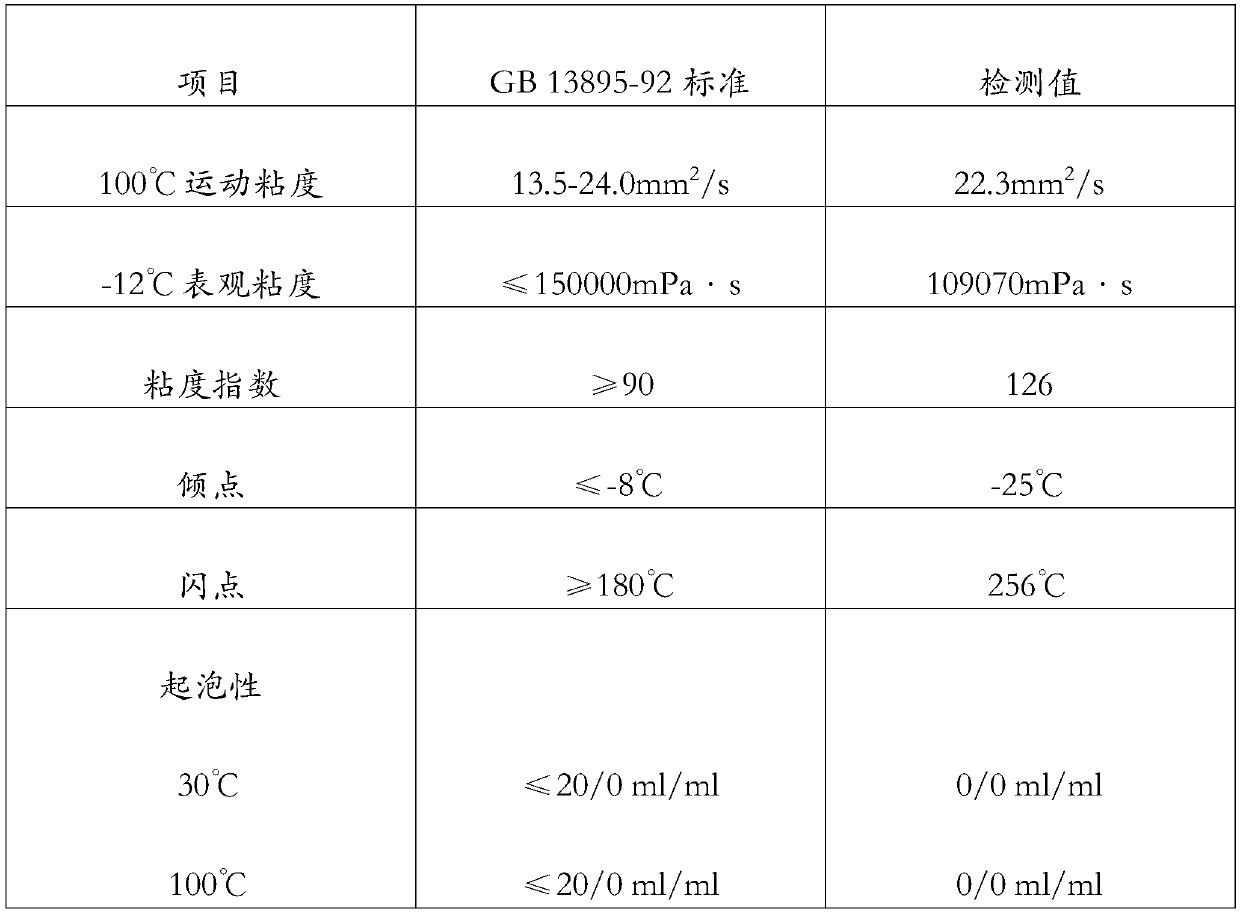

Examples

Embodiment 1

[0027] A modified gear oil comprising the following raw materials in parts by weight: 30kg of base oil, 1kg of anti-oxidant and anticorrosion agent, 1kg of antirust agent, 1kg of extreme pressure antiwear agent, 0.1kg of metal passivator, 1kg of demulsifier, Vegetable glue 3kg, thickener 2kg.

[0028] The production method of described modified gear oil, comprises the following steps:

[0029] (1) Add metal deactivator to the heated base oil, mix and stir evenly at constant temperature to obtain a mixed solution;

[0030] (2) Add the remaining raw materials into the mixed liquid, stir evenly, and filter to obtain the modified gear oil.

Embodiment 2

[0032] A modified gear oil comprising the following raw materials in parts by weight: 45kg of base oil, 2kg of anti-oxidant and anticorrosion agent, 1kg of antirust agent, 2kg of extreme pressure antiwear agent, 0.5kg of metal passivator, 2kg of demulsifier, Vegetable glue 4kg, thickener 3kg.

[0033] The production method of described modified gear oil, comprises the following steps:

[0034] (1) Add a metal deactivator to the base oil at a heating temperature of 80°C, mix and stir at a constant temperature for 25 minutes, and mix and stir evenly to obtain a mixed solution;

[0035] (2) Cool the mixed solution to 50° C., add the remaining raw materials into the mixed solution, and stir at a constant temperature for 60 minutes to mix evenly, and filter to obtain the modified gear oil.

Embodiment 3

[0037] A modified gear oil comprising the following raw materials in parts by weight: 30kg of a mixture of base oil 500N and base oil 150BS in a weight ratio of 2:3, an antioxidant and anticorrosion agent T203 and an antioxidant and anticorrosion agent in a weight ratio of 1:2 Corrosion agent T205 mixture 1kg, rust inhibitor T705 1kg, extreme pressure anti-wear agent T321 1kg, metal passivator T706 0.1kg, mixture of demulsifier T1001 and demulsifier DL-32 with a weight ratio of 1:3 1kg , vegetable glue 3kg, bentonite 2kg.

[0038] The production method of described modified gear oil, comprises the following steps:

[0039] (1) Add a metal deactivator to the base oil at a heating temperature of 80°C, mix and stir at a constant temperature for 25 minutes, and mix and stir evenly to obtain a mixed solution;

[0040] (2) Cool the mixed solution to 50°C, add the remaining raw materials into the mixed solution, and stir at a constant temperature for 60 minutes to mix evenly, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com