Synthetic lubricating oil composition for high and low temperature and preparation method thereof

A synthetic lubricating oil, general-purpose technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem that lubricating oil cannot be used universally, achieve excellent oxidation stability, high flash point, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

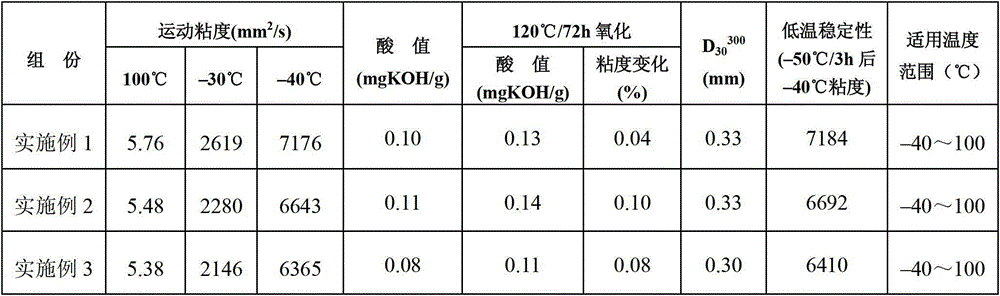

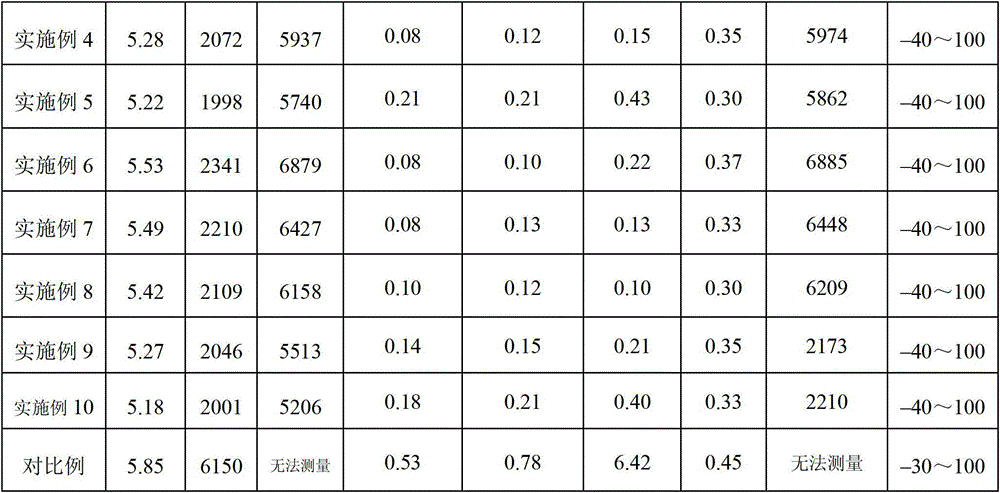

Embodiment 1

[0033] Take 0.5kg of amine neutralized aliphatic alcohol phosphate, 0.5kg of 2,6-di-tert-butyl-p-cresol, 0.02kg of N,N' dialkylaminomethylene benzotriazole, neutral dinonylnaphthalenesulfonic acid Add 3kg of barium into 10kg of API-classified V oil in turn, and stir at a constant temperature of 80°C for 1 hour to obtain a mixture; then add 90kg of API-classified IV oil into the above mixture, and stir at a constant temperature of 80°C for 1 hour , made of high and low temperature general-purpose synthetic lubricating oil.

Embodiment 2

[0035] Take 0.5kg of di-n-butyl phosphite, 2.5kg of 2,6-di-tert-butyl-p-cresol, 0.03kg of V, N' dialkylaminomethylene benzene triazole, and 2kg of neutral barium dinonylnaphthalenesulfonate , and then added to 12.5kg of API-classified V oil in turn, and stirred at a constant temperature of 60°C for 1 hour to obtain a mixture; then 87.5kg of API-classified IV oil was added to the above mixture, and stirred at a constant temperature of 90°C for 5 hours , made of high and low temperature general-purpose synthetic lubricating oil.

Embodiment 3

[0037] Take 1 kg of amine neutralized aliphatic alcohol phosphate, 1 kg of 2,6-di-tert-butyl-p-cresol, 0.03 kg of N, N'--dialkylaminomethylene benzotriazole, neutral dinonyl naphthalene sulfonic acid Add 2kg of barium into 15kg of API-classified V oil in turn, stir at 70°C for 2 hours to obtain a mixture; then add 85kg of API-classified IV oil into the above mixture, and stir at 100°C for 2 hours , made of high and low temperature general-purpose synthetic lubricating oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com