Polyether polyol, synthetic method thereof and lubricating oil

A technology of polyether polyol and synthesis method, which is applied in lubricating compositions, petroleum industry, etc., can solve the problems of high pour point and low viscosity index, and achieve the effect of low pour point, high viscosity index and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

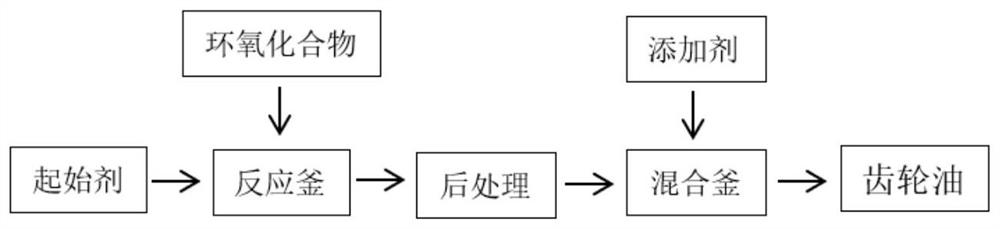

Method used

Image

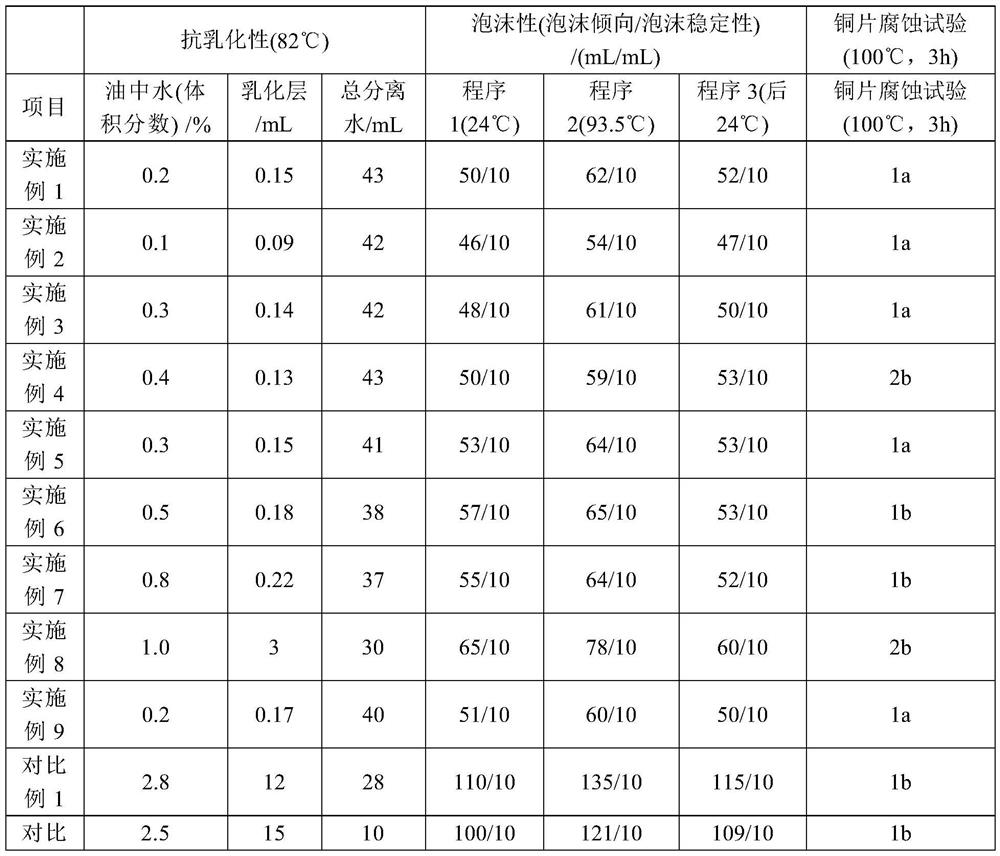

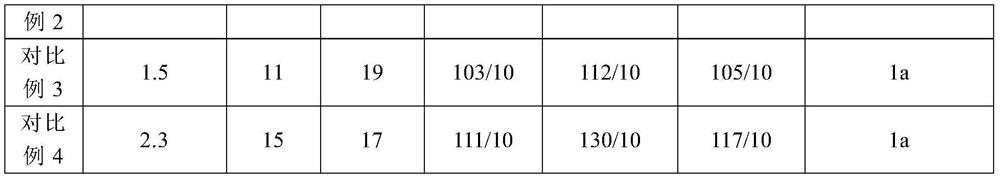

Examples

Embodiment 1

[0039] The present embodiment provides a kind of synthetic method of polyether polyol, comprises the steps:

[0040] Such as figure 1 As shown, put 100kg of C 16-18Alcohol (mass ratio of n-hexadecanol to n-stearyl alcohol is 7:3) and 0.2kg of potassium hydroxide were added to the reactor, and the air in the reactor was replaced with nitrogen for 3 times, and then vacuumed to -0.098MPa. Then be warming up to 90 ℃, feed the mixture of propylene oxide, ethylene oxide and butylene oxide, comprise propylene oxide 484.5kg in the mixture, oxyethane 57kg, butylene oxide 28.5kg, feed reaction time After 5 hours, after the feeding is complete, carry out slaking, degassing, post-treatment (that is, adjust the pH to 6.5), and obtain 1215 kg of polyether polyol.

[0041] This embodiment also provides a gear oil, its raw material composition: 607.5kg of the polyether polyol of this embodiment, 5.1kg of 2,6-di-tert-butyl-4-methylphenol, 2.55kg of N,N '-Disalicylidene-1,2-propyldiamine, 5....

Embodiment 2

[0044] The present embodiment provides a kind of synthetic method of polyether polyol, comprises the steps:

[0045] 280kg of C 12-14 Alcohol (the mass ratio of n-dodecyl alcohol to n-tetradecyl alcohol is 7:3) and 1.7kg of sodium metal are added to the reactor, and the air in the reactor is replaced with nitrogen for 3 times, and then vacuumed to -0.098MPa. Then be warming up to 135 ℃, feed the mixture of propylene oxide / ethylene oxide / butylene oxide, wherein propylene oxide 2394kg, ethylene oxide 159.6kg, butylene oxide 106.4kg, the time of feeding reaction is After 7 hours, after the feeding is complete, carry out aging, degassing, adjust the pH to 5.5, and obtain 5488 kg of polyether polyol.

[0046] This embodiment also provides a gear oil, its raw material composition: 5488kg of the polyether polyol of this embodiment, 90.8kg of 2,6-di-tert-butyl-4-methylphenol, 60.6kg of N,N' - Disalicylidene-1,2-butyldiamine, 90.8 kg of barium petroleum sulfonate and 333.5 kg of pota...

Embodiment 3

[0049] The present embodiment provides a kind of synthetic method of polyether polyol, comprises the steps:

[0050] 410kg of C 10 Alcohol (n-decyl alcohol) and 1.2kg of sodium metal were added to the reaction kettle, and the air in the reaction kettle was replaced with nitrogen for 3 times, and then vacuumed to -0.098MPa. Then heat up to 120°C, feed the mixture of propylene oxide / ethylene oxide / butylene oxide, wherein propylene oxide 2497kg, ethylene oxide 258kg, butylene oxide 115kg, the time of feed reaction is 6 hours , after the feeding is complete, carry out aging, degassing, adjust the pH to 7.0, and obtain 6027kg of polyether polyol.

[0051] This embodiment also provides a gear oil, its raw material composition: 6027kg of polyether polyol, 64kg of 2,6-di-tert-butyl-4-methylphenol, 5kg of N,N'-disalicylidene 1,2-butyldiamine, 18.8kg of barium petroleum sulfonate and 163kg of potassium triborate.

[0052] The preparation method of above-mentioned gear oil: above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com