Water-based cleaning agents for automobile parts and preparation method for water-based cleaning agents

A water-based cleaning agent and auto parts technology, applied in the field of mechanical processing, can solve the problems of waste liquid discharge polluting the environment, the cleaning agent has a short working life and high cleaning temperature, and achieves high cleaning efficiency, long working life and low cleaning temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

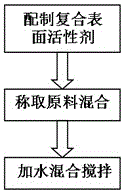

[0014] figure 1 It is a process step diagram of the method for preparing a water-based cleaning agent for automobile parts in an embodiment of the present invention; the water-based cleaning agent includes the following components by weight percentage: 8.5-12% of composite surfactant, 6-10% of composite auxiliary agent, mixed inorganic Salt 5-8%, solubilizer diethylene glycol ether 8-10%, corrosion inhibitor benzotriazole 0.25-0.4%, organic silicon defoamer 0.05-0.1%, deionized water 59.5-72.2%, all The preparation method includes the following steps: a) preparing a composite surfactant, b) weighing and mixing raw materials, and c) adding water for mixing and stirring.

[0015] The water-based cleaning agent for auto parts mentioned in the present invention uses deionized water as a solvent and a composite surfactant as a main body, and is prepared by adding composite auxiliary agents, mixed inorganic salts, solubilizers, corrosion inhibitors and defoamers. Among them, the co...

Embodiment 1

[0017] The specific preparation method is as follows:

[0018] a) To prepare a composite surfactant, first weigh 8% of alkylphenol polyoxyethylene ether and 0.5% of sodium lauryl sulfate by weight percentage, and then mix alkylphenol polyoxyethylene ether and tendecyl sulfate at room temperature. Sodium dialkyl sulfate is put into a magnetic stirrer and mixed evenly to make a composite surfactant.

[0019] b) Weigh the raw materials and mix them. First, weigh 3% of triethanolamine, 2.4% of sodium metasilicate, 0.6% of tetrasodium edetate, 1% of sodium fluoride, and 4% of chloride by weight percentage. Sodium, 8% diethylene glycol ether, 0.25% benzotriazole, 0.05% silicone defoamer, and then put them into a magnetic stirrer and mix them evenly with the complex surfactant.

[0020] c) Add water to mix and stir, first weigh 72.2% deionized water by weight percentage, then add the deionized water into a magnetic stirrer, stir at room temperature at a stirring speed of 40r / min for...

Embodiment 2

[0022] The specific preparation method is as follows:

[0023] a) To prepare a composite surfactant, first weigh 11% of alkylphenol polyoxyethylene ether and 1% of sodium lauryl sulfate by weight percentage, and then mix alkylphenol polyoxyethylene ether and tendecyl sulfate at room temperature. Sodium dialkyl sulfate is put into a magnetic stirrer and mixed evenly to make a composite surfactant.

[0024] b) Weigh the raw materials and mix, first weigh 5% triethanolamine, 4% sodium metasilicate, 1% tetrasodium edetate, 1.6% sodium fluoride, 6.4% Sodium chloride, 10% diethylene glycol ether, 0.4% benzotriazole, 0.1% silicone defoamer, and then put them into a magnetic stirrer and mix them evenly with the composite surfactant.

[0025] c) Add water to mix and stir, first weigh 59.5% deionized water by weight percentage, then add the deionized water into the magnetic stirrer, and stir for 50min at room temperature at a stirring speed of 50r / min to form a transparent solution. L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com