Patents

Literature

47results about How to "Simple passivation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

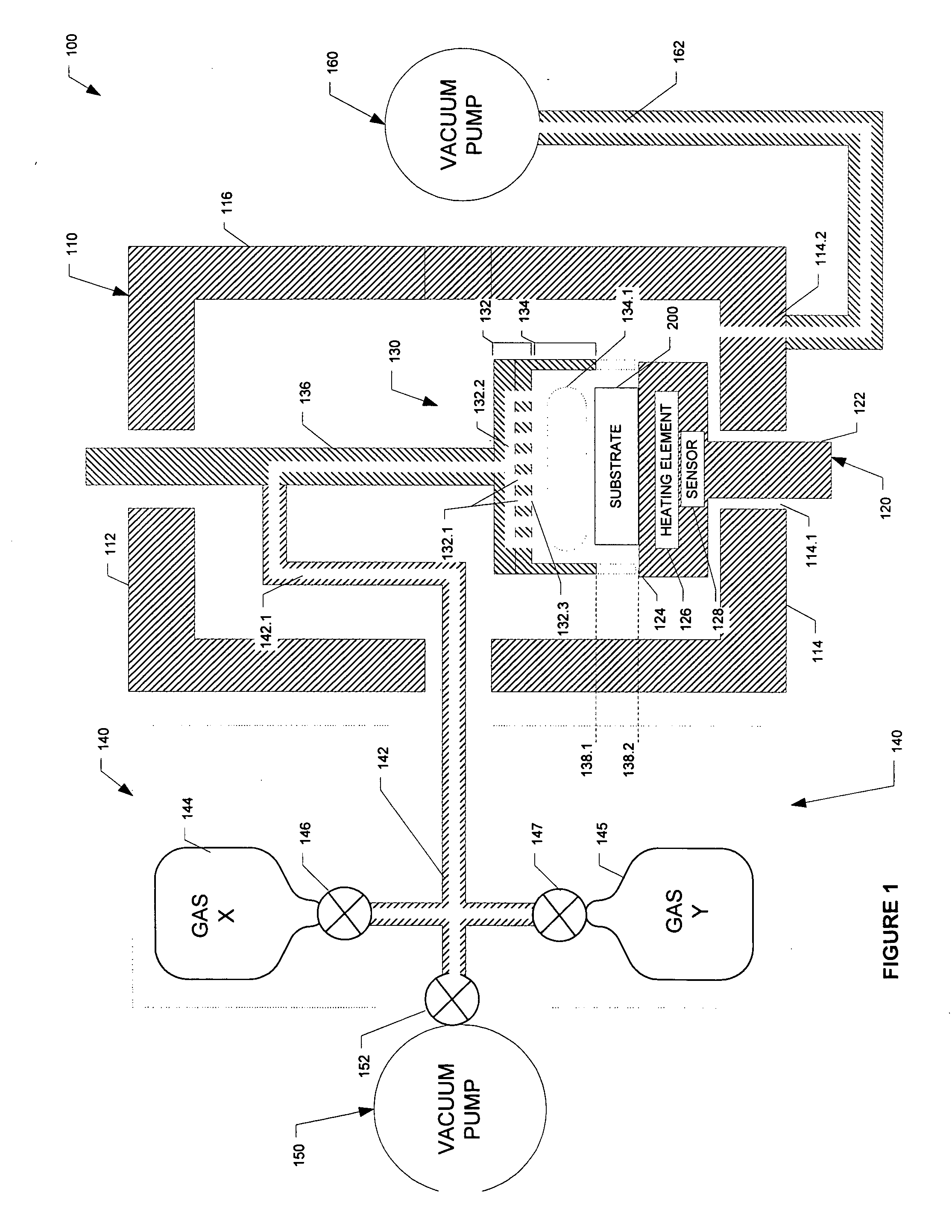

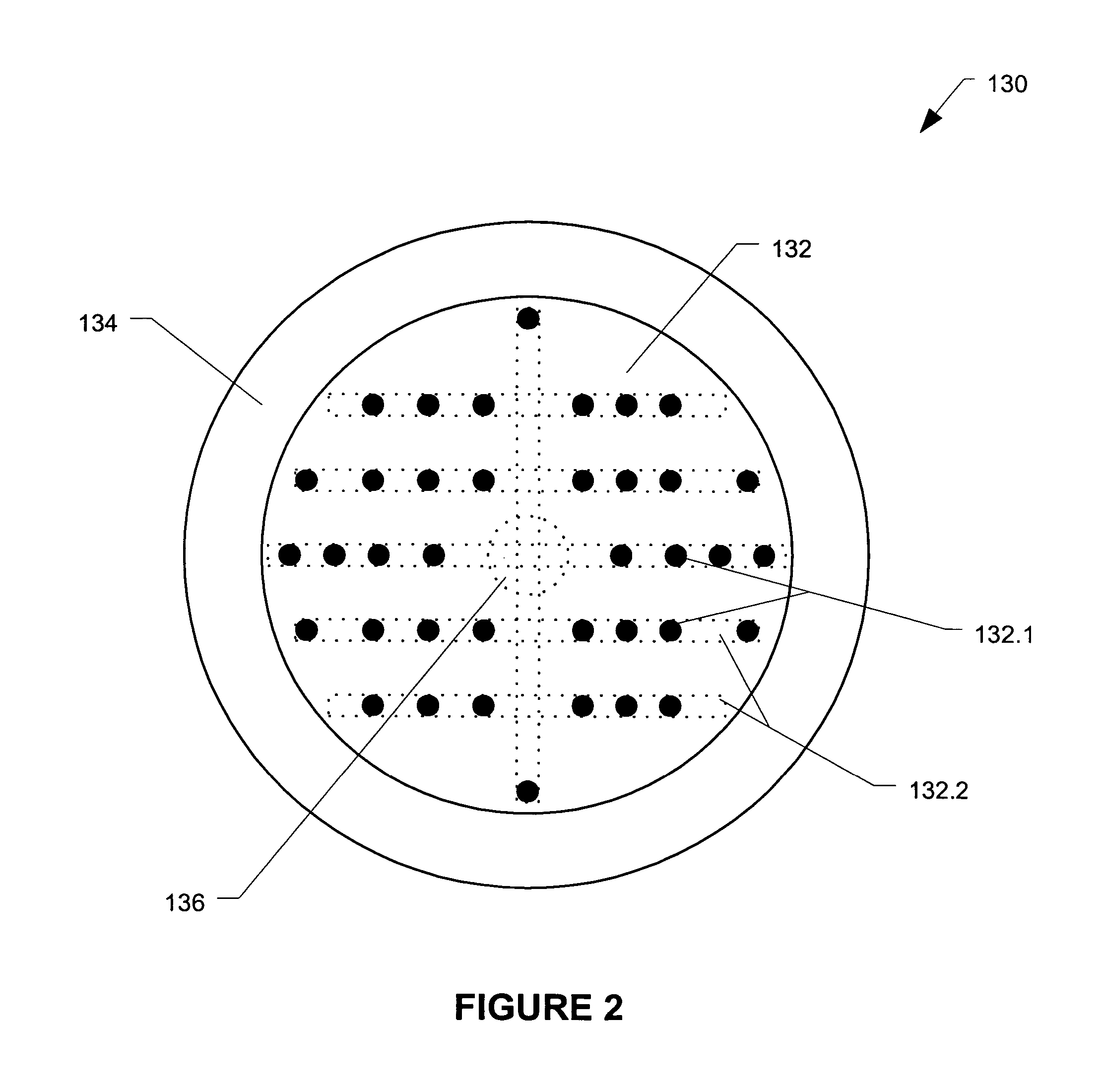

Methods, systems, and apparatus for uniform chemical-vapor depositions

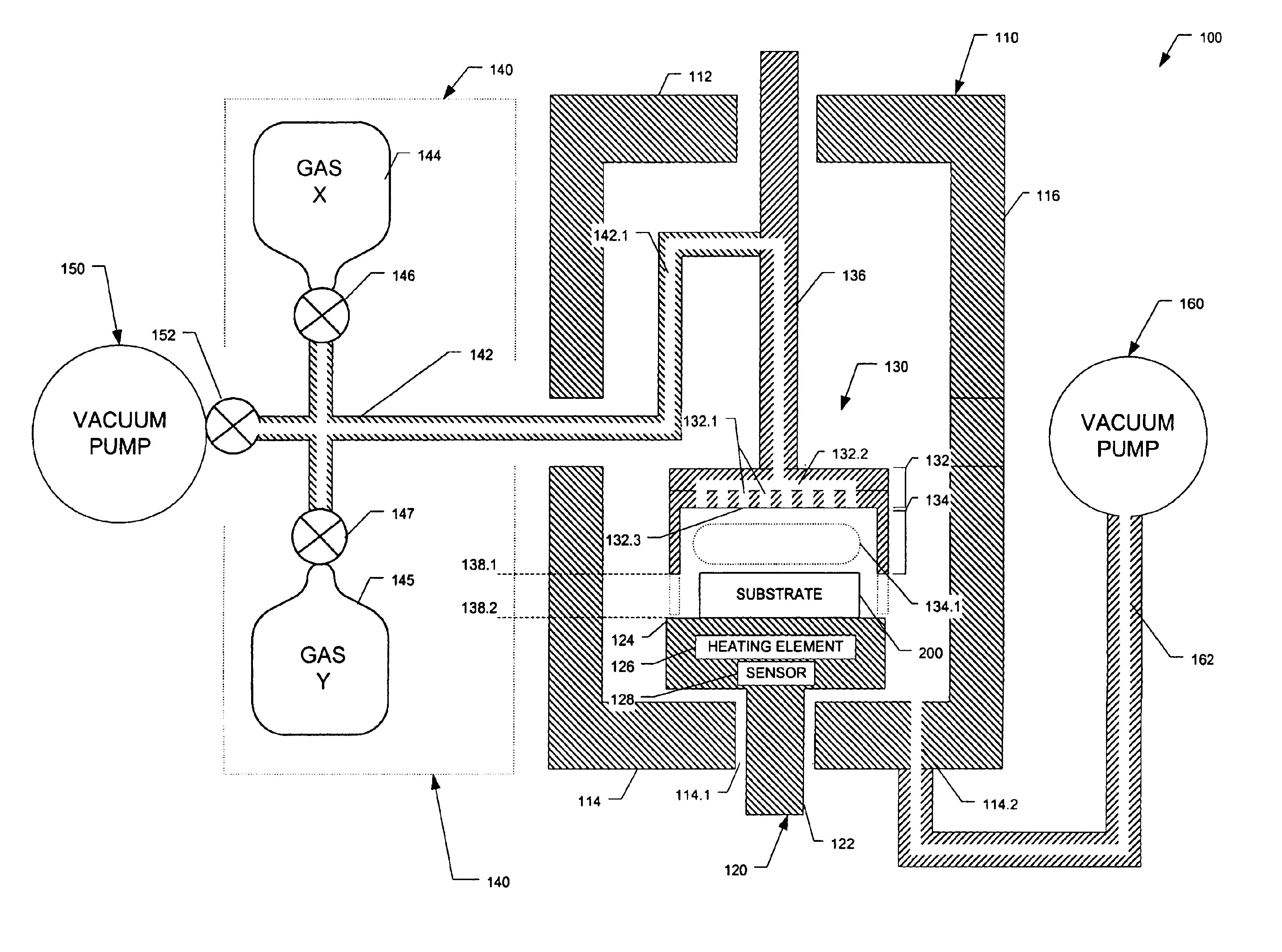

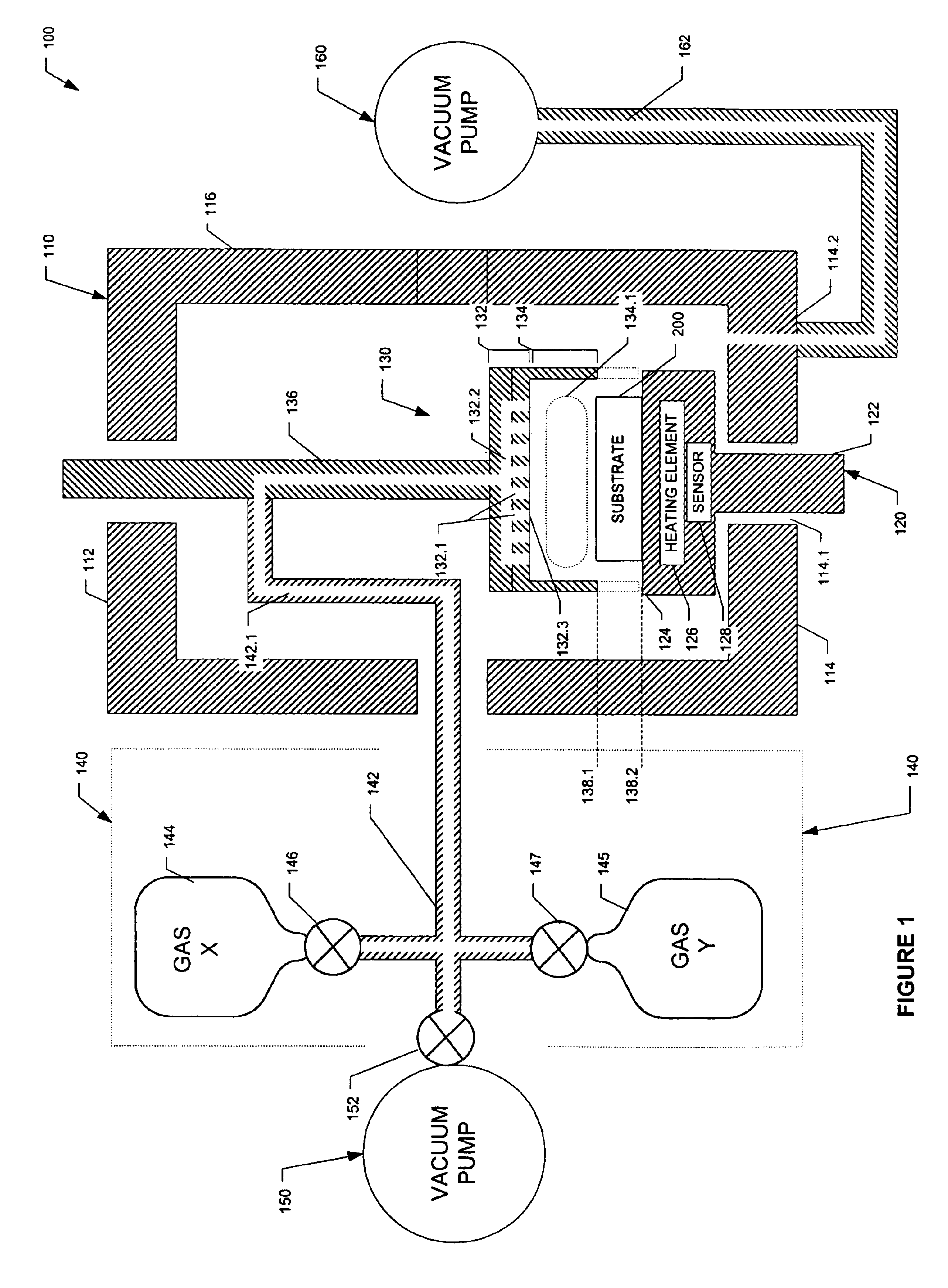

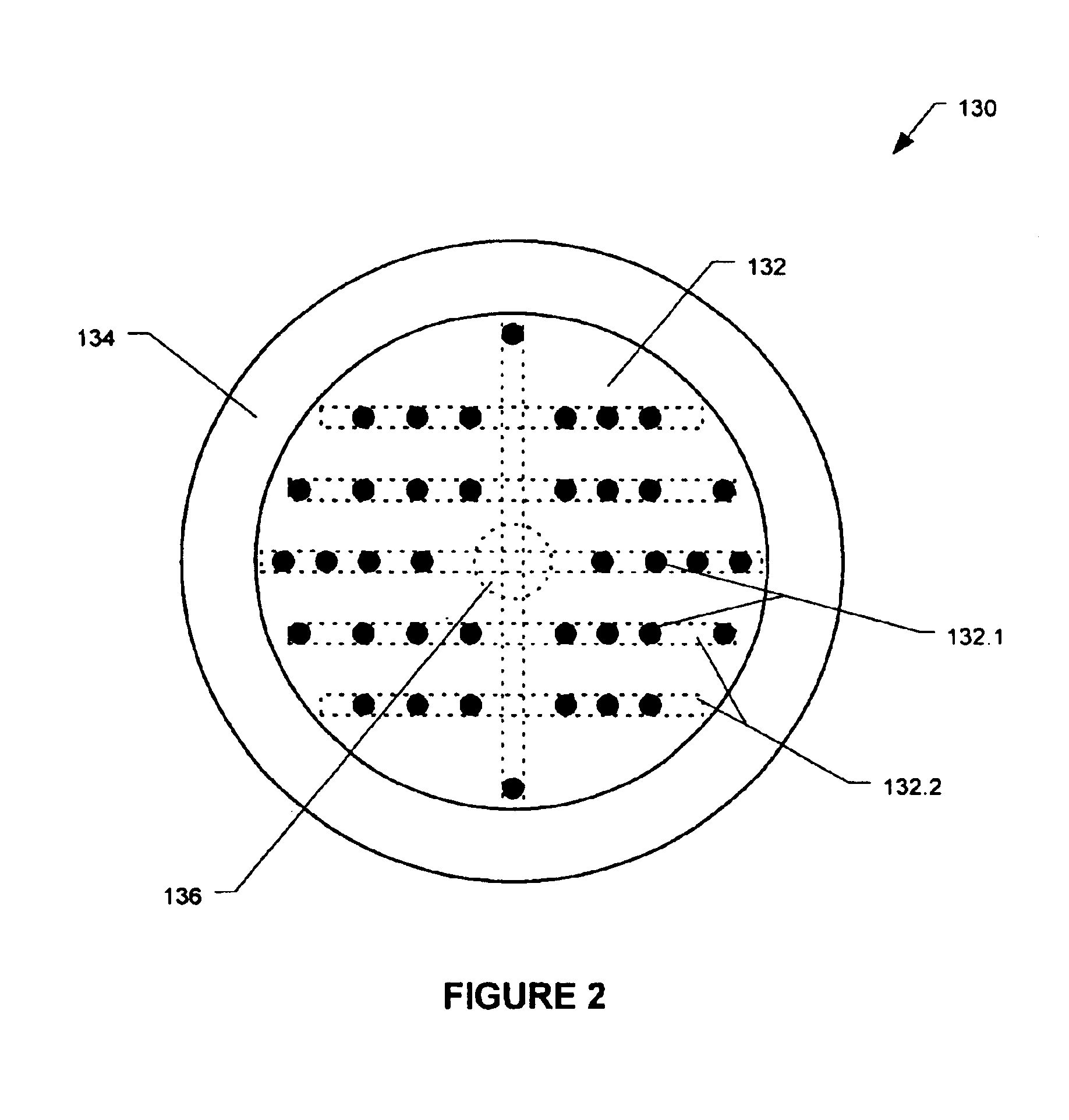

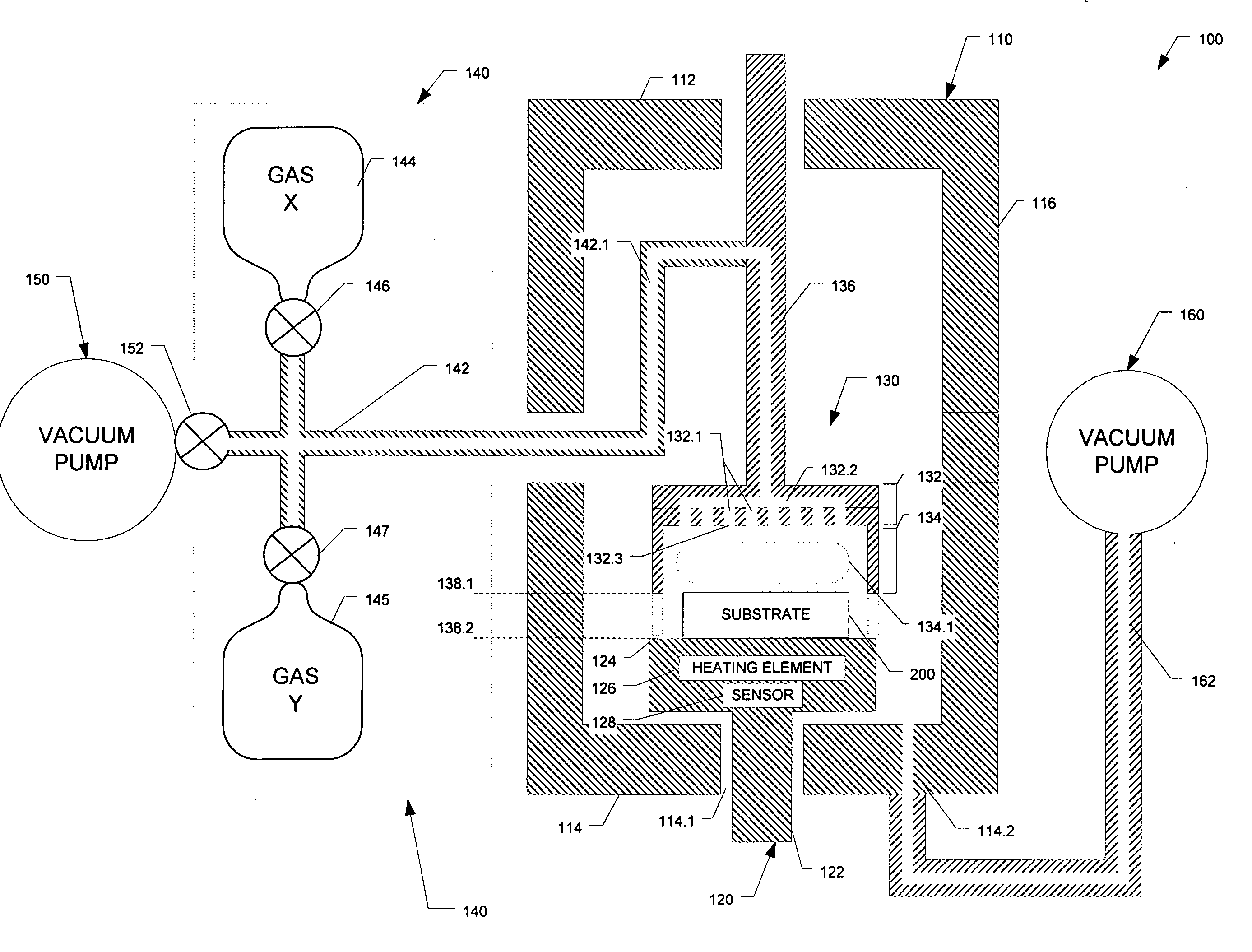

Integrated circuits, the key components in thousands of electronic and computer products, are generally built layer by layer on a silicon substrate. One common technique for forming layers is called chemical-vapor deposition (CVD.) Conventional CVD systems not only form layers that have non-uniform thickness, but also have large chambers that make the CVD process wasteful and slow. Accordingly, the inventor devised new CVD systems, methods, and apparatuses. One exemplary CVD system includes an outer chamber, a substrate holder, and a unique gas-distribution fixture. The fixture includes a gas-distribution surface having holes for dispensing a gas and a gas-confinement member that engages or cooperates with the substrate holder to form an inner chamber within the outer chamber. The inner chamber has a smaller volume than the outer chamber, which not only facilitates depositions of more uniform thickness, but also saves gas and speeds up the deposition process.

Owner:MICRON TECH INC

Methods, systems, and apparatus for uniform chemical-vapor depositions

InactiveUS20050034662A1Consumes less gasIncrease ratingsChemical vapor deposition coatingGas phaseDeposition process

Owner:MICRON TECH INC

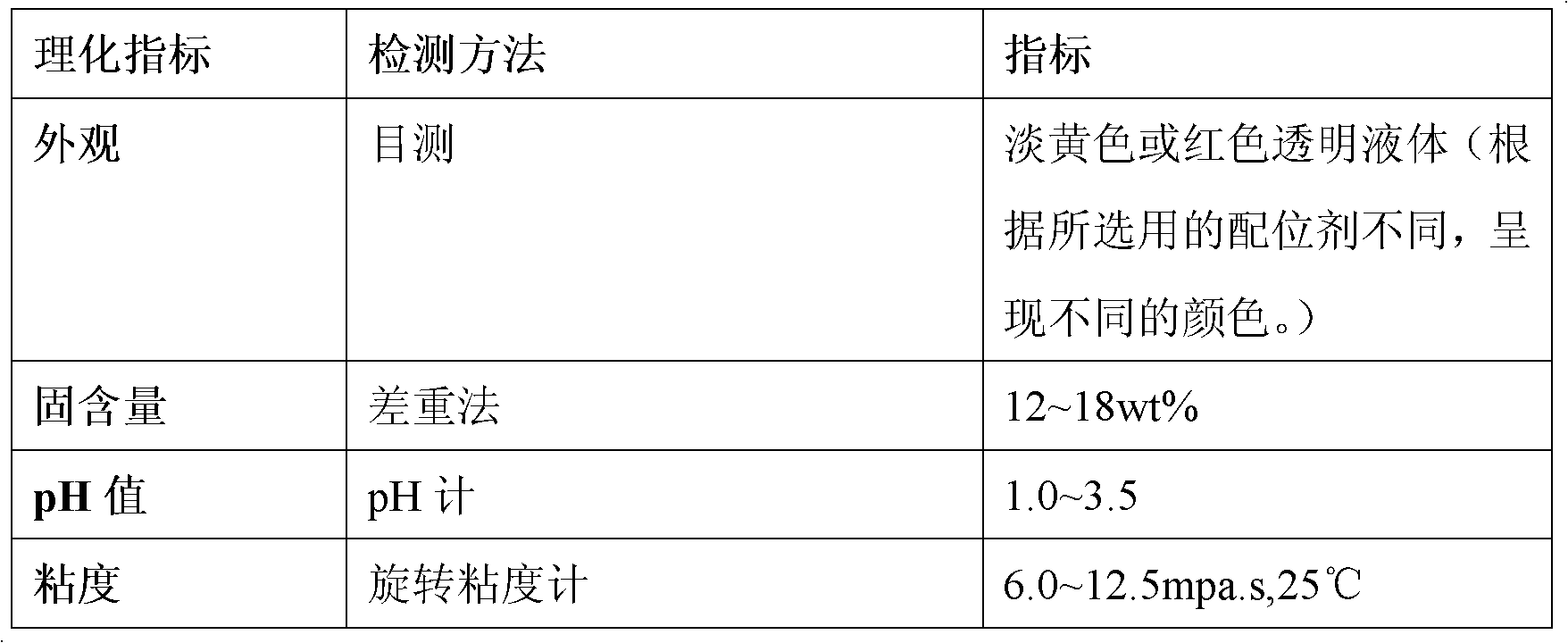

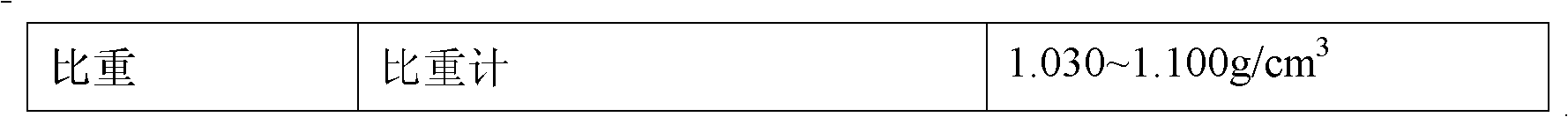

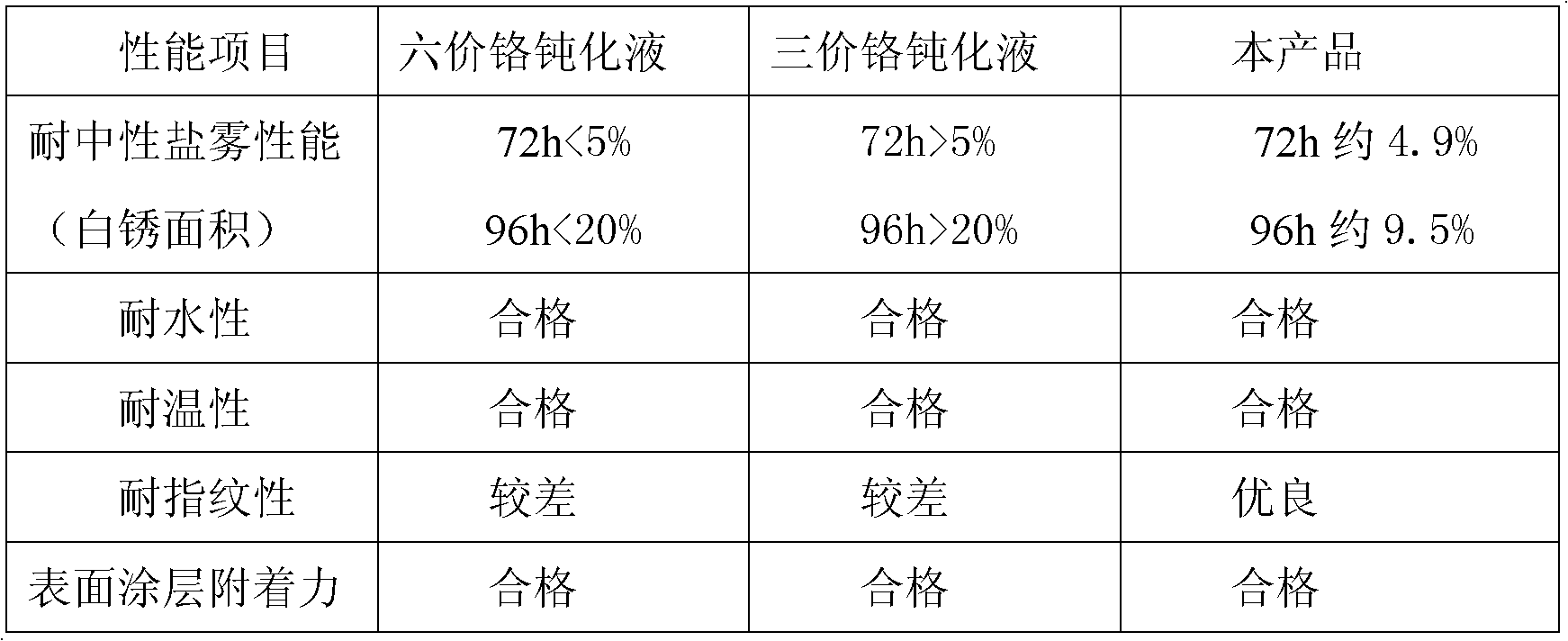

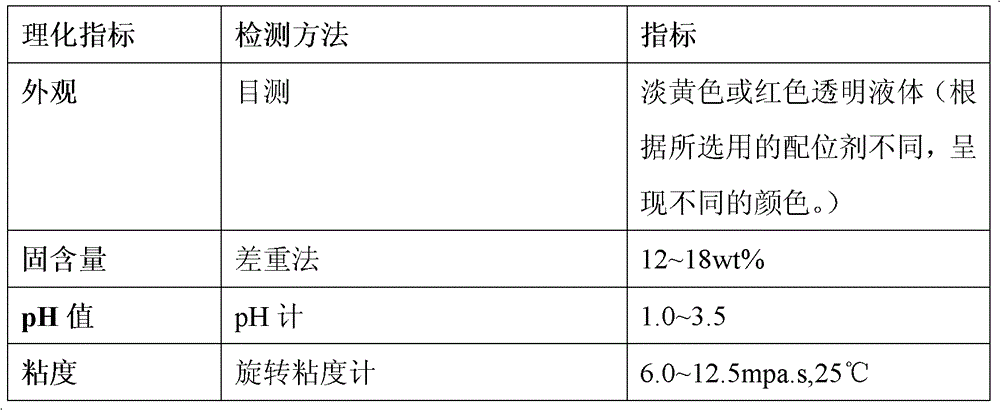

Composite film chromium-free passivant

InactiveCN101886260AGood physical propertiesImprove corrosion resistanceMetallic material coating processesOrganic acidChemical treatment

The invention relates to a composite film chromium-free passivant, which mainly comprises the following components of: a waterborne resin film-forming substance, an organic acid film-forming substance, an inorganic film-forming substance, a film-forming auxiliary agent, an additive, water and the like. The formula of the composite film chromium-free passivant is scientific and reasonable, does not comprise toxic and harmful substances such as chromium and the like, and meets the requirements of ROHS environmental protection laws and regulations which have been implemented by European Union since July 2006, so that the composite film chromium-free passivant is an environmentally-friendly chemical treatment agent. The composite film chromium-free passivant is suitable for hot galvanizing and electrogalvanizing post-processing technology, and the passivation process is simple and easy to operate. An organic and inorganic composite film is formed on the surface of a galvanized part after passivation by using the composite film chromium-free passivant. The composite film is colorless and transparent, has high corrosion resistance and can substitute for the traditional chromate to perform the passivation.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

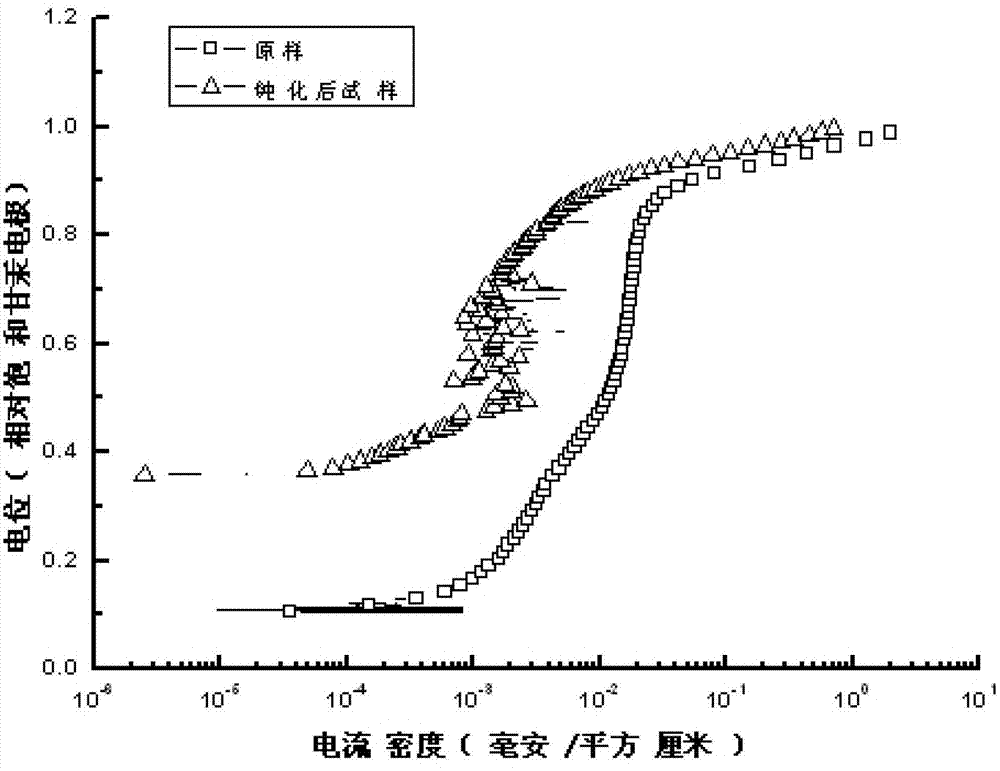

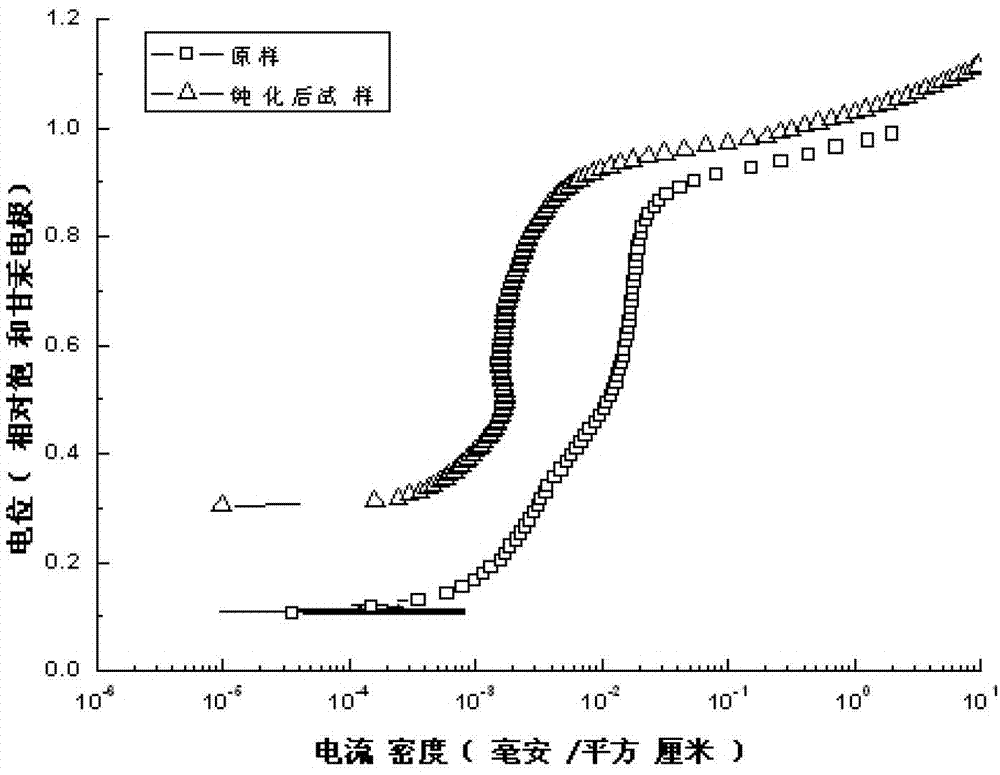

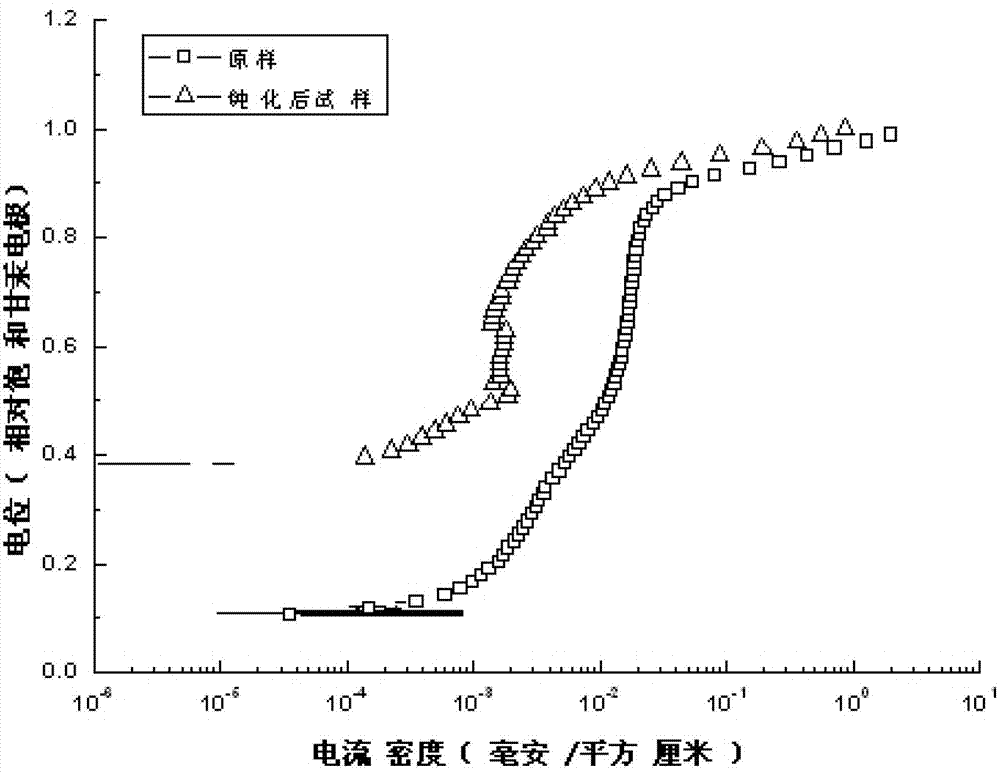

Chromium-free passivation liquid applied to surface of zinc-coated layer

ActiveCN102337532ASimple passivation processStable and reliable passivation processMetallic material coating processesHexavalent chromiumLanthanum

The invention discloses a chromium-free passivation liquid applied to the surface of a zinc-coated layer, belonging to the technical field of new materials for passivating the surfaces of zinc-coated materials (including zinc-coated steel plates and other zinc-coated parts0. The chromium-free passivation liquid does not contain metal element zirconium and is a chromium-free environmental-friendlypassivation liquid which can substitute for hexavalent chromium or trivalent chromium. Each liter of chromium-free passivation liquid comprises 20-100 g of metal element salt, 5-10 g of aqueous silane, 2-10 g of complexing agent, 10-120 g of nano filling material, 1-5 g of oxidizing agent, 5-50 g of film forming aid and the balance of water. In the chromium-free passivation liquid provided by theinvention, organic silicon modified acrylate is used as the film forming aid, cerium salt or lanthanum salt and molybdate are used as inorganic components, and the nano filling material and other aids are used as auxiliaries to form the organic and inorganic compound passivation liquid. The passivation effect of the passivation liquid even exceeds that of the hexavalent chromium or trivalent chromium passivation liquid and can totally substitute for the hexavalent chromium or trivalent chromium passivation liquid.

Owner:武汉迪赛新材料有限公司

Environment friendly stainless steel passivation solution and preparation method thereof

ActiveCN105316670APrevent infiltrationStrong adhesionMetallic material coating processesSodium molybdateUltraviolet

The invention aims at providing an environment friendly stainless steel passivation solution. The environment friendly stainless steel passivation solution comprises the following component of, by weight, 10-25 parts of citric acid, 5-15 parts of salicylic acid, 50-80 parts of hydrogen peroxide, 20-30 parts of sodium citrate, 5-8 parts of nanometer titania sol, 5-15 parts of stabilizing agents, 5-10 parts of inhibiting agents, 5-12 parts of sodium molybdate and 50-100 parts of deionized water. The invention also discloses a preparation method for the environment friendly stainless steel passivation solution. According to the environment friendly stainless steel passivation solution, the passivation effect is good, the binding force of a passivation film and a plating layer is high, and the coating property of the passivation film is good; the environment friendly stainless steel passivation solution has certain ultraviolet-proof property and antibacterial property, is free of toxic substances, and is harmless to the environment and human bodies.

Owner:NANJING WORLD SPECIAL STEEL

Inactivating process of galvanized steel sheet and inactivating liquid thereof

InactiveCN101182640AImprove bindingImprove adhesionMetallic material coating processesSheet steelTriethoxysilane

The invention discloses a passivation technique for a galvanized steel sheet and a passivation solution thereof. The r-aminopropyl-triethoxysilane water solution is applied onto a clean galvanized steel sheet surface. After the steel sheet is dried with the hot air, the sheet is immersed in the passivation solution. Finally, the sheet is dried again with the hot air. The passivation technique of the invention is simple, the passivation time is quite short, and the passivation effect is almost the same with that of the chromium passivation technique, so the invention is suitable for spreading and application.

Owner:CENT SOUTH UNIV

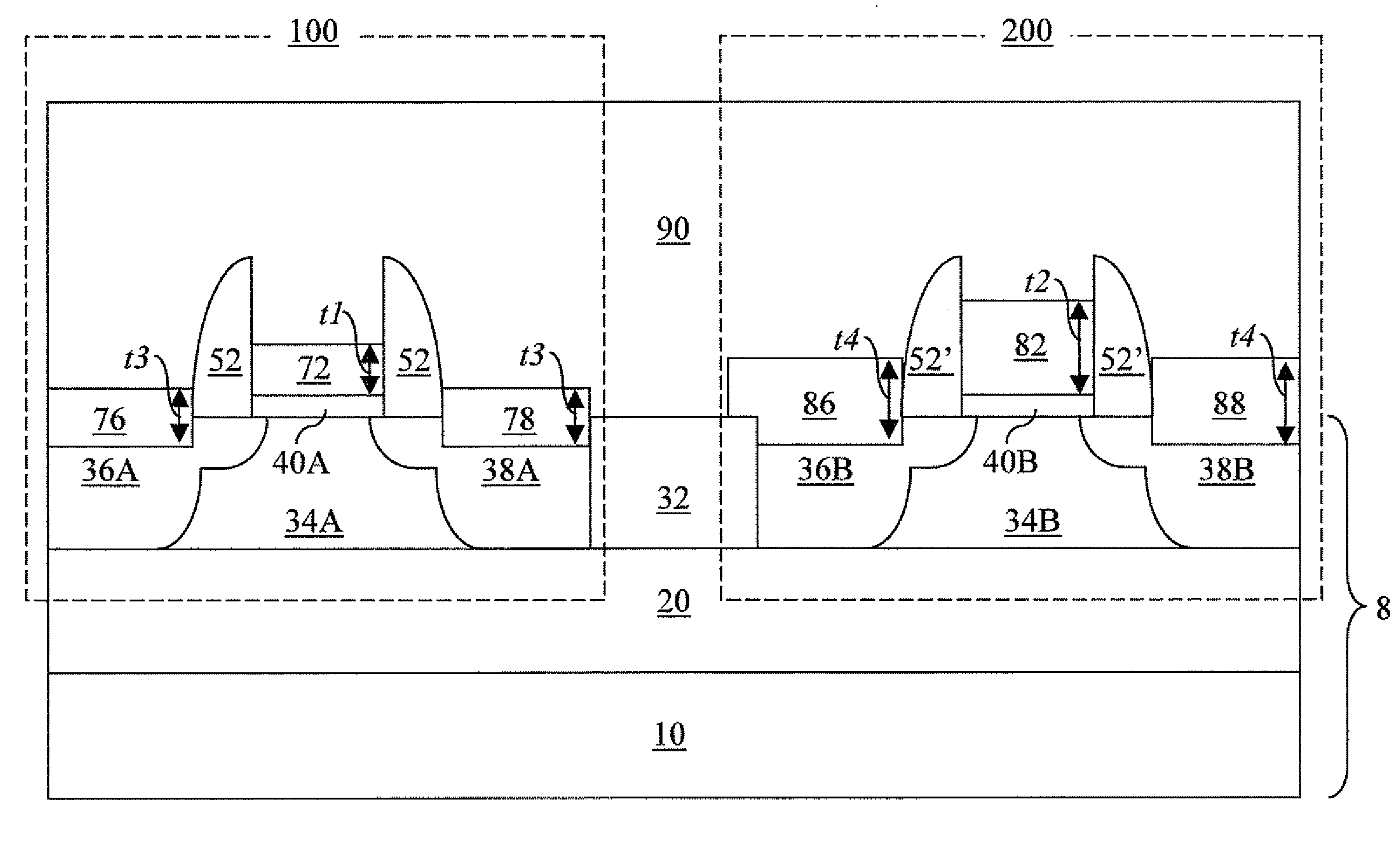

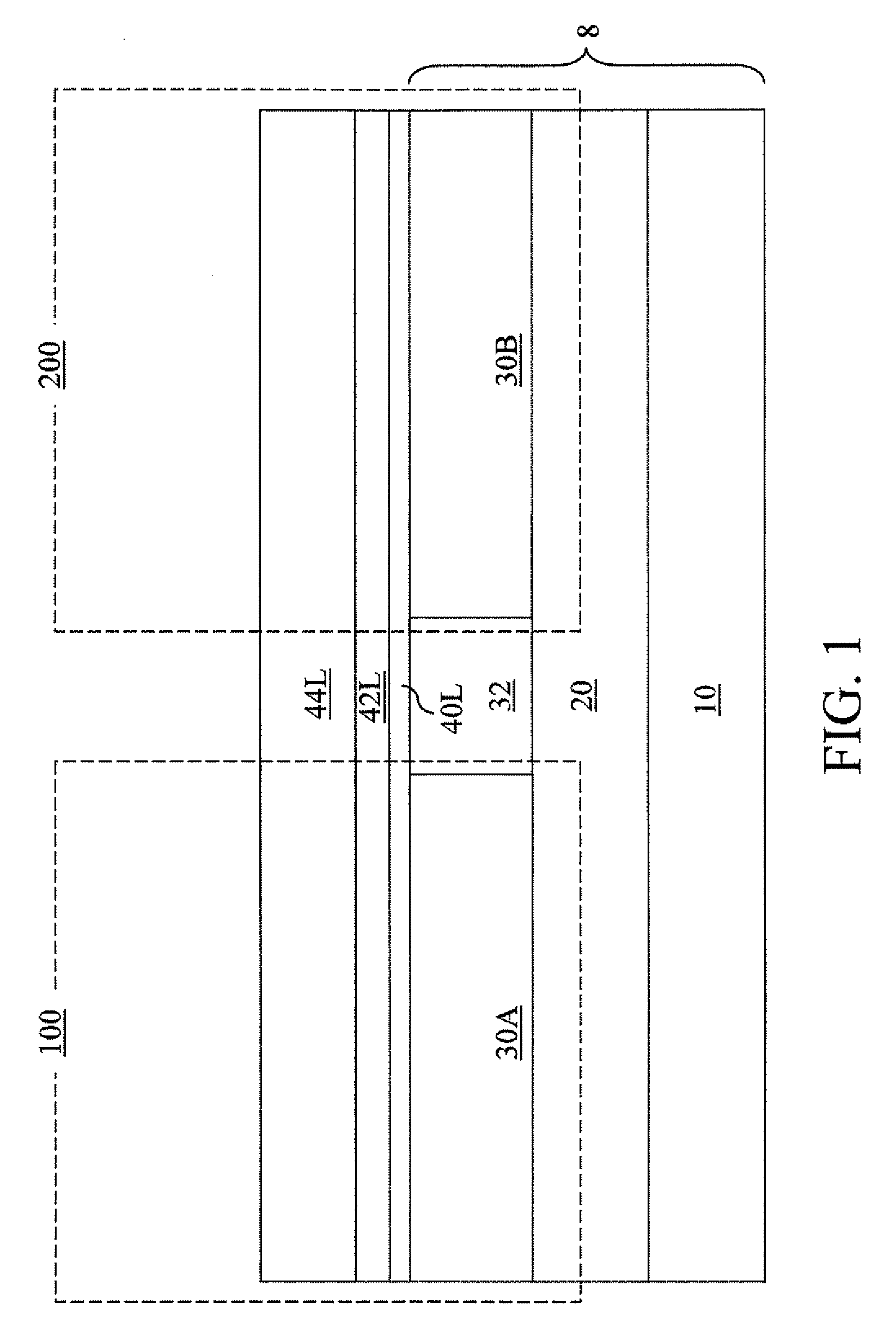

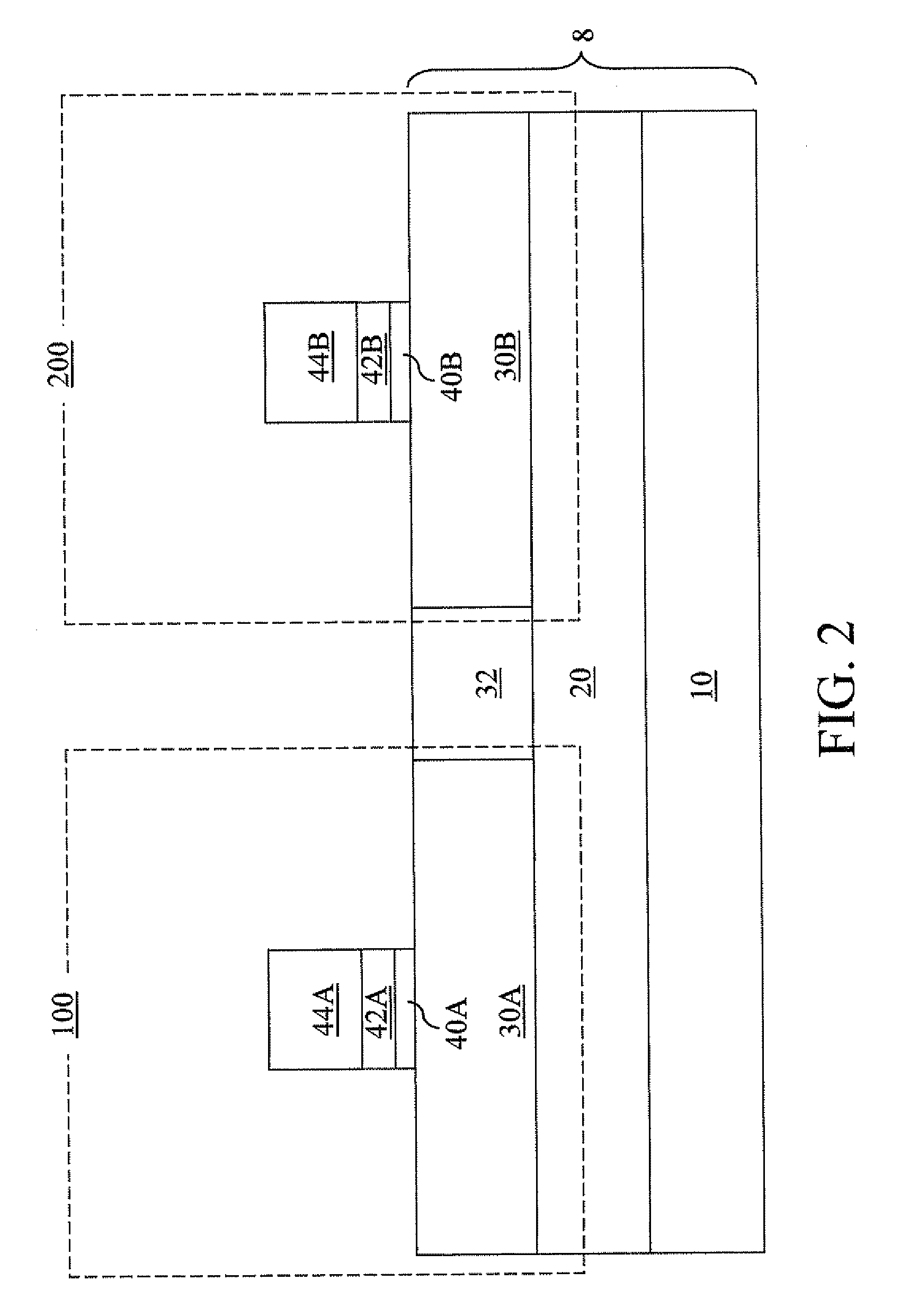

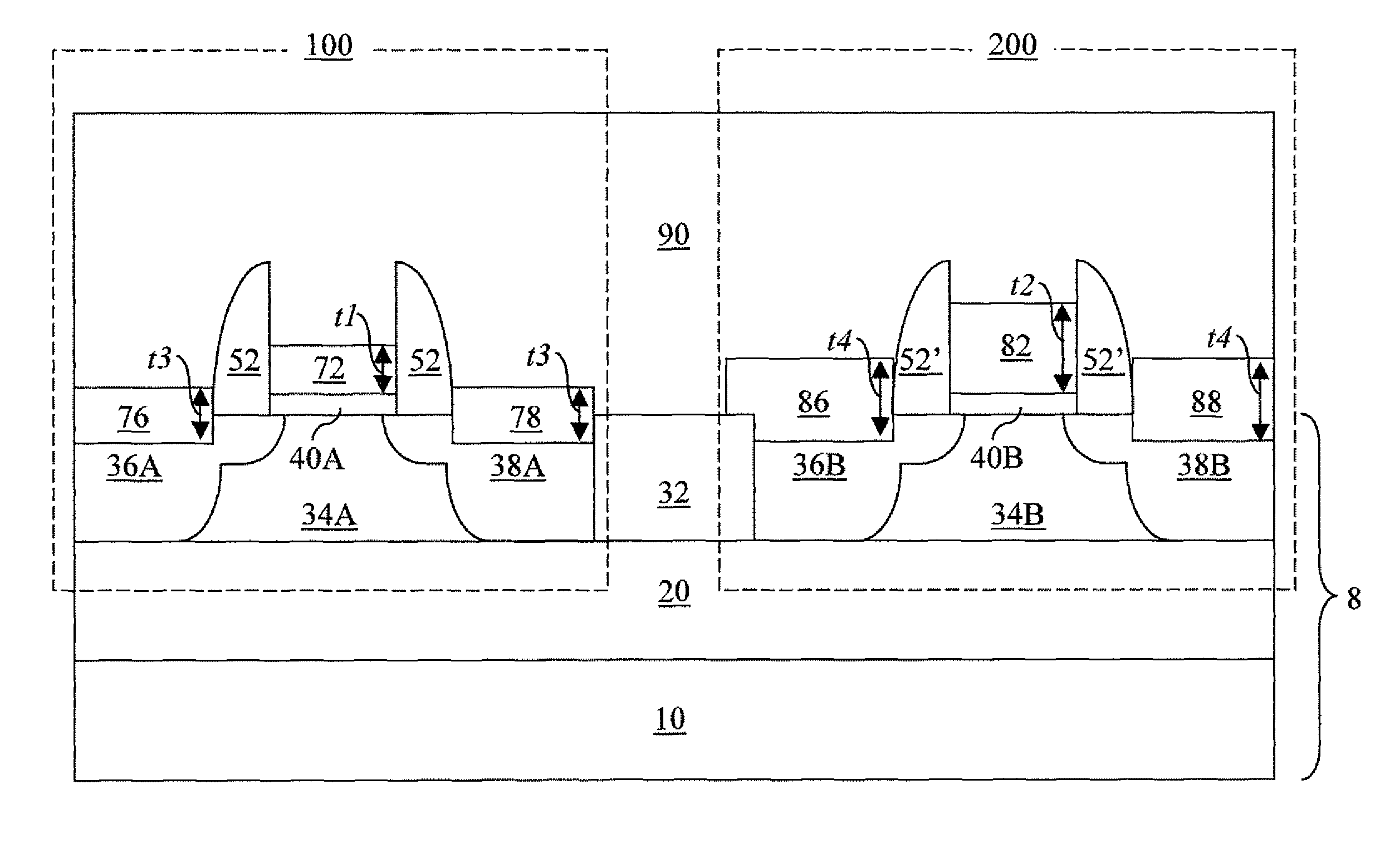

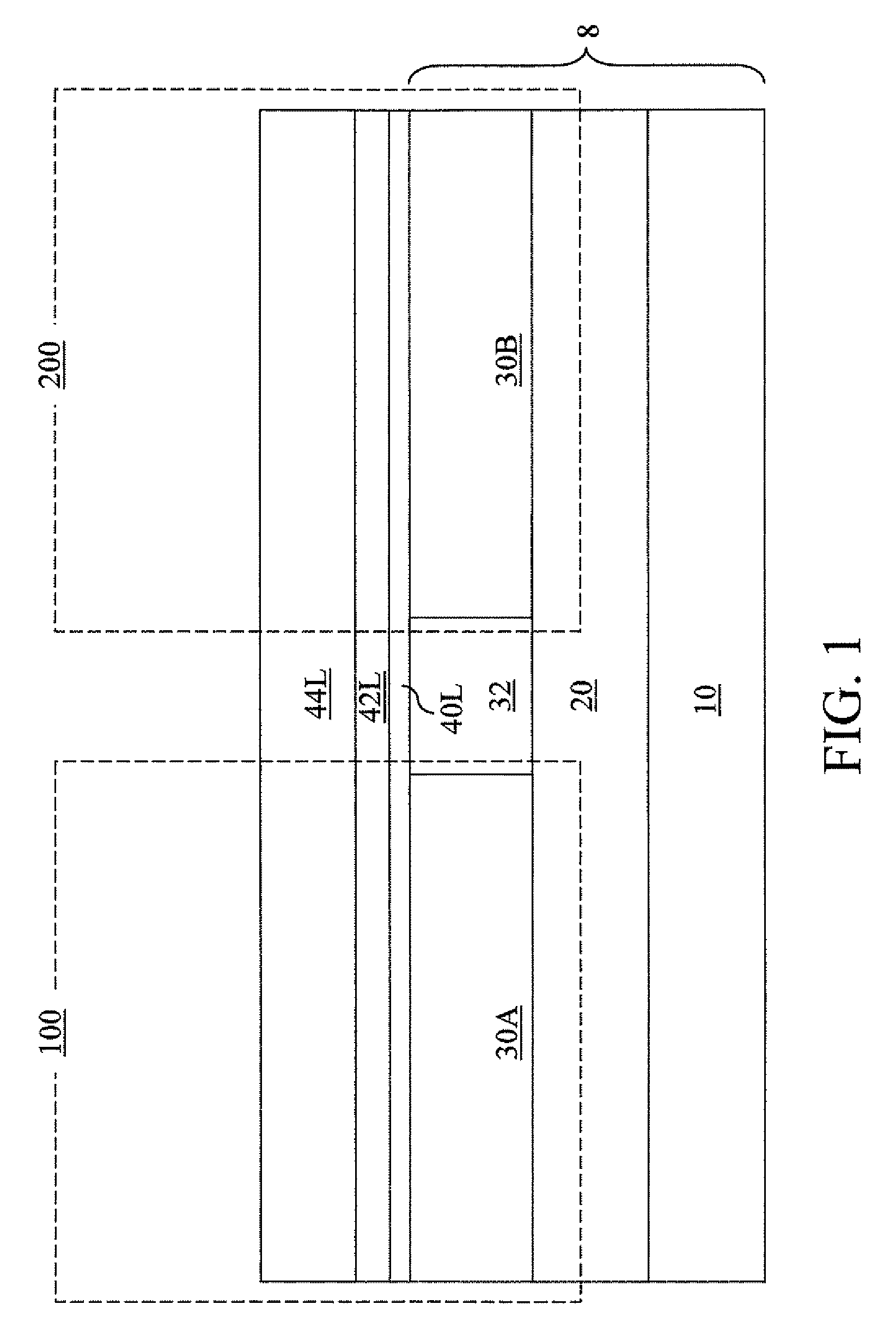

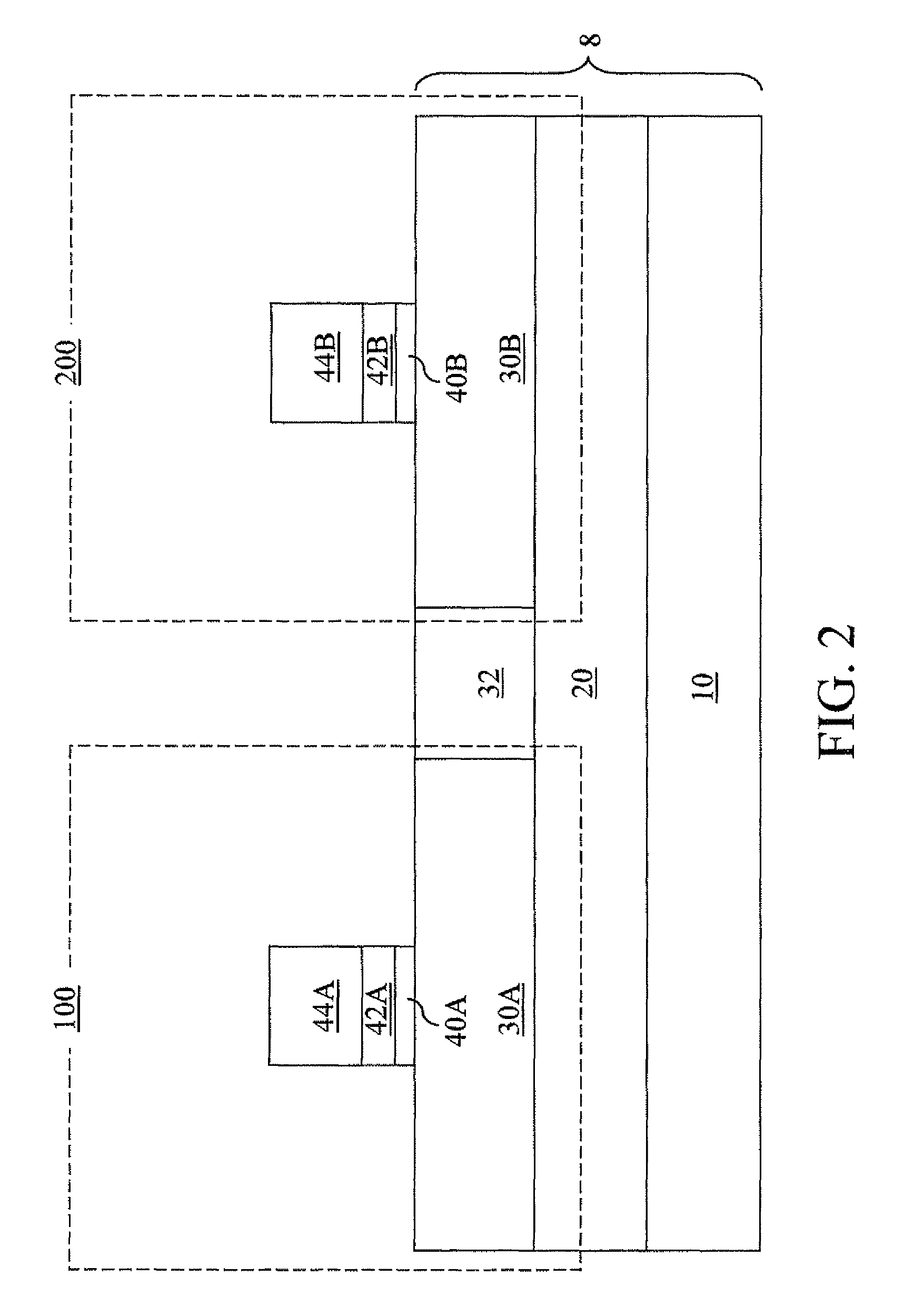

CMOS integration scheme employing a silicide electrode and a silicide-germanide alloy electrode

InactiveUS20090206413A1Reduce complexityLow costTransistorSemiconductor/solid-state device manufacturingGate dielectricSemiconductor materials

A p-type field effect transistor (PFET) and an n-type field effect transistor (NFET) are formed by patterning of a gate dielectric layer, a thin silicon layer, and a silicon-germanium alloy layer. After formation of the source / drain regions and gate spacers, silicon germanium alloy portions are removed from gate stacks. A dielectric layer is formed and patterned to cover an NFET gate electrode, while exposing a thin silicon portion for a PFET. Germanium is selectively deposited on semiconductor surfaces including the exposed silicon portion. The dielectric layer is removed and a metal layer is deposited and reacted with underlying semiconductor material to form a metal silicide for a gate electrode of the NFET, while forming a metal silicide-germanide alloy for a gate electrode of the PFET.

Owner:IBM CORP

Non-chromium inactivating technique of aluminum pipe for refrigerator, ice chest evaporator and deactivation liquid

ActiveCN101158037AImprove corrosion resistanceSimple processMetallic material coating processesAlkylphosphateSilanes

The invention relates to a non-chromium passivation technique and passivation solution of an aluminum pipe. The aluminum pipe is used for evaporators of ice refrigerators and ice chests. The invention belongs to the aluminum material surface treatment technical field. The invention aims at promoting the corrosion resistance of the aluminum pipe for evaporators of ice refrigerator and ice chest, etc. The continuous extrusion shape aluminum pipe is cooled off and quickly passivated in the passivation solution under the temperature from 20 DEG C to 90 DEG C. A tier of passivated film is formed on the surface of the aluminum pipe through airing and solidifying. The passivation solution contains passivant alkyl phosphate ester. The mass concentration of the passivant alkyl phosphate ester is from 1 percent to 15 percent. The mass concentration of the silane coupler is from 0.1 percent to 0.5 percent. The mass concentration of the sodium silicate is from 0.01 percent to 0.15 percent. The rest of the passivation solution is water. The passivated aluminum pipe is dried through wind under 20 DEG C to 60 DEG C and packed through the turn plate. The technique of the invention has the advantages of simple process, low cost and high speed, and the corrosion resistance of the passivated aluminum pipe is greatly promoted, and pharmaceuticals and passivation process has the performance of safety and environmental protection.

Owner:CENT SOUTH UNIV

Photovoltaic devices with depleted heterojunctions and shell-passivated nanoparticles

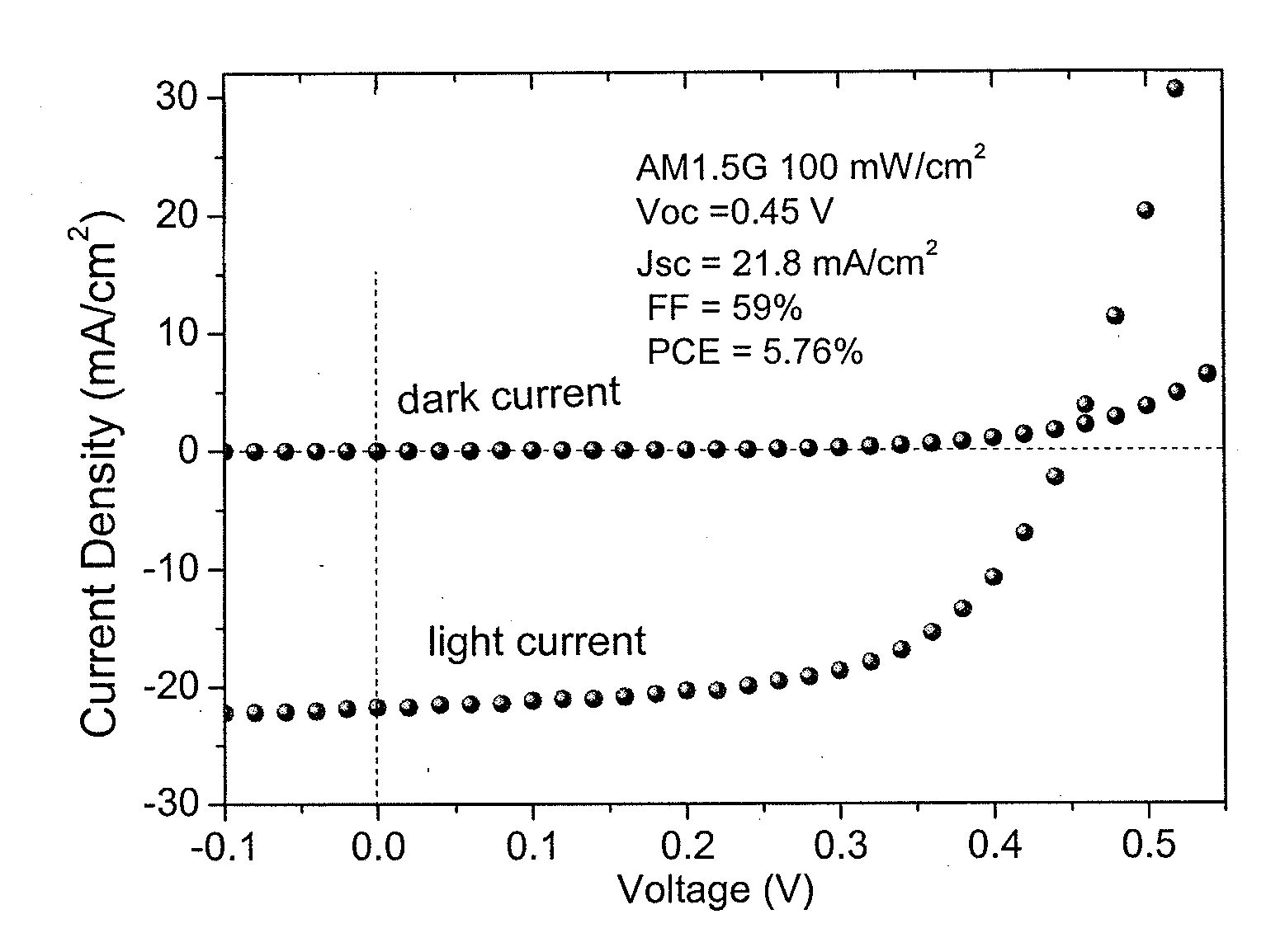

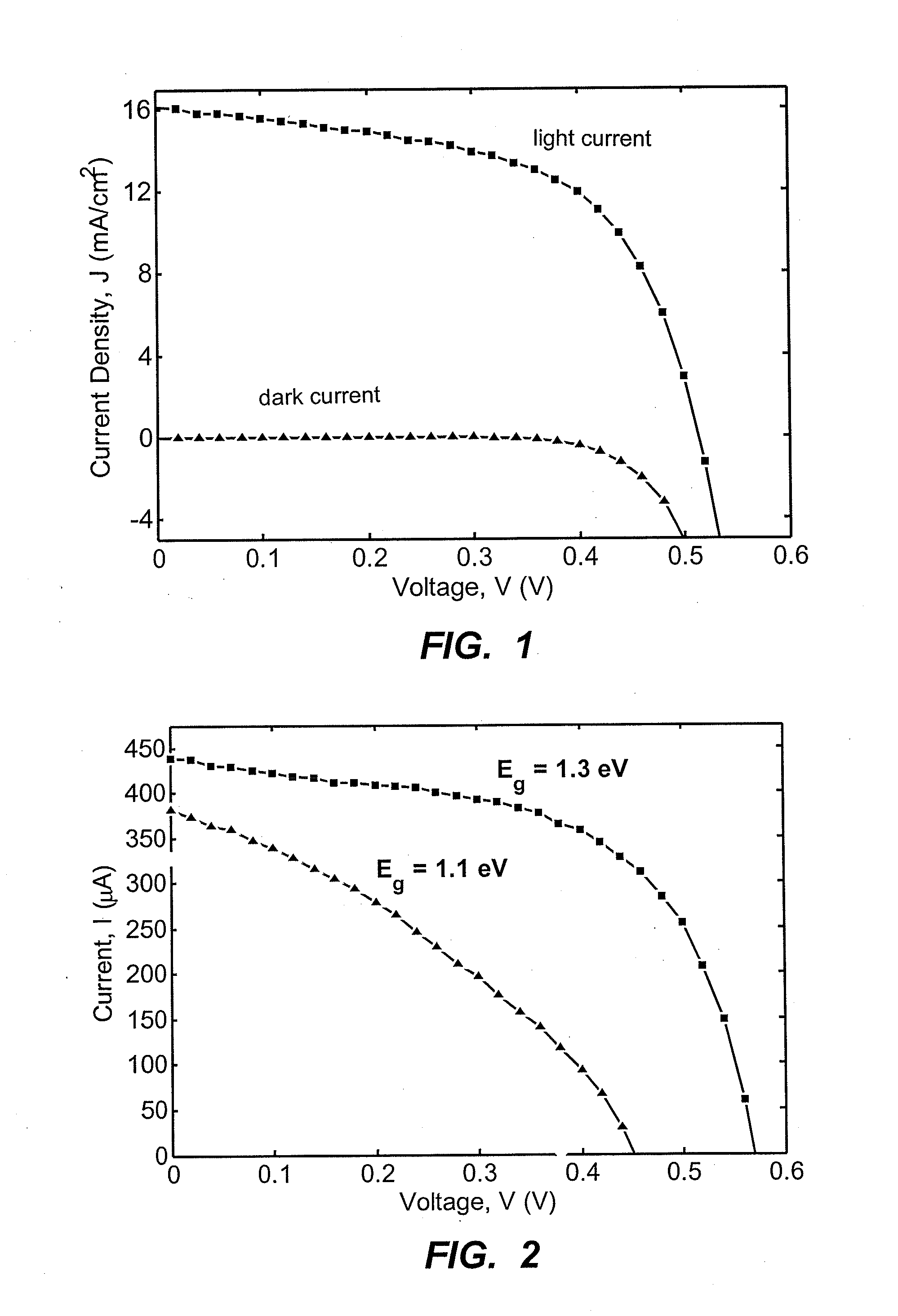

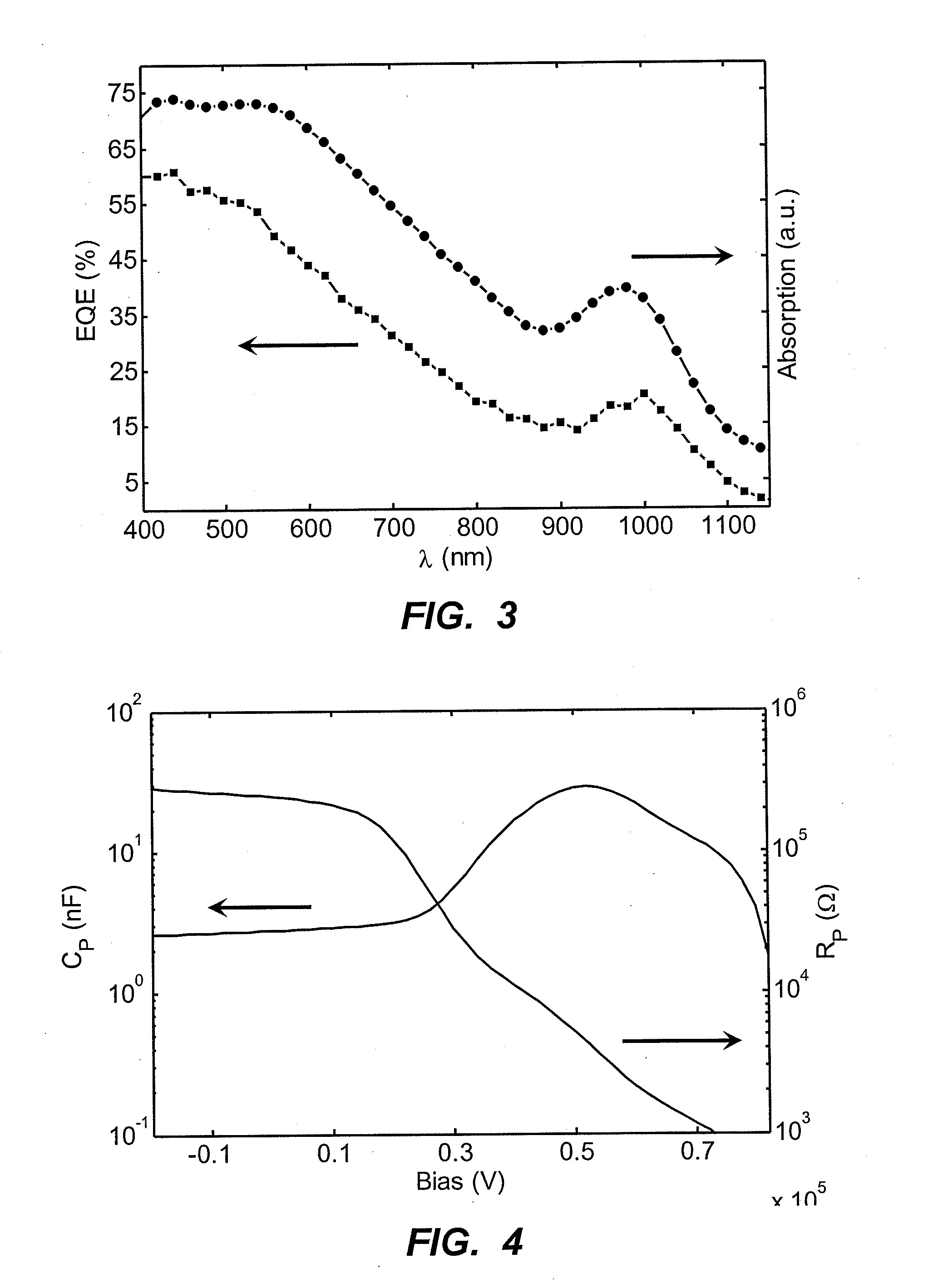

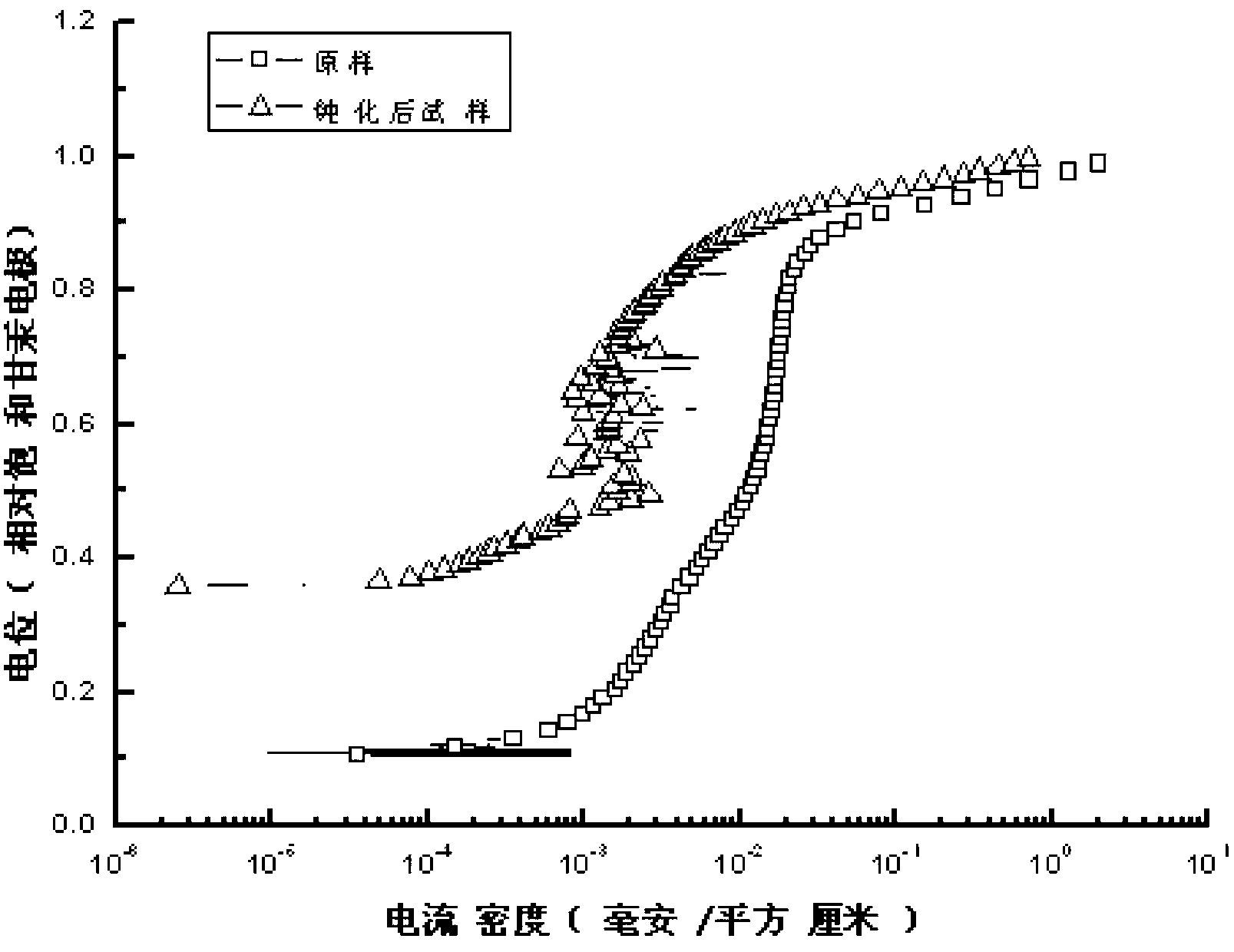

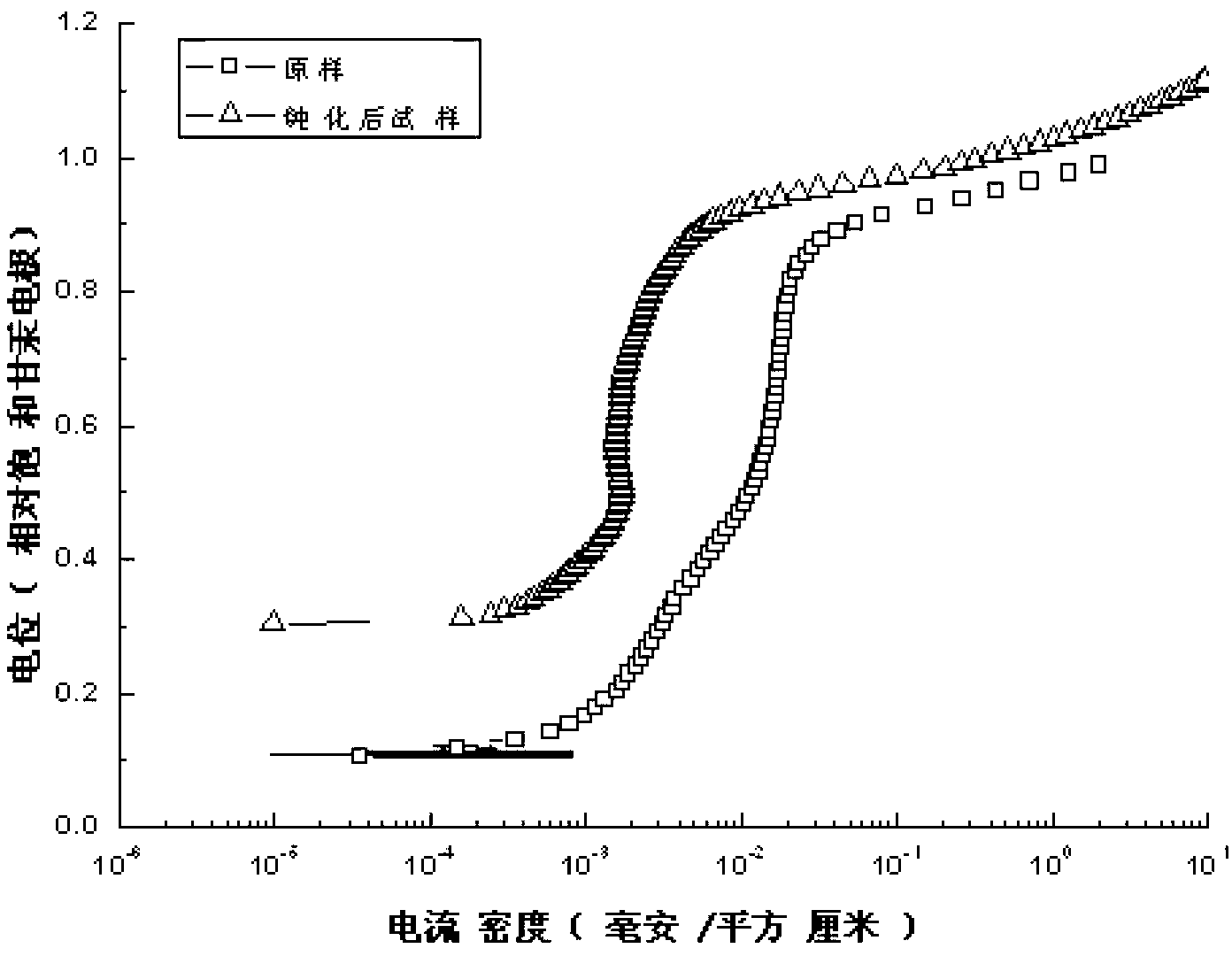

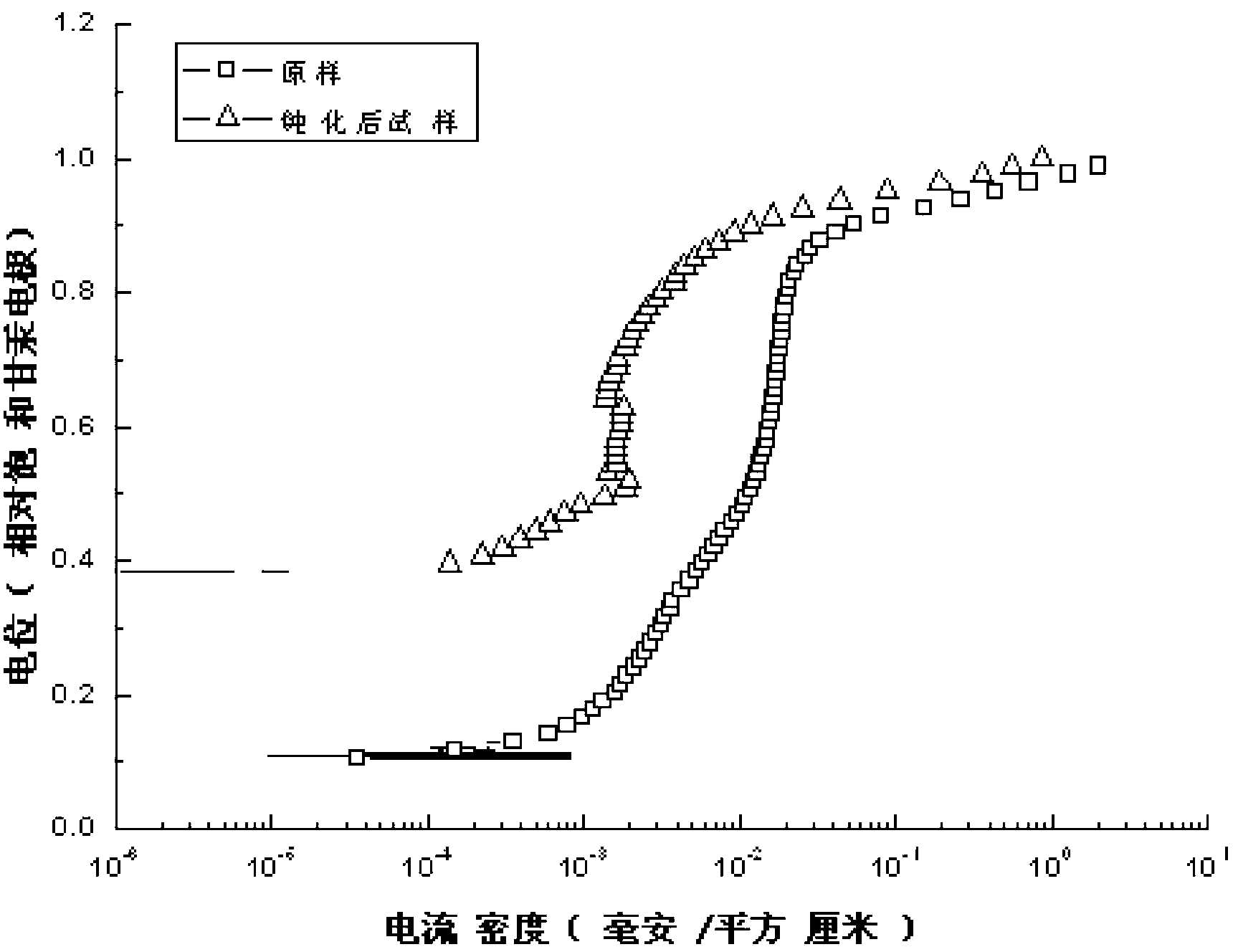

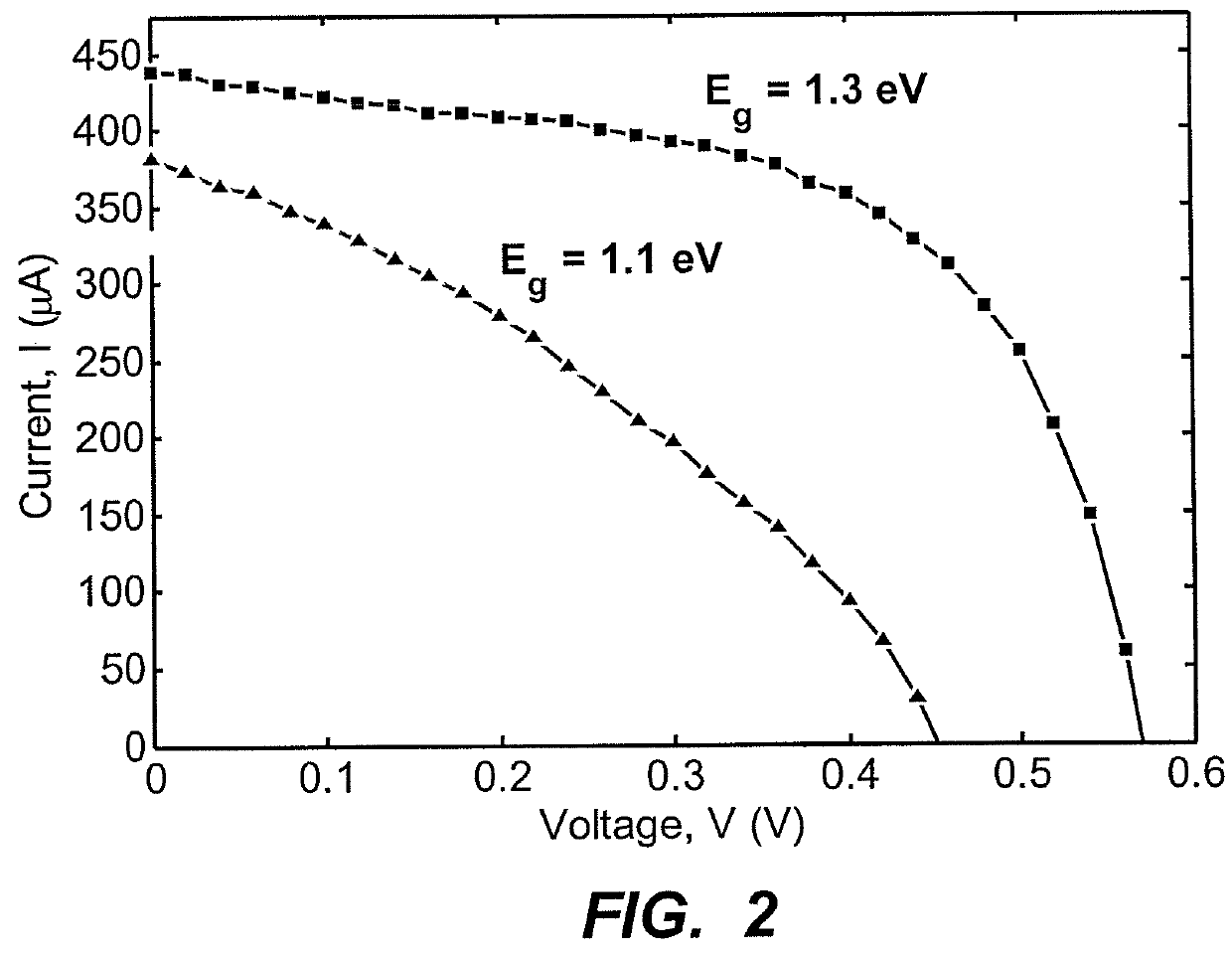

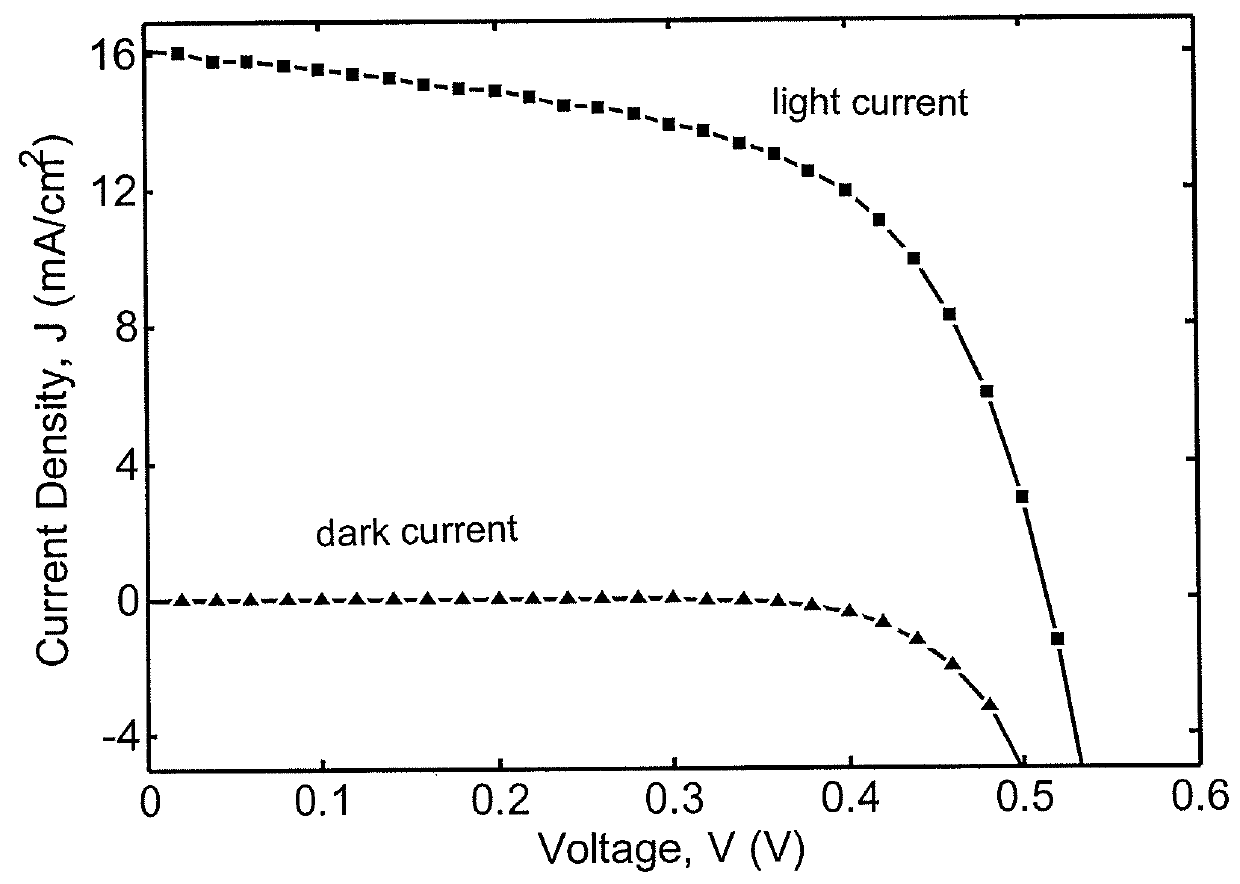

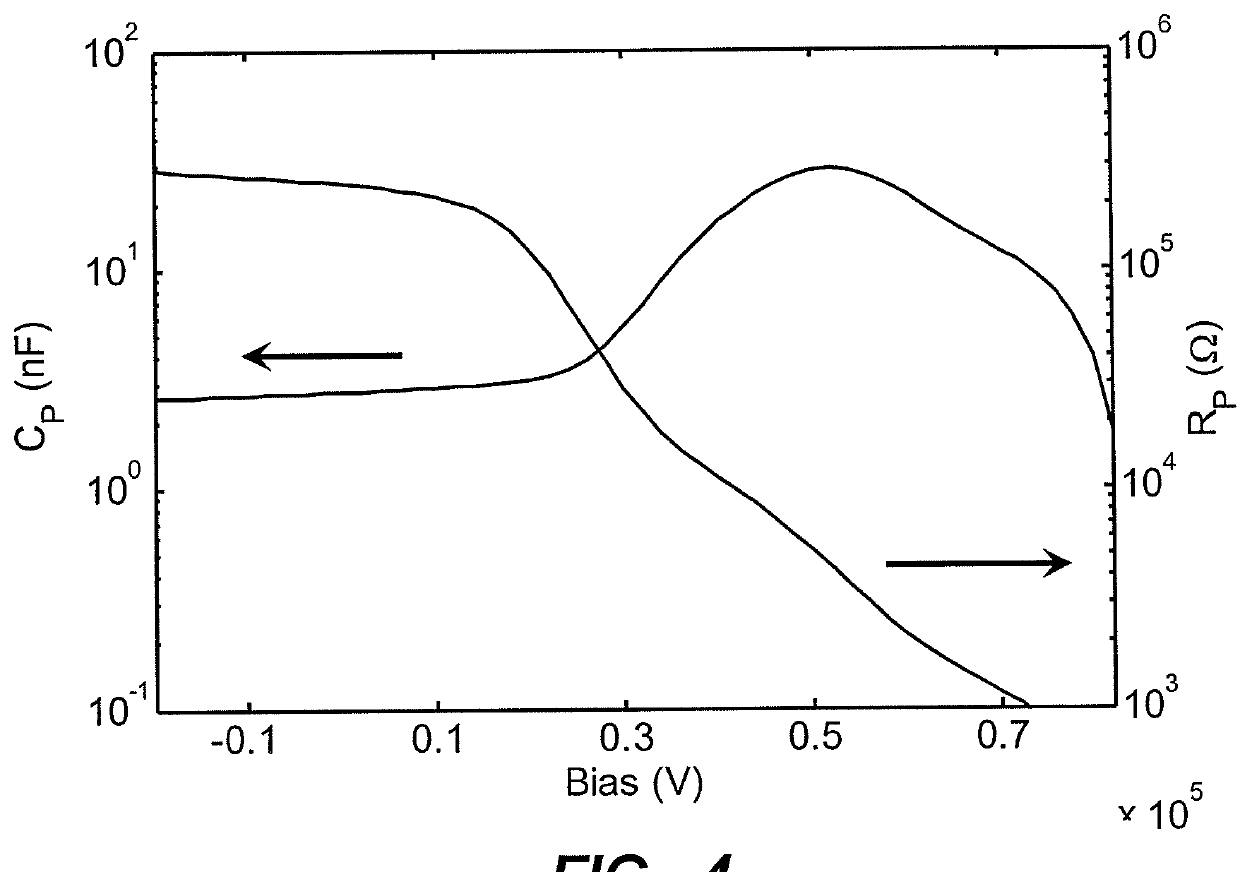

ActiveUS20110240106A1Well definedSimple passivation processSemiconductor/solid-state device manufacturingNanoopticsHeterojunctionCharge carrier

Photovoltaic cells are fabricated in which the compositions of the light-absorbing layer and the electron-accepting layer are selected such that at least one side of the junction between these two layers is substantially depleted of charge carriers, i.e., both free electrons and free holes, in the absence of solar illumination. In further aspects of the invention, the light-absorbing layer is comprised of dual-shell passivated quantum dots, each having a quantum dot core with surface anions, an inner shell containing cations to passivate the core surface anions, and an outer shell to passivate the inner shell anions and anions on the core surface.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

Chromium-free stainless steel passivating agent and passivation method using same

ActiveCN108998785ASimple passivation processImprove high temperature resistanceMetallic material coating processesOrganic acidChromium free

The invention discloses a chromium-free stainless steel passivating agent. The chromium-free stainless steel passivating agent comprises the following components in parts by weight: 10-15 parts of rare earth metal salt, 3-5 parts of organic acid, 8-10 parts of a silane coupling agent, 3-5 parts of a complexing agent, 3-5 parts of a film curing agent, 3-5 parts of an accelerant, 2-3 parts of water-soluble titanium oxide and the balance of deionized water. After adoption of a formula, a preparation process of the chromium-free stainless steel passivating agent is environment-friendly and pollution-free, and the prepared passivating agent is a novel environment-friendly product that does not contain substances forbidden in European Union ROSE instructions.

Owner:广东顺德中海源富环保科技有限公司

Method for preparing inorganic-organic composite passivation solution

ActiveCN105937029ASimple processLow costMetallic material coating processesHeavy metalsInorganic salts

The invention provides a method for preparing an inorganic-organic composite passivation solution. The method comprises the steps that nanosilicon dioxide is firstly added into water, polyvinyl chloride, citric acid and sodium bicarbonate are added, temperature is raised, a hydrochloric acid aqueous solution is added dropwise, stirring is carried out, the temperature is reduced to room temperature, filtering is carried out, and modified nanosilicon dioxide is obtained; then titanyl sulfate and sodium vanadate are added into H2O2, dispersing is carried out, and a complexing solution is obtained; then sodium molybdate is added into water, pH is adjusted to be neutral, the modified nanosilicon dioxide, accelerant and a film-forming agent are added, and an inorganic salt passivation solution is obtained; and finally a silane coupling agent KH570 and a silane coupling agent KH858 are added into ethanol water, pH is adjusted, the inorganic salt passivation solution is added, ultrasonic treatment is carried out, and the inorganic-organic composite passivation solution is obtained. The inorganic-organic composite passivation solution is an environment-friendly product and contains no heavy metal ions or volatile organic solvents polluting the environment; the passivation treatment process is simple and low in cost; and the inorganic-organic composite passivation solution can gradually replace a traditional chromate passivation solution, and environment-friendly production of galvanized plate passivation is achieved.

Owner:颍上县十里生态农业科技有限公司

Rare-earth passivation method for improving corrosion resistance of chromium carbide coating on stainless steel surface

InactiveCN103014694ANo pollution in the processNo effect on mechanical propertiesMetallic material coating processesChromium carbideRare earth

The invention provides a rare-earth passivation method for improving the corrosion resistance of a chromium carbide coating on a stainless steel surface, comprising the following steps of: carrying out deoiling and degreasing treatment on stainless steel plated with chromium carbide, and carrying out rare-earth passivation treatment. The rare-earth passivation method is characterized in that the rare-earth passivation treatment is that the stainless steel plated with the chromium carbide, which is subjected to the deoiling and degreasing treatment, is placed into a rare-earth passivation solution of KMnO4+Ce(NO3)3.6H2+Mg(NO3)2; then steps of washing and drying are carried out to obtain the passivated stainless steel plated with the chromium carbide. The rare-earth passivation method disclosed by the invention has the beneficial effects that simple passivation process, low machining cost, no pollution to the passivation solution and no influences on mechanical properties of the stainless steel plated with the chromium carbide. Meanwhile, a passivation process can obviously improve the corrosion resistance of the stainless steel plated with the chromium carbide.

Owner:DALIAN MARITIME UNIVERSITY

Environment-friendly composite colorful passivating solution and preparation method thereof

ActiveCN107740085AColorfulUniform film formationMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite colorful passivating solution and a preparation method thereof and belongs to the technical field of surface treatment of metal materials. Thepassivating solution comprises the components of 17-22 g / L of sodium silicate, 4-8 g / L of sodium molybdate, 6-10 g / L of sodium nitrate, 3-7 mL / L of hydrogen peroxide, 1-3 g / L of potassium fluoride, 2-6 mL / L of nitrilotrimethylene triphosphonic acid, 2-4 g / L of sodium gluconate, 2-4 mL / L of tartaric acid and the balance water, wherein the pH value of the passivating solution is 2.0-2.5. The preparation method of the passivating solution comprises the steps that the sodium silicate, the sodium molybdate, the sodium nitrate, the potassium fluoride, the nitrilotrimethylene triphosphonic acid, thesodium gluconate, the tartaric acid and the hydrogen peroxide are sequentially added into deionized water to be evenly mixed; the water with the constant volume is added to the needed volume; and sulfuric acid is used for adjusting the pH value to be 2.0-2.5, and thus environment-friendly composite colorful passivating solution is obtained. A galvanized layer passivated film treated by the passivating solution is colorful, bright in color, even in film forming and excellent in corrosion resistant performance; the passivating solution does not contain trivalent chromium, hexavalent chromium and other harmful substances and is environmentally friendly, free of pollution, simple in passivating process and high in passivating efficiency, and the corrosion resistance of a film layer is good.

Owner:KUNMING UNIV OF SCI & TECH

CMOS integration scheme employing a silicide electrode and a silicide-germanide alloy electrode

InactiveUS7749847B2Reduce complexityLow costTransistorSemiconductor/solid-state device manufacturingGate dielectricSemiconductor materials

A p-type field effect transistor (PFET) and an n-type field effect transistor (NFET) are formed by patterning of a gate dielectric layer, a thin silicon layer, and a silicon-germanium alloy layer. After formation of the source / drain regions and gate spacers, silicon germanium alloy portions are removed from gate stacks. A dielectric layer is formed and patterned to cover an NFET gate electrode, while exposing a thin silicon portion for a PFET. Germanium is selectively deposited on semiconductor surfaces including the exposed silicon portion. The dielectric layer is removed and a metal layer is deposited and reacted with underlying semiconductor material to form a metal silicide for a gate electrode of the NFET, while forming a metal silicide-germanide alloy for a gate electrode of the PFET.

Owner:IBM CORP

Stainless steel passivation liquid and passivation technology thereof

InactiveCN106939420AAvoid harmNo harmMetallic material coating processesAcetic anhydrideSand blasting

The invention discloses stainless steel passivation liquid and a passivation technology thereof. The stainless steel passivation liquid comprises, by weight, 40-50 parts of inorganic acid, 5-15 parts of hydrogen peroxide, 8-12 parts of cyclohexanol, 4-8 parts of 2-ethylhexyl epoxystearate, 4-6 parts of acetic anhydride, 2-4 parts of polyethyleneimine, 3-5 parts of carbomer resin, 2-4 parts of a penetrating agent, 1-3 parts of corrosion inhibitor and 10-20 parts of organic filler. The passivation technology of the stainless steel passivation liquid comprises polishing and rust removal, surface oil removal, first-time water washing, sand blasting, acid pickling passivation, second-time water washing and surface drying. The stainless steel passivation liquid is little in perniciousness, good in passivation effect and not prone to generating corrosive damage on a stainless steel product. The passivation technology is simple, operation is easy, the production cost is low, pollution to the environment is weak, and the standard of green and environment friendliness is met.

Owner:合肥协耀玻璃制品有限公司

Rare-earth passivation method for improving corrosion resistance of chromium carbide coating on stainless steel surface

InactiveCN103014694BNo pollution in the processNo effect on mechanical propertiesMetallic material coating processesChromium carbideRare earth

Owner:DALIAN MARITIME UNIVERSITY

Silicate blue-white passivation solution and preparation method thereof

InactiveCN107574430AColorfulUniform film formationMetallic material coating processesHazardous substanceMetallic materials

The invention discloses a silicate blue-white passivation solution and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The silicate blue-white passivation solution consists of 26-34g / L of sodium silicate, 2-4g / L malic acid, 8-12g / L sodium fluoride, 9-14mL / L hydrogen peroxide, 8-13mL / L amino trimethylene phosphonic acid and the balance water, and the pH of the silicate blue-white passivation solution is 3.0-3.5. The preparation method of the silicate blue-white passivation solution comprises the steps that sodium silicate, malic acid, sodiumfluoride, amino trimethylene phosphonic acid and hydrogen peroxide are sequentially added to deionized water and are mixed uniformly, water is added for constant volume treatment till the required volume is reached, and the pH is adjusted to 3.0-3.5 by adopting sulfuric acid, thus the silicate blue-white passivation solution is obtained. A zinc coating passivation film after the treatment by thesilicate blue-white passivation solution is blue-white, and is bright in color, the film forming is uniform, and the corrosion resistance is excellent; the silicate blue-white passivation solution isfree of trivalent chromium, sexavalent chrome and other hazardous materials, so that the silicate blue-white passivation solution is environment-friendly and pollution-free; a passivation technology is simple; the passivation efficiency is high; and the film layer corrosion resistance is good.

Owner:KUNMING UNIV OF SCI & TECH

Non-chromium inactivating technique of aluminum pipe for refrigerator, ice chest evaporator and deactivation liquid

ActiveCN100513639CImprove corrosion resistanceSimple passivation processMetallic material coating processesChromium freeSilanes

The invention relates to a chromium-free passivation process and a passivation solution for aluminum tubes used in evaporators of refrigerators and freezers. The invention belongs to the technical field of surface treatment of aluminum materials and aims to improve the corrosion resistance of aluminum tubes used in evaporators of refrigerators and freezers. The continuously extruded aluminum tube is cooled, quickly passivated in a passivation solution at 20°C to 90°C, and then air-dried and solidified to form a passivation film on the surface of the aluminum tube. The passivation solution contains a passivation agent The mass concentration of alkyl phosphate is 1-15%, the mass concentration of silane coupling agent is 0.1-0.5%, the mass concentration of sodium silicate is 0.01-0.15%, and the rest is water. The passivated aluminum tube is dried with wind at 20-60°C and then packaged on a turntable. The process flow is simple, the cost is low, the speed is fast, the corrosion resistance of the passivated aluminum tube is greatly improved, and the agent and the passivation process are safe and environment-friendly.

Owner:CENT SOUTH UNIV

Photovoltaic devices with depleted heterojunctions and shell-passivated nanoparticles

ActiveUS9382474B2Well definedSimple passivation processSemiconductor/solid-state device manufacturingNanoopticsHeterojunctionElectron hole

Photovoltaic cells are fabricated in which the compositions of the light-absorbing layer and the electron-accepting layer are selected such that at least one side of the junction between these two layers is substantially depleted of charge carriers, i.e., both free electrons and free holes, in the absence of solar illumination. In further aspects of the invention, the light-absorbing layer is comprised of dual-shell passivated quantum dots, each having a quantum dot core with surface anions, an inner shell containing cations to passivate the core surface anions, and an outer shell to passivate the inner shell anions and anions on the core surface.

Owner:THE GOVERNING COUNCIL OF THE UNIV OF TORONTO

Chromium-free passivation method of aluminum pipe for evaporator of refrigerator or freezer and passivation solution thereof

ActiveCN101775596BImprove corrosion resistanceSimple passivation processMetallic material coating processesChromium freePhosphate

Owner:CENT SOUTH UNIV +1

Environment-friendly composite color passivation solution and preparation method thereof

InactiveCN108531900ABright colorUniform thicknessMetallic material coating processesHazardous substancePotassium fluoride

The invention discloses an environment-friendly composite color passivation solution and a preparation method thereof, and belongs to the technical field of surface treatment of metal materials. The passivation solution comprises the components of 5-8g / L of tannic acid, 4-8mL / L of titanium trichloride, 4-7mL / L of nitric acid, 15-20mL / L hydrogen peroxide, 2-5mL / L concentrated sulfuric acid, 8-12mL / L of phosphoric acid, 2-7g / L of sodium silicate, 6-10g / L of potassium fluoride, 2-5mL / L of ascorbic acid, 4-7mL / L of aminotrimethylene fork phosphonic acid, and the balance water, and the pH value is1.5-2.0. A zinc plating coating passivation film treated by the passivation solution is bright in color, uniform in color and film thickness and excellent in corrosion resistance; and the passivationsolution has no trivalent chromium, hexavalent chromium and other harmful substances, environmental protection and no pollution are achieved, the passivation process is simple, the passivation efficiency is high, and corrosion resistance of the film is good.

Owner:KUNMING UNIV OF SCI & TECH

A sinter process for permanent magnet with high mechanical strength

InactiveCN109273241ASimple passivation processEasy to controlInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementAlloy

A technology for sinter permanent magnet with high mechanical strength comprises the following steps: S1, proportioning: taking rare earth element, iron, titanium, cobalt and ferroboron alloy as raw materials, weighing each raw material according to the following mass percentage: rare earth element 25%-35%, titanium 0.49%-0.51%, cobalt 0.58%-0.62%, boron 0.77%-1.28%, and the balance of iron and other inevitable impurities; S2, smelting: Put the raw material selected in S1 in FMI-I-500R vacuum smelt slab casting furnace, adopt rapid solidification process under vacuum degree of less than 10Pa,and then prepare that required rapid solidification slab; S3, hydrogen crushing: firstly, put the quick-setting piece prepared in S2 into the hydrogen crushing cylinder, then open the furnace door, clean the furnace chamber with a vacuum cleaner, remove the cylinder fixing pin, and put the hydrogen crushing cylinder into the furnace chamber with a charging truck. Compared with other passivation processes, the passivation process is simple and easy to control, and the corrosion resistance can be enhanced by forming a dense passivation film on the surface of the permanent magnet.

Owner:浙江嘉兴南湖电子器材集团有限公司

Alkaline gold passivation solution for zinc plating

ActiveCN109468630AImprove corrosion resistanceStrong adhesionMetallic material coating processesSodium molybdateMolybdate

The invention discloses an alkaline gold passivation solution for zinc plating, wherein the pH value of the passivation solution is 8.5- 9.5, and the composition and contents are as follows: sodium molybdate 20-30g / L, ammonia 15-20 mL / L, ammonium chloride 5-8 g / L, sodium fluoride 5-10 g / L, ethanol 13-20 mL / L, the balance being water. As the passivation solution of the invention does not contain toxic and harmful substances such as chromium, the possivation solution is novel and environmentally-friendly. The complementary,combination of ammonia water and molybdate in the passivation solution effectively avoids excessive zinc plating layer dissolusion by an acid solution, thus ensuring the thickness of the zinc plating layer and reducing the high requirement of molybdate for film thickness.The passivation solution is stable, the passivation process is simple, the corrosion resistance of the passivation film is high, the adhesion is strong, and the film thickness is uniform.

Owner:KUNMING UNIV OF SCI & TECH

Chromium-free passivation liquid applied to surface of zinc-coated layer

ActiveCN102337532BSimple passivation processStable and reliable passivation processMetallic material coating processesChromium freeSilanes

The invention discloses a chromium-free passivation liquid applied to the surface of a zinc-coated layer, belonging to the technical field of new materials for passivating the surfaces of zinc-coated materials (including zinc-coated steel plates and other zinc-coated parts0. The chromium-free passivation liquid does not contain metal element zirconium and is a chromium-free environmental-friendly passivation liquid which can substitute for hexavalent chromium or trivalent chromium. Each liter of chromium-free passivation liquid comprises 20-100 g of metal element salt, 5-10 g of aqueous silane, 2-10 g of complexing agent, 10-120 g of nano filling material, 1-5 g of oxidizing agent, 5-50 g of film forming aid and the balance of water. In the chromium-free passivation liquid provided by the invention, organic silicon modified acrylate is used as the film forming aid, cerium salt or lanthanum salt and molybdate are used as inorganic components, and the nano filling material and other aids are used as auxiliaries to form the organic and inorganic compound passivation liquid. The passivation effect of the passivation liquid even exceeds that of the hexavalent chromium or trivalent chromium passivation liquid and can totally substitute for the hexavalent chromium or trivalent chromium passivation liquid.

Owner:武汉迪赛新材料有限公司

Environment-friendly blue-white passivation liquid and preparation method thereof

InactiveCN108754475AImprove corrosion resistanceUniform film formationMetallic material coating processesEnvironmental resistanceThiourea

The invention discloses environment-friendly blue-white passivation liquid and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The passivation liquid comprises the components of 4-8 g / L of sodium silicate, 23-27 g / L of sodium nitrate, 1-5 g / L of nickel sulfate, 3-7 mL / L of titanium trichloride, 8-12 mL / L of hydrogen peroxide, 3-7 g / L of succinic acid, 0.35-0.45 g / L of benzylidene acetone, 1-3 g / L of thiourea and the balance deionized water, and the pH value is 0.5-1.5. The preparation method of the passivation liquid comprises the steps that the sodium silicate is dissolved in the deionized water; then the sodium nitrate, the nickel sulfate, the titanium trichloride, the hydrogen peroxide, the succinic acid, the benzylidene acetone andthe thiourea are sequentially added and evenly mixed; the deionized water is added to conduct constant volume to the required volume; and sulfuric acid is adopted to adjust the pH value to be 0.5-1.5,and then the silicate blue-white passivation liquid is obtained. A zinc coating passivation film treated through the passivation liquid is blue white, the color is bright, film forming is uniform, corrosion resistance is excellent, the passivation liquid does not contain trivalent chromium, hexavalent chromium and other harmful substances, environmental protection is achieved, pollution is avoided, the passivation process is simple, the passivation efficiency is high, and the film layer corrosion resistance is good.

Owner:KUNMING UNIV OF SCI & TECH

A kind of environment-friendly stainless steel passivation solution and preparation method thereof

ActiveCN105316670BPrevent infiltrationStrong adhesionMetallic material coating processesUltravioletSalicylic acid

The invention aims at providing an environment friendly stainless steel passivation solution. The environment friendly stainless steel passivation solution comprises the following component of, by weight, 10-25 parts of citric acid, 5-15 parts of salicylic acid, 50-80 parts of hydrogen peroxide, 20-30 parts of sodium citrate, 5-8 parts of nanometer titania sol, 5-15 parts of stabilizing agents, 5-10 parts of inhibiting agents, 5-12 parts of sodium molybdate and 50-100 parts of deionized water. The invention also discloses a preparation method for the environment friendly stainless steel passivation solution. According to the environment friendly stainless steel passivation solution, the passivation effect is good, the binding force of a passivation film and a plating layer is high, and the coating property of the passivation film is good; the environment friendly stainless steel passivation solution has certain ultraviolet-proof property and antibacterial property, is free of toxic substances, and is harmless to the environment and human bodies.

Owner:NANJING WORLD SPECIAL STEEL

Organic-inorganic environment-friendly composite color passivation solution and preparation method thereof

InactiveCN110983318AImprove corrosion resistanceImprove passivation efficiencyMetallic material coating processesMeth-Phosphoric acid

The invention discloses an organic-inorganic environment-friendly composite color passivation solution and a preparation method thereof, and belongs to the technical field of metal material surface treatment. The passivation solution comprises the following components: 20-35 g / L of sodium molybdate, 1-2 g / L of sodium fluosilicate, 4-6 g / L of nitric acid, 1-2 g / L of 2-undecyl-N-carboxymethyl-N-hydroxyl-imidazoline, 5-7 g / L of sodium citrate, 5-7 g / L of citric acid, 3-5 mL / L of hydrogen peroxide, 3-5 mL / L of lauryl sodium sulfate, 3-4 mL / L of amino trimethylene phosphonic acid, and the balance water; and the pH value is 4-5. A zinc plating passivation film treated by the passivation solution is bright in color and uniform in color and film layer thickness; the passivation solution contains no trivalent chromium, hexavalent chromium and other harmful substances, and is environment-friendly, free of pollution, simple in passivation process, high in passivation efficiency and excellent in film layer corrosion resistance.

Owner:KUNMING UNIV OF SCI & TECH

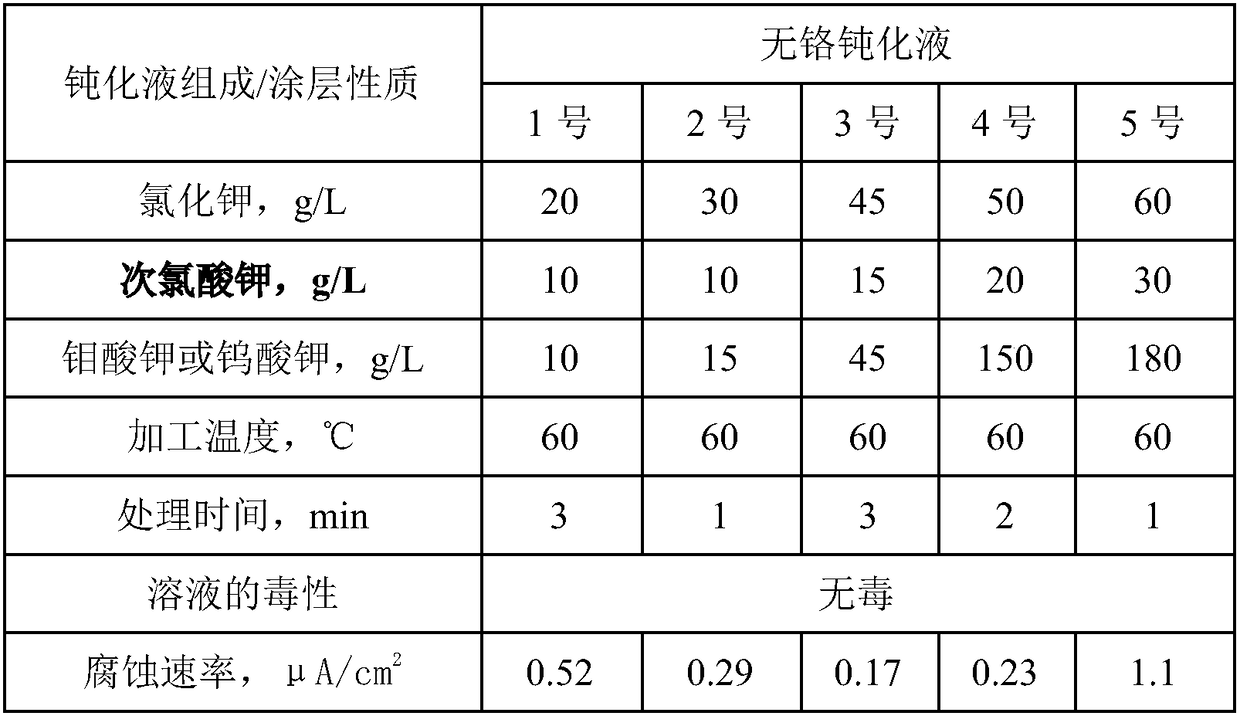

Chrome-free passivating liquid and passivating method for silver and silver coating

ActiveCN108385092APromote growthSimple passivation processMetallic material coating processesMolybdateHypochlorite

The invention belongs to the surface technical field of metallurgical metal materials and discloses a chrome-free passivating liquid and a passivating method for silver and a silver coating. Molybdateor tungstate, a removing agent and a complexing agent are included. The molybdate or tungstate can be selected from one or more of alkali metal molybdate or alkali metal tungstate; the removing agentcan be selected from chloride; and the complexing agent can be selected from hypochlorite. According to a passivating manner, the silver and the silver coating are soaked in a prepared solution, thedipping time is 1-3 min, and the dipping temperature does not exceed 60 DEG C; and the silver and the silver coating are taken out, washed and dried, and a silver and silver coating passivating film is obtained. The passivating solution does not contain hexavalent or trivalent chromium harmful to human bodies and the envrionment, the passivating process is simple, cost is low, controllability is good, a film layer grows fast and is good in corrosion resistance, and industrialized popularization can be performed in the industrial field.

Owner:威海畅享海天新材料科技股份有限公司

A rare earth passivation solution based on nano-attapulgite and its preparation and passivation process

ActiveCN107419254BImprove bindingWell mixedMetallic material coating processesRare-earth elementSodium Bentonite

The invention provides rare earth passivation liquid based on nanometer attapulgite and preparation and passivation processes thereof. The rare earth passivation liquid based on the nanometer attapulgite comprises rare earth coated natural bentonite, the nanometer attapulgite, a silane coupling agent, hydrogen peroxide, sulfuric acid, sodium nitrate and copper sulfate. The preparation method comprises the following steps: the silane coupling agent is added in ethanol water solution for uniform stirring, the nanometer attapulgite is added for uniform stirring to form nanometer attapulgite solution; the natural bentonite and rare earth elements are added in distilled water for magnetic stirring dissolution at room temperature to form rare earth coated bentonite solution; and after the two types of solution are mixed, aluminum silicate and auxiliaries are added for uniform mixing to form the rare earth passivation liquid based on the nanometer attapulgite. The silane coupling agent is used for modifying the rare earth elements, the nanometer attapulgite and the natural bentonite, and is combined with silicate; the prepared passivation liquid is stable and uniform; the passivation process is simple; the passivation effect is good; the use level of rare earth is reduced; and the cost is reduced.

Owner:湖州奇奇机电科技有限公司

A kind of environment-friendly composite color passivation solution and preparation method thereof

ActiveCN107740085BColorfulUniform film formationMetallic material coating processesEnvironmental resistanceHazardous substance

The invention discloses an environment-friendly composite colorful passivating solution and a preparation method thereof and belongs to the technical field of surface treatment of metal materials. Thepassivating solution comprises the components of 17-22 g / L of sodium silicate, 4-8 g / L of sodium molybdate, 6-10 g / L of sodium nitrate, 3-7 mL / L of hydrogen peroxide, 1-3 g / L of potassium fluoride, 2-6 mL / L of nitrilotrimethylene triphosphonic acid, 2-4 g / L of sodium gluconate, 2-4 mL / L of tartaric acid and the balance water, wherein the pH value of the passivating solution is 2.0-2.5. The preparation method of the passivating solution comprises the steps that the sodium silicate, the sodium molybdate, the sodium nitrate, the potassium fluoride, the nitrilotrimethylene triphosphonic acid, thesodium gluconate, the tartaric acid and the hydrogen peroxide are sequentially added into deionized water to be evenly mixed; the water with the constant volume is added to the needed volume; and sulfuric acid is used for adjusting the pH value to be 2.0-2.5, and thus environment-friendly composite colorful passivating solution is obtained. A galvanized layer passivated film treated by the passivating solution is colorful, bright in color, even in film forming and excellent in corrosion resistant performance; the passivating solution does not contain trivalent chromium, hexavalent chromium and other harmful substances and is environmentally friendly, free of pollution, simple in passivating process and high in passivating efficiency, and the corrosion resistance of a film layer is good.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com