Rare-earth passivation method for improving corrosion resistance of chromium carbide coating on stainless steel surface

A surface carbonization and stainless steel technology, applied in the passivation treatment of chromium carbide coating on the surface of stainless steel, and the treatment of chromium carbide coating on the surface of stainless steel, can solve the problems of rare reports, difficult process control, high production cost, etc., to improve corrosion resistance The effect of high reliability, low processing cost and simple passivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

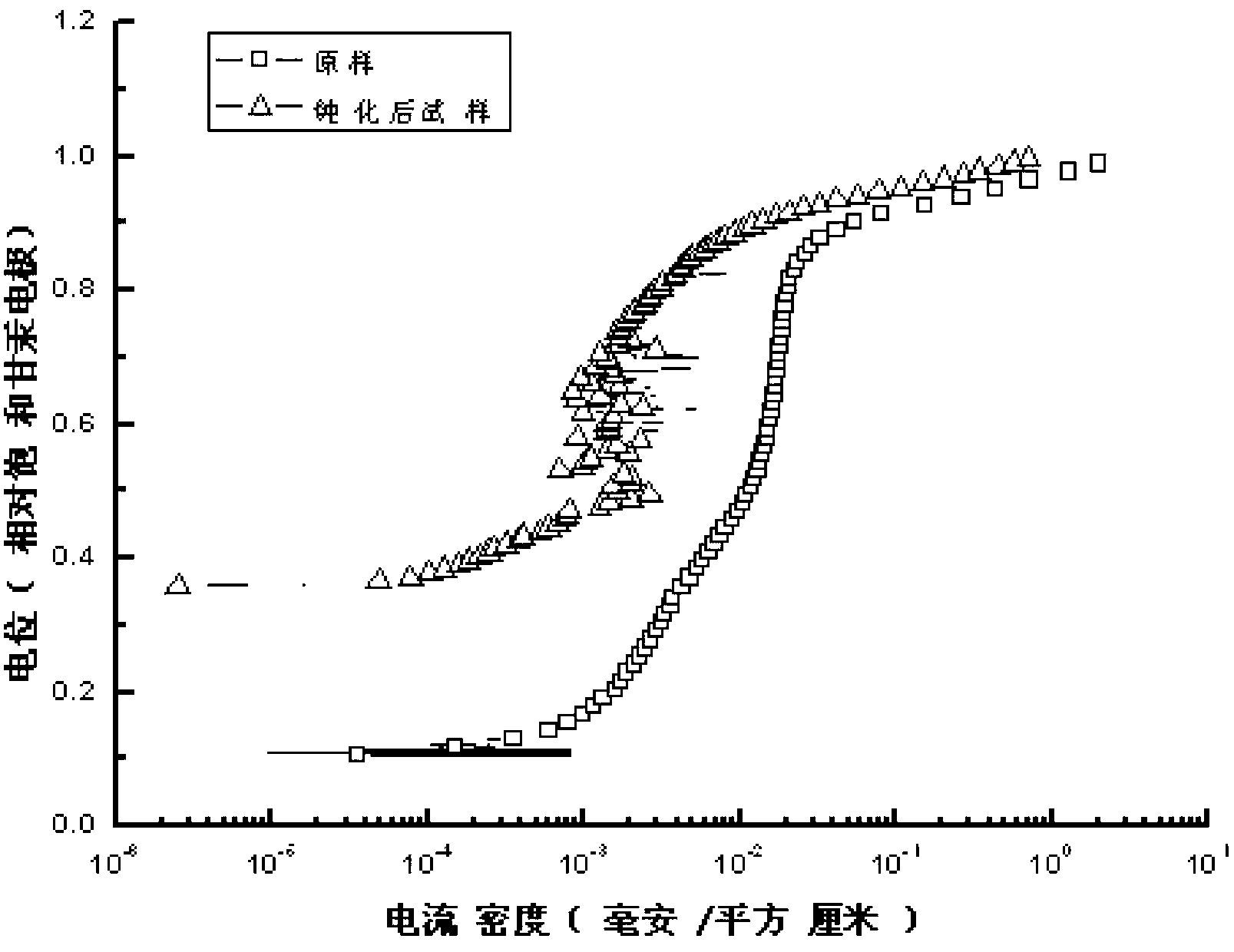

[0025] 40g / L KMnO with a pH value of 6 at 80°C for the chromium carbide-plated stainless steel plate after pretreatment 4 +5g / LCe(NO 3 ) 3 ·6H 2 O+100g / L Mg(NO 3 ) 2 In the rare earth passivation solution, passivate for 8 minutes, rinse it with deionized water and dry it after taking it out. 0.5mol / L H of the sample at 80°C before and after treatment 2 SO 4 The polarization curve in solution is as figure 1 , the corrosion resistance of chromium carbide plated stainless steel after passivation treatment is improved by nearly 1 order of magnitude.

Embodiment 2

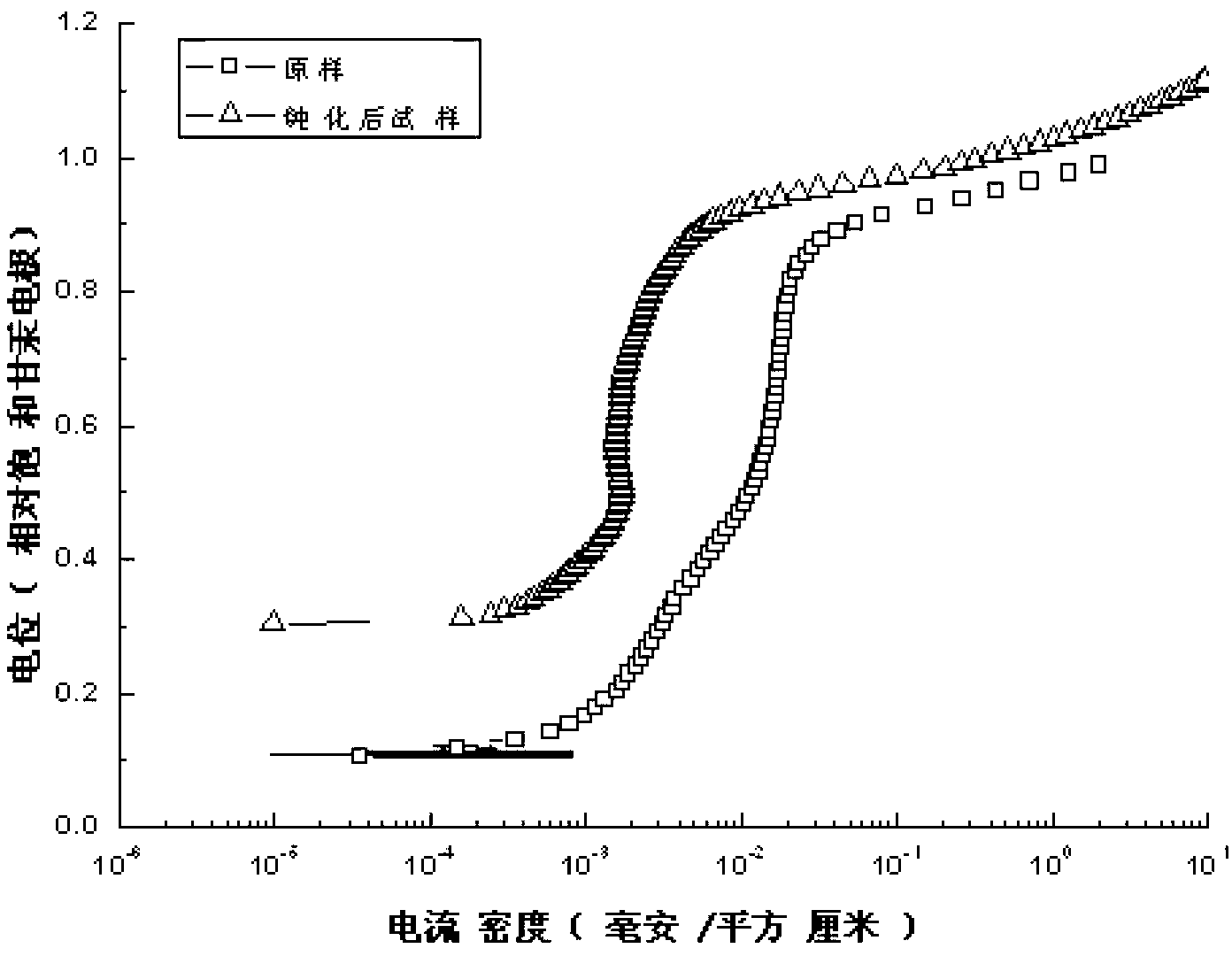

[0027] The pretreated chromium carbide plated stainless steel plate is 40g / L KMnO with a pH value of 3 at 70°C 4 +25g / LCe(NO 3 ) 3 ·6H 2 O+50g / L Mg(NO 3 ) 2 In the rare earth passivation solution, passivate for 4 minutes, rinse with deionized water and dry after taking it out. 0.5mol / L H of the sample at 80°C before and after treatment 2 SO 4 The polarization curve in solution is as figure 2 , the corrosion current density of chromium carbide-plated stainless steel after passivation treatment is reduced by nearly 1 order of magnitude.

Embodiment 3

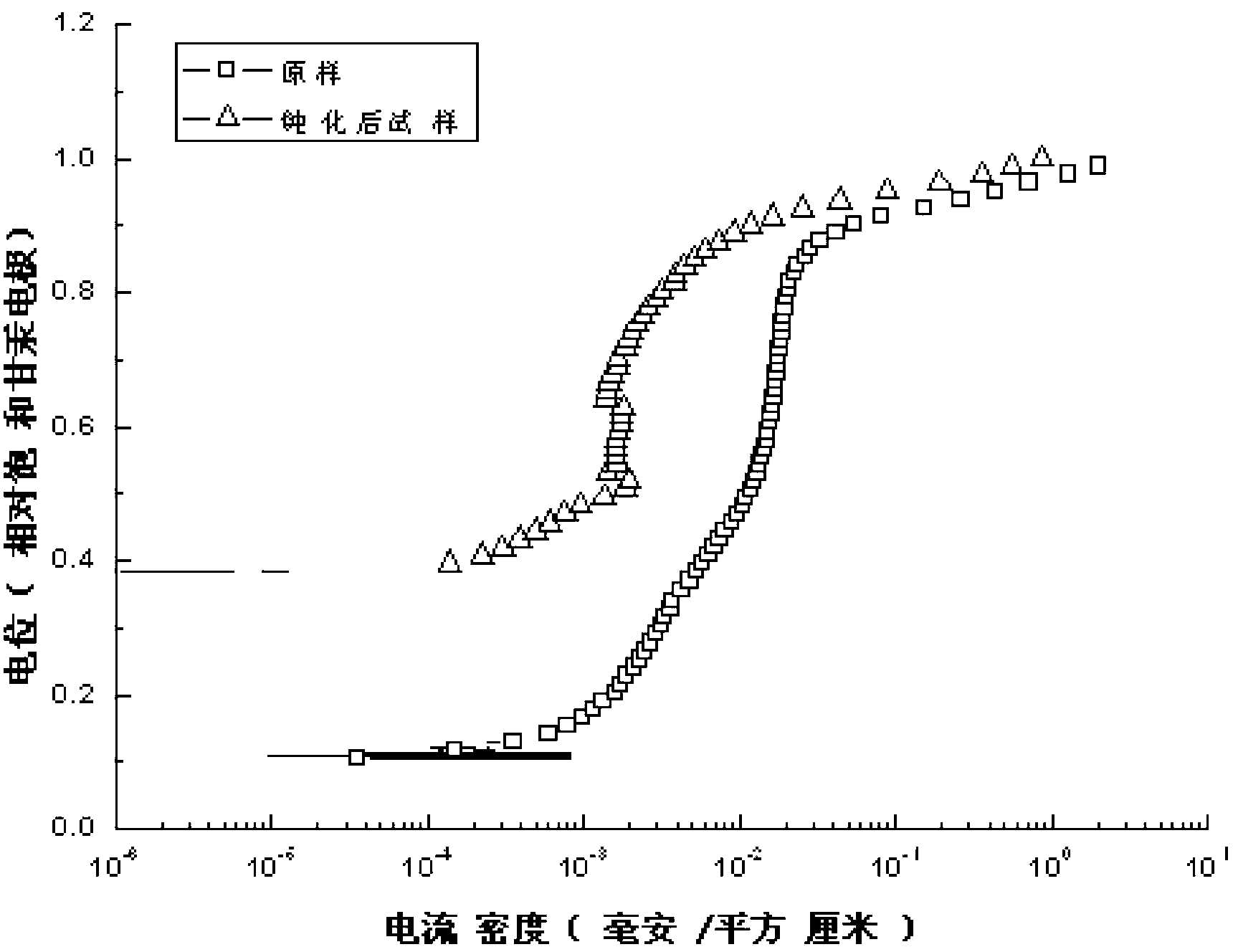

[0029] The pretreated chromium carbide plated stainless steel plate is 25g / L KMnO with a pH value of 5 at 40°C 4 +20g / L Ce(NO 3 ) 3 ·6H 2 O+100g / L Mg(NO 3 ) 2 In the rare earth passivation solution, passivate for 10 minutes, rinse with deionized water and dry after taking it out. 0.5mol / L H of the sample at 80°C before and after treatment 2 SO 4 The polarization curve in solution is as image 3 , Passivation treatment significantly reduces the corrosion current density of chromium carbide-plated stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com