Chrome-free passivating liquid and passivating method for silver and silver coating

A chrome-free passivation and silver coating technology, applied in the coating process of metal materials, etc., can solve the problems of toxic environmental pollution, etc., and achieve the effects of good controllability, low cost, and simple passivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A preparation and passivation method of silver and silver coating chromium-free passivation solution:

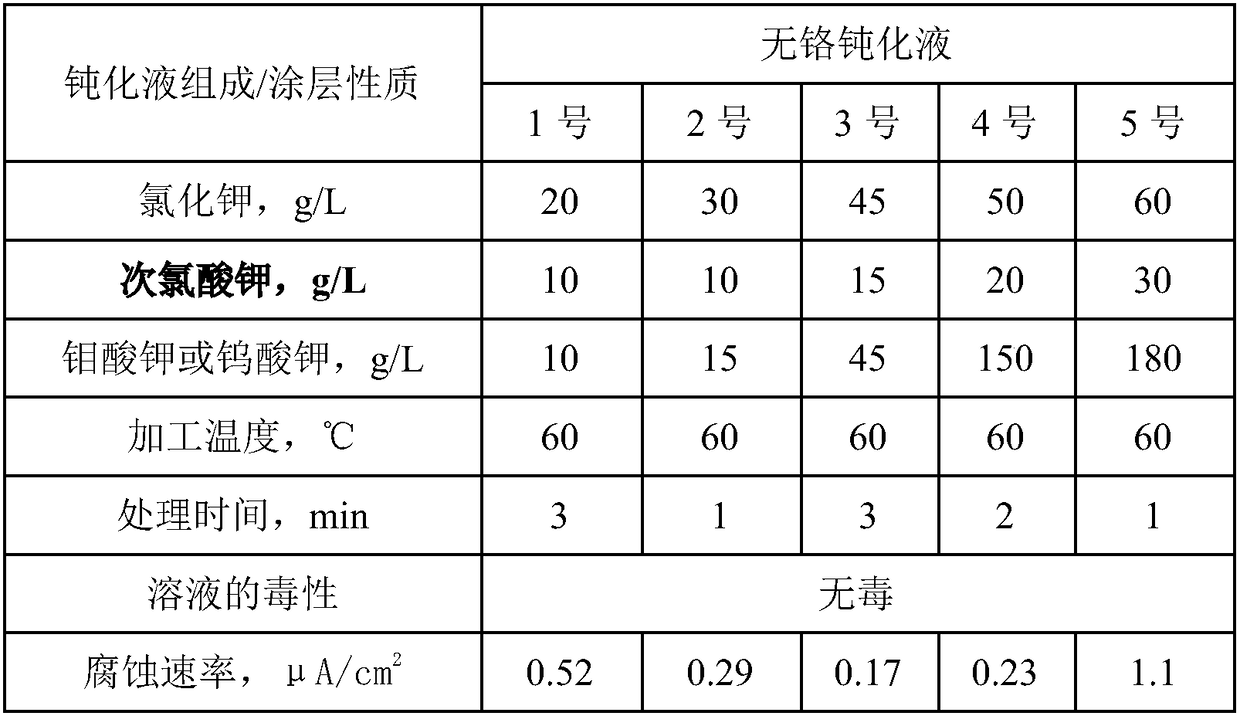

[0024] In a bath containing a chemically resistant material such as plastic, pour 2 / 3 of the volume of the bath with 60-70°C hot water. Then, add potassium molybdate or potassium tungstate, stir to dissolve, and then add potassium hypochlorite and potassium chloride. Adjust the amount of water so that it reaches the volume required for the experiment. The mass concentration of described potassium molybdate or potassium tungstate, potassium hypochlorite and potassium chloride is as shown in table 1. The experimental parts were immersed in the prepared passivation solution, the immersion temperature was 60°C, and the passivation time was shown in Table 1 to form a protective coating. Then, wash and dry the passivated experimental parts in clear water, and test the corrosion rate of the coatings obtained in each group of experiments. The measurement conditions are: wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com