Cutting fluid for processing cast iron and aluminum alloy mixture and preparation method thereof

A technology of aluminum alloy and mixed parts, applied in the field of metal cutting, can solve the problems of electrochemical corrosion of cast iron and aluminum alloy joints, rust of cast iron parts, blackening and corrosion of aluminum alloy parts, etc., and achieves good washing and cooling performance, The effect of reducing the amount of carry-out and prolonging the tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A cutting fluid for processing cast iron and aluminum alloy mixed parts, the specific preparation method is as follows:

[0036] a) Put 52.9g of deionized water, 10g of organic amine, 1g of anti-hard water agent, and 5g of compound anti-rust and preservative into the reaction kettle, and start stirring for no less than 30 minutes until the solid is completely dissolved and the system is uniform and transparent ;

[0037] b) Slowly drop 5g of surfactant into the reaction kettle, and continue to stir for 5-15min;

[0038] c) Slowly put 5g of composite lubricant into the reaction kettle, and the stirring time is 5-15min;

[0039] d) Slowly put 20g of base oil into the reaction kettle, stir until transparent, and the stirring time is 15-25min;

[0040] e) Under the premise that the temperature is not higher than 40°C, slowly put 1g of fungicide into the reaction kettle, stir until transparent, and the stirring time is 5-15min;

[0041] f) Put 0.1 g of defoamer into the r...

Embodiment 2

[0043] A cutting fluid for processing cast iron and aluminum alloy mixed parts, the specific preparation method is as follows:

[0044] a) Put 29.5g of deionized water, 3g of organic amine, 3g of anti-hard water agent, and 15g of compound anti-rust and preservative into the reaction kettle, and start stirring for no less than 30 minutes until the solid is completely dissolved and the system is uniform and transparent ;

[0045] b) Slowly drop 10g of surfactant into the reaction kettle, and continue to stir for 5-15min;

[0046] c) Slowly put 15g of composite lubricant into the reaction kettle, and the stirring time is 5-15min;

[0047] d) Slowly put 30g of base oil into the reaction kettle, stir until transparent, and the stirring time is 15-25min;

[0048] e) Under the premise that the temperature is not higher than 40°C, slowly put 5g of fungicide into the reaction kettle, stir until transparent, and the stirring time is 5-15min;

[0049] f) Put 0.5g of defoamer into the ...

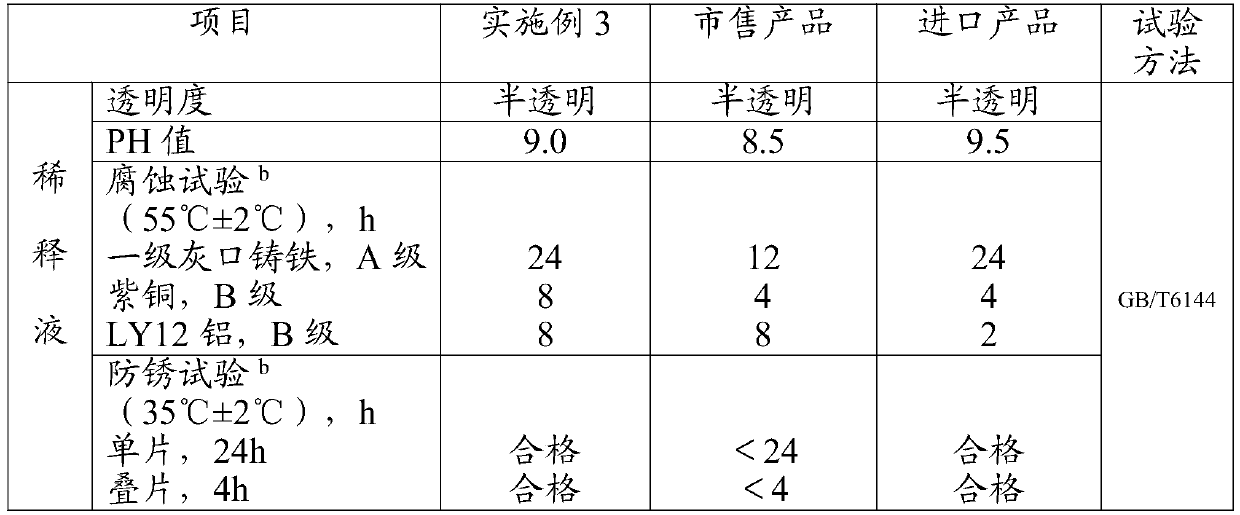

Embodiment 3

[0051] A cutting fluid for processing cast iron and aluminum alloy mixed parts, the specific preparation method is as follows:

[0052] a) Put 8.7g of deionized water, 5g of organic amine, 2g of anti-hard water agent, and 8g of compound anti-rust and preservative into the reaction kettle, and start stirring for no less than 30 minutes until the solid is completely dissolved and the system is uniform and transparent ;

[0053] b) Slowly drop 15g of surfactant into the reactor, and continue to stir for 5-15min;

[0054] c) Slowly put 8g of composite lubricant into the reaction kettle, and the stirring time is 5-15min;

[0055] d) Slowly put 50g of base oil into the reaction kettle, stir until transparent, and the stirring time is 15-25min;

[0056] e) Under the premise that the temperature is not higher than 40°C, slowly put 3g of fungicide into the reaction kettle, stir until transparent, and the stirring time is 5-15min;

[0057] f) Put 0.3g of defoamer into the reaction kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com