Epoxy glass flake anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and epoxy glass, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effects of improving temperature resistance and corrosion resistance, improving heat resistance, and good anti-rust and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

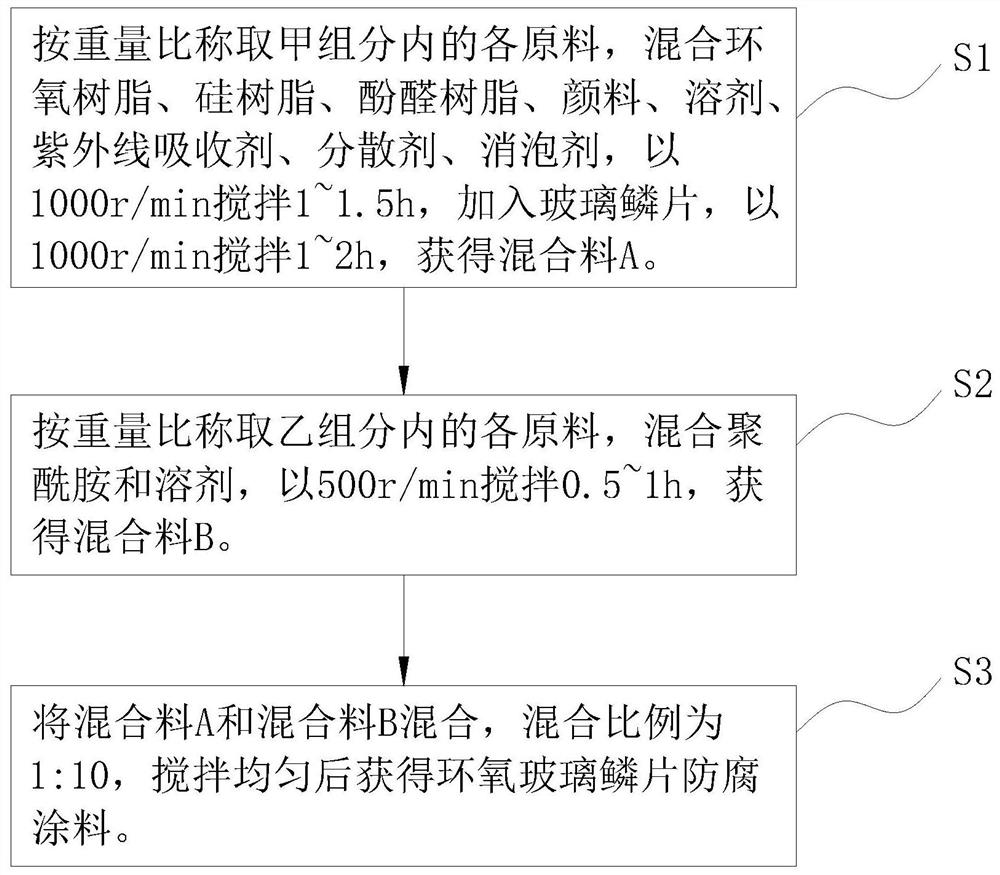

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a technical solution: an epoxy glass flake anti-corrosion paint and a preparation method thereof. The epoxy glass flake anti-corrosion paint includes two components, A and B.

[0023] Component A includes by weight: 18 parts of epoxy resin, 8 parts of silicone resin, 8 parts of phenolic resin, 15 parts of glass flakes, 12 parts of pigment, 8 parts of solvent, 7 parts of ultraviolet absorber, 0.7 part of dispersant, defoaming agent 0.7 parts of the agent.

[0024] Component B comprises by weight: 40 parts of polyamide, 20 parts of solvent;

[0025] And the weight ratio of component A and component B is 1:10.

[0026] Among them, the epoxy resin is bisphenol A solid epoxy resin, the particle size of the glass flakes is 300 mesh to 350 mesh, the solvent is a mixed solvent, which is made by mixing xylene and n-butanol at a volume ratio of 1:105, and the pigment is titanium dioxide. Mixed with phthalo blue. The ultraviolet absorber is 2-(2-hydroxy...

Embodiment 2

[0032] This embodiment provides a technical solution: an epoxy glass flake anti-corrosion paint and a preparation method thereof. The epoxy glass flake anti-corrosion paint includes two components, A and B.

[0033] Component A includes by weight: 15 parts of epoxy resin, 5 parts of silicone resin, 5 parts of phenolic resin, 10 parts of glass flakes, 85 parts of pigment, 10 parts of solvent, 10 parts of ultraviolet absorber, 1 part of dispersant, defoaming agent 1 dose.

[0034] Component B comprises by weight: 35 parts of polyamide, 15 parts of solvent;

[0035] And the weight ratio of component A and component B is 1:10.

[0036] Among them, the epoxy resin is bisphenol A solid epoxy resin, the particle size of the glass flakes is 300 mesh to 350 mesh, the solvent is a mixed solvent, which is made by mixing xylene and n-butanol at a volume ratio of 1:105, and the pigment is titanium dioxide. Mixed with phthalo blue. The ultraviolet absorber is 2-(2-hydroxy-5-methylphenyl)...

Embodiment 3

[0042] This embodiment provides a technical solution: an epoxy glass flake anti-corrosion paint and a preparation method thereof. The epoxy glass flake anti-corrosion paint includes two components, A and B.

[0043] Component A includes by weight: 20 parts of epoxy resin, 10 parts of silicone resin, 10 parts of phenolic resin, 18 parts of glass flakes, 8 parts of pigment, 5 parts of solvent, 5 parts of ultraviolet absorber, 0.5 part of dispersant, defoaming agent 0.5 parts of the agent.

[0044] Component B comprises by weight: 35 parts of polyamide, 15 parts of solvent;

[0045] And the weight ratio of component A and component B is 1:10.

[0046] Among them, the epoxy resin is bisphenol A solid epoxy resin, the particle size of the glass flakes is 300 mesh to 350 mesh, the solvent is a mixed solvent, which is made by mixing xylene and n-butanol at a volume ratio of 1:105, and the pigment is titanium dioxide. Mixed with phthalo blue. The ultraviolet absorber is 2-(2-hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com