Calcium sulfonate complex grease and preparation method thereof

A technology of compound calcium sulfonate and lubricating grease, applied in the direction of lubricating composition, petroleum industry, etc., to achieve the effect of shortening conversion time, good extreme pressure and anti-wear property, and improving oxidative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

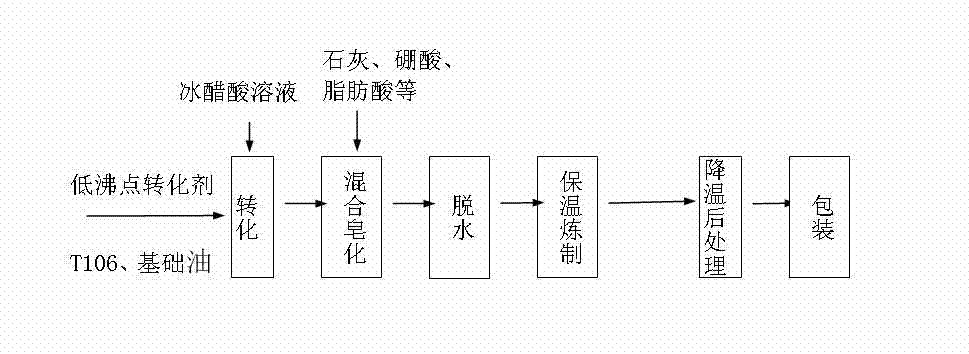

Method used

Image

Examples

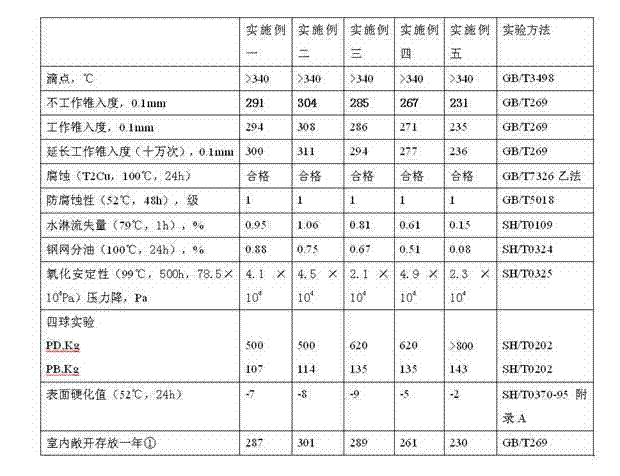

Embodiment 1

[0016] Add 10g of calcium carbonate and 300g of high-basic calcium sulfonate with a base value of 285mgKOH / g to 300g of 500SN mineral oil, add 7.1g of glacial acetic acid and 36g of water, stir evenly, heat up, and control the temperature at 75-85°C. After thickening, add 15g of lime (2-3 times of water to make an emulsion), 17g of boric acid (2-3 times of water to dissolve), add 17g of dodecyl hydroxystearic acid, add 40g of heavy alkylbenzenesulfonate calcium salt, Keep at 90-100°C for 40-45min, heat up to 130-135°C and keep for 25-30min, add 300g of 150BS base oil, stir evenly, cool and grind. The grease formula is composed of: 28.8% (weight) of high base value calcium sulfonate, 4.4% (weight) of conversion accelerator, 0.7% (weight) of glacial acetic acid, 3.8% (weight) of calcium dodecylbenzenesulfonate, lime 1.5% (weight), lauryl hydroxystearic acid 1.6% (weight), boric acid 1.6% (weight), base oil 57.6% (weight), the physical and chemical performance analysis results of...

Embodiment 2

[0018] Add 90g of high-basic calcium sulfonate with a base value of 420 mgKOH / g to 180g of 100# naphthenic base oil, add 4g of water, 2g of propanol, and 0.6g of glacial acetic acid, stir evenly, raise the temperature, and control the temperature at 60-70 ℃, after the material thickens, add 0.6g lime (2-3 times water to make emulsion), 0.6g boric acid (2-3 times hot water to dissolve), keep at 90-100℃ for 80-90min, heat up to 140 Keep at -150°C for 10-15 minutes, add 322.2g of 150BS base oil, stir evenly, cool and grind. The formula of lubricating grease consists of: 15% (weight) of calcium sulfonate with high base value, 1% (weight) of conversion accelerator, 0.1% (weight) of glacial acetic acid, 0.1% (weight) of lime, 0.1% (weight) of boric acid, and 83.7% (weight) of base oil The physical and chemical performance analysis results of the lubricating grease are shown in Table 1.

Embodiment 3

[0020] Add 280g of high-basic calcium sulfonate with a base value of 304mgKOH / g to 290g of PAO10, add 7.6g of glacial acetic acid and 39g of water, stir evenly, heat up, and control the temperature at 90-100°C. After the material thickens, add 21g Lime (2-3 times water to make emulsion), 11g boric acid (2-3 times hot water to dissolve), add 15.4g dodecyl hydroxystearic acid, add 20g dodecylbenzenesulfonic acid, keep at 100-120℃ 30-40min, heat up to 145°C and keep for 10-15min, add 310g of 150BS base oil, stir evenly, cool and grind. The grease formula is composed of: 28.2% (weight) of high base value calcium sulfonate, 3.9% (weight) of conversion accelerator, 0.8% (weight) of glacial acetic acid, 2.0% (weight) of dodecylbenzenesulfonic acid, and 2.1% (weight) of lime % (weight), lauryl hydroxystearic acid 1.5% (weight), boric acid 1.1% (weight), base oil 60.4% (weight), the physical and chemical performance analysis results of the lubricating grease are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com