A non-sticky petrolatum anti-corrosion paste

An anti-corrosion paste, non-stick technology, used in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as difficult to achieve protective effects, rust removal, difficult painting and maintenance, and complex bolt fastener structures. , to achieve good corrosion protection effect, easy construction and post-maintenance operation, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

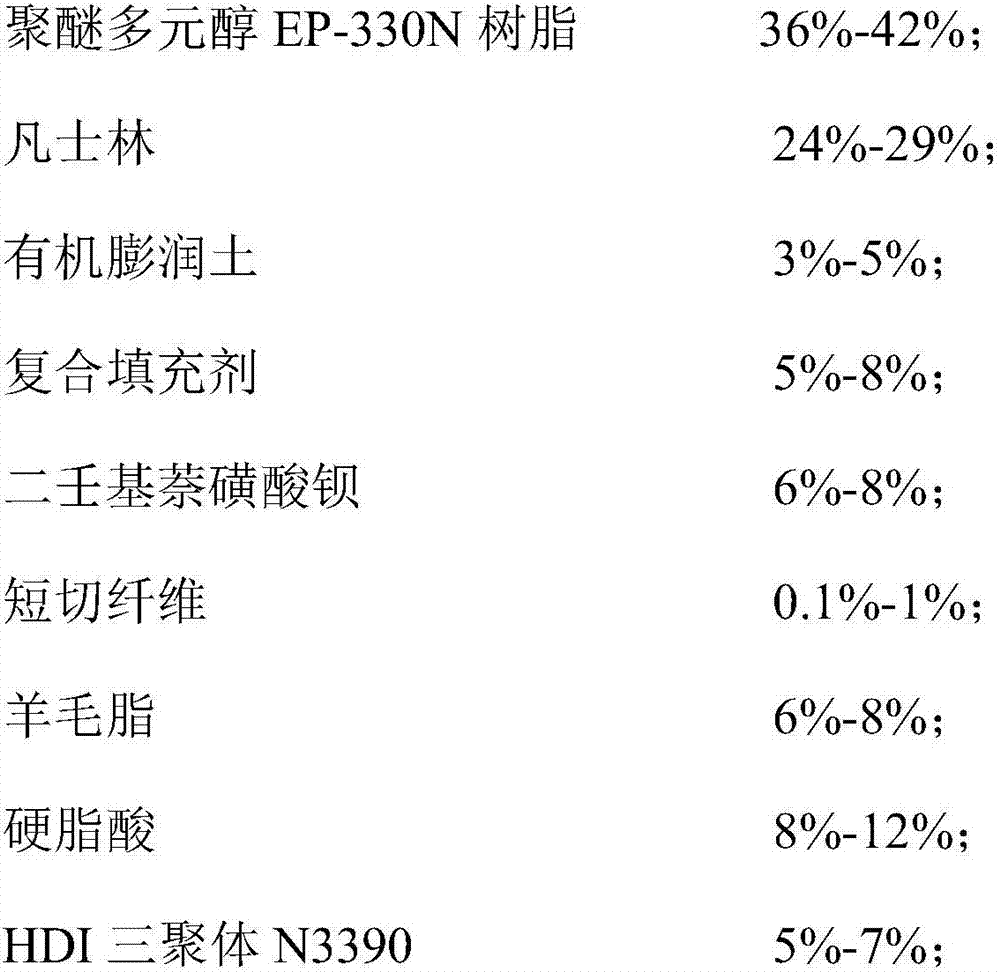

[0024] Non-stick petrolatum anti-corrosion paste by weight percentage, polyether polyol EP-330N resin 38%, vaseline 25%, organic bentonite 3%, composite filler 6%, barium dinonyl naphthalene sulfonate 6%, chopped Fiber 1%, Lanolin 7%, Stearic Acid 9%, and HDI Trimer (N3390) 5%.

[0025] Determination of the general properties of the material obtained in the examples, see Table 1.

[0026] Table 1 Performance test results of non-stick petrolatum anti-corrosion paste

[0027]

[0028] Temperature-resistant fluidity test method:

[0029] This experiment is used to test whether the petrolatum anti-corrosion paste will flow under the test temperature conditions, so as to determine the maximum applicable temperature of this type of petrolatum anti-corrosion paste. Place the test piece coated with the sample in a constant temperature air bath at 50°C, and place it vertically for 24 hours, and observe whether the sample film flows to the reference line.

[0030] Pretreatment of ...

Embodiment 2

[0035] Non-stick petrolatum anti-corrosion paste by weight percentage, polyether polyol EP-330N resin 39%, vaseline 26%, organic bentonite 3%, composite filler 5%, barium dinonyl naphthalene sulfonate 6%, chopped Fiber 1%, Lanolin 6%, Stearic Acid 9%, and N3390HDI Trimer 5%.

[0036] The effects and characteristics are the same as those in Example 1. Test according to the standards in Table 1. Visual inspection is gray and viscous; the dropping point is greater than 80°C; at 50±2°C, the film does not flow after being placed vertically for 24 hours, and has good temperature resistance and fluidity; no rust in the water-paste displacement test; salt water immersion test, neutral salt The results of fog test (1000h) and ultraviolet aging test (300h) are good, there is no change in the sample, no rust, and good aging resistance.

[0037] Using the non-sticky petrolatum anticorrosion paste of the above composition, the self-curing elastomeric organic coating is formed, the coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com