Patents

Literature

106results about How to "Improves corrosion protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene heat-conducting anticorrosive water-based paint, and preparation and application methods thereof

ActiveCN106366710AAvoid polluting the environmentImproves corrosion protection performanceAnti-corrosive paintsCvd graphenePre treatment

The invention belongs to a surface treatment technique, and relates to a graphene heat-conducting anticorrosive water-based paint, and preparation and application methods thereof. The invention is characterized in that the graphene heat-conducting anticorrosive water-based paint is formed by mixing a component I and a component II in a weight ratio of 100:(58-65). The preparation method comprises the following steps: preparing the component I; and mixing the component I and component II. The application method comprises the following steps: substrate pretreatment; coating; and curing. The graphene heat-conducting anticorrosive water-based paint avoids environment pollution, and has the advantages of higher anticorrosive property and wider application range.

Owner:北京石墨烯技术研究院有限公司

Lubricating oil compositions having improved corrosion and seal protection properties

InactiveUS20080128184A1Improved performance characteristicsReduce friction lossLubrication of auxillariesLubricant conduit arrangementsChemical compositionNitrogen

A fully formulated lubricating oil, lubricated surface, and lubricant additive concentrates for lubricants providing improved lubricant characteristics. The lubricating oil composition has therein a dispersant mixture derived from a reaction product of polyalkylene compound, a carboxylic acylating agent, and a polyamine. The polyalkylene compound of at least one dispersant in the dispersant mixture has a number average molecular weight of at least about 1200 and at least one dispersant in the dispersant mixture contains boron such that a weight ratio of boron to nitrogen (B / N) in the dispersant mixture ranges from above about 0.25 to about 1.0.

Owner:AFTON CHEMICAL

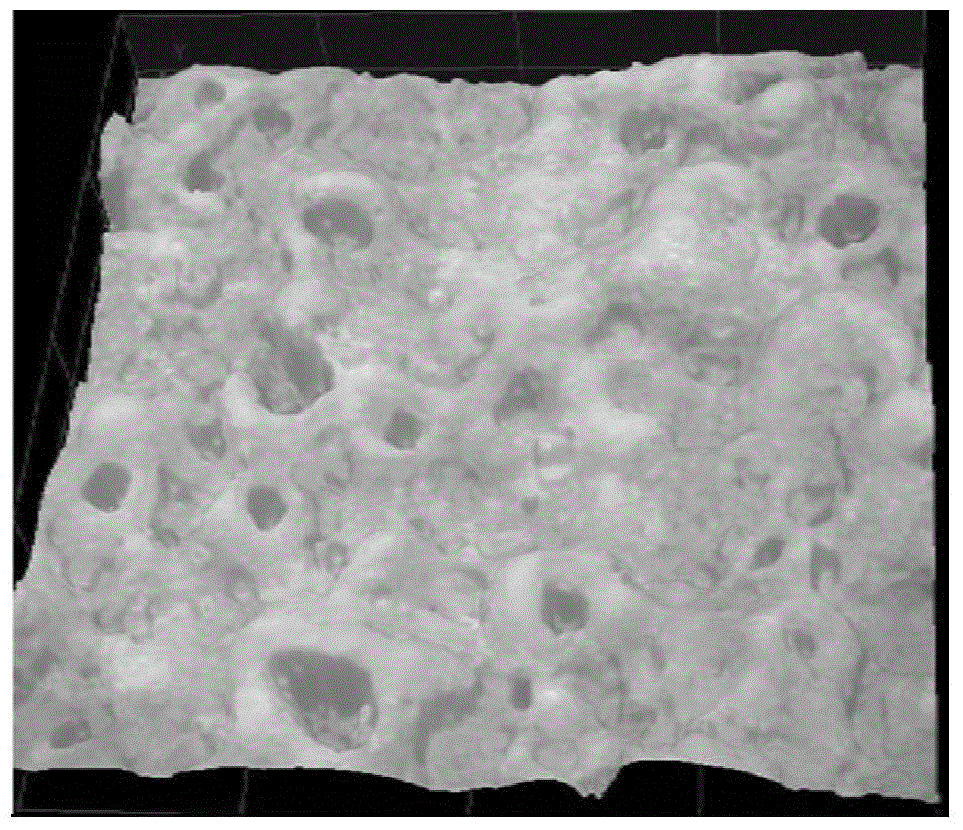

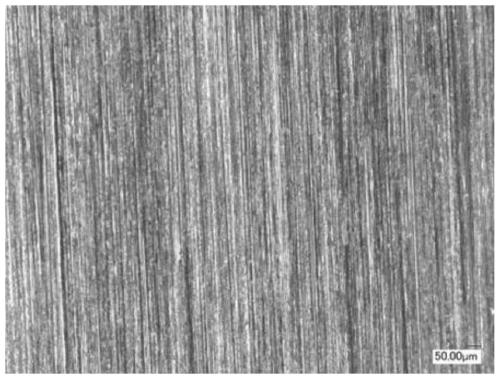

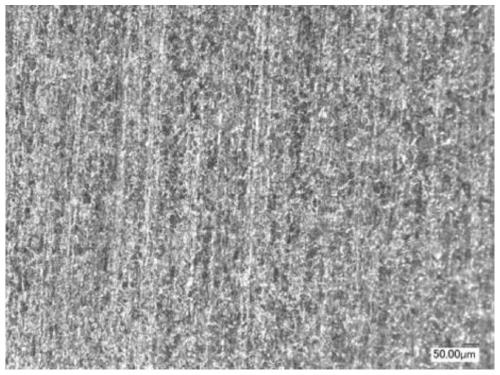

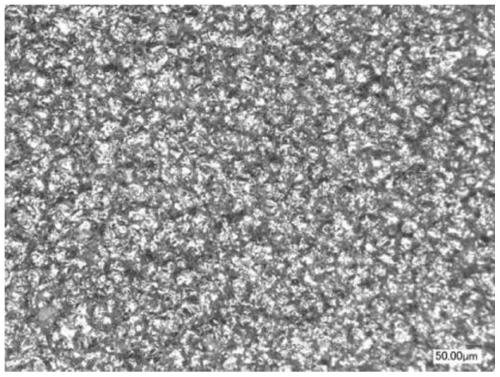

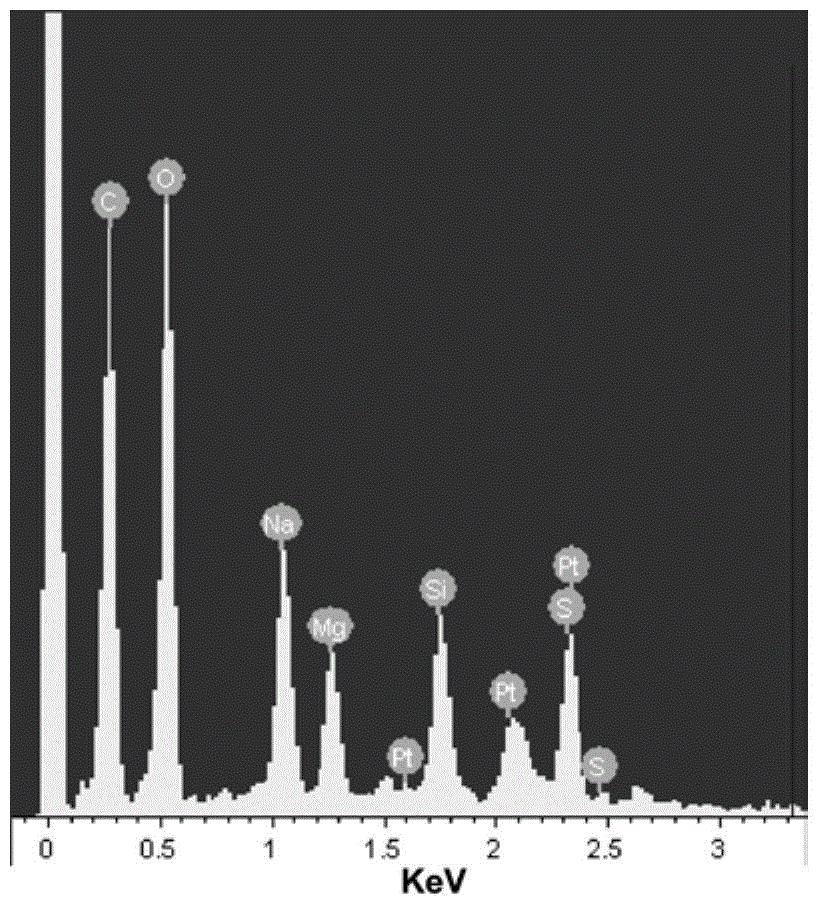

Preparation method and hole sealing method of magnesium alloy surface ceramic coating

ActiveCN104651908ALow energy consumption for growthImprove compactnessAnodisationMicro arc oxidationThermal spraying

The invention discloses a preparation and hole sealing method of a magnesium alloy surface ceramic coating. The method comprises the steps of preparing an electrolyte containing 0.15-0.25mol / l of anion PO4<3->, 0-0.5mol / l of F<->, 0.75-1.2mol / l of cation NH4<+>, 0-0.4mol / l of K<+> or Na<+> and 0.25-0.5mol / l of a stabilizer; and selecting a magnesium alloy workpiece as an anode, selecting a stainless steel plate as a cathode, and performing arc-free oxidation by adopting direct current or pulse current to obtain the ceramic coating. The magnesium alloy workpiece is oxidized by adopting an arc-free oxidation method, so that the surface of the coating is smooth, the film forming speed is high, the compactness of the coating is good, the corrosion resistance is greatly improved, and the preparation cost is relatively low; by adopting nano SiO2 dispersion as a hole sealing agent and combining a vacuum impregnation technology, the hole-sealed ceramic coating has good corrosion, abrasion, heat and pollution resistance and the like and is simple in process and easy to operate, the corrosion protection performance of the magnesium alloy surface is effectively improved, meanwhile, the hole sealing technology can also be applied to hole sealing treatment of light alloy micro-arc oxidation coatings, hot spray coatings and plated coatings of aluminum and titanium.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

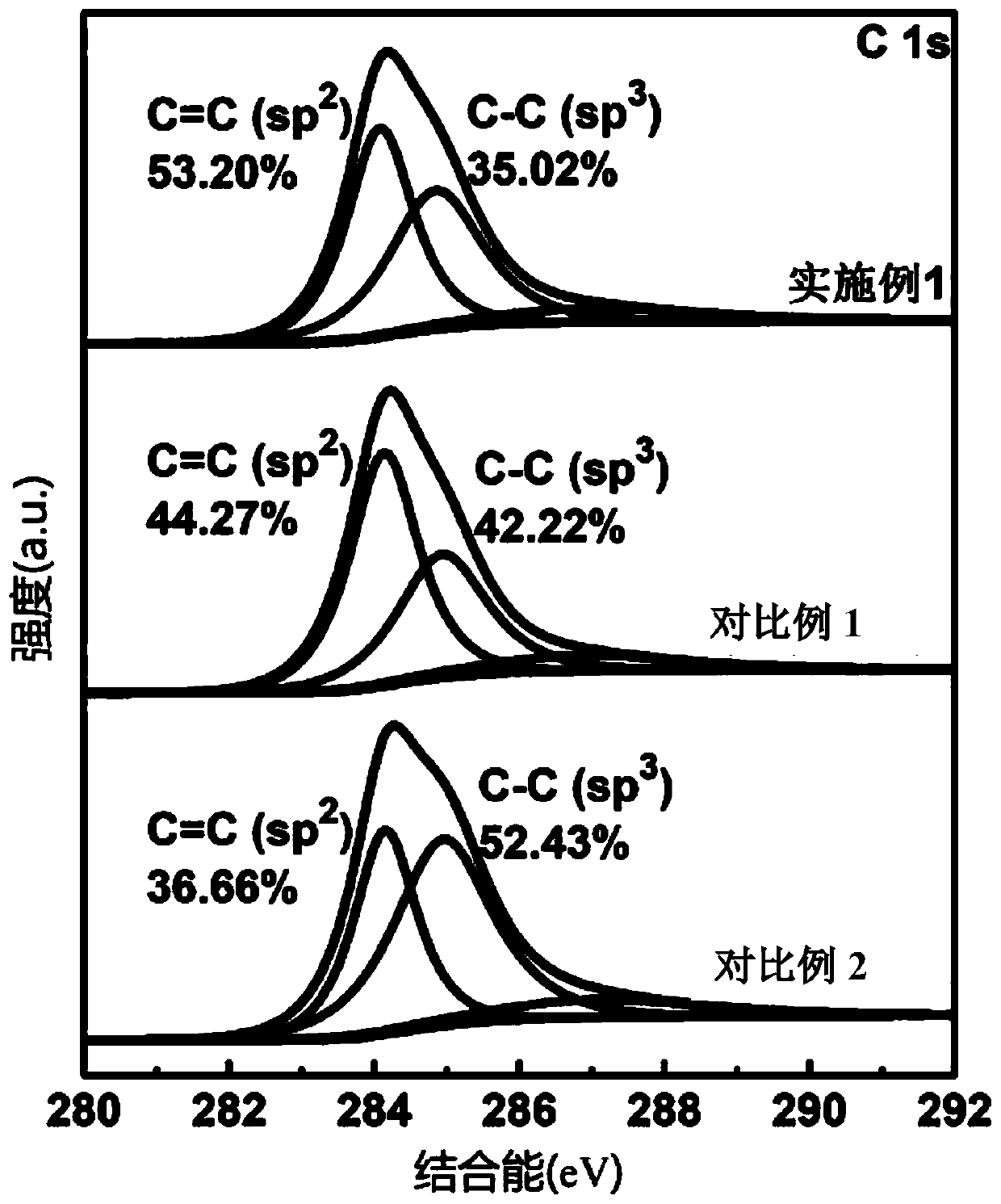

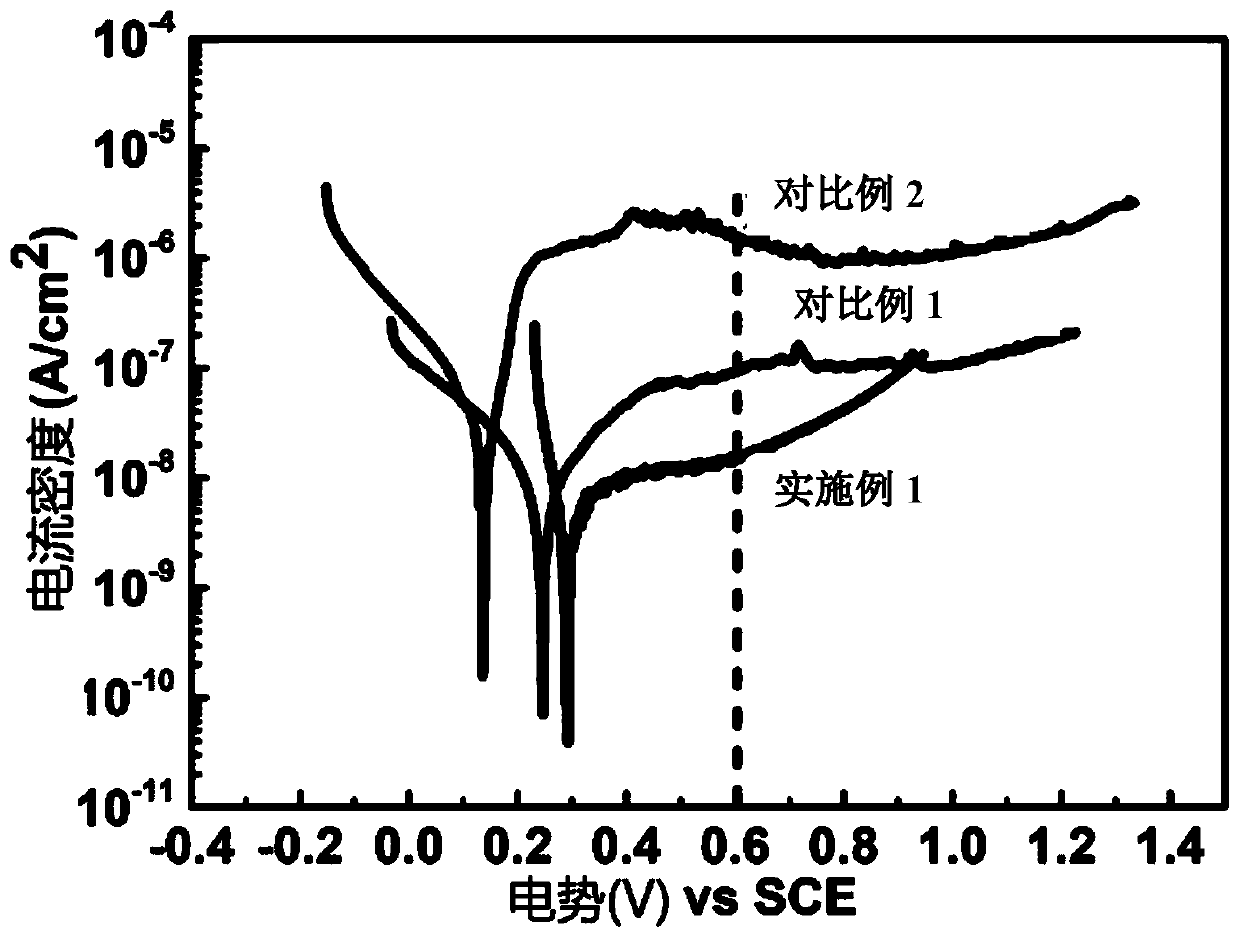

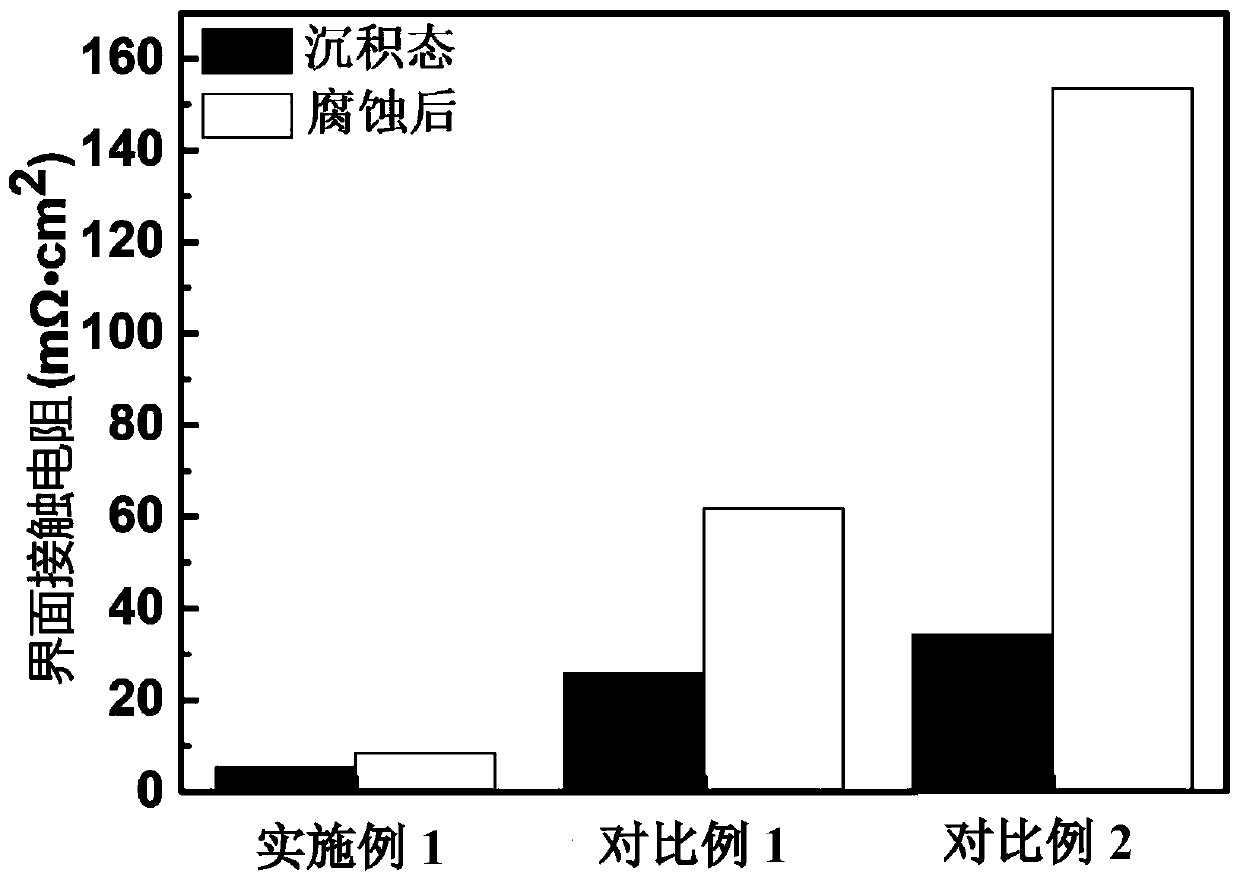

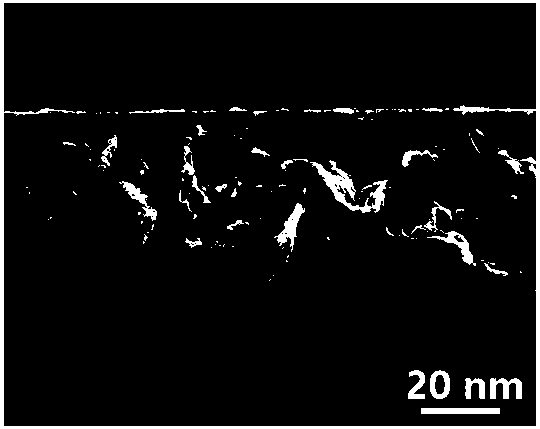

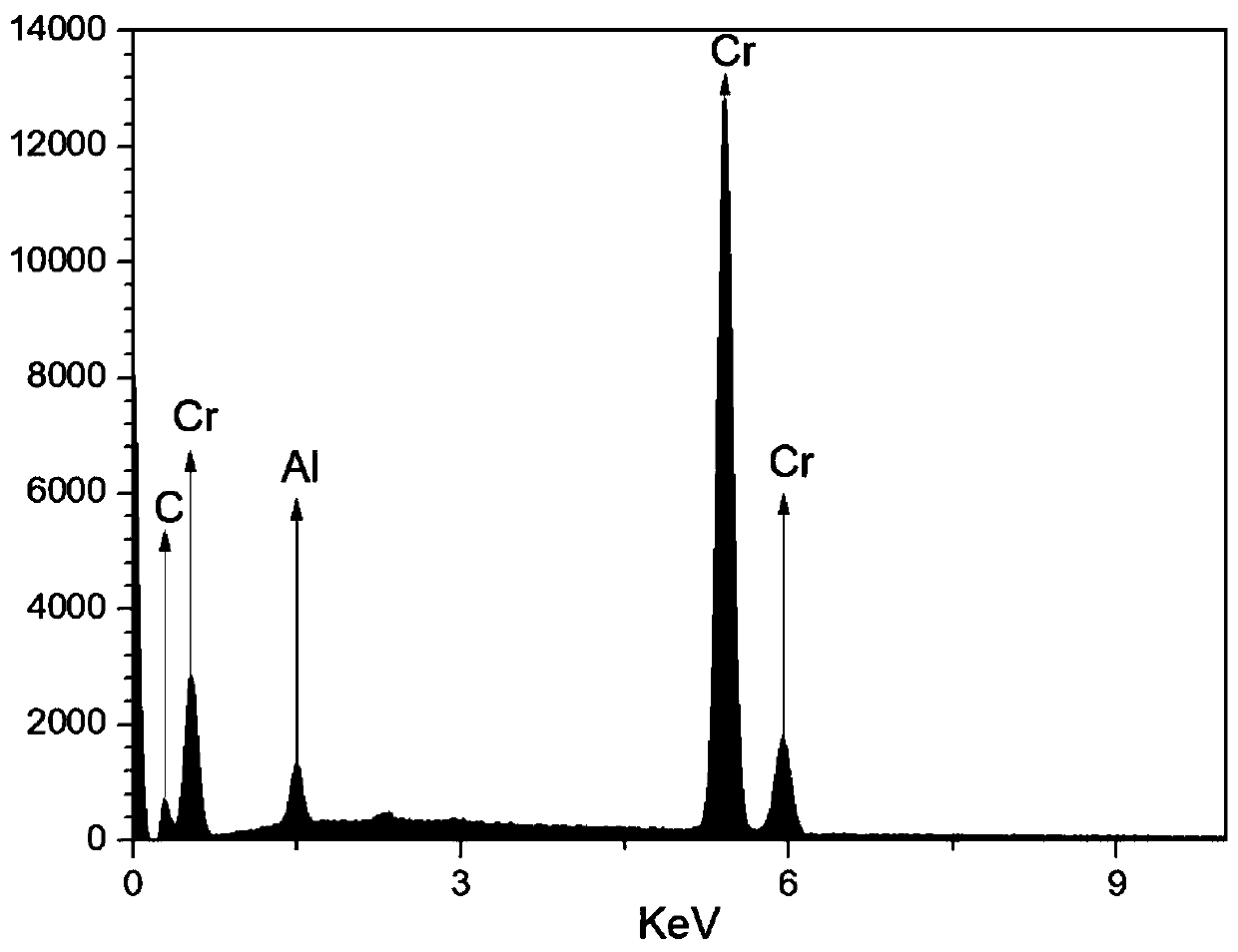

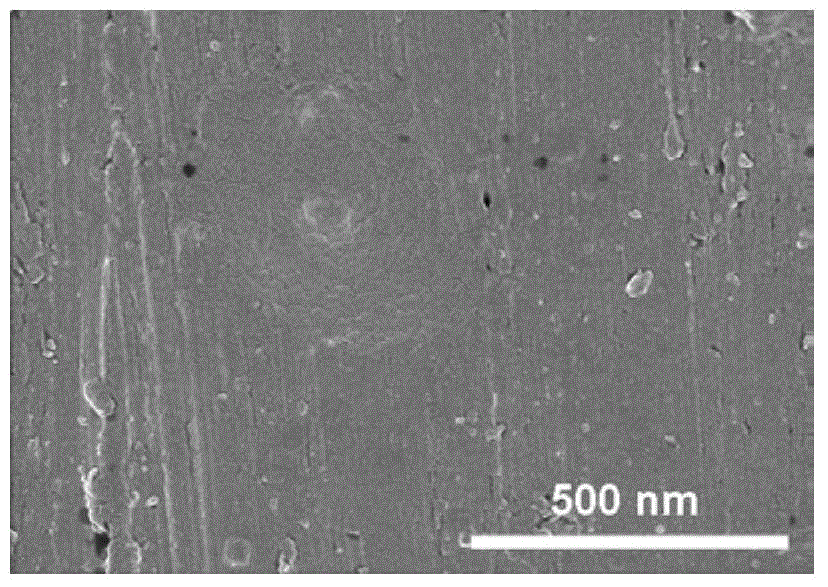

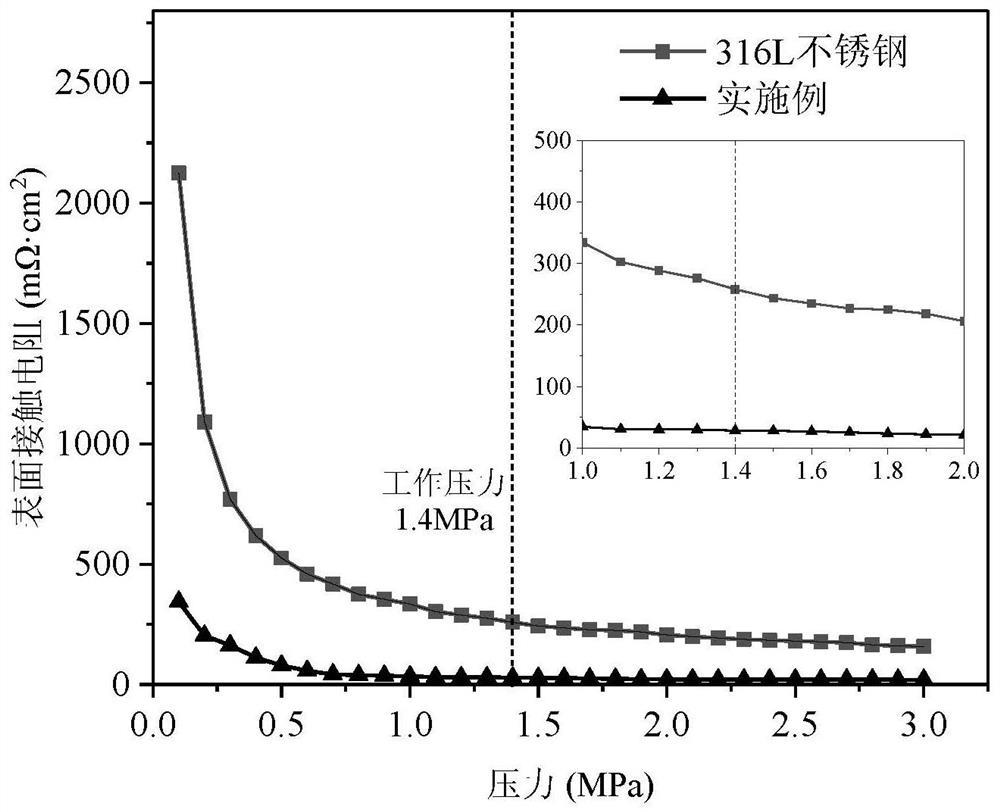

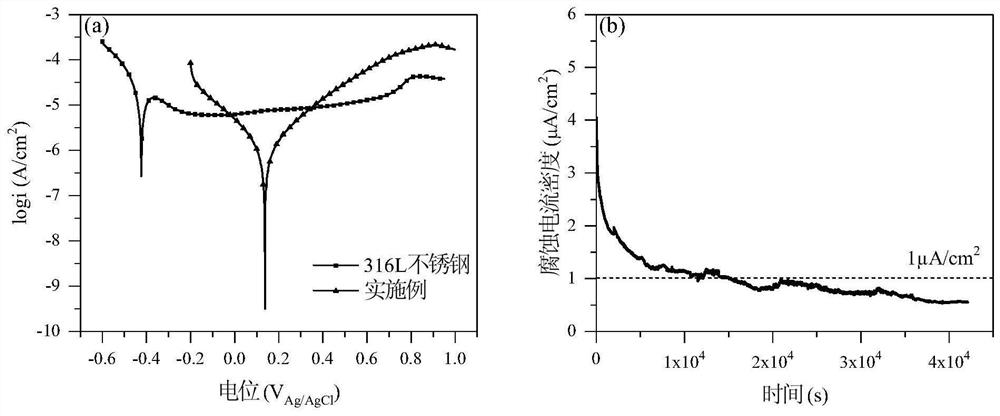

Metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and preparation method and application thereof

ActiveCN110684946ASmooth structureSmooth internal structure Dense structureVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and a preparation method and application thereof. The preparation method of the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer comprises the following steps: with a chromium target as the target, a high-power pulse magnetron sputtering technology is adopted to deposit a chromium transition layer on the surface of a metal bipolar plate; with a graphite target as the target, a direct-current magnetron sputtering technology isadopted to deposit an amorphous carbon layer on the surface of the chromium transition layer to obtain the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer; and process conditions adopted by the direct-current magnetron sputtering technology comprises the sputtering source center magnetic field intensity of 40-60 mT, the edge magnetic field intensity of 10-20 mT and the power of 0.8-1.0 kW. The provided chromium transition layer is smooth in surface and compact in internal structure, and can effectively improve the film base bonding strength; and meanwhile, through optimization of an amorphous carbon layer preparation process, the amorphous carbon layer achieves excellent electric conductivity and corrosion resistance, and can permanently and effectively protect the metal bipolar plate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

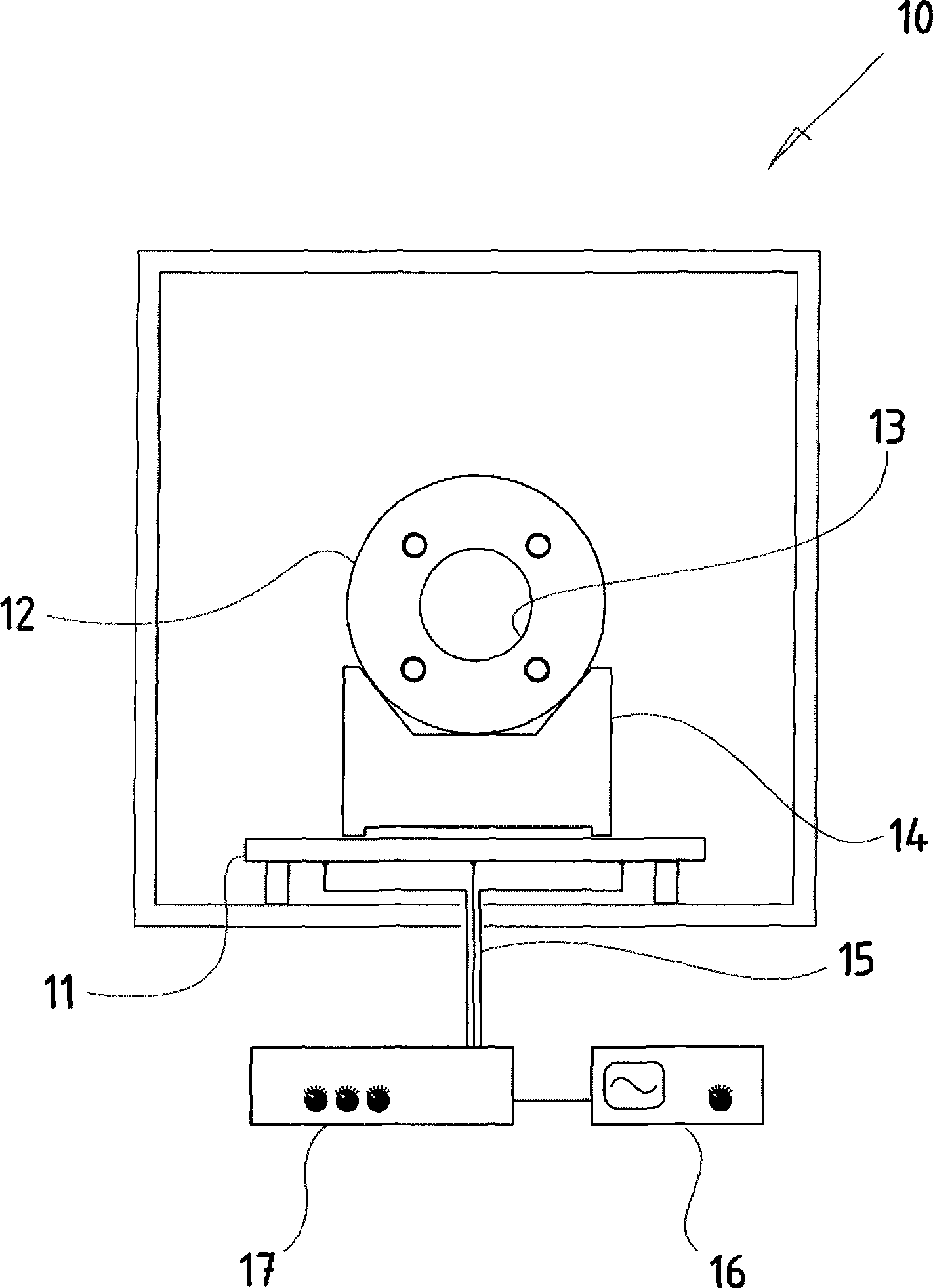

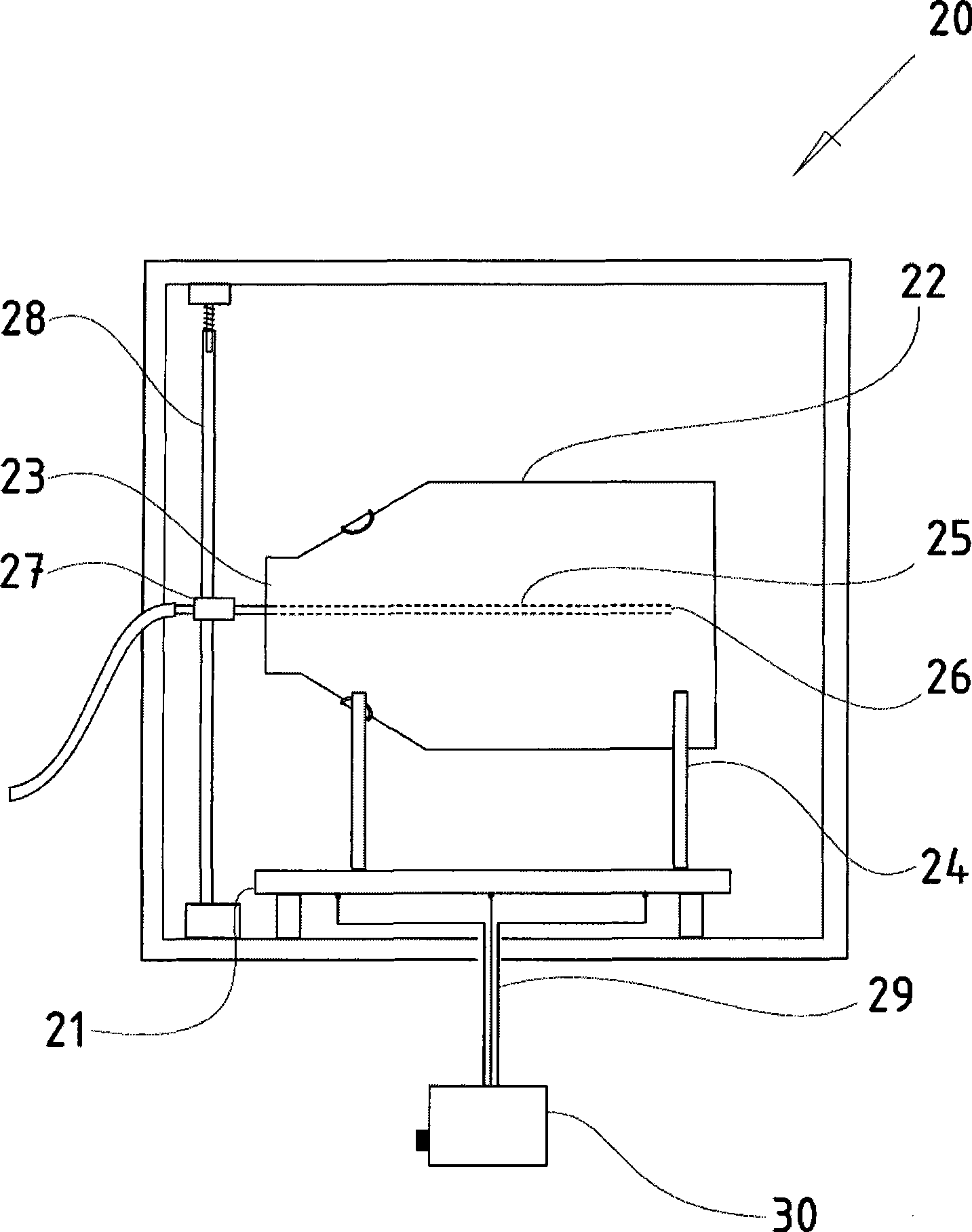

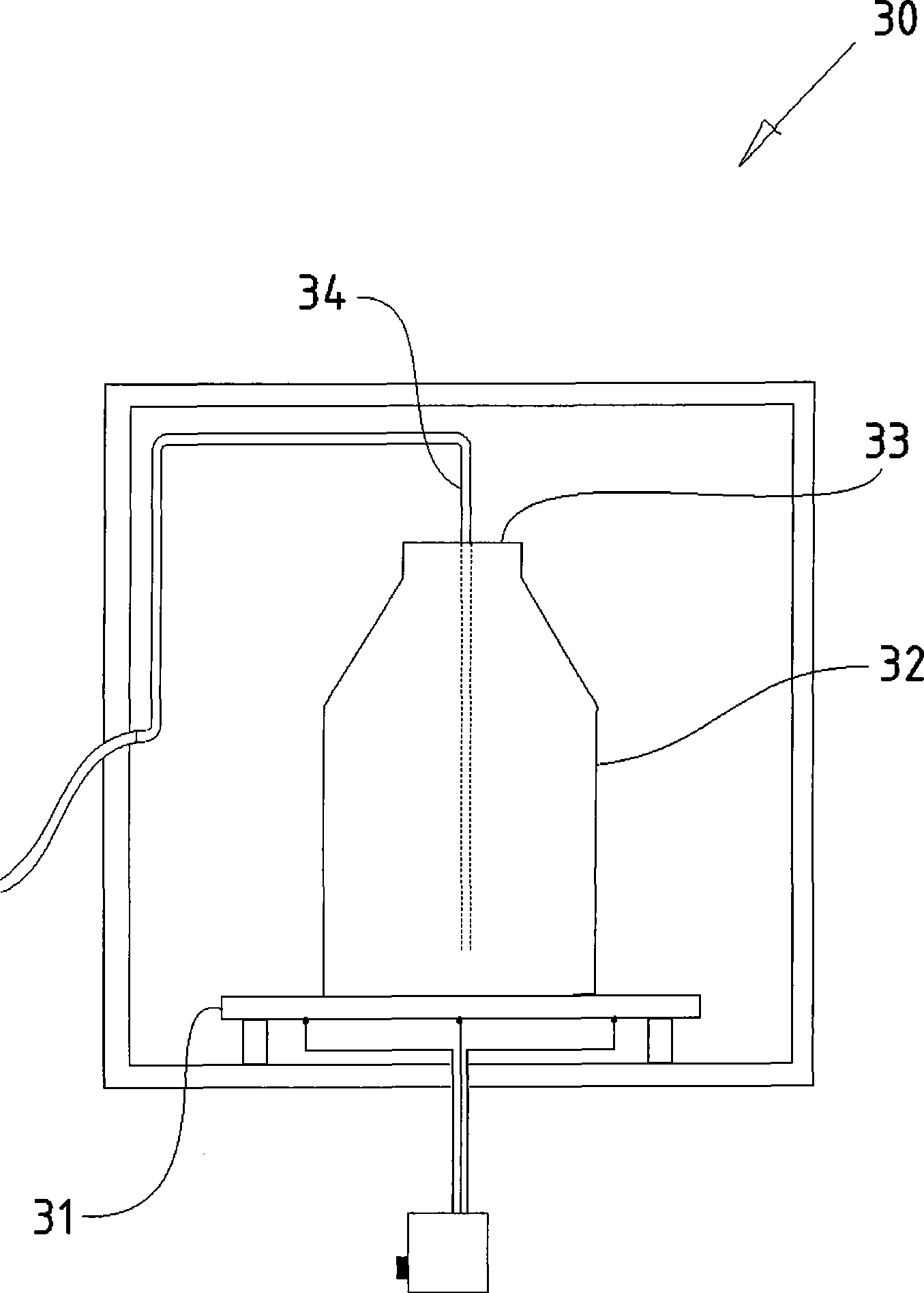

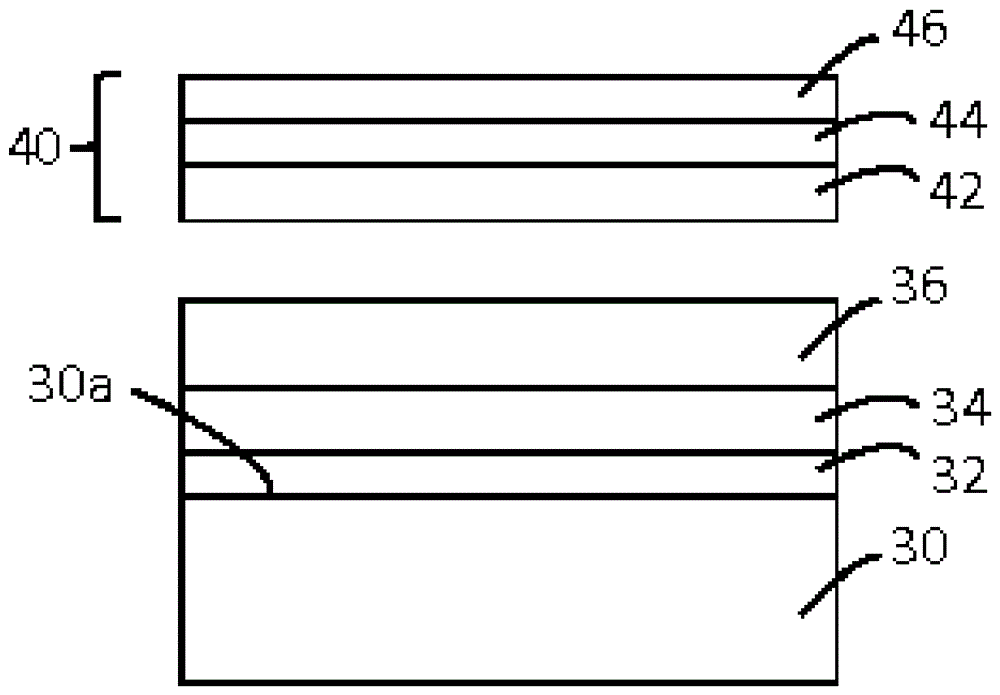

Method and device for plasma-assisted chemical vapour deposition on the inner wall of a hollow body

InactiveCN101522941AEasy to cleanLow costElectric discharge tubesSemiconductor/solid-state device manufacturingChemical vapor depositionMaterials science

The invention relates to a method for plasma-assisted chemical vapour deposition for coating, or removing material from, the inner wall of a hollow body (42). A gas lance (44) is introduced into the hollow body (42), and a cavity plasma (45) is formed by applying an electrical high-frequency field to a high-frequency electrode (41), forming a plasma cloud arranged on the tip of the gas lance.

Owner:拉尔夫·斯坦

Preparation method for protective coating doped and modified by silicon dioxide and application of preparation method

The invention discloses a preparation method for a protective coating doped and modified by silicon dioxide and an application of the preparation method. According to the method provided by the invention, through a solvothermal method, in the process of preparing mesporous silicon dioxide nanoparticles, an organic corrosion inhibitor is added directly, a soft template does not need to be removed,corrosion inhibitor supported mesoporous silicon dioxide powder is obtained by a one-step method, and the powder is mixed into a coating to improve the protective properties of the coating; when the mesoporous silicon dioxide nanoparticles are generated, the organic corrosion inhibitor is dissolved into hydrophobic micelles of a silicon dioxide template, and then loaded into the silicon dioxide, after the corrosion inhibitor supported mesoporous silicon dioxide powder is mixed into the coating, corrosion inhibition performance can be provided for a metal substrate, and the corrosion protectionability of the coating can be improved; and the method is applicable to various common metal substrates and coatings, has a simple process and low costs, and is suitable for industrialized applications.

Owner:ZHEJIANG UNIV

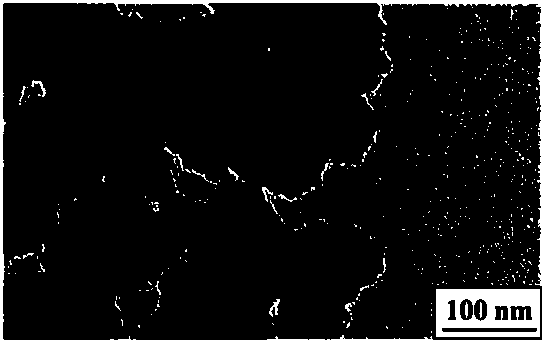

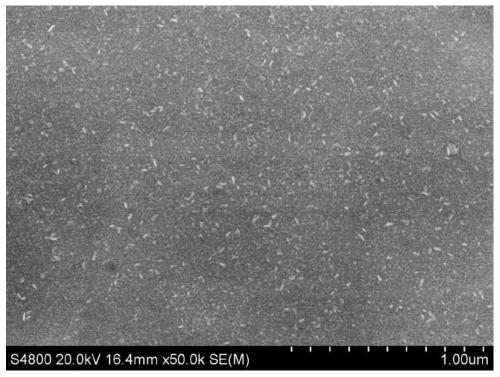

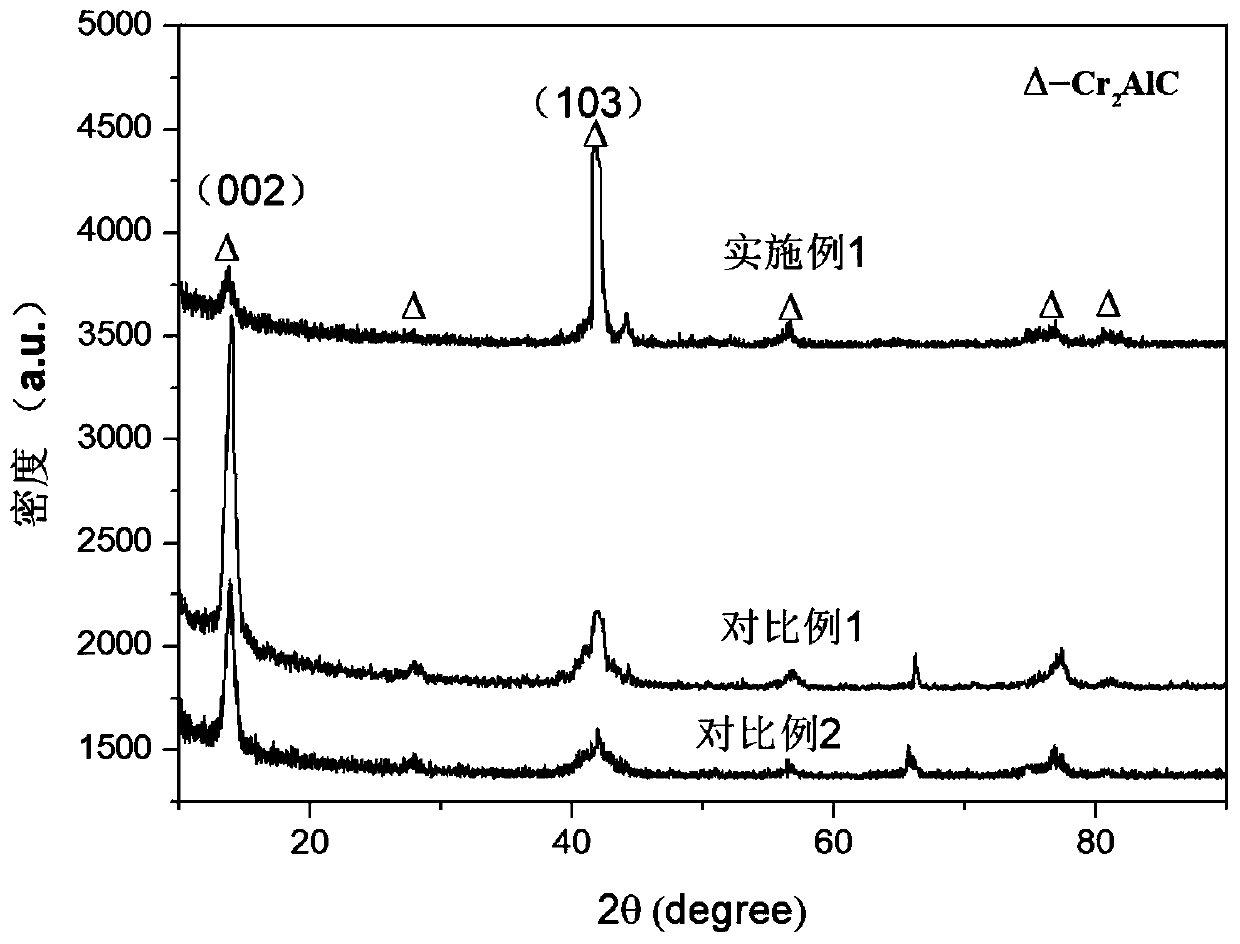

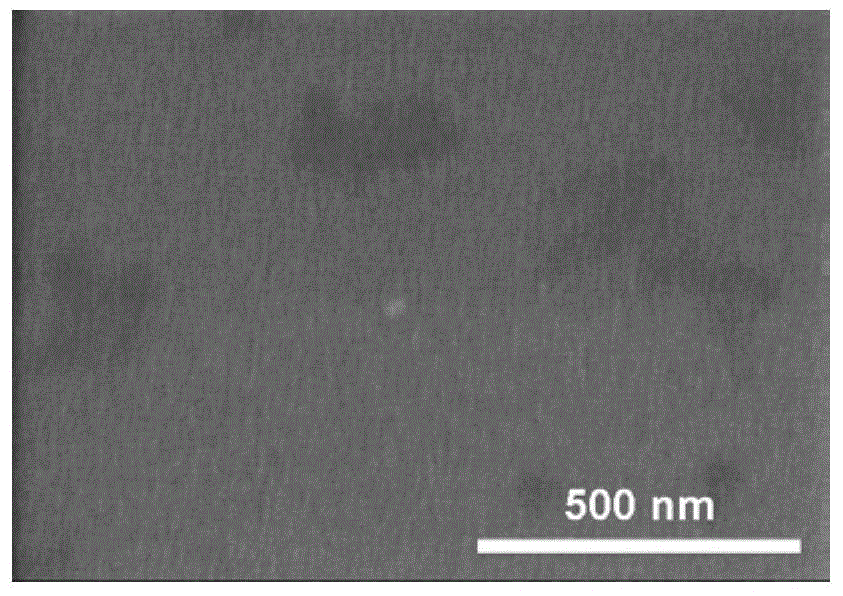

Preparing method and application of Cr-Al-C series MAX phase coating

ActiveCN111519157AImprove stabilityHigh degree of bindingVacuum evaporation coatingSputtering coatingPhysical chemistrySputter deposition

The invention discloses a preparing method and application of a Cr-Al-C series MAX phase coating. The method includes the steps of firstly, forming a Cr-C layer on the surface of a base body through deposition by means of electric arc ion sputter deposition, wherein the thickness of the Cr-C layer is 0.5-5 [mu]m; then, forming an Al layer on the surface of the Cr-C layer through deposition by means of magnetic control sputter deposition to obtain an Al / Cr-C coating; and finally, performing heat treatment to obtain the Cr-Al-C series MAX phase coating with (103) crystal face preferred orientation. The coating has high electric conductivity and corrosion resistance; and compared with the prior art, the Cr-Al-C series MAX phase coating prepared through the method improves the interface electric conductivity between the coating and the base body and also improves the corrosion resistance, and has excellent electric conductivity, corrosion resistance and protection property in a severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

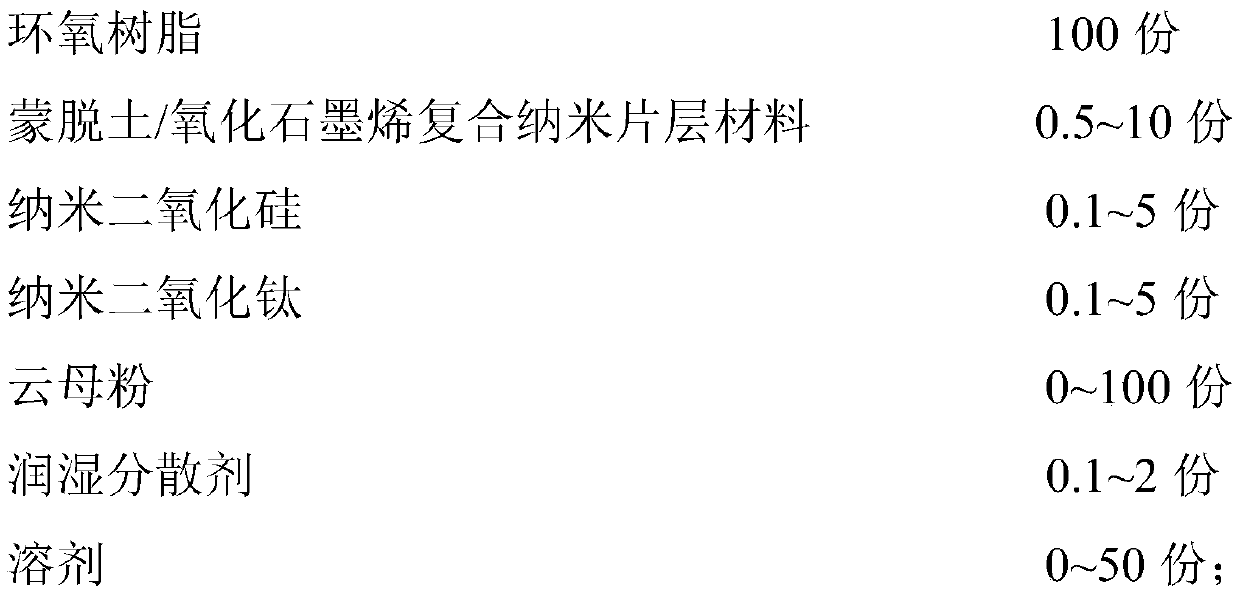

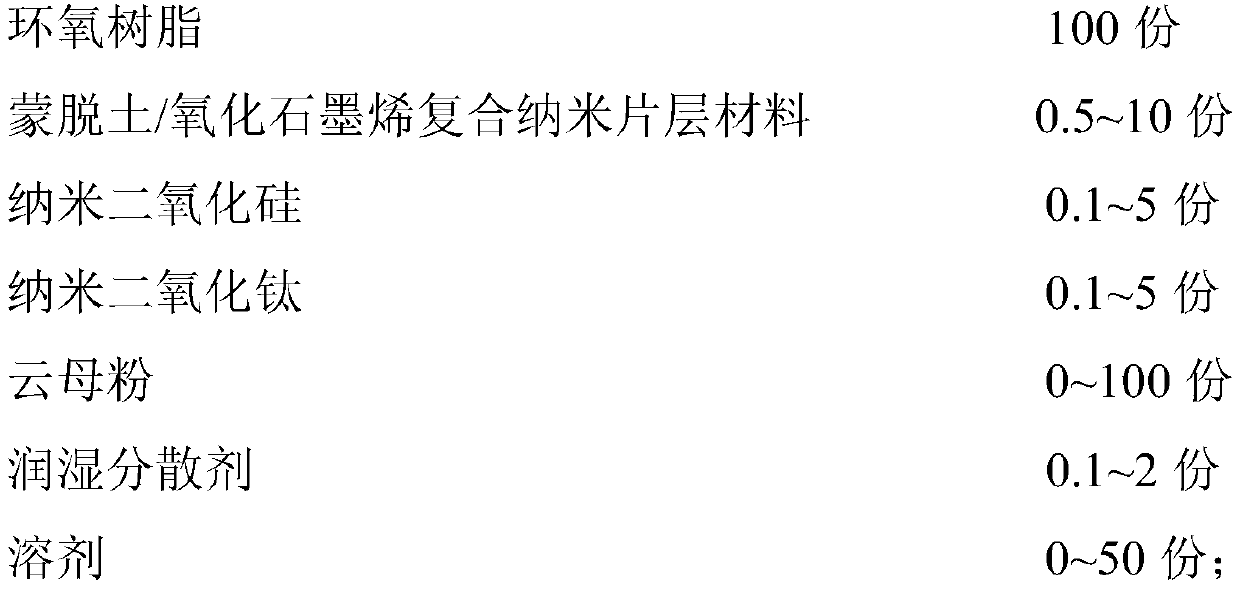

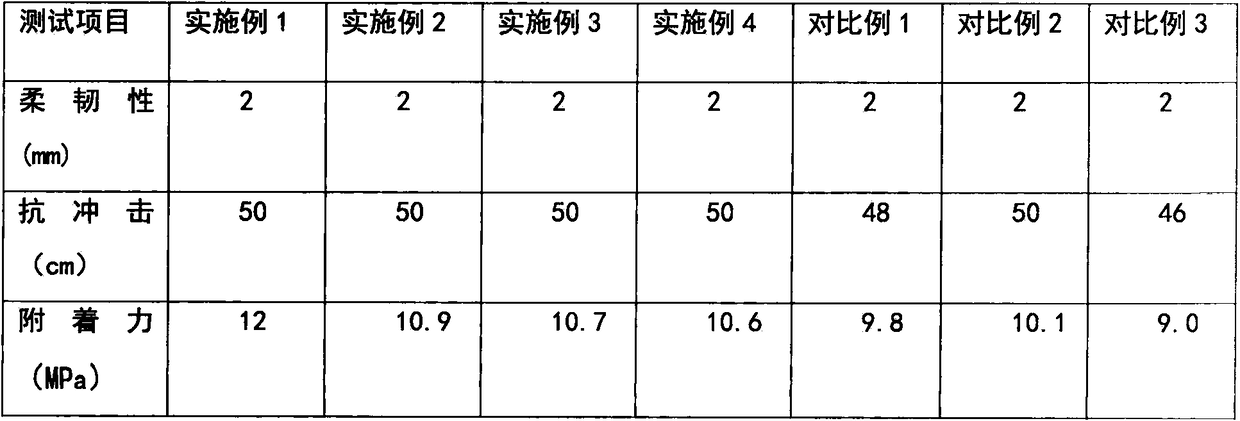

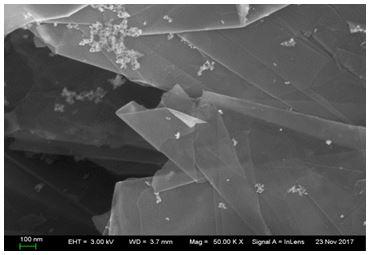

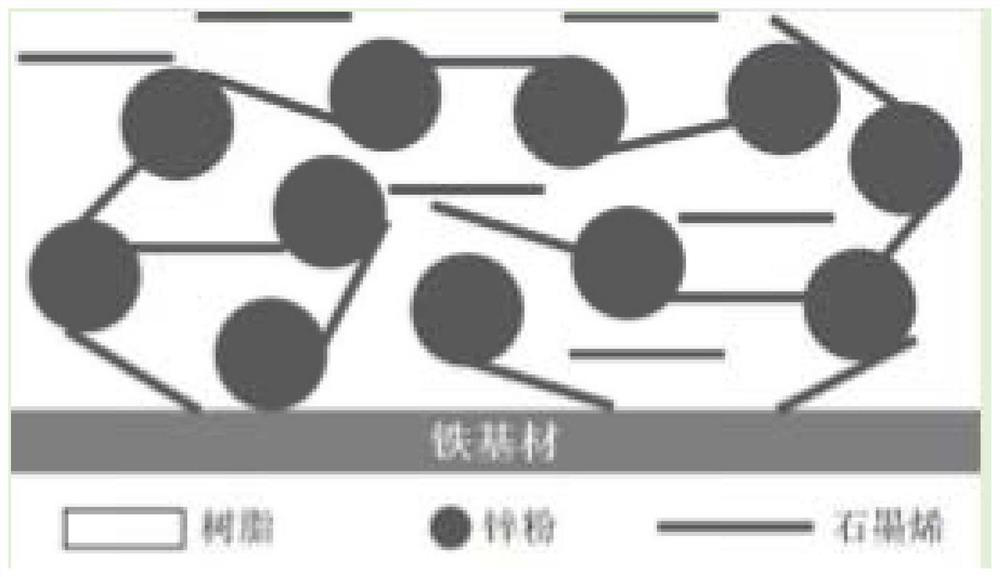

Montmorillonite/graphene oxide composite nanosheet layer material modified epoxy resin anticorrosive paint as well as preparation method and application thereof

ActiveCN110643266AImproves corrosion protectionAnti-corrosive paintsEpoxy resin coatingsOxide compositeFirming agent

The invention belongs to the technical field of material science, and particularly discloses montmorillonite / graphene oxide composite nanosheet layer material modified epoxy resin anticorrosive paintas well as a preparation method and application thereof. The anticorrosive paint comprises a component A and a component B. The component A comprises epoxy resin, a montmorillonite / graphene oxide composite nanosheet layer material, nano silicon dioxide, nano titanium dioxide, mica powder, a wetting dispersant and a solvent, and the component B comprises a curing agent, an antifoaming agent, a leveling agent and a solvent, wherein the mass ratio of the component A to the component B is 100: (20-100). Through an ion exchange reaction, the composite nano-powder material formed by mutual intercalation of two two-dimensional lamellar materials of modified montmorillonite and graphene is prepared. Compared with montmorillonite and graphene oxide which are independently used, the montmorillonite / graphene oxide composite nanosheet layer material can provide better corrosion protection performance for the epoxy resin paint.

Owner:中科广化(重庆)新材料研究院有限公司 +2

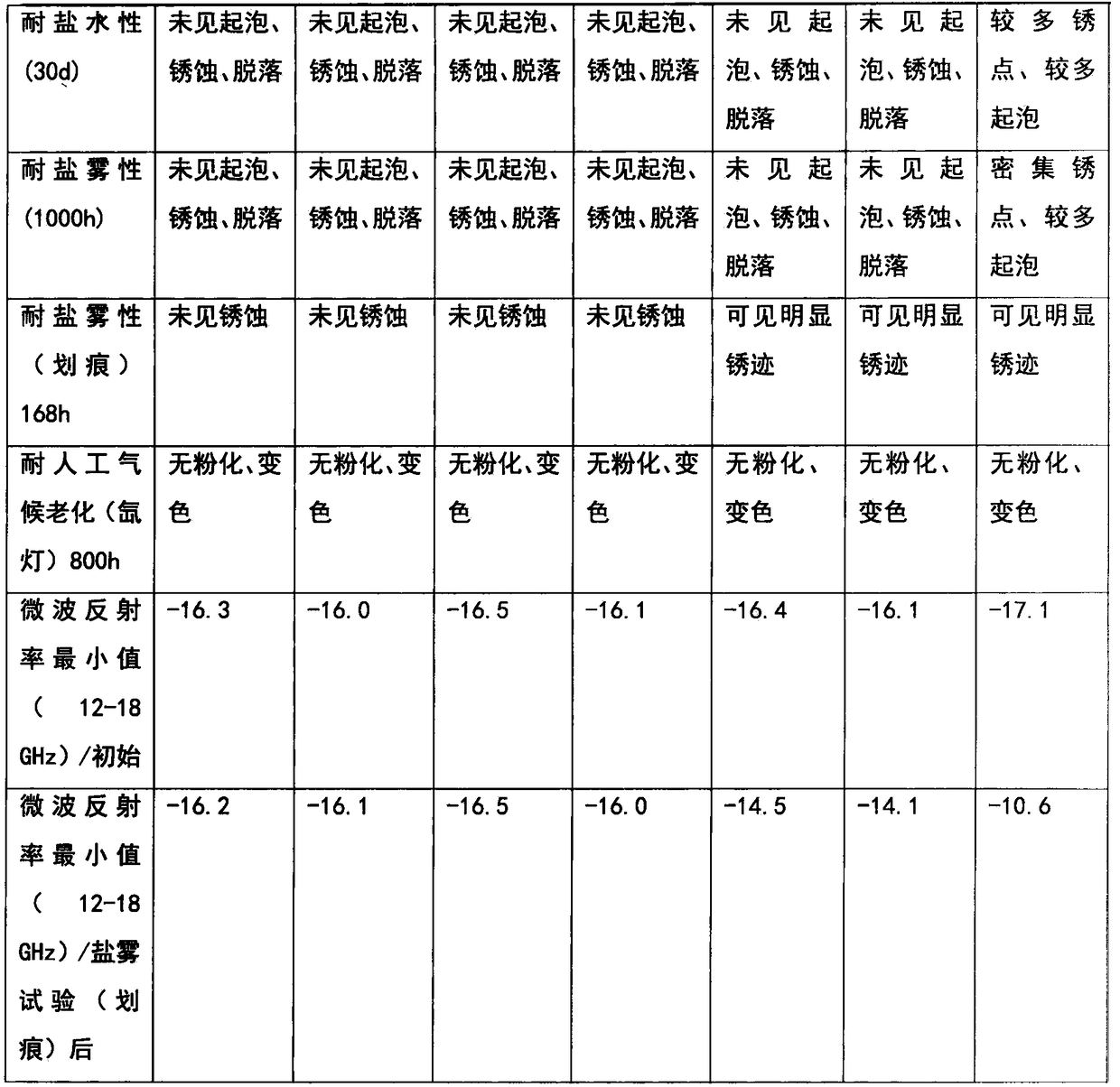

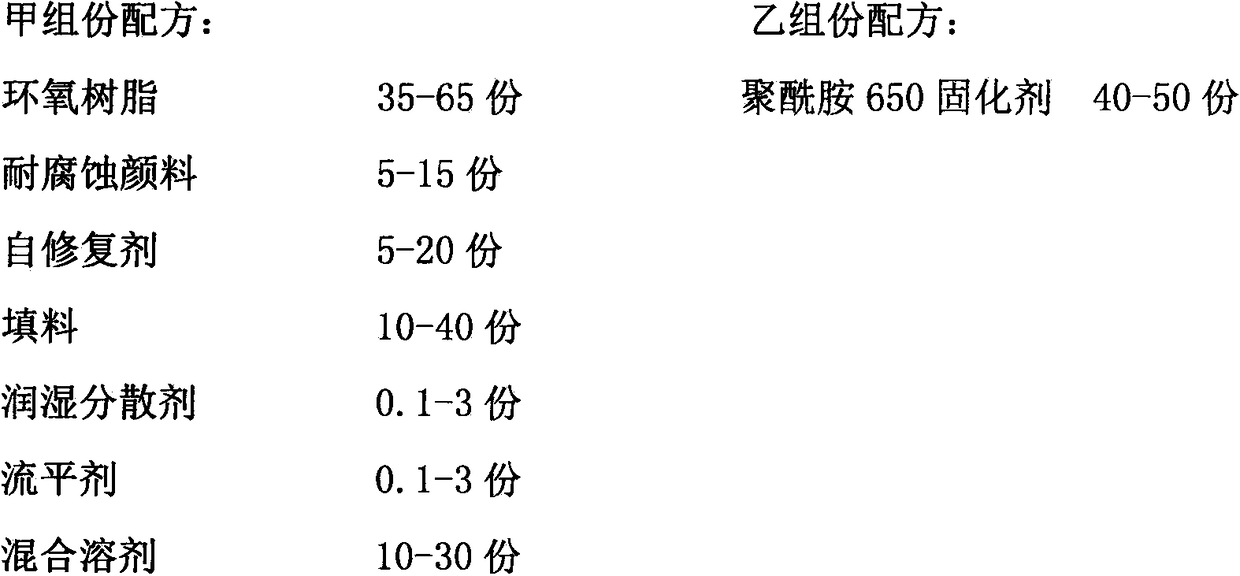

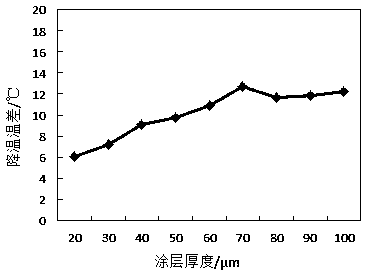

Corrosion reinforcement self-repair composite coating

InactiveCN108822691ARealize self-healing anti-corrosion strengthening functionImproves corrosion protectionAnti-corrosive paintsPolyurea/polyurethane coatingsSolventCorrosion resistant

The invention discloses a corrosion reinforcement self-repair composite coating. The composite coating is composed of laminated priming coat layers and finishing coat layers, the paint of the primingcoat layer employs a system of a component A and a component B, the component A comprises epoxy resin, a self-repairing agent, a corrosion-resistant pigment, a filling material, an auxiliary agent, and a solvent, the component B is a curing agent, the paint of the finishing coat layer employs a system of a component A and a component B, the component A comprises high-weatherability resin, a modified microwave absorbent, the filling material, the auxiliary agent, and a solvent, and the component B is the curing agent. The corrosion reinforcement self-repair composite coating can effectively solve the technical problems that novel protection capability can be timely firmed while damage is generated, and the protection performance of the routine coating is loss.

Owner:山东格物新材料科技有限公司

Aqueous graphene high-thermal-conductivity anticorrosive coating material for power batteries, and preparation method thereof

InactiveCN110835487AImprove thermal conductivityImprove cooling effectAnti-corrosive paintsHeat-exchange elementsPower batteryGraphite

The invention relates to an aqueous graphene high-thermal-conductivity anticorrosive coating material for power batteries, and a preparation method thereof, wherein the aqueous graphene high-thermal-conductivity anticorrosive coating material is a two-component coating material, and is prepared by mixing an aqueous heat-resistant resin as a film-forming matrix, graphene powder, a thermal conducting filler, an antirust filler and other functional aids. According to the invention, with the coating material, the problems of reduced use stability and reduced safety caused by closed working environment and difficult heat dissipation of the existing power battery are solved, and the corrosion protection performance is improved while the heat-conducting property of the coating is improved; by using the temperature-resistant aqueous resin as the coating film-forming matrix, the organic matter emission of the coating material is reduced so as to protect the ecological environment; and by introducing the novel graphene carbon material with high heat conductivity coefficient, unique lamellar structure and small size effect, the problem of insufficient heat conductivity of the traditional heat-conducting coating material is solved, and the heat dissipation performance and the corrosion resistance of the coating material are further improved.

Owner:中环海化(厦门)船舶智能涂料有限公司

Preparation method of sintered NdFeB magnet surface composite coating

ActiveCN109652798AImprove matchHigh bonding strengthMetallic material coating processesAlloyWear resistance

The invention discloses a preparation method of a sintered NdFeB magnet surface composite coating. The preparation method comprises the following steps of uniformly mixing metal-based alloy powder with a metal-based reinforcing material; preparing a metal-based cladding layer on the surface of sintered NdFeB obtained after pretreatment through a plasma cladding process; uniformly mixing ceramic-based powder with a ceramic-based reinforcing material; preparing a ceramic-based cladding layer on the metal-based cladding layer through the plasma cladding process; and conducting heat treatment on asintered NdFeB magnet obtained after coating. The composite coating prepared through the method is compact and free of pores and has the advantages of being high in binding force, corrosion resistance and wear resistance; and the more excellent corrosion protection effect can be provided for the sintered NdFeB magnet.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

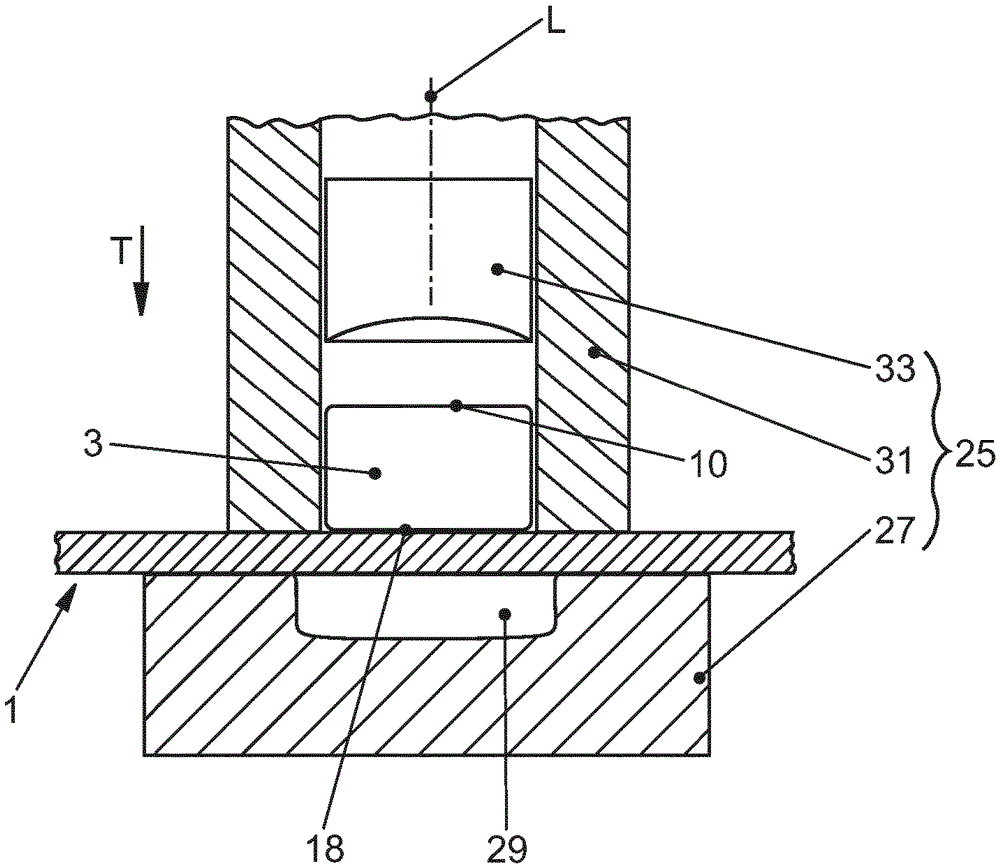

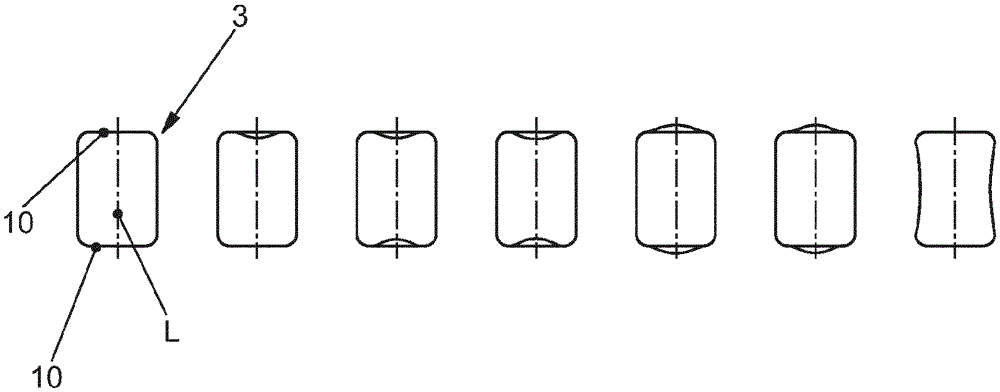

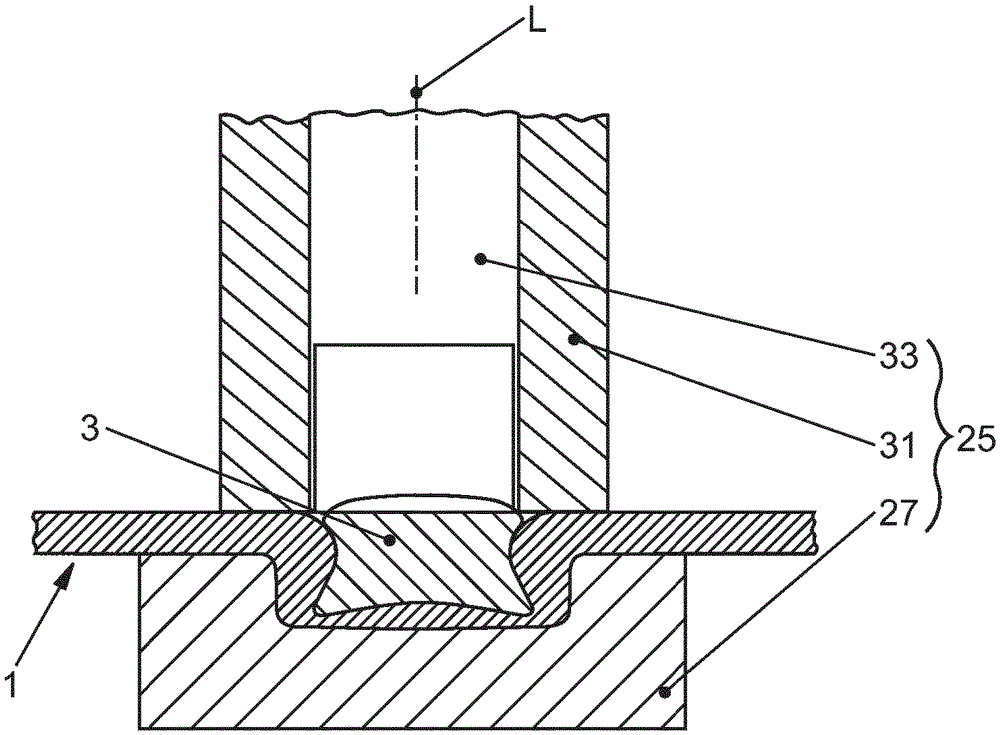

Method for connecting at least two sheet metal parts

ActiveCN105492155ALow costNot intrusiveVehicle componentsWelding/soldering/cutting articlesEngineeringSpot welding

The invention relates to a method for connecting at least two sheet metal parts (1, 5), wherein an impressing element is fastened to the first sheet metal part (1) and then the impressing element (3) fastened to the first sheet metal part (1) is welded to the second sheet metal part (5), in particular by spot welding. According to the invention, in order to fasten the impressing element to the first sheet metal part (1), the impressing element (3) is pressed into the material of the first sheet metal part (1) in a deep-drawing direction (T) in a deep-drawing process and enters into a form-locked connection to the first sheet metal part (1) under plastic deformation.

Owner:VOLKSWAGEN AG

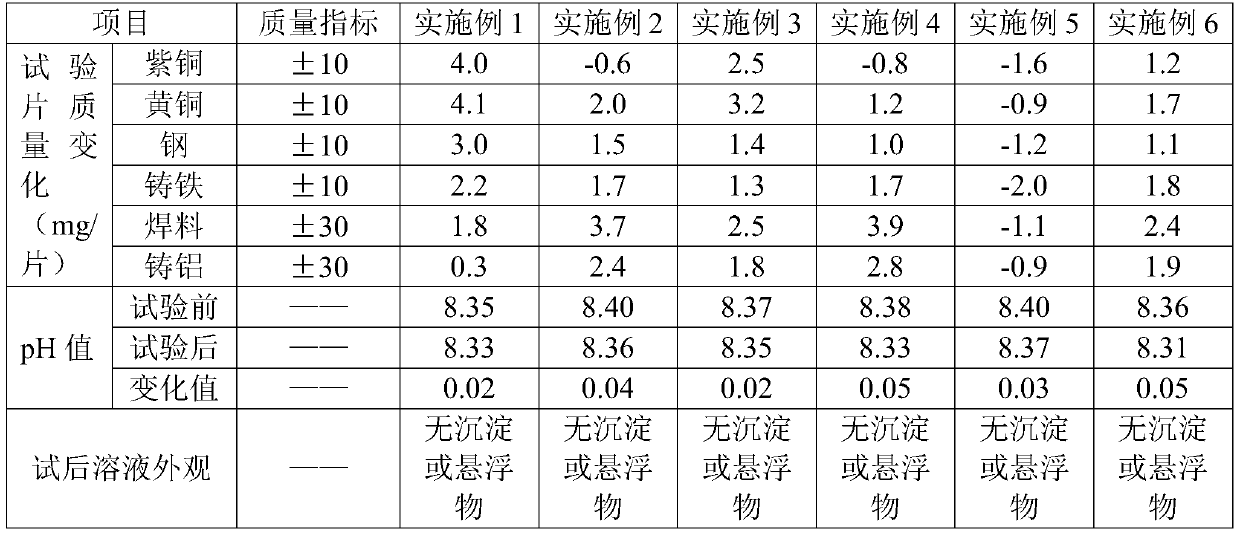

Environment-friendly type long-life engine coolant

InactiveCN109957381APromote environmental protectionImproves corrosion protectionHeat-exchange elementsKetoneFatty acid

The invention relates to an environment-friendly type long-life engine coolant, which comprises the following raw materials (by weight): 40-50 parts of deionized water, 50-60 parts of polyol, 0.04-0.5part of inorganic base, 0.6-1.1 parts of monobasic fatty acid, 0.2-1.3 parts of dibasic fatty acid, 0.1-0.5 part of triazine triaminocaproic acid, 0.1-0.4 part of amino acid, 0.1-0.4 part of sulfonicsiloxane ketone, 0.1-0.2 part of a triazole compound, 0.005-0.01 part of an emulsified silicon oil antifoaming agent, and 0.005-0.01 part of a dye. The engine coolant of the invention contains no inorganic acid salts such as silicate, borate, nitrite, phosphate, etc., thus improving environmental protection property of the engine coolant. By using a special organic aluminium alloy corrosion inhibitor, aluminium alloy corrosion prevention effect of the engine coolant is enhanced, and the problem that a special aluminium alloy corrosion inhibitor silicate in a traditional engine coolant has poor heat stability is solved. The engine coolant of the invention has decay resistance, pH value can be maintained for a long time, and the problem that pH value is reduced obviously in the using process of a traditional engine coolant is solved.

Owner:FAW JIEFANG AUTOMOTIVE CO

Magnesium alloy surface composite coating and preparation method thereof

InactiveCN110306181AImprove mechanical propertiesImprove carrying capacityAnodisationSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

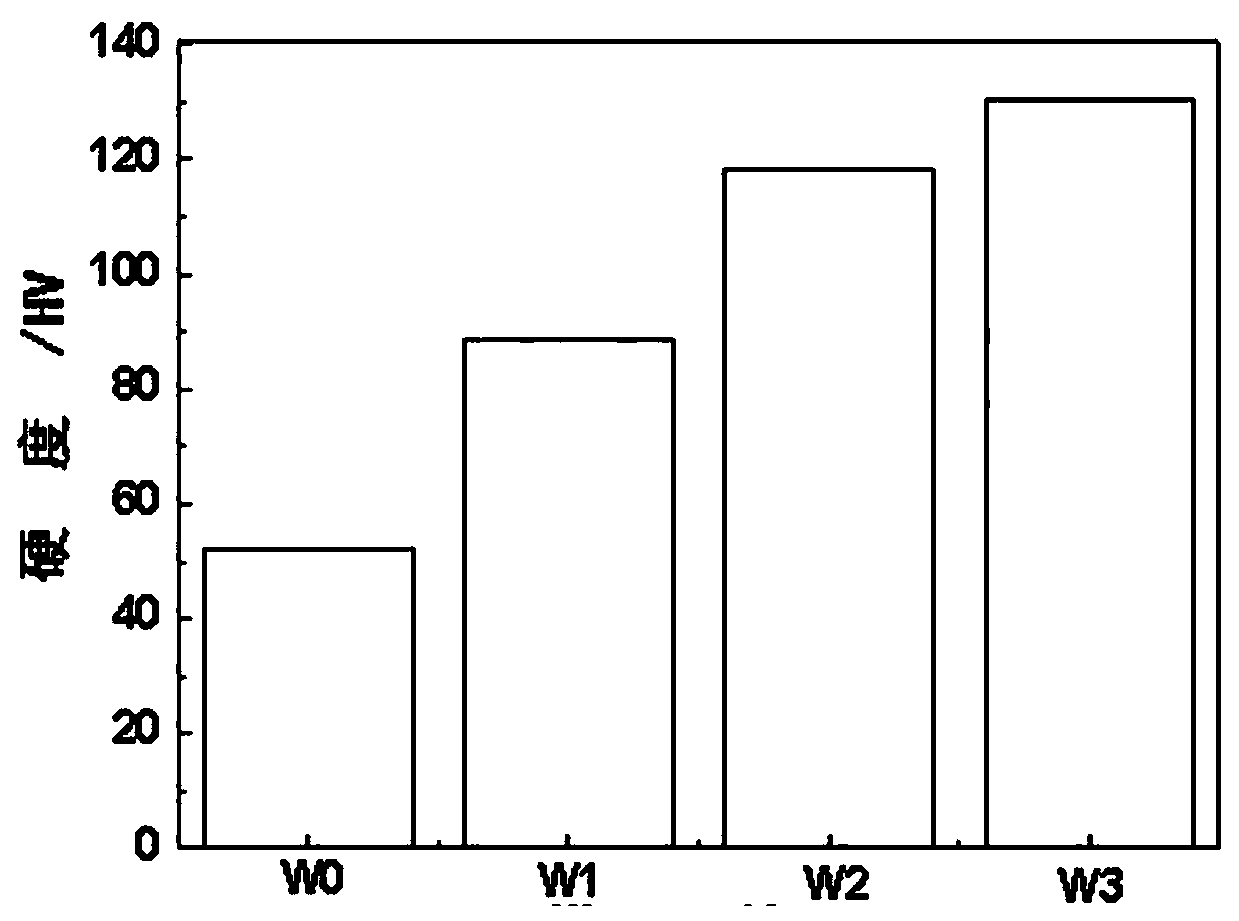

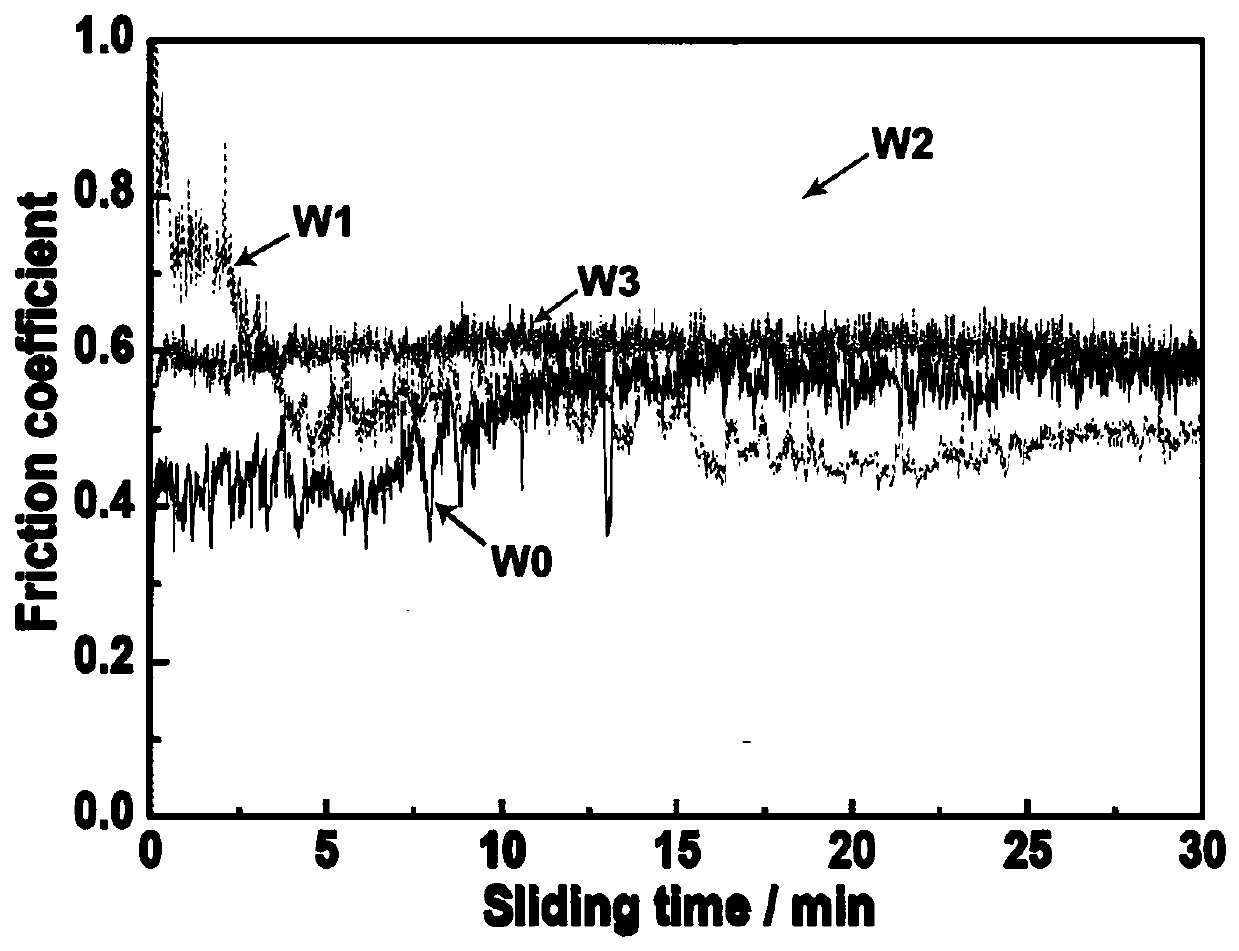

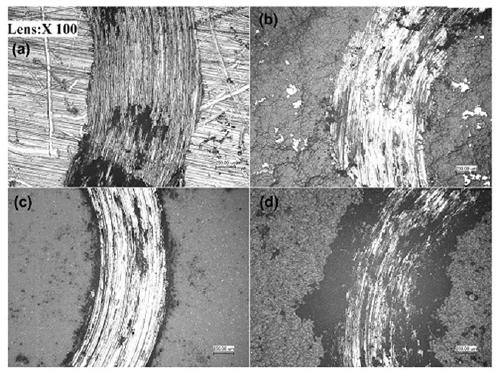

The invention belongs to the technical field of magnesium alloy surface modification, and particularly relates to a magnesium alloy surface composite coating and a preparation method thereof. The magnesium alloy surface composite coating is characterized by comprising an aluminum metal layer and a micro-arc oxidation ceramic coating, wherein the aluminum metal layer is sprayed on the surface of amagnesium alloy matrix through cold spraying technology, and the micro-arc oxidation ceramic coating grows in situ on the aluminum metal layer through micro-arc oxidation technology. According to themagnesium alloy surface composite coating and preparation method thereof, the design of preparing a high-performance AL-MAO composite coating through aluminum cold spraying- micro-arc oxidation composite technology is adopted, the AL-MAO composite coating has a better hardness value than a single pure aluminum coating and a MAO coating, the mechanical property and the bearing capacity of the matrix are obviously improved, and the bearing capacity and the friction and wear resistance ability of the magnesium alloy can be effectively improved; the AL-MAO composite coating has relatively high hardness bearing capacity and better friction and wear resistance ability, is more obvious in improving the friction and wear characteristic of the matrix, and shows better reliability and longer servicelife; and a pure aluminum metal layer is introduced between the matrix and the MAO coating, so that the comprehensive performance of the composite coating is improved.

Owner:UNIV OF SCI & TECH LIAONING

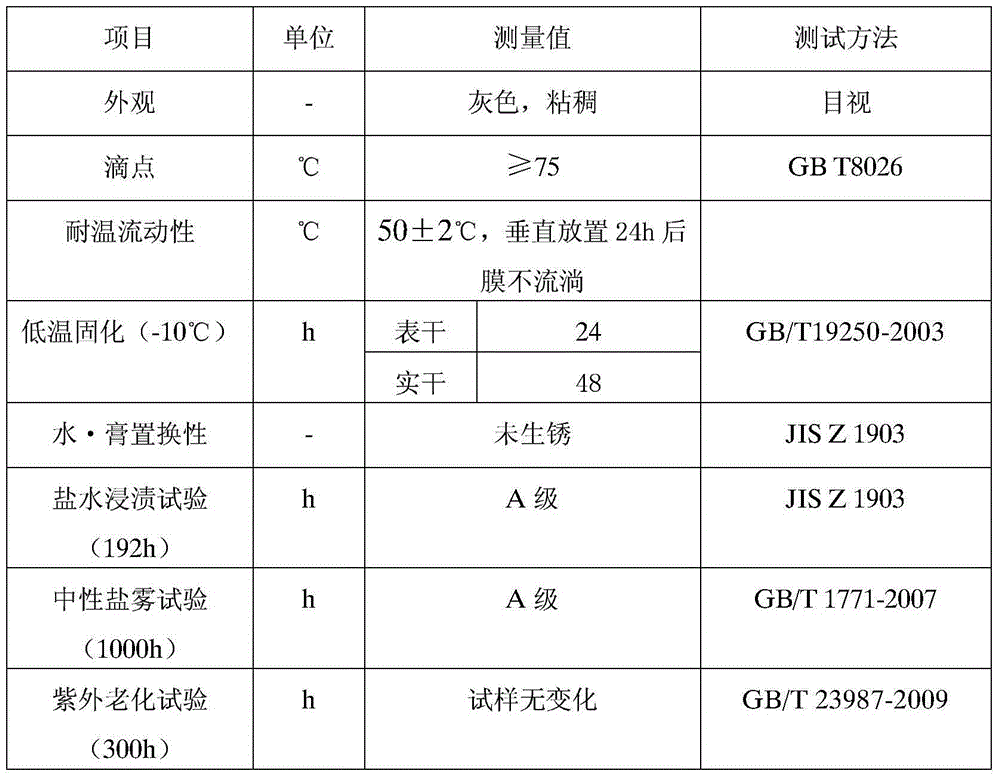

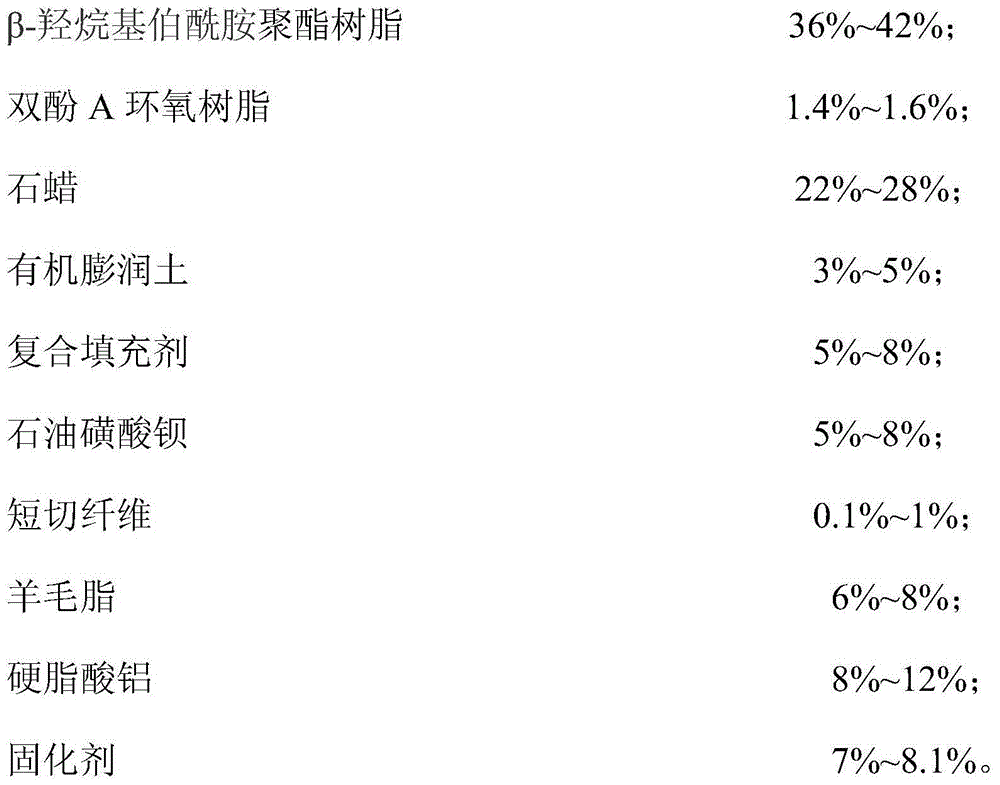

Low-temperature non-adhesive petrolatum anticorrosion paste

ActiveCN104946097AAvoid crackingGood anti-corrosion and anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsFiberALUMINUM STEARATES

The invention relates to a low-temperature non-adhesive petrolatum anticorrosion paste which is characterized by containing the following components in percentage by mass: 36-42% of beta-hydroxyalkyl primary amide polyester resin, 1.4-1.6% of bisphenol A epoxy resin, 22-28% of paraffin, 3-5% of organobentonite, 5-8% of composite filler, 5-8% of barium petroleum sulfonate, 0.1-1% of chopped fiber, 6-8% of lanolin, 8-12% of aluminum stearate and 7-8.1% of curing agent. The low-temperature non-adhesive petrolatum anticorrosion paste can be quickly solidified in a high-cold low-temperature environment to form a continuous organic cover layer. The cover layer can not easily crack in the low-temperature environment, and has favorable corrosion resistance. The low-temperature non-adhesive petrolatum anticorrosion paste is convenient for construction, has favorable adhesive force, has the physical isolation protective action, and can perform the function of favorable corrosion protection for bolt fasteners. The low-temperature non-adhesive petrolatum anticorrosion paste can resist rain and snow at low temperature, does not shed or crack, and facilitates the construction and later maintenance operation.

Owner:STATE GRID CORP OF CHINA +2

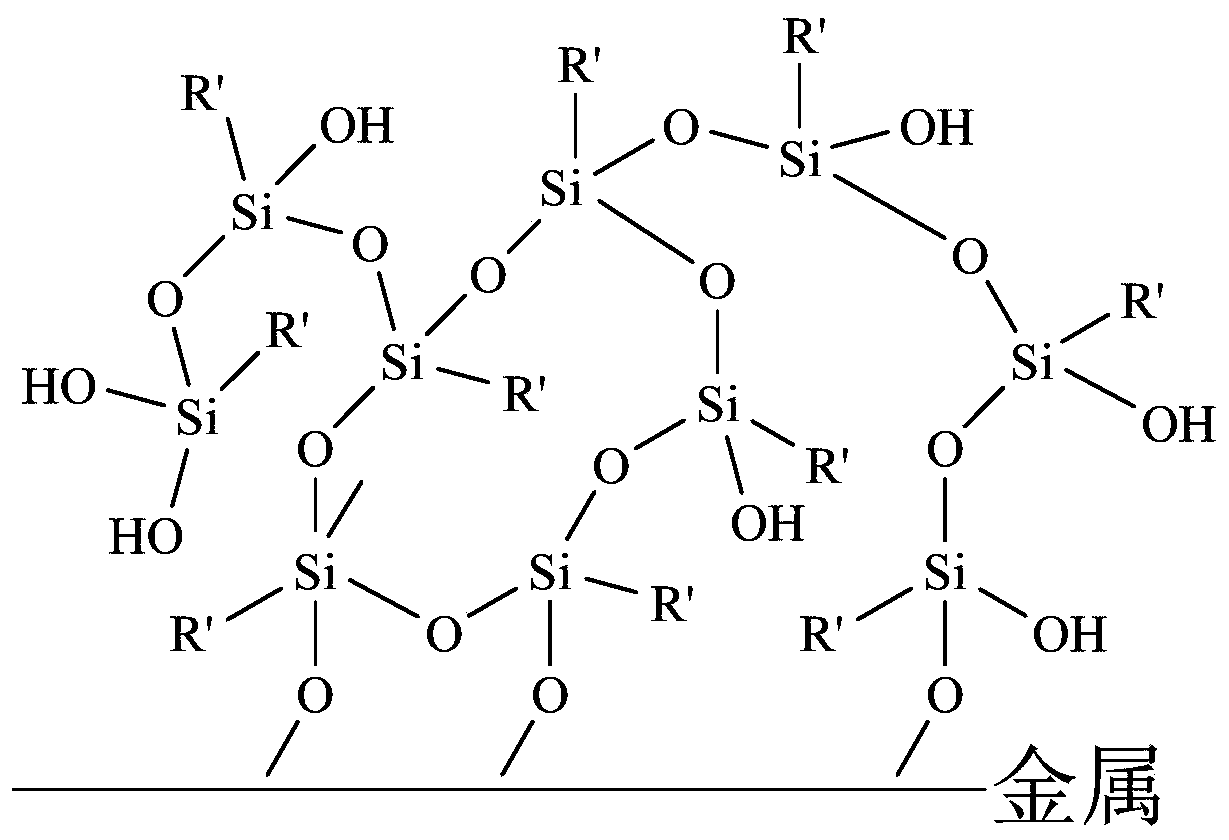

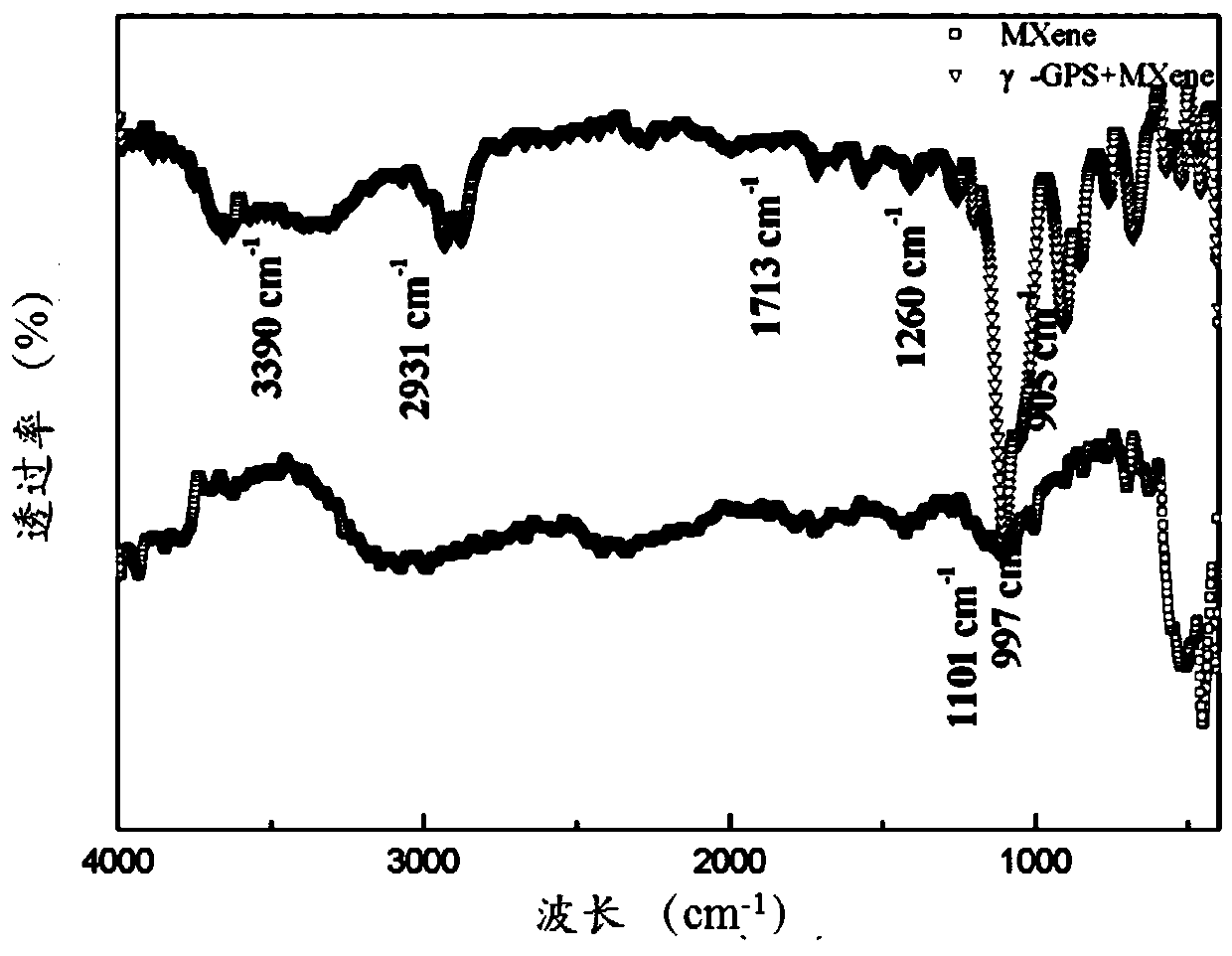

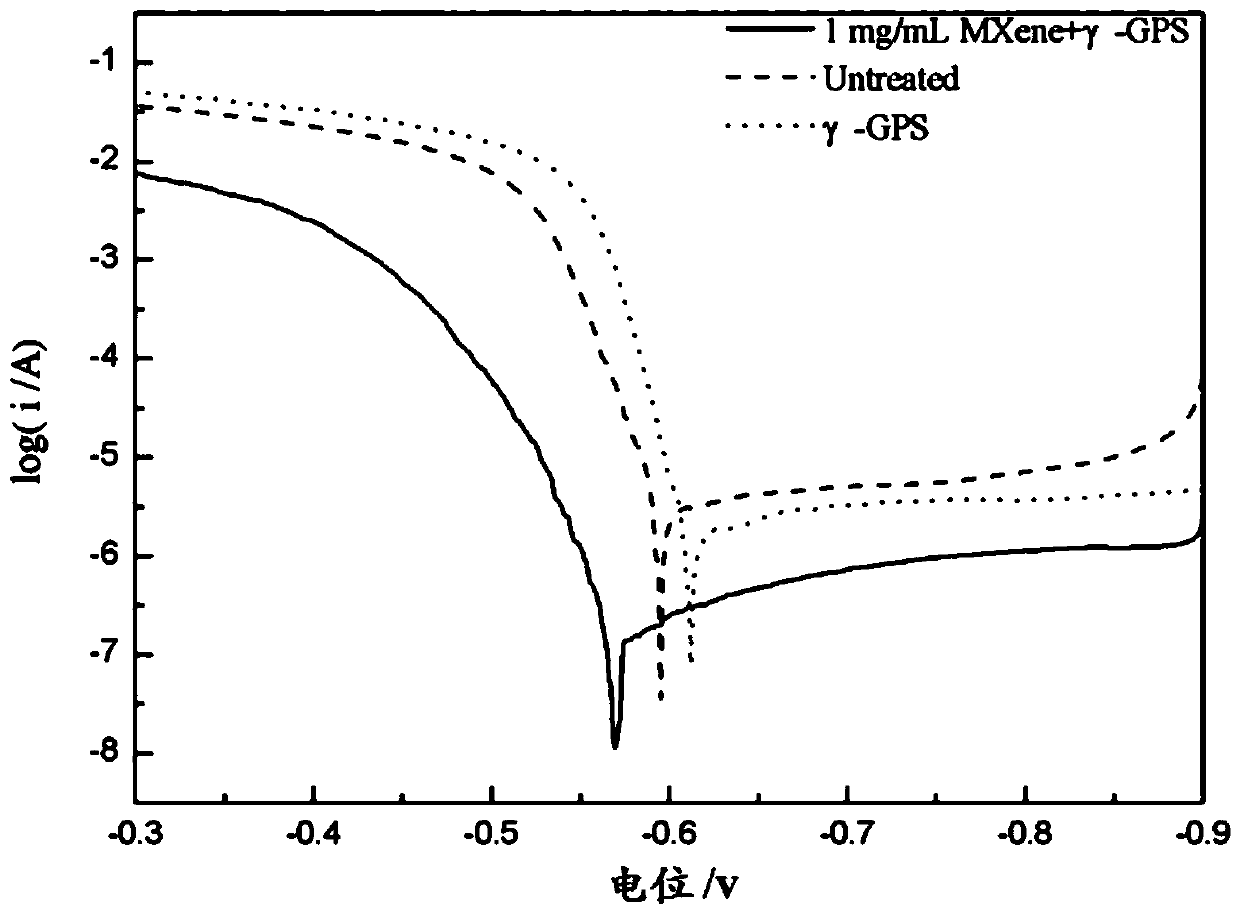

Application of MXene/silane surface composite silane film in metal corrosion protection

ActiveCN110527995ASimplify process stepsShort hydrolysis timeMetallic material coating processesCorrosion resistantSurface finishing

The invention belongs to the field of metal corrosion protection, and particularly relates to application of an MXene / silane surface composite silane film in metal corrosion protection. The method comprises the following steps: preparing and hydrolyzing an MXene / silane mixed solution, carrying out surface treatment on a metal sample, dipping the metal sample in a mixed silane hydrolysate, and curing to form a film. The MXene / silane surface composite silane film protective surface treatment technology is adopted, the defect that a single silane film is not compact is overcome, the operation iseasy, safety and environmental protection are achieved, diffusion of a corrosive medium can be effectively hindered by doping the MXene, and the corrosion resistance of the silane film is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anticorrosive weather-resistant functional integrated water-based graphene coating and preparation method thereof

InactiveCN111378346ASolve the problem of short corrosion protection periodImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsGraphene coatingWeather resistance

An anticorrosive weather-resistant functional integrated water-based graphene coating is a two-component coating, and is prepared by taking water-based epoxy resin, water-based hydroxyl resin and a water-based hydroxyl resin curing agent as resin base materials, taking a graphene material, iron oxide red, barium sulfate, titanium dioxide and the like as anticorrosive weather-resistant functional pigments and fillers, and supplementing other functional aids. At present, a traditional anticorrosive coating is difficult to meet the use requirements of ships, bridges, containers and other outdoorequipment. An 'interpenetrating network' structure of epoxy resin / polyurethane is introduced into a coating system, so that the coating has the advantages of high strength and good shielding propertyof an epoxy resin material as well as good flexibility and excellent weather resistance of a polyurethane material, and the ageing resistance of the coating is improved; meanwhile, a graphene materialwith a large specific surface area and a two-dimensional lamellar structure is introduced into the coating system, so that the shielding performance of the coating is improved, and the corrosion protection capability of the coating is improved. The preparation method is simple; and the coating has excellent corrosion resistance and weather resistance and has important practical significance and wide market prospects.

Owner:中环海化(厦门)船舶智能涂料有限公司

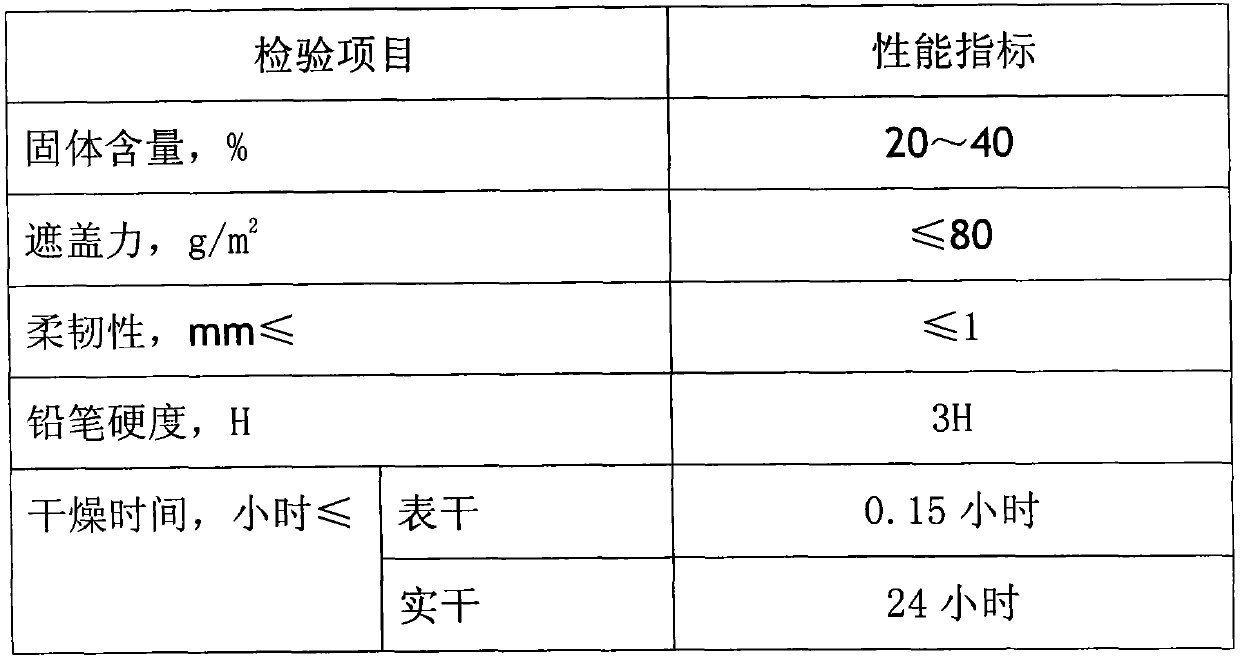

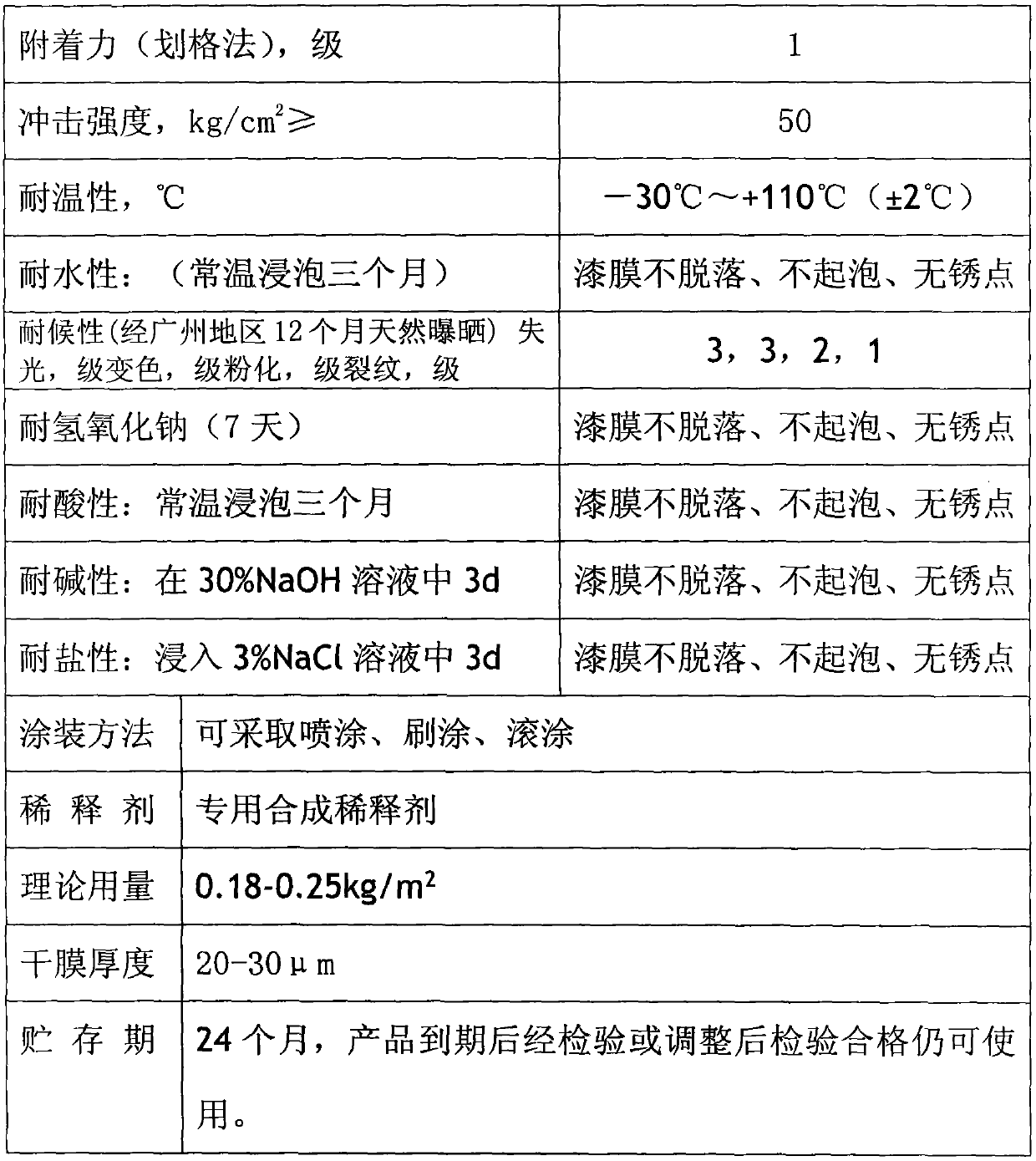

Specific anticorrosion paint for chemical equipment and production method thereof

InactiveCN104212258AEasy constructionLong storage periodAnti-corrosive paintsChemistryTritolyl Phosphates

The invention discloses specific anticorrosion paint for chemical equipment and a production method thereof. The specific anticorrosion paint comprises chlorosulfonated polyethylene, acrylic copolymeric resin, tritolyl phosphate, melamine-formaldehyde resin, titanium dioxide, n-butanol, ethyl acetate, butyl acetate, xylene and dibutyl phthalate. The production method comprises the following steps of adding chlorosulfonated polyethylene, acrylic copolymeric resin, tritolyl phosphate, melamine-formaldehyde resin and titanium dioxide into a dispenser, carrying out mixing stirring, taking the mixture, grinding the mixture until fineness is 20 microns, putting the ground mixture into the dispenser, adding ethyl acetate, butyl acetate, xylene, dibutyl phthalate and the n-butanol into the dispenser with stirring, carrying out full homogenization, putting the uniform mixture into a filter, carrying out filtration and carrying out packaging by a barrel. The production method has simple processes. The specific anticorrosion paint can be fast dried and has good electrochemical corrosion resistance and chemical corrosion resistance, good adhesion and a long service life. The specific anticorrosion paint can be widely used for modern petroleum chemical engineering and can be used for anti-corrosion coating of harshly corroded equipment such as devices for preparing alkali, acid and salt from natural gas.

Owner:HULUDAO HENGTONG SPECIAL PAINT

Water-based graphene zinc powder anticorrosive paint and preparation method thereof

InactiveCN114276707AEnvironmentally friendlyImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEmulsionFirming agent

The invention belongs to the field of chemical engineering, and particularly relates to a water-based graphene zinc powder anticorrosive coating, a preparation method thereof and application of the water-based graphene zinc powder anticorrosive coating in the field of corrosion resistance. The component A and the component B are mixed according to the mass ratio of (0.8-1.5): 3 when being compounded; wherein the component A comprises an epoxy resin emulsion, graphene water and an auxiliary agent, and the component B comprises a curing agent, zinc powder, a pigment filler, an auxiliary agent and a solvent. Compared with a traditional water-based graphene zinc powder coating in the market, the salt fog resistance time of the coating is greatly prolonged, specifically, the salt fog resistance time can reach 2500h or above, and corrosion at scratches spreads within 1.5 mm.

Owner:SHENYANG RES INST OF CHEM IND

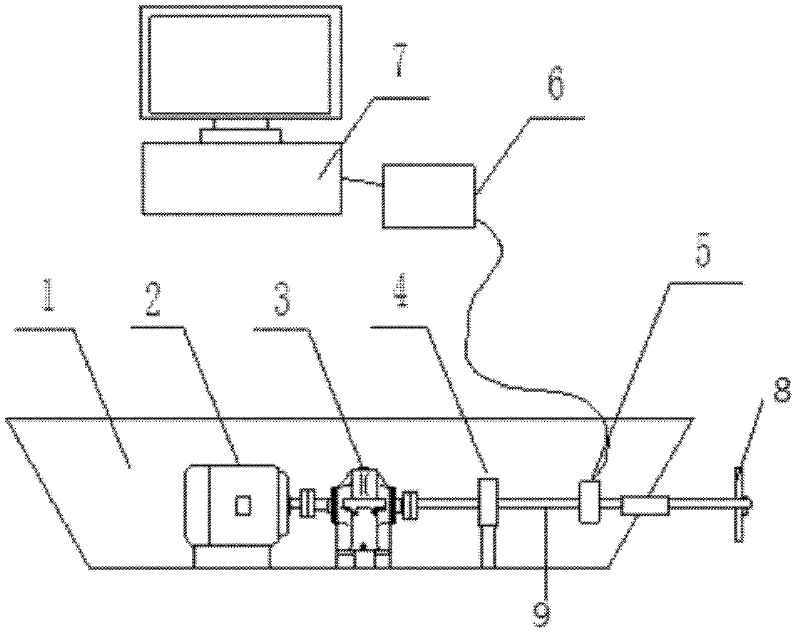

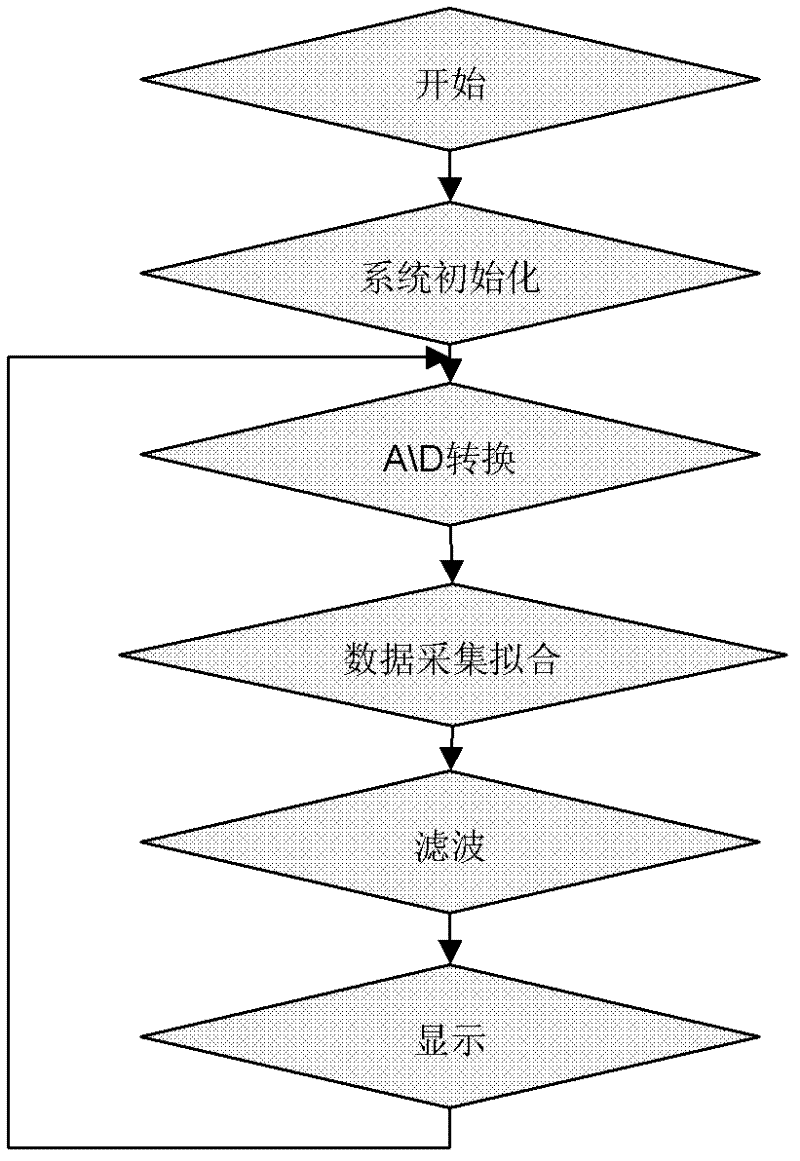

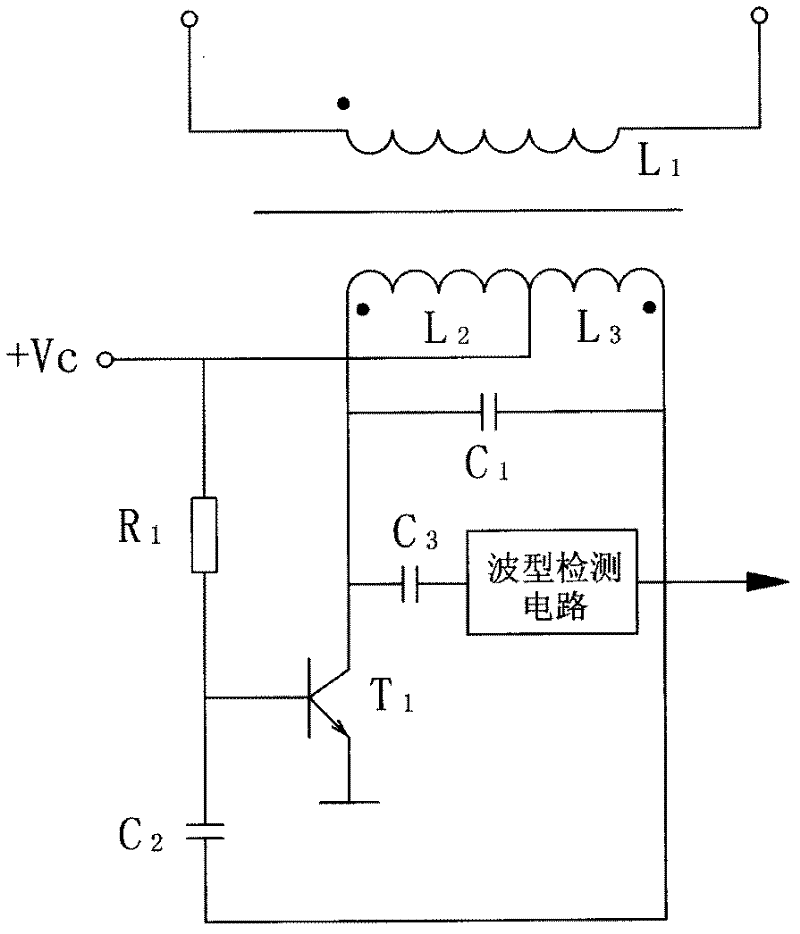

Current detecting device for ship stern shaft

ActiveCN102508001AImproves corrosion protectionImprove navigation safetyCurrent/voltage measurementCommunication interfaceCurrent sensor

The invention belongs to the technical field of electric quantity detection, and particularly relates to a current detecting device for a ship stern shaft. A sensor circuit unit is fixedly mounted at the rear end of a bearing block of the ship stern shaft to be detected and is provided with a finished or self-designed current sensor; the sensor circuit unit is fixedly connected with the ship stern shaft by means of welding or through a sliding ring to realize smoothness of weak current; a data acquisition circuit unit is mounted in a space of a computer hardware case and respectively electrically communicated with a computer and the sensor circuit unit through communication interface circuits; and the current of the stern shaft passes through a propeller, returns to a hull through joints of a driving motor, a speed reducer and the bearing blocks, and then passes through the sensor circuit unit and the data acquisition circuit unit, so that data are processed and displayed by the aid of self-programming software installed in a computer. The current detecting device is simple in overall structure, reliable in principle, low in manufacturing cost, convenient in use and operation, accurate in data detection, wide in application range and applicable to detecting the current of stern shafts of various ships.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

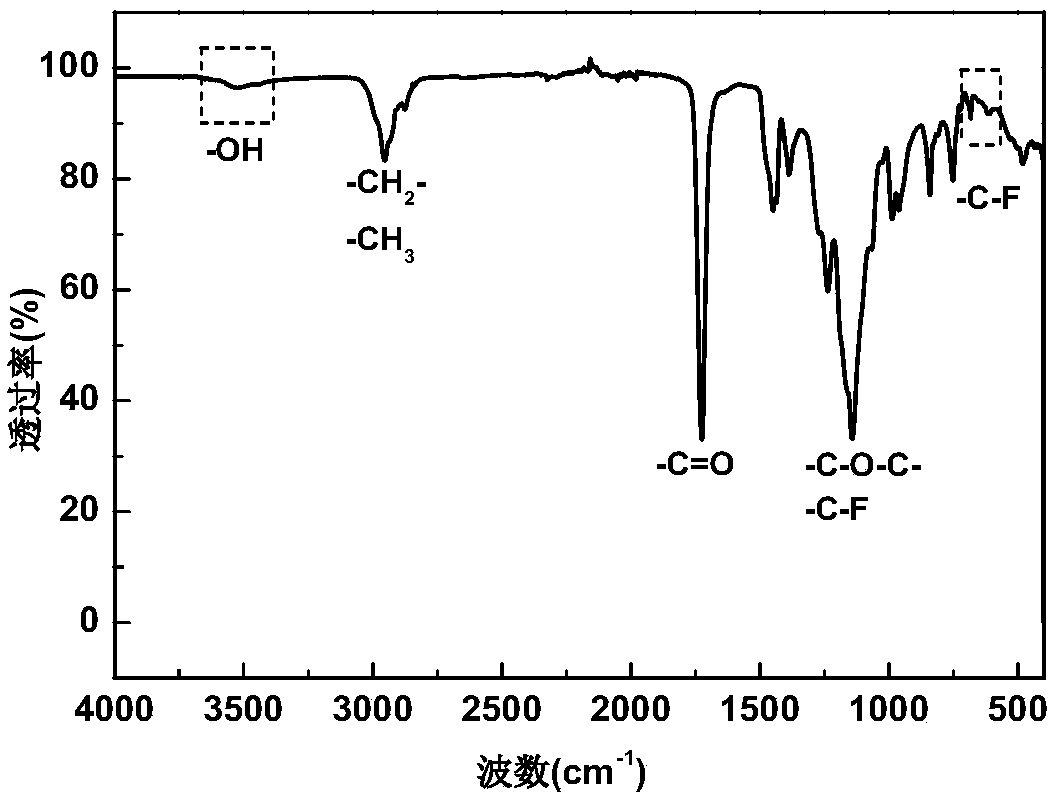

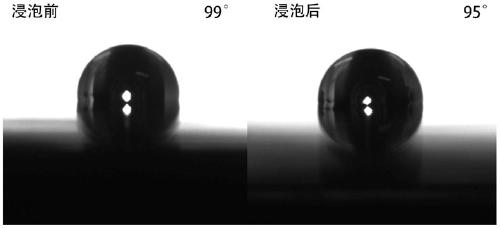

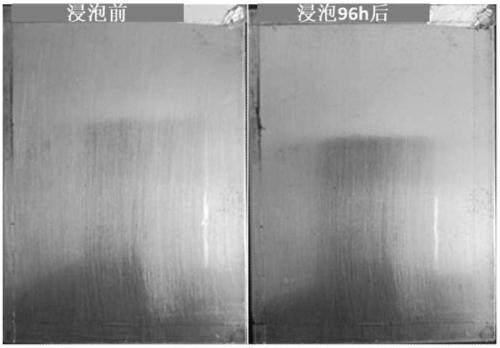

Fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint and preparation method thereof

InactiveCN109135485AImproves corrosion protectionLong-lasting corrosion protectionAnti-corrosive paintsPolymer scienceSolvent

The invention belongs to the technical field of fluoride and siloxane modified acrylate polymer anti-corrosive paint preparation, and particularly relates to fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint and a preparation method thereof. A catalyst-containing solvent is added in mixed liquid of acrylic comonomer, an organic fluorine modifierand an organic silicone modifier and subjected to polymerization to obtain the fluorine and silicone copolymerization modification amphiphilic acrylate polymer anti-corrosive paint; 40.0-52.0 parts bymass of acrylic comonomer, 2.0-15.0 parts by mass of organic fluorine modifier, 1.0-3.0 parts by mass of organic silicone modifier, 0.05-1.0 part by mass of catalyst and 45.0-50.0 parts by mass of solvent are applied. Accordingly, a fluorine and silicone copolymerization modification amphiphilic acrylate polymer can improve the corrosion protection property of coating.

Owner:南通中国科学院海洋研究所海洋科学与技术研究发展中心

Marine anti-fouling and corrosion-resistant coating

InactiveCN104263140AImproves corrosion protectionImprove adhesionAntifouling/underwater paintsPaints with biocidesTin FluoridesEthylic acid

The invention discloses a marine anti-fouling and corrosion-resistant coating. The marine anti-fouling and corrosion-resistant coating is prepared from the following raw materials: bisbutyl tin oxide, carbon black, n-butanol, tributyl tin fluoride, tributyl benzyl ammonium chloride, vanillin, titanium dioxide, butyl acetate, polyvinyl acetate resin, glycol ethyl ether acetate, butyl rubber, p-tert-butylphenol formaldehyde resin, perchloroethylene, vaseline, toluene, stearic acid, magnesium oxide, antimony oxide, a silane coupling agent, iron oxide, a thixotropic agent, an auxiliary filler and a corrosion-resistant filler. The coating has the characteristics of good corrosion resistance and anti-fouling performance, can tolerate acid and alkali environments and has a good protection effect on the surface of a hull.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

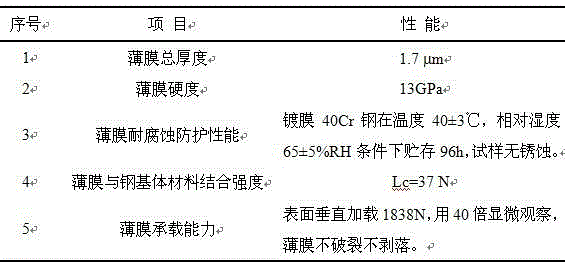

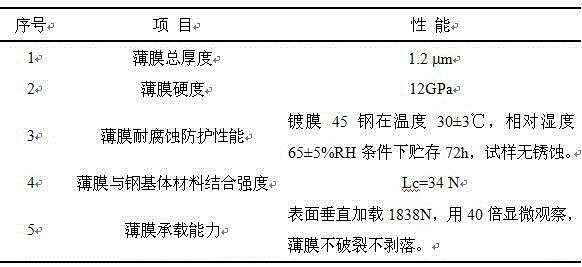

TiN/Ti/Si/Ti multi-layer wear-resistant corrosion-resistant thin film material and preparation method thereof

ActiveCN104630725AHigh hardnessImprove carrying capacityVacuum evaporation coatingSputtering coatingHigh humidityWear resistant

The invention discloses a TiN / Ti / Si / Ti multi-layer wear-resistant corrosion-resistant thin film material and a preparation method thereof. A thin film has a 4-layer structure, and from the surface of a substrate material to the surface of the multi-layer thin film, the multi-layer thin film is successively composed of a Ti layer, an amorphous Si layer, a dense Ti layer and a TiN layer. The thin film simultaneously has the hardness of more than 10 GPa and good corrosion-resistant and protection performance. Through addition of the amorphous Si layer and the dense Ti layer, formation of needle holes, micro-cracks and other structural defects penetrating through the multi-layer thin film is avoided, and the shortcomings of poor corrosion-resistant and protection performance of a traditional TiN thin film are better solved. The multi-layer thin film is suitable for wear resistance, corrosion resistance and protection of the surface of the substrate material easy to rust. At the same time, the thin film is also suitable for use in salt fog, high temperature and high humidity and other environmental conditions easily causing corrosion infringement.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

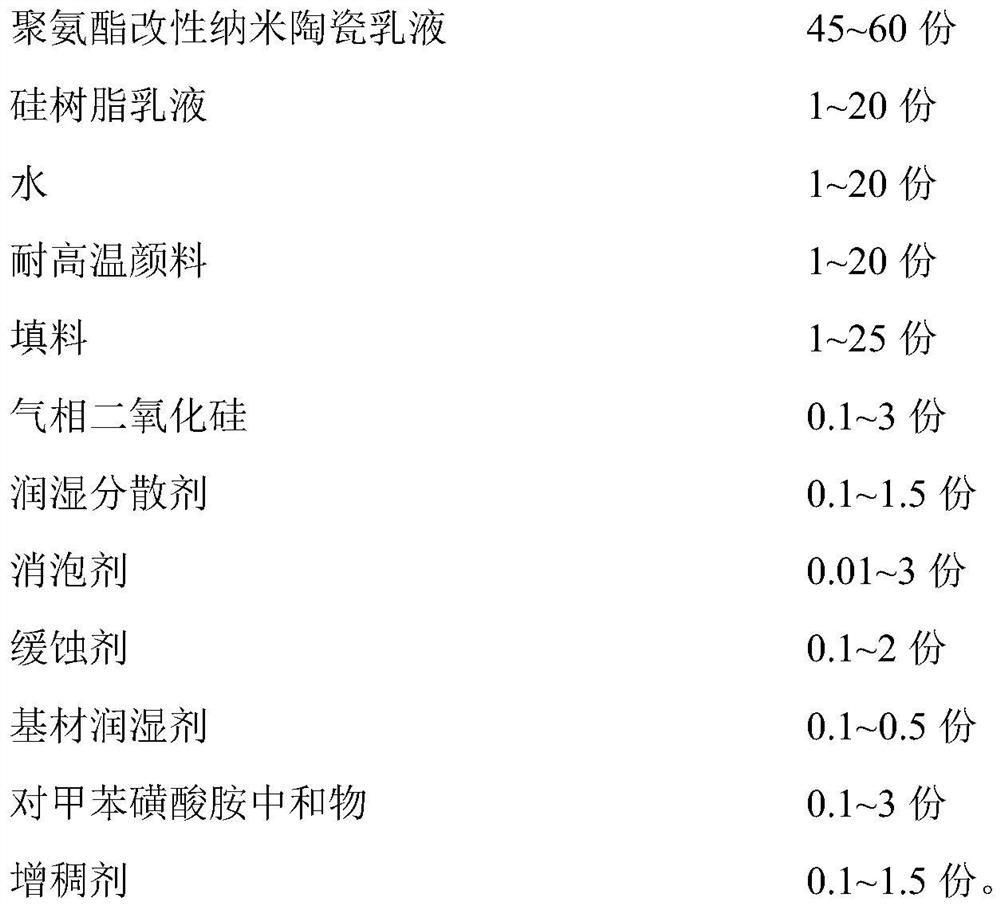

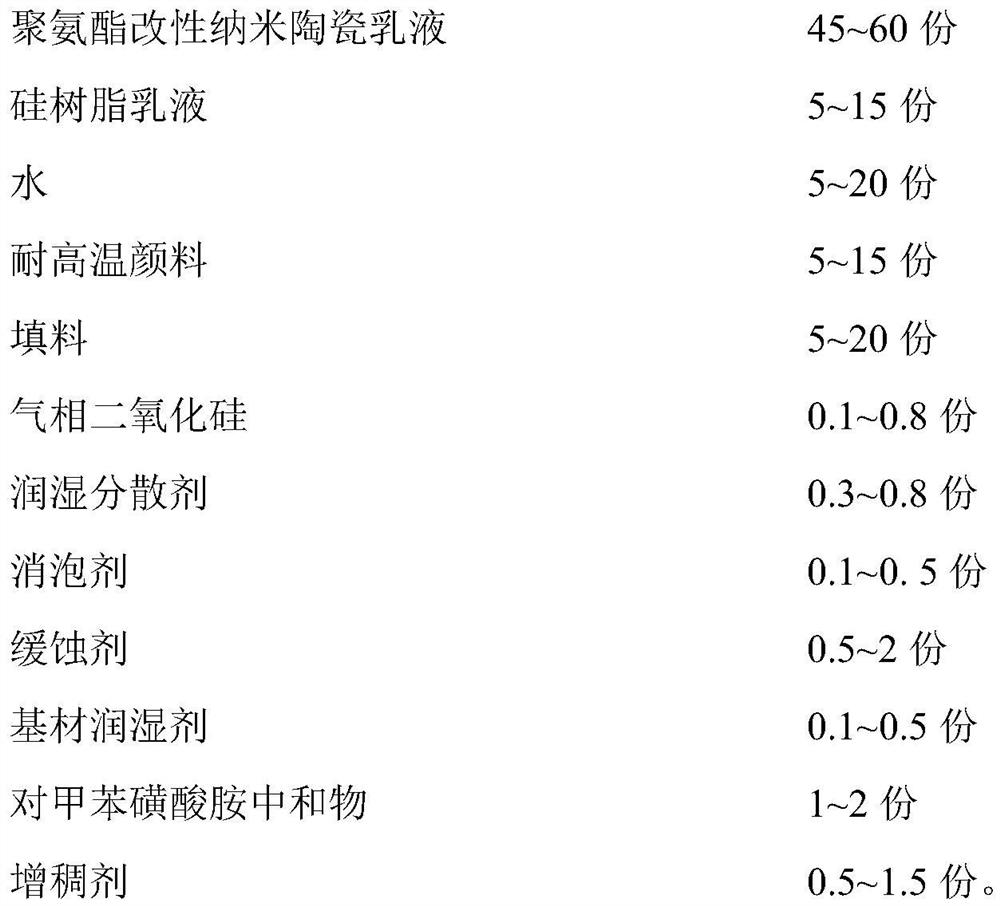

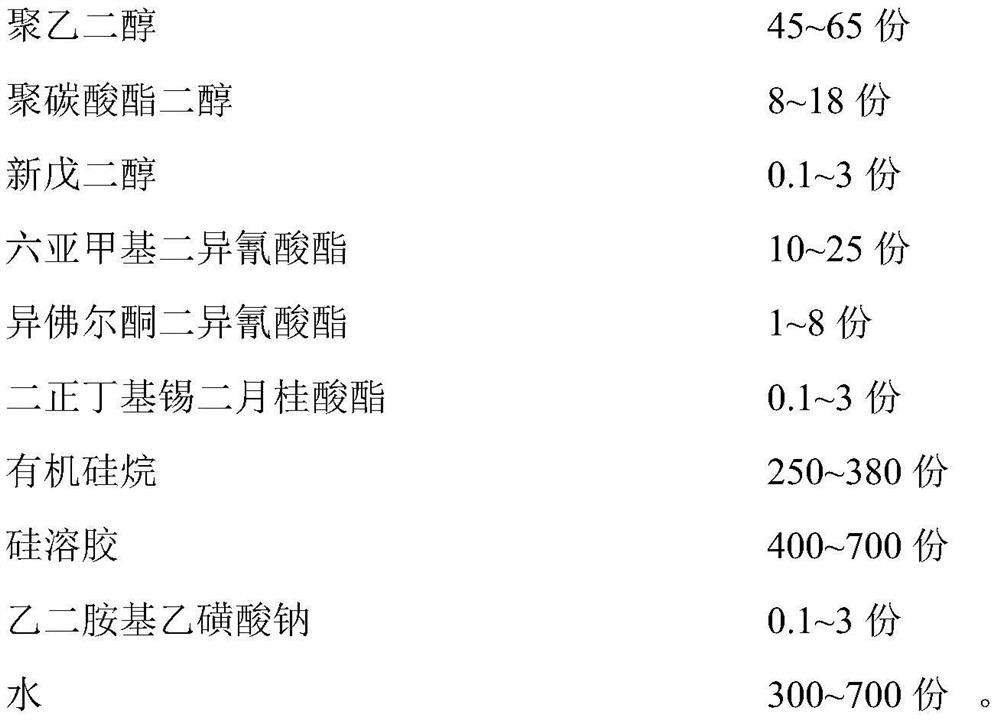

Water-based ceramic coating and preparation method thereof

ActiveCN112094514AImprove bending resistanceImprove brittle connectionsFireproof paintsAnti-corrosive paintsCeramic coatingNanoceramic

The invention discloses a high-toughness water-based ceramic coating. The coating is a water-based, single-component, baked and dried product and is prepared from polyurethane modified nano ceramic emulsion, silicon resin emulsion, a high-temperature-resistant pigment, a filler, auxiliaries, an ammonium toluene-4-sulphonate neutralizer and water. The coating is convenient to construct and extremely low in coating VOC emission, has excellent flame retardance, heat resistance, corrosion medium shielding, bending resistance and impact resistance, and is an excellent choice for high-temperature-resistance and high-durability anti-corrosion protective coating.

Owner:NANJING CHANGJIANG PAINT

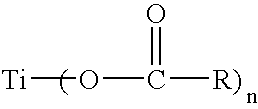

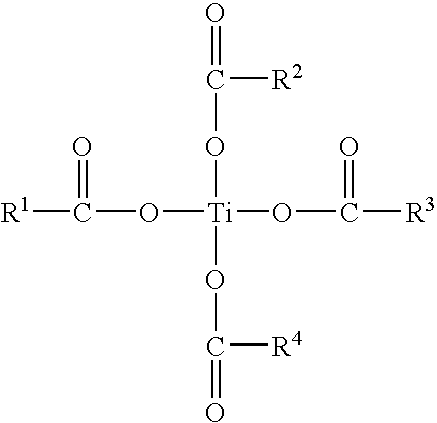

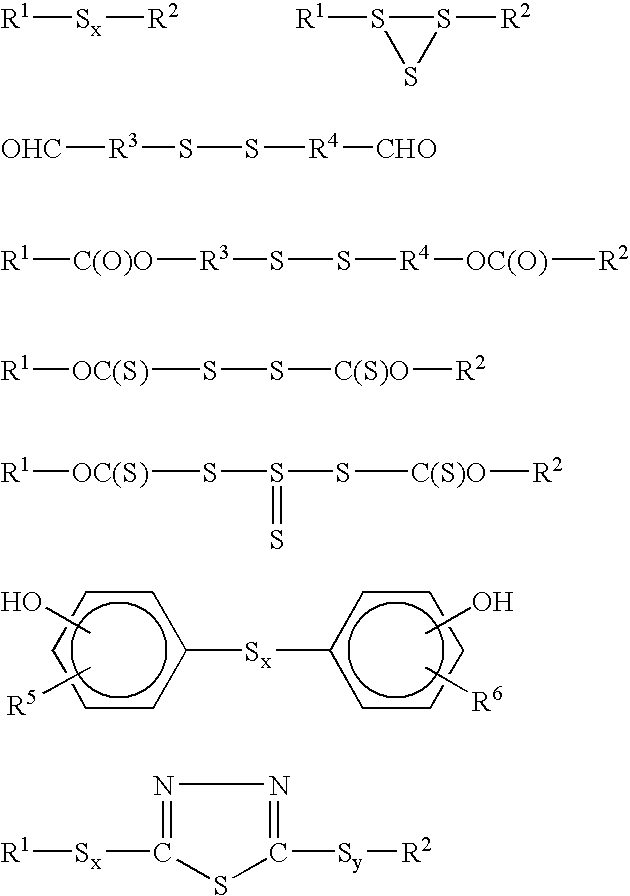

Corrosion resistant compositions for titanium brazing and coating applications and methods of application

InactiveCN104870690AImproves corrosion protectionImprove corrosion resistanceWelding/cutting media/materialsSpecial surfacesTitaniumTransition temperature

A composition comprising titanium, a small amount of at least one platinum group metal and alloying elements for lowering melting point of the composition to below titanium beta transus temperature.

Owner:佩萨赫塞德尔

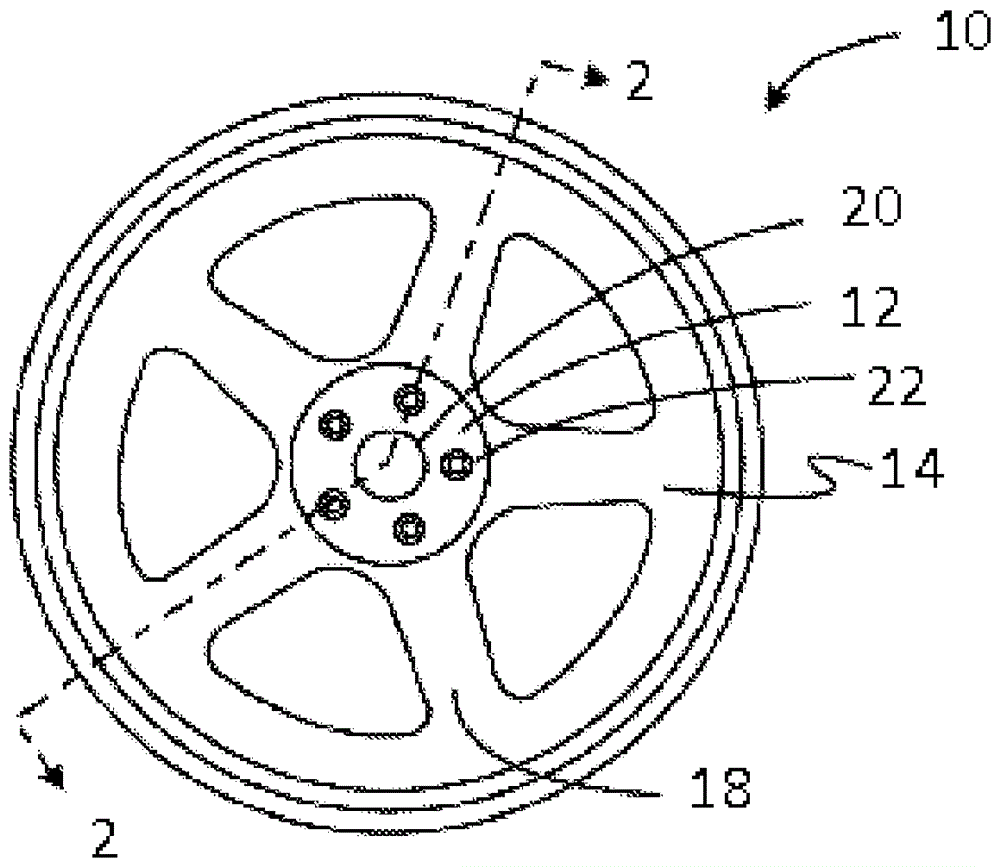

Method of making enhanced surface coating for light metal workpiece

InactiveCN106660319AImproves corrosion protectionAnodisationLiquid surface applicatorsMicro arc oxidationCorrosion resistant

A light metal workpiece with enhanced surface protection. The workpiece comprises a metal or alloy matrix having an exposed surface. A corrosion resistant oxide layer is formed in at least a portion of the exposed surface using a micro-arc oxidation technique. A first coating is applied onto at least a portion of the oxide layer using an electro-coating technique and is configured to seal the oxide layer. A second coating is applied onto at least a portion of the first coating, the second coating comprising a powder coating material. An appearance coating may optionally be applied onto at least a portion of the second coating, wherein the appearance coating includes at least one of a base coat, a color coat, and a clear coat.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Graphene oxide quantum dot as well as preparation method and application thereof as corrosion inhibitor

ActiveCN109763135APromote oxidation reactionEvenly dispersedElectrolysis componentsNanotechnologyDispersityElectrolysis

The invention discloses a graphene oxide quantum dot as well as a preparation method and application thereof as a corrosion inhibitor, and belongs to the technical field of the corrosion inhibitor. The preparation method comprises the following steps: taking a graphite bar as a positive electrode and a noble electrode as a negative electrode; using an ammonium salt aqueous solution of hydroxyl-containing organic carboxylic acid as electrolyte, and electrolyzing at constant voltage; filtering the electrolyte after completing the electrolyzing by using a microfiltration membrane, carrying out dialysis purification on filtrate through deionized water, and drying, thus obtaining the graphene oxide quantum dot. The graphene oxide quantum dot disclosed by the invention has good dispersity in anaqueous solution; the preparation method disclosed by the invention is simple, green and environment-friendly, and the graphene oxide quantum dot has a good corrosion prevention effect on a carbon steel material in an acidic solution.

Owner:HUAZHONG UNIV OF SCI & TECH

Magnesium alloy containing cell response anticorrosion coating as well as preparation method and application thereof

InactiveCN104593851AImproves corrosion protectionSolve corrosiveAnodisationProsthesisOsteoblastLayer by layer self assembly

The invention discloses a magnesium alloy containing cell response anticorrosion coating as well as a preparation method and application thereof, wherein a cell response anticorrosion coating is arranged on the surface of the magnesium alloy, and is composed of a plasma anodization coating and a lamination structure; the lamination structure is formed by using chitosan-sodium polystyrene sulfonate as a repetitive unit to cover the plasma anodization coating. According to the invention, the magnesium alloy surface is coated through a plasma anodization technology, and the cell response anticorrosion coating is constructed on the magnesium alloy surface by combining with a layer-by-layer self-assembly technology, so that the corrosion resistance of a magnesium alloy base material is improved, and the adhesion and growth of osteoblasts on the material surface are promoted, thus, the requirements on magnesium alloy as an implanted material are satisfied, the problems of poor corrosion resistance and poor cell compatibility of magnesium alloy are solved effectively, the clinical application range of magnesium alloy is expanded, and the long-term effectiveness of clinical applications is improved.

Owner:CHONGQING UNIV

Composite chromium-free corrosion inhibition passivator as well as preparation and application thereof

The invention provides a composite chromium-free corrosion inhibition passivator as well as preparation and application thereof. The passivator is composed of an agent A and an agent B in a mass ratioof 1 : 2.5-2.8, wherein the agent A comprises humic acid, barium metaborate, magnesium nitride, hydrogenated polydimethylsiloxane and styrene-acrylic emulsion; the agent B comprises phosphate, nanoscale mineral powder, plant slurry, bis (dicarbonyl cyclopentadiene iron), a silane coupling agent, waterborne silicon resin and deionized water. According to the composite chromium-free corrosion inhibition passivator as well as the preparation and application thereof, the self-made agent A and the self-made agent B are compounded, the synergistic effect of the components is remarkably improved through reasonable raw material selection and treatment, safety and high efficiency are achieved, the prepared passivator is stable in film layer and high in binding force, the passivator has good corrosion-resistant protection effects on chemical reagent, acid-base environment and various heavy metal pollutions, the overall wear resistance is obviously improved, the comprehensive quality is obviously improved, the protection period is effectively prolonged, and the passivator is worthy of popularization and application.

Owner:安徽禹锋数据科技有限公司

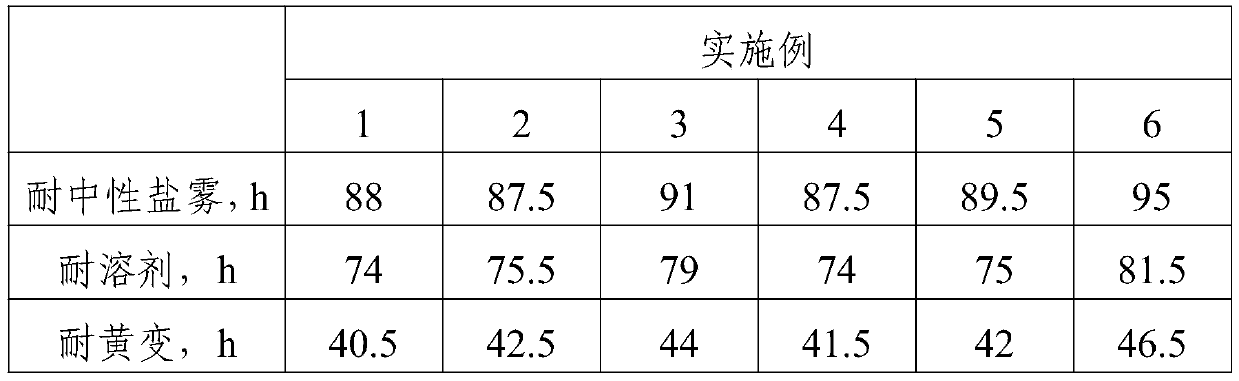

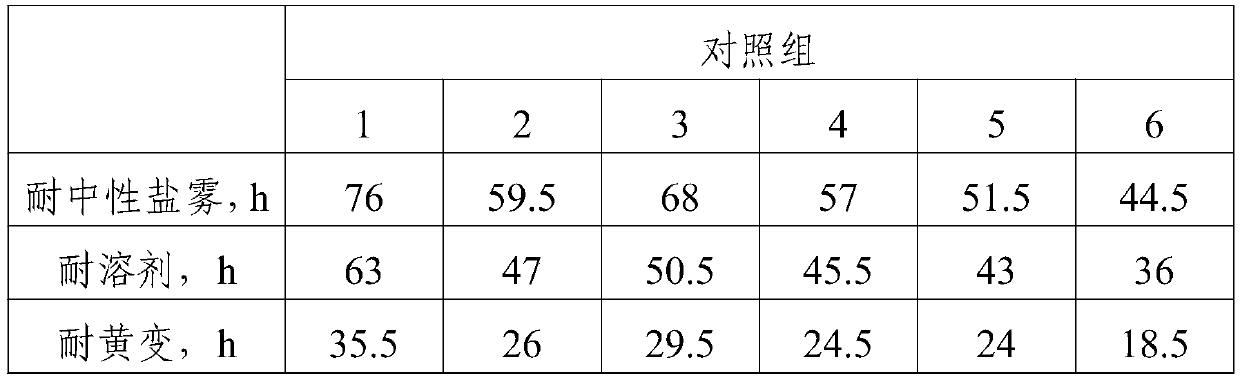

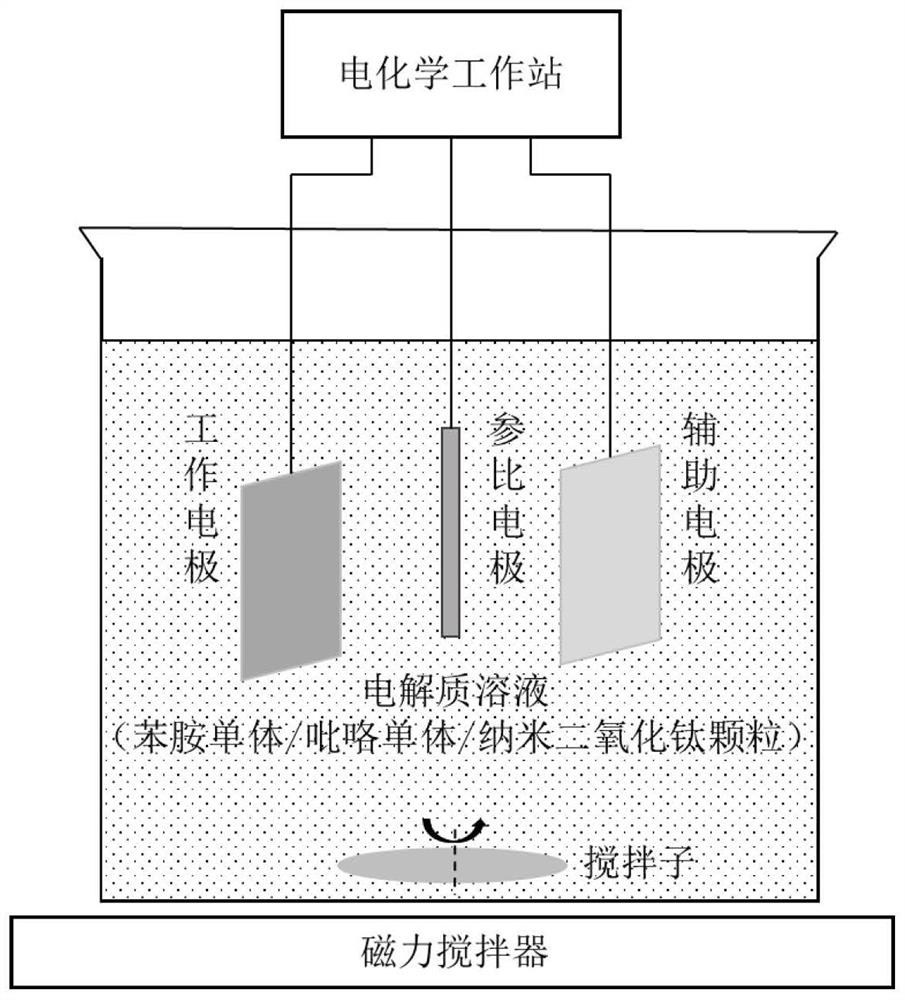

Preparation method of polyaniline-base composite coating applied to stainless steel bipolar plate

PendingCN113403663AReduce surface contact resistanceExcellent corrosion resistance and durabilityElectrolytic coatingsFinal product manufacturePyrroleGalvanic deposition

The invention relates to a preparation method of a high-corrosion-resistance and high-conductivity conductive polymer composite coating applied to a stainless steel bipolar plate of a proton exchange membrane fuel cell. The method comprises the following steps of preparing an aniline-pyrrole mixed solution, adding nano titanium dioxide particles and fully dispersing, preparing an electrolyte, and pretreating a stainless steel base material; and compounding and electrodepositing the polyaniline-base composite coating on the surface of stainless steel. The polyaniline-base composite coating has excellent corrosion resistance and stability and good conductivity, the use efficiency of the proton exchange membrane fuel cell can be improved, the service life of the proton exchange membrane fuel cell can be prolonged, the process is simple, the raw material cost is low, and the coating is suitable for industrial grade production.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com