TiN/Ti/Si/Ti multi-layer wear-resistant corrosion-resistant thin film material and preparation method thereof

A corrosion-resistant film and film material technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of surface TiN film peeling, TiN film application limitation, abnormal wear of moving parts, etc. Corrosion resistance and protection performance, overcoming the limitation of applicable environment and applicable matrix materials, and improving the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

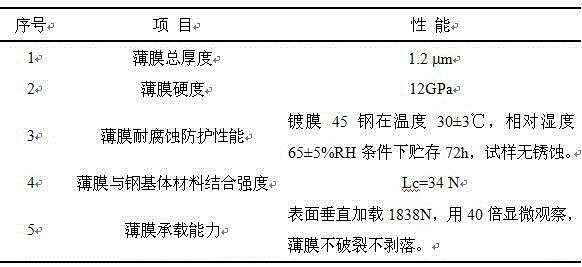

[0039] Choose 45 steel as the base material.

[0040] Step 1. Target preparation and installation

[0041] 1) Preparation of Ti target: process the Ti ingot into a cylindrical target with a diameter of Φ80mm and a thickness of 5mm;

[0042] 2) Preparation of polycrystalline Si target: the Si material is directly molded into a cylindrical target with a thickness of Φ80mm and a thickness of 5mm;

[0043] 3) Install the Ti target and the polycrystalline Si target on the target base of the magnetron sputtering coating device respectively, and connect the magnetron sputtering power supply respectively;

[0044] Step 2. Install and prepare coating base material

[0045] Put the clean 45 steel base material to be coated into the coating vacuum chamber, and adjust the target distance between the coating surface of the base material and the Ti and Si targets to 70mm;

[0046] Step 3, ion bombardment treatment

[0047] Vacuum the coating vacuum chamber to the background pressure of ...

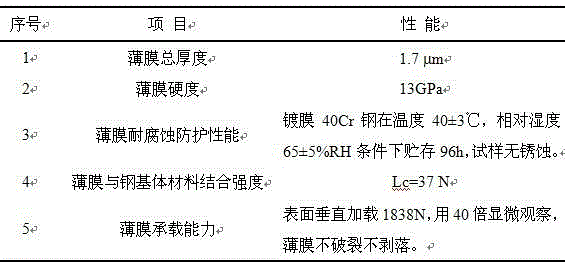

Embodiment 2

[0057] Choose 40Cr steel as the base material.

[0058] Step 1. Target preparation and installation

[0059] 1) Preparation of Ti target: process the Ti ingot into a cylindrical target with a diameter of Φ80mm and a thickness of 4mm;

[0060] 2) Preparation of polycrystalline Si target: the Si material is directly molded into a cylindrical target with a thickness of Φ80mm and a thickness of 4mm;

[0061] 3) Install the Ti target and the polycrystalline Si target on the target base of the magnetron sputtering coating device respectively, and connect the magnetron sputtering power supply respectively;

[0062] Step 2. Install and prepare coating base material

[0063] Put the clean 40Cr steel base material to be coated into the coating vacuum chamber, and adjust the target distance between the coating surface of the base material and the Ti and Si targets to 80mm;

[0064] Step 3, ion bombardment treatment

[0065] Vacuum the coating vacuum chamber to the background pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com