Low-temperature non-adhesive petrolatum anticorrosion paste

A non-sticky, anti-corrosion paste technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as difficult to achieve protective effects, achieve good corrosion protection effects, not easy to crack, construction and post-maintenance operations easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

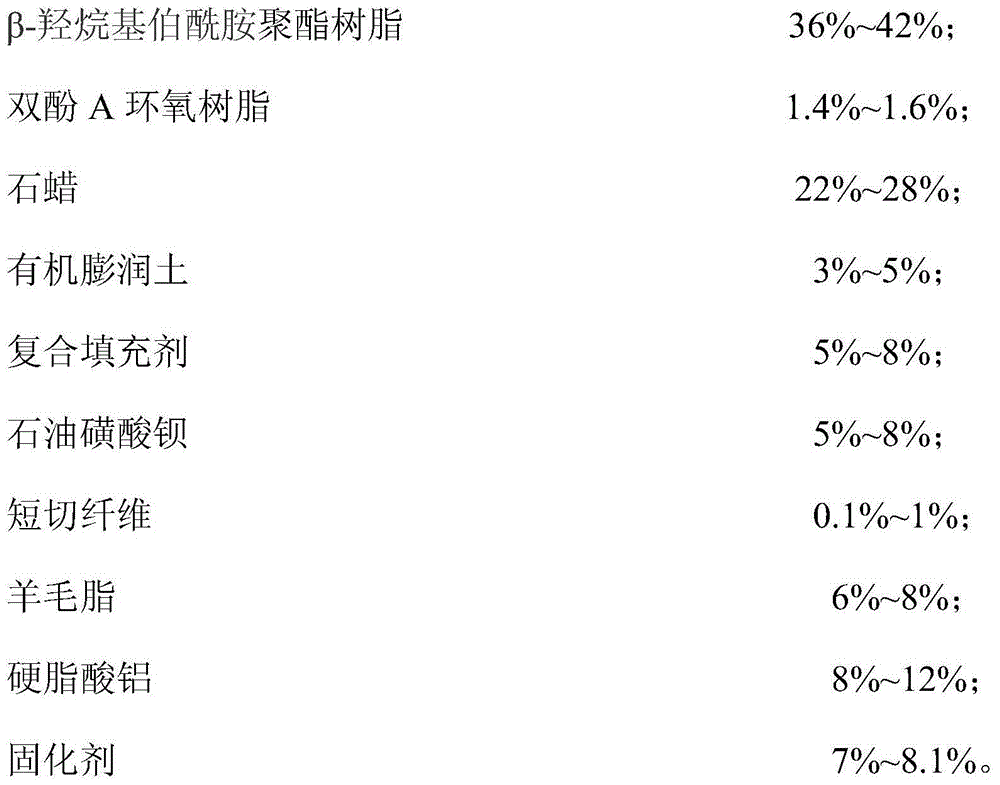

[0026] A non-stick petrolatum anti-corrosion paste for low temperature, the non-stick petrolatum anti-corrosion paste for low temperature contains 40% of β-hydroxyalkyl primary amide polyester resin and 1.5% of bisphenol A epoxy resin , 23% paraffin, 3% organic bentonite, 6% composite filler, 5% barium petroleum sulfonate, 0.5% chopped fiber, 6% lanolin, 8% aluminum stearate and curing agent N, N, N', N'-Tetrakis(2-hydroxyethyl)adipamide (β-HAA) 7%.

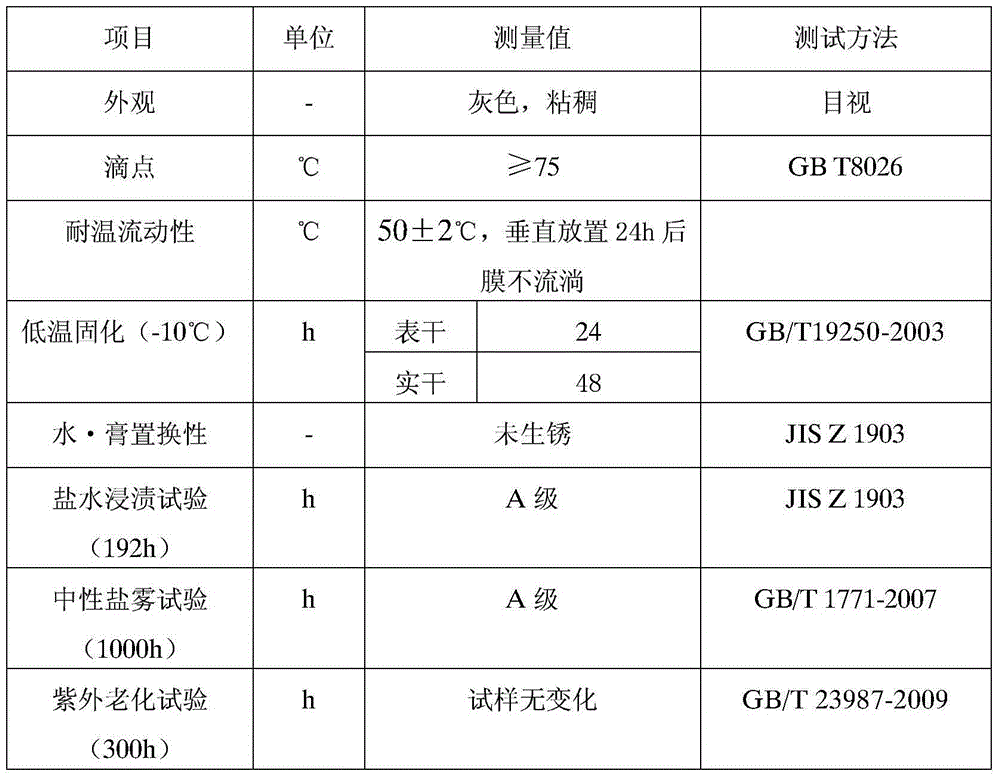

[0027] Determination of the general properties of the material obtained in the examples, see Table 1.

[0028] Table 1 Performance test results of non-stick petrolatum anti-corrosion paste for low temperature

[0029]

[0030] Temperature-resistant fluidity test method:

[0031] This experiment is used to test whether the petrolatum anti-corrosion paste will flow under the test temperature conditions, so as to determine the maximum applicable temperature of this type of petrolatum anti-corrosion paste. Place the test piece ...

Embodiment 2

[0037] A non-stick petrolatum anti-corrosion paste for low temperature, the non-stick petrolatum anti-corrosion paste for low temperature contains 38% of β-hydroxyalkyl primary amide polyester resin and 1.5% of bisphenol A epoxy resin , 24% paraffin, 3% organic bentonite, 6% composite filler, 5% barium petroleum sulfonate, 0.2% chopped fiber, 7% lanolin, 8% aluminum stearate and curing agent N, N, N', N'-Tetrakis(2-hydroxyethyl)adipamide (β-HAA) 7.3%.

[0038] Test according to the standards in Table 1. Visual inspection is gray and viscous; the dropping point is greater than 75°C; at 50±2°C, the film does not flow after being placed vertically for 24 hours, and has good temperature-resistant fluidity; it can be cured normally at -10°C, and the low-temperature curing effect is good; water-paste replacement The test does not rust; the results of the salt water immersion test, neutral salt spray test (1000h), and ultraviolet aging test (300h) are good, the sample does not chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com