Specific anticorrosion paint for chemical equipment and production method thereof

A technology for anti-corrosion coatings and chemical equipment, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of unfavorable sustainable development of the chemical industry, inability to protect chemical equipment, poor ultraviolet erosion resistance, etc., to achieve good wear resistance, Good corrosion protection performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

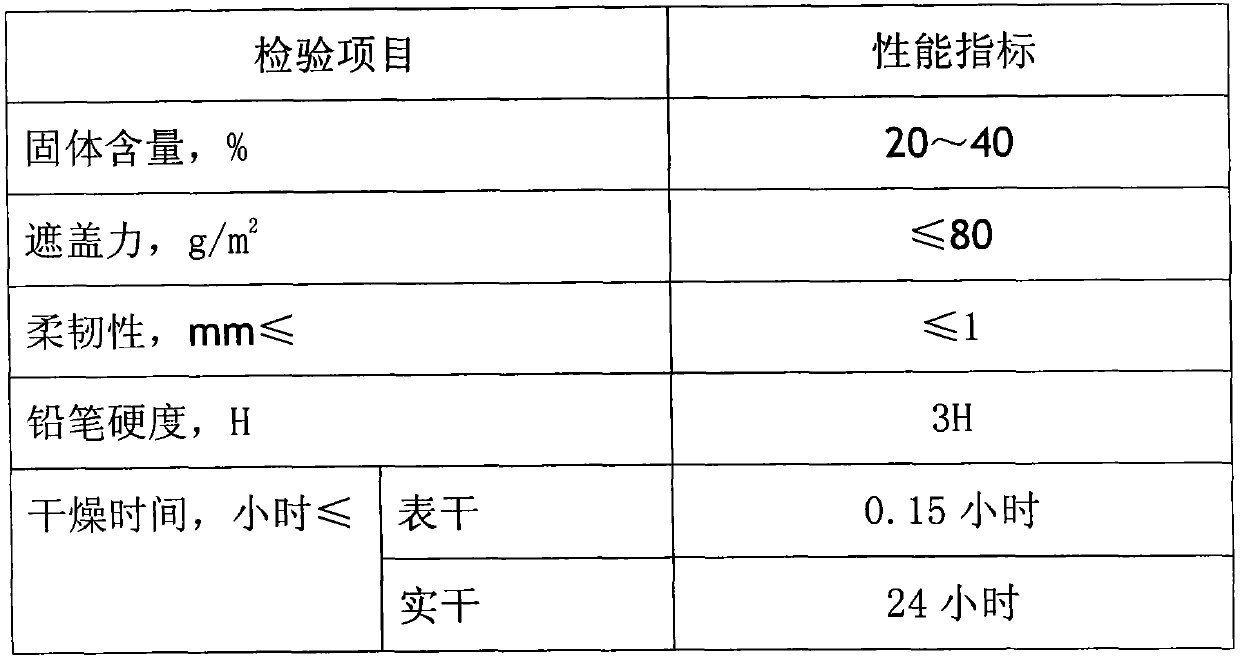

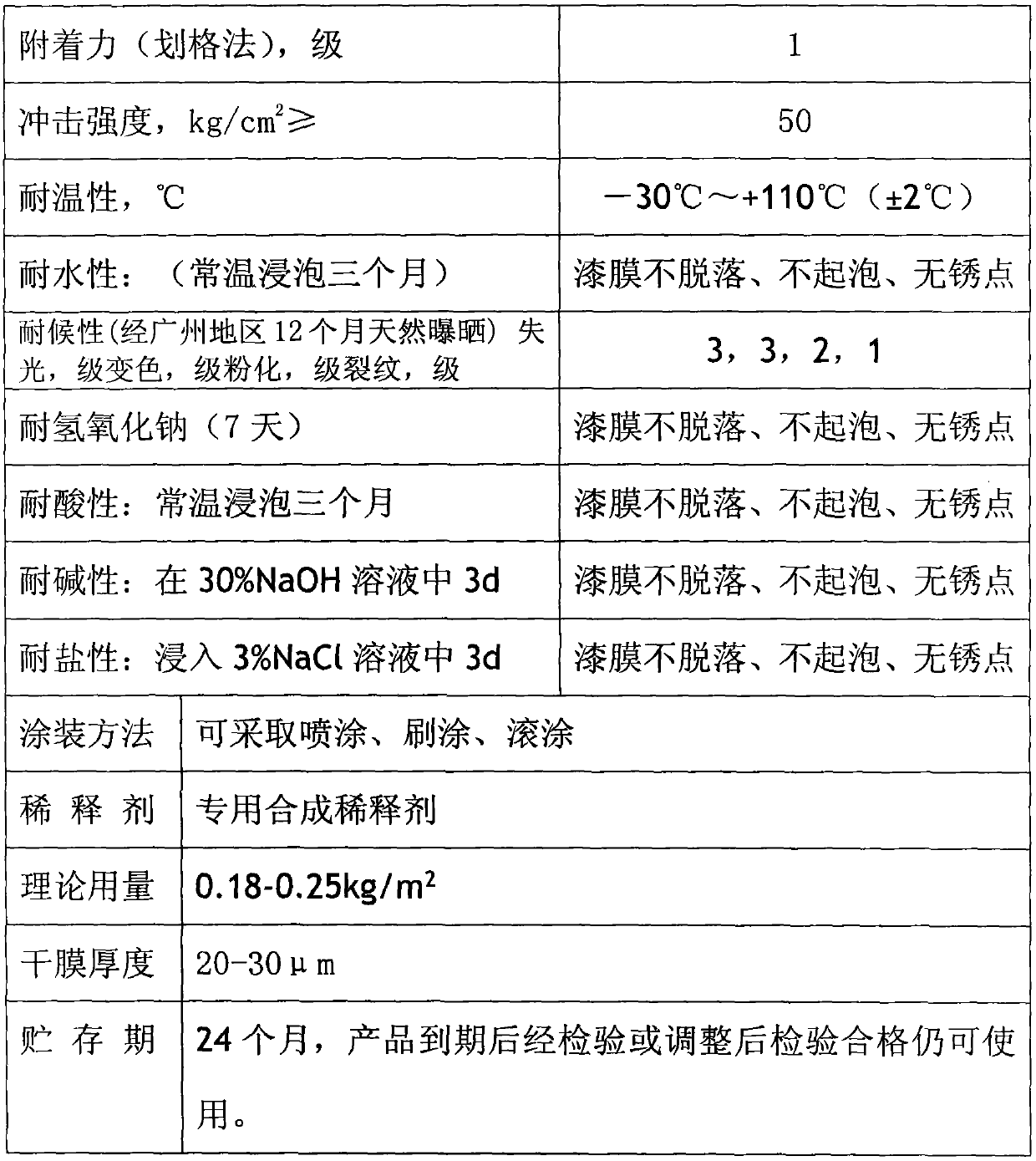

[0009] The present invention is a kind of special anticorrosion coating for chemical equipment. The components of the anticorrosion coating are: 8% of chlorosulfonated polyethylene, 8% of acrylic acid copolymer resin, 0.25% of tricresyl phosphate, 2% of melamine formaldehyde resin, Rutile titanium dioxide is 7%, n-butanol is 22%, ethyl acetate is 30%, butyl acetate is 11%, xylene is 11.5%, and dibutyl phthalate is 0.25%.

[0010] The acrylic acid copolymer resin is a mixture of butyl methacrylate and methacrylamide copolymer resin, and its components are: 75% of butyl methacrylate and 25% of methacrylamide copolymer resin.

[0011] The production method of implementing the product of the present invention is: 8% chlorosulfonated polyethylene, 8% acrylic acid copolymer resin, 0.25% tricresyl phosphate, 2% melamine formaldehyde resin and 7% titanium dioxide are added in the high-speed disperser Perform mixing treatment, then add 15% n-butanol to dilute, and stir for 30 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com