Method for connecting at least two sheet metal parts

A technology for plate parts and connecting parts, applied in welding equipment, vehicle parts, welding/welding/cutting items, etc., can solve the problems of costly manufacturing and achieve the effect of simple geometric structure of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

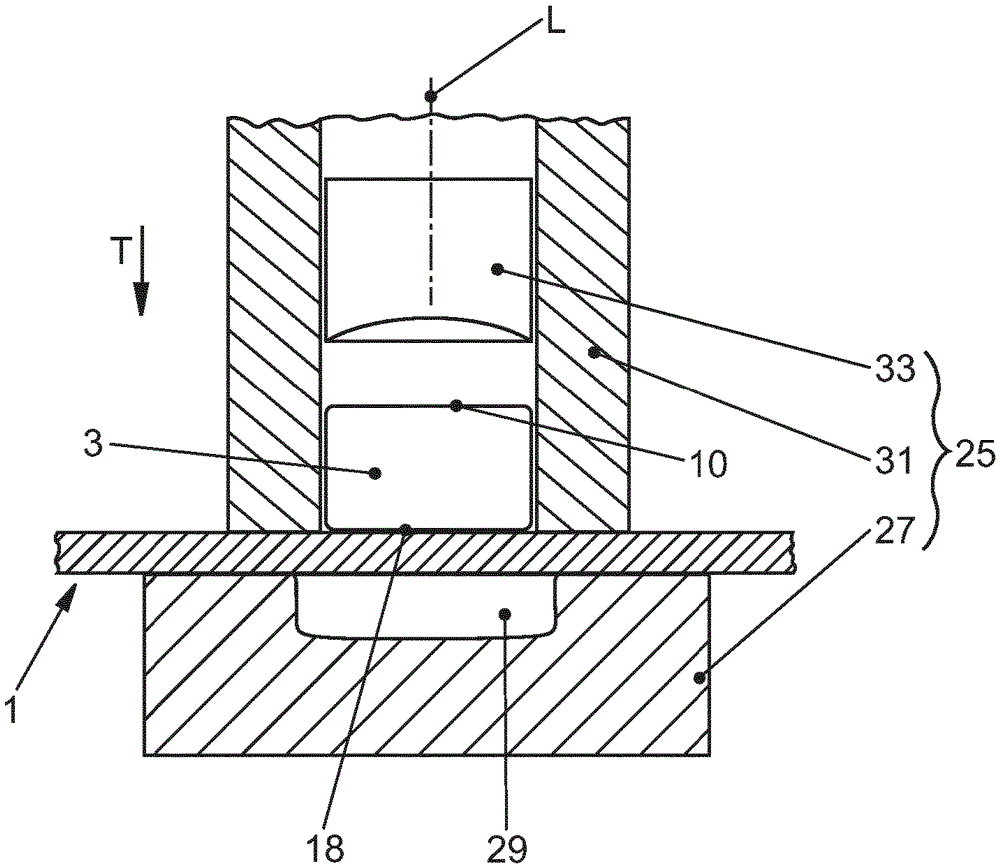

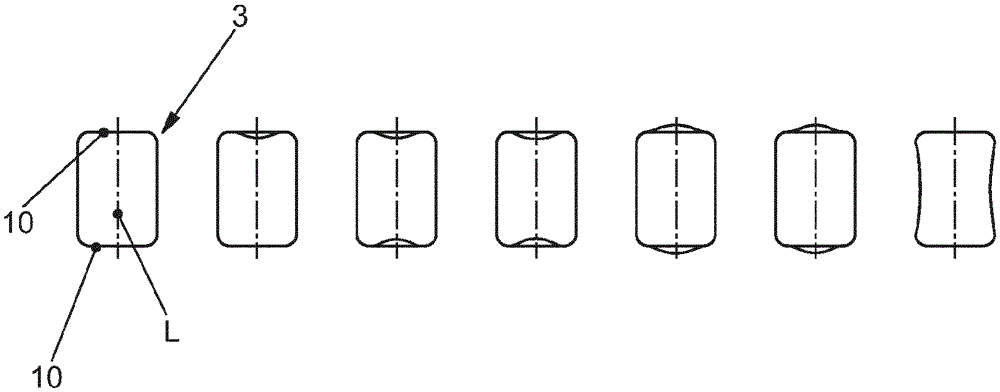

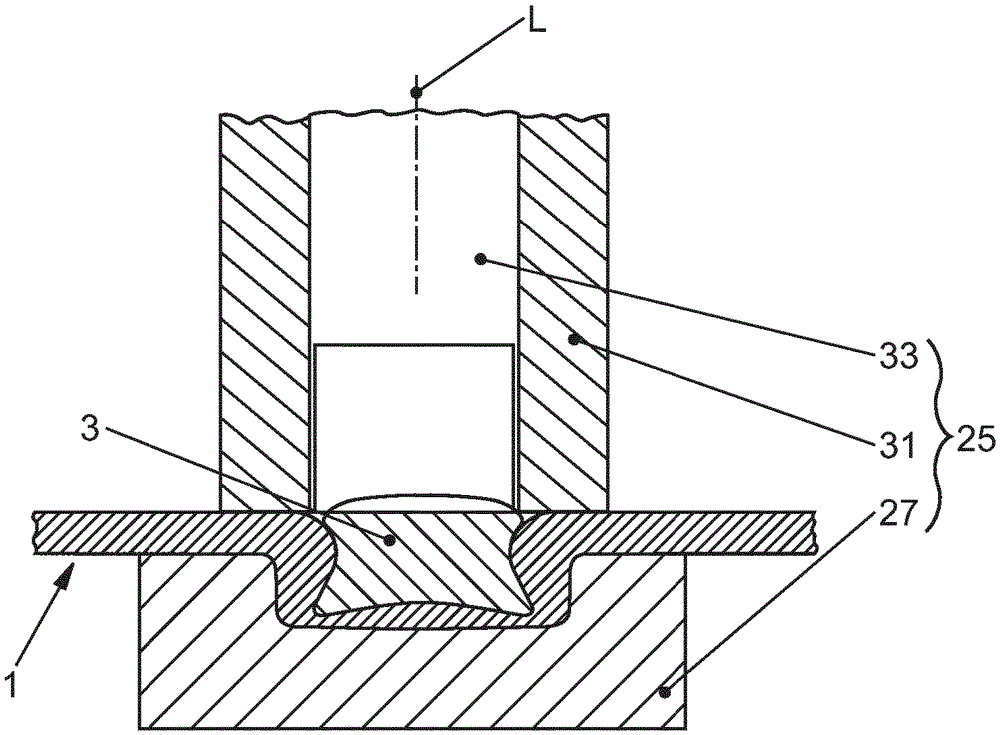

[0030] exist figure 1 The panel connection formed by the aluminum panel part 1 and the steel panel part 5 is shown in . In this panel connection, the aluminum panel part 1 is connected to the panel part 5 by means of a steel punch-in element 3 . The production of the aluminum-steel connection shown is carried out in two stages, that is to say first with a deep drawing process in which the steel punching element 3 is extruded into the aluminum sheet part 1 and with a subsequent Resistance spot welding, in which the sheet steel part 5 is welded to the end 7 of the plunger element 3 protruding from the aluminum sheet part 1 .

[0031] as from figure 1 As follows, the aluminum sheet part 1 has a deep-drawn punched recess 9 which protrudes downwards from the base plane of the aluminum sheet part 1 approximately in the shape of a pot. The plunger element 3 is pressed into the punched recess 9 in a form-fitting manner. The punched recess 9 is closed downwards, ie the aluminum mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com