Method of making enhanced surface coating for light metal workpiece

A light metal and coating technology, applied in surface reaction electrolytic coating, metal material coating process, device for coating liquid on the surface, etc., can solve problems such as low chipping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

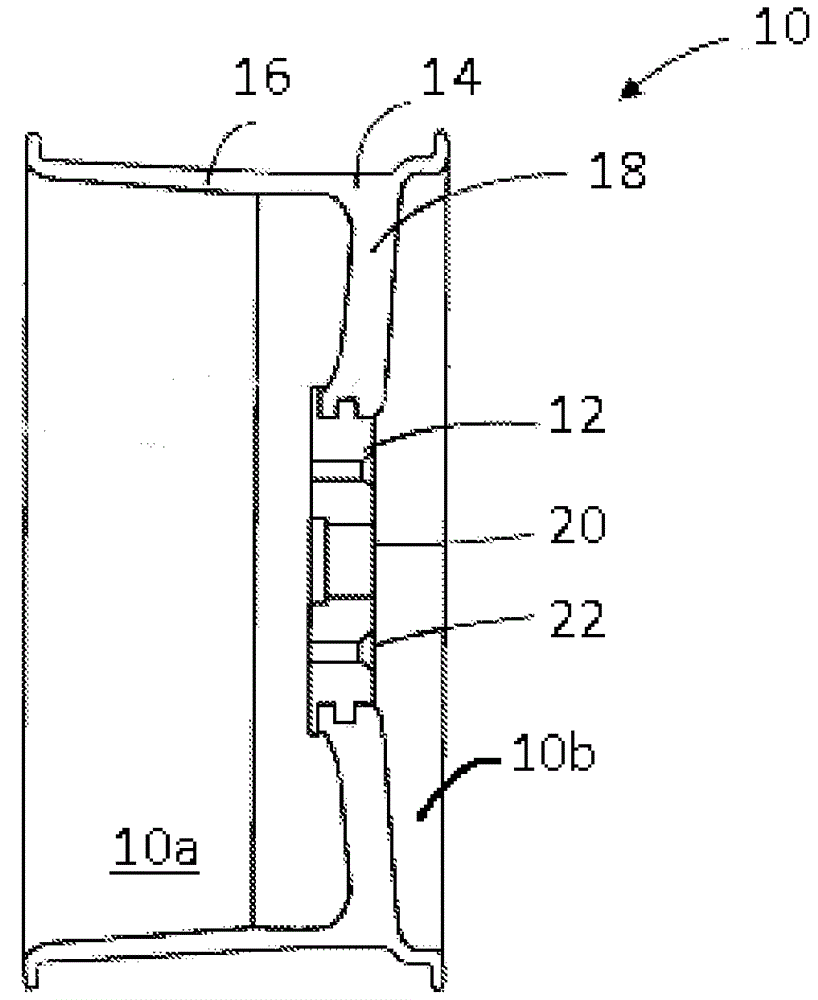

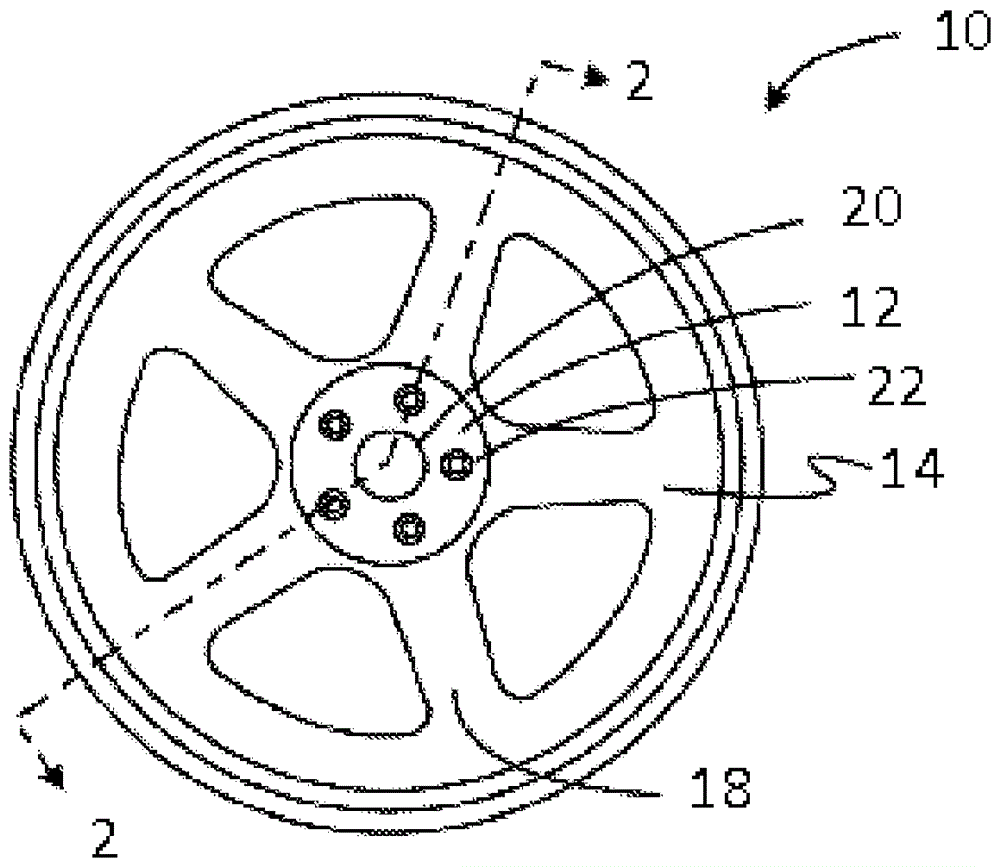

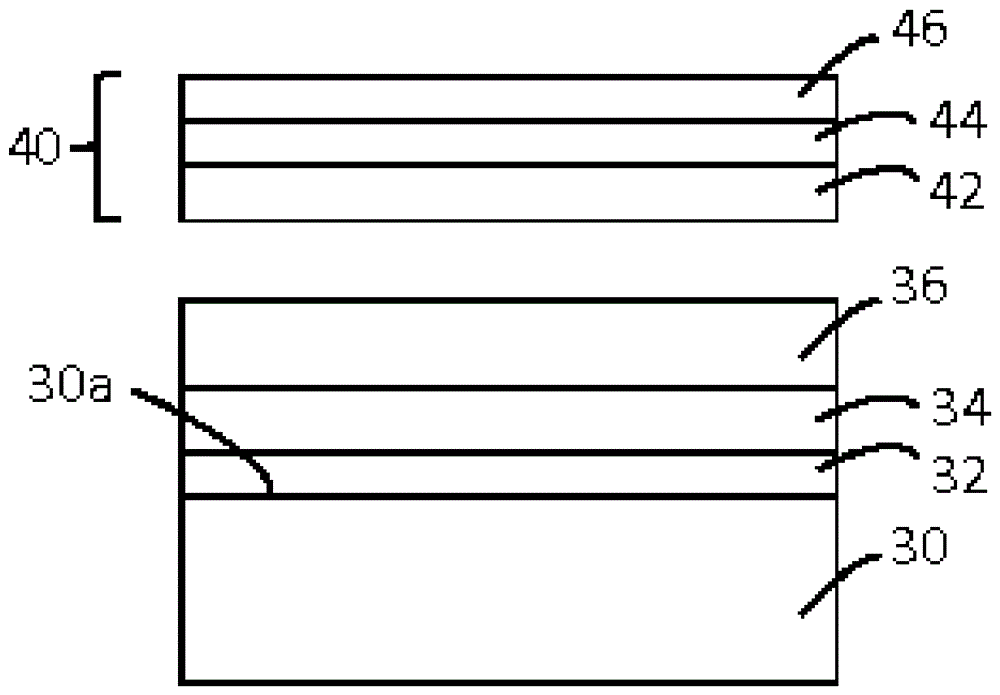

Method used

Image

Examples

Embodiment Construction

[0015] The following description is merely exemplary in nature and is not intended to limit the present disclosure, its application or use. The phrase “at least one of A, B, and C” used herein should be understood as using a non-exclusive logical “or” to represent logic (A or B or C). It should be understood that the steps in the method can be executed in a different order without changing the principle of the present disclosure. The range disclosure includes the disclosure of all ranges and sub-ranges in the entire range.

[0016] The headings (such as "Background" and "Summary of the Invention") and subheadings used herein are intended to be used only for the general organization of the subject matter in the present disclosure, and are not intended to limit the disclosure of the present invention or any aspect thereof. The description of multiple embodiments with stated features is not intended to exclude other embodiments with additional features, or other embodiments includi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com