Graphene oxide quantum dot as well as preparation method and application thereof as corrosion inhibitor

A technology of graphene quantum dots and graphite rods, which is applied in the field of graphene oxide quantum dots and its preparation, can solve the problems of corrosion inhibitor toxicity, environmental pollution, water eutrophication, etc., to hinder corrosion factors and reduce metal corrosion rate , the effect of good solution dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

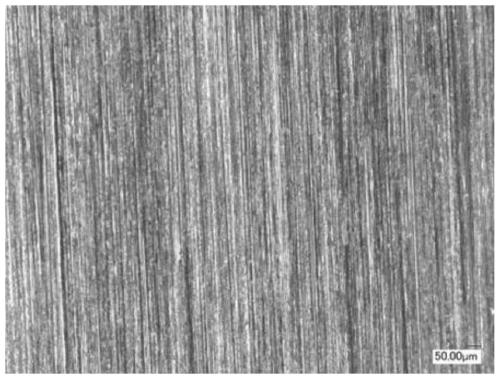

[0026] With a particle size of 43μm and a density of 1.7g / cm 3 The graphite rod is used as the working electrode and the auxiliary electrode, the electrolyte is 0.4mol / L ammonium citrate aqueous solution, at 40°C, the electrolysis voltage is 4V, and the electrolysis time is 8h. At the end of the reaction, the electrolyte was brown. After filtering through a 0.22 μm filter membrane, it was purified by dialysis and deionized water for 72 hours. The graphene oxide quantum dots prepared in Example 1 were obtained after rotary evaporation, concentration and drying.

Embodiment 2

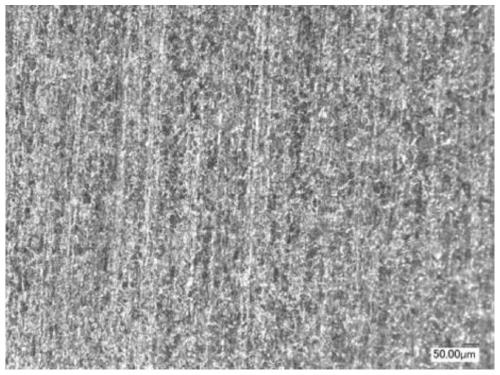

[0028] With a particle size of 800μm and a density of 1.72g / cm 3 The graphite rod is used as the working electrode and the auxiliary electrode, the electrolyte is 0.3mol / L ammonium tartrate aqueous solution, at 20°C, the electrolysis voltage is 9V, and the electrolysis time is 12h. At the end of the reaction, the electrolyte was dark brown. After filtering through a 0.22 μm filter membrane, it was purified by dialysis and deionized water for 72 hours, and the graphene oxide quantum dots prepared in Example 2 were obtained after rotary evaporation, concentration and drying.

Embodiment 3

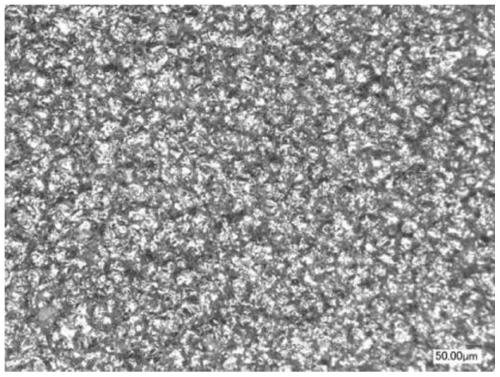

[0030] With a particle size of 43μm and a density of 1.7g / cm 3 The graphite rod is used as the working electrode and the auxiliary electrode, the electrolyte is 0.2mol / L ammonium hydroxypropionate aqueous solution, at 10°C, the electrolysis voltage is 12V, and the electrolysis time is 24h. At the end of the reaction, the electrolyte solution was brown. After filtering through a 0.22 μm filter membrane, it was purified by dialysis and deionized water for 72 hours, and the graphene oxide quantum dots prepared in Example 3 were obtained after rotary evaporation, concentration and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com