Copper etching solution with long etching life

A copper etching and etching technology, applied in the field of electronic chemicals, can solve the problems of unstable hydrogen peroxide, easy decomposition, and increase the cost of the etching process, and achieve the effect of stabilizing the etching rate, prolonging the service life, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

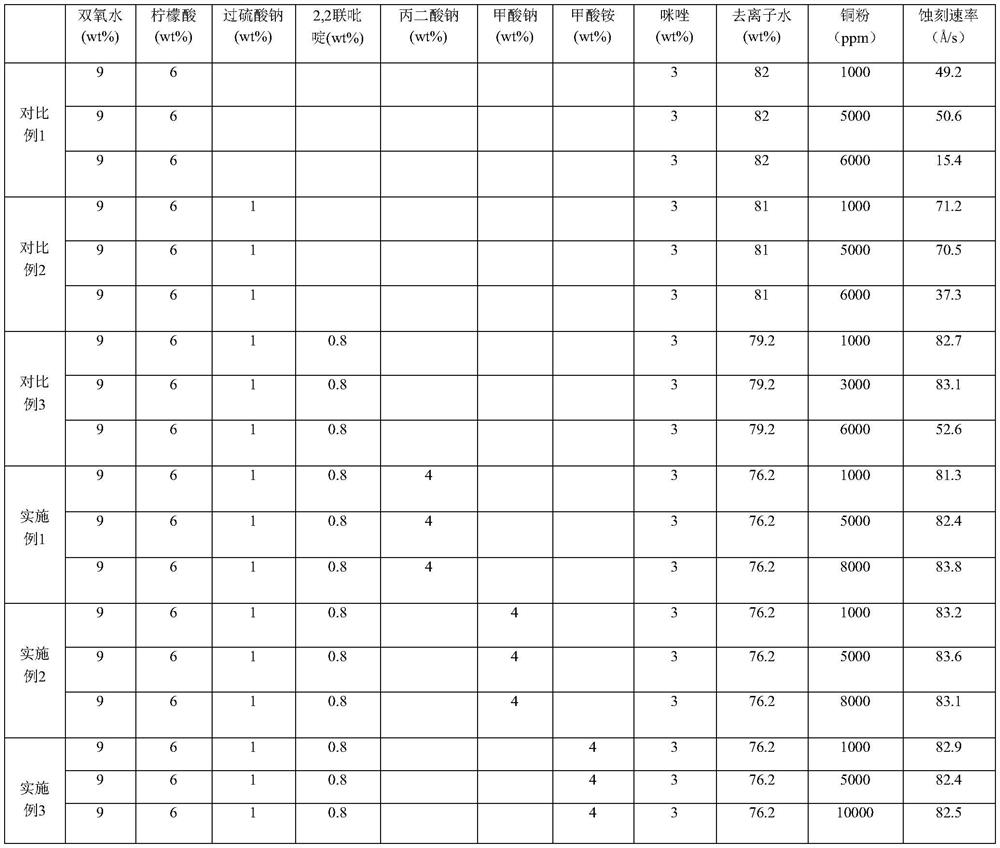

Embodiment 1

[0028] Embodiment 1 provides the copper etchant of high etching rate and high stability, specifically:

[0029] The copper etching solution is composed of hydrogen peroxide, citric acid, sodium persulfate, 2,2-bipyridine, sodium malonate, imidazole and deionized water.

[0030] Wherein, the massfraction of hydrogen peroxide is 9%; The massfraction of citric acid is 6%; The massfraction of sodium persulfate is 1%; The massfraction of 2,2-bipyridine is 0.8%; The massfraction of sodium malonate is 4%; the mass fraction of imidazole is 3%, and the balance is deionized water.

[0031] Heat the above-prepared copper etching solution to 35°C, conduct an etching experiment on metallic copper on a glass substrate, record the time required for a certain thickness of copper to be etched away, and calculate the etching rate. At the same time, gradually add copper powder to the etching solution to simulate the etching process, and then test the etching rate of the etching solution on the ...

Embodiment 2

[0033] Embodiment 2 provides the copper etchant of high etching rate and high stability, specifically:

[0034] The copper etching solution is composed of hydrogen peroxide, citric acid, sodium persulfate, 2,2-bipyridyl, sodium formate, imidazole and deionized water.

[0035] Wherein, the mass fraction of hydrogen peroxide is 9%; the mass fraction of citric acid is 6%; the mass fraction of sodium persulfate is 1%; the mass fraction of 2,2-bipyridine is 0.8%; the mass fraction of sodium formate is 4%; The mass fraction of imidazole is 3%, and the balance is deionized water.

[0036] Heat the above-prepared copper etching solution to 35°C, conduct an etching experiment on metallic copper on a glass substrate, record the time required for a certain thickness of copper to be etched away, and calculate the etching rate. At the same time, gradually add copper powder to the etching solution to simulate the etching process, and then test the etching rate of the etching solution on th...

Embodiment 3

[0038] Embodiment 3 provides the copper etchant of high etching rate and high stability, specifically:

[0039] The copper etching solution is composed of hydrogen peroxide, citric acid, sodium persulfate, 2,2-bipyridyl, ammonium formate, imidazole and deionized water.

[0040] Wherein, the mass fraction of hydrogen peroxide is 9%; the mass fraction of citric acid is 6%; the mass fraction of sodium persulfate is 1%; the mass fraction of 2,2-bipyridine is 0.8%; the mass fraction of ammonium formate is 4% ; The mass fraction of imidazole is 3%, and the balance is deionized water.

[0041] Heat the above-prepared copper etching solution to 35°C, conduct an etching experiment on metallic copper on a glass substrate, record the time required for a certain thickness of copper to be etched away, and calculate the etching rate. At the same time, gradually add copper powder to the etching solution to simulate the etching process, and then test the etching rate of the etching solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com