Patents

Literature

65results about How to "Stable etch rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flat glass substrate attenuation etching liquid

The invention relates to a reduction etching liquid for base plates of sheet glass, components percentage by weight of which comprise: hydrofluoric acid holding 5-25%, strong acid holding 5-30% and pure water holding 45-90%. The reduction etching liquid for base plates of sheet glass of the invention is less in volatilization and toxicity. The using rate of the etching liquid is high and etching speed is rapid and stable. Costs of waste liquor treatment and subsequent treatment are low. The etching effect is excellent. Therefore, the invention has wide prospects for application.

Owner:BOE TECH GRP CO LTD +2

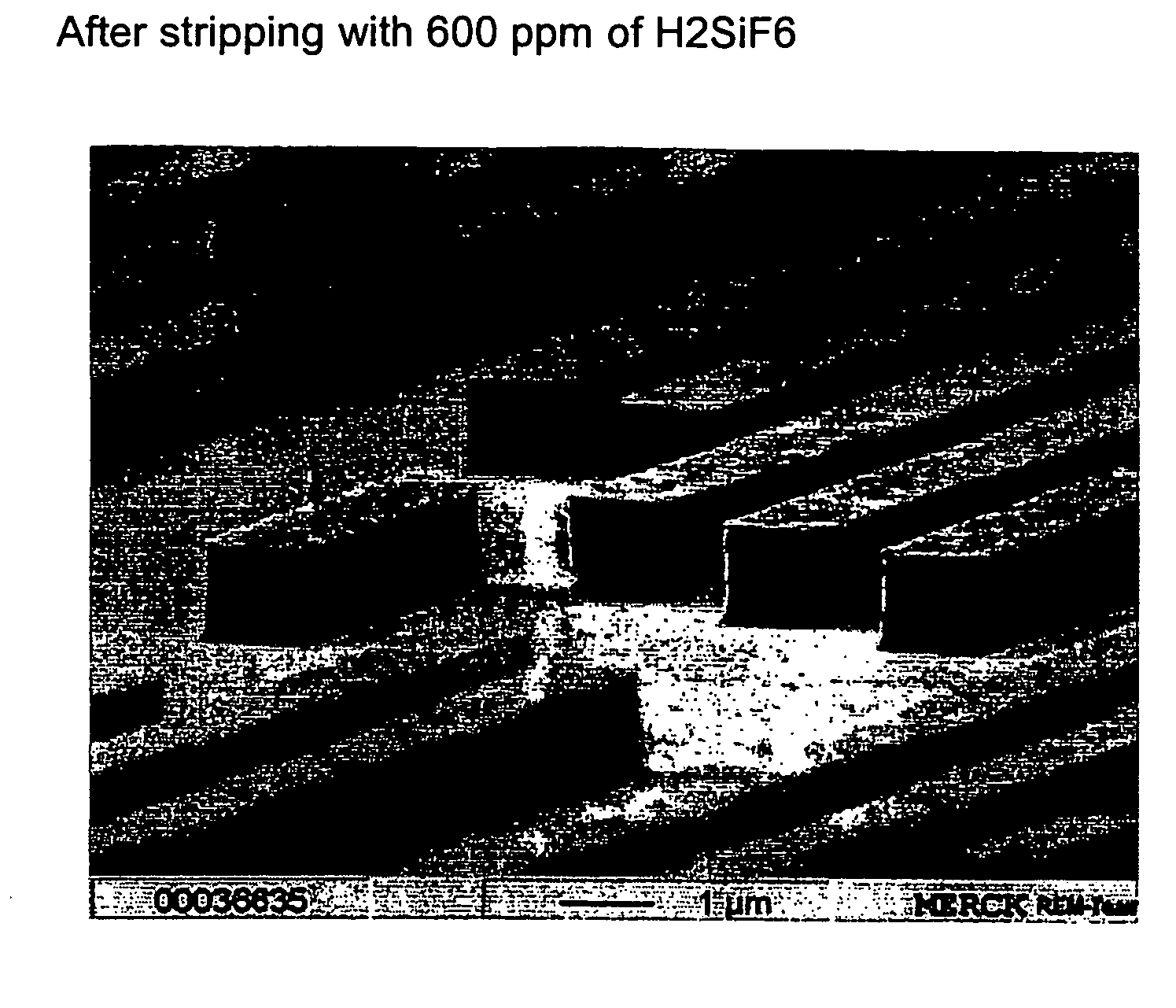

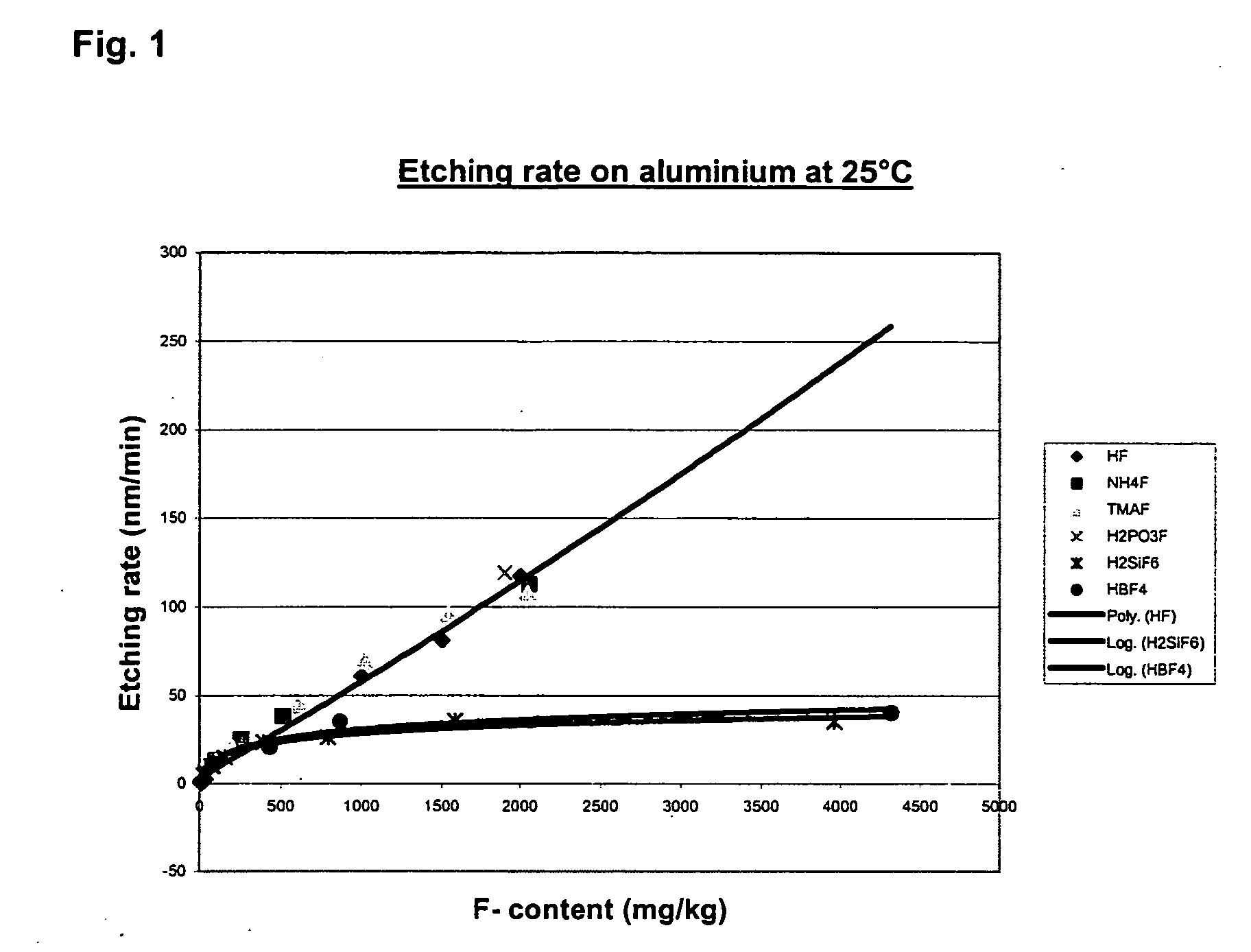

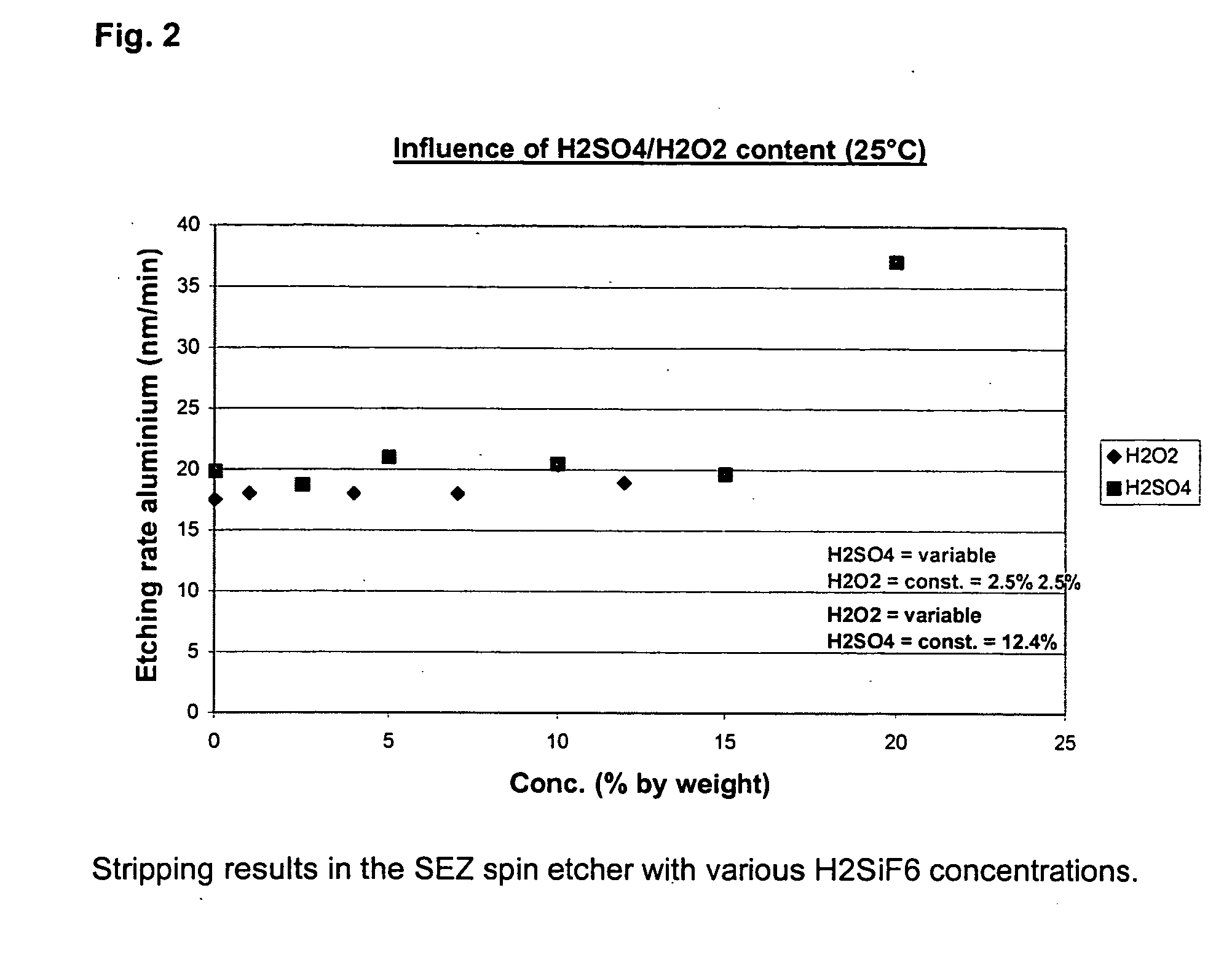

Composition for the removing of sidewall residues

InactiveUS7417016B2Stable etch rateDecorative surface effectsDetergent mixture composition preparationNuclear chemistryMetal

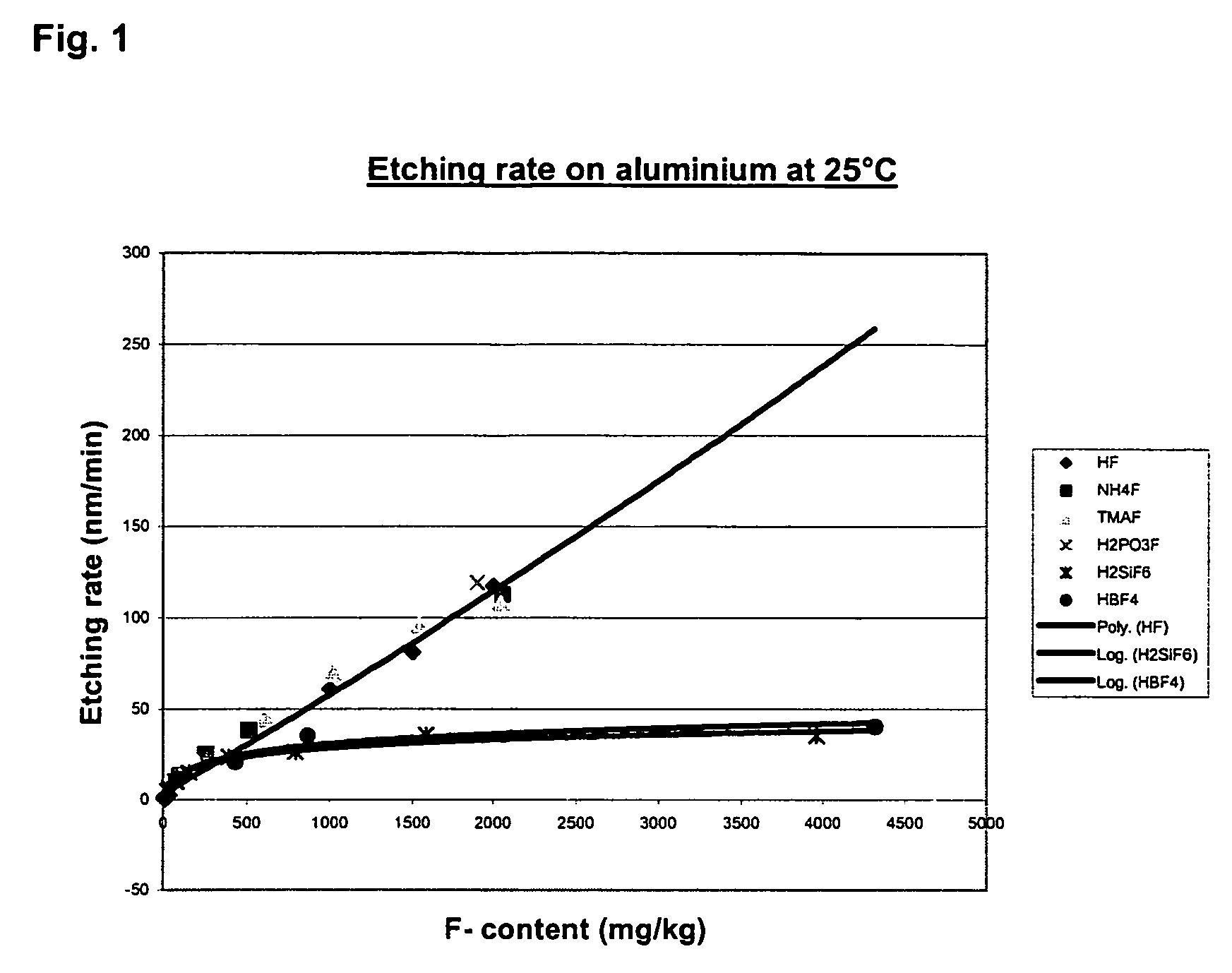

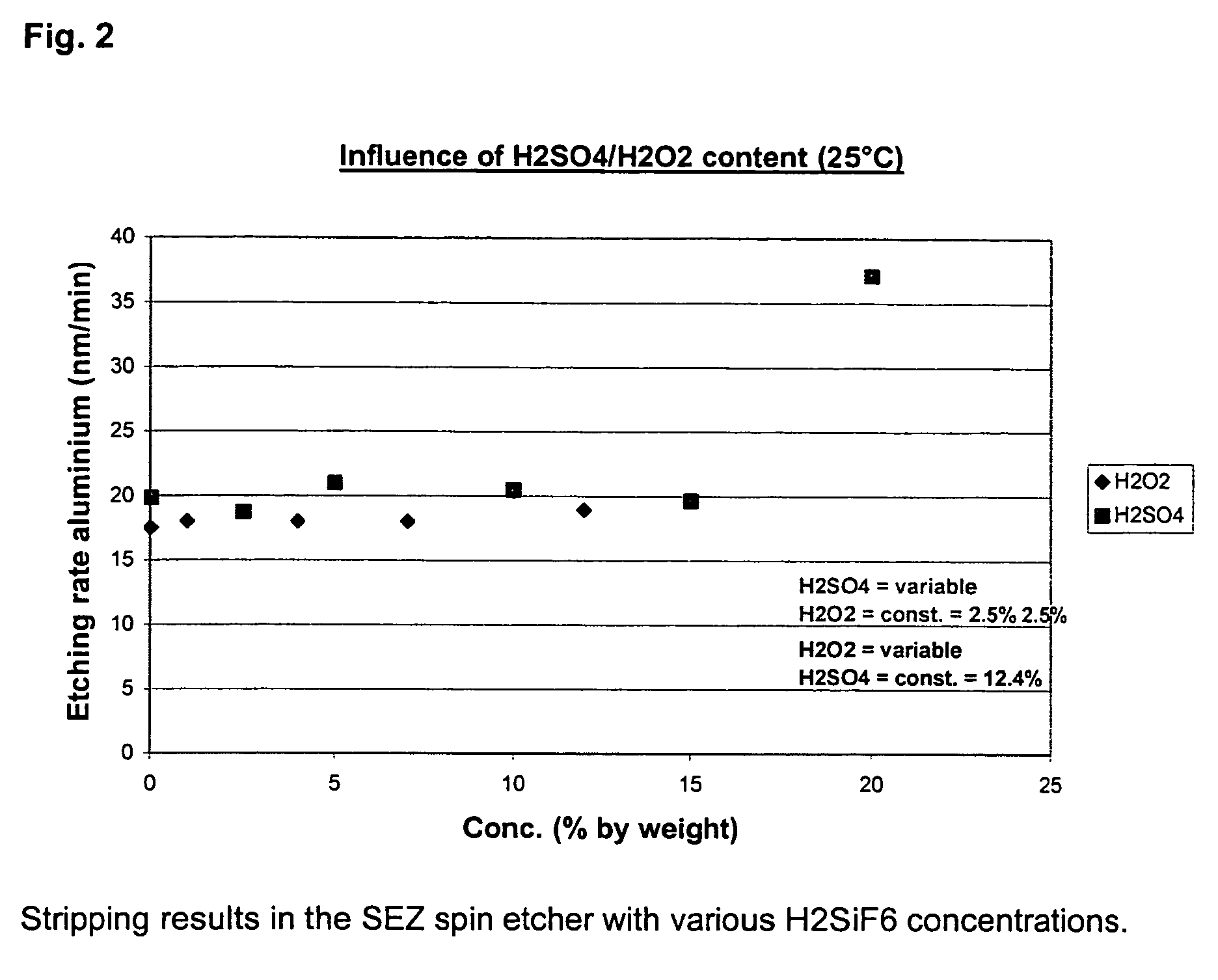

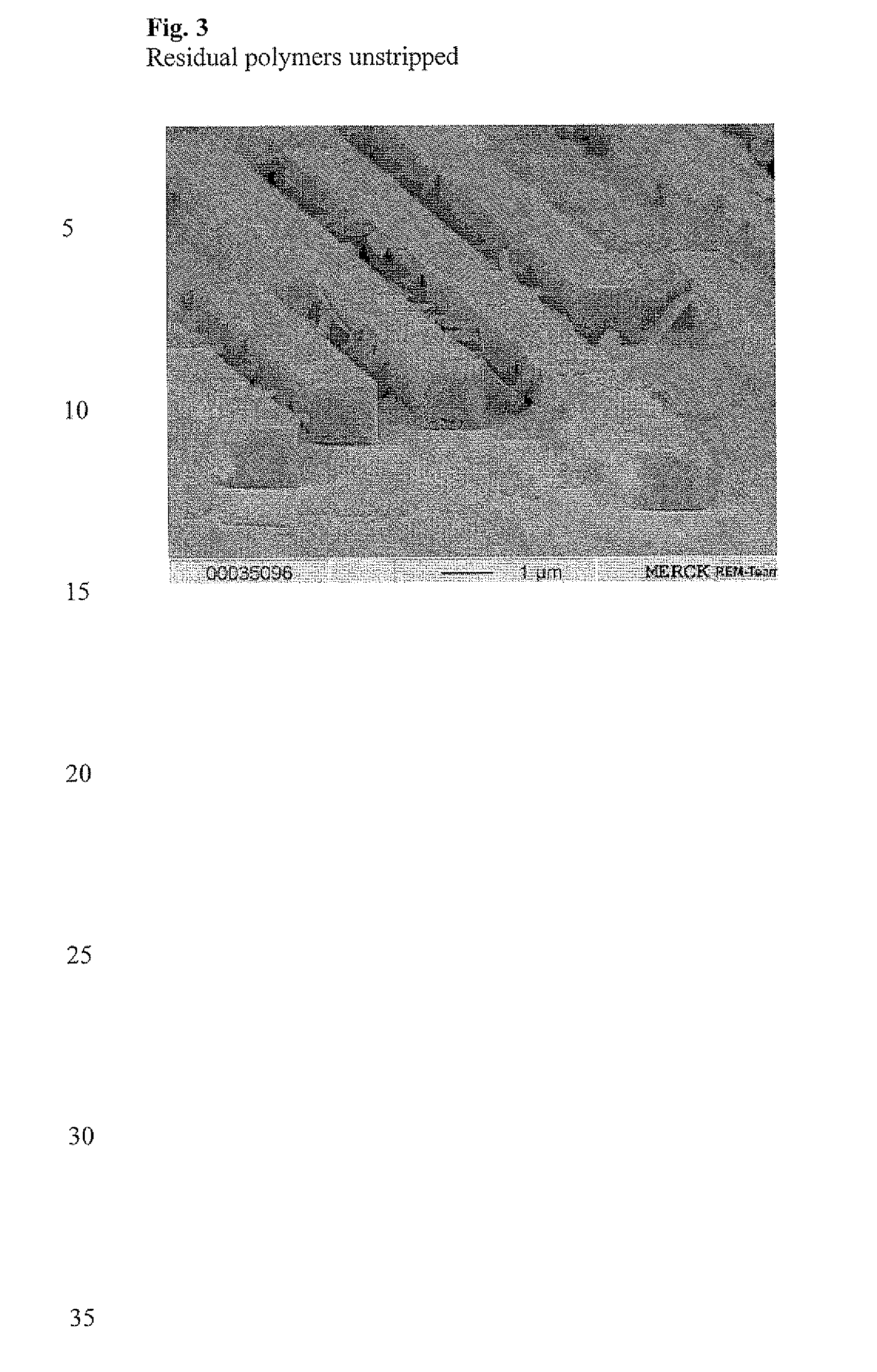

The present invention relates to a composition for the removal of so-called “sidewall residues” from metal surfaces, in particular from aluminium or aluminium-containing surfaces, in particular from aluminium or aluminium-containing surfaces, during the production of semiconductor elements.

Owner:BASF AG

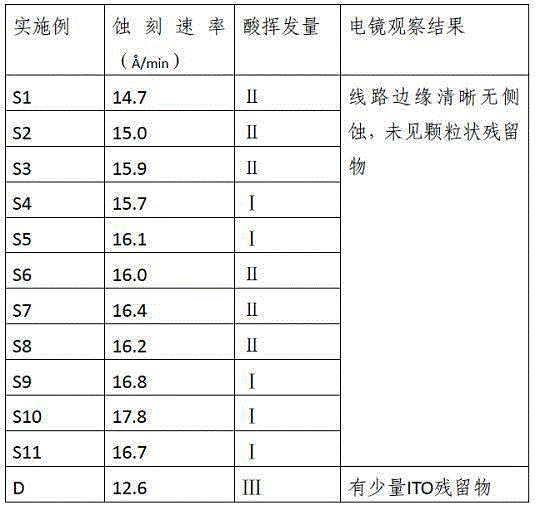

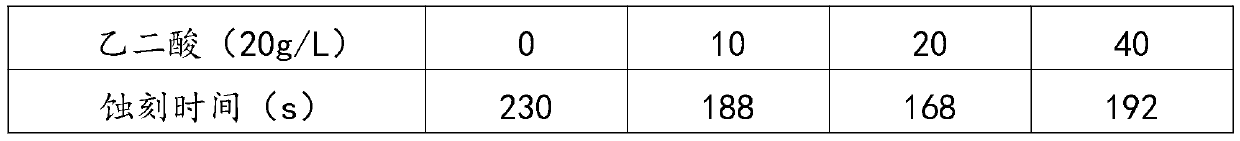

High generation tablet personal computer ITO etching solution

ActiveCN105295923AImprove job stabilitySolve acid mist volatilizationSurface treatment compositionsAcetic acidEtching

The present invention discloses a high generation tablet personal computer ITO etching solution, which comprises, by weight, 4-16% of sulfuric acid, 7-22% of nitric acid, 0.1-10% of acetic acid, 0.01-5% of an additive, and the balance of water, wherein the additive contains an anionic gemini surfactant, and the anionic gemini surfactant is a phosphate type gemini surfactant and / or phosphate salt type gemini surfactant. According to the present invention, according to the ITO etching system using the sulfuric acid / nitric acid / acetic acid three-acid system, the gemini surfactant is added, such that the problems of acid mist volatilization and nitric acid decomposition due to local etching surface temperature increase during the ITO etching process are solved, the work stability of the etching solution is improved, and the etched line has characteristics of clear edge, no lateral etching, and no pinhole and gap generation.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Acidic etching solution, as well as preparation method and application thereof

The invention relates to an acidic etching solution, as well as a preparation method and an application thereof. The acidic etching solution comprises 1-20% by weight of hydrofluoric acid, 20-60% by weight of nitric acid, 1-20% by weight of fluosilicic acid and the balance of water. The preparation method comprises the following steps of: with fluorine hydride gas or hydrofluoric acid, 70-98% by weight of nitric acid water solution and silicon or silicon dioxide as raw materials, mixing according to the mixture ratio to get the acidic etching solution. The acidic etching solution is used for etching silicon wafers, GaAs wafers, GaP wafers or InP wafer. The acidic etching solution disclosed by the invention is different from the traditional etching solution, acetic acid, phosphoric acid and the like, which can cause greater burden on an environment, are not required, peculiar smell can be avoided, and wastes can also be reduced.

Owner:SHANGHAI ZHENGFAN TECH +2

TFT (thin film transistor) glass substrate reducer, preparation method thereof and TFT glass substrate reducing process

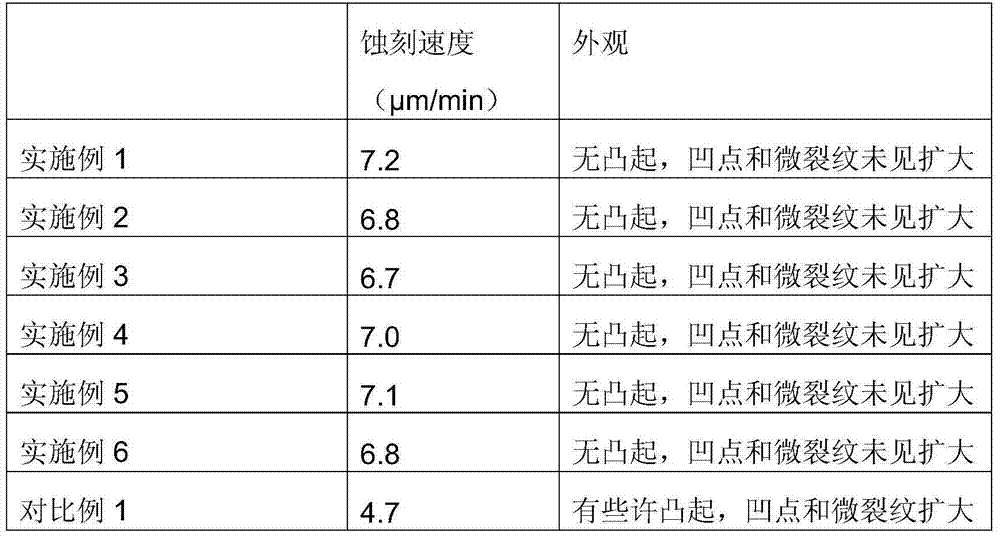

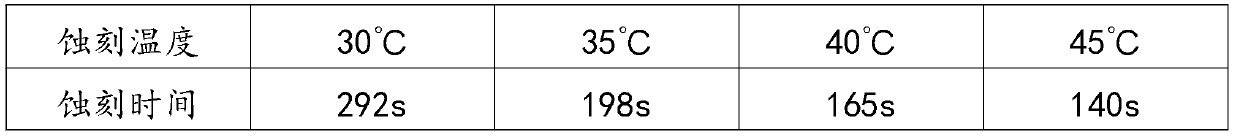

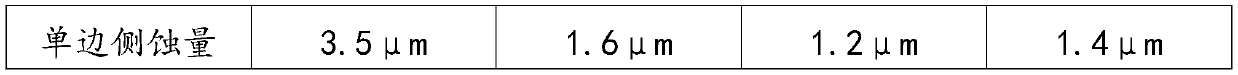

The invention provides a TFT (thin film transistor) glass substrate reducer. The TFT glass substrate reducer comprises 10-12% of hydrofluoric acid, 4-6% of ammonium bifluoride, 5-8% of nitric acid, 5-8% of sulfuric acid and the balance of water. The TFT glass substrate reducer is characterized by mixing all the components of the TFT glass substrate reducer together, thus obtaining a finished product. The TFT glass substrate reducer can stabilize the etching rate, has better borosilicate glass material etching effects, and can effectively control amplification of pits and scratch defects of the glass in a chemical etching process, soften the glass powder to solve the problem of edge raising in the etching process and meet the TFT glass substrate reducing quality requirement safely, stably and effectively, thus meeting the requirements of customers.

Owner:HUIZHOU CITY QINGYANG IND

Copper seed etching solution used for wafer level package

InactiveCN110499509AFacilitated reaction mechanismReduce the impact of side erosionReaction temperatureSurface-active agents

The invention discloses a copper seed etching solution used for wafer level package. The etching solution comprises the following components, 40-60g / L of hydrogen peroxide, 5-35g / L of inorganic acid,5-35g / L of organic acid, 1-30g / L of copper ions, 1-2g / L of chloride ions and 1-2g / L of surface active agents according to the concentration proportion. The components are mixed in proportion, the mixing reaction temperature is between 30 DEG C and 50 DEG C, the reaction time is 1s-400s, and the copper seed etching solution is formed after mixing. Chelating agents formed by mixing the hydrogen peroxide and the inorganic acid and the copper ions can be subjected to chelation to form water-soluble complexes, so that equilibrium is reached; and the chloride ions play a role in maintaining the PH value of a system in the solution, maintains charge balance of the system in the etching process and prolongs the service life of the etching solution. The copper seed etching solution has the characteristics of being stable in performance, suitable for superfine circuits, small in lateral erosion and hardly corrosive to copper and aluminum.

Owner:成功环保科技(南通)有限公司

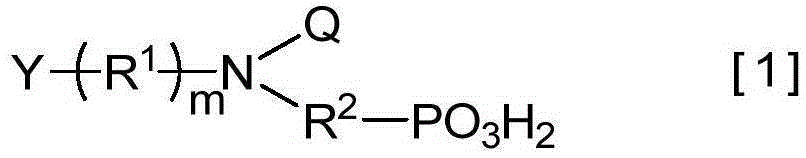

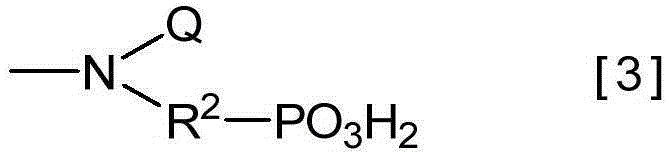

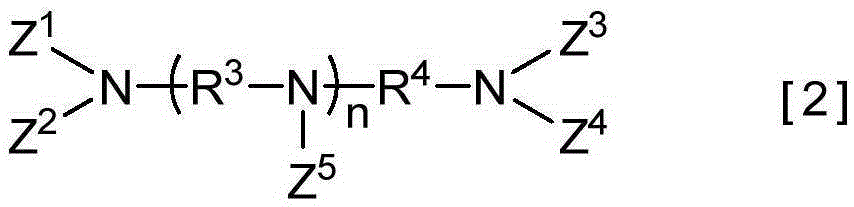

Etching agent, etching method and etching agent preparation liquid

ActiveCN105378901AAvoid decompositionSolution to short lifeSemiconductor/solid-state device manufacturingDecompositionNuclear chemistry

The objective of the present invention is to provide: an etching agent for a titanium-based metal on a semiconductor substrate, which is suppressed in decomposition of hydrogen peroxide, has a long service life, and has less need for control of the hydrogen peroxide concentration in the etching agent even in cases where the etching agent is used for a semiconductor substrate that has a titanium-based metal and copper metal or a copper alloy; an etching method; and an etching agent preparation liquid which is mixed with hydrogen peroxide for use. The present invention relates to: an etching agent for a titanium-based metal on a semiconductor substrate which has the titanium-based metal and copper metal or a copper alloy arranged on top of the titanium-based metal, said etching agent being an aqueous solution that contains at least (A) hydrogen peroxide, (B) a phosphonic acid-based chelating agent having a nitrogen atom in the structure, (C) an alkali metal hydroxide and (D) an organic acid having at least one hydroxyl group and at least three carboxyl groups; an etching method which is characterized by using this etching agent; and an etching agent preparation liquid which is mixed with hydrogen peroxide for use.

Owner:FUJIFILM CORP

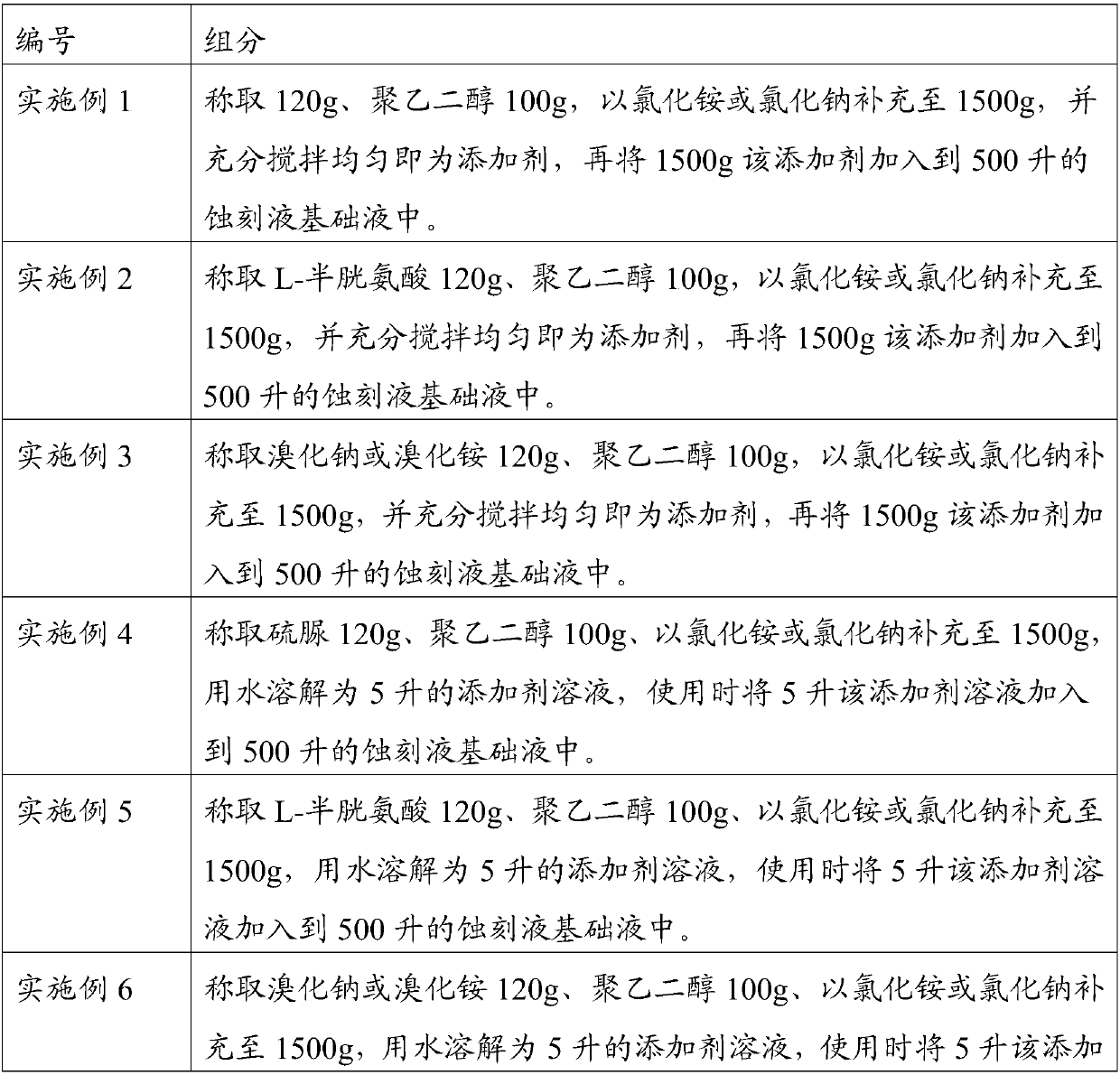

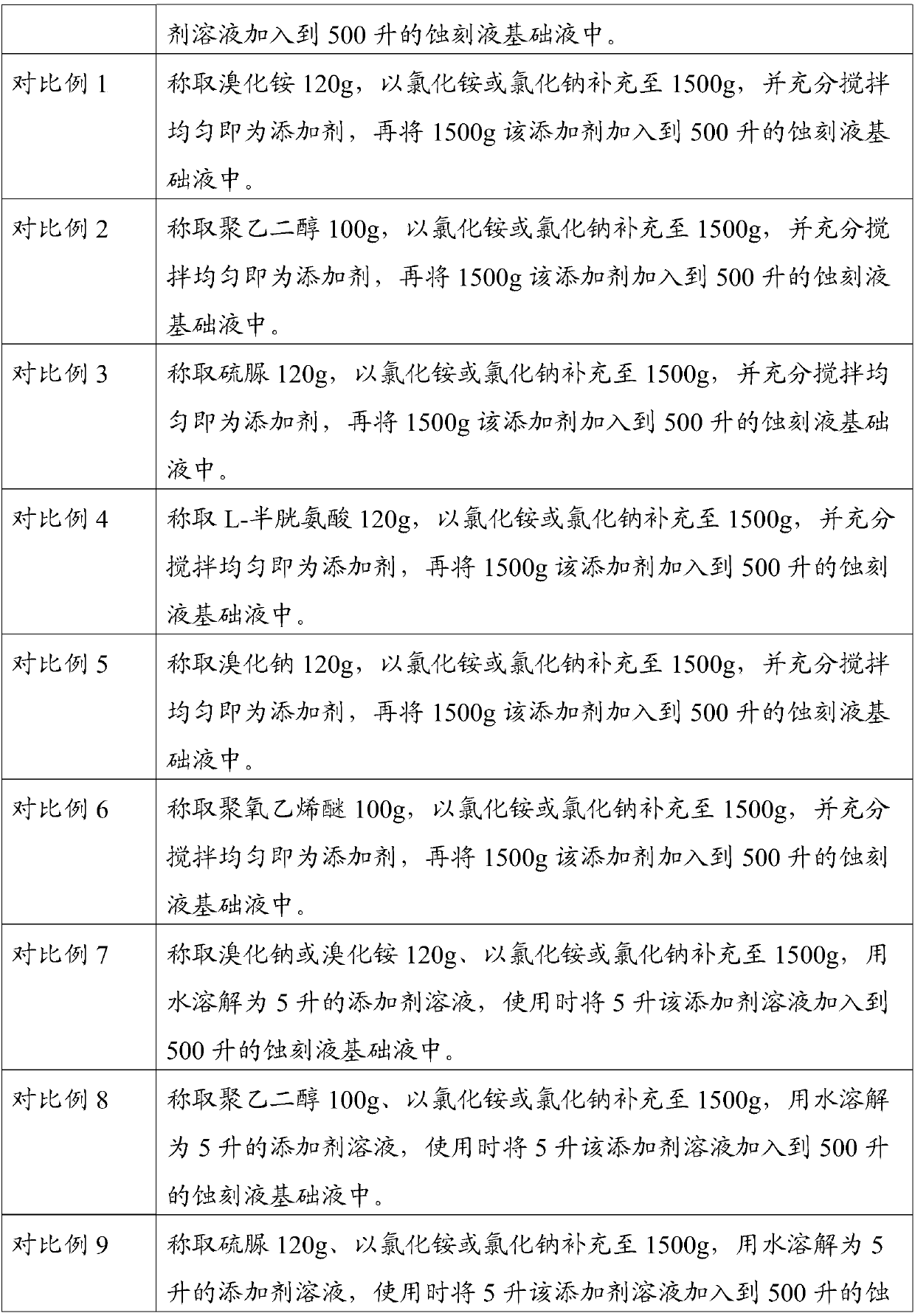

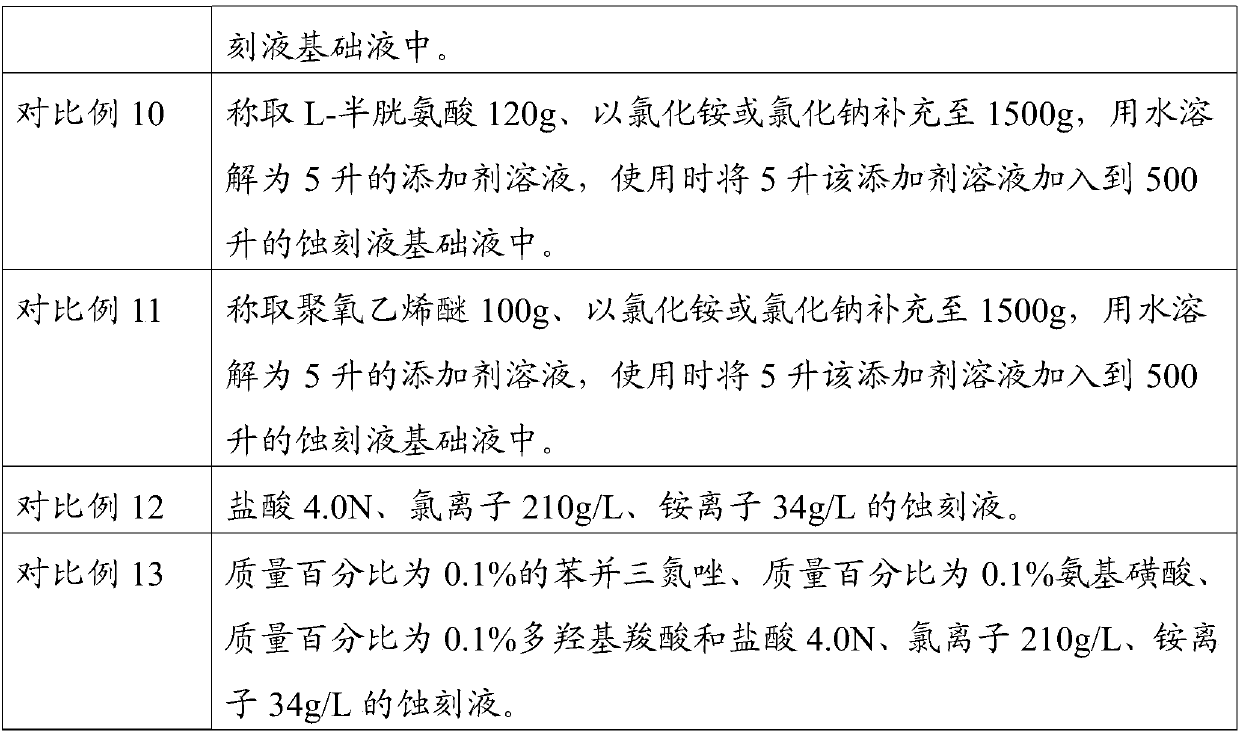

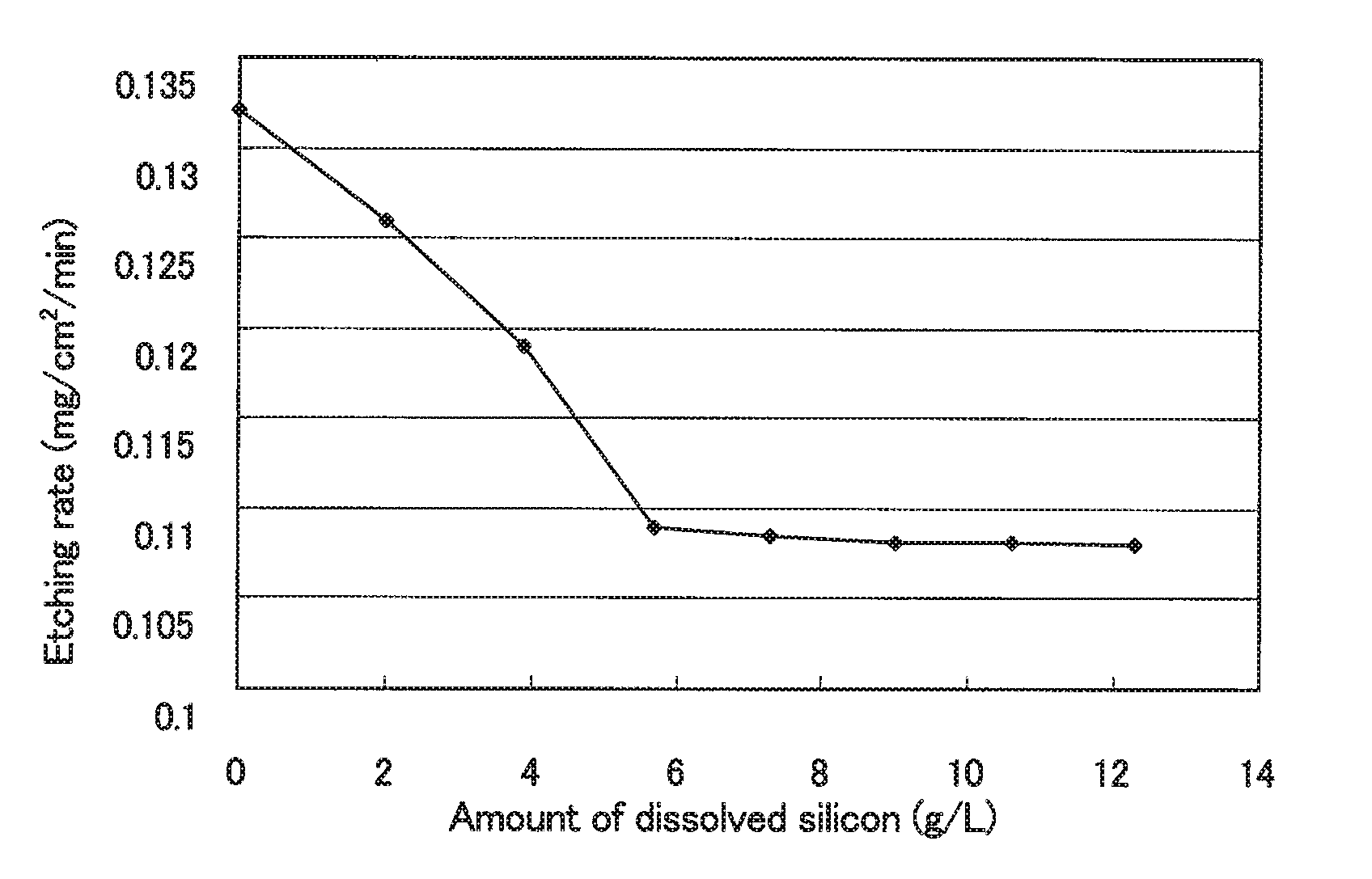

Additive for acidic etching solution and the acidic etching solution

ActiveCN107747094AOvercome the problem that the etching rate first drops and then stabilizesEtching speed is fastEtchingElectrolysis

The invention discloses an additive for acidic etching solution and the acidic etching solution. The additive includes, by mass, 1-200 parts of a nonionic surfactant and 1-200 parts of a stabilizer, wherein the stabilizer is at least one of sulfur-containing urea, mercaptan and bromides. The acidic etching solution comprises an etching basic liquid and the additive. The acidic etching solution canbe used for producing printed circuit boards, which has thick copper layer (copper thickness being 70 [mu]m or higher) or large to-be-etched area (to-be-etched area being more than 50%, especially whole-plate etching), and is free of instable or low speed during the etching. In addition, the additive can be used for directly producing bulk copper plates in a circuit board etching process withoutextra addition of an electrolysis additive.

Owner:侯延辉

Etching solution for silicon wafer

InactiveCN109321253AReduce uniformityGuaranteed uniformitySurface treatment compositionsReaction ratePhosphoric acid

The invention discloses an etching solution for a silicon wafer. The etching solution is mainly prepared from electronic-grade nitric acid, electronic-grade hydrofluoric acid, electronic-grade sulfuric acid, electronic-grade phosphoric acid, electronic-grade acetic acid, a surfactant and ultrapure water, wherein the nitric acid serves as an oxidizing agent and can oxidize silicon into silicon oxide, the hydrofluoric acid serves as a dissolving agent and can dissolve and remove the silicon oxide so as to realize etching of the silicon wafer, the sulfuric acid can improve the viscosity of the solution, stabilize the reaction rate, not change the etching morphology and improve the etching uniformity, the phosphoric acid can also improve the viscosity of the solution, improve the mass transferresistance, decrease the etching rate and not change the etching morphology, the acetic acid serves as a diluent and can reduce the ionization degree of the nitric acid, inhibit the oxidation capacity of the nitric acid, decrease the reaction rate and influence the surface morphology after etching, and the surfactant can reduce the surface tension of the solution and improve the surface morphology of the etched silicon wafer. The etching solution has the advantages of being stable and controllable in etching rate and uniform and flat in etching surface.

Owner:湖北兴福电子材料股份有限公司

Selective etching solution for metal tungsten and copper

The invention discloses an etching solution capable of selectively etching metal copper and metal tungsten. The etching solution comprises an oxidant, an organic acid, a chelating agent, a pH regulator and a copper etching inhibitor. According to the selective etching solution for the metal copper and the tungsten disclosed by the invention, the low etching rate of the metal copper can be guaranteed while the metal tungsten is efficiently etched, and etching of the metal copper is avoided to the maximum extent. In the etching process, the pH regulator such as imidazole stabilizes the pH value of the etching solution, and large fluctuation of the pH value of the etching solution is avoided, so that large fluctuation is caused to the etching rate and the etching stability of metal copper and tungsten; the chelating agent and copper ions generated in the etching solution rapidly form coordination bonds to be chelated, and decomposition of an oxidizing agent hydrogen peroxide and stability of a hard etching solution caused by accumulation of the copper ions in the etching solution are avoided; in the etching process of copper ion etching inhibitors such as aminotetrazole, etching of copper ions is inhibited, and high-selectivity etching of metal tungsten relative to copper is guaranteed.

Owner:湖北兴福电子材料股份有限公司

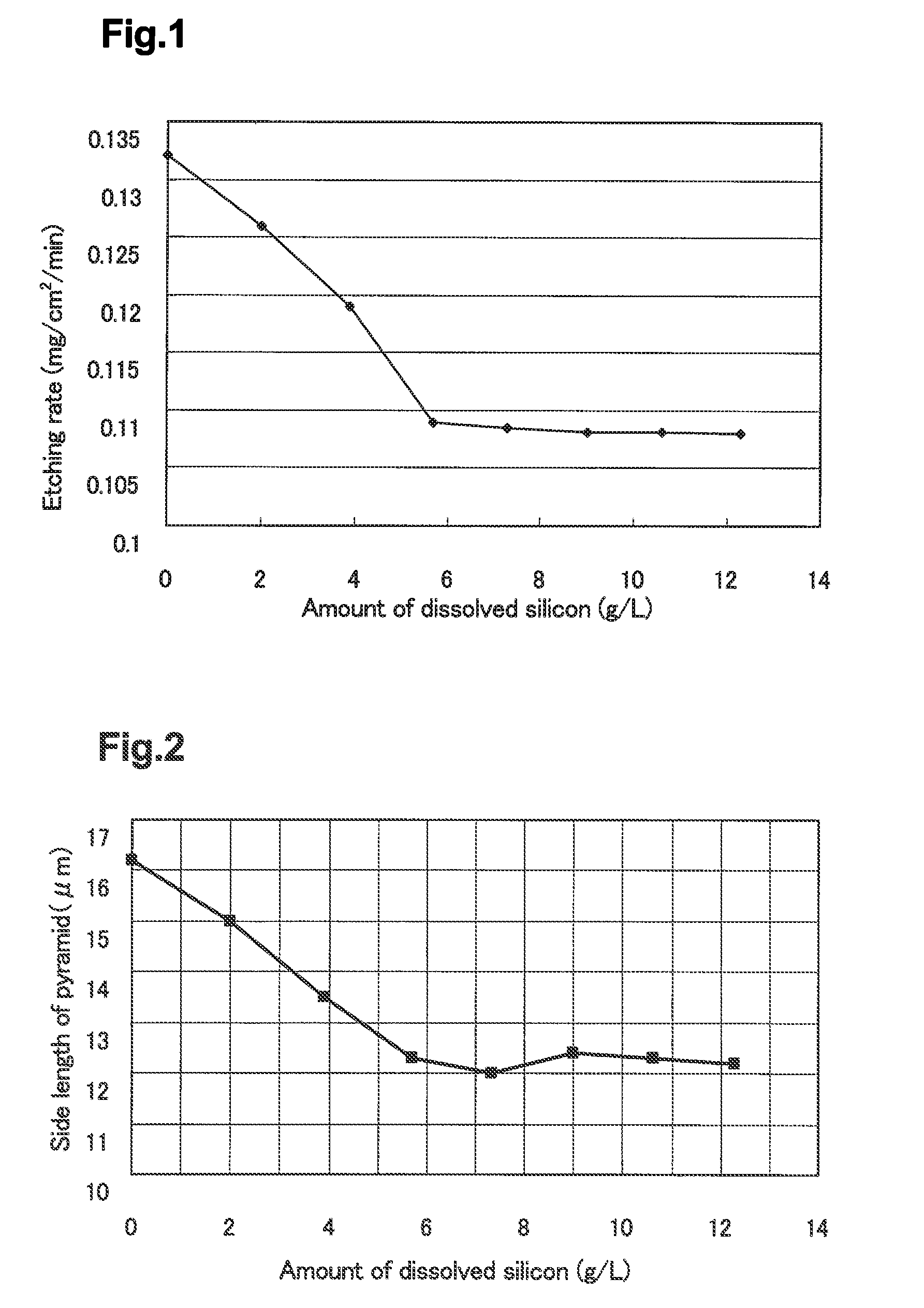

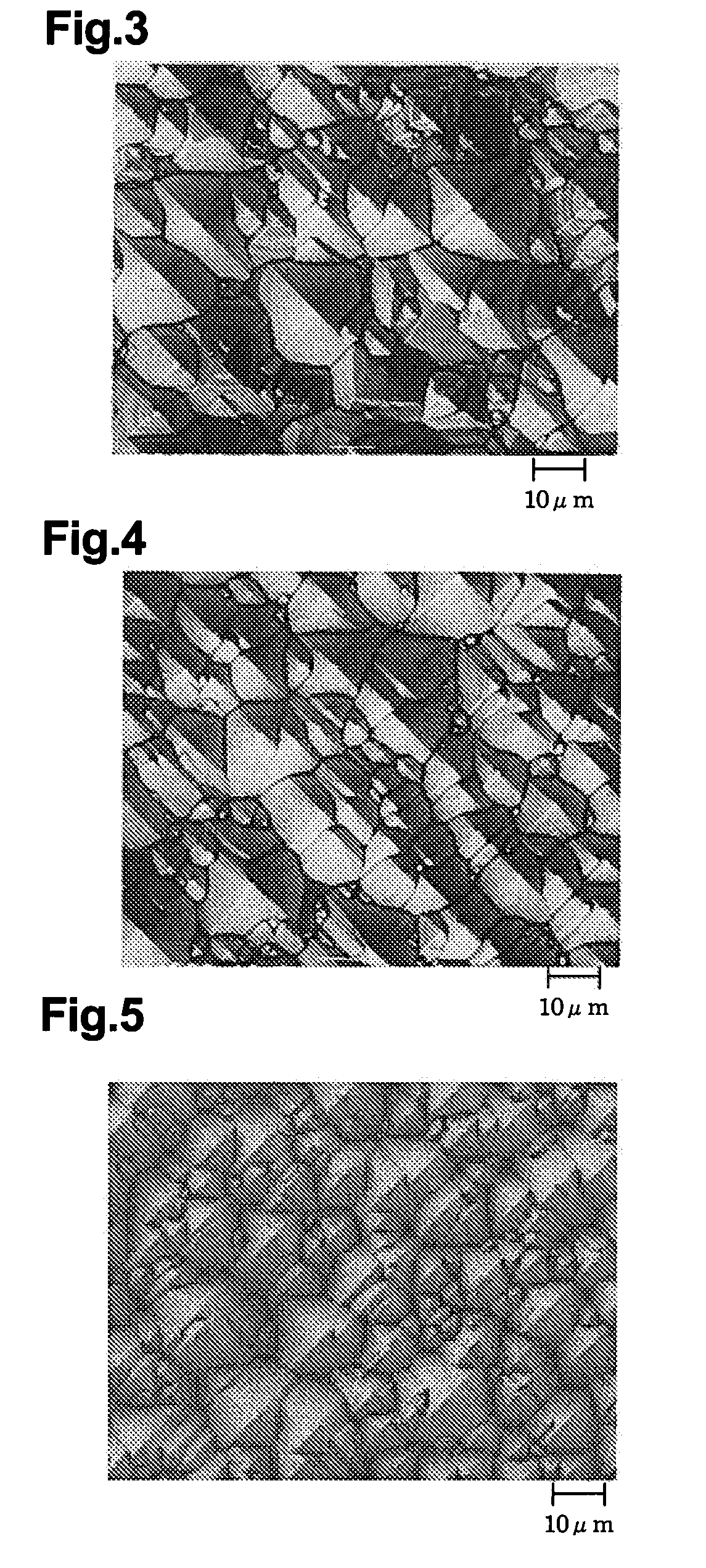

Process for producing semiconductor substrate, semiconductor substrate for solar application and etching solution

InactiveUS20090266414A1Promote conversionStable etch rateSemiconductor/solid-state device manufacturingPhotovoltaic energy generationCarbon numberCarboxylic acid

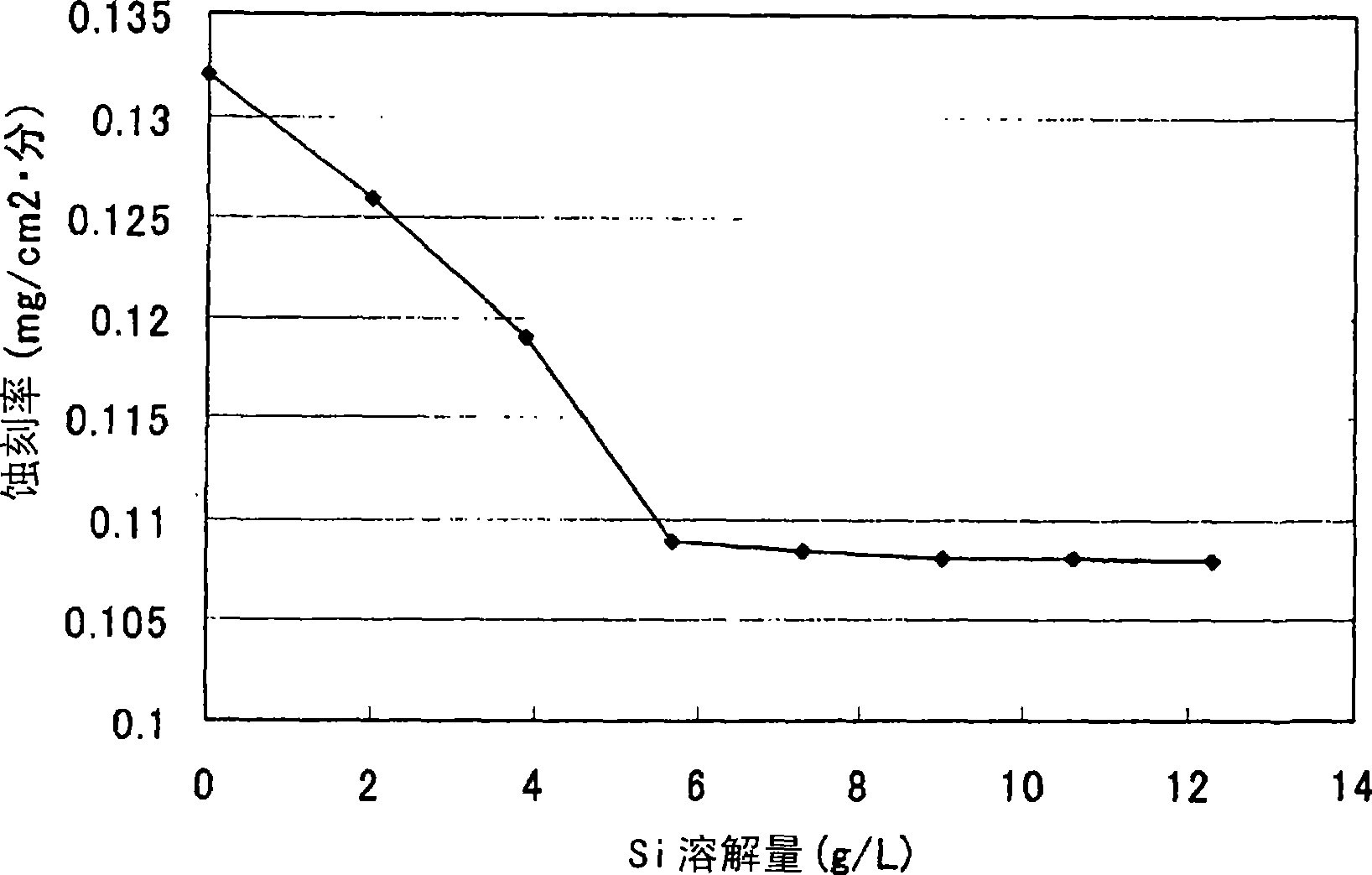

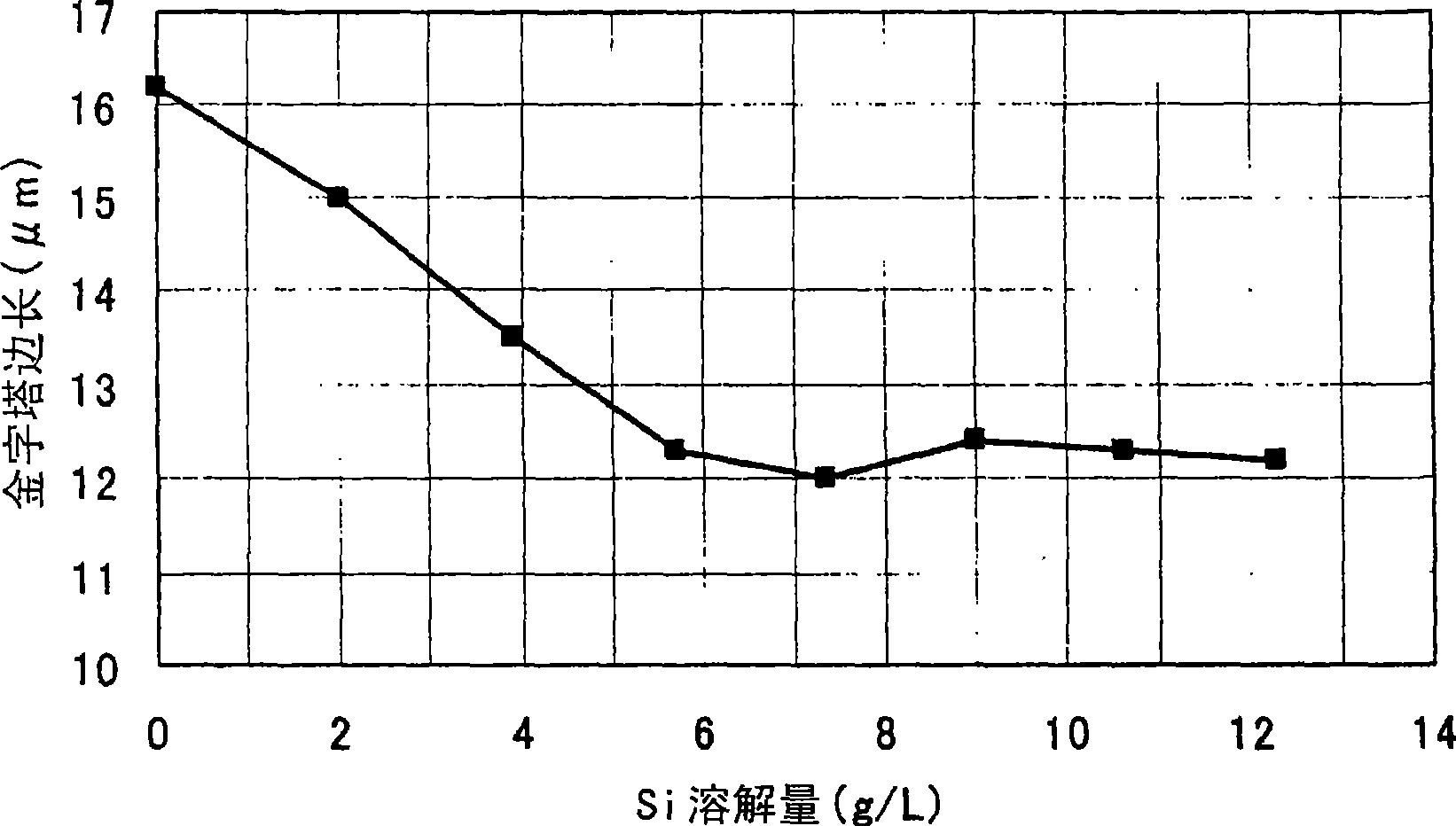

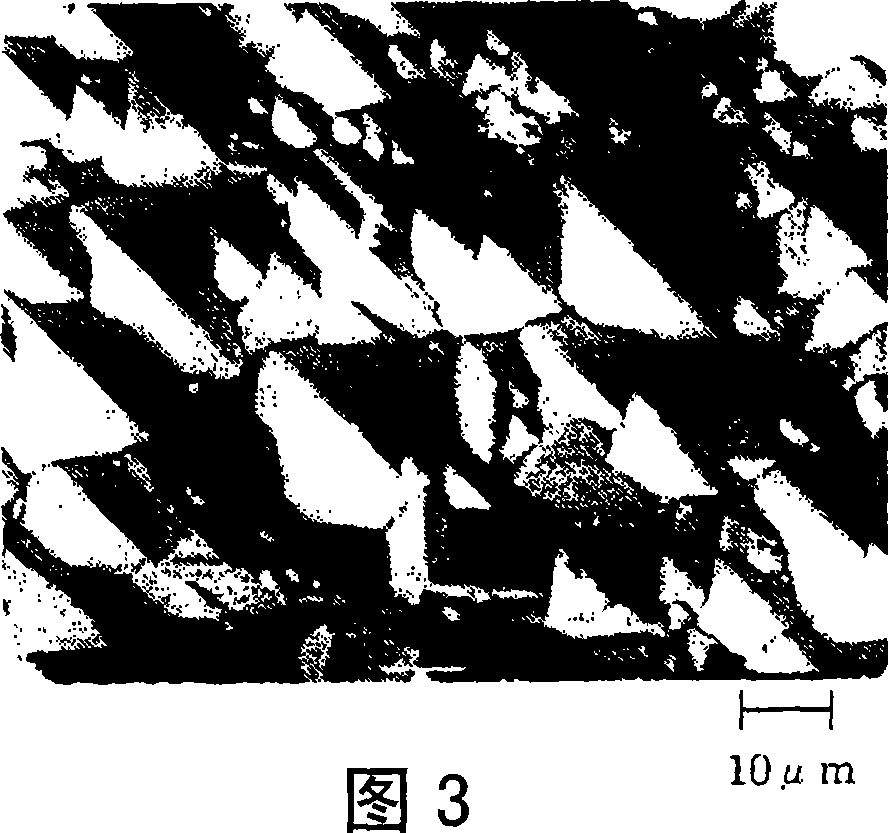

Provided are: a process for producing safely at low cost a semiconductor substrate excellent in photoelectric conversion efficiency, and stable in an etching rate and a pyramid shape, which is capable of uniformly forming a fine uneven structure with desired size suitable for a solar cell on the surface thereof; a semiconductor substrate for solar application having a uniform and fine pyramid-shaped uneven structure in a plane; and an etching solution for forming a semiconductor substrate having a uniform and fine uneven structure, which has a high stability at initial use. The process comprises etching a semiconductor substrate with the use of an alkaline etching solution containing at least one kind selected from the group consisting of carboxylic acids having a carbon number of 1 to 12 and having at least one carboxyl group in a molecule, salts thereof, and silicon, to thereby form an uneven structure on the surface of the semiconductor substrate.

Owner:MIMASU SEMICON IND CO LTD +1

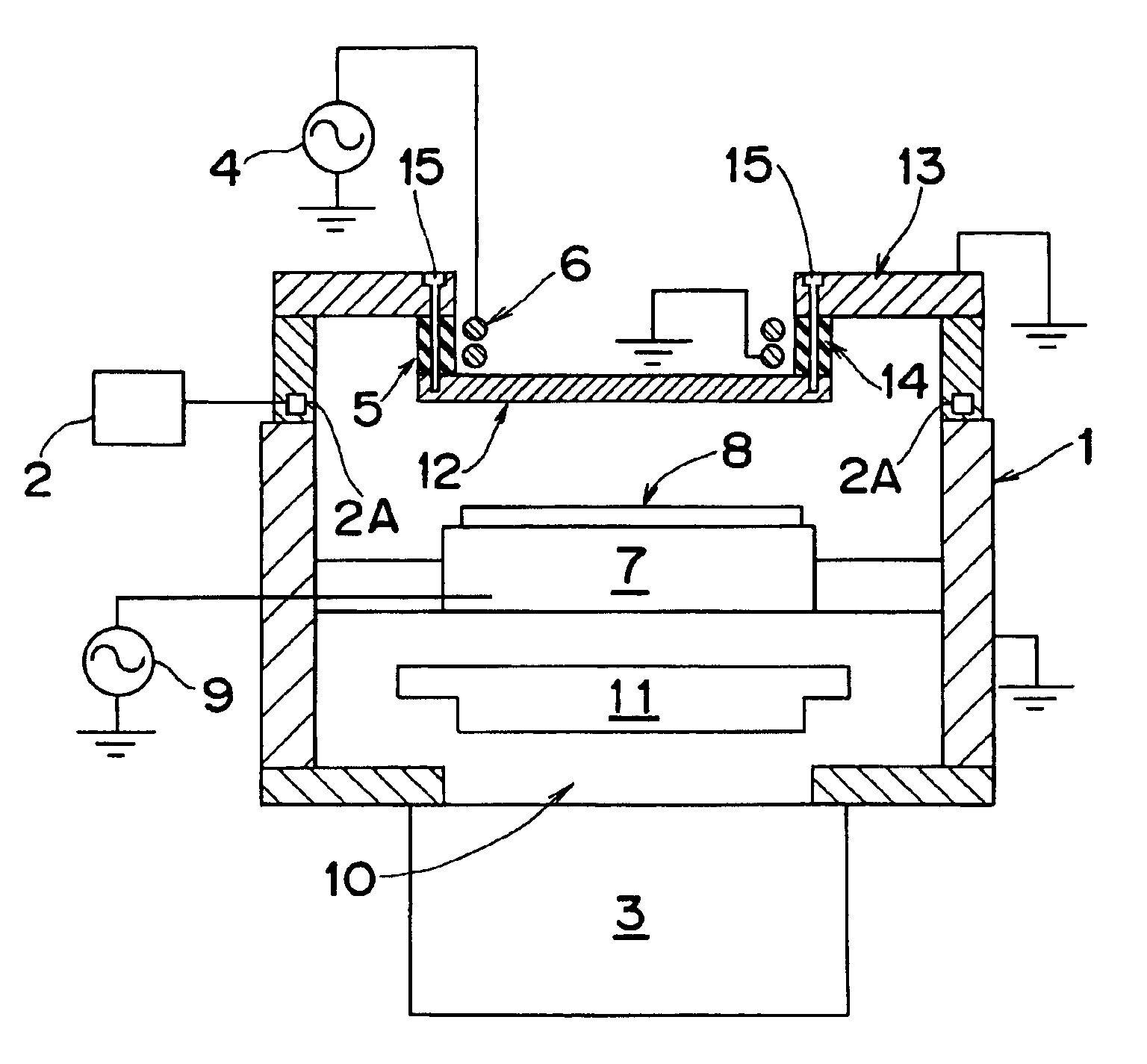

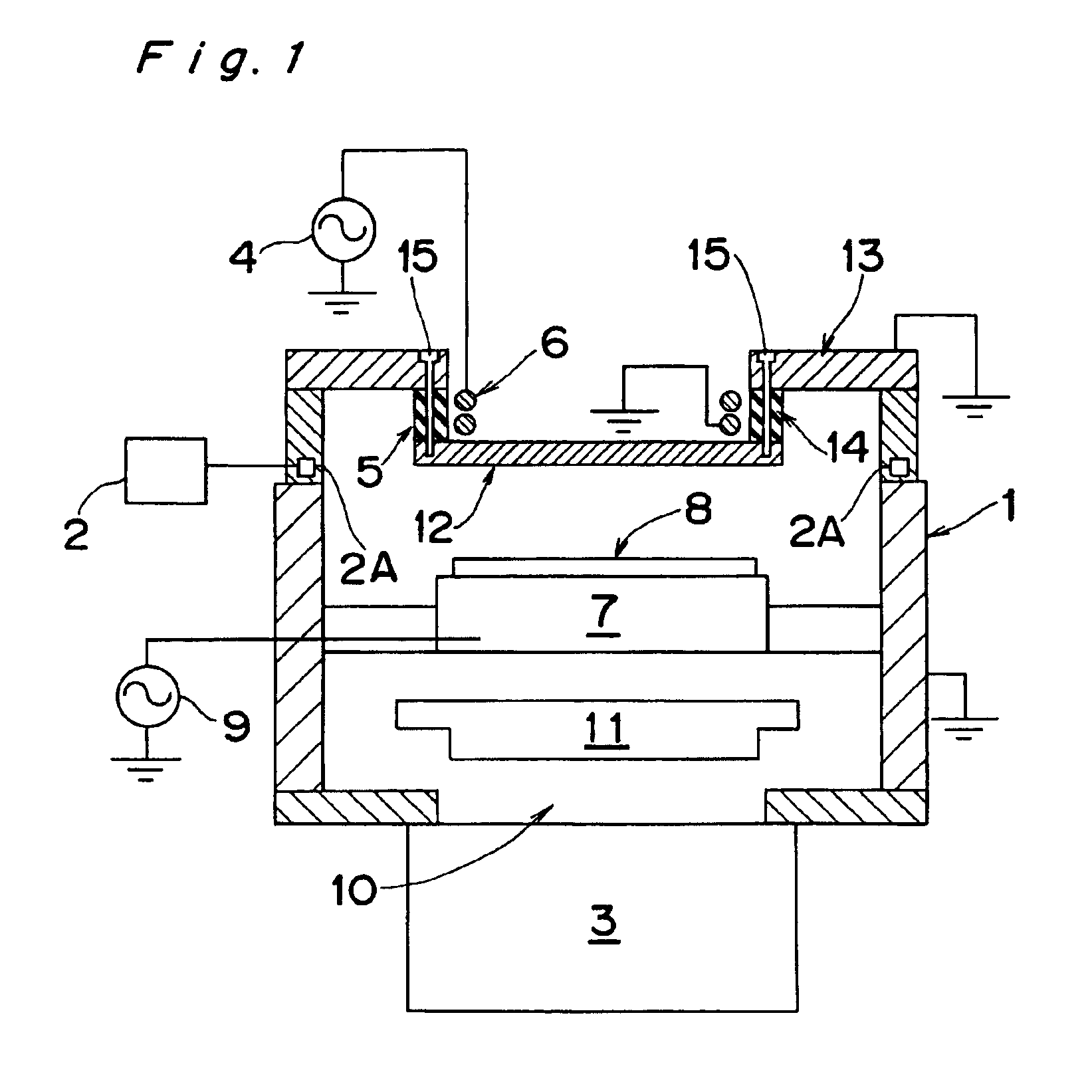

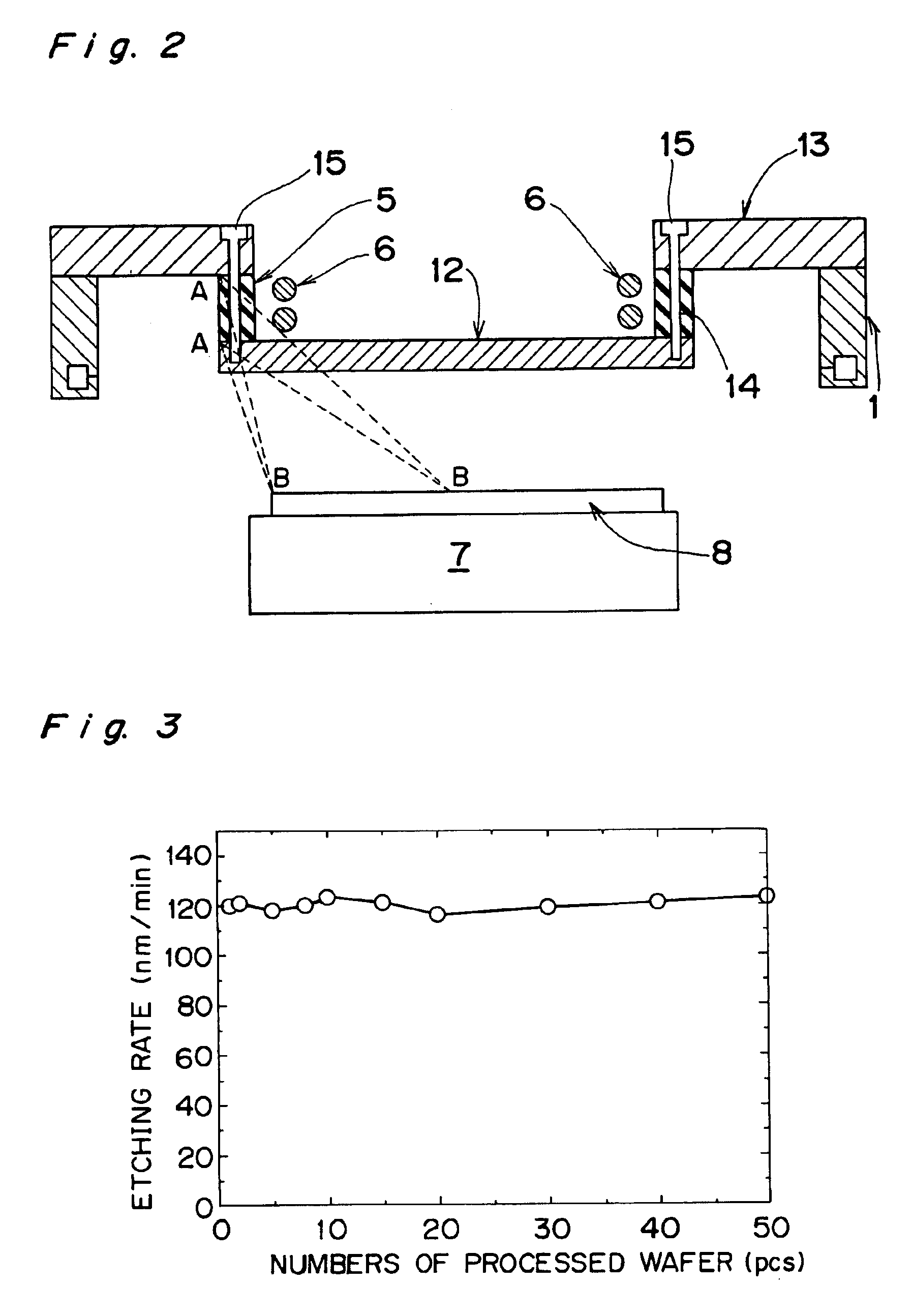

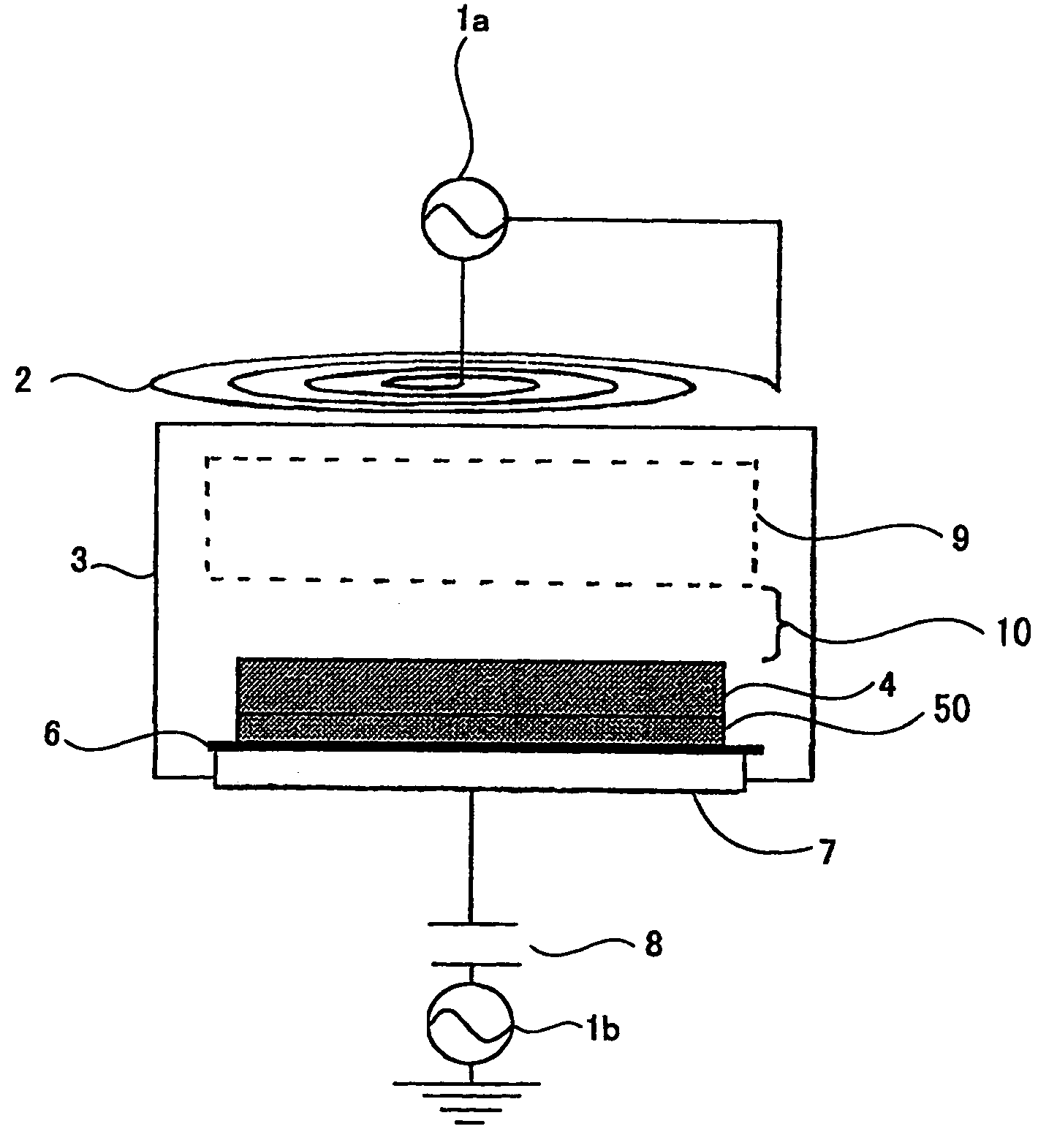

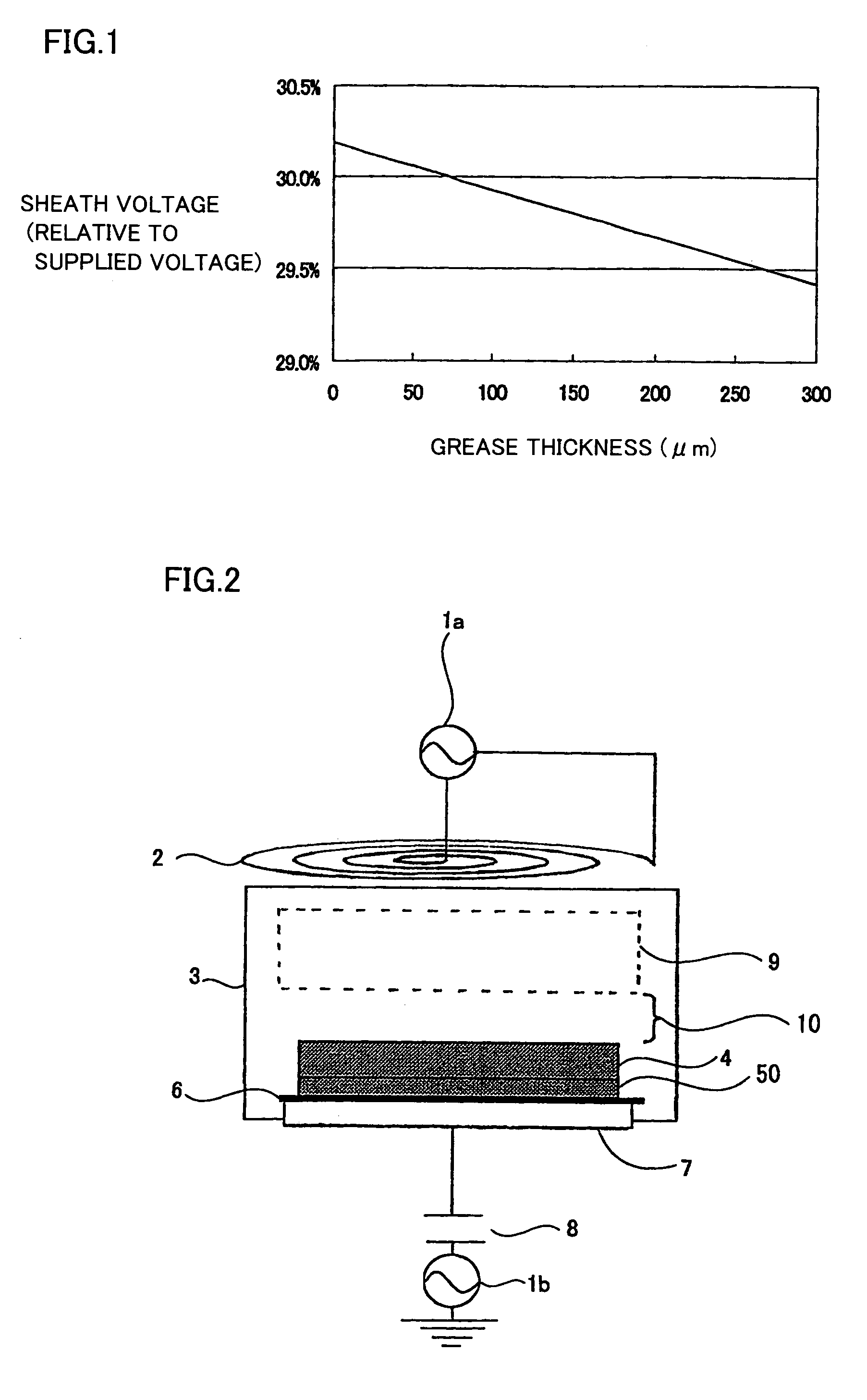

Plasma processing method and apparatus

InactiveUS6905625B2Uniform plasma treatmentStable etch rateTransistorPolycrystalline material growthDielectricHigh frequency power

A plasma processing method includes exhausting the interior of a vacuum chamber while supplying gas into the vacuum chamber, and while maintaining the interior of the chamber at a desired pressure. A high-frequency power of 100 kHz to 100 MHz is applied to a coil provided in the vicinity of a dielectric window provided so as to face a substrate placed on a substrate electrode in the vacuum Thus, plasma is generated in the vacuum chamber to process the substrate or a film on the substrate by the generated plasma while particles which tend to move straight from a surface of the substrate or from a surface of the film on the substrate toward a wall surface of the dielectric window inside the vacuum chamber are kept interrupted by a metal plate.

Owner:PANASONIC CORP

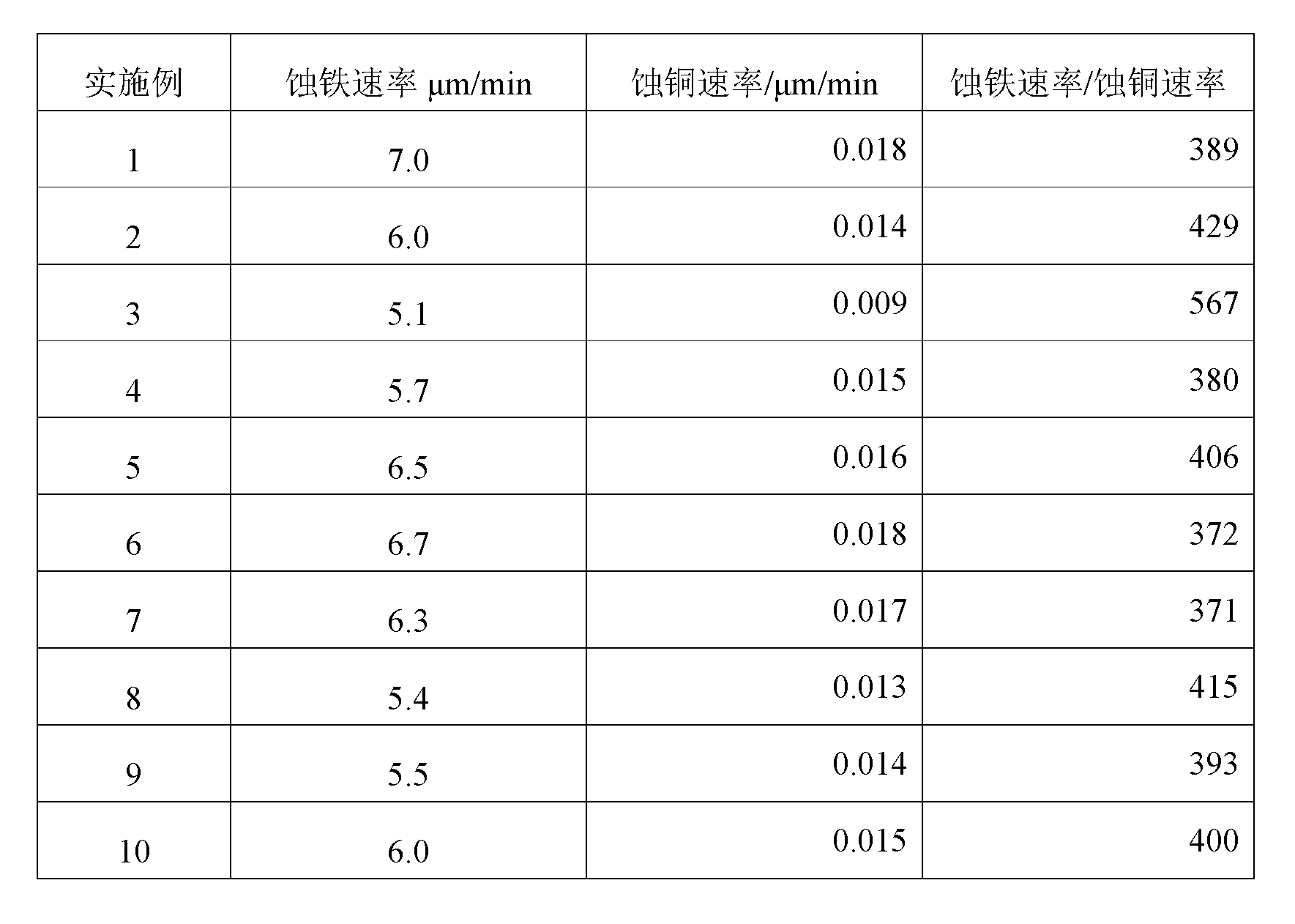

Selective iron etching solution and etching method

The invention discloses selective iron etching solution, comprising 4-250g / L of a water-soluble aromatic nitro-compound, 2-10mol / L of inorganic acid, 0.1-2g / L of a corrosion inhibitor and the balance of deionized water. A novel selective etching system is adopted; the etching method is fast in iron etching speed, stable in etching speed, even in etched surface, small in side corrosion, regular in side boundary and small in copper etching speed; the iron etching speed and the copper etching speed are greater than or equal to 200; the etching solution does not contain the materials with large volatility, such as hydracids or nitric acid; the etching solution is greener and more environment-friendly; and the etching solution is suitable for selective etching of the surface of a copper base material, and is also suitable for refined processing of carbon steel or low-alloy steel and members thereof.

Owner:KUNSHAN CITY BANMING ELECTRONICS SCI & TECH

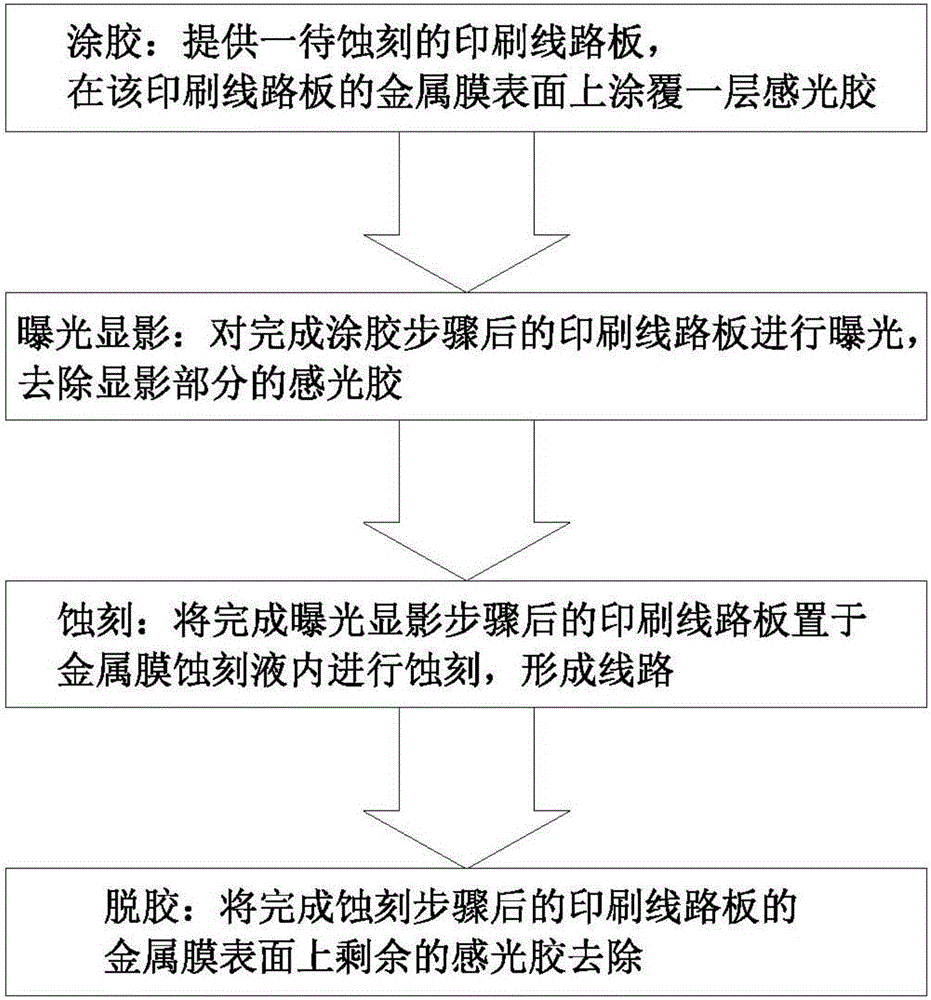

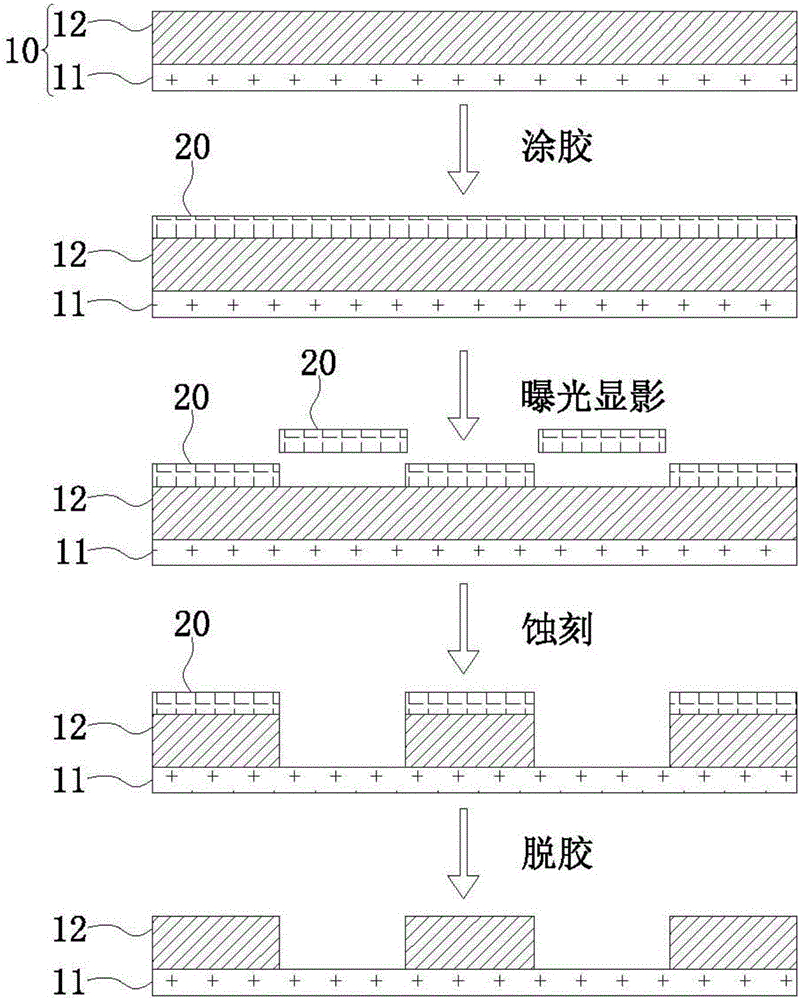

Metal film etching liquid and method for etching printed circuit board

InactiveCN105925980AEtching speed is fastGuaranteed to lastConductive material chemical/electrolytical removalManufacturing technologyLiquid-crystal display

The invention relates to the technical field of manufacturing of printed circuit boards, in particular to metal film etching liquid and a method for etching a printed circuit board. The metal film etching liquid is prepared from, by mass percent, 3%-16% of FeCl3, 4%-17% of HCl, 0.5%-3.12% of NaClO3, 0.001%-0.18% of a surface active agent and the balance water. By means of the metal film etching liquid prepared through the formula and used for etching the printed circuit board, it can be guaranteed that a metal film of the printed circuit board is etched more finely, and the phenomenon of poor etching cannot happen; and the metal film etching liquid and the method are suitable for manufacturing of metal film forming circuit patterns of printed circuit boards of semiconductor devices, liquid crystal display devices, touch control products, IC cards and the like and have wider application prospects.

Owner:SHENZHEN LEAGUER OPTRONICS

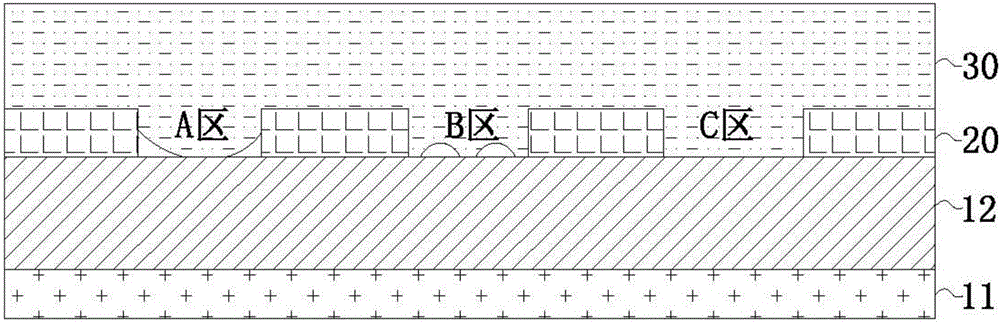

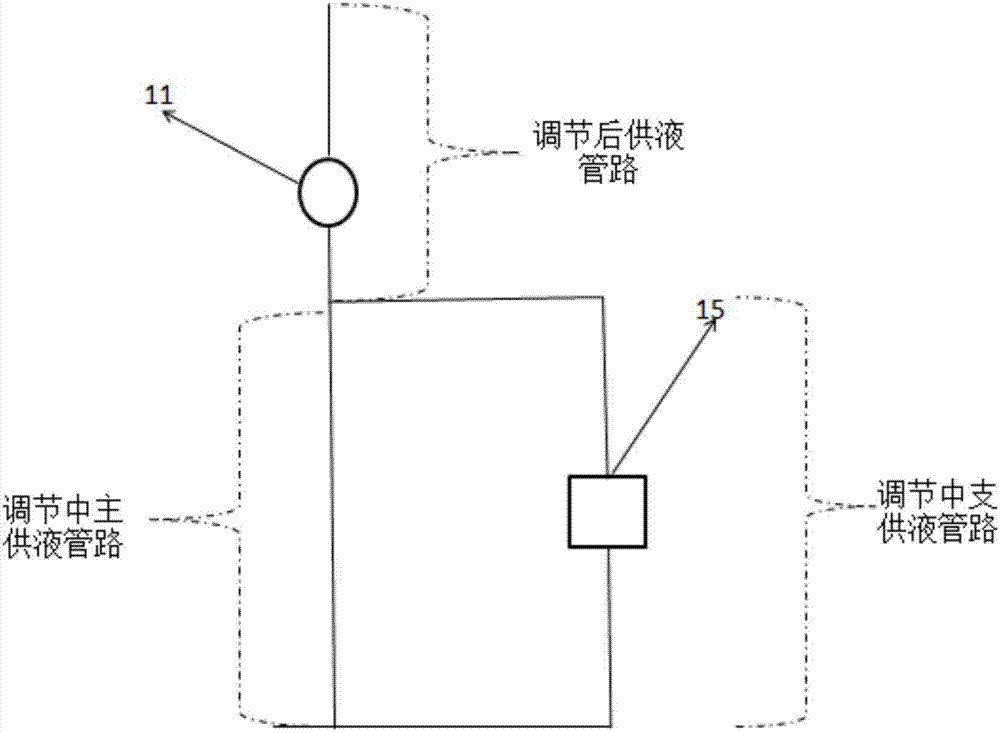

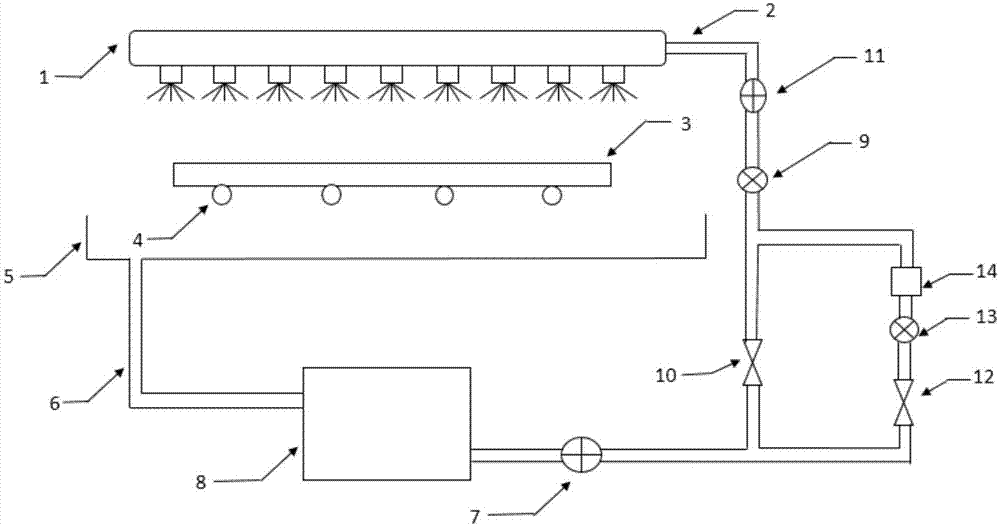

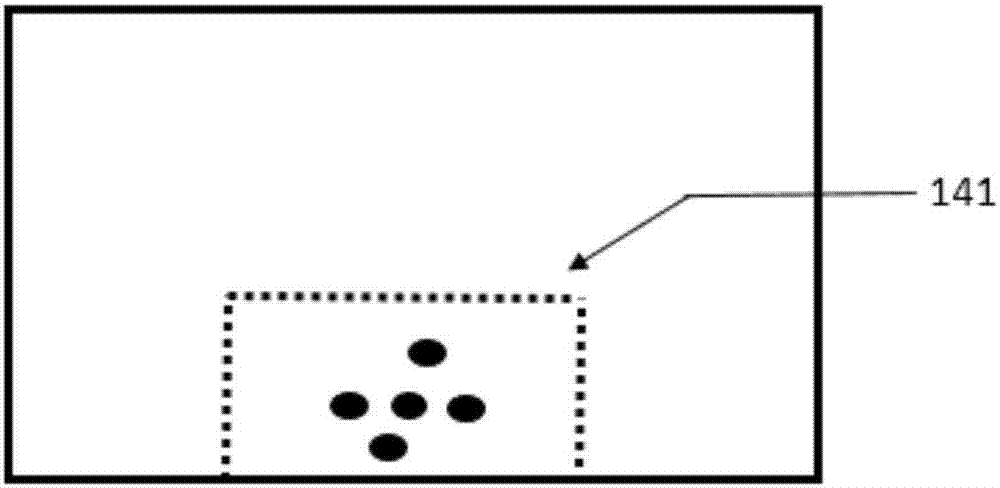

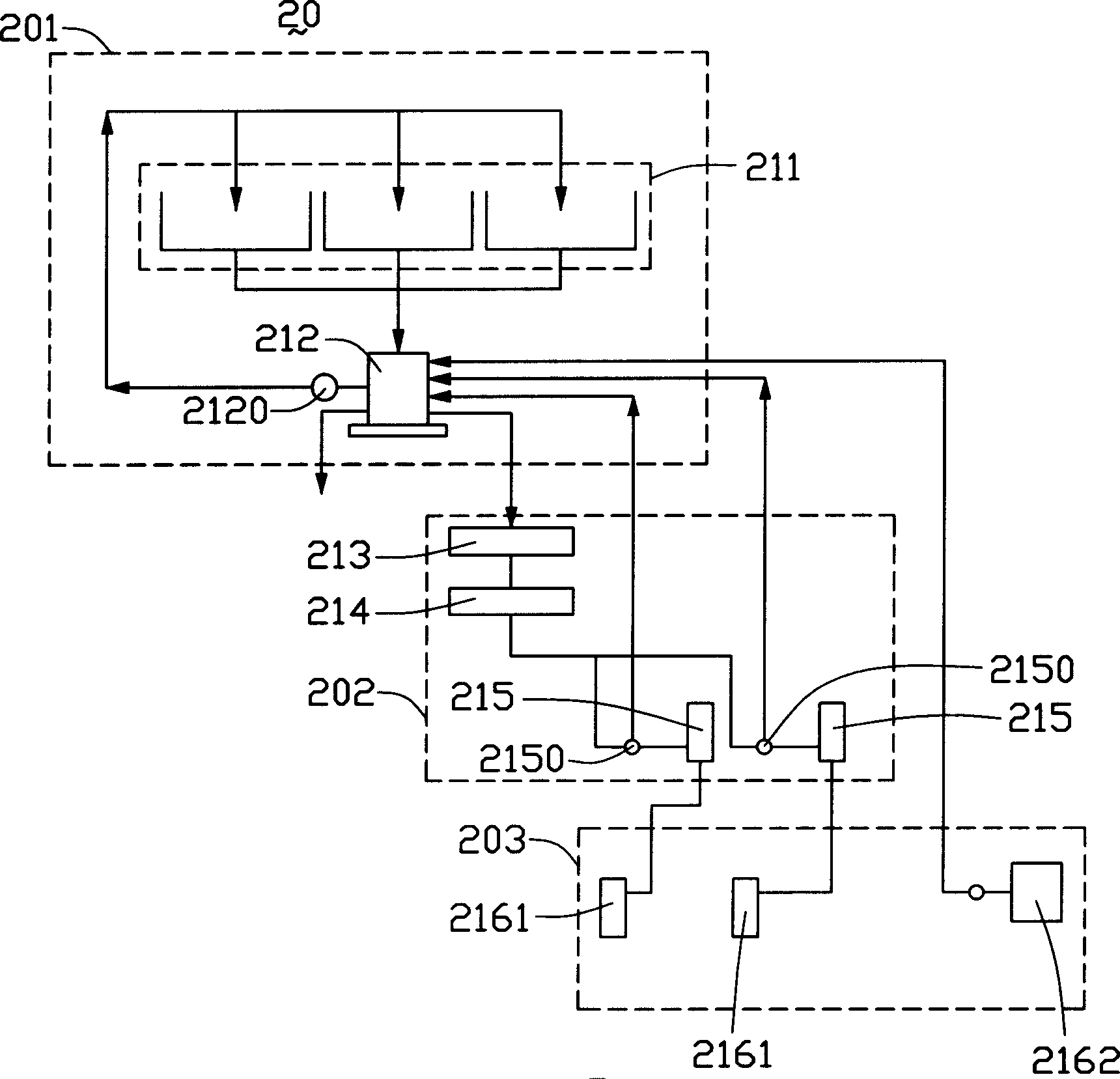

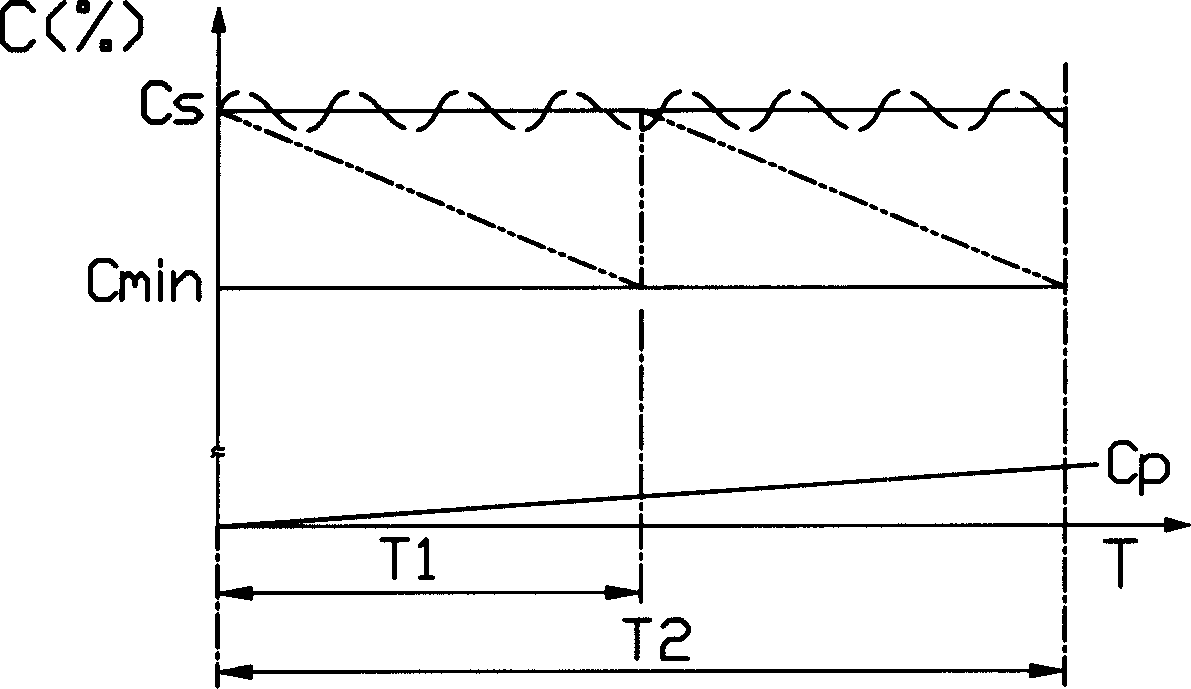

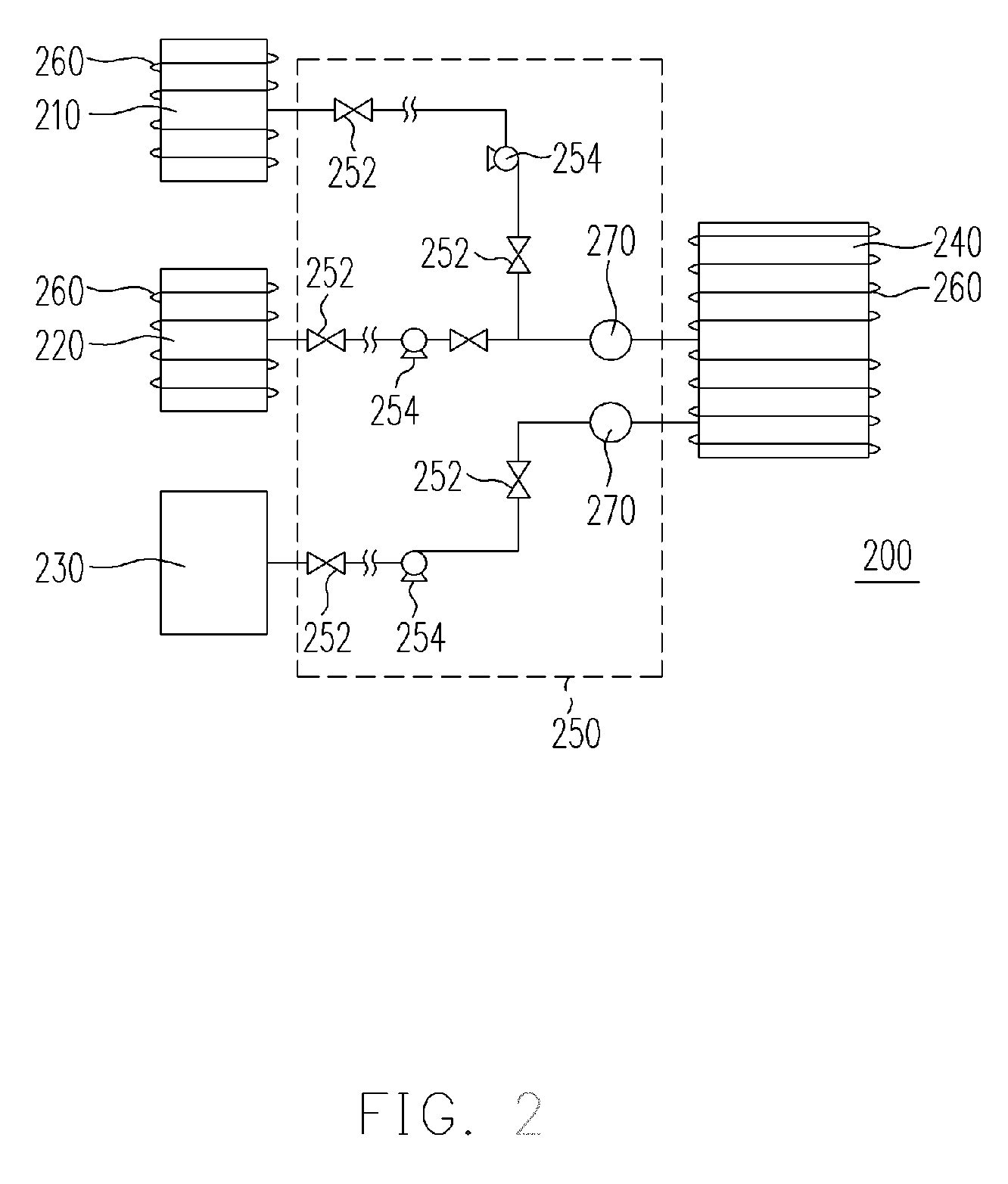

Metal ion concentration regulation device and method, and etching equipment

The invention discloses a metal ion concentration regulation device and method, and etching equipment. The metal ion concentration regulation device comprises a liquid supply pipeline, a metal ion regulation system, a metal ion detection system and a control circuit. The metal ion regulation system and the metal ion detection system are sequentially in the liquid supply pipeline in the direction of etching liquid flowing through the liquid supply pipeline and both communicate with the liquid supply pipeline. The control circuit is electrically connected with the metal ion regulation system and the metal ion detection system and is used for controlling the metal ion regulation system to regulate the concentration of metal ions in the etching liquid according to the current metal ion concentration, transmitted by the metal ion detection system, of the etching liquid and preset metal ion concentration upper and lower threshold values. Through cooperative operation of all the components, the metal ion concentration regulation device conducts regulation on the concentration of metal ions in the etching process, so that the etching rate tends to be stable, the etching effect is improved, and the probability of short circuiting, disconnection and the like of metal conducting wires is reduced.

Owner:BOE TECH GRP CO LTD

Composition for the removing of sidewall residues

ActiveUS20060086372A1Stable etch rateDecorative surface effectsDetergent mixture composition preparationNuclear chemistryMetal

The present invention relates to a composition for the removal of so-called “sidewall residues” from metal surfaces, in particular from aluminium or aluminium-containing surfaces, in particular from aluminium or aluminium-containing surfaces, during the production of semiconductor elements.

Owner:BASF AG

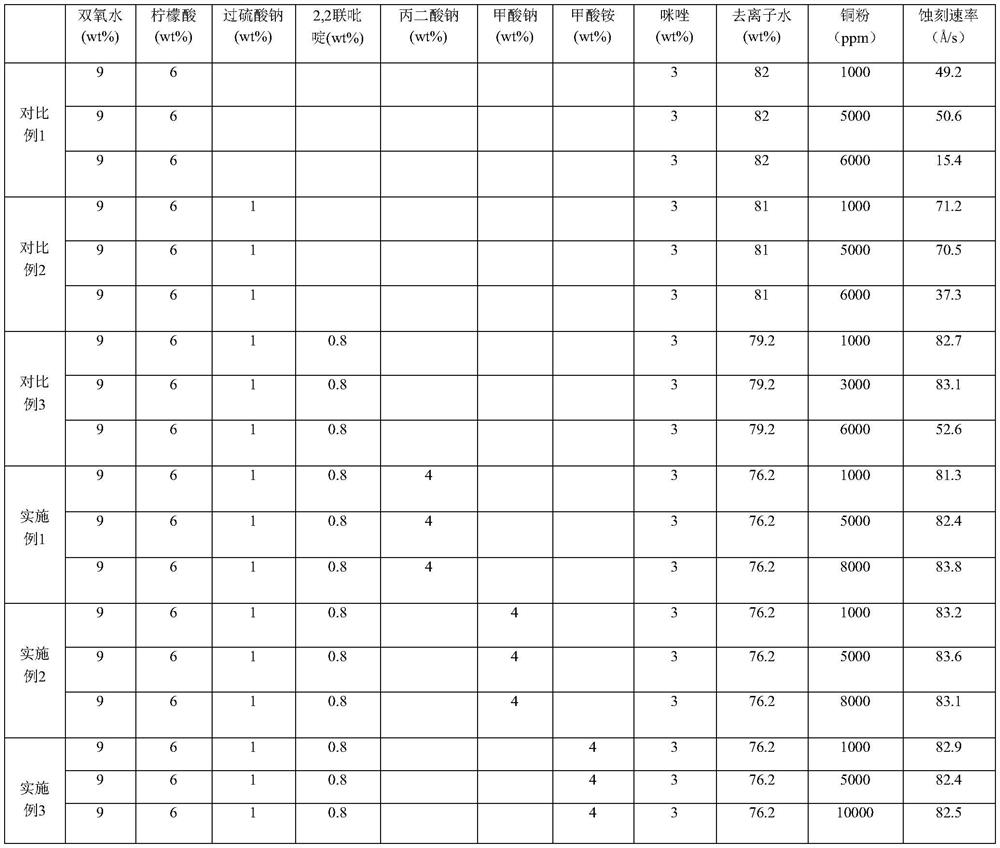

Copper etching solution with long etching life

The invention relates to a copper etching solution with high stability and long etching life. The etching solution is composed of hydrogen peroxide, organic acid, a secondary oxidant, chelating agentsand a pH regulator. In the etching solution, the synergistic effect of the hydrogen peroxide and the secondary oxidant overcomes the defects of low etching rate, too fast oxidant consumption, short etching life and the like; citric acid and other organic acid can promote the dissolution process of copper oxide in the etching solution, and meanwhile, the organic acid can also be used as a pH buffer agent to keep the pH of the etching solution changing in a small range and improve the stability; and a variety of chelating agents are combined for use, different coordination atoms are fully and quickly combined with divalent copper ions to generate a more stable metal chelate, the copper ions are prevented from promoting the decomposition of the hydrogen peroxide, and the service life of thecopper etching solution is prolonged. The copper etching solution provided by the invention can keep stable and uniform in a long etching time, the service life of the etching solution is prolonged, and the etching cost is reduced.

Owner:湖北兴福电子材料股份有限公司

Method for manufacturing semiconductor substrate, solar semiconductor substrate, and etching liquid

InactiveCN101432855AImprove photoelectric conversion efficiencyShape stableSemiconductor/solid-state device manufacturingPhotovoltaic energy generationConvex structureCarboxylic acid

This invention provides a safe and low-cost semiconductor substrate manufacturing method, which can form a fine concave-convex structure, which can realize excellent photoelectric conversion, can realize stable etching rate and pyramid shape, and is suitable for solar batteries, in a desired size evenly on the surface of a semiconductor substrate. There are also provided a solar semiconductor substrate having an even and fine pyramid-shaped concave-convex structure evenly in a plane, and an etching liquid, which is highly stable in use in an early stage and can form a semiconductor substrate having an even and fine concave-convex structure. A semiconductor substrate is etched with an alkaline etching liquid containing at least one member, selected from the group consisting of carboxylic acids having 1 to 12 carbon atoms and containing at least one carboxyl group per molecule and their salts, and silicon to form a concave-convex structure on the surface of the semiconductor substrate.

Owner:MIMASU SEMICON IND CO LTD

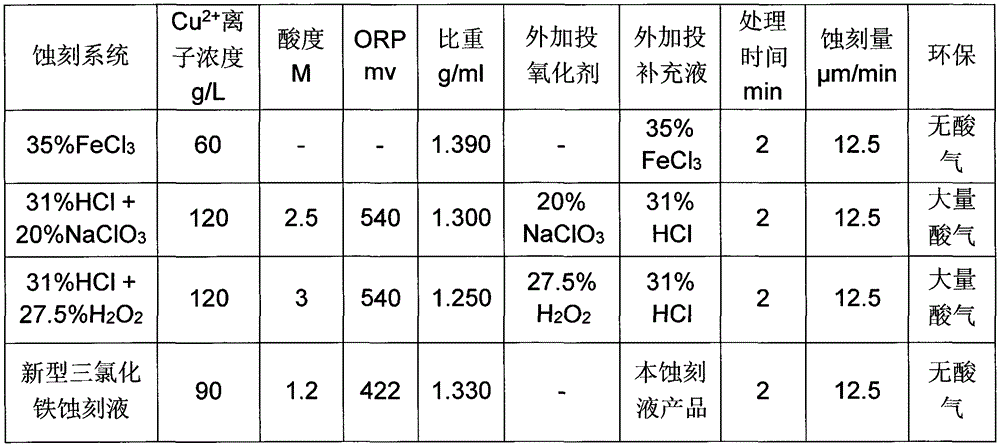

Novel ferric trichloride etching solution

InactiveCN105887088AEnvironmental Process ImprovementImprove liquidityCopper chlorideOxidizing agent

A novel ferric trichloride etching solution of the invention is a novel monad liquid etching technical product based on a traditional [ferric trichloride + hydrochloric acid] etching system and with acidic copper chloride etching as the leading factor. By combining advantages of two copper etching oxidants ferric trichloride and copper chloride, etching rate is stabilized and etching quality is enhanced. Production cost is reduced, and the environmental protection problem generated by an acidic copper chloride and oxidizing agent etching technology widely applied nowadays is overcome.

Owner:叶涛

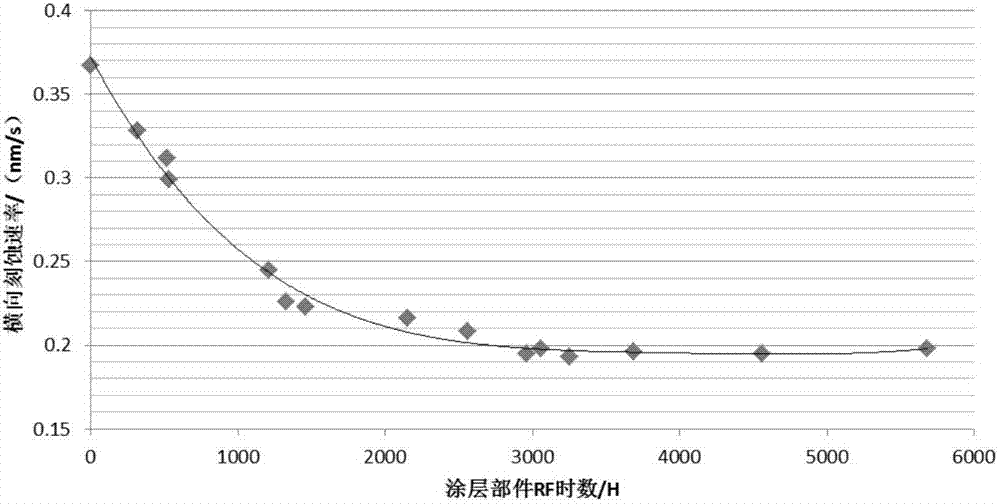

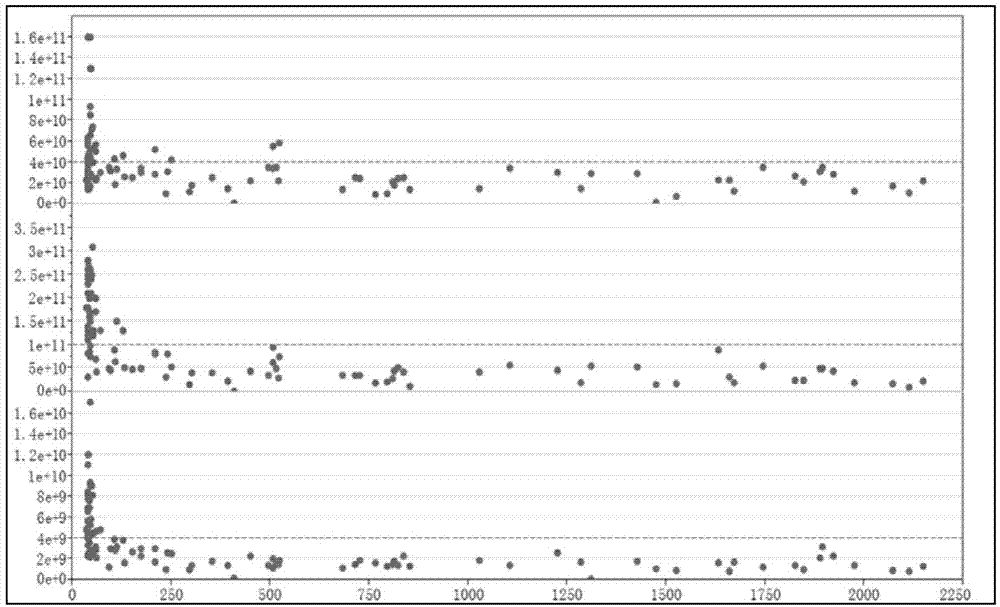

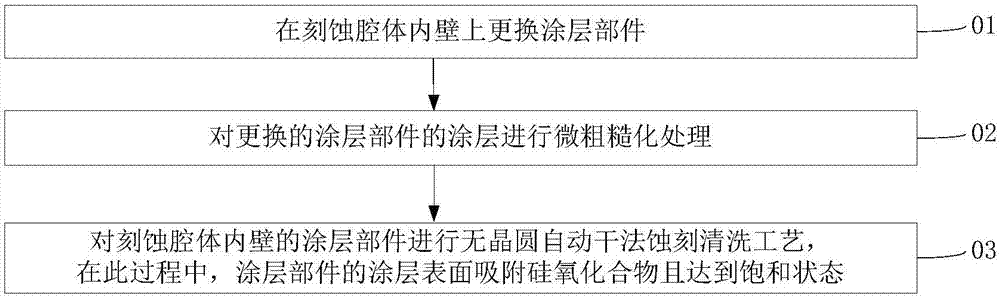

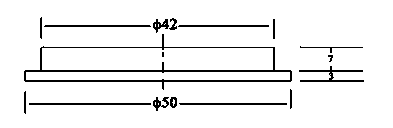

Optimization method for optimizing environment stability of etching cavity

ActiveCN106887381AAchieve stabilityEliminate pollutionElectric discharge tubesSemiconductor/solid-state device manufacturingCoated surfaceSilicon oxygen

The present invention provides an optimization method for optimizing the environment stability of an etching cavity. The method comprises the steps of replacing a coating member on the inner wall of the etching cavity; subjecting the coating with the replaced coating member to the micro-roughening treatment; and subjecting the coating member on the inner wall of the etching cavity to the wafer-free automatic dry-etching and cleaning process. During the above process, silicon-oxygen compounds are adsorbed on the coating surface of the coating member and the adsorption is in a saturated state. According to the technical scheme of the invention, the environment drifting phenomenon of the etching cavity, caused by the replacement of new components, is improved. Meanwhile, the environment stability of the etching cavity is improved, so that the key dimension stability of the etching process is improved. Moreover, the electrical performances of wafers and the yield of products are improved, and the rejection rate is reduced.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

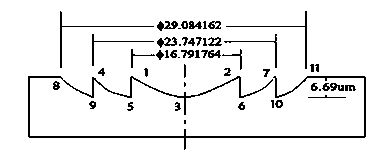

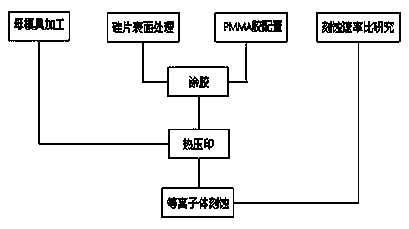

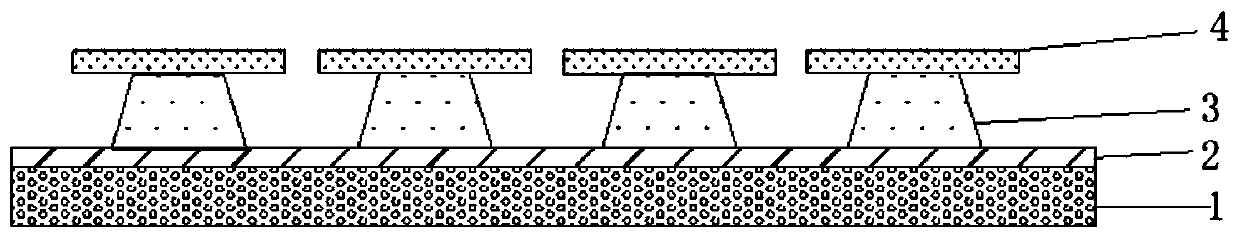

Manufacturing method for three-dimension controllable silicon based mold

The invention relates to manufacturing of a silicon based mold in mold pressing manufacturing technologies, and the method is used for machining a three-dimensional shape with a continuously variable embossment structure on a silicon base. The main machining steps include: 1. making a female die with a continuous curved surface appearance embossment structure on a metal material by a single-point diamond turning technology; 2. performing spin coating of a layer of polymer film on a silicon substrate; 3. transferring the embossment structure on the die to the polymer by a hot stamping technology; and 4. transferring the embossment structure on the glue to the silicon material at a same proportion through plasma etching, thus obtaining the silicon based mold. The method provided by the invention has the advantages of controllable appearance, simple process, fast speed, and good repeatability.

Owner:XIAN TECHNOLOGICAL UNIV

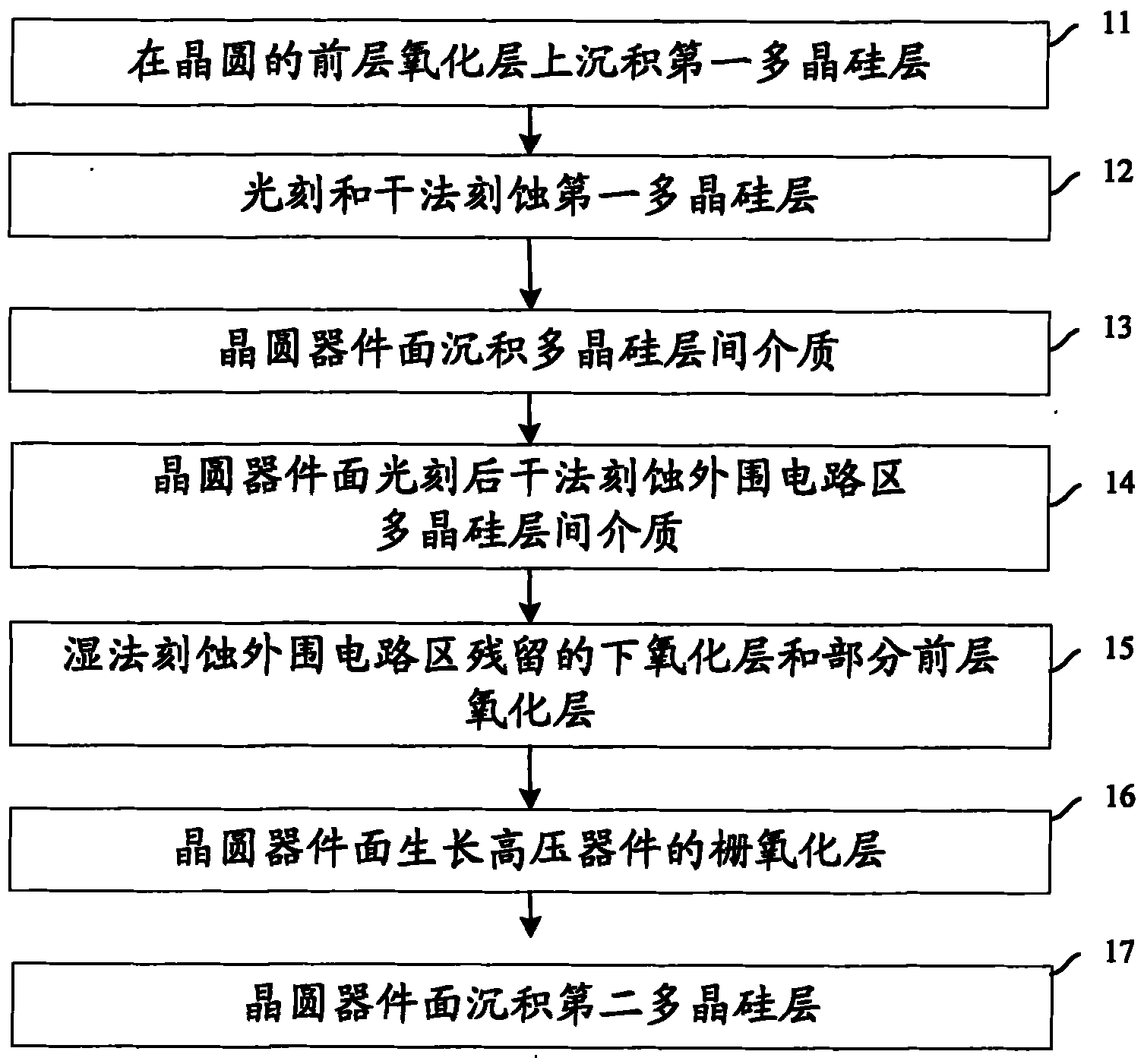

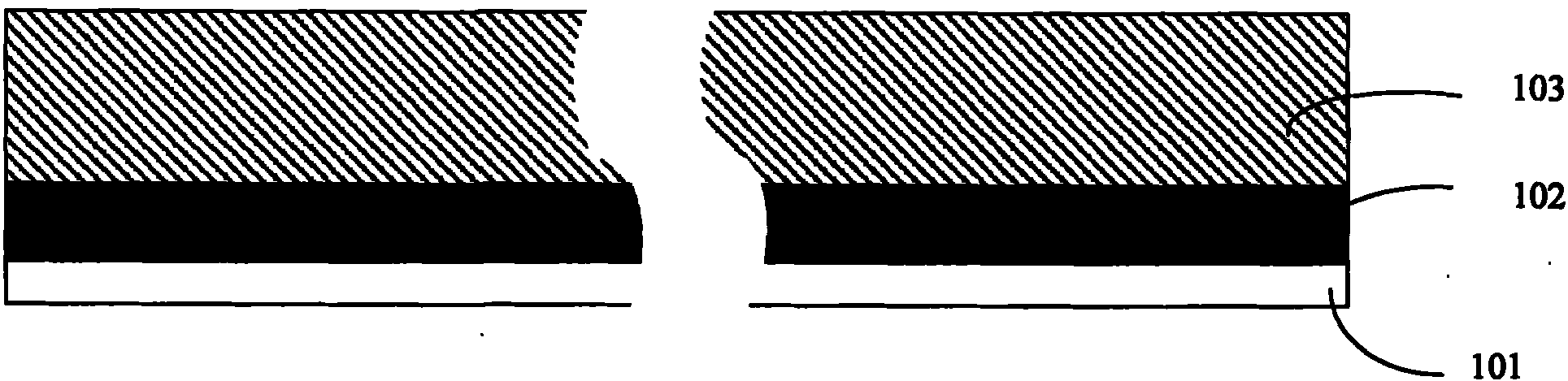

Method for etching interpoly dielectric

InactiveCN102054782AUniform thicknessAvoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricHigh pressure

The invention discloses a method for etching interpoly dielectric. The method comprises the following steps of: etching an upper oxidation layer of the interpoly dielectric by a first wet method, etching a nitride layer by a dry method, and finally etching a lower oxidation layer and a front oxidation layer under the lower oxidation layer by a second wet method. The flat front oxidation layer canbe obtained by the method provided by the invention, damage to a silicon substrate and the failure rate of electrical property thickness of a gate oxide of a high-voltage device are reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

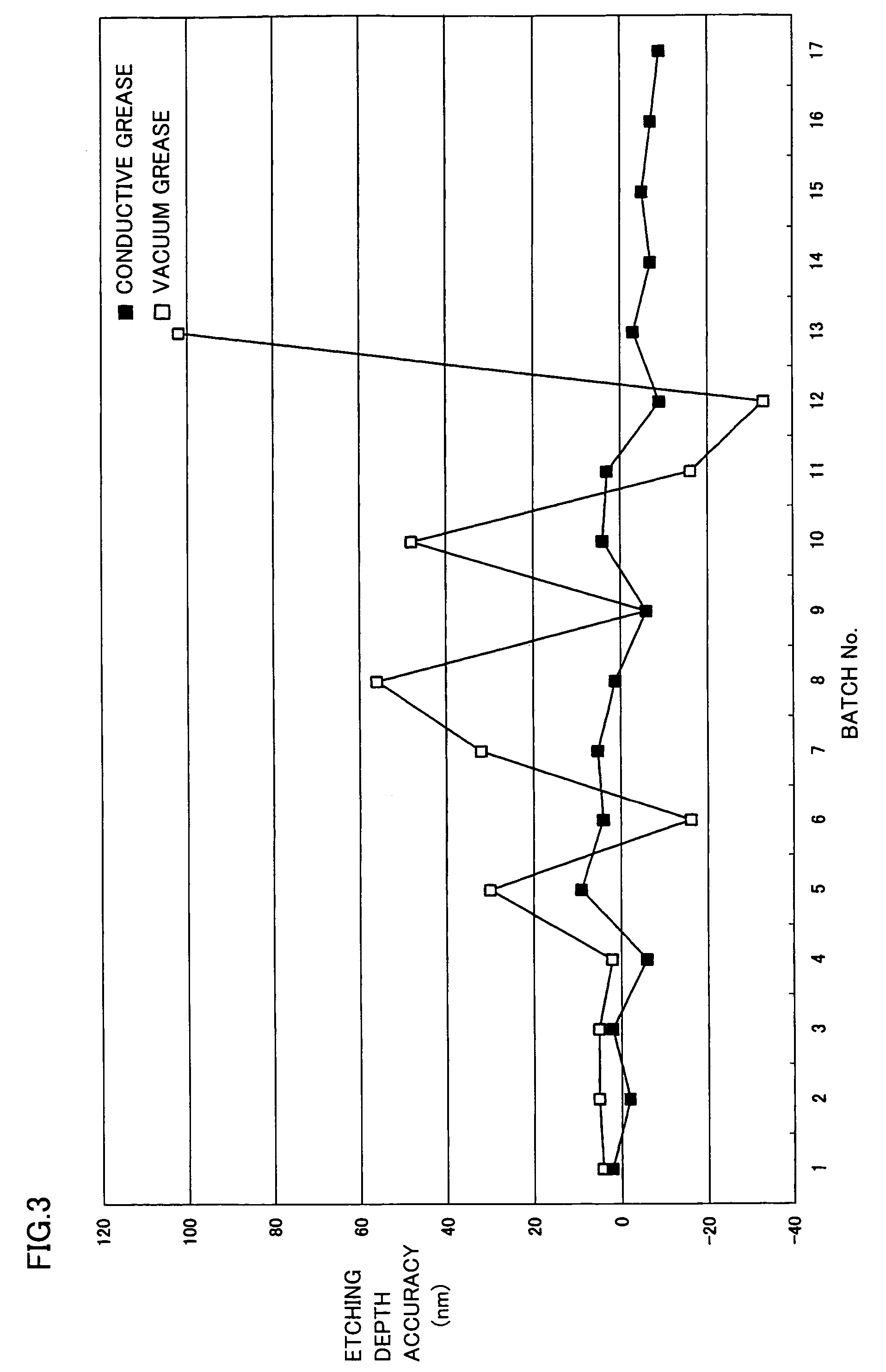

Dry etching method and diffractive optical element

ActiveUS7528073B2Avoid heatComplex structureSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A dry etching method is provided, in which dry etching is performed in such a manner that a conductor to which an insulative substrate is attached is brought in electric, intimate contact with an electrode. In the dry etching method, the insulative substrate is attached to the conductor by means of a conductive grease. A diffractive optical element manufactured with the dry etching method is also provided.

Owner:SUMITOMO ELECTRIC IND LTD

Etching solution of low doped silicon electrode

InactiveCN109575923AUniform surfaceStable etch rateSurface treatment compositionsUltrapure waterRadical ion

The invention discloses etching solution of a low doped silicon electrode. The etching solution comprises the following main components according to a total weight of the etching :45-65% of sulfuric acid, 1-10% of nitric acid, 1-10% of ammonium fluoride, 1-10% of ammonia chloride, and 5-52% of ultrapure water. The etching solution is capable of, through using the nitric acid with low content, reducing a whole etching rate; through using the ammonium fluoride to replace hydrofluoric acid, guaranteeing the stable etching rate; and adding the ammonia chloride as a replenisher of an ammonium radical ion, generating intensive small bubbles in an etching process, and conveniently controlling roughness on the surface of a silicon electrode. The etching solution is capable of completely removingdamage caused by grinding, stable in etching rate, uniform in etching surface, and controllable in surface roughness.

Owner:湖北兴福电子材料股份有限公司

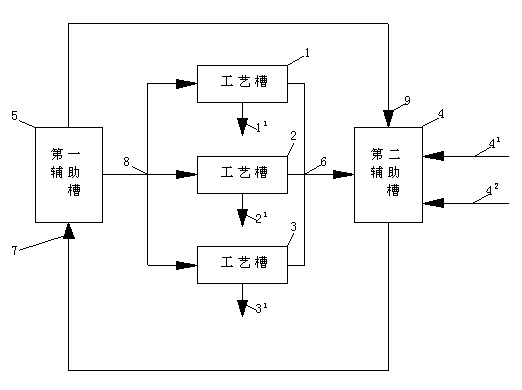

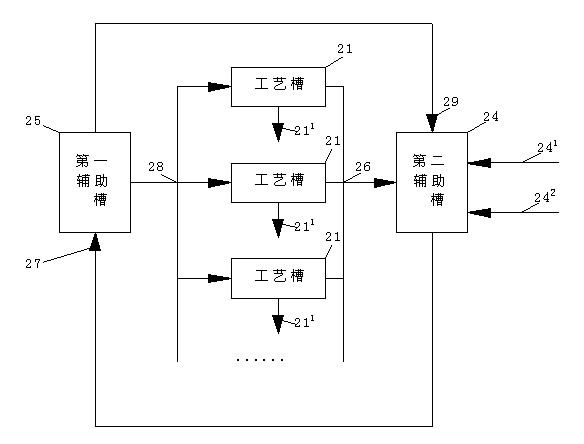

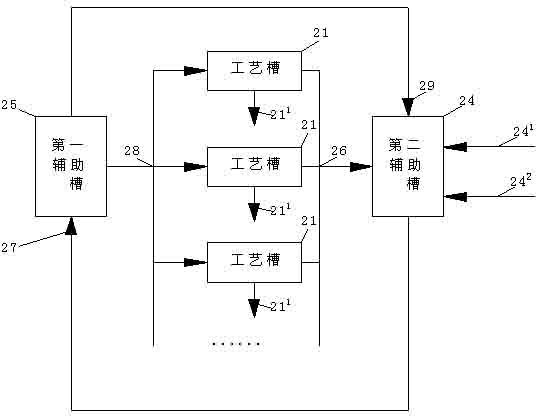

Pipeline system and method for improving stability of etching speed selectivity ratio

ActiveCN102420127AFix damageStable etch rateSemiconductor/solid-state device manufacturingSilicon chipMicroelectronics

The invention relates to the field of microelectronics, in particular to a pipeline system and method for improving the stability of an etching speed selectivity ratio. According to the pipeline system and method for improving the stability of the etching speed selectivity ratio, disclosed by the invention, an auxiliary trench is additionally arranged and is connected with a plurality of process trenches to form a circulation, thereby etching solutions in various process trenches tend to be identical and the etching speeds tend to be identical; in addition, the volume of the etching solution participating in the circulation is increased and the content change of SiO2 is relatively reduced, thereby the etching speed selectivity ratio is relatively stable; acid change setting is omitted anda small amount of etching solution is drained at set intervals or after a certain amount of silicon chips are produced; and the etching solution is supplemented from the auxiliary trench, and therebythe problem of greater damage to an oxidation film caused when the content of SiO2 in the novel etching solution is relatively and excessively high and silicon nitride is etched is solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

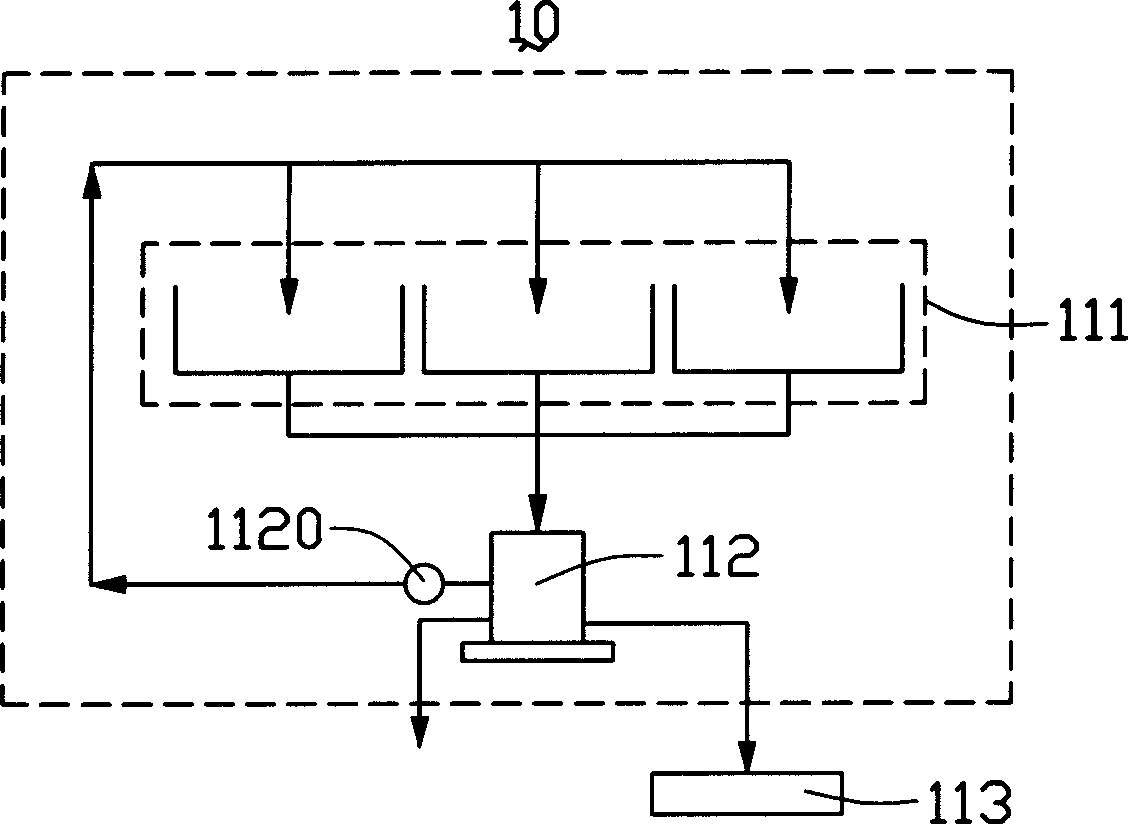

Single-acid micro adding device and method

The invention discloses a single acid trace adding device which consists of a etching unit and an adding monitor unit. The etching unit includes a etch room and a acid blending socket; the monitor unit includes a single acid test device, a single acid compensation calculator and a single acid adding socket; the test device is connected with the blending socket, the calculator is connected with the test device and the adding socket while the adding socket is connected with the blending socket; the blending socket, test device, calculator and the adding socket are connected in turn end to end forming the close single acid adding circuit.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

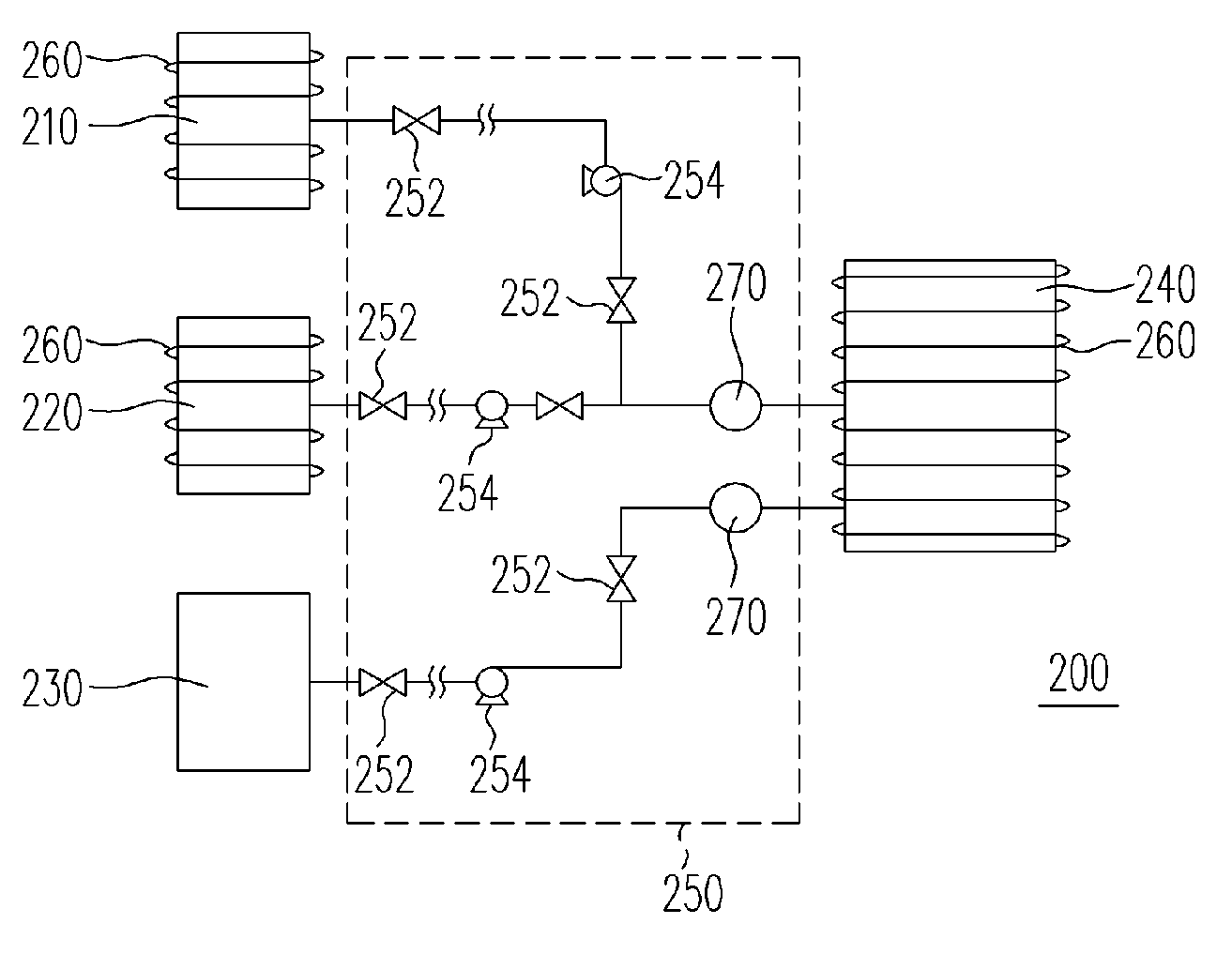

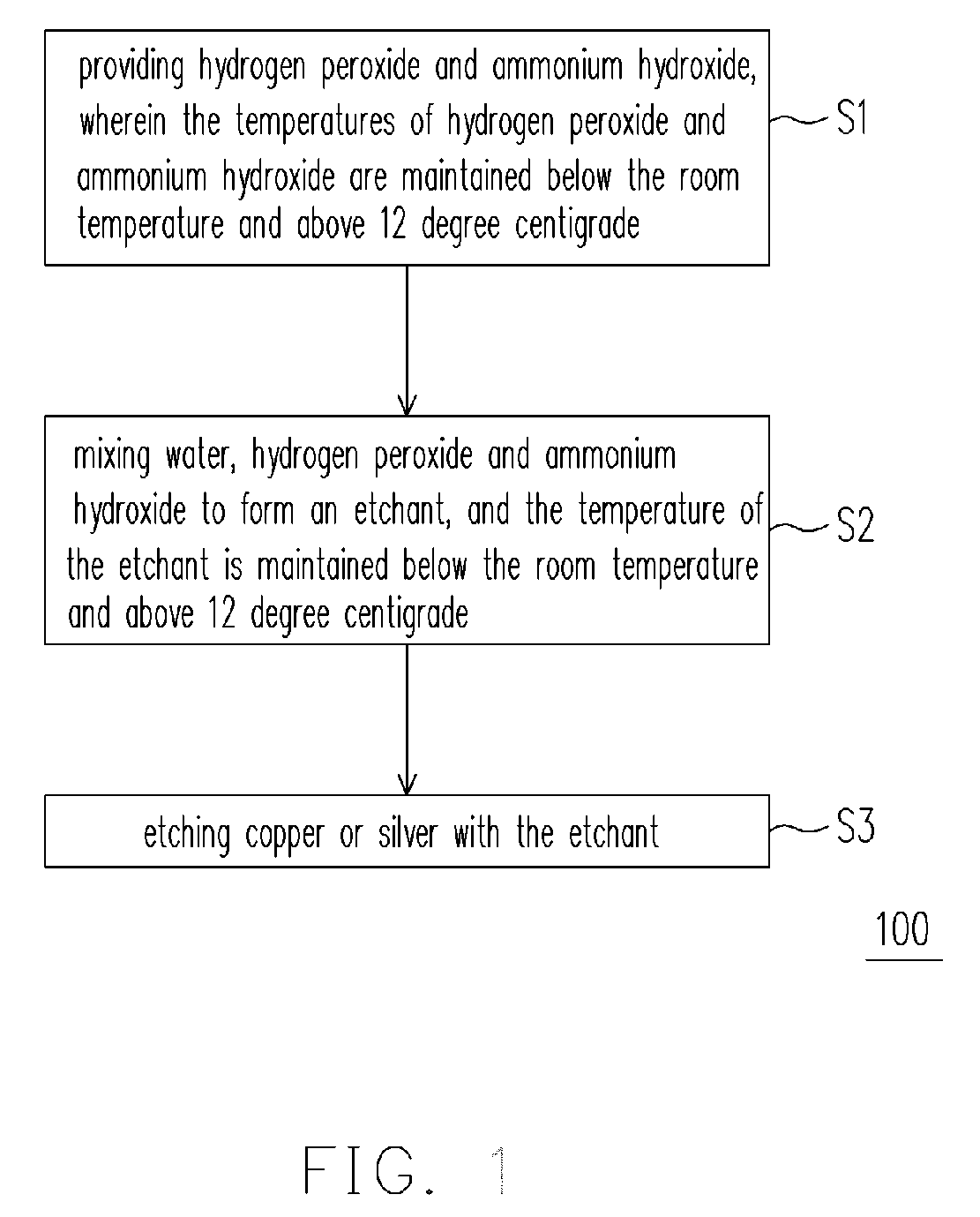

Etching apparatus

InactiveUS20070000609A1Decrease rate of vaporizationStable etch rateSemiconductor/solid-state device manufacturingPipingAmmonium hydroxide

An etching apparatus, for etching copper or silver, which includes a hydrogen peroxide tank, an ammonium hydroxide tank, a water tank, an etching tank, a piping system and a temperature control device, is provided. The piping system connects the hydrogen peroxide tank, the ammonium hydroxide tank, the water tank to the etching tank, and the temperature control device is disposed around the hydrogen peroxide tank, the ammonium hydroxide tank and the etching tank to maintain the temperatures of them below the room temperature and above 12 degree centigrade. An etching process is also provided. First, hydrogen peroxide and ammonium hydroxide having a temperature in a temperature-range below the room temperature and above 12 degree centigrade, is provided. Then, water, hydrogen peroxide and ammonium hydroxide are mixed to be an etchant with a temperature maintained in said temperature temperature-range. Next, the etchant is utilized for etching copper or silver.

Owner:TAI WEI JEN +3

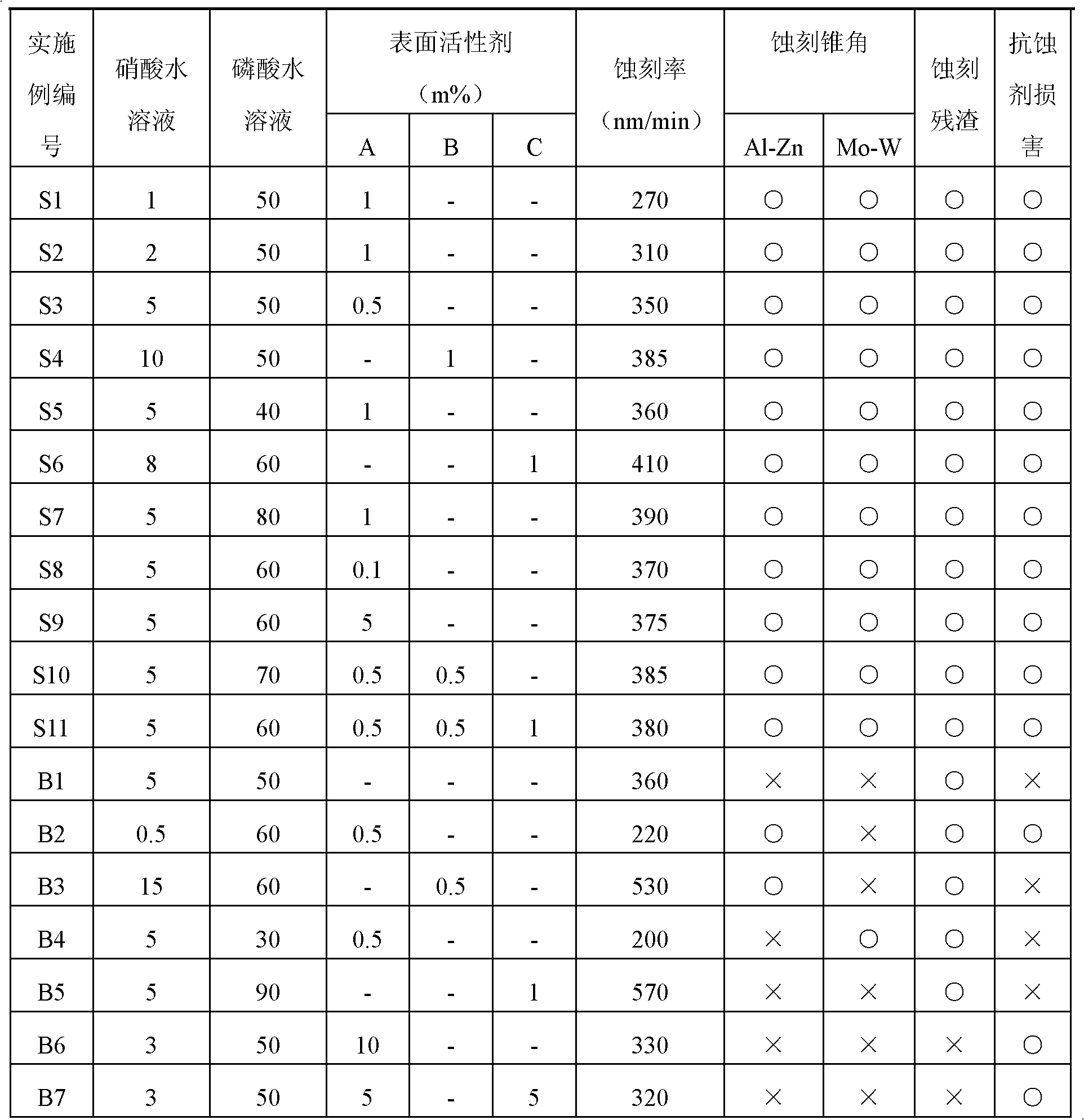

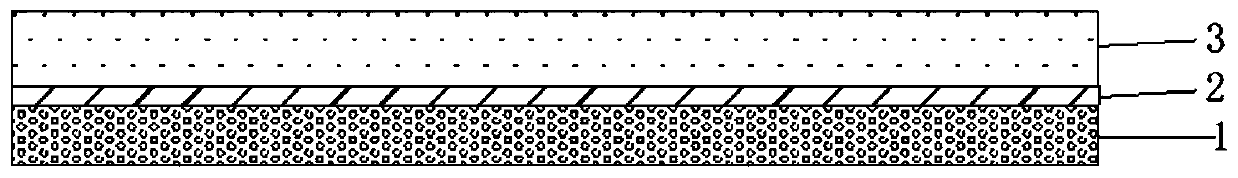

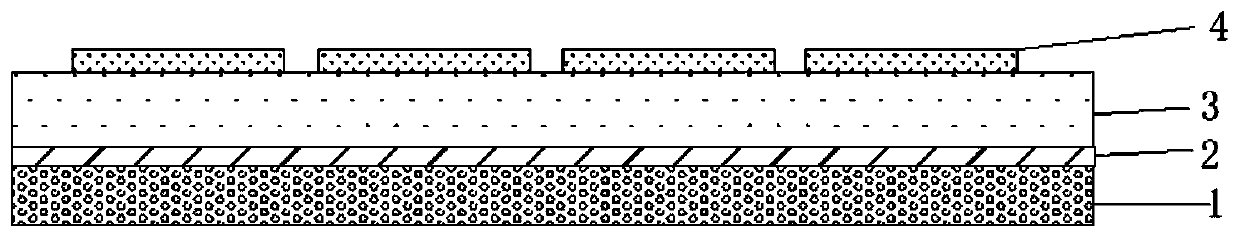

Etchant of molybdenum and/ or aluminum containing metal film for OLED (Organic Light Emitting Diode) and preparation method thereof

ActiveCN102392248BImprove solid-liquid interfacial tensionImprove wettabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhosphoric acidSURFACTANT BLEND

The invention discloses an etchant of a molybdenum and / or aluminum containing metal film for an OLED (Organic Light Emitting Diode) and a preparation method thereof. The etchant comprises nitric acid aqueous solution, phosphoric acid aqueous solution, betaine ampholytic surfactant and water, wherein the nitric acid aqueous solution accounts for 1-10%, preferably 2-8%, of the total weight of the etchant; the phosphoric acid aqueous solution accounts for 40-80%, preferably 50-70%, of the total weight of the etchant,; the betaine ampholytic surfactant accounts for 0.1-5%, preferably 0.5-2%, of the total weight of the etchant; and the balance is water. By the adoption of the etchant, solid liquid interface tension between the etchant and the metal film can be effectively improved, and the surface wettability of metal is improved. The etching speed is stabilized, and etching precision is improved; and more importantly, a taper angle can be effectively controlled to 20-70 degrees, and no etching residue is generated. The etchant has the advantages of high efficacy, high precision and important application value.

Owner:绵阳艾萨斯电子材料有限公司

Thinning etching solution additive for AMOLED substrate glass

The invention discloses an etching solution additive for AMOLED substrate glass thinning, which is composed of the following components according to weight percentage: 17-21% of hydrofluoric acid, 8-14% of phosphoric acid, 15-24% of nitric acid, and 7-7% of sodium hypochlorite 12%, brightener 6-13%, leveling agent 5-9%, surfactant 5-10%, solvent 38-54%. The etching solution prepared by the additive of the present invention has long service life and stable process; the etching solution prepared by the additive of the present invention, the etched plate surface is smooth and smooth, and no subsequent processing is required; the etching solution prepared by the additive of the present invention can stabilize the etching rate and improve the etching coefficient ratio and uniformity, and the addition of surfactants can increase the etching speed; effectively reduce the amount of hydrochloric acid used, which is beneficial to production efficiency in the process, and is economical and practical, the preparation method is simple, and no harmful gas is generated during the etching process.

Owner:HEFEI HUIKE JINYANG TECH

Etching liquid used for thick aluminum circuit board, and method

ActiveCN109788655AImprove linearityIncrease etch factorConductive material chemical/electrolytical removalAluminium chlorideAluminum Ion

The invention provides etching liquid used for a thick aluminum circuit board, and a method. The etching liquid comprises the following main ingredients: concentrated hydrochloric acid, acetic acid, hydrofluoric acid and the balance of aluminum ions. The method specifically comprises the following steps that: laminating one surface of an aluminum foil with one layer of protection film, and laminating the other surface of the aluminum foil with a dry film; according to a preset condition, carrying out selective exposure on different positions of the dry film, removing the dry films on unexposedpositions to expose the aluminum foils under the dry films; and dissolving through the etching liquid to remove the exposed aluminum foils, and removing the dry films on the aluminum foils to obtainthe etched thick aluminum circuit board which needs to be prepared. By use of the etching liquid formed by hydrochloric acid, phosphoric acid, acetic acid and hydrofluoric acid at a certain ratio, thick aluminum etching can be realized, in addition, the acetic acid and the phosphoric acid added in the etching liquid can effectively improve the linearity of the circuit, the etching factor of the circuit is improved through the added hydrofluoric acid, an etching rate is stabilized through added aluminum chloride or dissolved aluminum, and therefore, thick aluminum etching meets use requirements.

Owner:MFLEX YANCHENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com