Method for manufacturing semiconductor substrate, solar semiconductor substrate, and etching liquid

A manufacturing method and semiconductor technology, applied in the field of etching solution, can solve the problems of environmental safety, uneven shape and size of waste liquid treatment, etc., and achieve the effects of excellent photoelectric conversion efficiency, excellent stability and stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

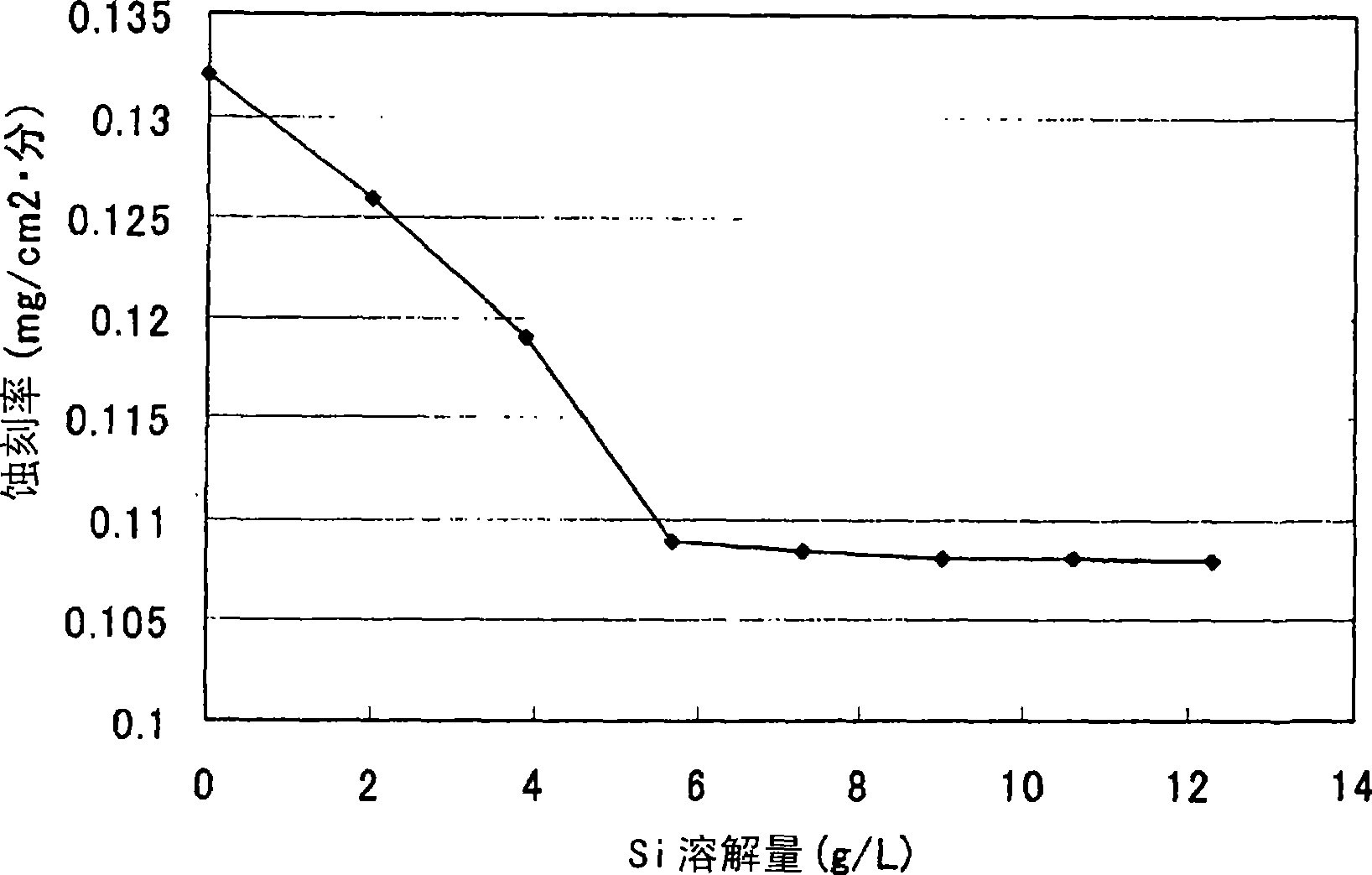

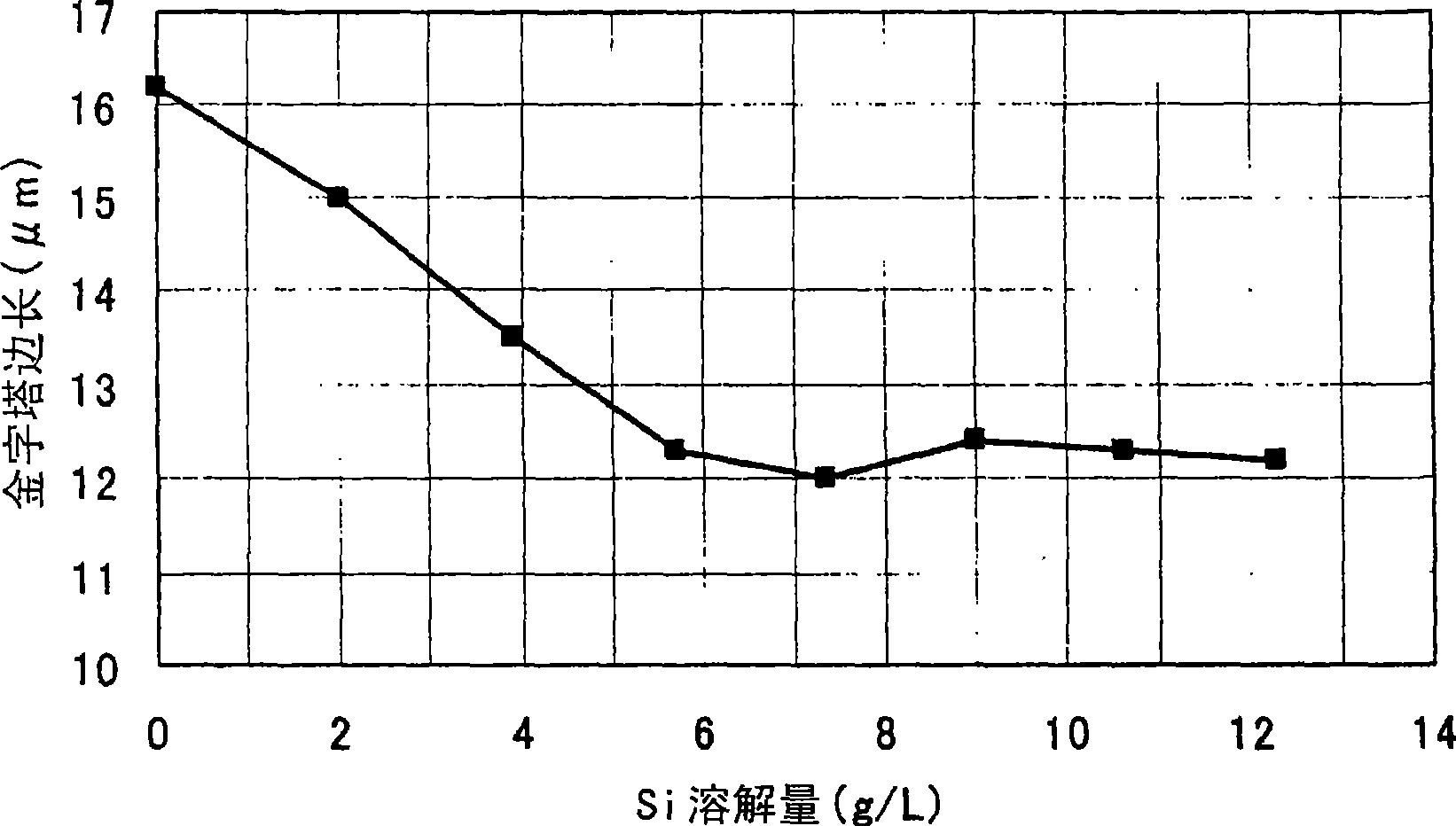

[0059] The etching solution is used to add 50g / L (0.43mol / L) hexanoic acid and a prescribed amount of potassium silicate (dissolved silicon: 0, 2.0, 3.9, 5.7, 7.3, 9.0, 10.6 Or 12.3g / L) etching solution, after immersing a single crystal silicon substrate (a square with a side of 126mm and a thickness of 200μm) with a (100) plane on the surface at 90°C for 30 minutes, the silicon substrate after the etching treatment was detected The dissolution loss, calculate the etch rate. In addition, the surface of the etched substrate was observed with a scanning electron microscope to detect the side length of the pyramid. In addition, here, the pyramid side length is the concavo-convex structure with a unit area of 265 μm × 200 μm, select 10 places from the larger one in order, detect the side lengths of the bottom surfaces of these pyramid structures, and take the average value of the side lengths ( the maximum side length of the base).

[0060] figure 1 It is a graph of the relat...

experiment example 2

[0063] Except that the concentration of the KOH aqueous solution was changed to 12.5% by weight, the same experiment as in Experimental Example 1 was carried out to calculate the etching rate, and the same result as in Experimental Example 1 was obtained.

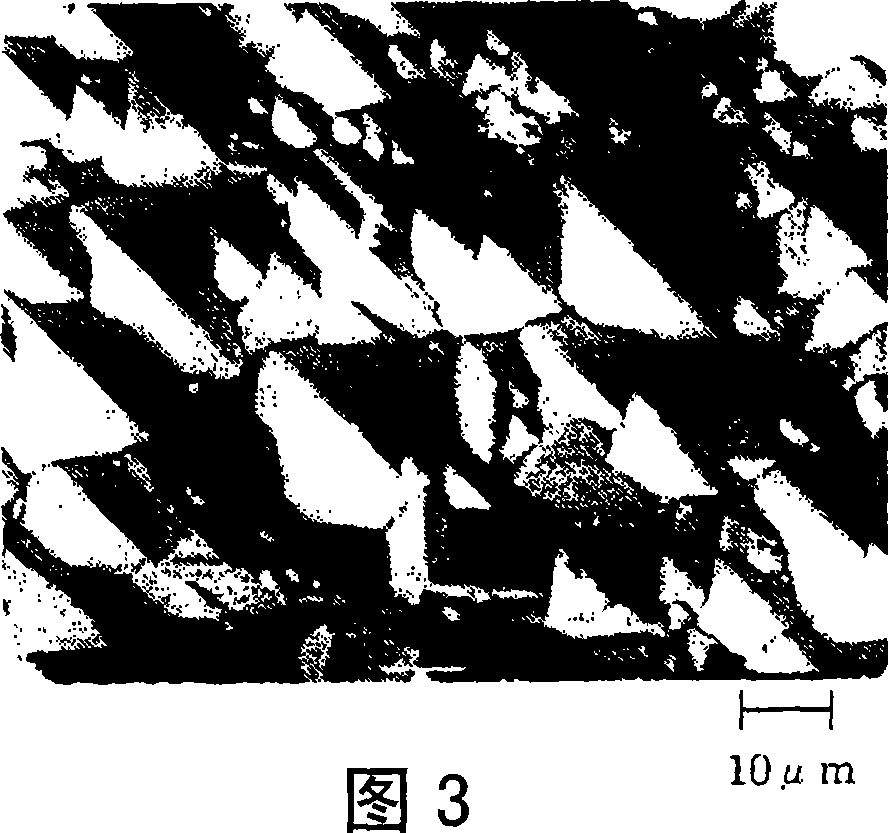

[0064] In addition, when the silicon dissolution amount was 5.7 g / L, the surface of the substrate after the etching treatment was observed with a scanning electron microscope, and the side length of the pyramid was detected, and the side length of the pyramid was 10 μm. The scanning electron microscope photo (magnification: 500 times) as Figure 7 shown.

experiment example 3

[0066] Except having used the etchant which added 50 g / L (0.35 mol / L) of octanoic acid instead of hexanoic acid, the same experiment as Experimental example 1 was implemented, and the etch rate was calculated. The result is as Figure 8 shown. like Figure 8 It was shown that the etching rate was stabilized by dissolving silicon in an alkaline solution to which octanoic acid was added.

[0067] In addition, when the silicon dissolution amount was 5.7 g / L, the etched substrate surface was observed with a scanning electron microscope, and the pyramid side length was detected, and the pyramid side length was 15 μm. Its scanning electron microscope photo (magnification: 500 times) such as Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com