TFT (thin film transistor) glass substrate reducer, preparation method thereof and TFT glass substrate reducing process

A glass substrate and thinning liquid technology, applied in TFT glass substrate thinning liquid and its preparation, TFT glass substrate thinning technology field, can solve the problems of adhesion to the pipe groove wall, high risk, high cost of waste liquid treatment, etc. , to meet the effect of thinning quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

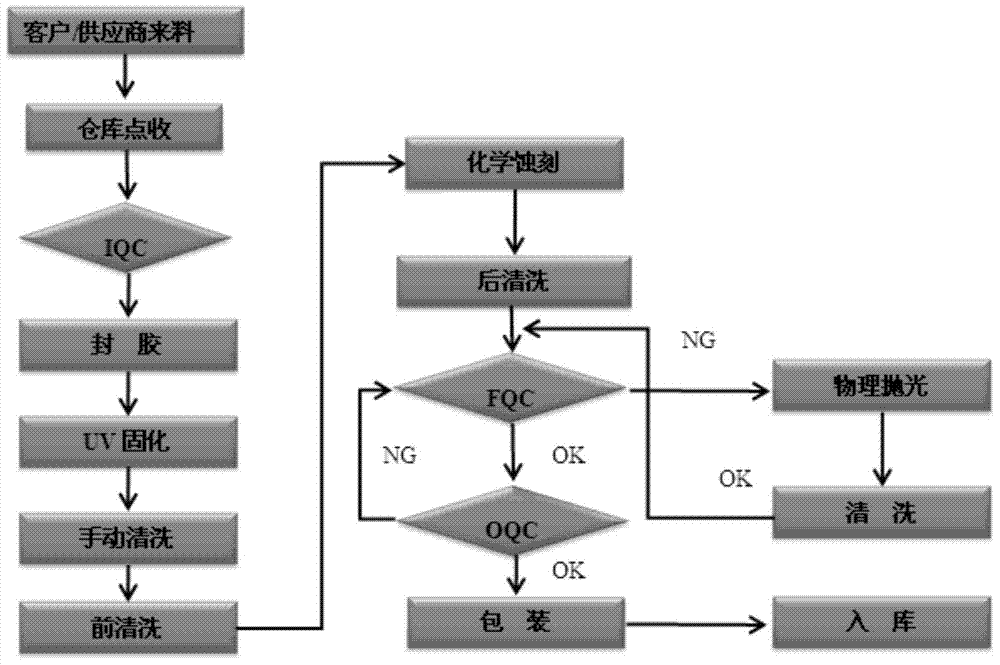

Image

Examples

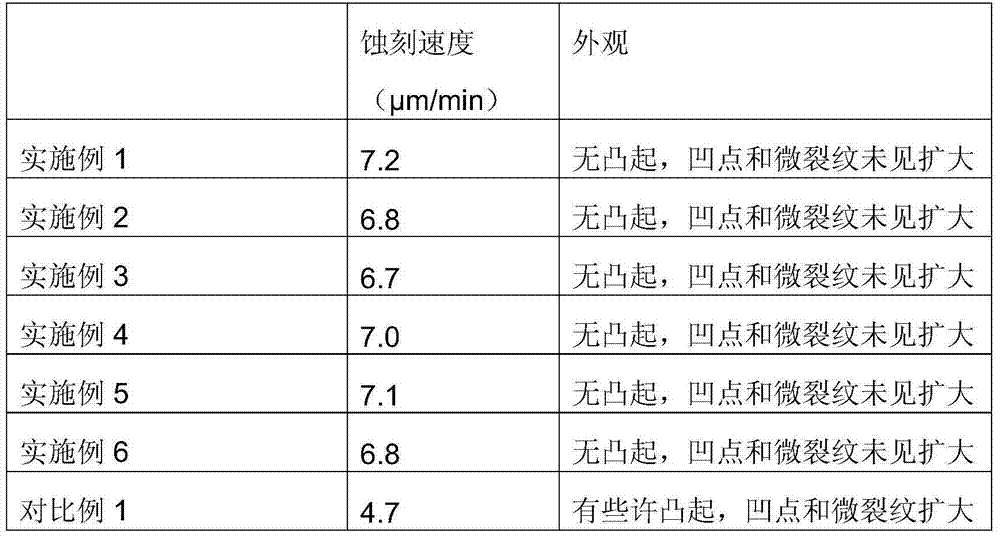

Embodiment 1

[0042] A TFT glass substrate thinning solution, according to mass percentage, its components include:

[0043] Hydrofluoric acid 10%,

[0044] Ammonium bifluoride 5%,

[0045] Nitric acid 8%,

[0046] Sulfuric acid 8%,

[0047] Ultrapure water 69%.

[0048] Add the ultrapure water, hydrofluoric acid, ammonium bifluoride, nitric acid, and sulfuric acid in the formula to the acid mixing container and mix them in sequence. After stirring and dispersing with a mixer at a stirring speed of 120r / min~200r / min for 40~60min, you can get Finished TFT glass substrate thinning solution.

Embodiment 2

[0050] The difference between this embodiment and the embodiment is that the components of the TFT glass substrate thinning solution include:

[0051] Hydrofluoric acid 12%,

[0052] Ammonium bifluoride 4%,

[0053] Nitric acid 7%,

[0054] Sulfuric acid 5%,

[0055] Ultrapure water 72%.

Embodiment 3

[0057] The difference between this embodiment and the embodiment is that the components of the TFT glass substrate thinning solution include:

[0058] Hydrofluoric acid 11%,

[0059] Ammonium bifluoride 6%,

[0060] Nitric acid 8%,

[0061] Sulfuric acid 5%,

[0062] Ultrapure water 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com