Etching agent, etching method and etching agent preparation liquid

An etchant and aqueous solution technology, which is applied in the field of etchant for titanium-based metals, can solve the problems of shortened solution life and high copper leaching, and achieve the effects of stable etching rate, prolonging solution life, and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

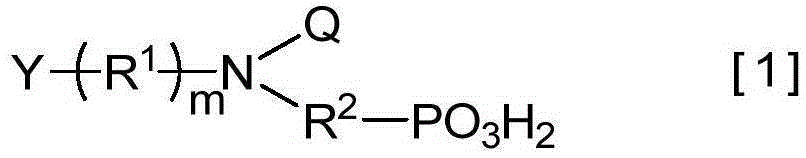

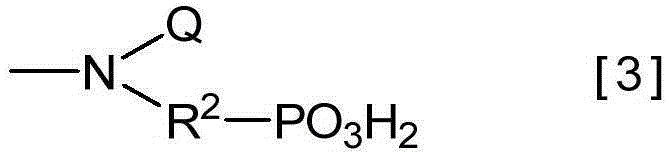

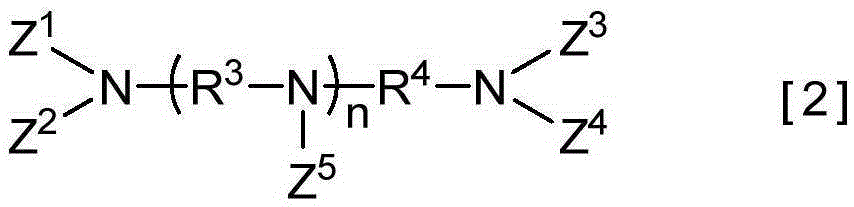

[0080] As long as the preparation method of the etchant of the present invention is capable of preparing (A) hydrogen peroxide, (B) a phosphonic acid chelating agent having a nitrogen atom in the structure, (C) an alkali metal hydroxide and (D) having at least 1 Hydroxyl and at least 3 carboxyl organic acids, and (E) pH regulators and (F) aqueous solutions of surfactants used as needed, the preparation method itself is not particularly limited. Specific examples of the preparation method include, for example, the following method: adding (B) a phosphonic acid-based chelating agent having a nitrogen atom in the structure, (C) an alkali metal hydroxide, and (D) having After the organic acid having at least 1 hydroxyl group and at least 3 carboxyl groups, if necessary, add (F) surfactant, and further add (E) pH adjuster to adjust pH if necessary, and then stir to form a uniform aqueous solution. The etchant of the present invention thus prepared may be subjected to filtration tre...

Embodiment 1

[0116] Embodiment 1 Preparation-1 of etchant of the present invention

[0117] Hydrogen peroxide (manufactured by Wako Pure Chemical Industries, Ltd.), diethylenetriaminepenta(methylenephosphonic acid) 7 sodium salt (32 % aqueous solution) (manufactured by Italmatch Japan Co., Ltd.), potassium hydroxide (manufactured by Wako Pure Chemical Industries, Ltd.), and citric acid (manufactured by Komatsuya Co., Ltd.), were stirred appropriately to obtain the etchant of the present invention. The obtained etchant had a pH of 9.0. This etchant was referred to as etchant 1.

experiment example 1~3

[0125] Experimental example 1-3 Immersion test of etchant 1-3

[0126] Each etchant obtained in Example 1 and Comparative Examples 1-2 was filled in a polypropylene container, and a 1 cm x 2 cm titanium plate (manufactured by RAREMETALLIC) and a 2 cm x 2 cm titanium plate were placed in the etchant heated to 40° C. One copper plate (manufactured by Rare Metallic Co., Ltd.) of 2 cm was dipped simultaneously for 300 minutes. During etching, 100 μL for metal content analysis and 100 μL for hydrogen peroxide analysis were sampled at predetermined intervals (30, 60, 180, and 300 minutes).

[0127] Each etchant sampled for metal content analysis was diluted 100 times with 1% nitric acid aqueous solution, and metal titanium and metal copper were measured using a plasma emission spectrometer (device name: ICP-AESSPS-3100; manufactured by SII Corporation). content. The dissolved amounts of metal titanium and metal copper per unit area of the titanium plate and the copper plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com