Patents

Literature

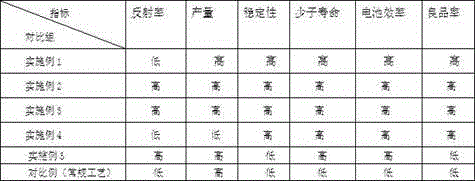

34results about How to "Etch stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

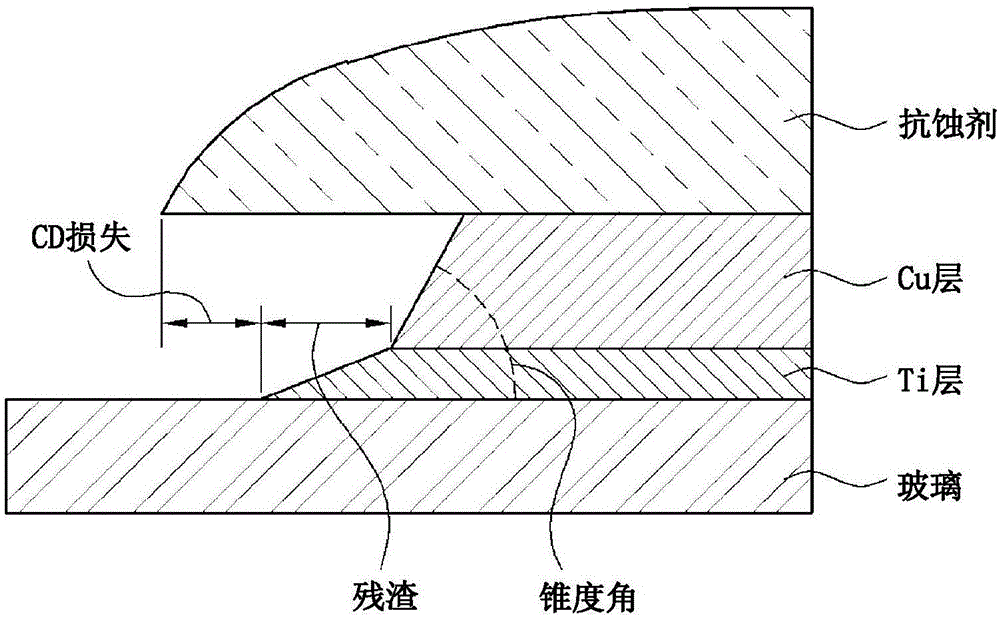

Novel TFT copper-molybdenum laminated film etching liquid composition and etching method

The invention discloses a novel TFT copper-molybdenum laminated film etching liquid composition. The composition is prepared from the following components in percentage by weight: 5-30% of hydrogen peroxide, 0.1-5% of H2SO4, persulfide, chloride, 0.05-0.3% of a hydrogen peroxide stabilizer, 0.005-0.3% of a metal complexing agent, 0.005-0.2% of a surface active agent, 0.001-1% of imidazole additive as well as the balance of water, wherein the persulfide and the chloride are 0.01-0.5% in total in percentage by weight. The novel TFT copper-molybdenum laminated film etching liquid composition is uniform in copper-molybdenum laminated film etching, moderate in etching rate and long in service life.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Etching method and etching polishing liquid

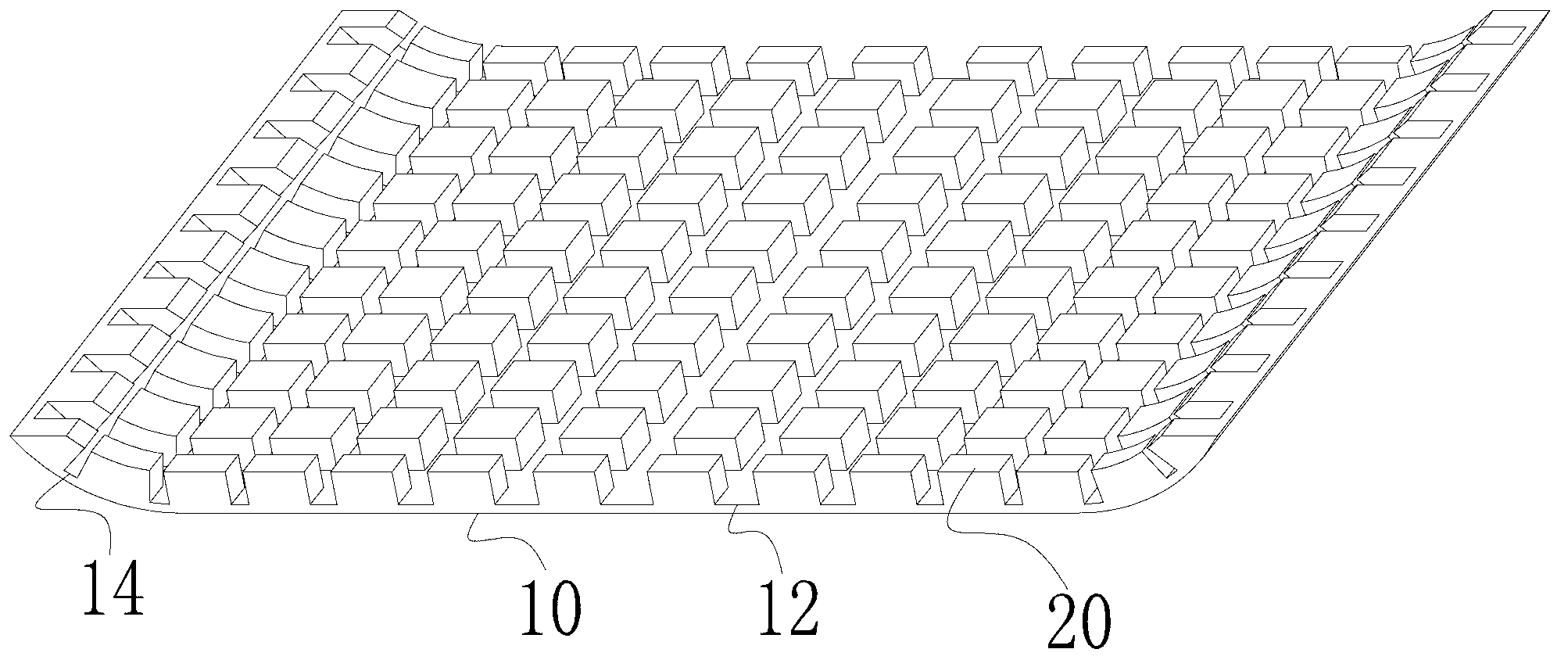

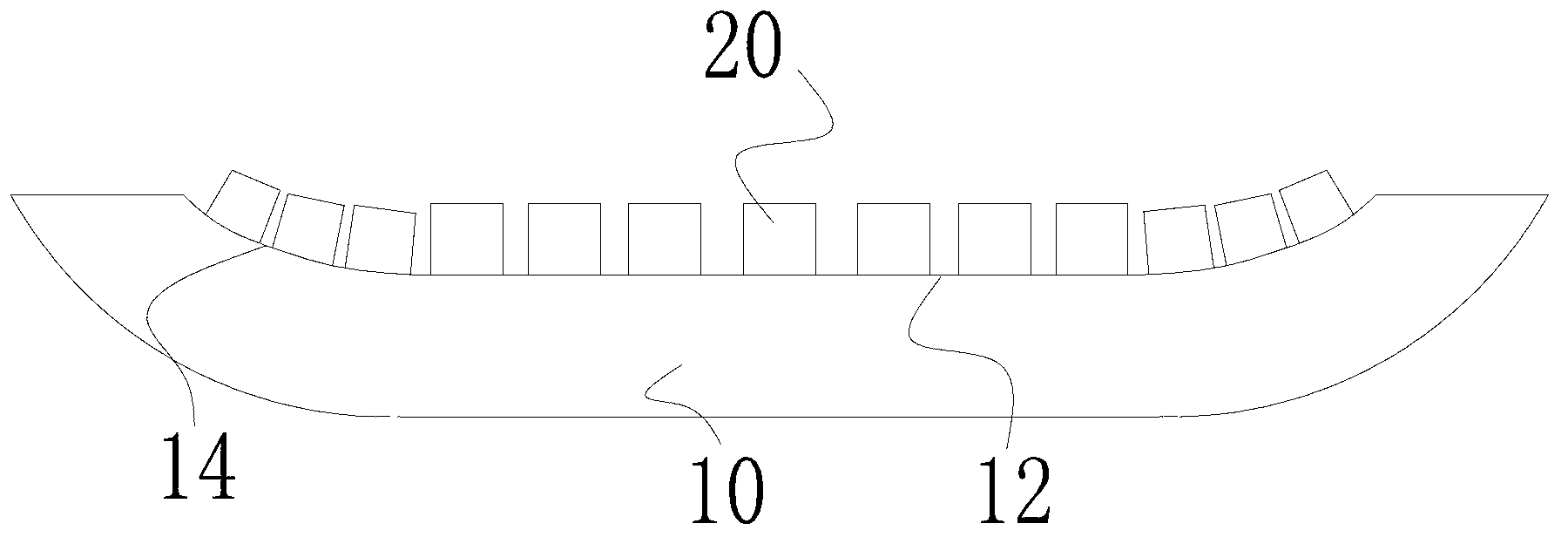

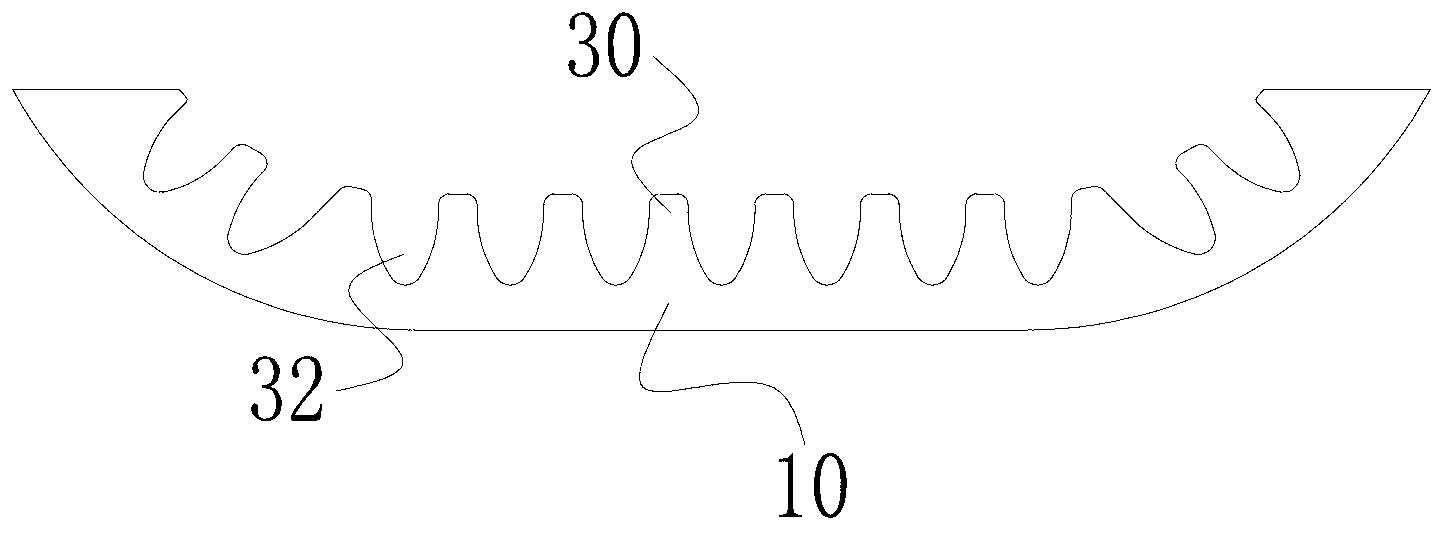

The invention discloses a method for etching a flat surface of a metal product and a curved surface connected with the flat surface. According to the method, a concavo-convex continuous microstructure is formed in the surface of the metal product by controlling the size of mask blocks and mask gap on the flat surface and the curved surface of the metal product and controlling related process parameters such as etching time, etching pressure and the like in an etching process; the depth of each pit is gradually reduced from the center of the flat surface to the edge of the curved surface; the section of the pit is shaped like a trough arc of sine wave; each projection does not have an obvious edge; the adaption part of the projection is in smooth transition; the section of the projection is similar to a quadrangular shape; the whole structure is in gentle transition; the microstructure takes on gradual transition connection of from existence to null and has good visual and tactile effects; and the requirements on higher anti-skid performance and attractive appearance can be met.

Owner:GUANGDONG UNIV OF TECH

Etching agent, etching method and etching agent preparation liquid

ActiveCN105378901AAvoid decompositionSolution to short lifeSemiconductor/solid-state device manufacturingDecompositionNuclear chemistry

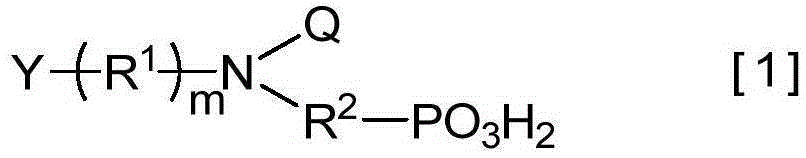

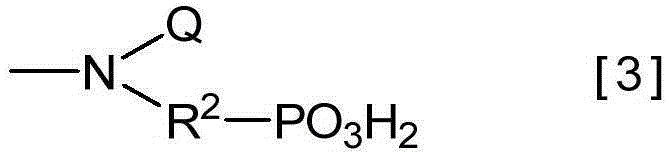

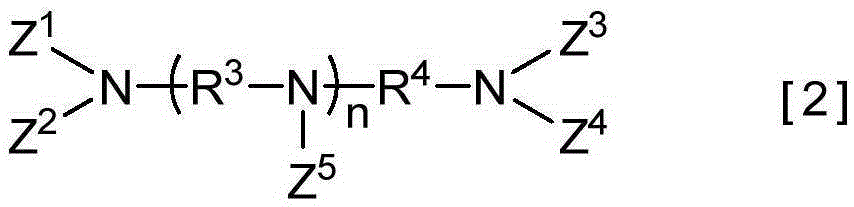

The objective of the present invention is to provide: an etching agent for a titanium-based metal on a semiconductor substrate, which is suppressed in decomposition of hydrogen peroxide, has a long service life, and has less need for control of the hydrogen peroxide concentration in the etching agent even in cases where the etching agent is used for a semiconductor substrate that has a titanium-based metal and copper metal or a copper alloy; an etching method; and an etching agent preparation liquid which is mixed with hydrogen peroxide for use. The present invention relates to: an etching agent for a titanium-based metal on a semiconductor substrate which has the titanium-based metal and copper metal or a copper alloy arranged on top of the titanium-based metal, said etching agent being an aqueous solution that contains at least (A) hydrogen peroxide, (B) a phosphonic acid-based chelating agent having a nitrogen atom in the structure, (C) an alkali metal hydroxide and (D) an organic acid having at least one hydroxyl group and at least three carboxyl groups; an etching method which is characterized by using this etching agent; and an etching agent preparation liquid which is mixed with hydrogen peroxide for use.

Owner:FUJIFILM CORP

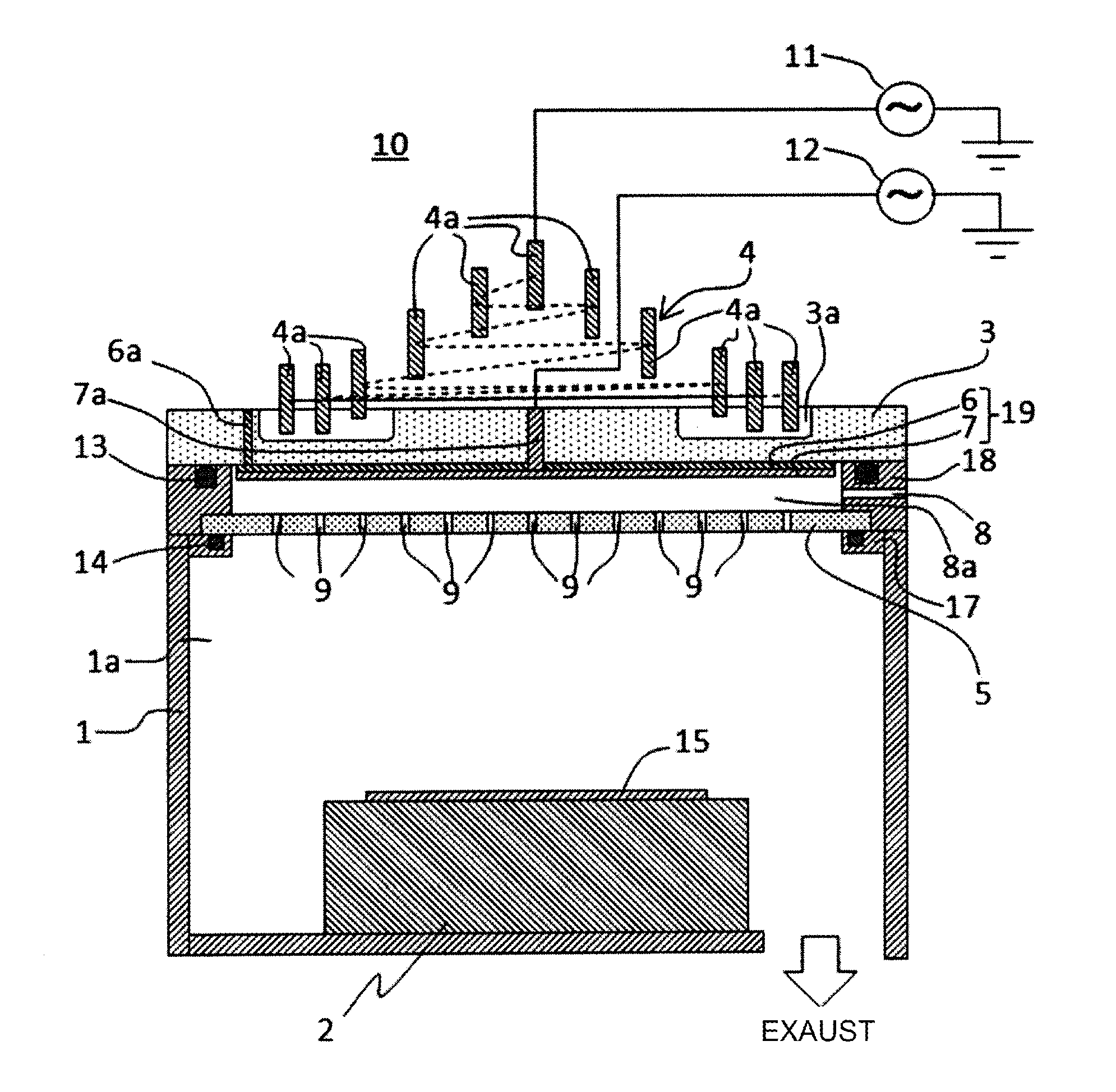

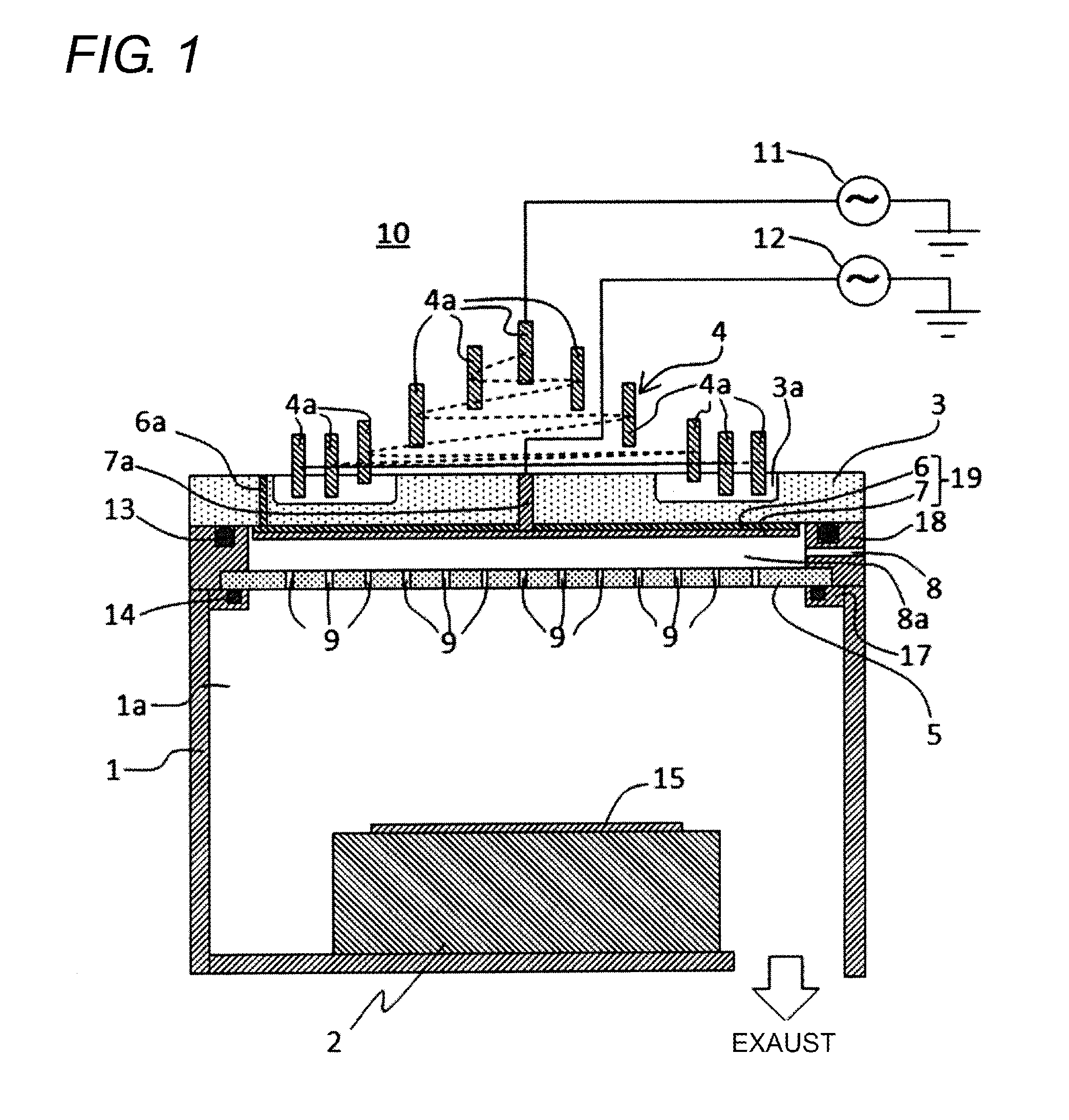

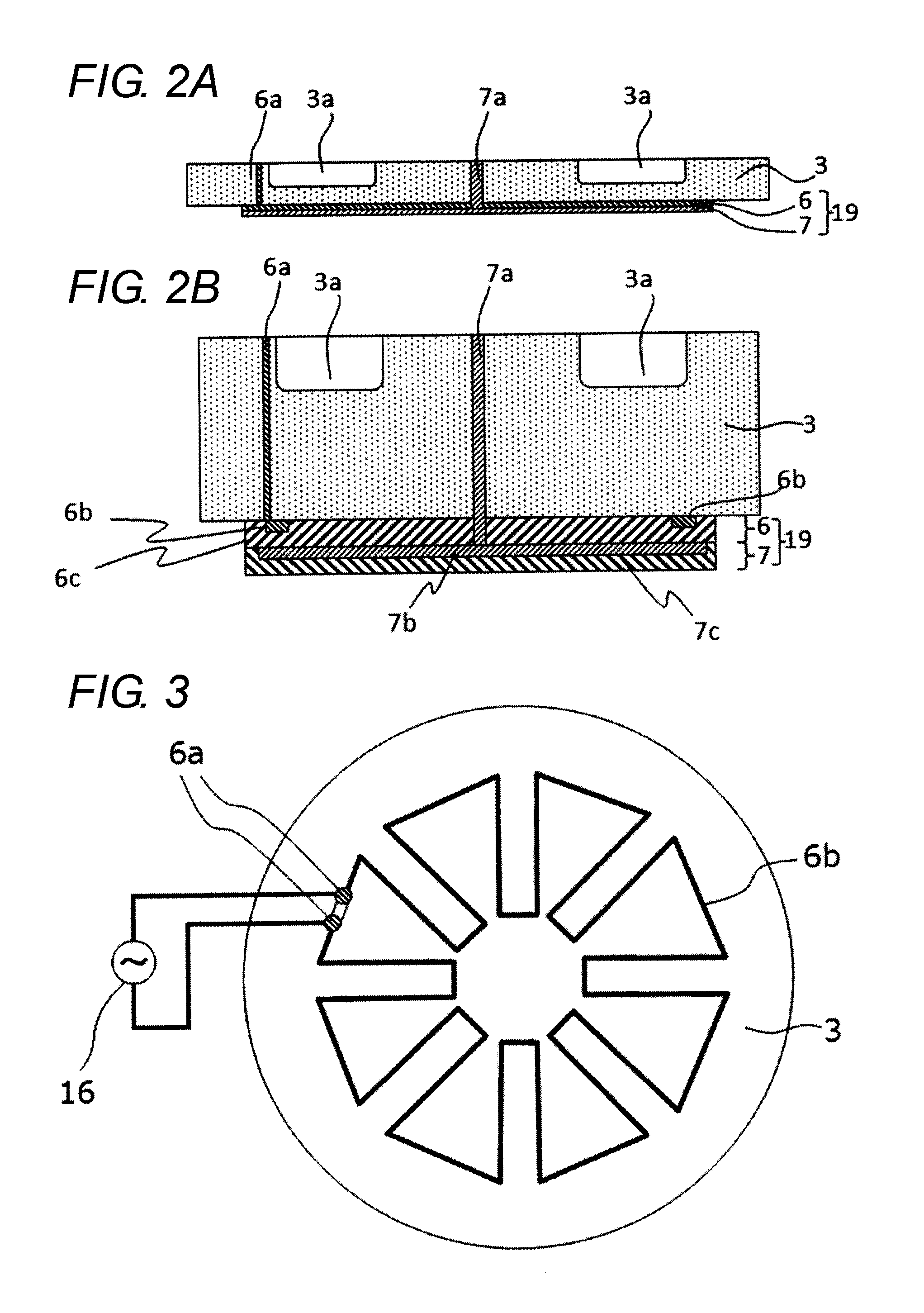

Plasma processing apparatus

InactiveUS20160118284A1Avoid stickingEtch stableElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricEngineering

A plasma processing apparatus includes: a vessel which includes a reaction chamber, atmosphere within the reaction chamber capable of being depressurized; a lower electrode which supports an object to be processed within the reaction chamber; a dielectric member which comprises a first surface and a second surface opposite to the first surface, and which closes an opening of the vessel such that the first surface opposes an outside of the reaction chamber and the second surface opposes the object to be processed; and a coil which opposes the first surface of the dielectric member, and which generates plasma within the reaction chamber. An electrode pattern and an insulation film which covers the electrode pattern are formed on the second surface of the dielectric member.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

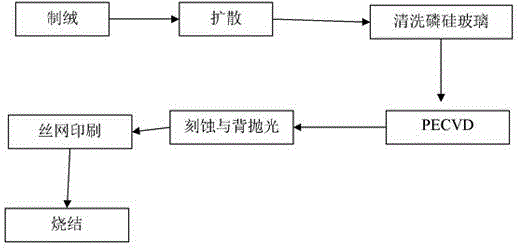

Solar cell production process

InactiveCN104966760AEtch stableEasy to polishFinal product manufactureSemiconductor/solid-state device manufacturingSilicon chipEtching

The invention discloses a solar cell production process including the steps of texturing, diffusion, phosphor silicon chip cleaning, silicon nitride plating, etching and back polishing, screen printing, and sintering. In the step of phosphor silicon chip cleaning, a mixed solution of HF or HF and HNO3, HCI is adopted; and in the step of etching and back polishing, a silicon chip is soaked in alkali lye having a concentration of 5-35%, and the back side of the silicon chip is etched and polished. The production process is stable, and is good in etching effect and good in polishing.

Owner:ZUNYI NORMAL COLLEGE

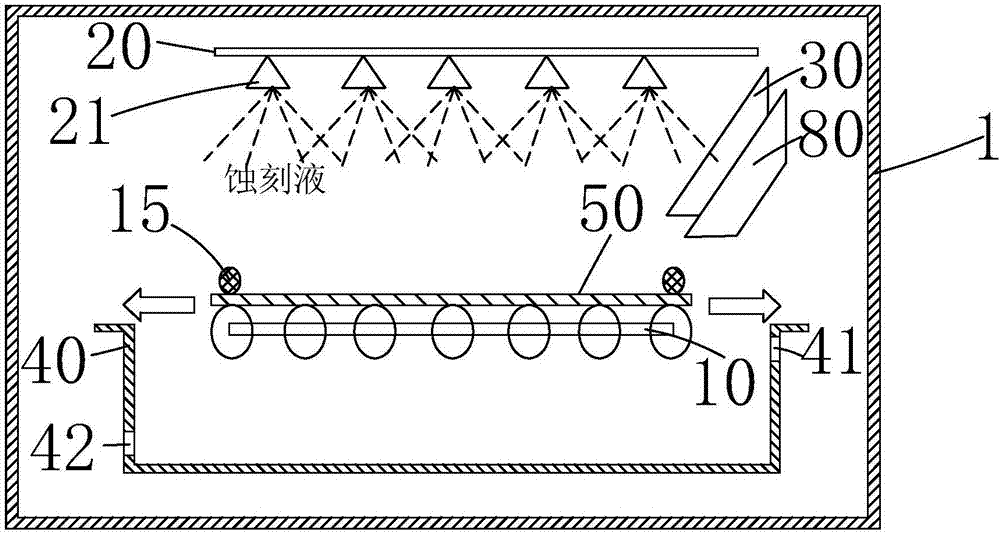

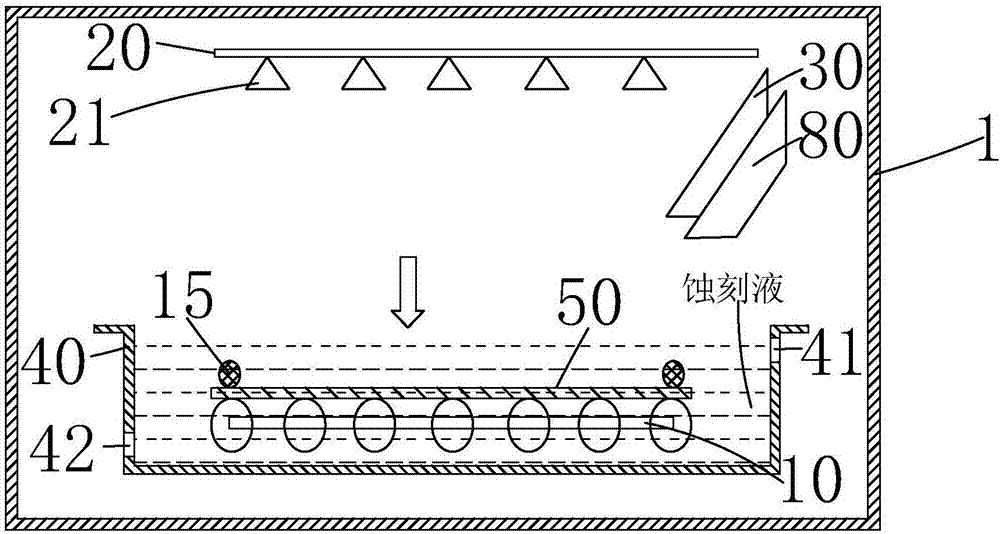

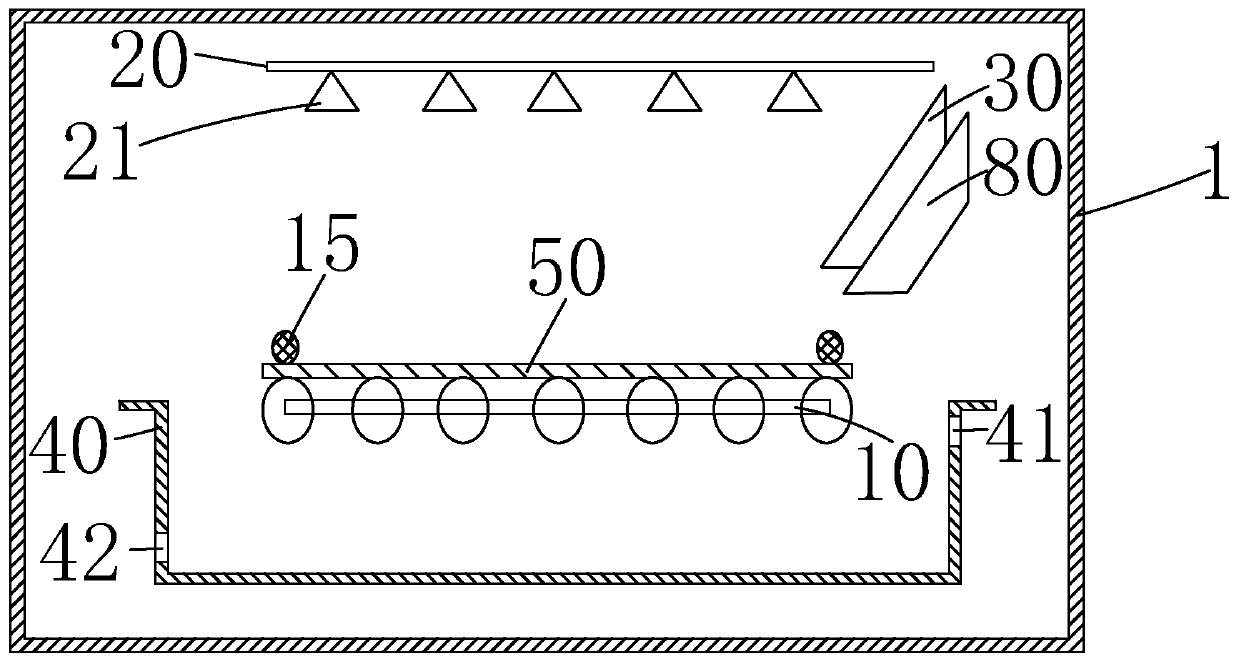

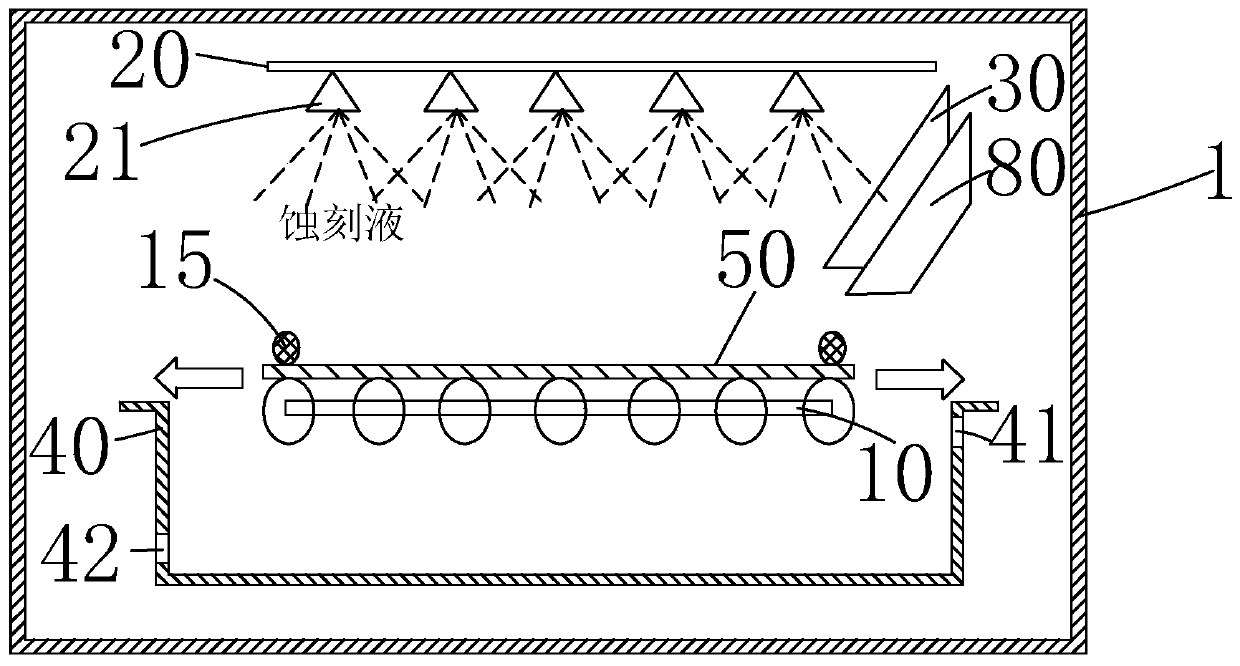

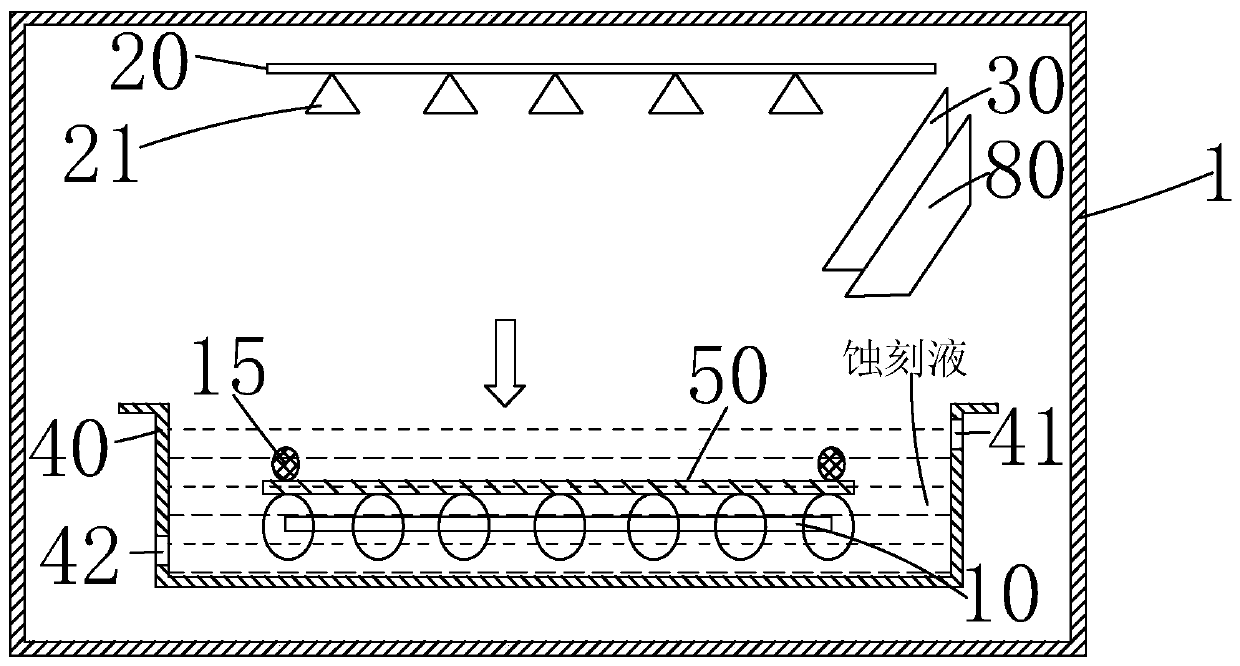

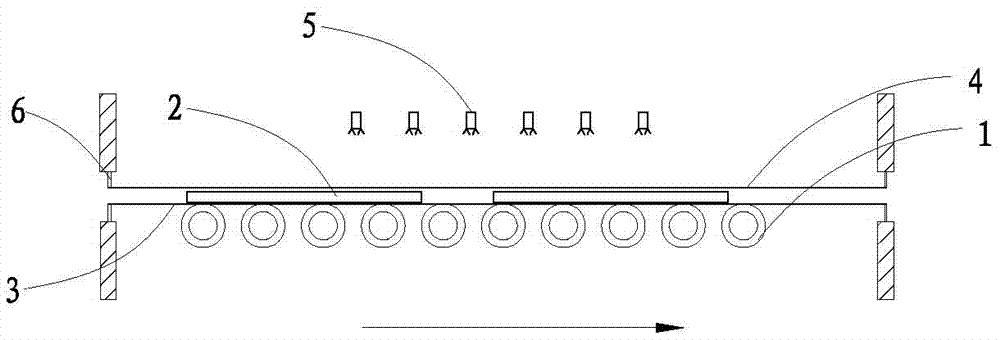

Wet etching equipment

ActiveCN107316826ASmall structureSmall footprintSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides wet etching equipment. The wet etching equipment comprises a bearing platform used for bearing a substrate, a spraying pipe which is arranged above the bearing platform for spraying an etching liquid to the surface of the substrate, a liquid knife which is arranged between the bearing platform and the spraying pipe and used for coating the surface of the substrate with the etching liquid, and an etching groove which is formed below the bearing platform and used for accommodating the etching liquid and the substrate; therefore, the three kinds of etching modes, including a spray mode, a dip mode and a puddle mode, can be integrated into the same etching unit, so that the machine table structure is reduced, the occupied space of the machine table is reduced, and the maintenance cost and time are lowered; and in addition, the substrate on the bearing platform moves along with the bearing platform in the etching process, without needing to transfer the substrate independently, so that the etching process is more stable, thereby reducing generation of mura.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

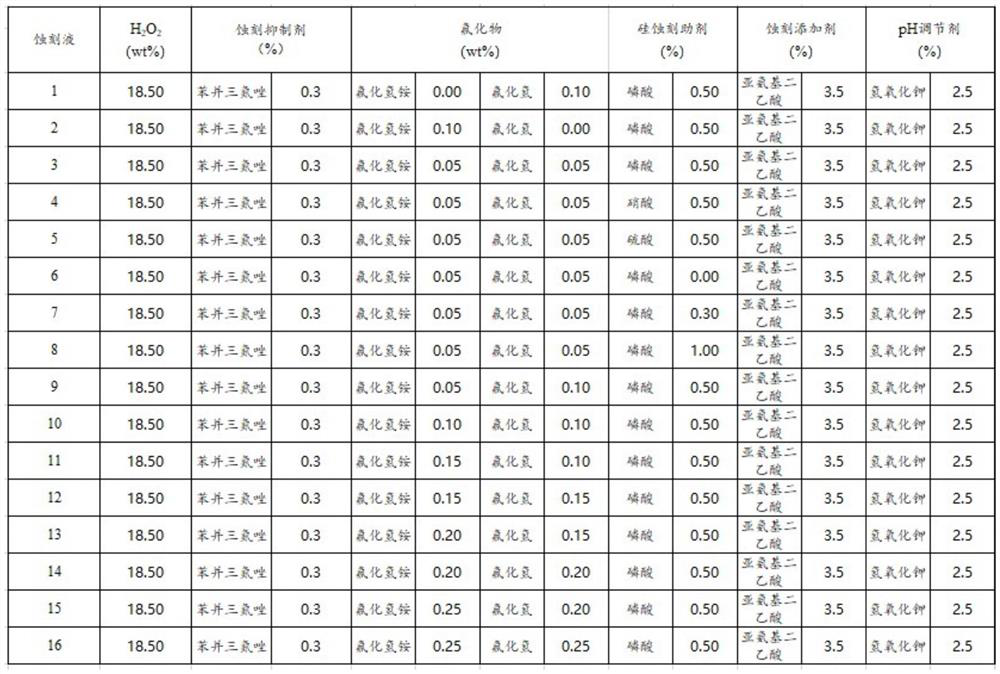

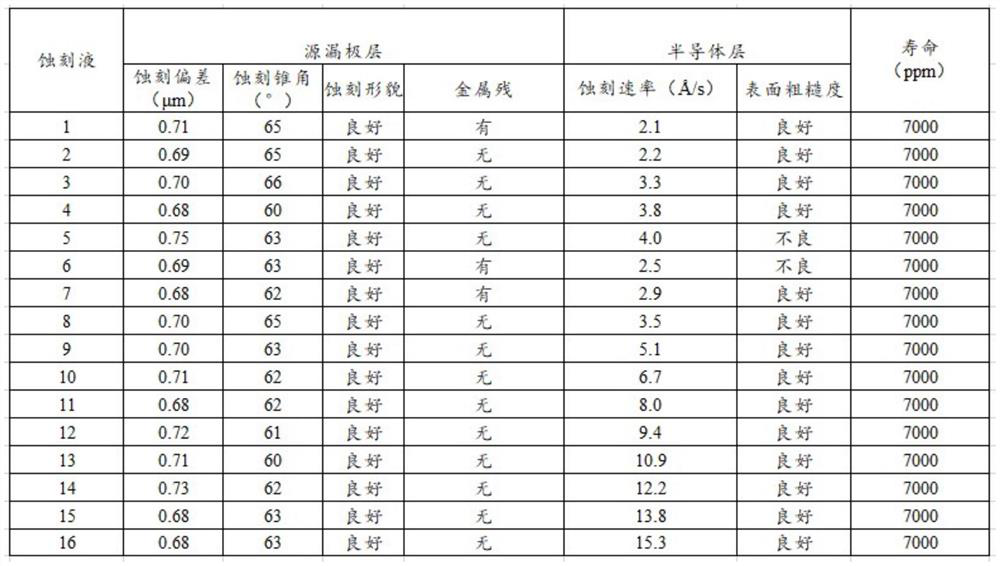

Etching solution composition and etching method for copper-molybdenum film layers

The invention discloses an etching solution composition and an etching method for copper-molybdenum film layers. The etching solution composition comprises hydrogen peroxide, a hydrogen peroxide stabilizer, an etching additive, a pH regulator and deionized water. The etching solution composition does not contain fluoride, so that the etching solution composition is friendly to production line operators and the environment, and the waste etching solution treatment cost is greatly reduced; and meanwhile, the etching requirements of current conventional copper / molybdenum film layers can be met, and the etching process is stable.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Etchant composition, method for etching multilayered film, and method for preparing display device

ActiveCN106795633APrevent or heatExtended replacement cycleSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidDisplay device

Disclosed are: an etchant composition comprising (A) a copper ion source, (B) a source of an organic acid ion having one or more carboxyl groups in a molecule, (C) a fluoride ion source, (D) an etching controller, a surface oxidizing power enhancer or a combination thereof as a first additive, and (E) a surfactant as a second additive; a method for etching a multilayered film; and a method for preparing a display device.

Owner:SAMYOUNG PURE CHEM +2

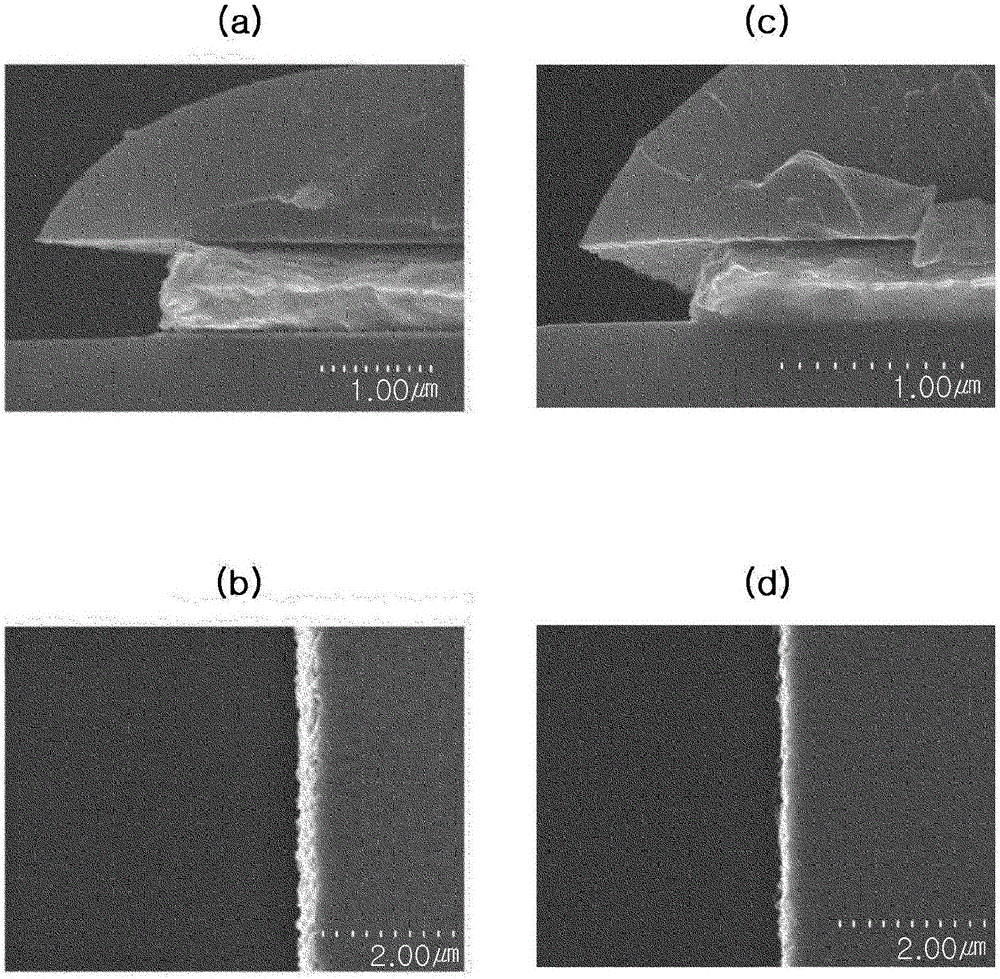

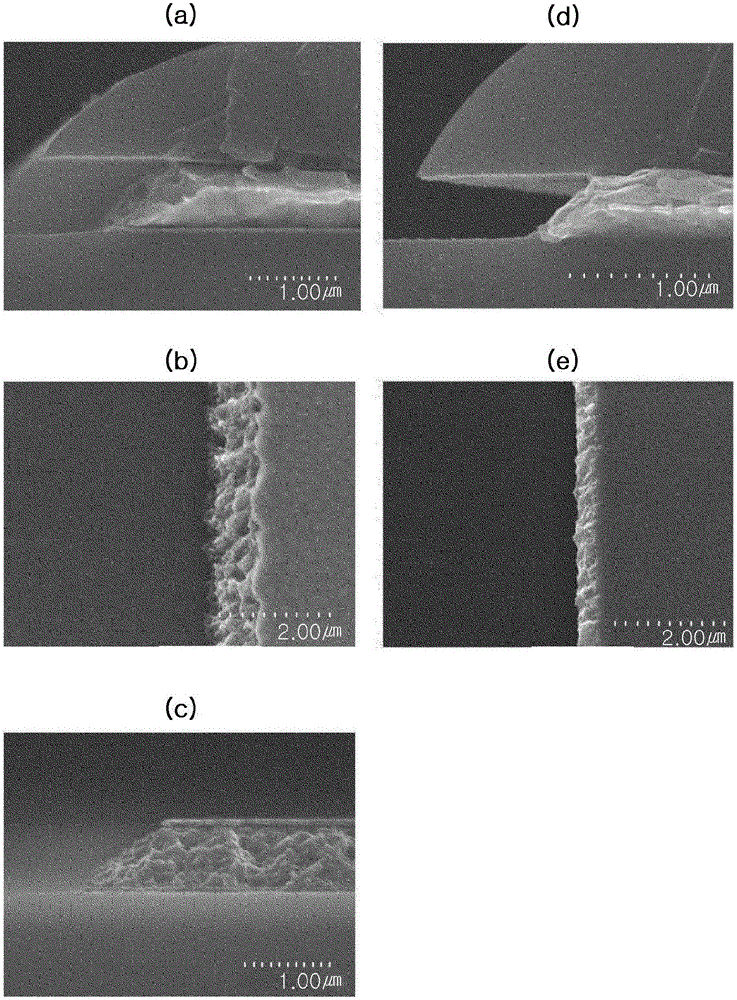

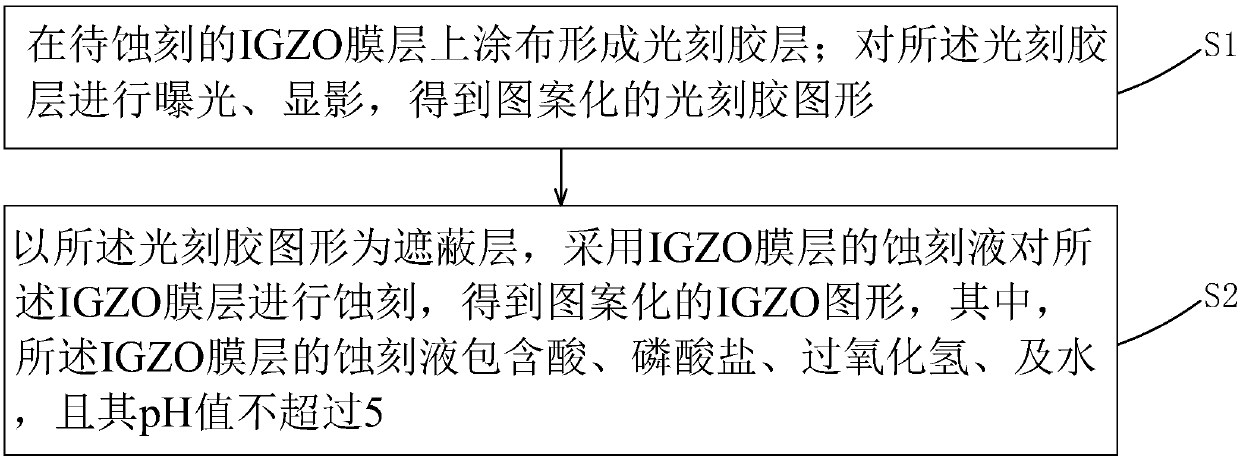

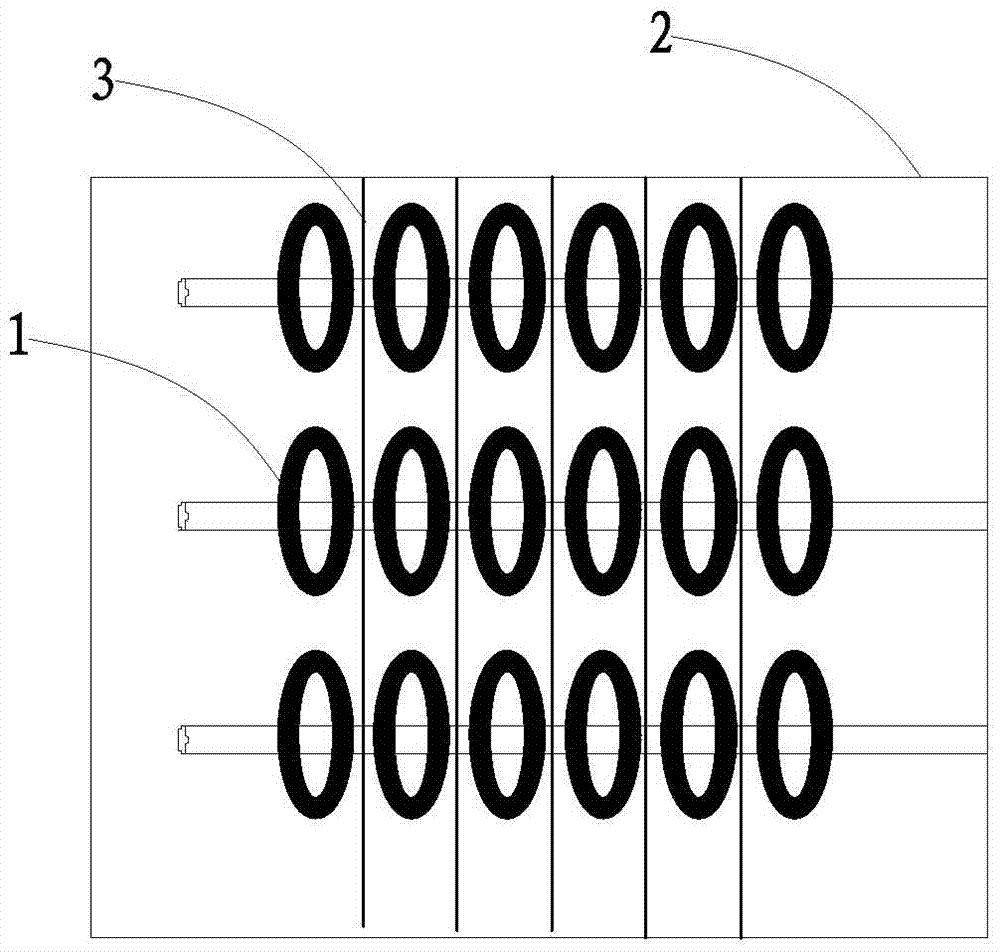

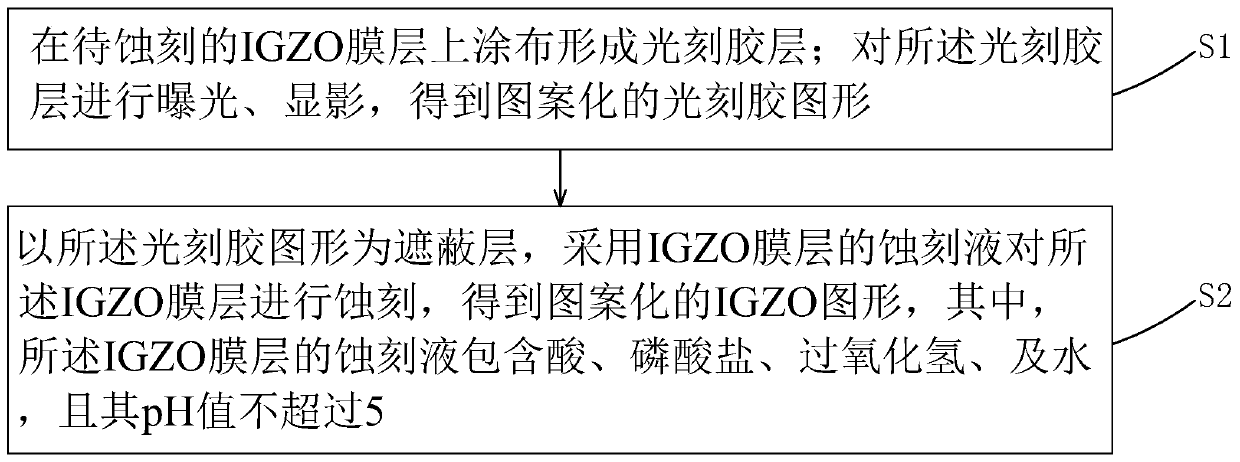

Etching solution for IGZO film and etching method thereof

ActiveCN107564809AEtch stableImprove stabilitySemiconductor/solid-state device manufacturingSurface treatment compositionsPhosphateIndium gallium zinc oxide

The invention provides an etching solution for an IGZO (Indium Gallium Zinc Oxide) film and an etching method thereof. The etching solution for the IGZO film comprises an acid, a phosphate, hydrogen peroxide and water, and the pH value of the etching solution is not more than 5. By adopting the etching solution, the etching rate can be effectively controlled, so that the etching rate is uniform; the IGZO film can be etched stably, and some impuritiesaffecting the electrical properties of the IGZO are not introduced at the same time, so that the stability of an IGZO-TFT (Thin Film Transistor) device can be effectively improved. The etching method for the IGZO film adopts the etching solution for the IGZO film. By adopting the etching method, the etching rate can be effectively controlled, so that the etching rate is uniform; the IGZO film can be etched stably, and some impuritiesaffecting the electrical properties of the IGZO are not introduced at the same time, so that the stability ofan IGZO-TFT device can be effectively improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Etching composition

ActiveCN1670624AEtch stableEtching speed is fastSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayTransparent conducting film

To provide an etching composition for a thin-film transistor liquid-crystal display device employed for selective etching of a transparent conductive film (such as an ITO film) of the thin-film transistor liquid-crystal display, the etching composition having a property of a low aging rate, minimizing the influence on other metal wirings so that a stable etching can be effected, and having a high etching rate and the capability of reducing side etching.

Owner:DONGJIN SEMICHEM CO LTD

Copper-aluminum film etching solution

ActiveCN112877695ALow in hydrogen peroxideImprove securityFinal product manufactureInorganic phosphateActive agent

The embodiment of the invention discloses a copper-aluminum film etching solution. The copper-aluminum film etching solution comprises the following components in percentage by weight relative to the total weight of the etching solution: 4%-10% of hydrogen peroxide, 0.1%-1% of a hydrogen peroxide stabilizer, 0.05%-0.5% of an etching inhibitor, 10%-30% of a chelating agent, 0.2%-2% of a surfactant, 0.2%-5% of inorganic phosphate or inorganic hydrophosphate, 0.1%-5% of inorganic acid, 0-0.05% of fluoride and the balance of deionized water. The etching solution provided by the invention has relatively long service life.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

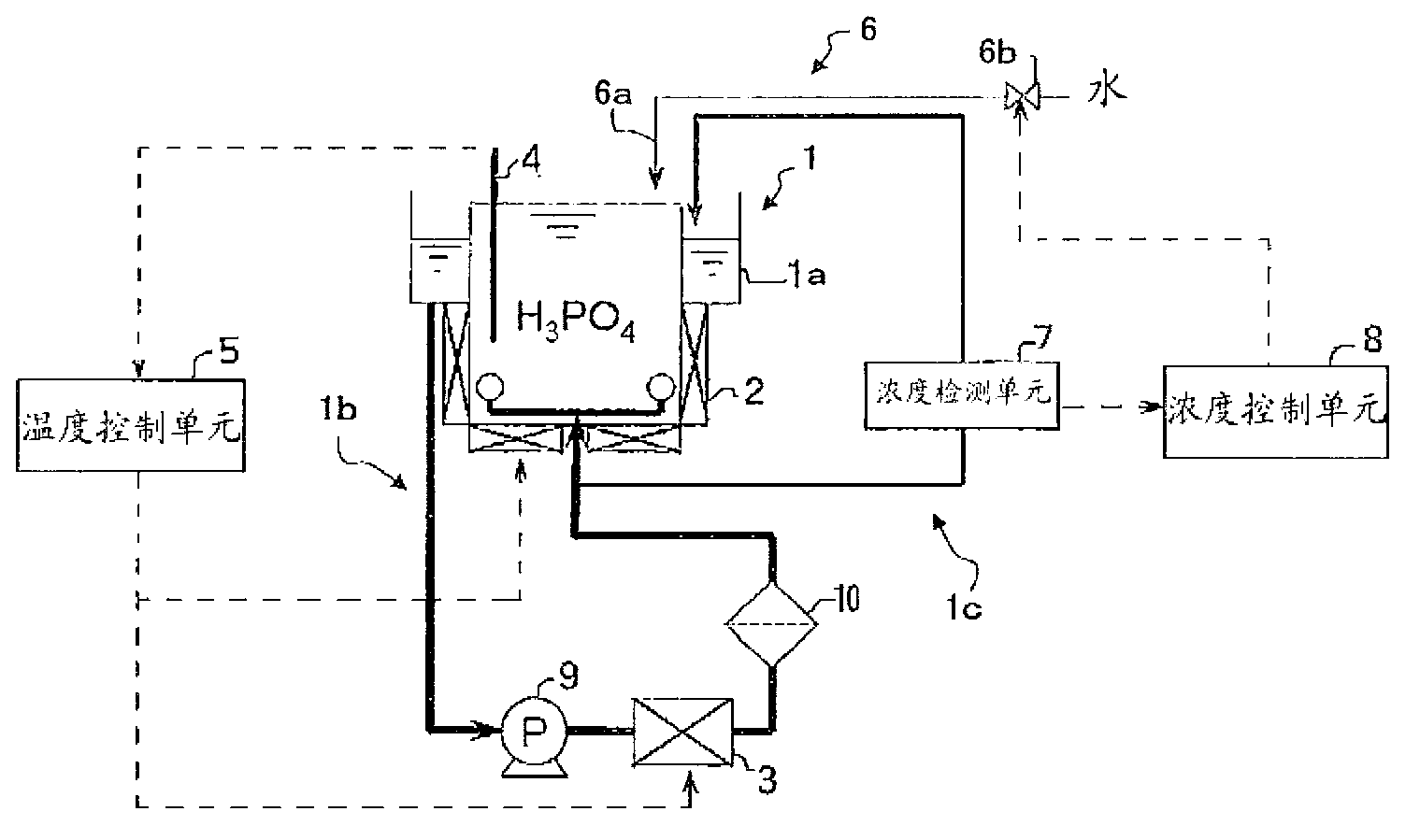

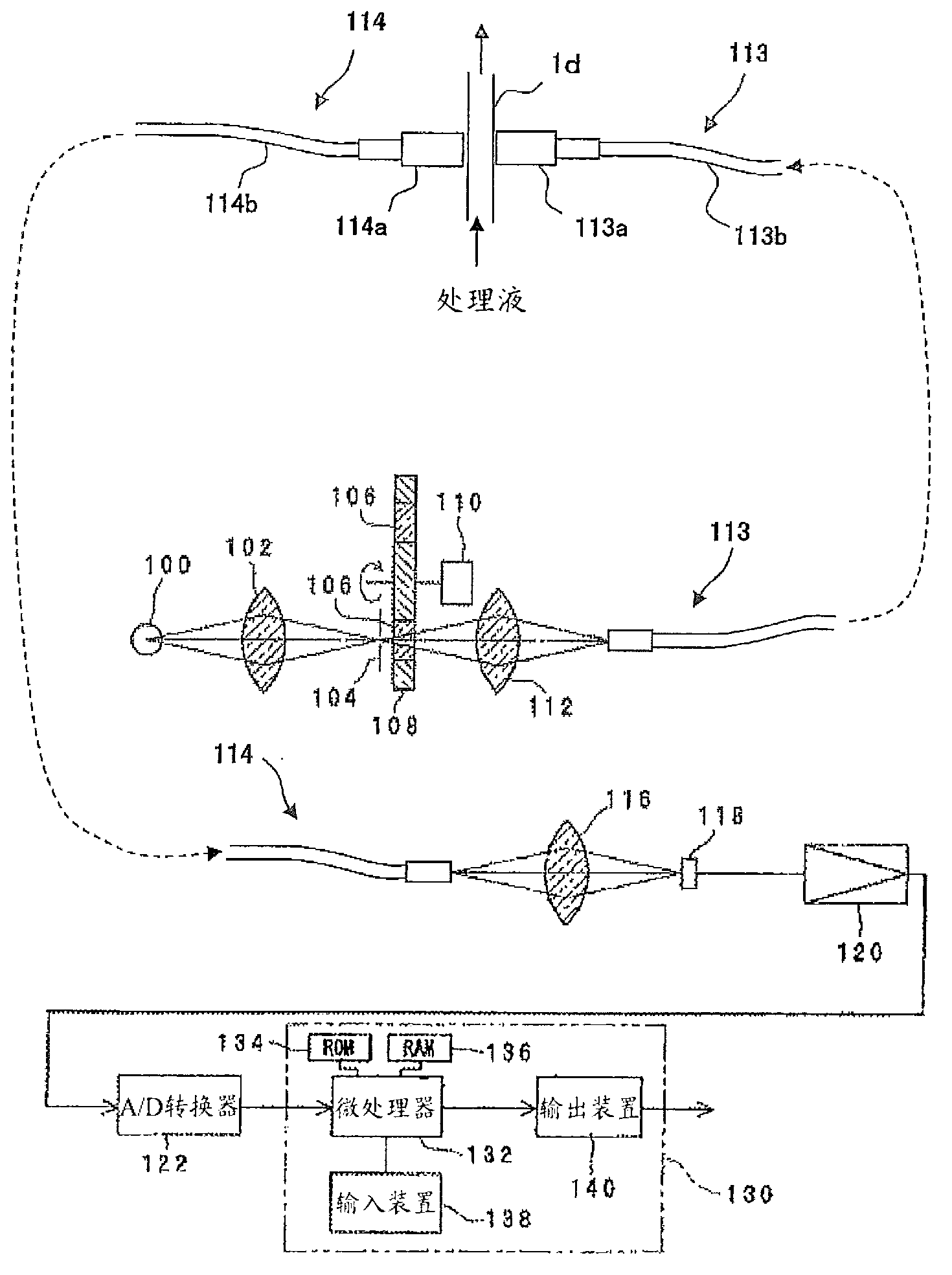

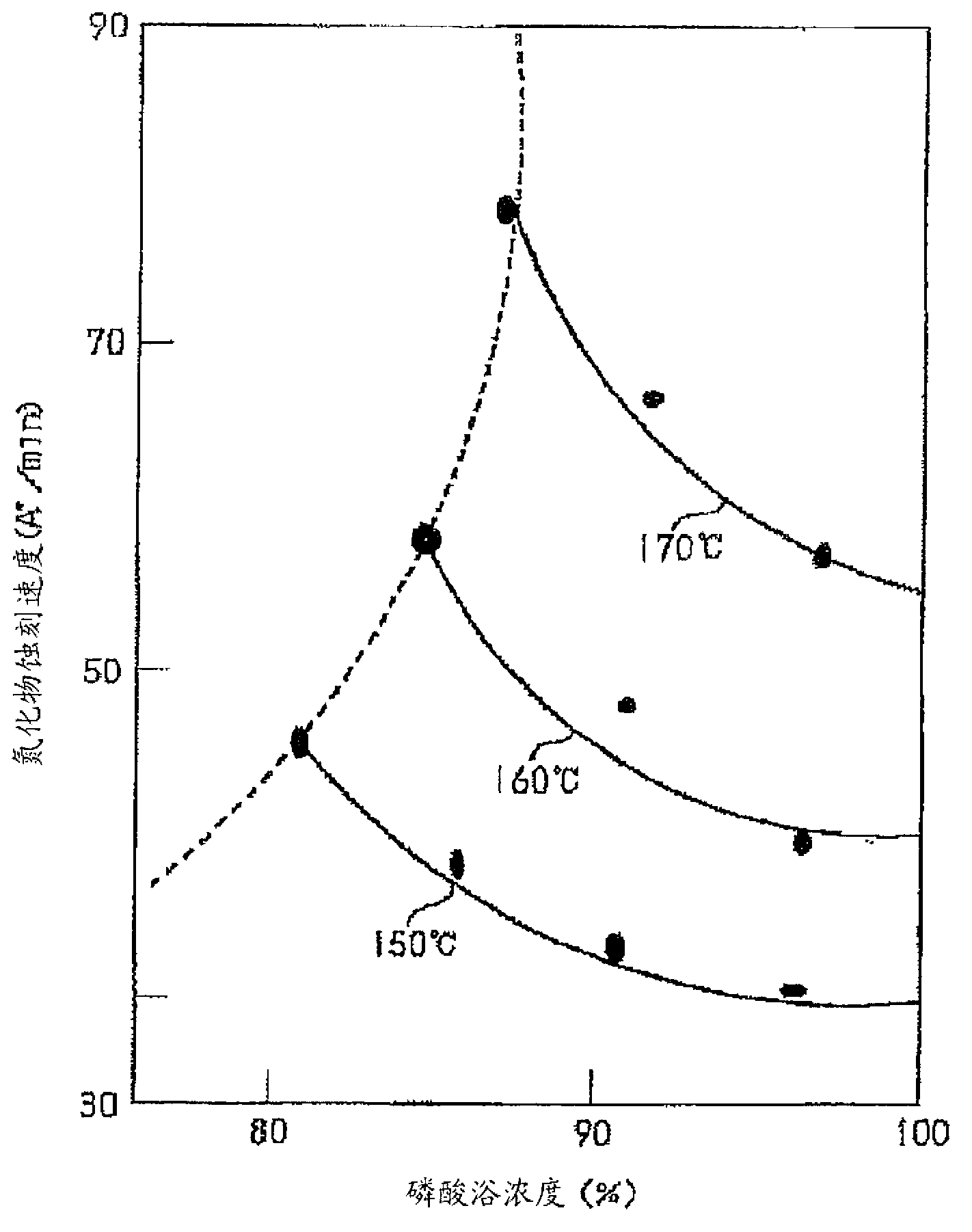

Substrate processing device

ActiveCN103155113AEtch stableReduce the amount of etchingDecorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Engineering

Disclosed is a substrate processing device that can directly detect the concentration of a processing liquid, and thus is able to perform independent concentration control mostly without being affected by the temperature of the processing liquid, and is able to accurately perform chemical processing of a substrate. The substrate processing device, which processes by immersing the substrate in the processing liquid comprising a mixture of a chemical and a diluting liquid, is provided with: a processing tank (1) that retains the processing liquid; heating means (2, 3) that heat the processing liquid; a temperature detection means (4) that detects the temperature of the processing liquid; a temperature control means (5) that operates the aforementioned heating means (2, 3) in a manner so that the detected temperature approaches a set temperature; a replenishing means (6) that replenishes the diluting liquid in the processing liquid; a concentration detection means (7) that detects the concentration of the processing liquid by measuring the light absorption characteristics of the processing liquid; and a concentration control means (8) that operates the aforementioned replenishing means (6) in a manner so that the detected concentration approaches a set concentration.

Owner:KURASHIKI BOSEKI KK +1

Copper-molybdenum metal etching solution and application thereof

The invention discloses a copper-molybdenum metal etching solution and application thereof. The copper-molybdenum metal etching solution comprises the following components in percentage by weight: 1-21wt% of hydrogen peroxide, 0.01-10 wt% of a shape control agent, 0.01-5 wt% of an etching stabilizer, 1-13 wt% of a chelating agent, 0.01-8 wt% of a pH regulator, 0.01-2.39 percent of an etching additive and the balance of deionized water. According to the copper-molybdenum metal etching solution disclosed by the invention, the consistent etching rate on a copper-molybdenum double-layer metal structure layer can be kept in the etching process, the defect of copper hollowing corrosion caused by oxidation-reduction potential difference of copper-molybdenum double-layer metal is overcome, and a copper-molybdenum metal structure layer meeting the requirements is prepared.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Etching solution for touch screen and preparation method thereof

InactiveCN104327857AAvoid it happening againReduce pollutionSurface treatment compositionsEtchingThiazole

The invention relates to the technical field of etching solutions and particularly relates to an etching solution for a touch screen and a preparation method thereof. Each liter of the etching solution consists of following raw materials: 180-220ml of hydrochloric acid, 5-20g of sodium dihydrogen phosphate, 70-90ml of hydrofluoric acid, 40-50ml of hydrogen peroxide, 3-7ml of 4-methyl-5-(2-acetoxylethyl)thiazole, 0.1-1ml of hexadecylpyridinium chloride and the balance water. In the invention, ferric trichloride is replaced by the hydrofluoric acid and the hydrogen peroxide so that the etching solution is free from being changed frequently, thereby not only saving resources but also reducing environmental pollution. Meanwhile, with addition of the hexadecylpyridinium chloride and the sodium dihydrogen phosphate having a slowly-releasing effect with combination of the hydrochloric acid, the hydrofluoric acid and the hydrogen peroxide, the etching solution is stable in etching, is moderated in etching, is uniform in etching, allows edges of the shape of an electrode to be tidy and is basically free of a side-erosion phenomenon.

Owner:JIANGXI PINGBO ELECTRONICS

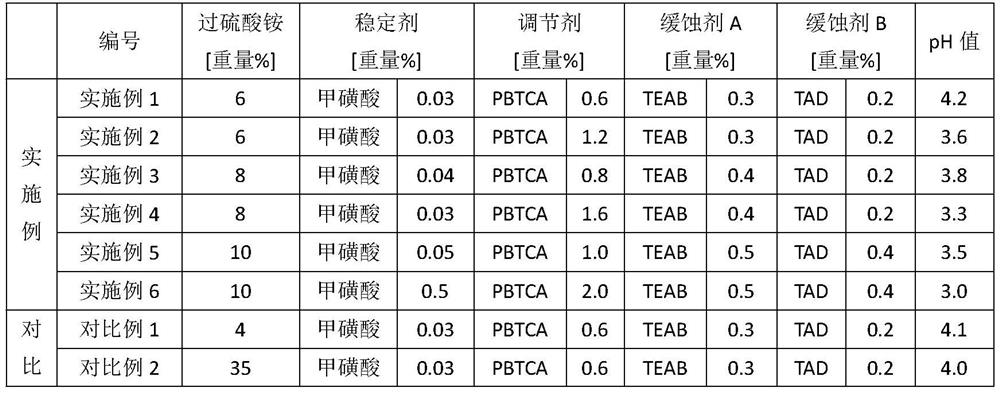

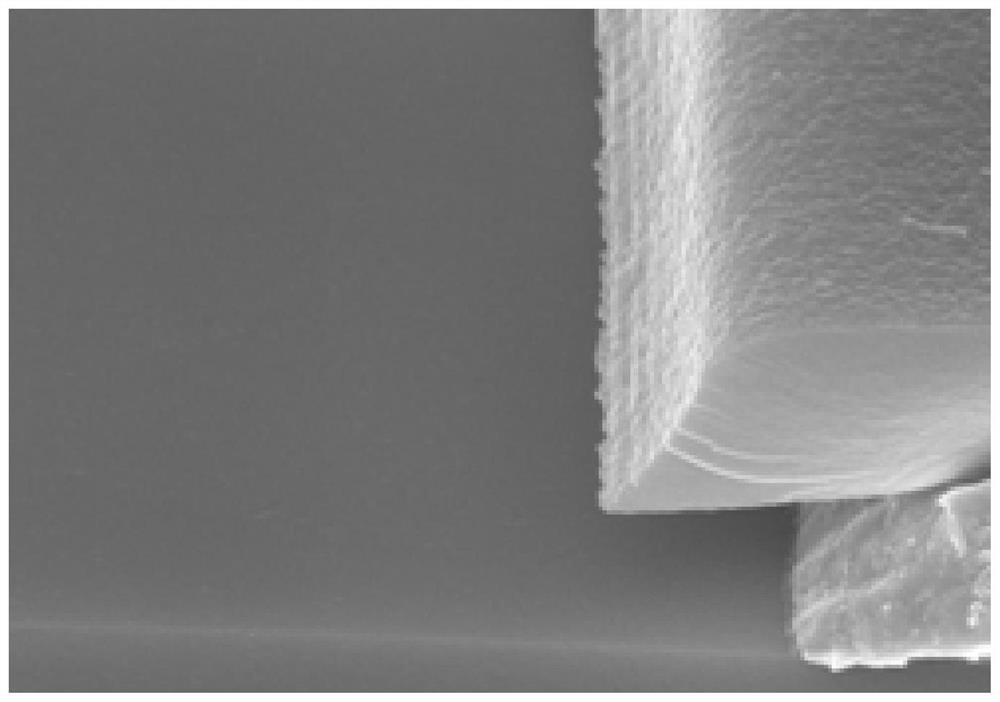

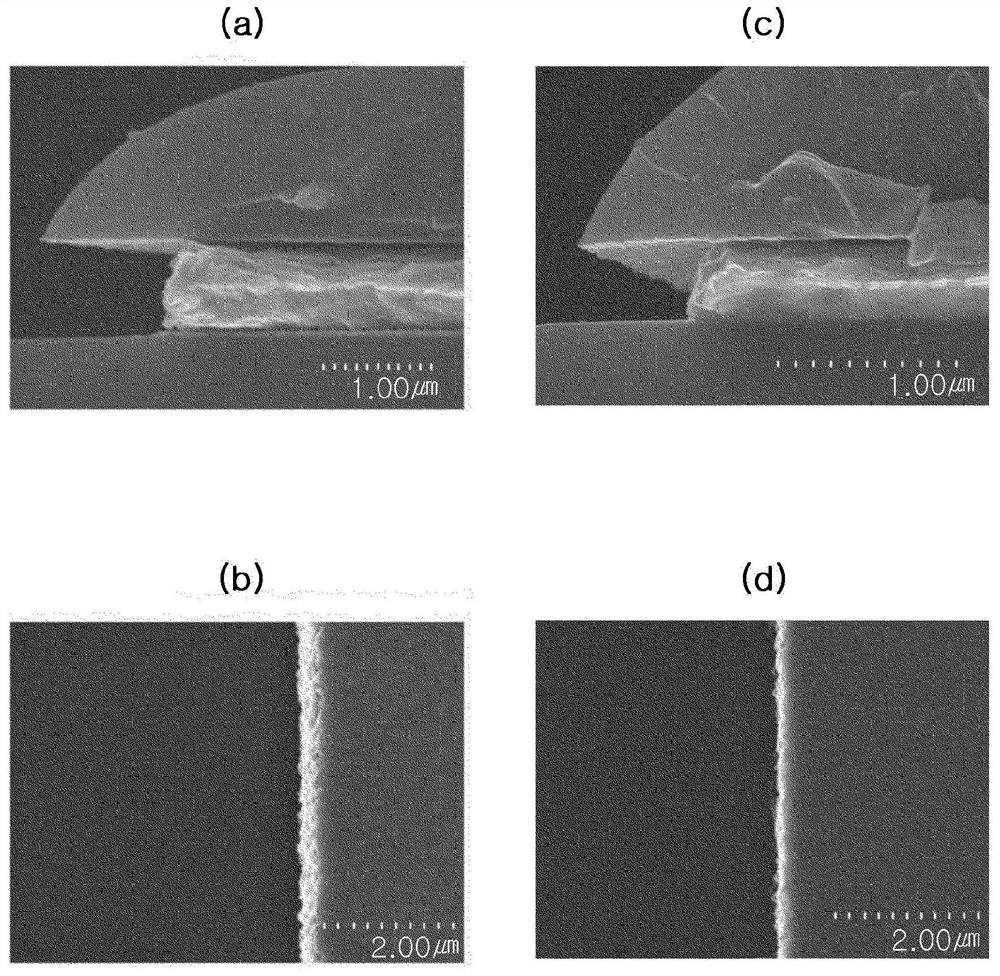

Ammonium persulfate system etching solution for etching TFT copper-molybdenum alloy layer

InactiveCN111876780AThere is no decomposition and exothermic phenomenoNo stabilityEtchingMetallic materials

The invention belongs to the technical field of chemical etching of metal materials, and particularly discloses an ammonium persulfate system etching solution for etching a TFT copper-molybdenum alloylayer. The etching solution is prepared from the following raw materials in percentage by weight: 5%-30% of ammonium persulfate, 0.01%-1% of a stabilizer, 0.1%-10% of a regulator, 0.05%-0.5% of a corrosion inhibitor A, 0.05%-0.5% of a corrosion inhibitor B and the balance of ultrapure water. The ammonium persulfate system etching solution for etching the TFT copper-molybdenum alloy layer is goodin etching characteristic, good in etching slope straightness, free of molybdenum residues and undercut and very high in industrial value.

Owner:武汉迪赛新材料有限公司

Etching solution composition and method for forming metal circuit

The invention provides an etching solution composition and a method for forming a metal circuit. The etching solution composition comprises 10-20wt% of hydrogen peroxide, 4-13wt% of organic acid, 1-5wt% of hydrogen peroxide stabilizer, 2-10wt% of organic base, 0.001-1wt% of corrosion inhibitor, 2-5wt% of PH buffering agent and 47-80wt% of deionized water. The method comprises the step of etching acopper-containing metal film by using the etching solution composition to pattern the copper-containing metal film to form the metal circuit.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Nanometer treatment method for stainless steel

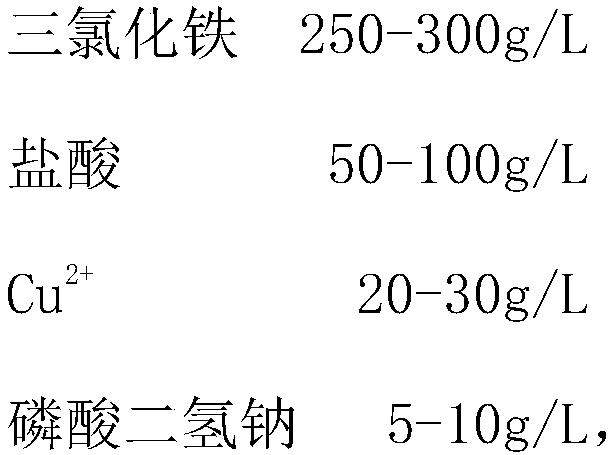

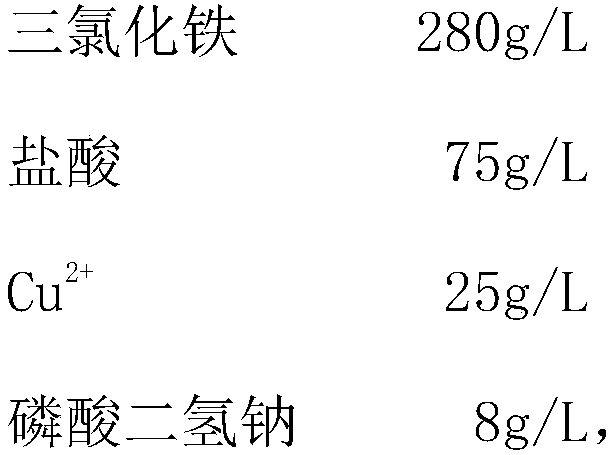

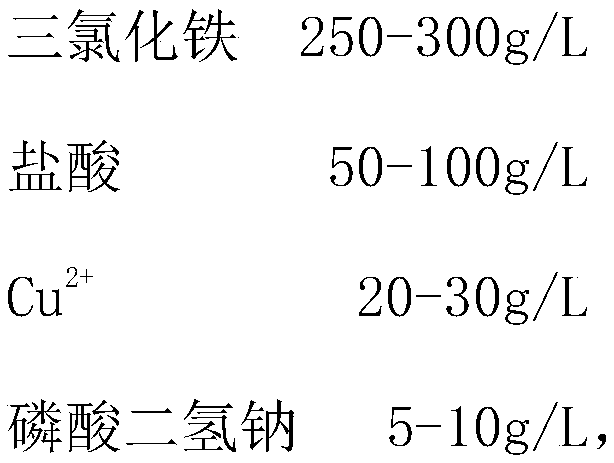

The invention discloses a nanometer treatment method for stainless steel. The nanometer treatment method comprises the steps of degreasing, hot water cleaning, dry ice cleaning, nanometer treatment, water washing, dry ice cleaning, alkaline etching, twice successive water cleaning, neutralization and water washing. In the nanometer treatment step, 250-300 g / L of ferric trichloride, 50-100 g / L of hydrochloric acid, 20-30 g / L of Cu2+ and 5-10 g / L of sodium dihydrogen phosphate are selected to be used. Nanometer treatment is conducted for 60-240 seconds at the temperature of 20-60 DEG C. The nanometer treatment method is mild in reaction and uniform in etching speed; pits at the nanometer scale can be formed in the surface of the stainless steel, and the formed pits are uniform; and the process is completed by one step, so that the time cost is saved. Copper ions are used, and therefore, etching can be implemented steadily; formed holes are uniform in depth; the formed pits are filled with resin in the injection molding process, so that tight connection is achieved between the resin and the surface of the stainless steel; and the bonding strength between the resin and the steel is improved.

Owner:安徽新合富力科技有限公司

Fluorine-free etching agent and etching method thereof

The embodiment of the invention discloses a fluoride-free etching agent and an etching method thereof. The fluoride-free etching agent comprises the following components of, in percentage by weight, 1wt%-25wt% of hydrogen peroxide, 0.01wt%-3wt% of an etching stabilizer, 1wt%-20wt% of an etching inhibitor, 0.01wt%-4wt% of a pH adjusting agent, 1wt%-10wt% of an auxiliary oxidant, 0.01wt%-0.8wt% of an etching additive, and the balance deionized water. The fluorine-free etching agent is stable in etching, does not contain fluorine, does not damage a glass substrate, is easy in waste water recovery, and more importantly, solves the metal molybdenum residue phenomenon generated in the copper / molybdenum etching process, and can obtain a better patterned metal layer.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Wet electron chemical silicon-based material etching solution and preparation method thereof

The invention particularly relates to a wet electronic chemical silicon-based material etching solution. The solution comprises the following components in parts by weight: 25-45 parts of methanesulfonic acid; 10-30 parts of fluoride; 30-60 parts of a water-soluble acid; 0.5-9.5 parts of a complexing agent; 0.5-3.5 parts of a wetting agent; and the balance of water which makes the total parts of the components be 100 parts. The water-soluble acid comprises at least one of nitric acid, sulfuric acid, phosphoric acid, perchloric acid, sulfinic acid, formic acid, acetic acid, citric acid, isocitric acid and glycolic acid. The fluoride comprises at least one of trifluoromethanesulfonic acid, sodium fluoride, sodium hydrogen fluoride, ammonium fluoride, ammonium hydrogen fluoride, ammonium fluoborate, potassium fluoride, potassium hydrogen fluoride, aluminum fluoride, fluoboric acid, lithium fluoride, potassium fluoborate and calcium fluoride. The wet electron chemical silicon-based material etching solution can be used for safely, stably and efficiently etching a silicon substrate, can well solve the problem of insoluble byproducts generated in the etching process, has lower industrial safety risk in the production process, and lowers the cost required in a wastewater treatment procedure.

Owner:国创深圳新材料有限公司

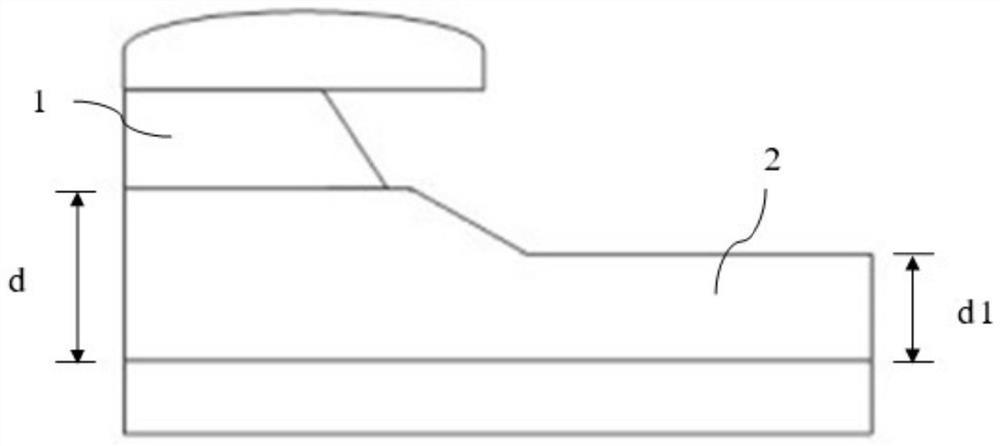

Etching solution and manufacturing method of array substrate using etching solution

PendingCN114086180AGood etchingLow costSolid-state devicesSemiconductor/solid-state device manufacturingTitanium metalFluoride

The invention discloses an etching solution and a manufacturing method of an array substrate using the etching solution. The etching solution comprises the following components in percentage by mass: 10 to 20% of hydrogen peroxide, 0.05 to 5% of an etching inhibitor, 0.1 to 2% of a fluoride composition, 0.5 to 5% of a silicon etching aid, 2 to 10% of an etching additive, and a solvent. The etching solution has excellent etching performance on copper / molybdenum, copper / titanium or copper / molybdenum titanium metal layers of source and drain electrode layers, is low in cost, and can etch a semiconductor layer and reduce metal residues while keeping long service life of a device, so that problems caused by a subsequent dry etching process are reduced, even the dry etching process of the semiconductor layer can be directly omitted, the manufacturing cost is reduced, and the device stability is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

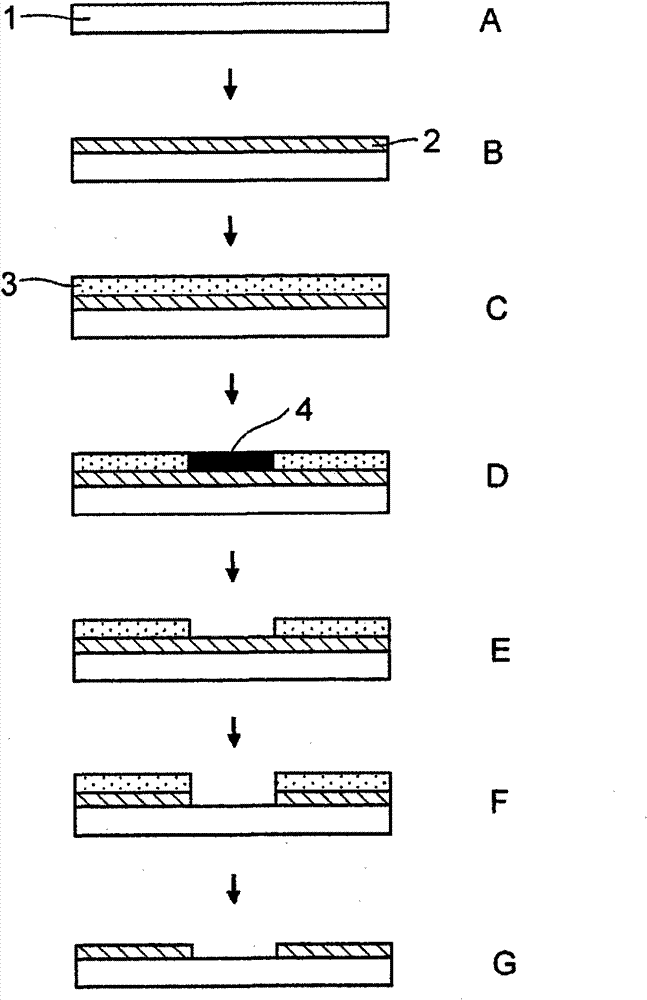

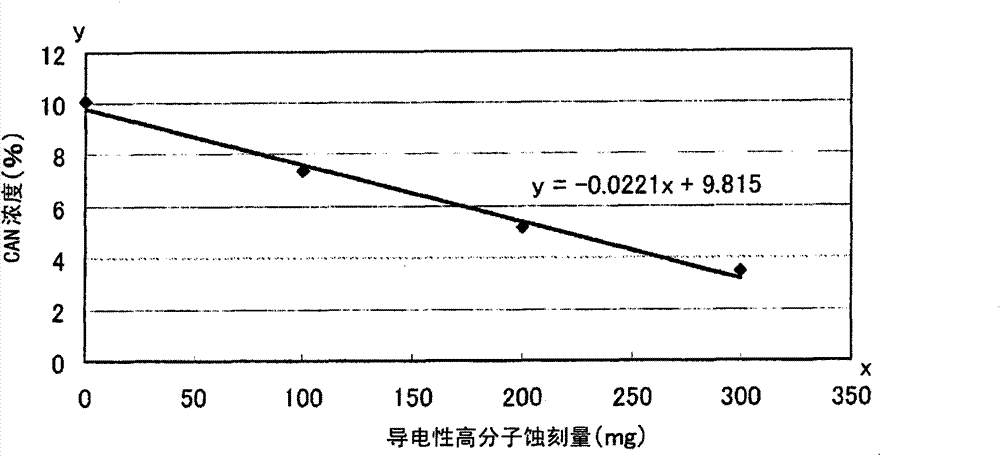

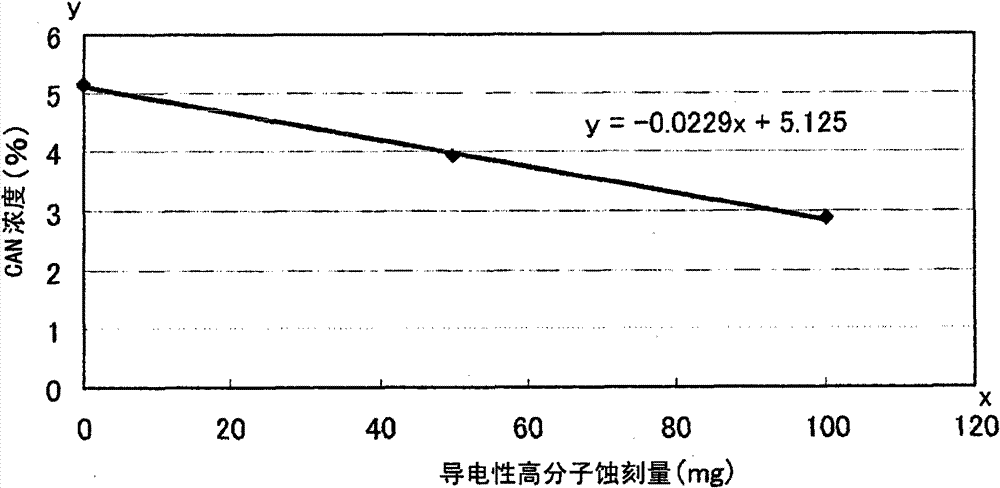

Etching method and substrate having conductive polymer

InactiveCN101981098BSimple and easy to manageEtch stableConductive layers on insulating-supportsSolid-state devicesPotential measurementConductive polymer

An object of the present invention is to provide an etching method that enables control of etching of a conductive polymer using a specific cerium (IV) compound to be carried out simply and easily, thus ensuring that etching is carried out stably, and to provide a substrate having a conductive polymer that has been etched by the etching method. The etching method of the present invention includes an etching step of etching a conductive polymer using an etching liquid containing a specific cerium (IV) compound, an analysis step of analyzing the etching liquid by at least one analysis means selected from the group consisting of oxidation-reduction potential measurement, oxidation-reduction titration, and electrical conductivity measurement, and a control step of controlling the etching step according to the results obtained in the analysis step.

Owner:TSURUMISODA +1

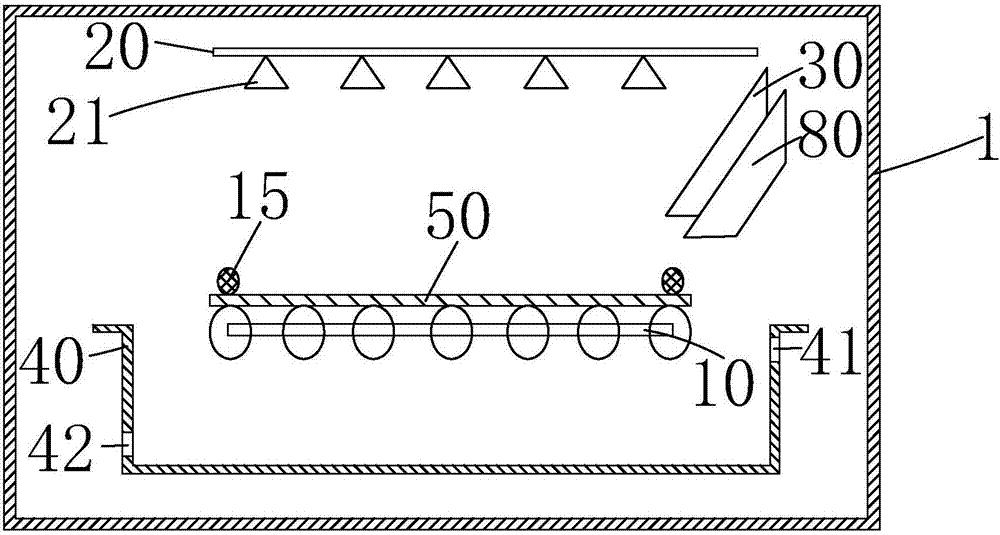

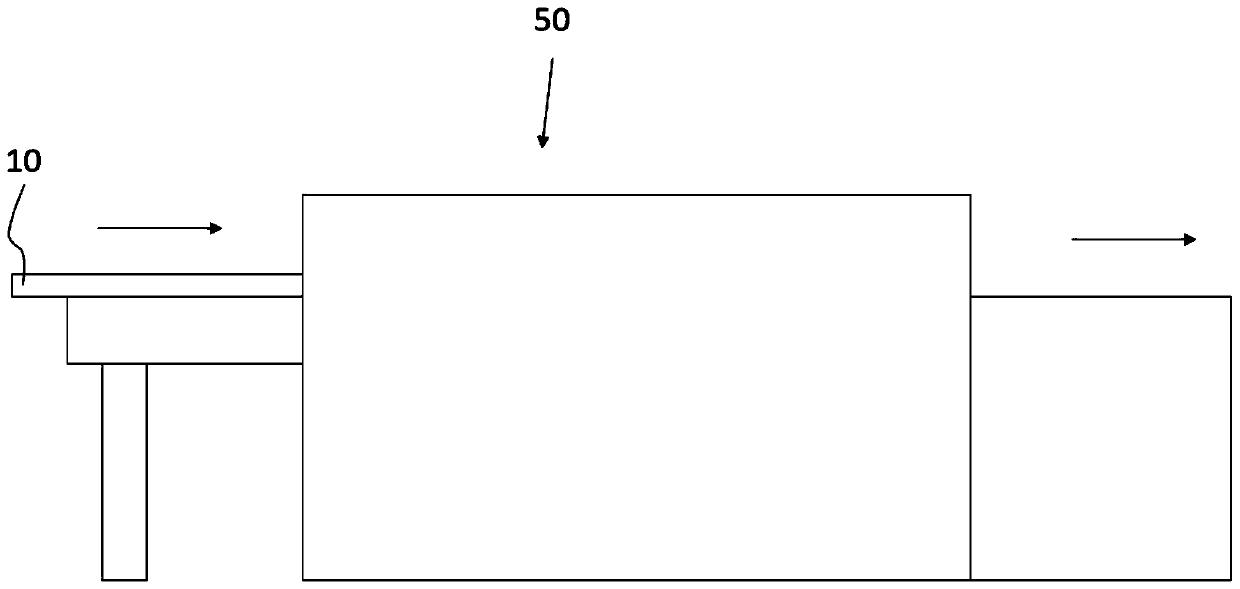

Wet etching equipment

ActiveCN107316826BSmall structureSmall footprintSemiconductor/solid-state device manufacturingEtchingEngineering

The invention provides wet etching equipment. The wet etching equipment comprises a bearing platform used for bearing a substrate, a spraying pipe which is arranged above the bearing platform for spraying an etching liquid to the surface of the substrate, a liquid knife which is arranged between the bearing platform and the spraying pipe and used for coating the surface of the substrate with the etching liquid, and an etching groove which is formed below the bearing platform and used for accommodating the etching liquid and the substrate; therefore, the three kinds of etching modes, including a spray mode, a dip mode and a puddle mode, can be integrated into the same etching unit, so that the machine table structure is reduced, the occupied space of the machine table is reduced, and the maintenance cost and time are lowered; and in addition, the substrate on the bearing platform moves along with the bearing platform in the etching process, without needing to transfer the substrate independently, so that the etching process is more stable, thereby reducing generation of mura.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Filming method of silicon wafer after IMD CMP

InactiveCN1300831CShorter production cycleEtch stableSemiconductor/solid-state device manufacturingIntegrated circuitMetal

This invention discloses a silicon IMD CMP film process method, which reduces the production circle and flats the isolation layer oxygen film between the silicon metal align wires and improves the integration quality. The key points of this technique lies in the following: to automatically choose relative PCO film forming conditions according to the thickness of the remain film of silicon pad IMD and CMP.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

An etching line process for increasing fishing line

ActiveCN105755574BAvoid dentsGood flexibilityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsEtchingEngineering

The invention relates to the technical field of touch screen etching, and in particular relates to an etching line process with a fishing line. The etching line process comprises the following steps: (1) providing a soft substrate, and adding an etching-resistant ink layer on the surface of an ITO conductive layer of the soft substrate in a silk-screen manner; (2) powering on etching equipment to etch the soft substrate, setting a first fishing line contacting the lower surface of the soft substrate between adjacent rollers 1, driving the soft substrate to move through a roller group, spraying an etching liquid through a plurality of nozzles, and removing parts uncovered by the etching-resistant ink layer, of the ITO conductive layer; (3) spraying an ink removing liquid through an ink removing device, and removing the etching-resistant ink layer. As the fishing line which is good in softness and acid-base resistance is threaded between an etching line and rollers, and the fishing line is arranged above the soft substrate, so that the soft substrate can be prevented from being warped up or sunk down in the etching process; components of the etching liquid are matched with one another, so that etching can be performed uniformly and stably, and edges of etched electrode patterns can be tidy; the etching line process is low in cost, simple in process and high in etching efficiency.

Owner:DONGGUAN PINGBO ELECTRONICS

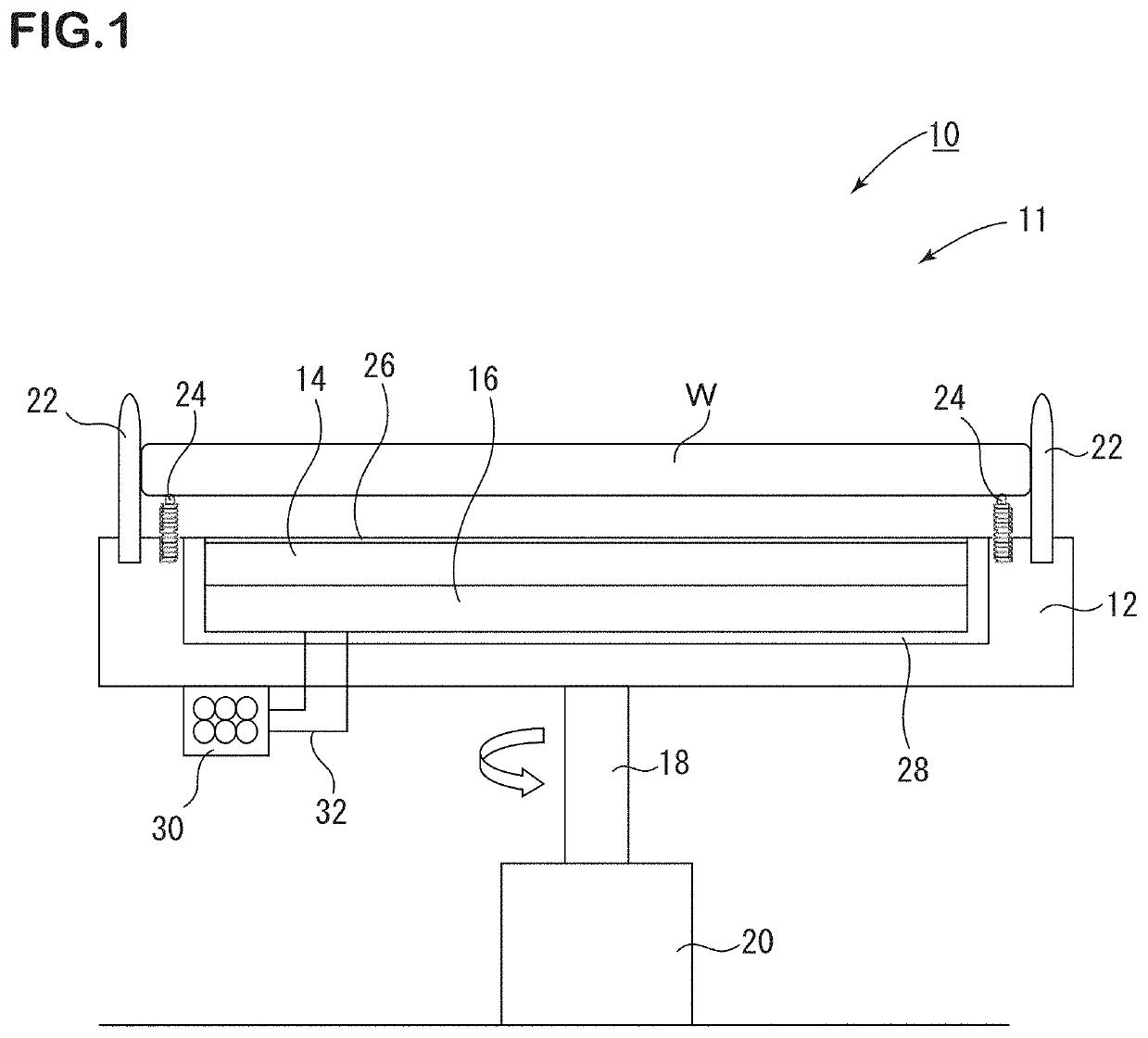

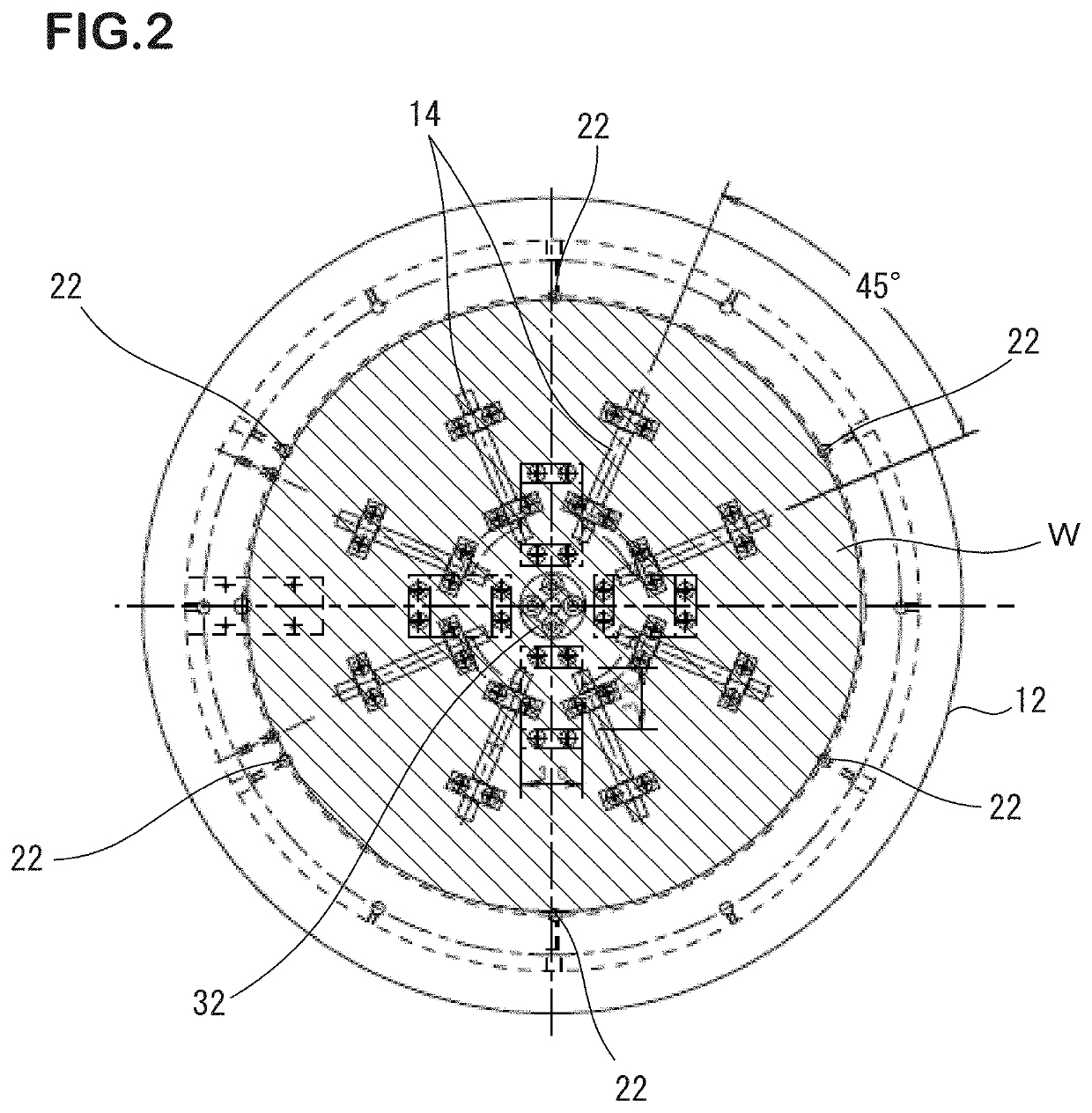

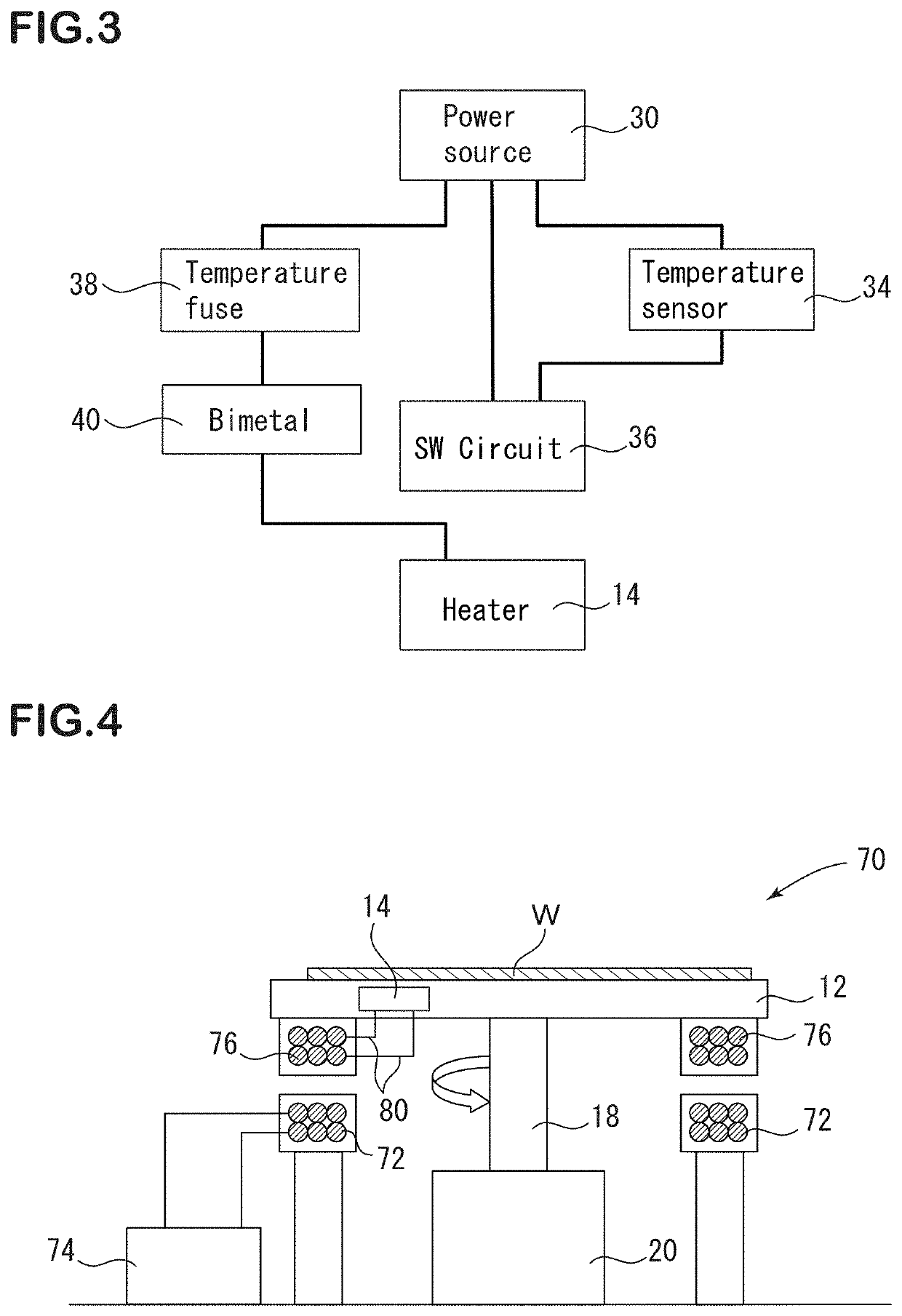

Wafer heating and holding mechanism and method for rotary table, and wafer rotating and holding device

ActiveUS11056362B2Etch stableSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRotary stageRotational axis

Provided are a wafer heating and holding mechanism for a rotary table, a wafer heating method for a rotary table, and a wafer rotating and holding device with which a wafer put on a rotary table can be heated while being rotated stably under a state in which an in-plane temperature distribution of the wafer is maintained. The wafer heating and holding mechanism for a rotary table of a wafer rotating and holding device comprises: a rotary shaft; a rotary table placed on an end of the rotary shaft and configured to hold a wafer on an upper surface of the rotary table; a drive motor configured to supply motive power to the rotary shaft; and a heater provided above the rotary table and below the wafer while avoiding contact with the wafer to heat the wafer.

Owner:MIMASU SEMICON IND CO LTD

A kind of etchant for touch screen and preparation method thereof

InactiveCN104327857BAvoid it happening againReduce pollutionSurface treatment compositionsEtchingThiazole

The invention relates to the technical field of etching solution, in particular to an etching solution for a touch screen and a preparation method thereof. Each liter of the etching solution consists of the following raw materials: 180-220 mL of hydrochloric acid, 5-20 g of sodium dihydrogen phosphate, 70-90 mL of hydrofluoric acid, Hydrogen peroxide 40-50mL, 4-methyl-5-(2-acetoxyethyl)thiazole 3-7mL, cetylpyridinium chloride 0.1-1mL, the balance is water. The present invention replaces ferric chloride with hydrofluoric acid and hydrogen peroxide, so there is no need to frequently replace the etching solution, which not only saves resources but also reduces pollution to the environment. Used in conjunction with sodium dihydrogen phosphate, hydrochloric acid, hydrofluoric acid, and hydrogen peroxide, the etching is stable, the etching speed is moderate, and the etching is uniform. The edges of the etched electrode pattern are neat and there is basically no side etching.

Owner:JIANGXI PINGBO ELECTRONICS

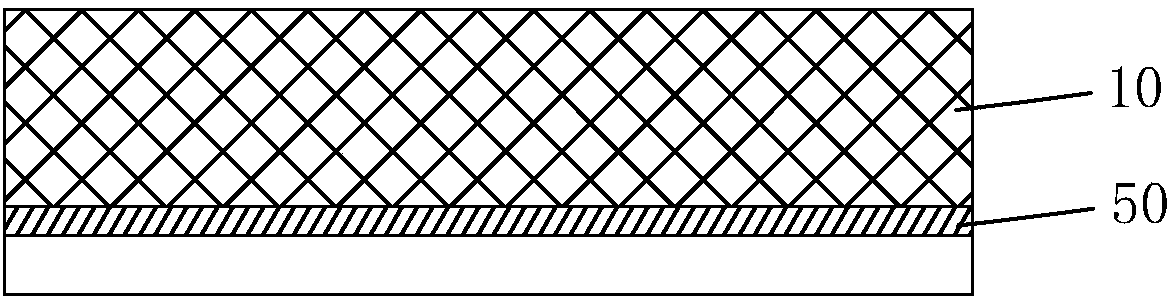

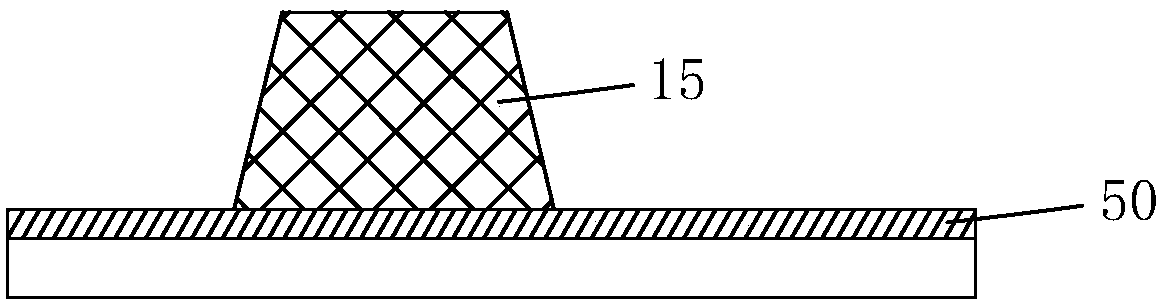

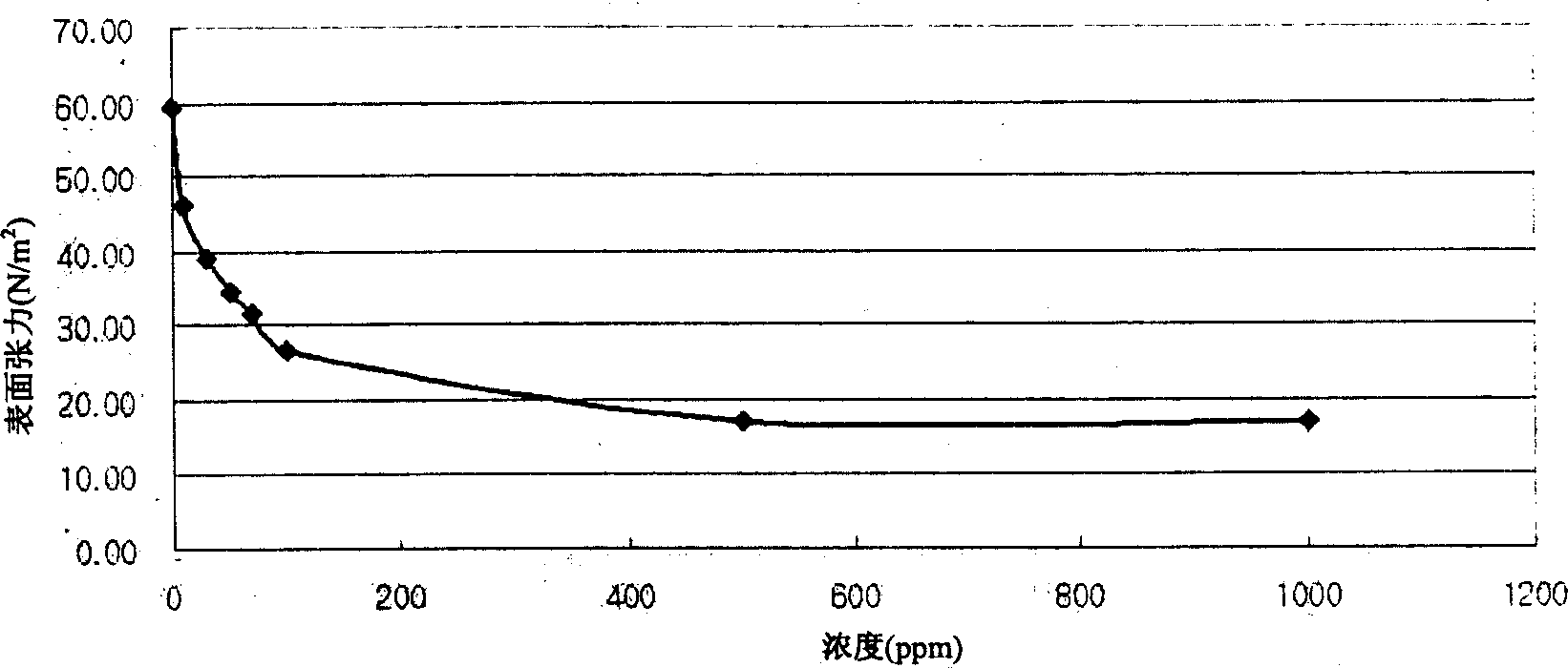

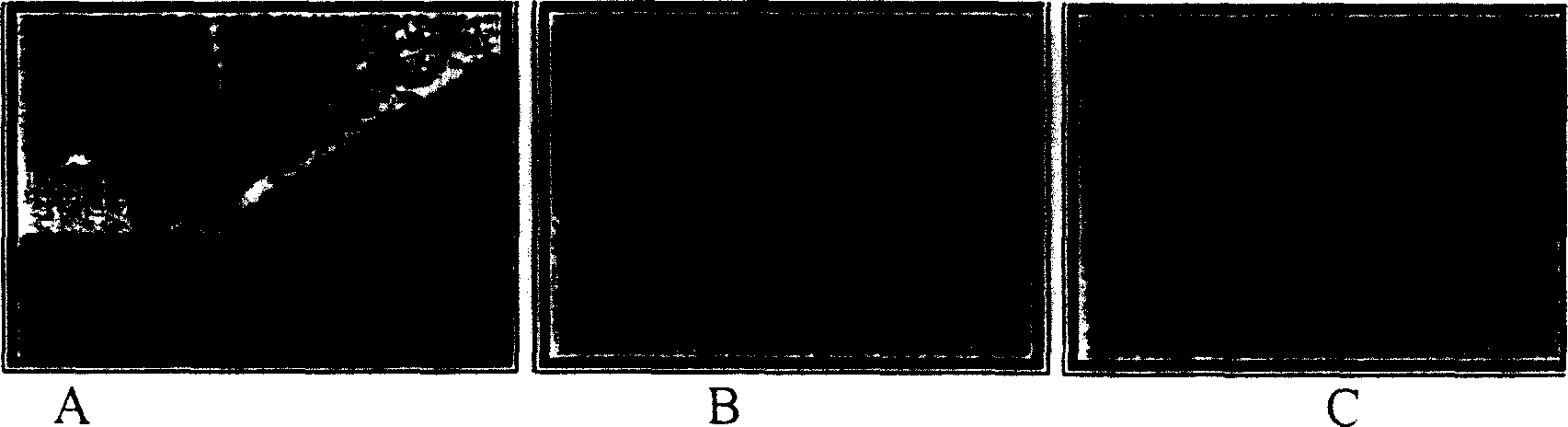

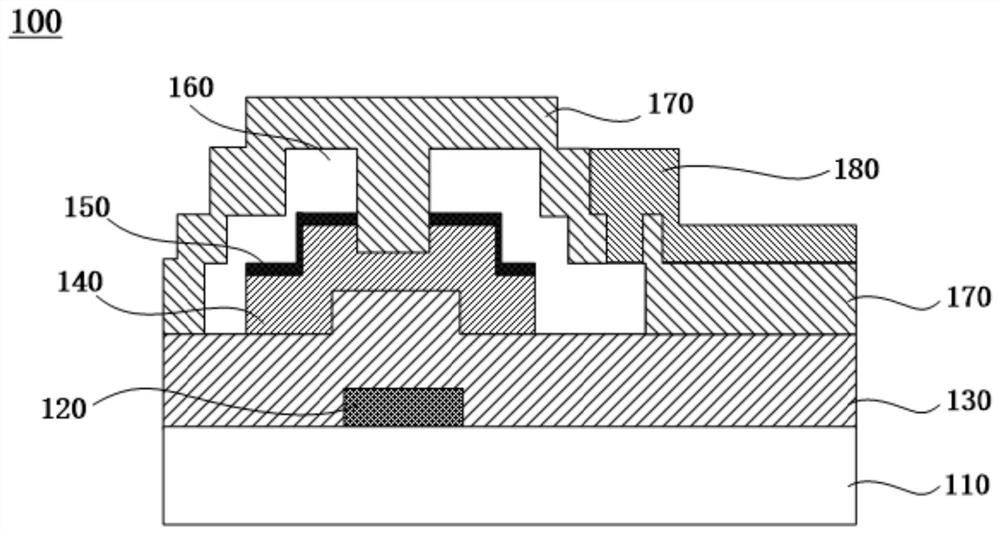

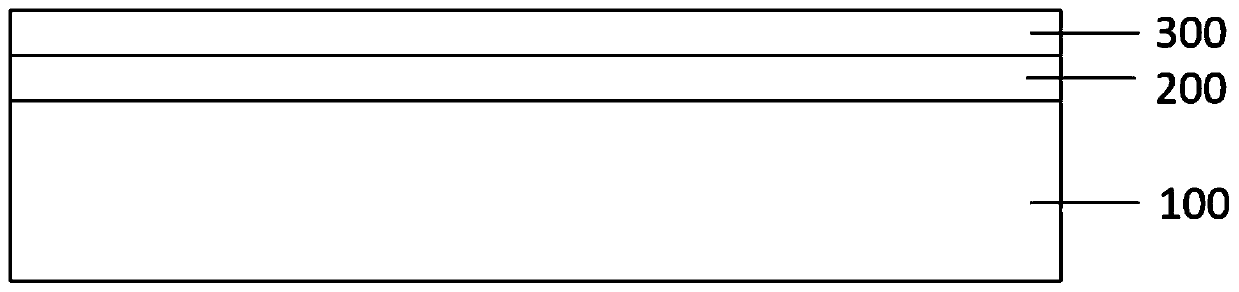

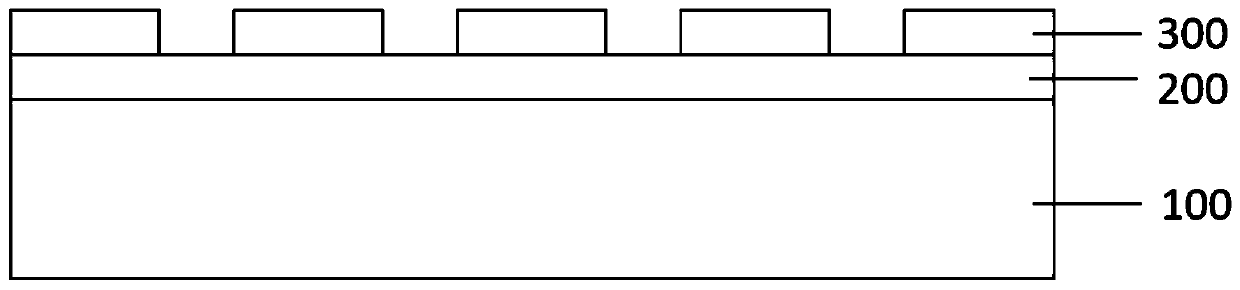

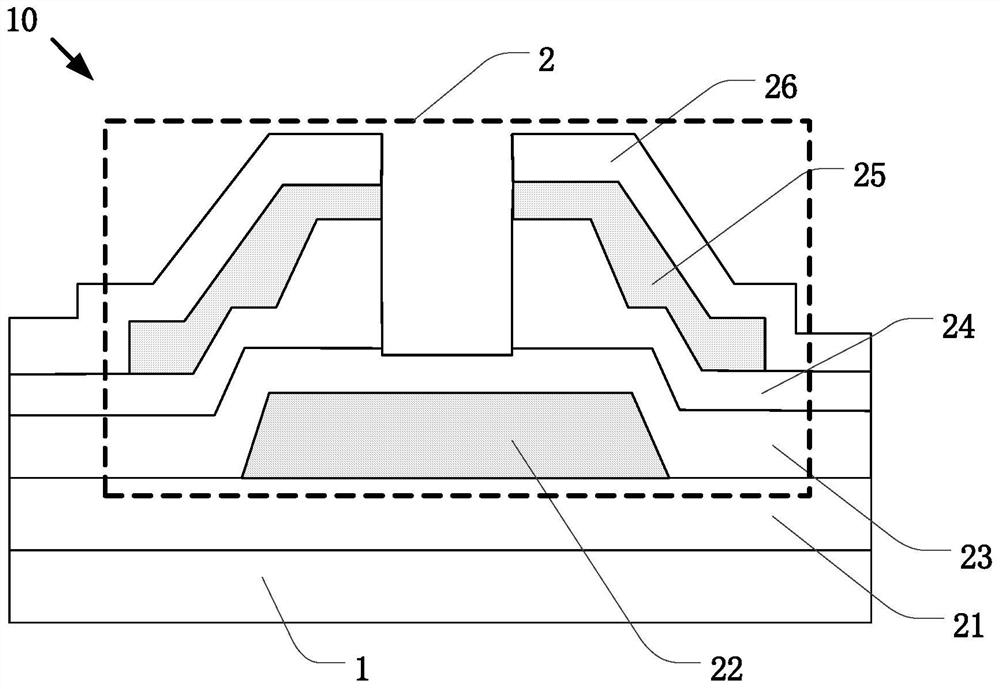

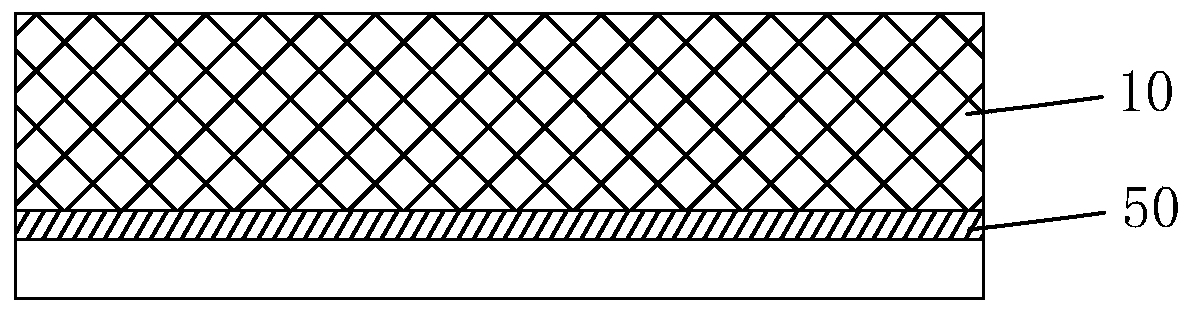

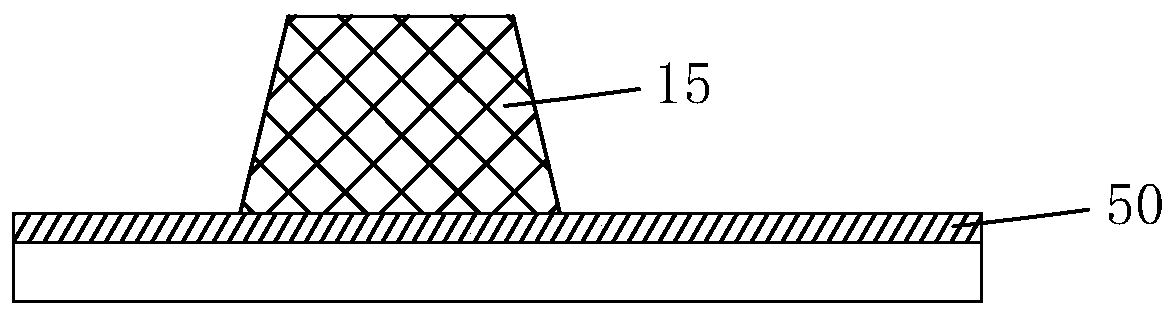

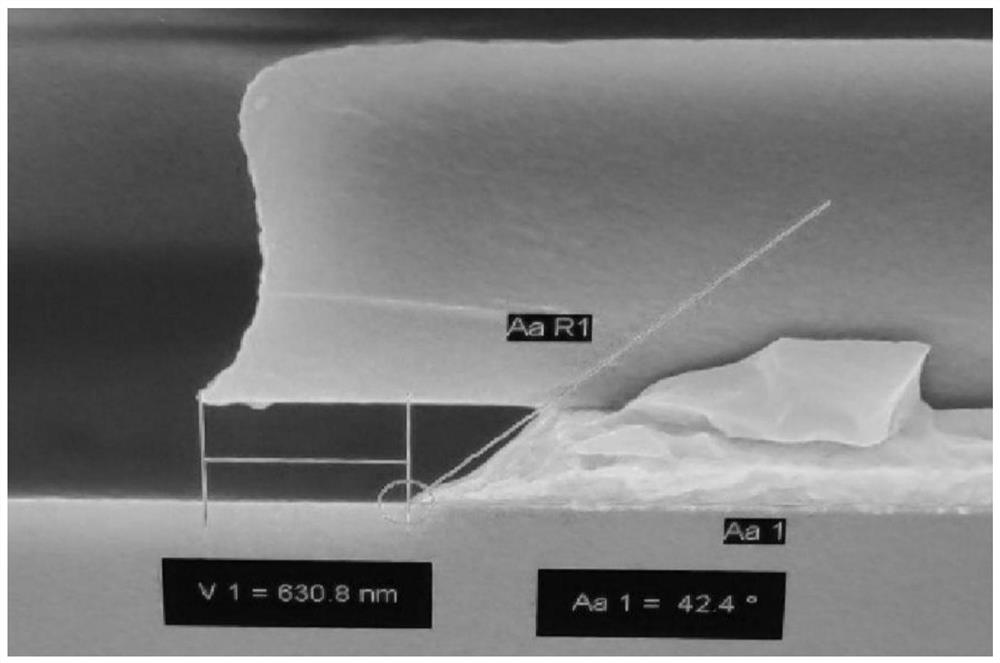

Etching solution of igzo film layer and etching method thereof

ActiveCN107564809BEtch stableImprove stabilitySemiconductor/solid-state device manufacturingSurface treatment compositionsPhosphateImpurity

An etching solution for an IGZO film layer and an etching method therefor; the etching solution comprises an acid, a phosphate, hydrogen peroxide and water, and the pH value of the etching solution does not exceed 5, and the solution may effectively control etching rate such that etching rate is uniform, and thus an IGZO film layer (50) may be stably etched without introducing impurities that affect the electrical properties of IGZO, thereby effectively improving the stability of an IGZO-thin film transistor (TFT) device. The etching method for an IGZO film layer employs the foregoing etching solution for an IGZO film layer, and may effectively control etching rate such that etching rate is uniform, and thus an IGZO film layer (50) may be stably etched without introducing impurities that affect the electrical properties of IGZO, thereby effectively improving the stability of an IGZO-TFT device.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A kind of tft copper molybdenum laminated film etchant composition and etching method

The invention discloses a TFT copper-molybdenum laminated film etching solution composition. The components and weight percentages of the composition are: 5-30% hydrogen peroxide, 0.1-5% H2SO4, persulfide, chloride, 0.005-0.3% hydrogen peroxide stabilizer, 0.005-0.3% metal complexing agent, 0.005-0.2% surfactant, 0.001-1% azole additives and the balance of water, the sum of the weight percentages of persulfide and chloride 0.01-0.5%. The TFT copper-molybdenum laminated film etchant composition etches the copper-molybdenum laminated film uniformly, has moderate etching rate and long service life.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

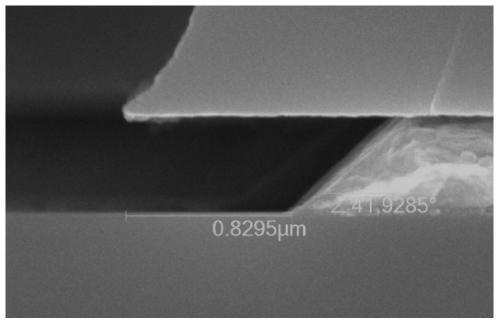

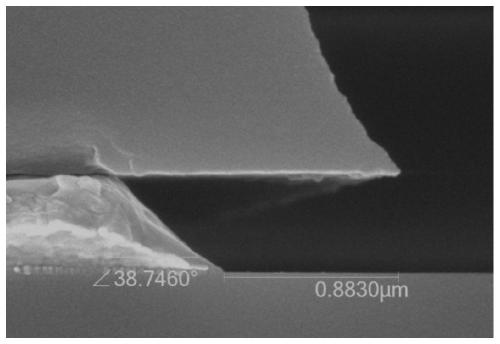

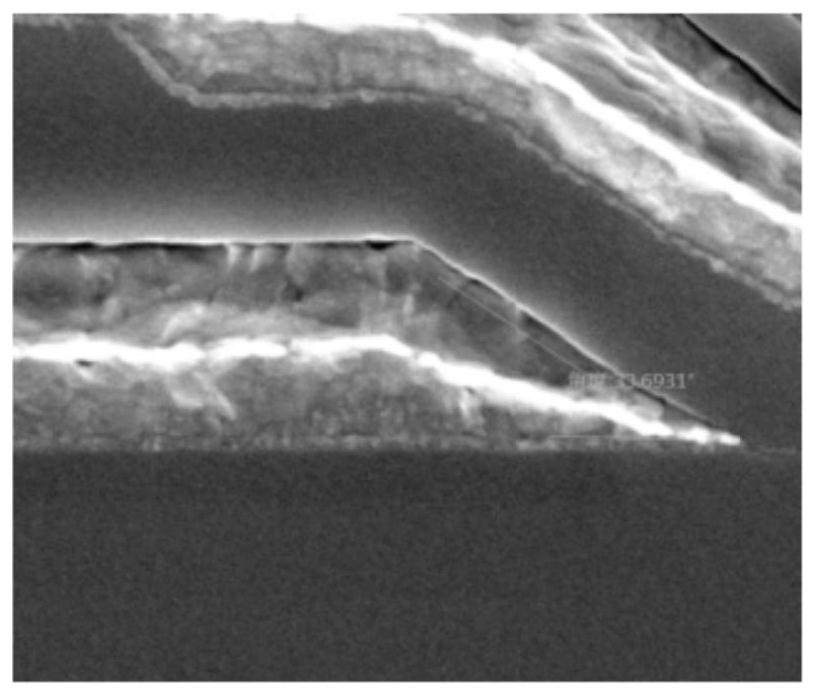

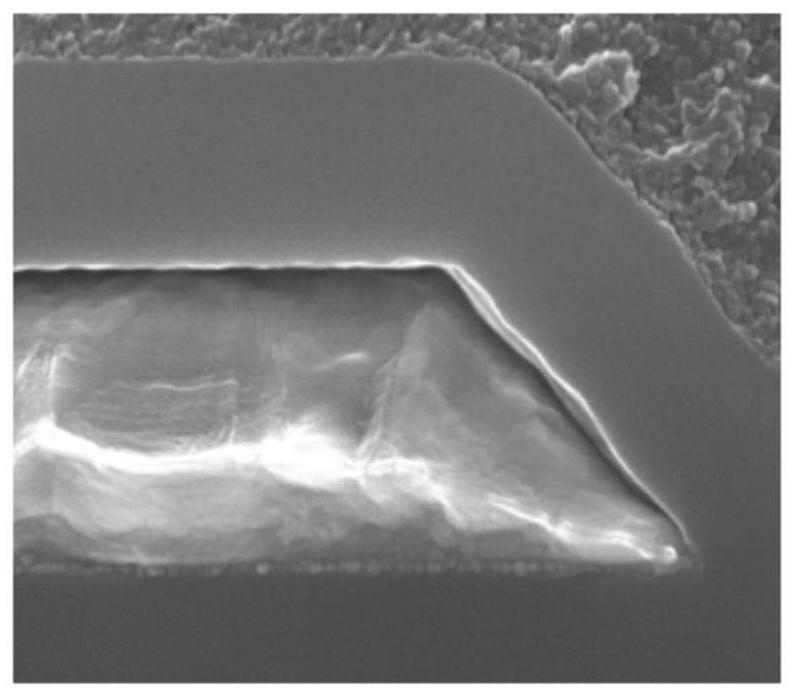

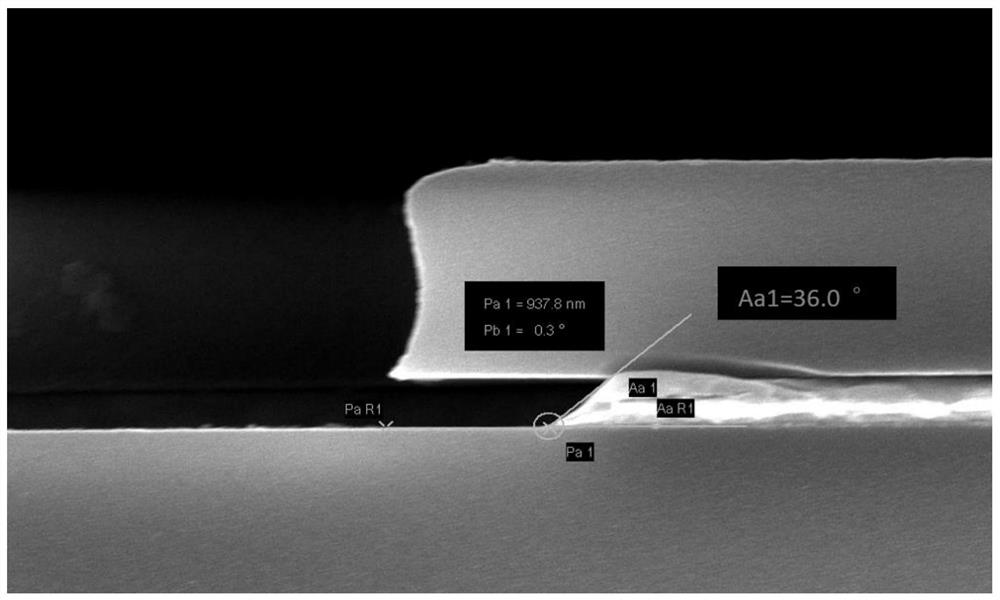

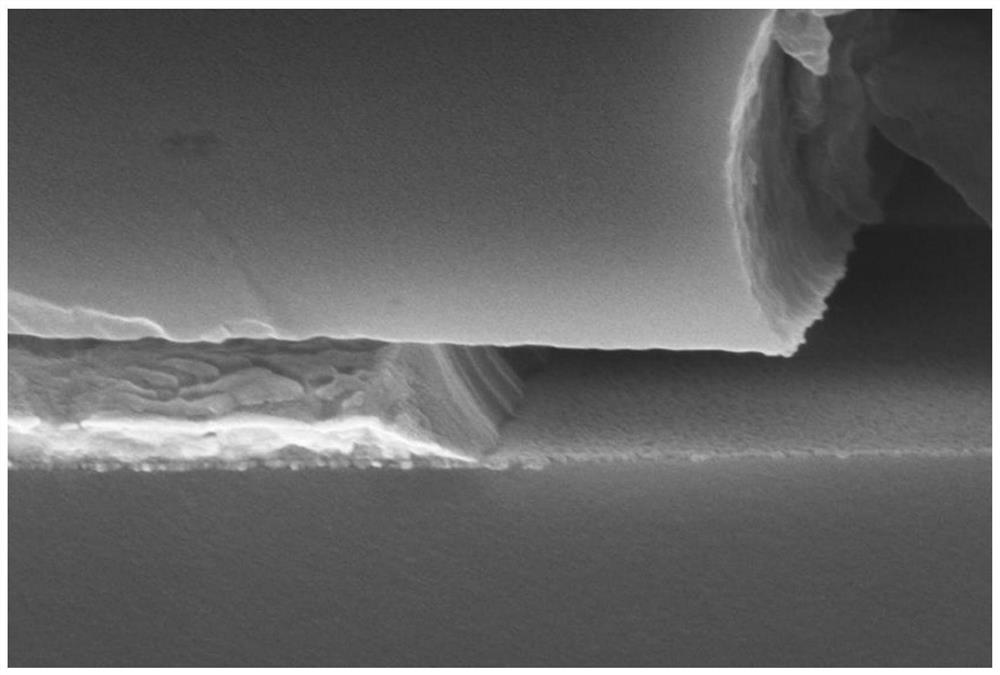

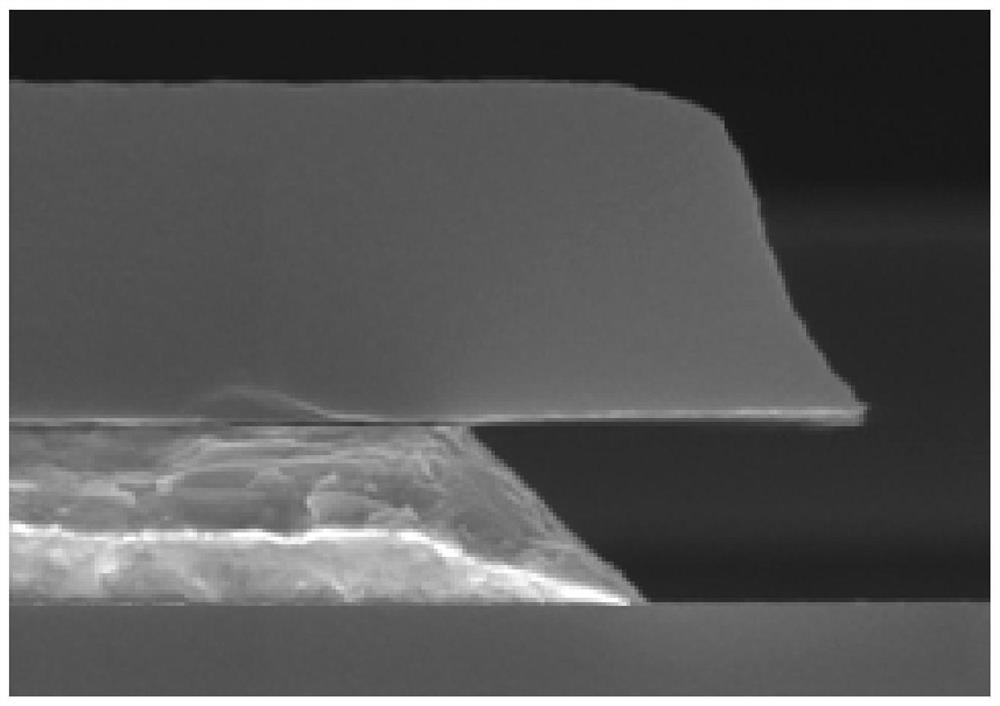

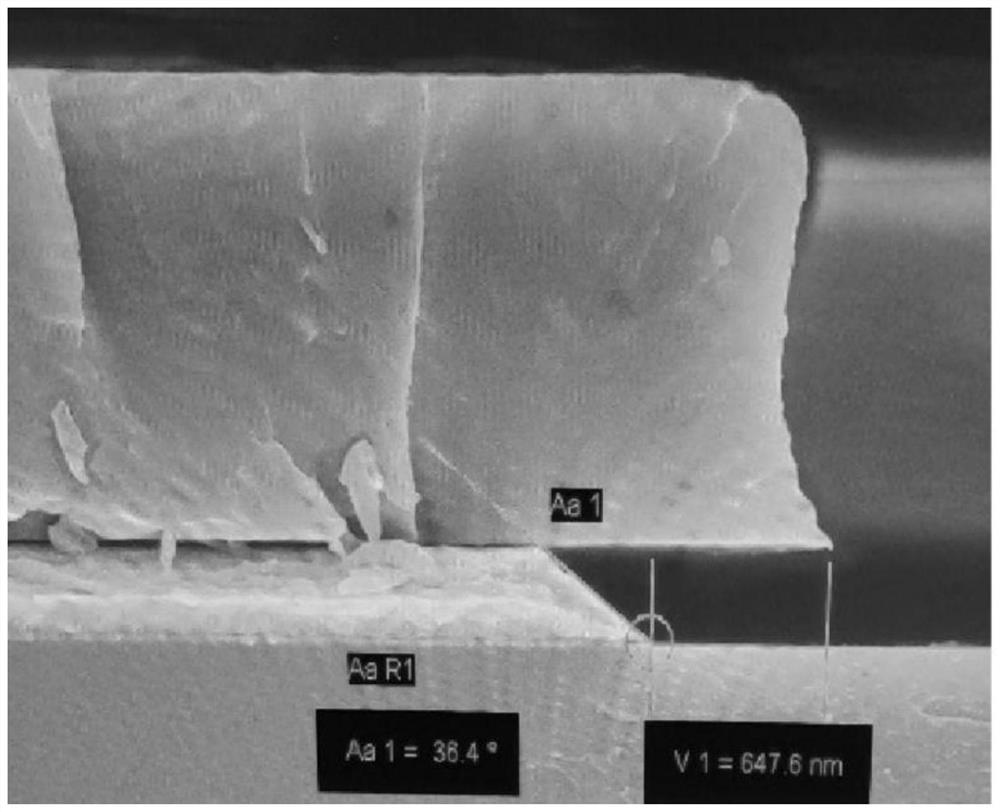

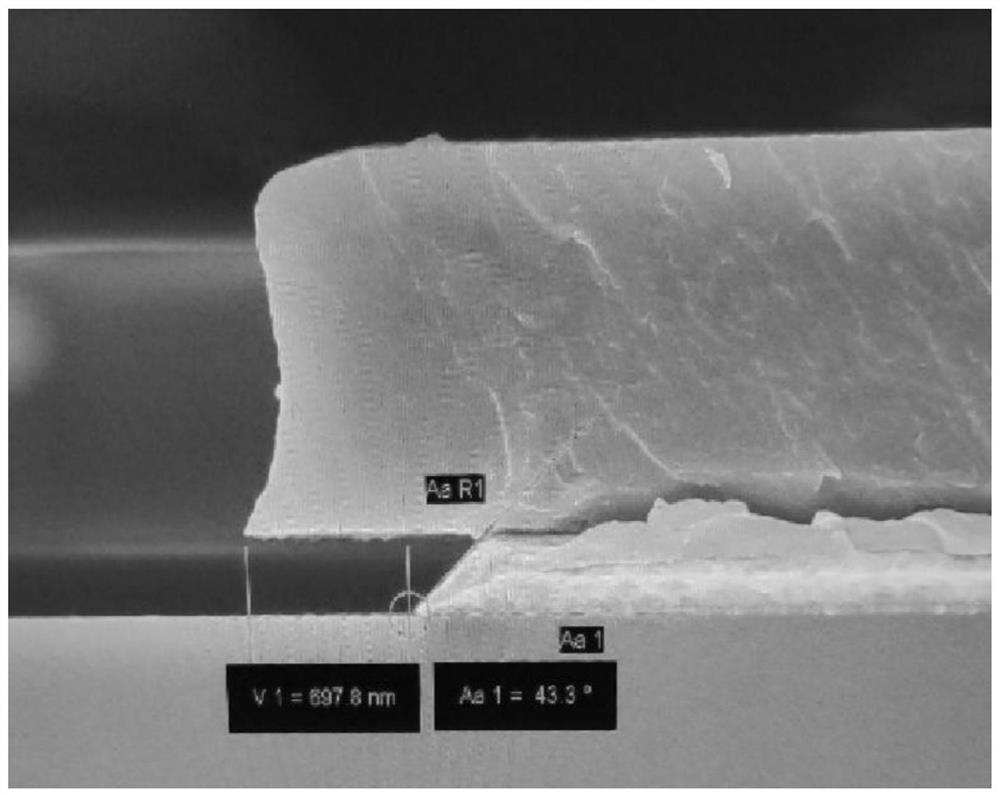

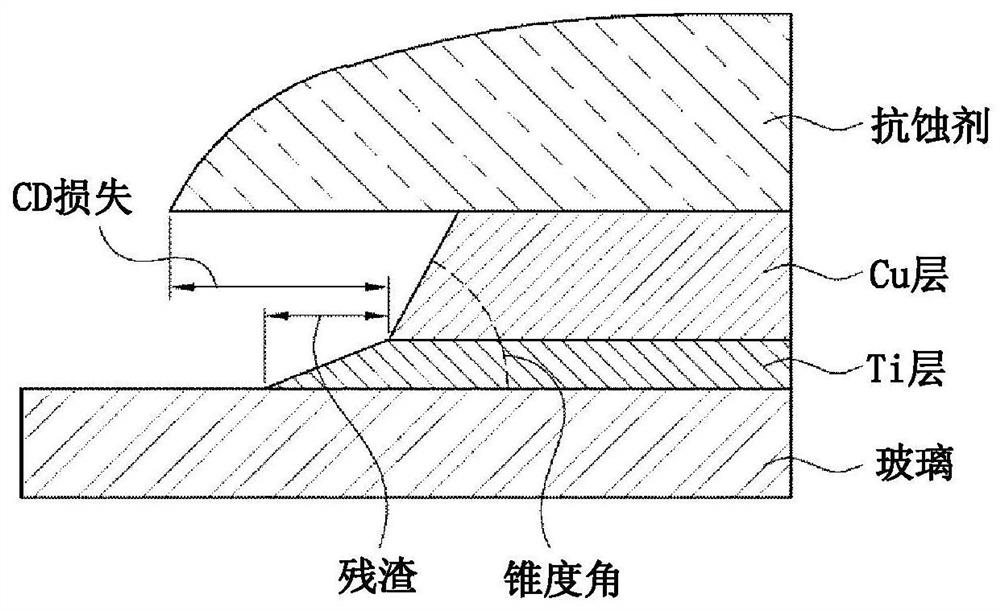

Copper-molybdenum lamination etchant for tft-lcd process

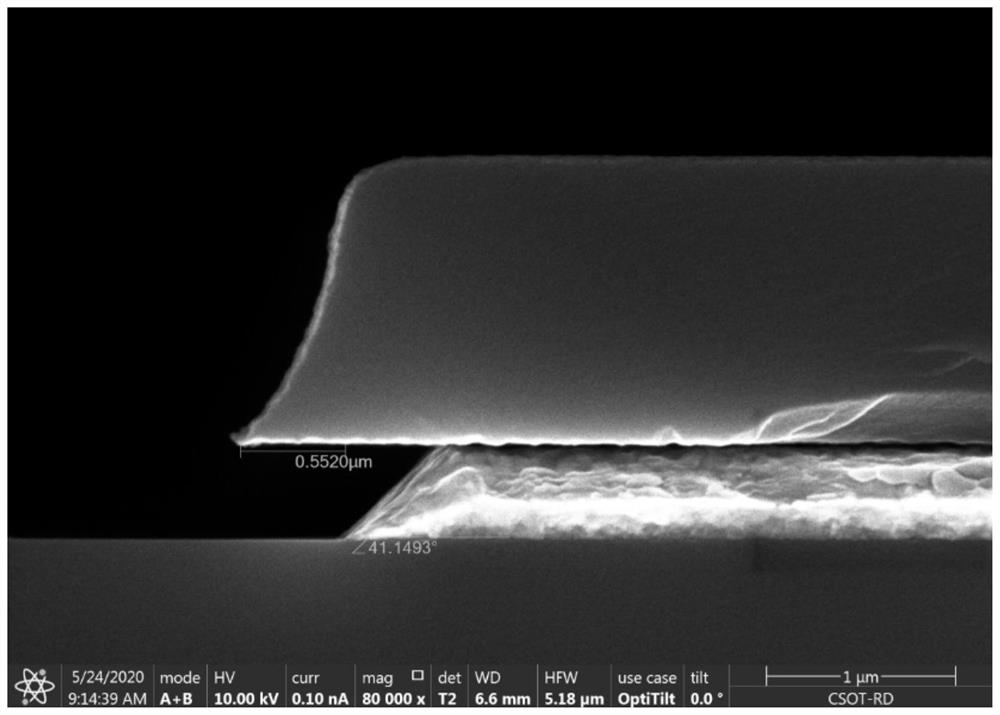

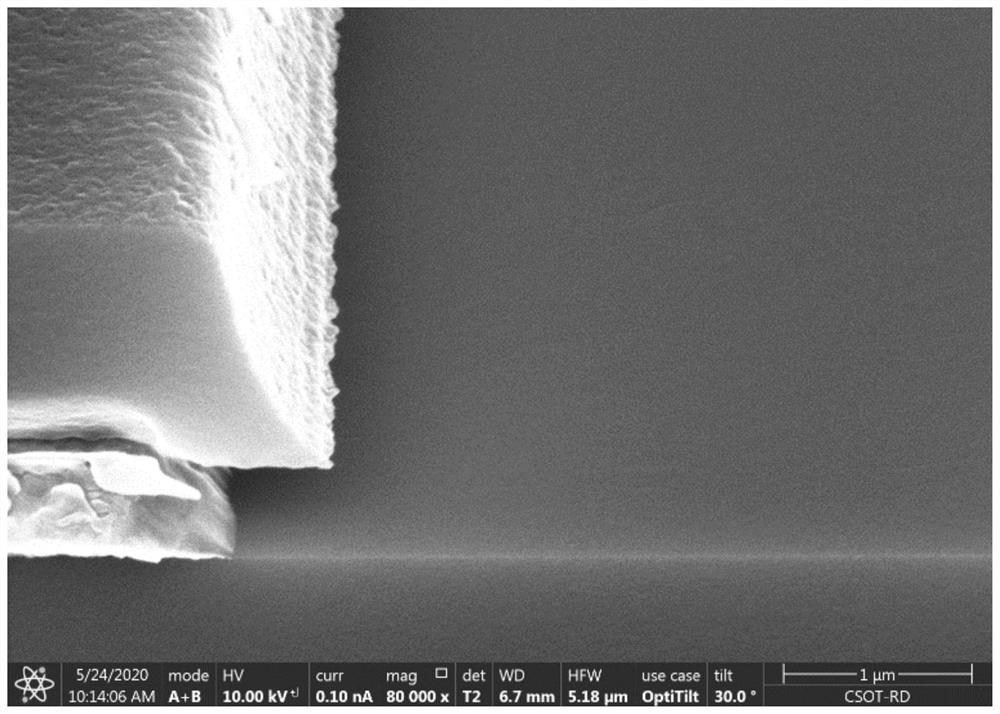

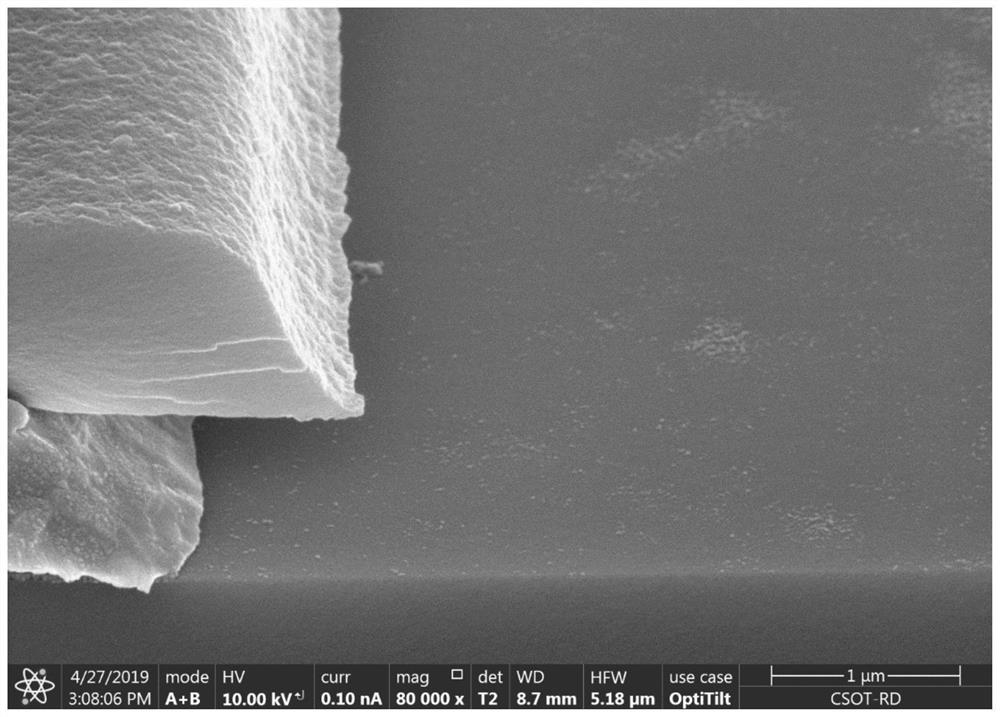

ActiveCN112030165BExtend your lifeEtch stableSolid-state devicesSemiconductor/solid-state device manufacturingEtchingCu2 ions

The invention belongs to the technical field of chemical etching of metal materials, and specifically discloses an etching solution for a copper-molybdenum composite layer used in a TFT-LCD manufacturing process. The etching solution is composed of the following raw materials in weight percentage: 5%~25% hydrogen peroxide, 2%~4% chelating agent, 1%~2% regulator, 0.05%~0.5% stabilizer, 0.05% ~0.5% Corrosion Inhibitor A, 0.05%~0.5% Corrosion Inhibitor B, 0.5%~1% Multi-functional Additive and the rest ultrapure water. The etching solution for copper-molybdenum composite layer used in the TFT-LCD manufacturing process of the present invention has good etching properties. The content of copper ions in the etching solution can keep the etching angle at 35-50° from 1000 to 7000 ppm, CDloss at 0.80±0.20um, and the etching slope is straight Good hardness, no molybdenum residue, no undercut. It can replace imported products and has great industrial value.

Owner:武汉迪赛新材料有限公司

Etching solution composition, method for etching multilayer film, and method for manufacturing display device

ActiveCN106795633BPrevent or heatExtended replacement cycleSolid-state devicesSemiconductor/solid-state device manufacturingActive agentPhysical chemistry

The present invention relates to an etching solution composition, an etching method for a multilayer film, and a method for manufacturing a display device, wherein the etching solution composition of the present invention comprises: (A) a supply source of copper ions; (B) having 1 in the molecule An organic acid ion supply source of more than two carboxyl groups; (C) a fluoride ion supply source; (D) an etch regulator, a surface oxidation power enhancer, or a combination thereof as a first additive; and (E) as a second additive of surfactants.

Owner:SAMYOUNG PURE CHEM +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com