Etching solution for IGZO film and etching method thereof

An etching solution and film layer technology, applied in chemical instruments and methods, surface etching compositions, electrical components, etc., can solve the problems of particularly large influence, abnormality, IGZOVth drift leakage current, etc., to achieve uniform etching rate, improve Stability, stable etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

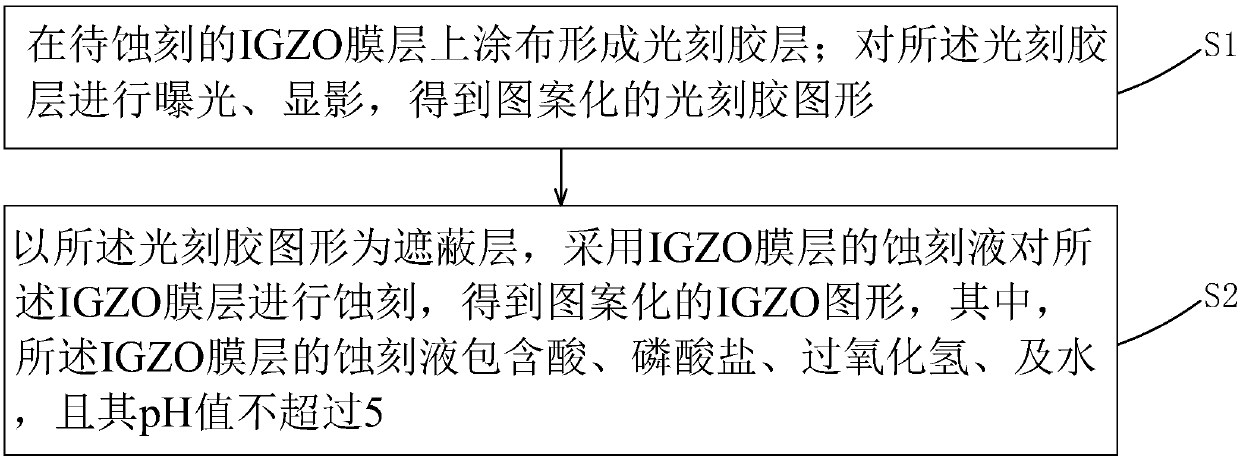

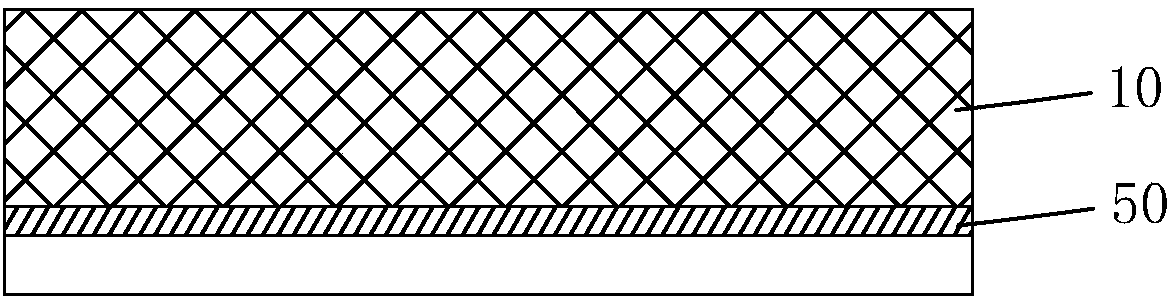

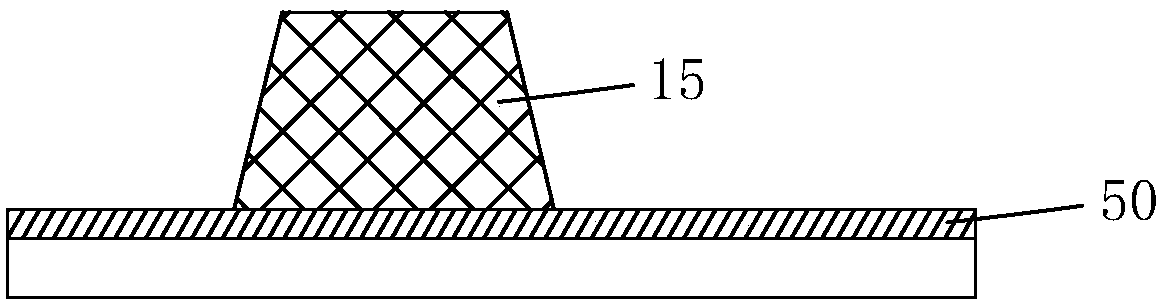

[0023] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0024] The invention provides an etching solution for an IGZO film layer, which contains acid, phosphate, hydrogen peroxide, and water; the pH value of the etching solution for the IGZO film layer is not more than 5.

[0025] Specifically, in the etchant of the IGZO film layer, the mass percentage of the acid is 2%-5%, the mass percentage of the phosphate is 5%-10%, and the mass percentage of the hydrogen peroxide is 15%. %-22%, water is the balance.

[0026] Specifically, the acid is a mixed acid of inorganic acid and organic acid.

[0027] Further, the inorganic acid is phosphoric acid, and the organic acid is at least one selected from acetic acid, oxalic acid, and oxalic acid.

[0028] Specifically, the phosphate is at least one of dihyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com