Substrate processing device

A substrate processing device and processing liquid technology, applied in decorative art, technology for producing decorative surface effects, electrical components, etc., can solve the problem of rising concentration of processing liquid, inability to measure concentration, unstable etching speed of silicon nitride film, etc. problem, to achieve the effect of reducing the amount of etching, increasing the amount of etching, and stabilizing the etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

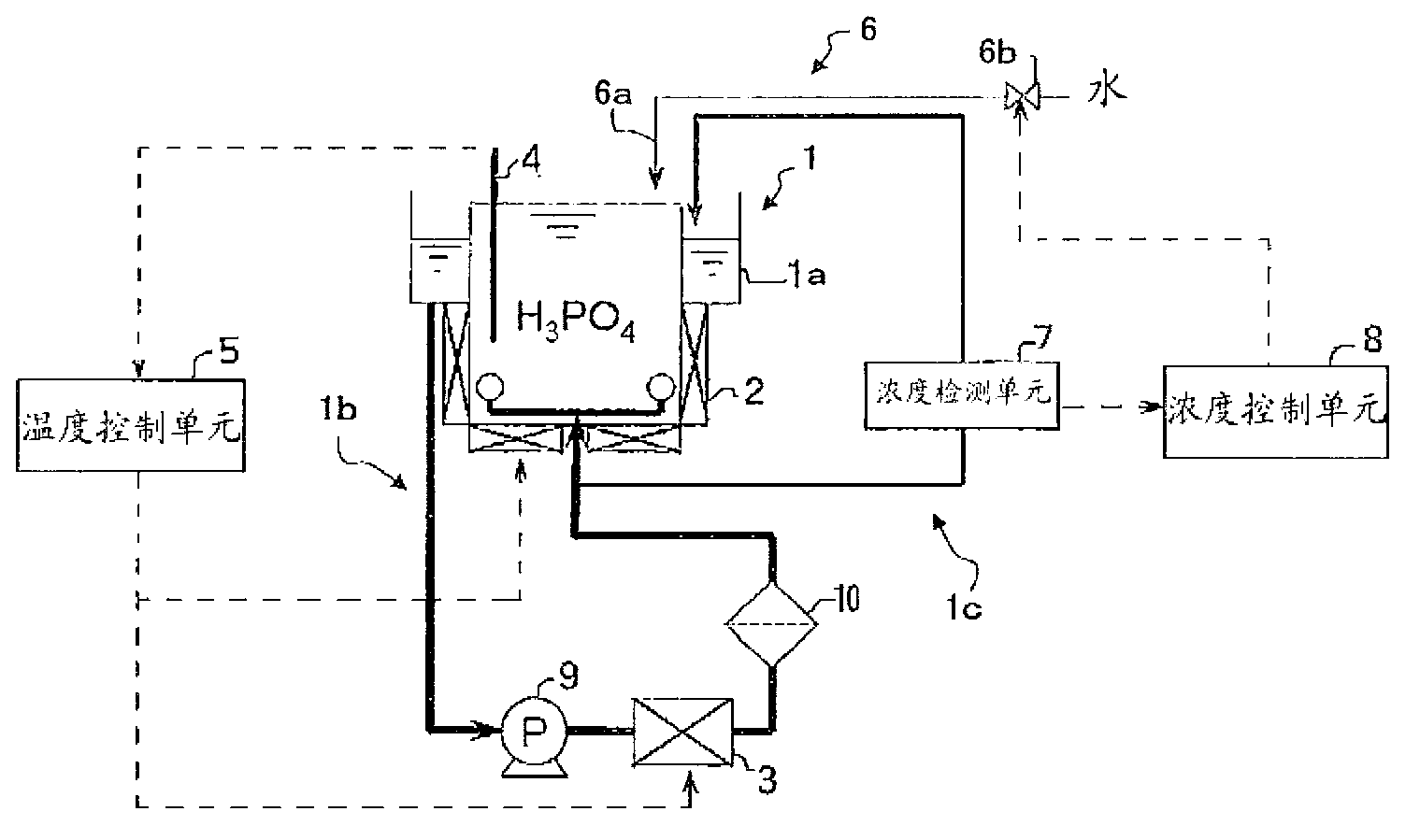

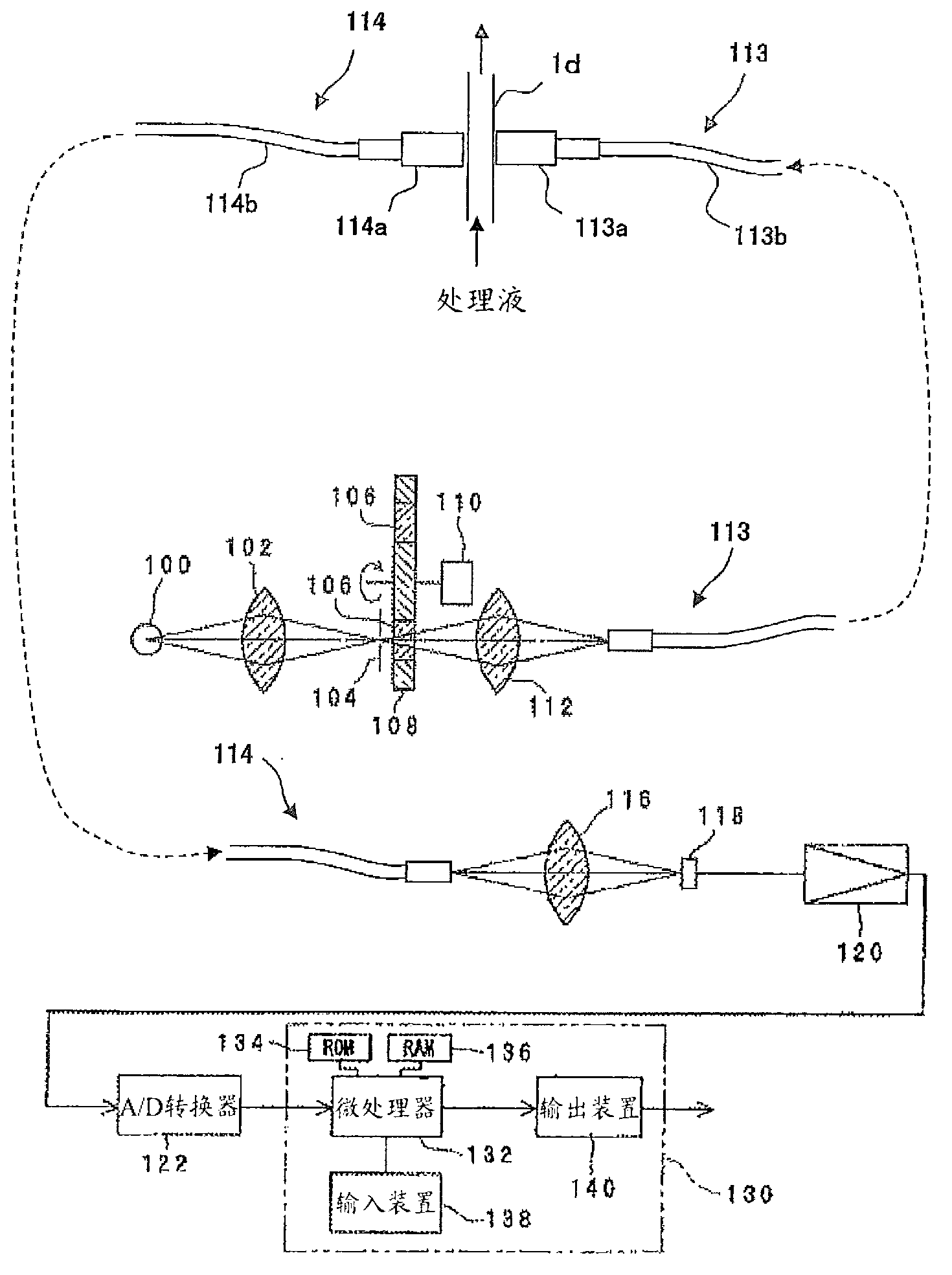

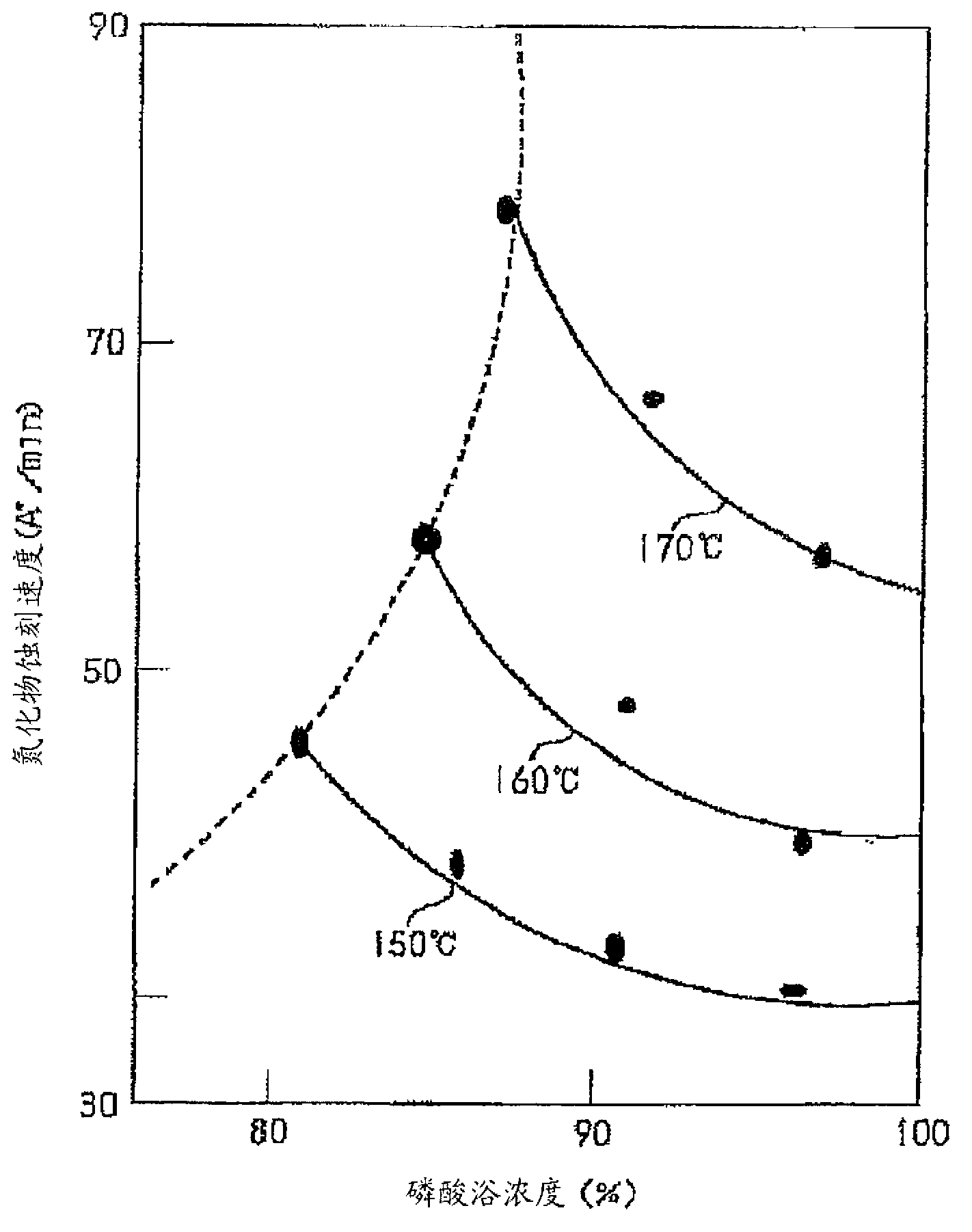

[0026] The substrate processing apparatus of the present invention heats a processing liquid obtained by mixing a chemical liquid and a diluent, and processes a substrate by immersing it in the processing liquid. In this embodiment, the following device is used as an example for description, that is, the treatment liquid is a phosphoric acid solution containing phosphoric acid as a chemical liquid and water as a diluent, the phosphoric acid solution is heated, and a substrate (such as a Silicon wafers) are dipped into the phosphoric acid solution for etching.

[0027] This substrate processing apparatus includes a processing tank 1 for storing a phosphoric acid solution. A recovery tank 1 a for recovering phosphoric acid solution overflowing from the treatment tank 1 is provided around the treatment tank 1 . The phosphoric acid solution recovered from the recovery tank 1a is returned to the treatment tank 1 through the circulation pipe 1b.

[0028] A circulation pump 9 , a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com