Etchant composition, method for etching multilayered film, and method for preparing display device

A technology of composition and etching solution, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of deterioration of operating environment, change of etching rate, dissolution of resist, etc., to prevent etching residues or precipitates, The effect of maximizing linearity and reducing the amount of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

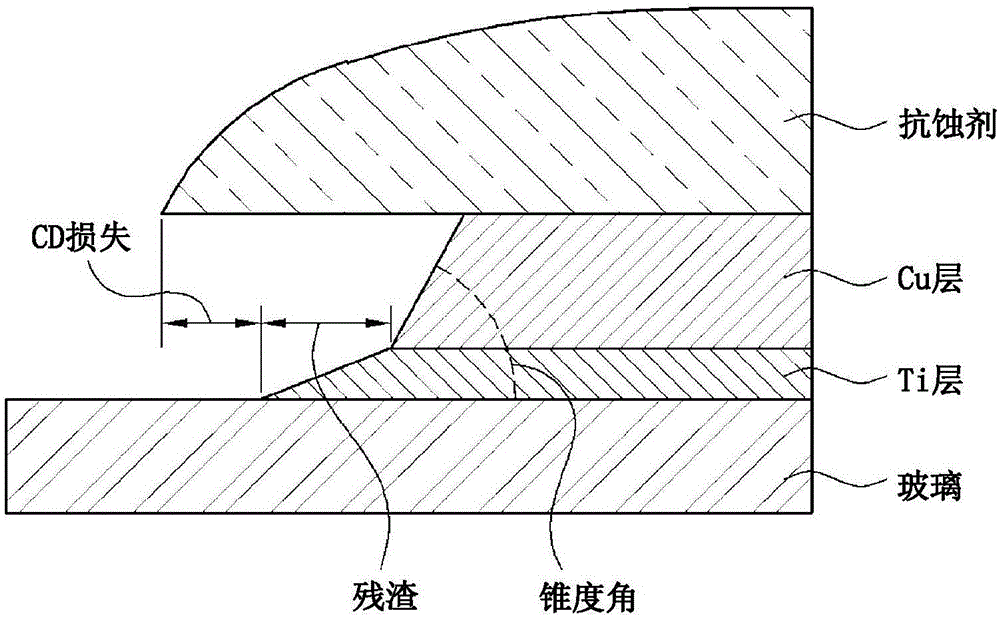

[0112] Production example 1: Fabrication of titanium / copper / titanium / glass substrate

[0113] A layer made of titanium (metal) is formed by sputtering titanium on a glass substrate (size: 150mm×150mm) Next, a layer made of copper (metal) is formed by sputtering copper After that, a layer made of titanium (metal) is formed by sputtering titanium Thus, a three-layer film structure of titanium / copper / titanium is produced. A resist was applied thereto, a line pattern mask (line width: 20 μm) was exposed and transferred, and developed to form a resist pattern, thereby producing a titanium / copper / titanium / glass substrate.

manufacture example 2

[0114] Production example 2: Production of copper / titanium / glass substrate

[0115] A layer made of titanium (metal) is formed by sputtering titanium on a glass substrate (size: 150mm×150mm) Next, a layer made of copper (metal) is formed by sputtering copper In this way, a copper / titanium 2-layer structure is produced. A resist was applied thereto, a line-shaped pattern mask (line width: 20 μm) was exposed and transferred, and developed to form a resist pattern, thereby producing a copper / titanium / glass substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com