One-spindle three-spinning viscose filament semicontinuous centrifugal spinning process and its spinning machine

A viscose filament, centrifugal spinning technology, applied in viscose-made rayon, wet spinning, textiles and papermaking, etc. The problem of uneven number and easy drift of filaments can improve the spinnability of spinning, the number of single filaments is uniform, and the equipment maintenance is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

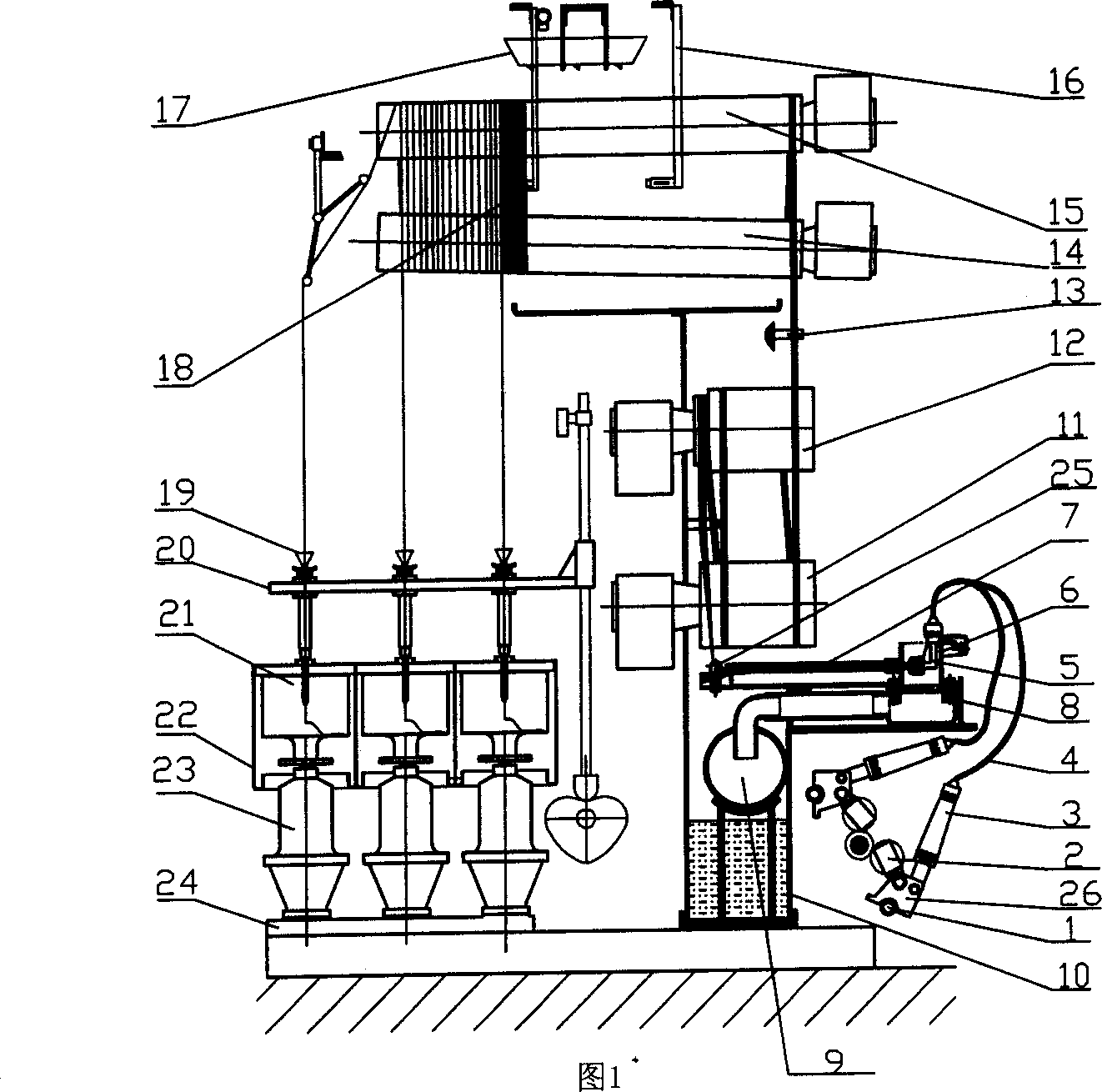

[0032] Process: (1) Viscose metering: Viscose is metered by a gear metering pump, and each nozzle corresponds to an independent metering unit, that is, a pair of metering gears in the metering pump.

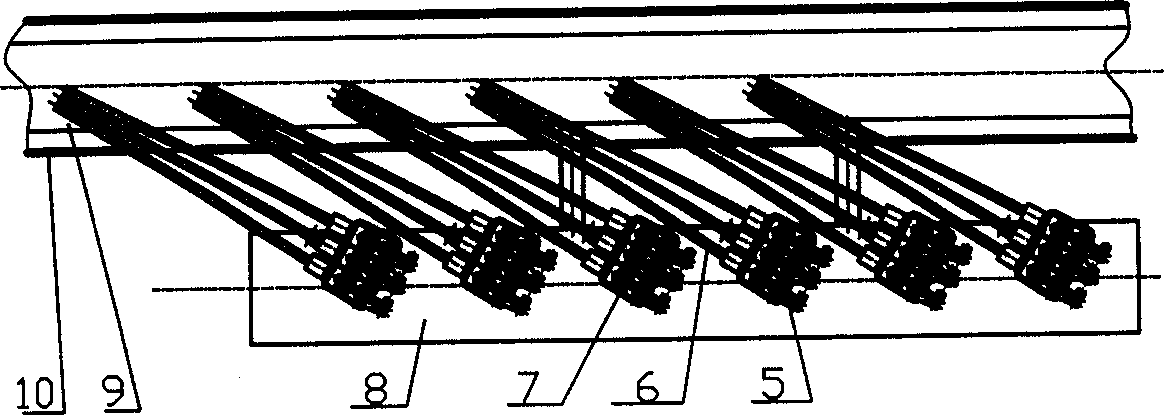

[0033] (2) Viscose filtration: filter with a candle filter.

[0034] (3) Solidification and decomposition reaction of viscose and acid bath: forming in tube, acid bath composition: sulfuric acid content 125-135 g / L, sodium sulfate content 260-270 g / L, zinc sulfate content 10-11 g / L . The acid bath temperature is 51-52°C. The inner diameter of the forming tube is φ6±0.3 mm, and the length of the forming tube is 650±1.0 mm.

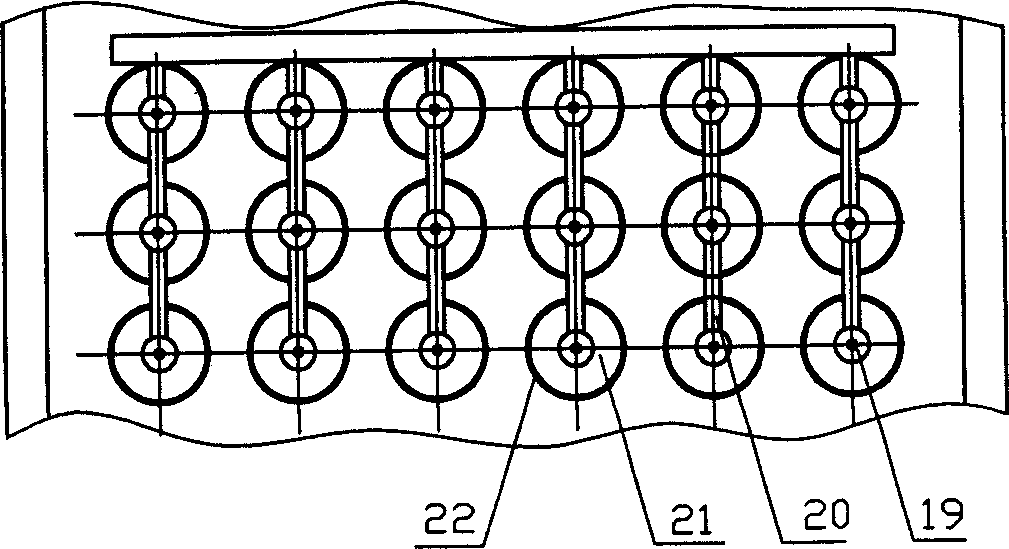

[0035] (4) Deacidification of silk strands: Rinse the middle part of the acid removal roller with soft water to remove acid and salt in the strands.

[0036] (5) Winding and forming of silk cakes: three bundles of silk strips per ingot respectively pass through the lifting funnel and the rotating centrifugal cylinder to form three silk cakes.

[0037] (6) ...

Embodiment 2

[0040] Process: (1) Viscose metering: Viscose is metered by a gear metering pump, and each nozzle corresponds to an independent metering unit, that is, a pair of metering gears in the metering pump.

[0041] (2) Viscose filtration: filter with a candle filter.

[0042] (3) Coagulation and decomposition reaction of viscose and acid bath: forming in tube, acid bath composition: sulfuric acid content 127-137 g / L, sodium sulfate content 265-275 g / L, zinc sulfate content 11-12 g / L . The acid bath temperature is 52-53°C. The inner diameter of the forming tube is φ6.5±0.3 mm, and the length of the forming tube is 750±1.0 mm.

[0043] (4) Deacidification of silk strands: Rinse the middle part of the acid removal roller with soft water to remove acid and salt in the strands.

[0044] (5) Winding and forming of silk cakes: three bundles of silk strips per ingot respectively pass through the lifting funnel and the rotating centrifugal cylinder to form three silk cakes.

[0045] (6) S...

Embodiment 3

[0048] Process: (1) Viscose metering: Viscose is metered by a gear metering pump, and each nozzle corresponds to an independent metering unit, that is, a pair of metering gears in the metering pump.

[0049] (2) Viscose filtration: filter with a candle filter.

[0050] (3) Solidification and decomposition reaction of viscose and acid bath: forming in tube, acid bath composition: sulfuric acid content 130-140 g / l, sodium sulfate content 265-275 g / l, zinc sulfate content 11-12 g / l . The acid bath temperature is 52-53°C. The inner diameter of the forming tube is φ7.0±0.3 mm, and the length of the forming tube is 900±1.0 mm.

[0051] (4) Deacidification of silk strands: Rinse the middle part of the acid removal roller with soft water to remove acid and salt in the strands.

[0052] (5) Winding and forming of silk cakes: three bundles of silk strips per ingot respectively pass through the lifting funnel and the rotating centrifugal cylinder to form three silk cakes.

[0053] (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com