Patents

Literature

141results about How to "Reduce waste volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

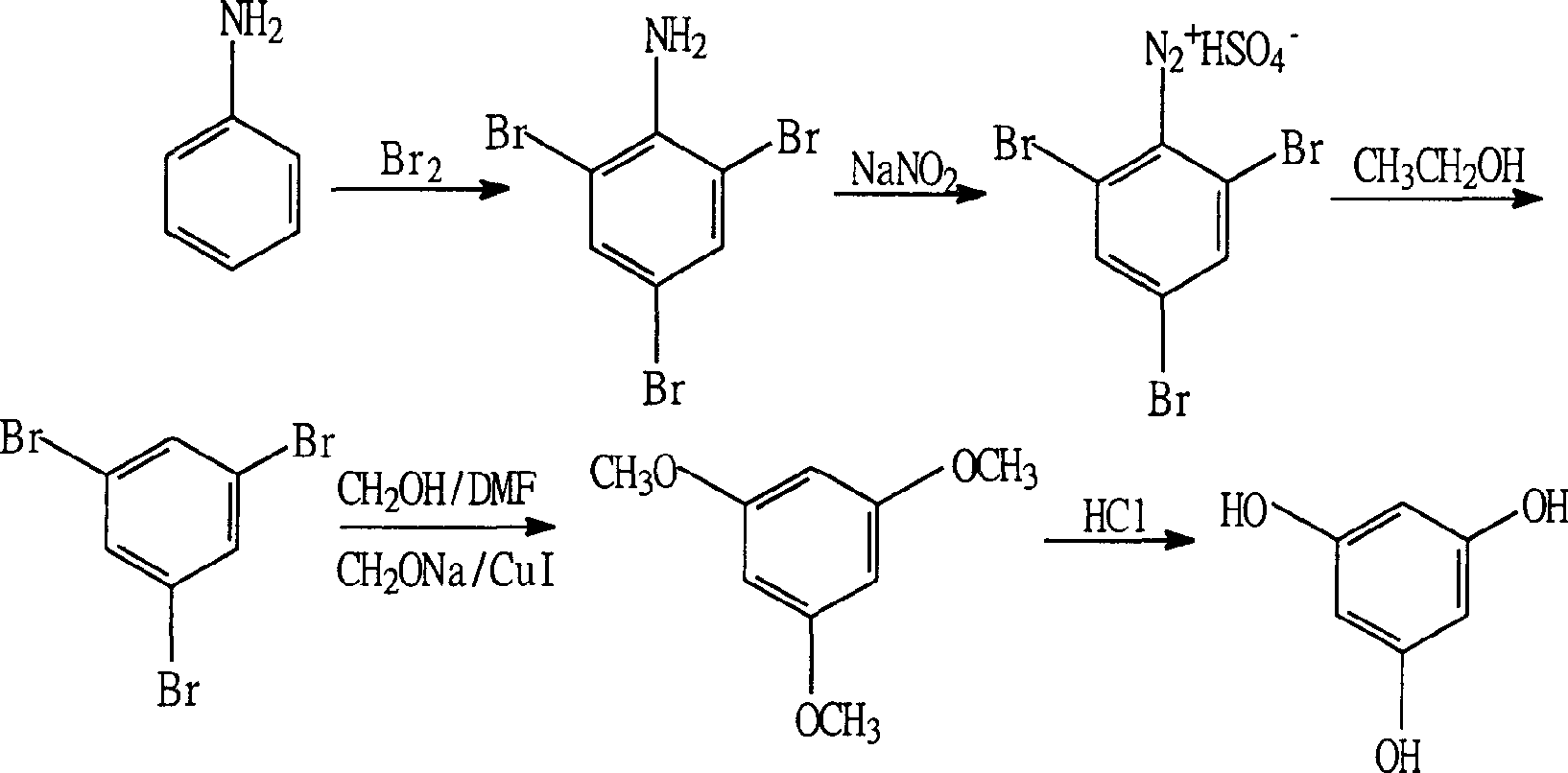

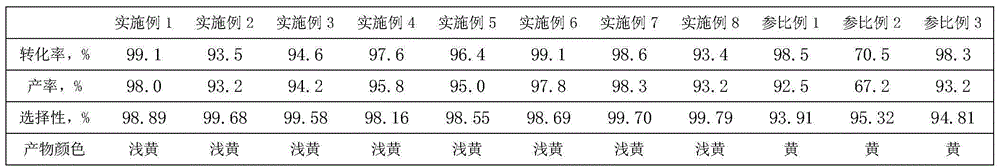

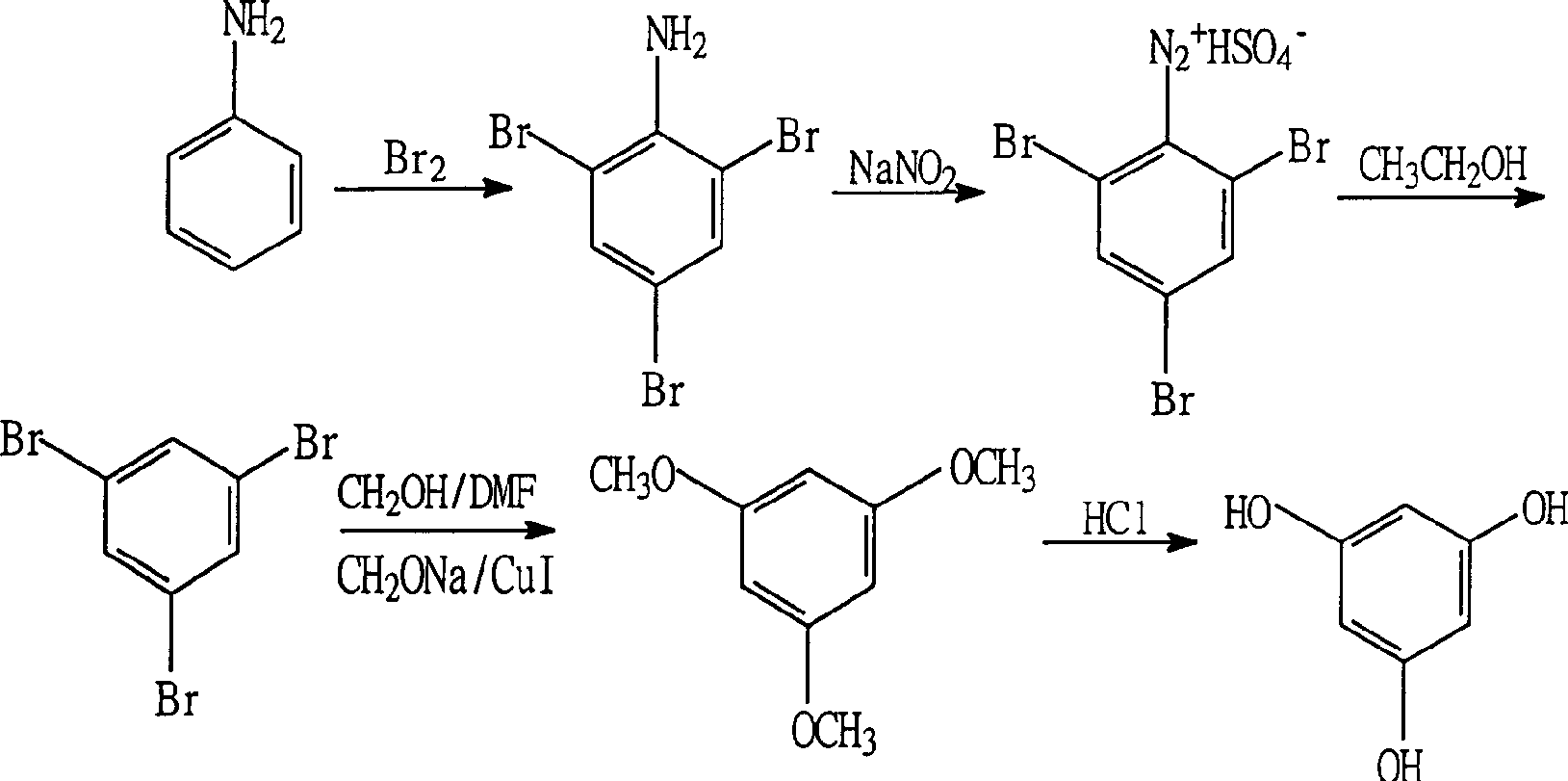

Process for preparing phloroglucinol

InactiveCN1491927AHigh purityShort reaction timeOrganic chemistryOrganic compound preparationBenzeneHydrolysate

The present invention relates to the preparation process of phloroglucinol superior to available preparation process. The present invention features that the preparation process of phloroglucinol includes the complexing reaction between anhydrous aluminum trichloride as complaxing agent and 1, 3, 5-trimethoxy benzene, hydrolysis in concentrated hydrochloric acid solution, cooling and crystallization of hydrolysate to obtain coarse phloroglucinol product, decolorizing with active carbon and re-crystallization in water to obtain refined phloroglucinol product. The said preparation process of the present invention has phloroglucinol product with good color and high purity, short reaction time, less waste liquid exhaust, simple operation condition and high reaction stability.

Owner:ZHEJIANG NHU CO LTD

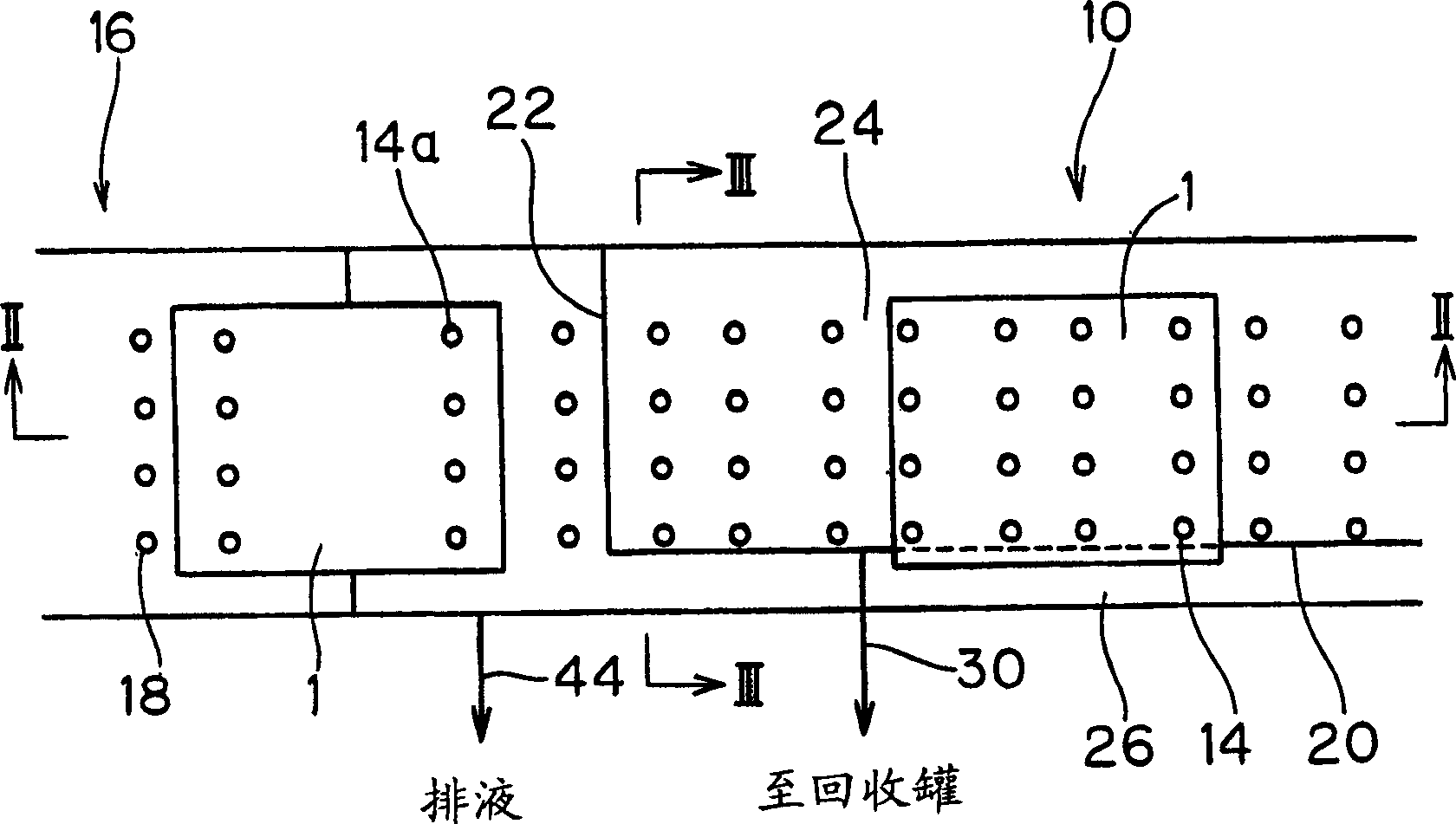

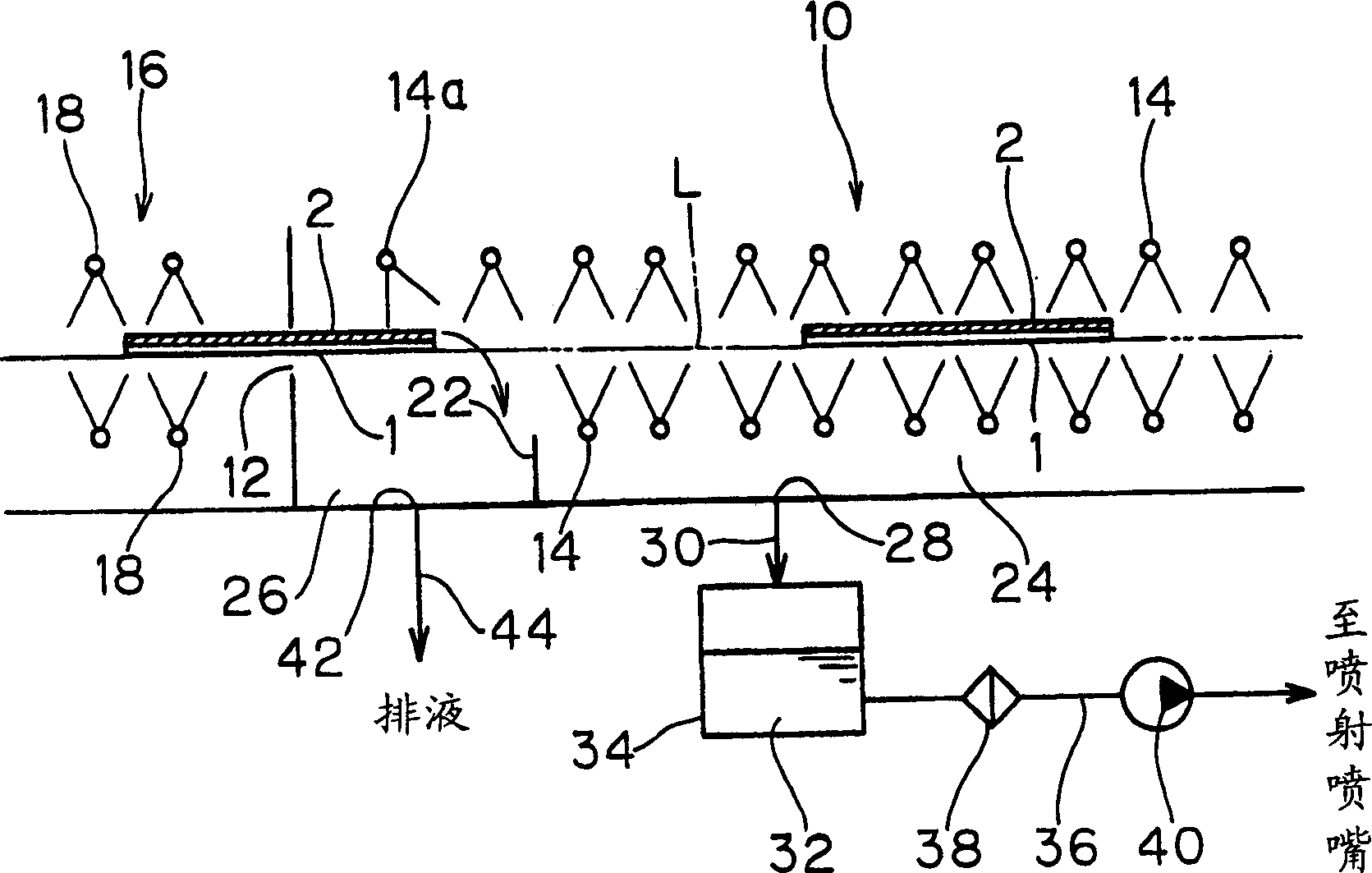

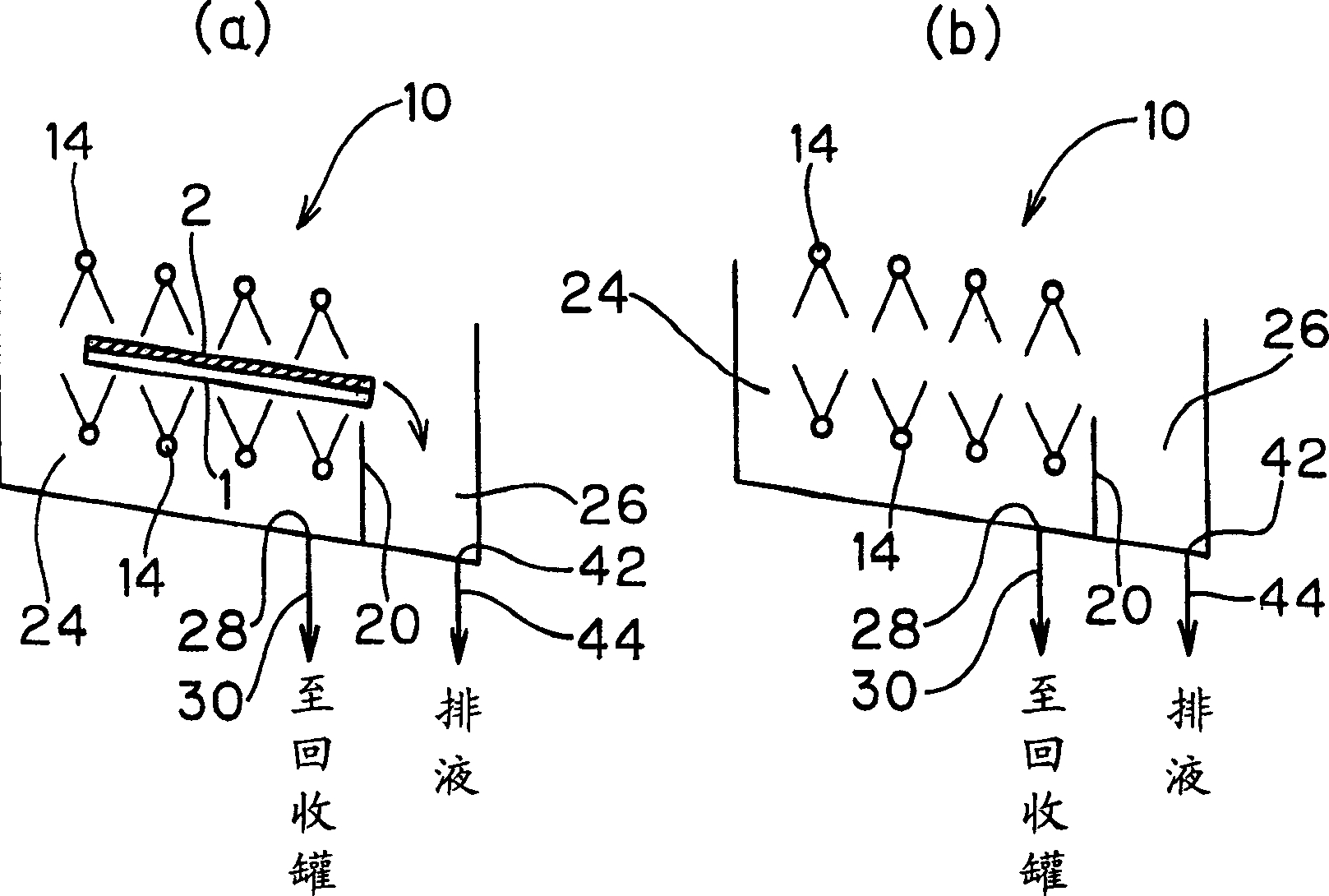

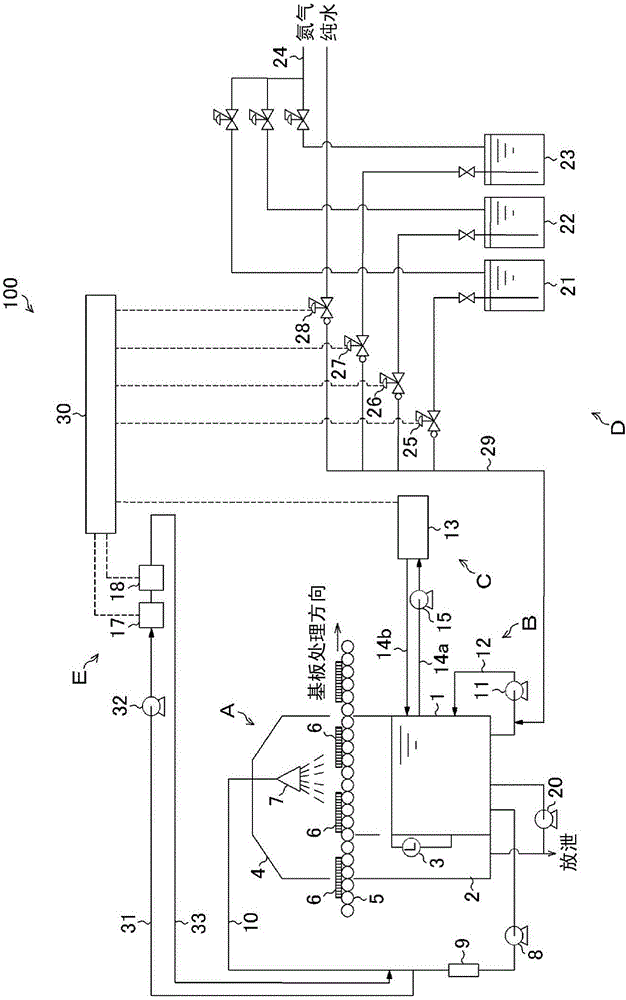

Substrate processing appts.

InactiveCN1447395AReduce processing efficiencyImprove utilization efficiencySemiconductor/solid-state device manufacturingCleaning using liquidsLiquid wasteWater flow

The purpose of the present invention is to provide a kind of apparatus that can reduce the used amount of processing liquid, have less liquid waste, maintain high processing efficiency, and suppress the contamination of component in liquid circulation path to the minimum. In the direction perpendicular to the conveying direction, the substrate 1 is conveyed in an inclined state relative to the horizontal plane. In the vicinity of the position right below the lower side edge of substrate on the inner bottom plane of the water washing processing tank 10, the isolation plate is erect along the substrate conveying direction so as to separate the inner bottom portion of the water washing processing tank and divide it into the followings: the recycling tank portion 24 for recycling pure water that expels from the pure water expelling nozzle 14 without flowing through the substrate face; and the exhausted liquid tank portion 26 for accommodating the used pure water that is expelled from pure water expelling nozzle to flow toward the lower substrate side and falls from the edge. Therefore, pure water recycled inside the recycling tank portion can be used again; and the used pure water flowing inside the exhausted liquid tank portion is exhausted.

Owner:DAINIPPON SCREEN MTG CO LTD

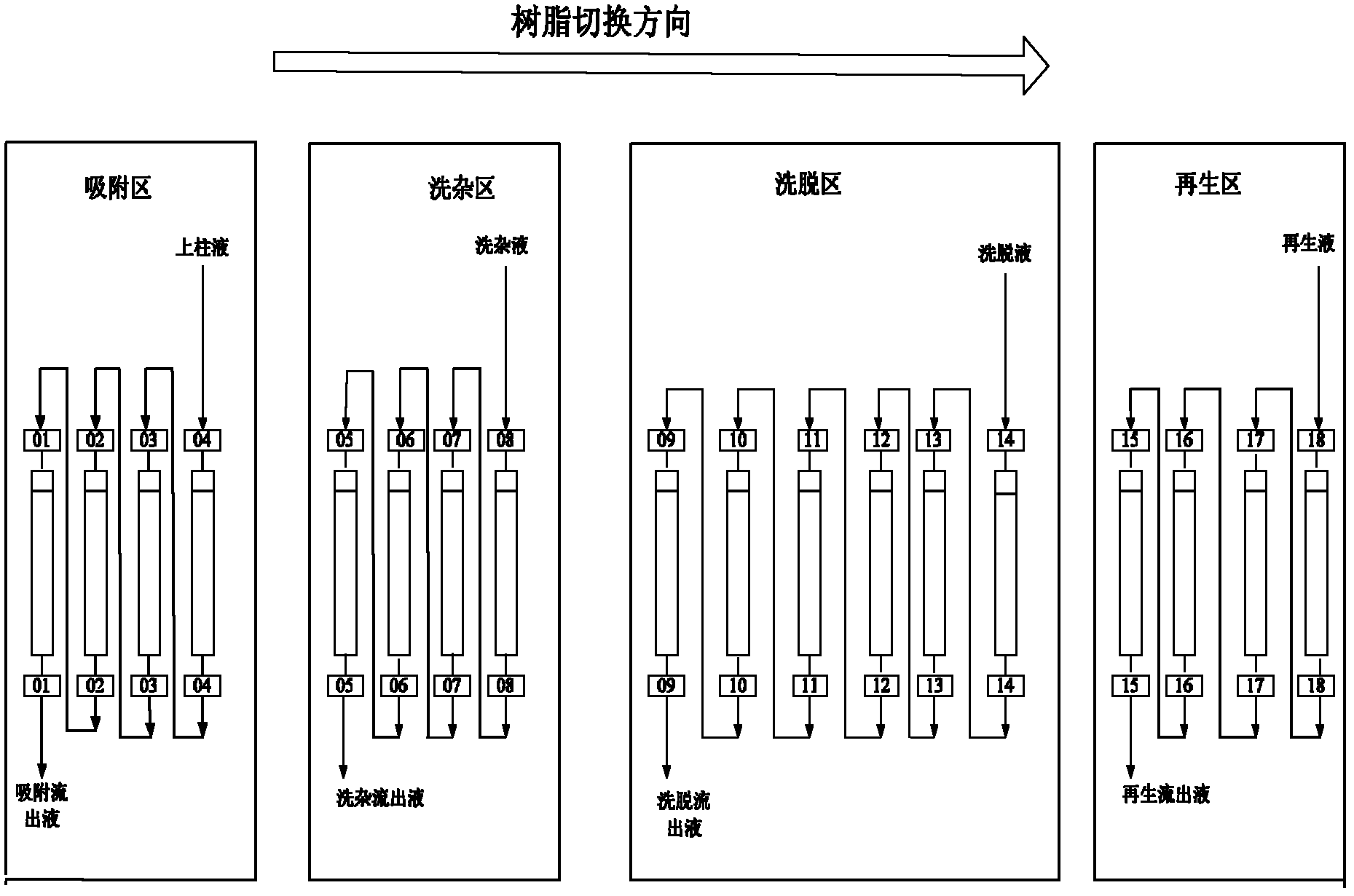

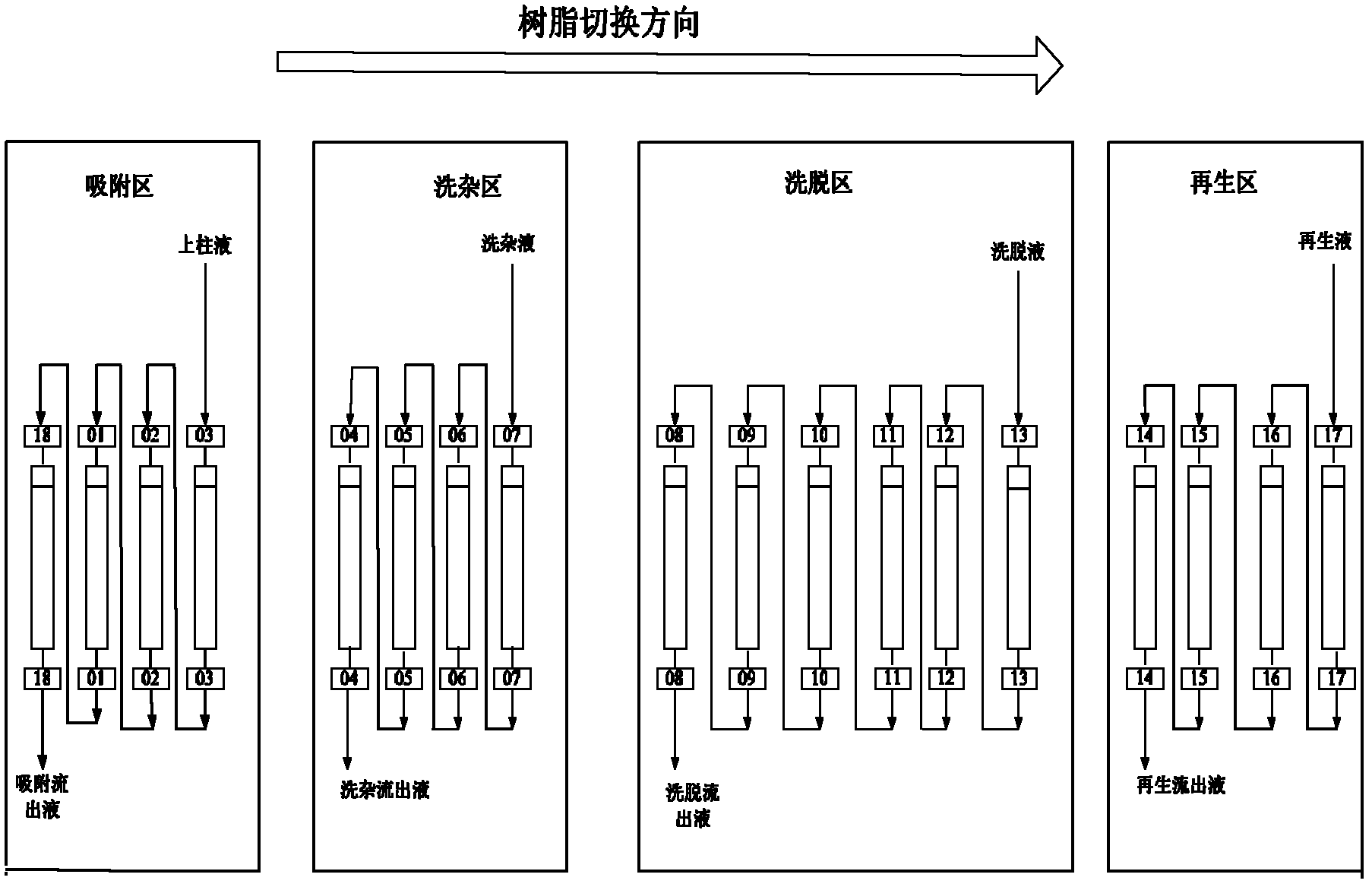

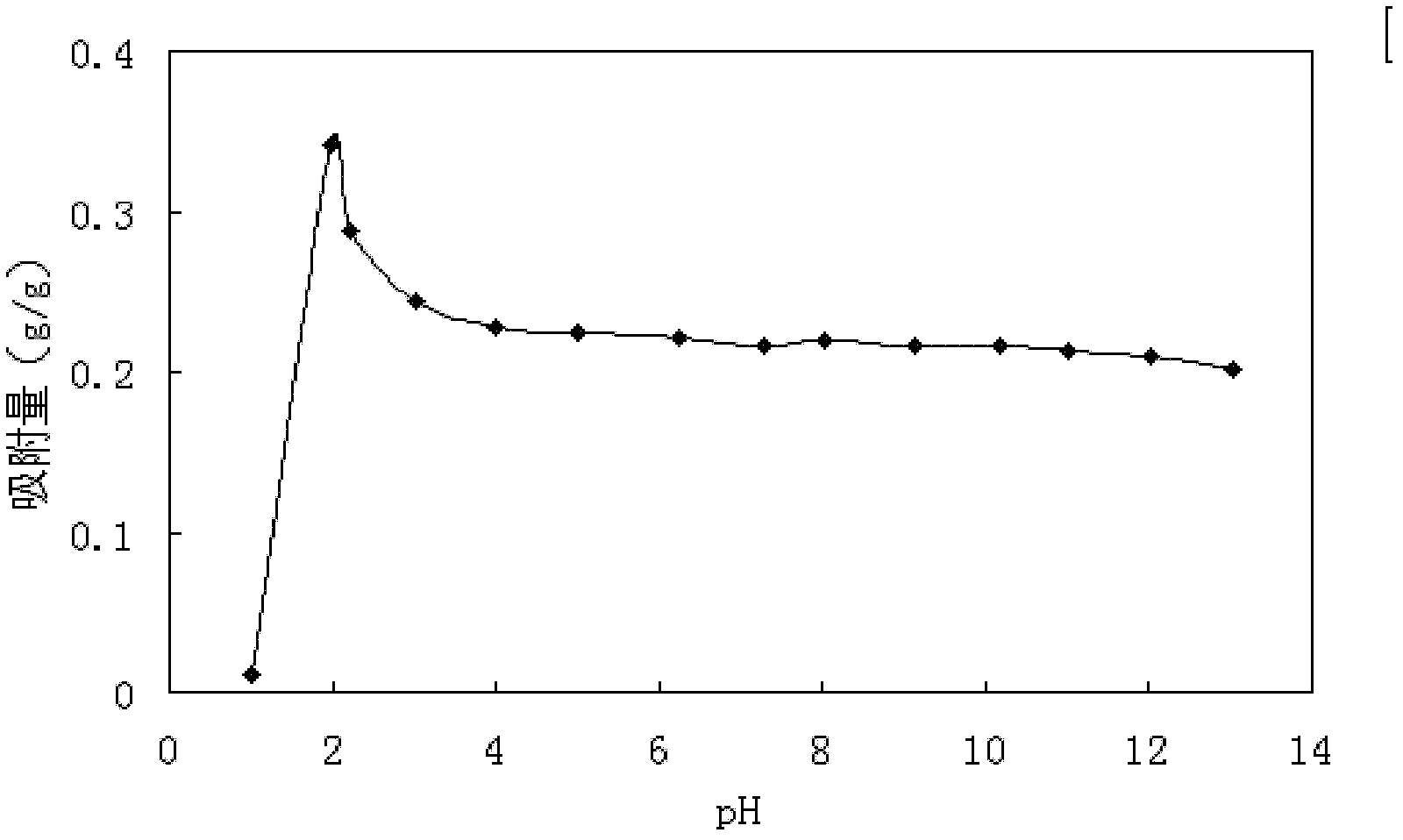

Method for continuously separating sialic acid

ActiveCN102532208ASave pipesSmall footprintSugar derivativesSaccharide compounds with non-saccharide radicalsPurification methodsUltrafiltration

The invention discloses a method for continuously separating sialic acid, wherein sialic acid is prepared through microbial fermentation by taking N-acetyl glucosamine and sodium pyruvate as substrates; fermentation liquor is processed through filtration and ultrafiltration so as to obtain sialic acid clear liquid; sialic acid clear liquid is pumped in a continuous ion exchange system provided with OH-type anion exchange resin for adsorption; deionized water is adopted for leaching; a sodium chloride solution is adopted for elution; a sodium hydroxide solution is adopted for resin regeneration; eluent containing sialic acid is collected, is leached through an ethanol water solution, and then is added with ethyl acetate for dilution crystallization; and crystals are dried under reduced pressure, so that pure sialic acid is obtained. The separation and purification method is simple, convenient and feasible, achieves good effect and low running cost, and can implement the separation from kilogram class to ton class according to the separation amount; and in addition, products that are obtained by adopting the method gain excellent results on yield coefficient and product quality, and the product quality is ensured..

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

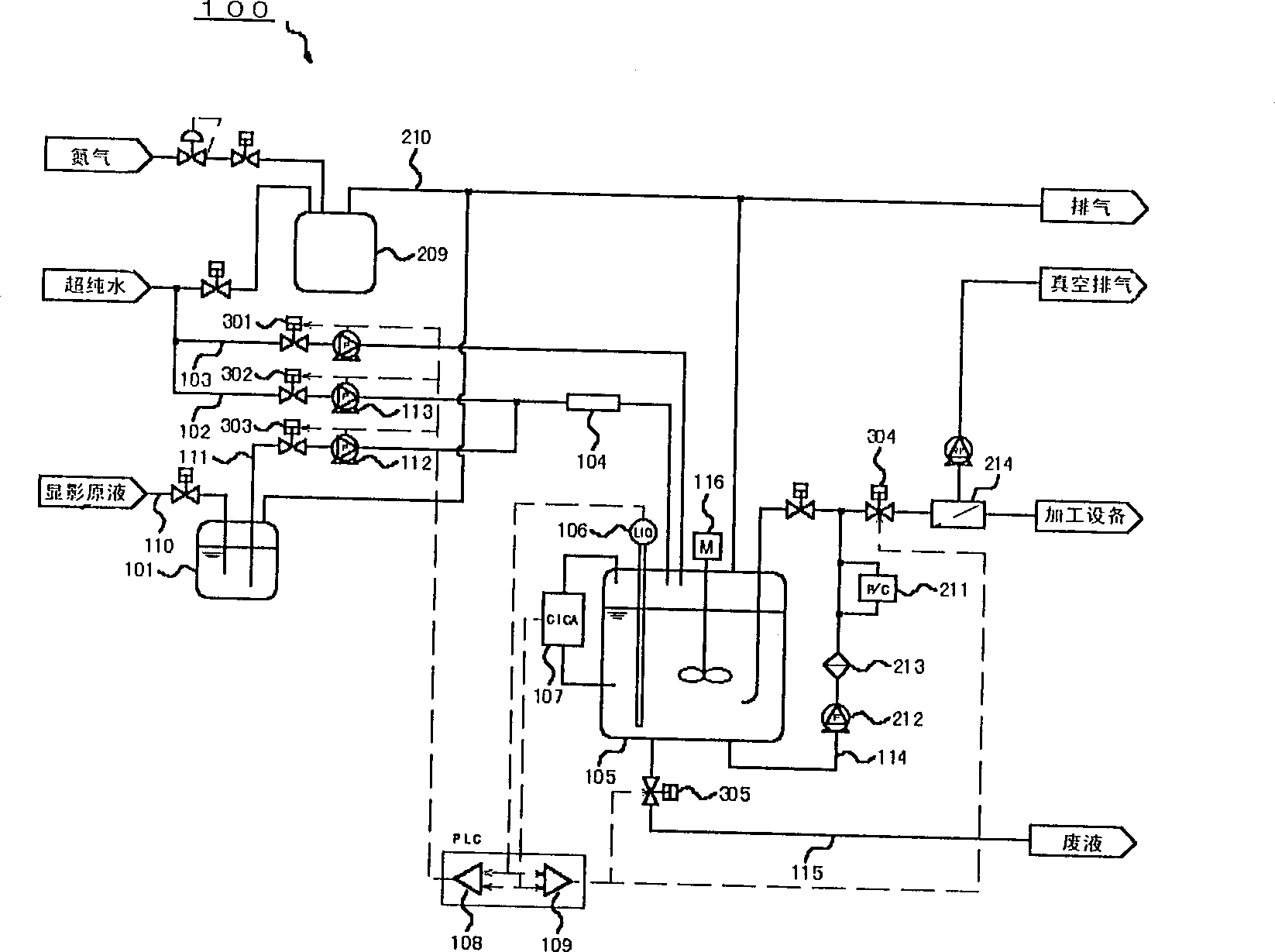

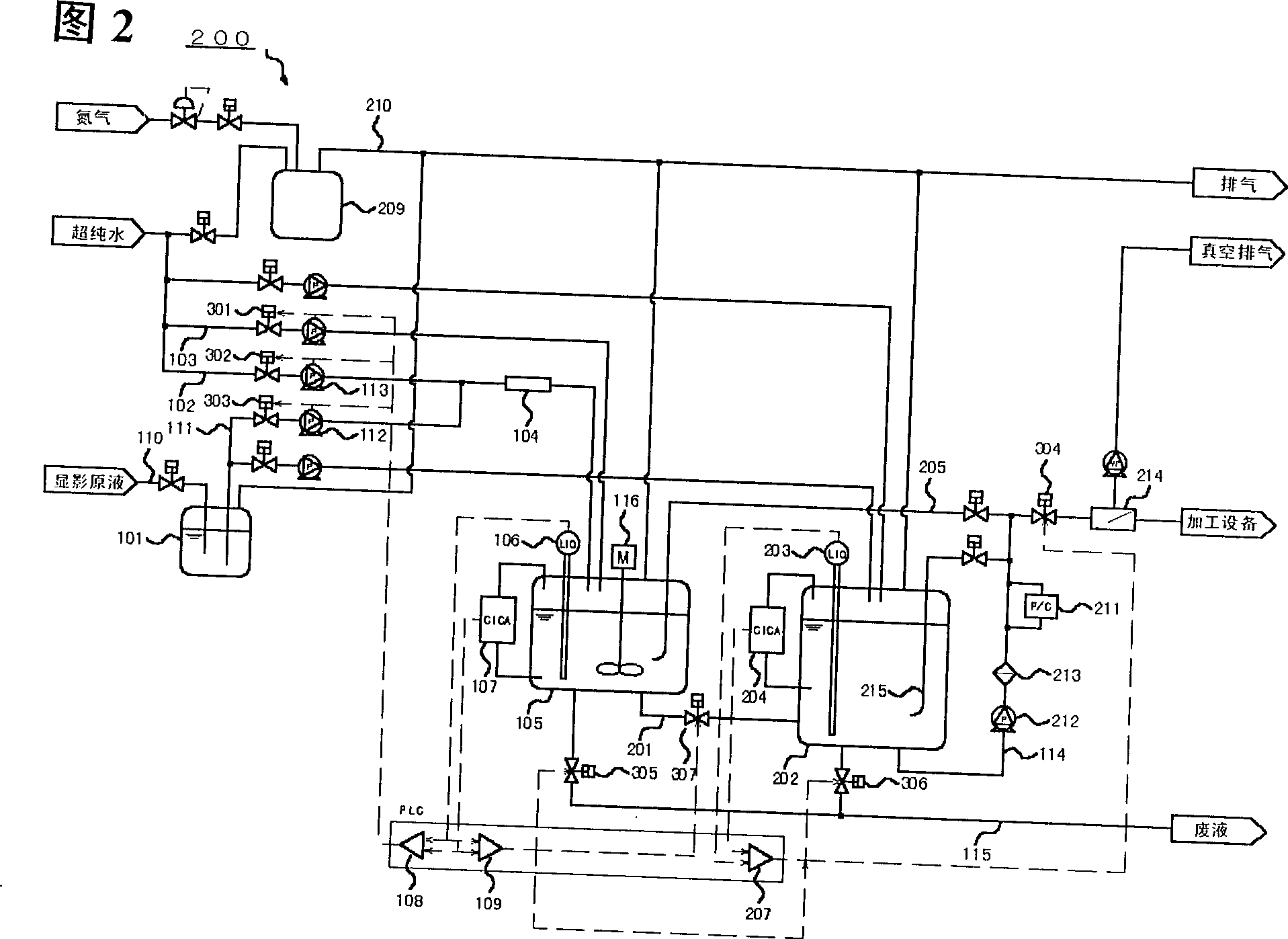

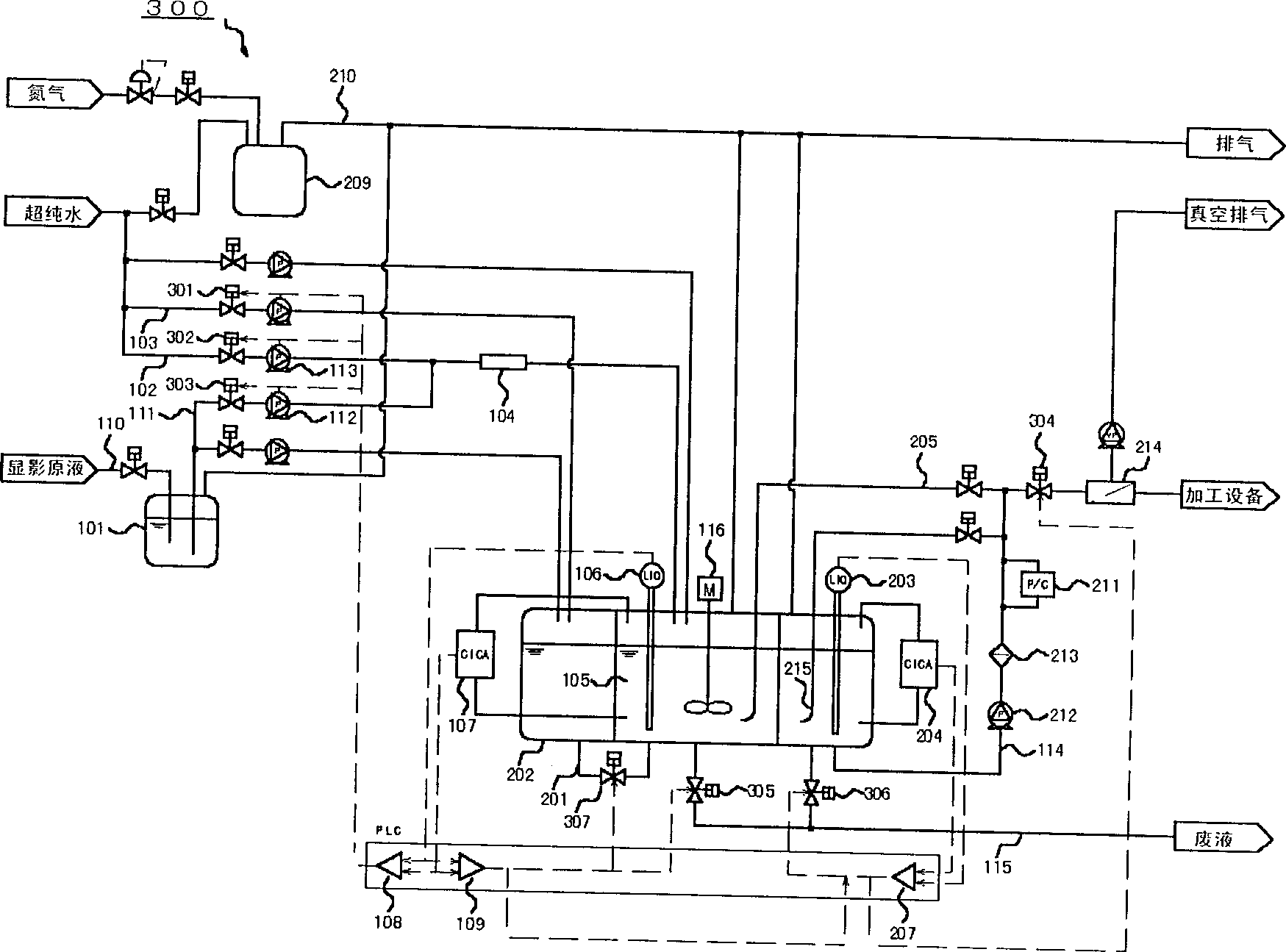

Developing liquid mfg. device and method

InactiveCN1373393AEasy to adjustHigh precisionLiquid processingSemiconductor/solid-state device manufacturingProcess engineeringWater supply

Provided is a developing solution manufacturing device and method, the device comprising: a preparation tank for supplying and stirring a developing stock solution and pure water to prepare an alkali-based developing solution; and a first liquid volume measuring device for measuring the amount of the alkaline-based developing solution in the preparing tank; A first alkali concentration measuring device for measuring the alkali concentration of the alkali-based developer in the preparation tank; adjusting the amount of the alkali-based developer in the preparation tank based on the measured values of the first liquid volume measuring device and the first alkali concentration measuring device a first liquid volume control device; and adjusting at least one of the supply volume of the developing stock solution and the supply volume of pure water supplied to the preparation tank based on the measured values of the first liquid volume measurement device and the first alkali concentration measurement device liquid supply control device.

Owner:NAGASE & COMPANY +1

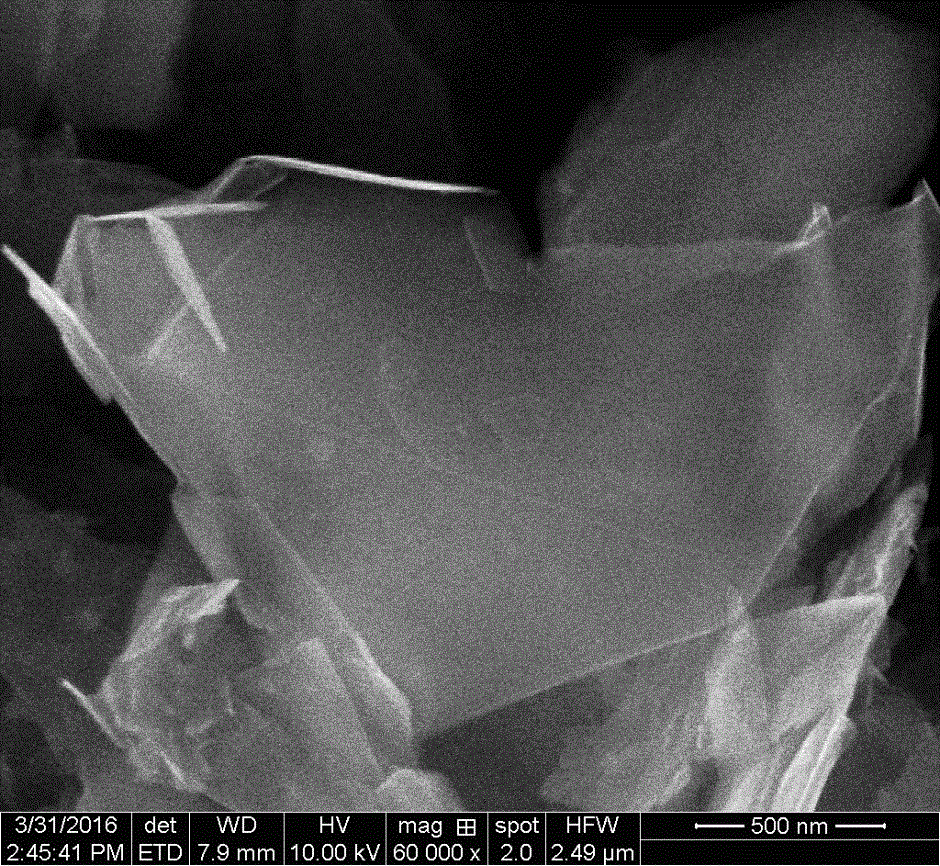

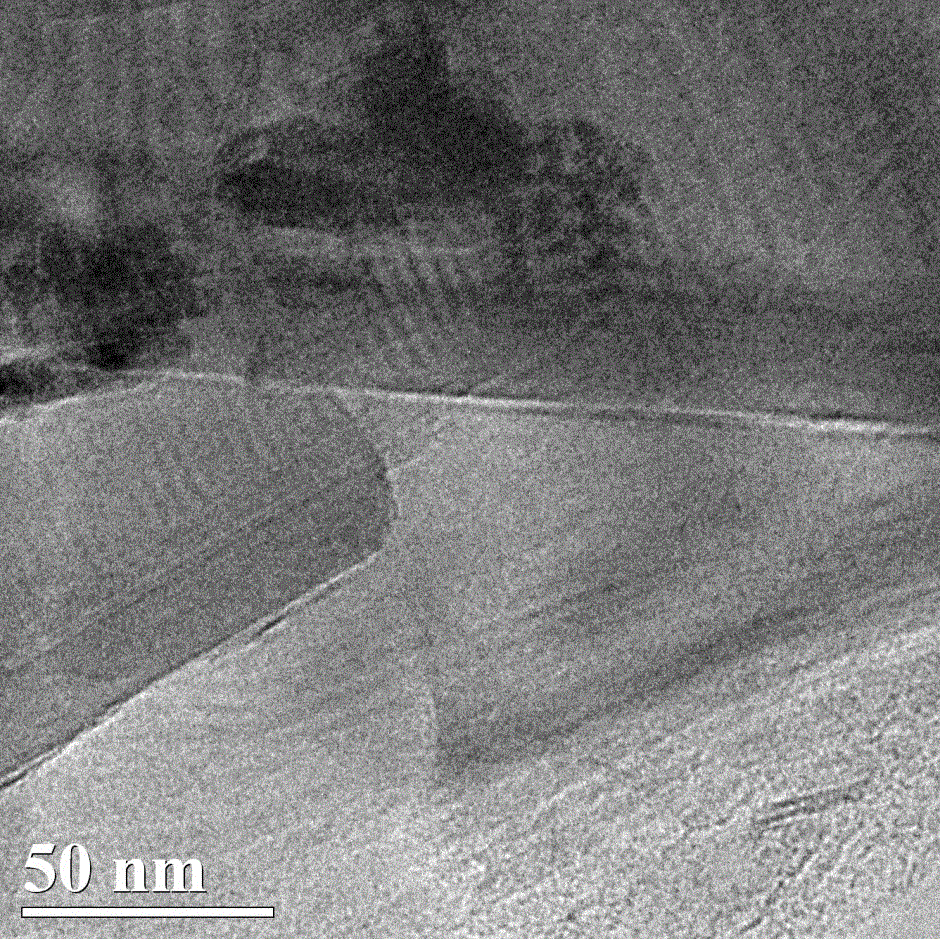

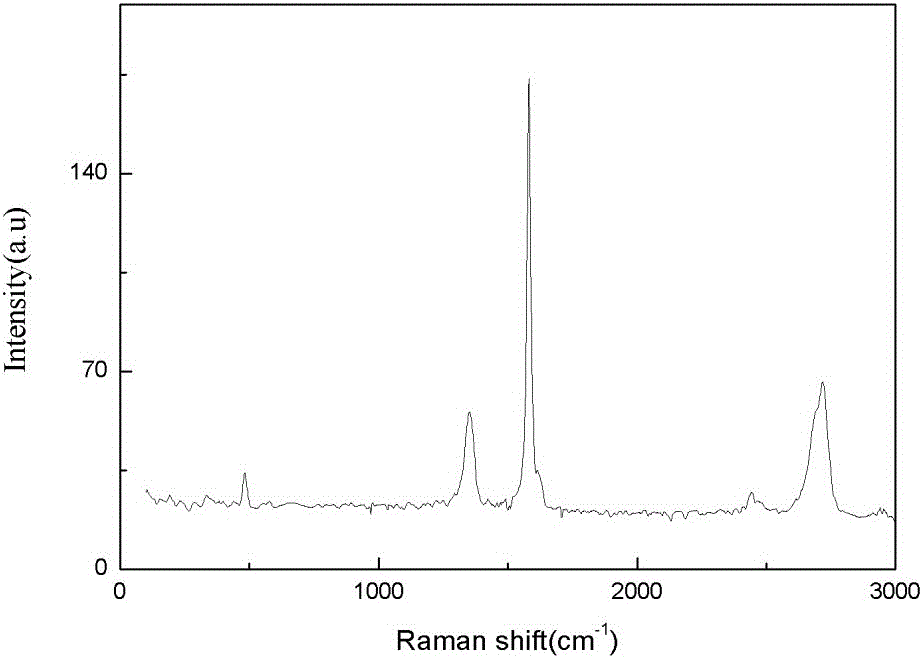

Low-cost preparation method of graphene

The invention belongs to the technical field of graphene preparation, and in particular relates to a method for preparing graphene at low cost. The invention combines the advantages of liquid phase exfoliation and mechanical ball milling to prepare graphene. Firstly, the graphite powder is ultrasonically exfoliated in an organic solvent, so that the layer spacing between atoms in the graphite becomes larger and the van der Waals force is weakened, and then the planetary ball mill is used. The exfoliated graphite powder is subjected to wet rapid high-energy ball milling, and the shear force exerted by the grinding ball on the graphite is used to exfoliate the graphite layer by layer into graphene. The graphite used in the present invention has a wide range of sources, and the organic solvent is also a common industrial solvent, with low cost and simple operation process, and can be used for large-scale production.

Owner:UNIV OF JINAN

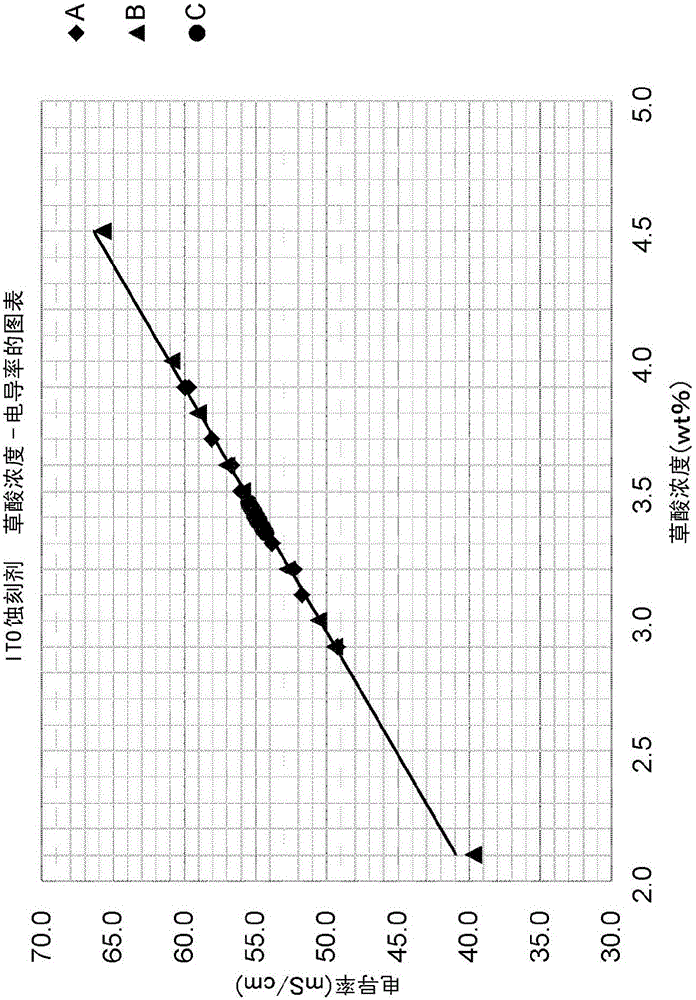

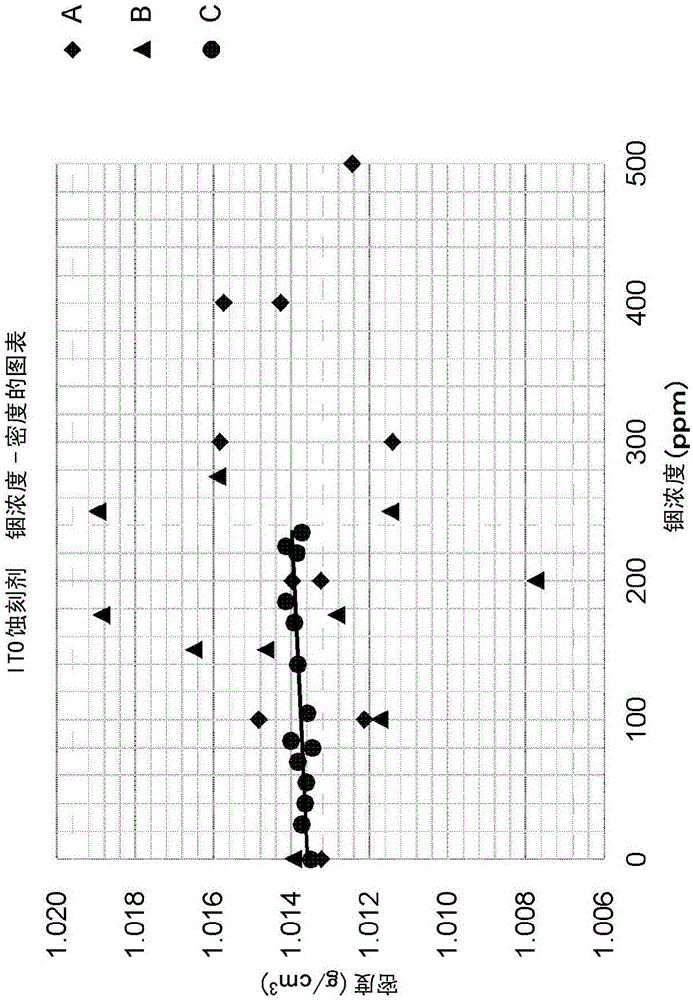

Etching solution managing apparatus, dissolved metal concentration measuring apparatus and dissolved metal concentration measuring method

InactiveCN105278566AControl concentrationThe concentration is accurately calculatedAnalysing fluids using sonic/ultrasonic/infrasonic wavesControlling ratio of multiple fluid flowsPhysical chemistryAcid concentration

The invention provides an etching solution managing apparatus, a dissolved metal concentration measuring apparatus and a dissolved metal concentration measuring method that can monitor the concentration of the etching solution and the concentration of the dissolved metal so that a replenisher is automatically supplied in a concentration fixed way and the dissolved metal is separated and recycled. The etching solution managing apparatus comprises a first property value measurement mechanism that measures a first property value related to the acid concentration of the etching solution; a second property value measurement mechanism that measures a second property value related to the concentration of the dissolved metal; a replenisher transmission controlling mechanism that controls the transmission of the supplied replenisher based on the relation between the acid concentration and the first property value and the measurement result of the first property value; a dissolved metal recycling and removing mechanism hat recycle and remove the dissolved metal based on the relation between the concentration of the dissolved metal and the second property value and the measurement result of the second property value.

Owner:HIRAMA LAB

Method for synthesizing phthalate compounds

InactiveCN104592030AReduce the temperatureSave energyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholCatalytic effect

The invention provides a method for synthesizing phthalate compounds. By taking a weak acid as a main catalyst assisted by a composite catalyst formed by other co-catalysts, the phthalate compounds are synthesized. The method specifically comprises the following steps: adding phthalic anhydride, alcohol and the composite catalyst into a reactor, wherein the molar ratio of phthalic anhydride and alcohol is 1: (2.1-5.0) and the addition of the composite catalyst is 0.2-10wt% of phthalic anhydride; and sealing the reactor, raising the temperature till boiling, reacting for 0.5-2 hours and rectifying to obtain a product. The method not only can realize a catalytic effect of concentrated sulfuric acid, but also overcome the defects. Moreover, the used catalyst can be separated and reused by using a conventional method, so that the separating flow is greatly simplified and continuous production is facilitated.

Owner:NANJING COLLEGE OF CHEM TECH

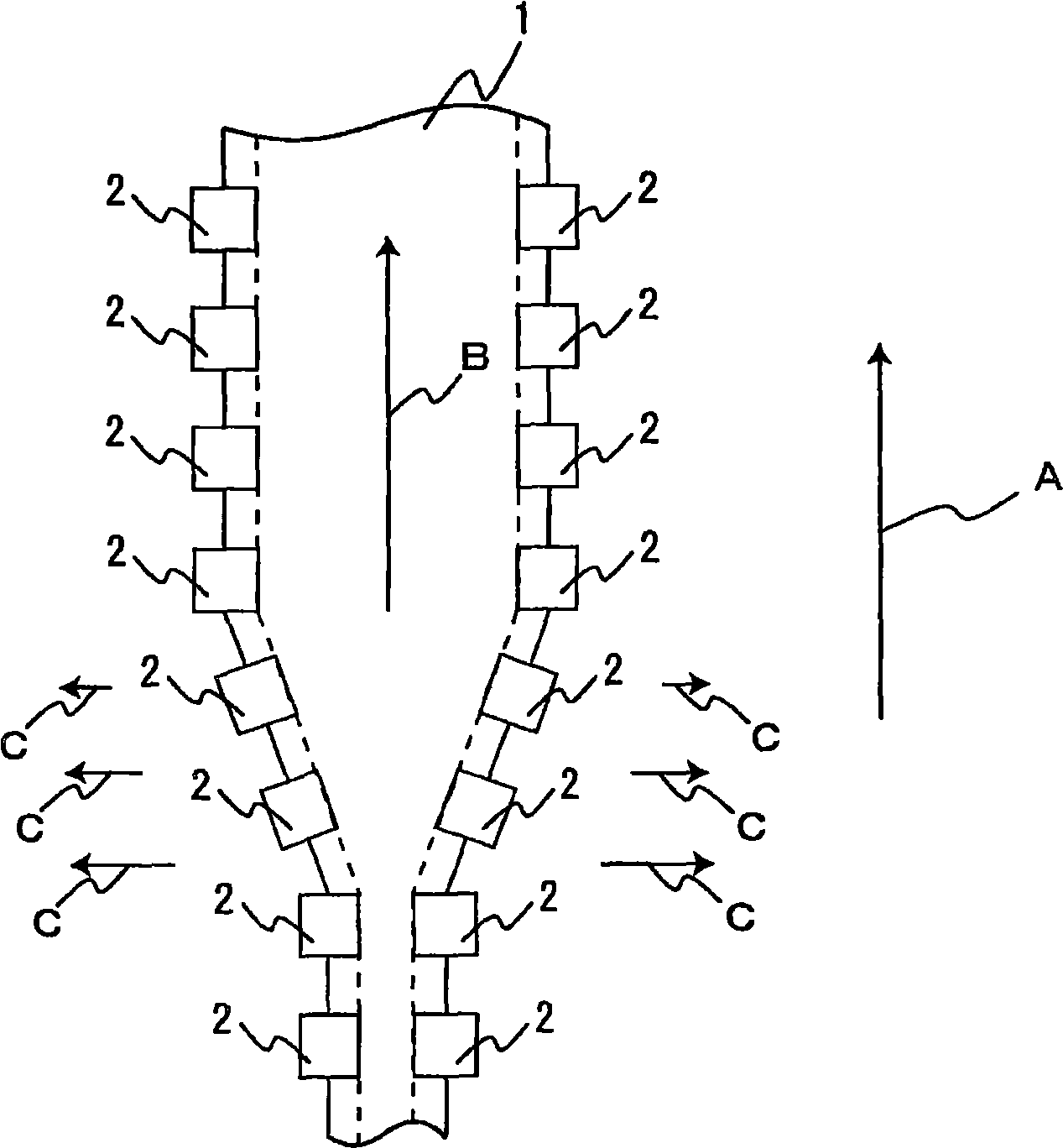

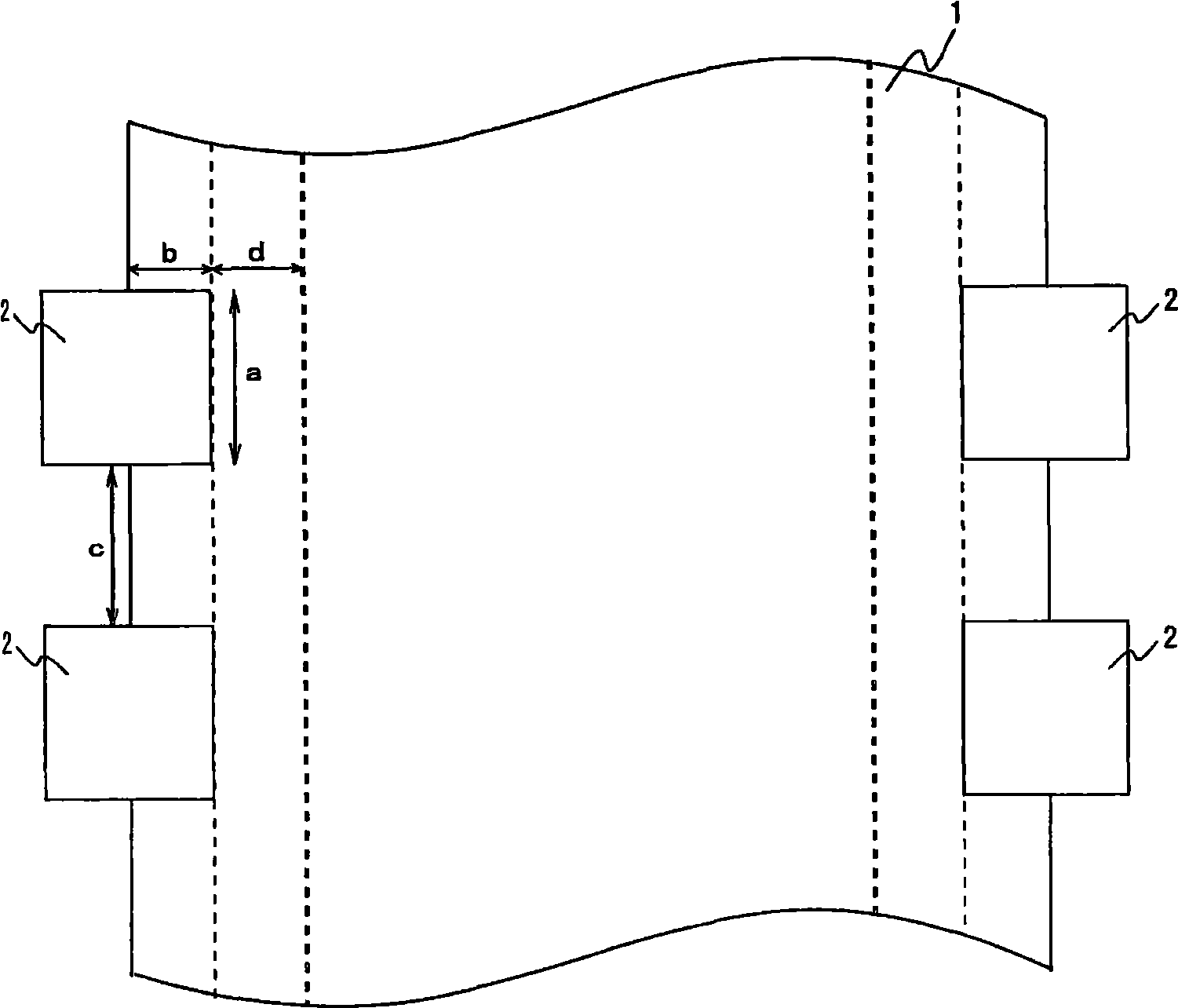

Process for producing polarizer, polarizer, polarizing plate, optical film, process for producing composite polarizing plate, composite polarizing plate, and image display device

InactiveCN101501538AReduce the use effectReduce waste volumePolarising elementsOptical articlesEngineeringPolarizer

This invention provides a process for producing a polarizer which can simultaneously realize the contact of a liquid with a hydrophilic polymer film and stretching of the hydrophilic polymer film in the widthwise direction by a tenter method or the like, using a small and simple production apparatus. The production process comprising a widthwise direction stretching step of holding both ends in the widthwise direction of a hydrophilic polymer film (1), being continuously supplied, by holding means (2), allowing the holding means (2) to travel in the longitudinal direction of the film (1), bringing the film (1) into contact with a liquid, and further moving the holding means (2), which holds at least one side of both the ends of the film (1) in its widthwise direction, to the outer side of the film (1) in its widthwise direction to stretch the film (1) in its widthwise direction, and a dying step of dying the film (1) with a dichroic substance. In the widthwise direction stretching step, the contact of the liquid is carried out by at least one of spraying and coating of the liquid, and the widthwise direction stretching step is carried out in at least one of the dying step and another step different from the dying step.

Owner:NITTO DENKO CORP

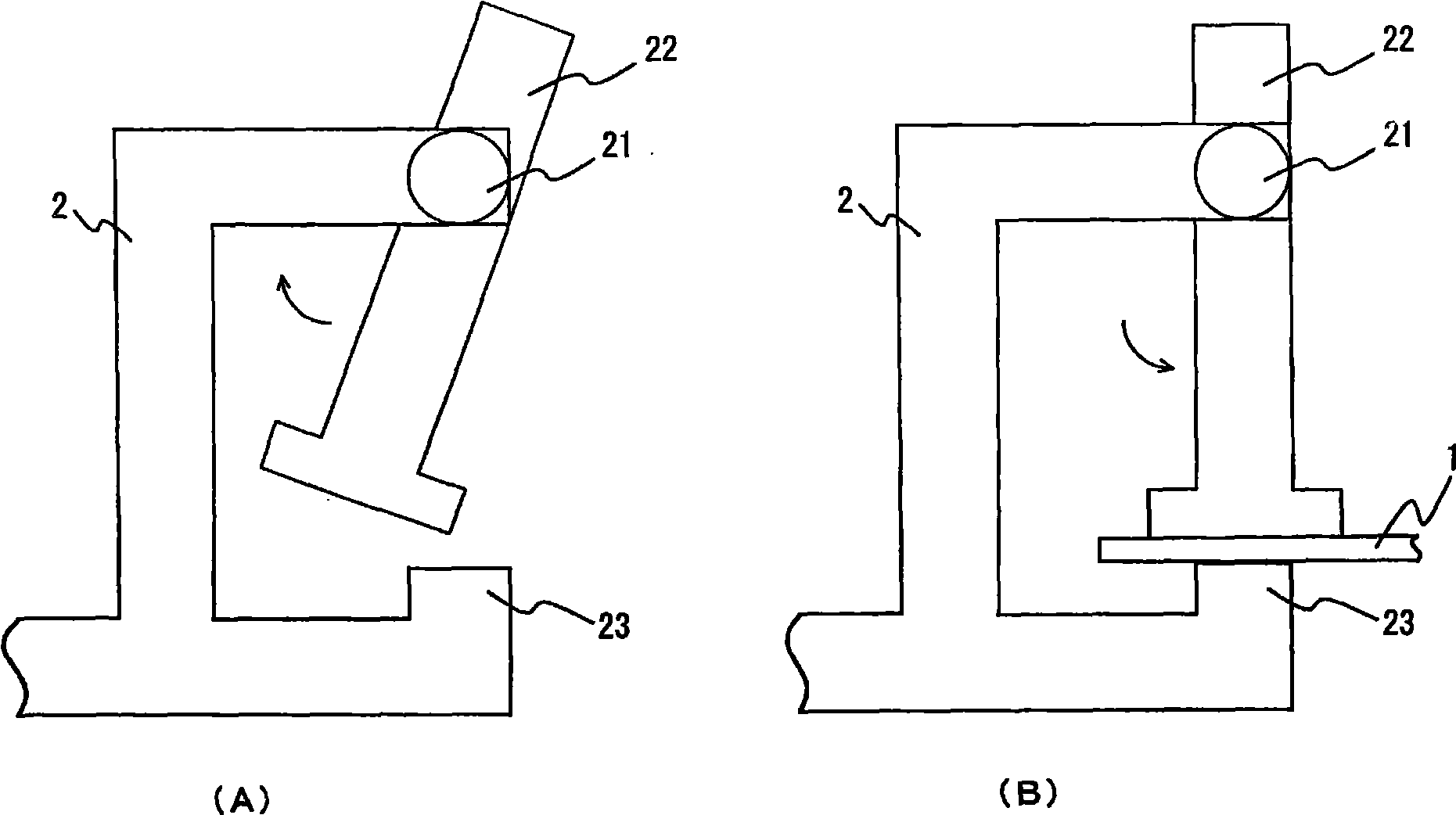

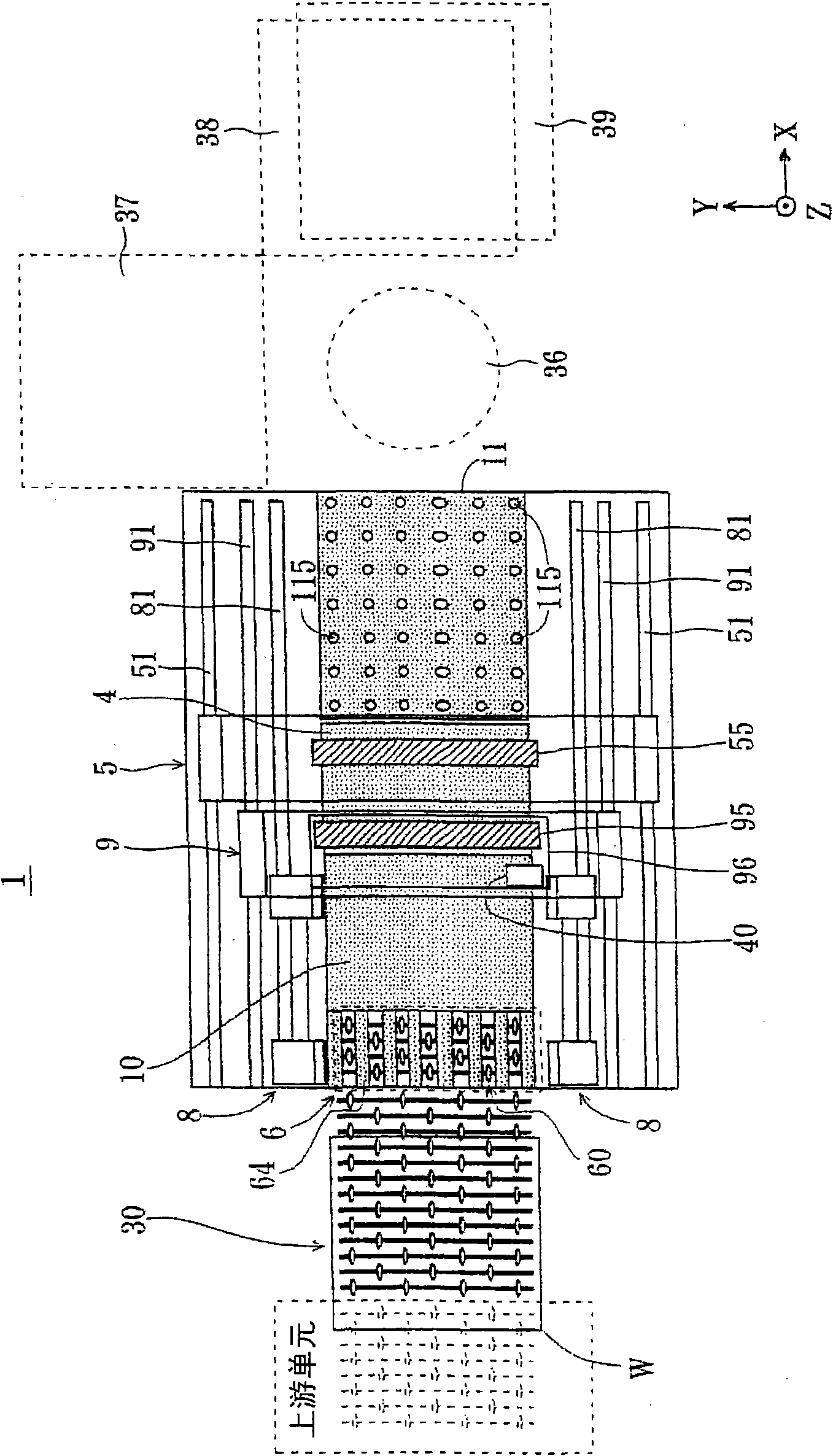

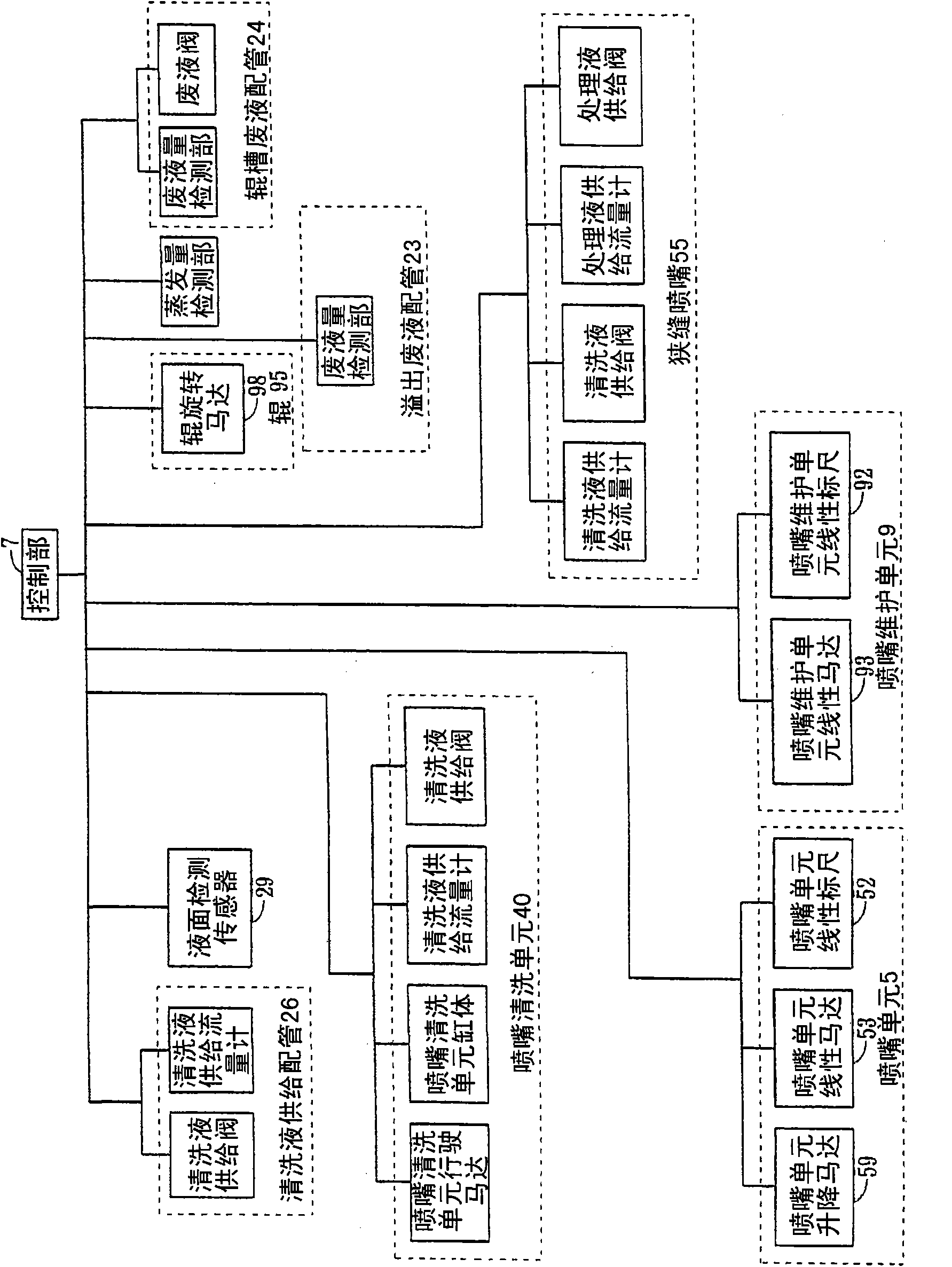

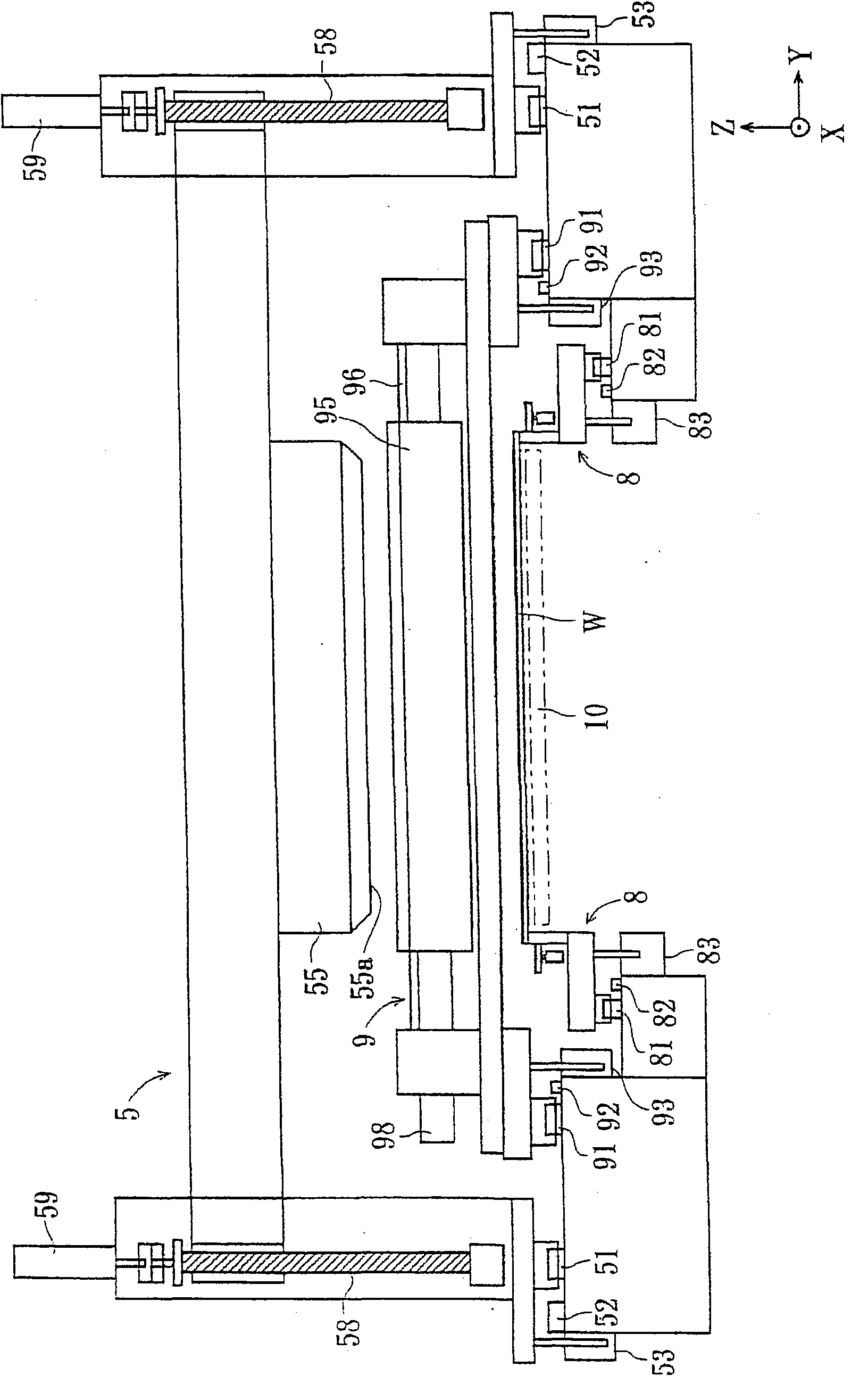

Substrate processing apparatus

ActiveCN101856646AReduce supplyReduce waste volumeLiquid surface applicatorsSpraying apparatusEngineeringNozzle

This invention provides a substrate processing apparatus which makes good use of cleaner for initializing mechanism, and simplifies tubing structures. A nozzle maintenance unit of the substrate processing apparatus comprises a roller, a roller groove for holding the roller, a nozzle cleaning unit for cleaning the nozzle and a stand-by for the nozzle cleaning unit. The roller groove and the stand-by groove are connected with each other by a connecting pipe, wherein the solution within the stand-by groove is totally sent to the roller groove. Therefore, the cleaning fluid exhausted from the slit nozzle and the nozzle cleaning unit and processing fluid are stored in the roller groove temporarily; the fluid can be used to clean the outer circle surface of the roller which is sprayed with the processing fluid in the pre-spraying, moreover, because it is sufficient to install an exhaust tubing, an overflow effluent tubing and a roller groove effluent tubing on the roller groove, the tubing structure is simplified.

Owner:DAINIPPON SCREEN MTG CO LTD

Rancidity-prone waste biogas utilization method based on in-subarea inoculation and quick start

The invention belongs to the technical field of solid waste pollution control, and relates to a method for making biogas from waste, which comprises the following steps: (1) pretreating the waste; (2) feeding the waste into a waste loading area for hydrolysis and acidification; (3) feeding the material subjected to hydrolysis and acidification in step (2) into a microbial inoculum loading area, and performing biogas production reaction under the effect of the microbial inoculum; (4) flowing out the material treated in step (3) from the microbial inoculum loading area, and returning to the waste loading area for further hydrolysis and acidification; and (5) repeating the cycle from step (2) to step (4) multiple times until the conversion of the waste into biogas is maximized. The invention overcomes the disadvantages of high rancidity possibility, long gas production start time, low gas production yield and gas production rate and the like of the waste conventional biogas utilization system, can greatly accelerate the gas production process of the rancidity-prone waste with a small amount of microbial inoculum, increases the gas production yield of the waste, lowers the amounts of leavings and waste liquids, and decreases the volume of a reactor and the operating cost.

Owner:TONGJI UNIV

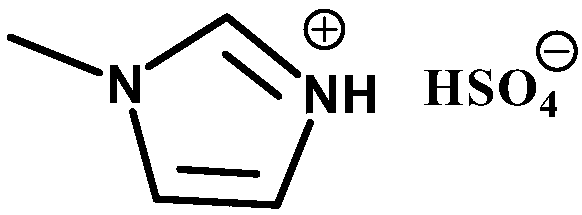

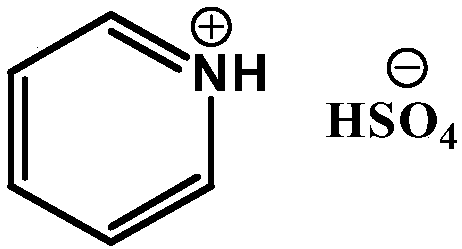

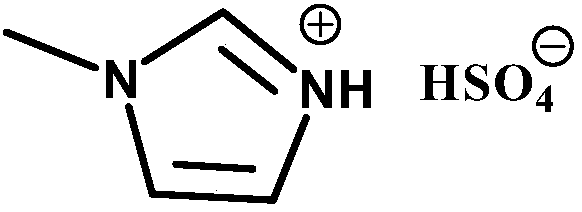

Synthesis method of tackifying alkylphenol formaldehyde resin

ActiveCN107722204ALow steam pressureNon-flammableBulk chemical productionOrganic solventSynthesis methods

The invention provides a synthesis method of tackifying alkylphenol formaldehyde resin. The synthesis method comprises the following steps: firstly, adding alkylphenol and an acidic catalyst into a reaction still; secondly, slowly adding 65 to 80 percent of the total amount of formaldehyde aqueous solution after the temperature is raised to 50 to 60 DEG C; carrying out reflux reaction for 1 to 3 hours and steaming out all water, then stopping distillation, slowly adding the remaining formaldehyde aqueous solution and steaming out the water; thirdly, after the reaction time is ended, raising the temperature to 140 to 160 DEG C; distilling out residual water and unreacted alkylphenol in a vacuum state; fourthly, distilling out entrained water and the unreacted alkylphenol, and drying an organic phase by distilling; adding water into the reaction still for washing, separating out a water phase and drying the organic phase to obtain a product disclosed by the invention. According to the preparation method disclosed by the invention, acidic ionic liquid is used as a solvent and a catalyst and replaces the acidic catalyst and the solvent in the synthesis method of the traditional alkylphenol formaldehyd resin, so that the extensive use of organic solvents is effectively avoided.

Owner:SHANDONG YANGGU HUATAI CHEM

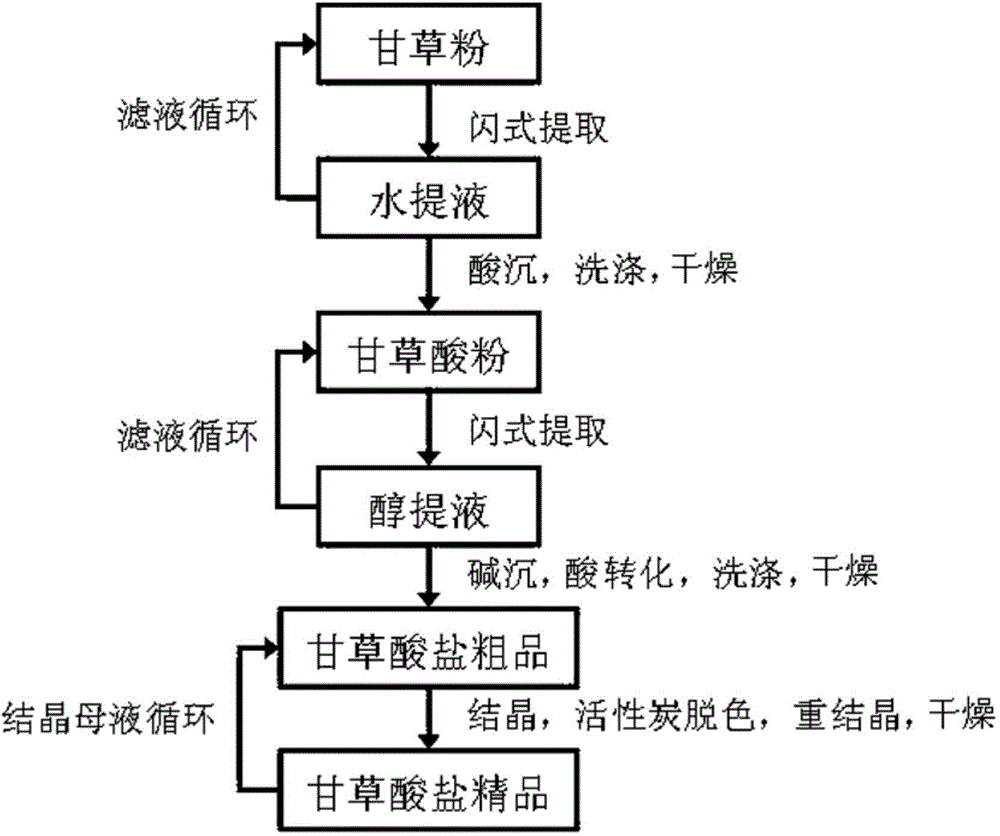

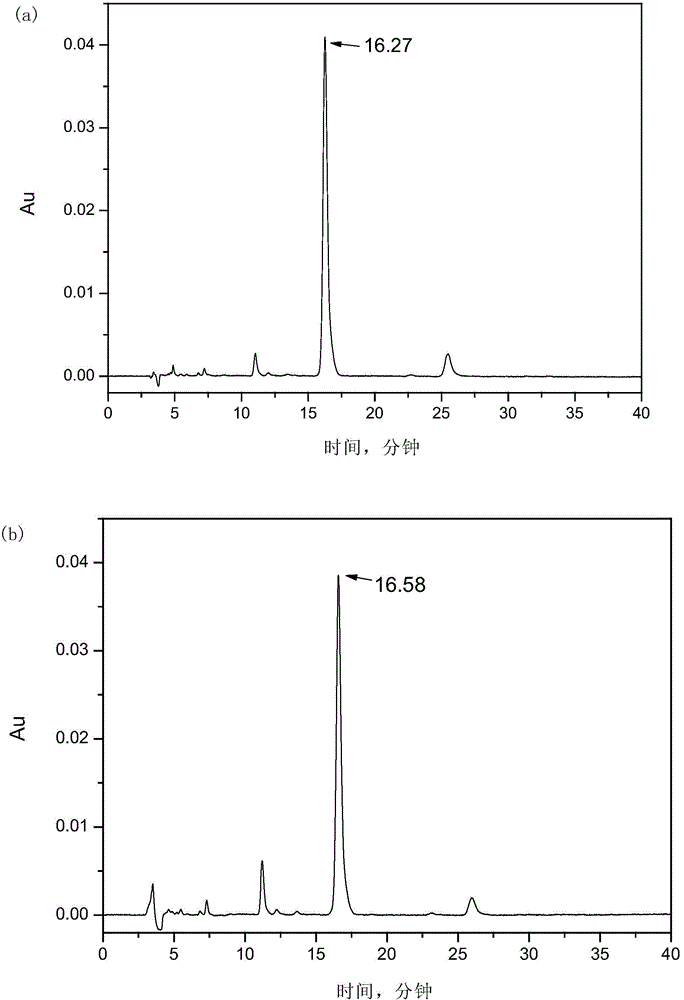

Method for rapidly extracting and purifying glycyrrhizic acid and salts thereof

InactiveCN104151389AAchieve recyclingReduce waste volumeSugar derivativesSteroidsRoom temperatureSolvent

The invention discloses a method for rapidly extracting and purifying glycyrrhizic acid and salts thereof. The method comprises the steps of: by taking licorice rhizomes as a raw material, preparing glycyrrhizic acid by using a flash extraction technology; by taking glycyrrhizic acid powder as a raw material, preparing glycyrrhetates by using the flash extraction technology. According to the method disclosed by the invention, an effect of rapid extraction at room temperature is achieved; compared with existing processes, the cyclic utilization of solvents can be realized, thereby significantly reducing the amount of waste liquid, reducing the energy consumption, shortening the extraction time, and improving the quality of products.

Owner:EAST CHINA UNIV OF SCI & TECH +1

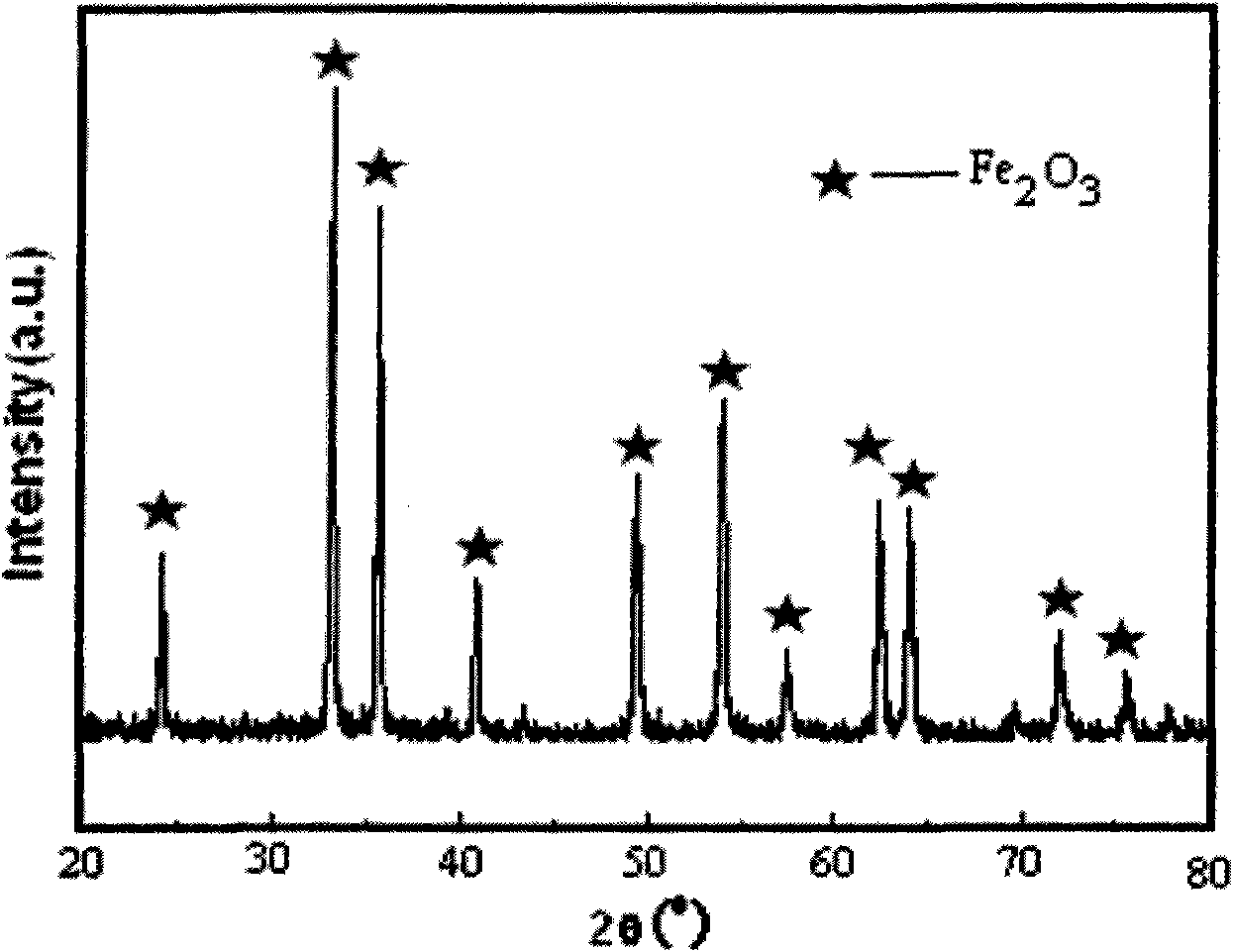

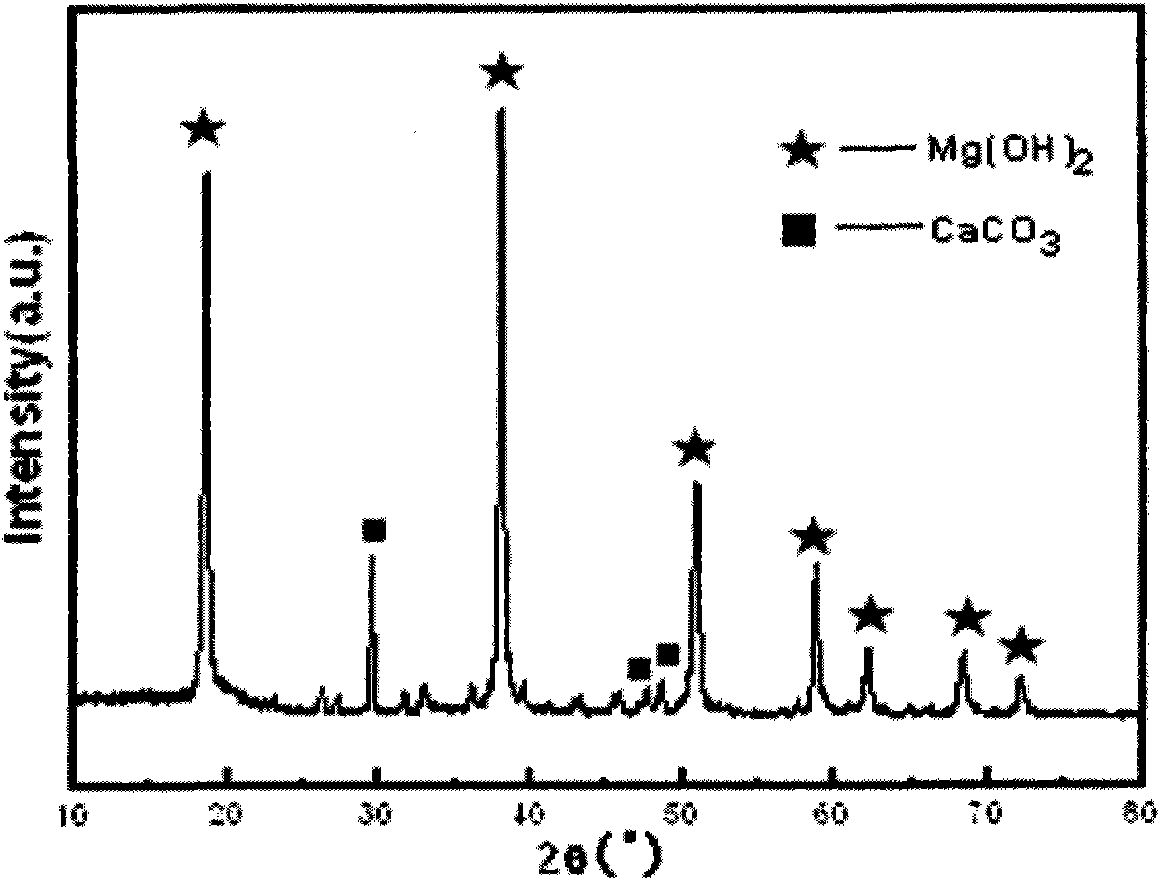

Method for extracting metallic elements of ferrum, magnesium and calcium from molybdenum milltailings

InactiveCN101831542AImprove technical and economic indicatorsImprove resource recoveryProcess efficiency improvementHydrometallurgyImpurity

The invention relates to a method for extracting metallic elements of ferrum, magnesium and calcium from molybdenum milltailings, belonging to the technical field of wet-process metallurgy and comprehensive utilization of tailings. The method comprises the following steps of: treating the molybdenum milltailings by using a hydrochloric acid solution to obtain pickle liquor and adding hydrogen peroxide to the pickle liquor to oxidize Fe<2+> totally into Fe<3+>; dropping ammonia water into the solution and controlling the pH value to prepare a crude Fe(OH)3 precipitate; dissolving the crude Fe(OH)3 in acid, filtering and then dropping the ammonia water to carry out a precipitation reaction; filtering and calcining at a high temperature of 750 DEG C to obtain a Fe2O3 product with a purity larger than 98 weight percent; dropping NaOH to ferrum precipitate filter liquor and controlling the pH value to remove impurity elements; continuing to dropping NaOH and controlling the pH value to obtain a Mg(OH)2 product with a purity larger than 83 weight percent; and dropping Na2CO3 into magnesium precipitate filter liquor to obtain a CaCO3 product with a purity larger than 97 weight percent. The process adopts full liquid-phase operations and has no waste gas pollution, and a tail solution is mainly a NaCl and NaOH mixture solution which is easy to treat. The recovery rates of the ferrum, the magnesium and the calcium all reach higher than 80 percent, and meanwhile, the enrichment of trace elements such as molybdenum, tungsten, copper, and the like in the tailings is also realized.

Owner:UNIV OF SCI & TECH BEIJING

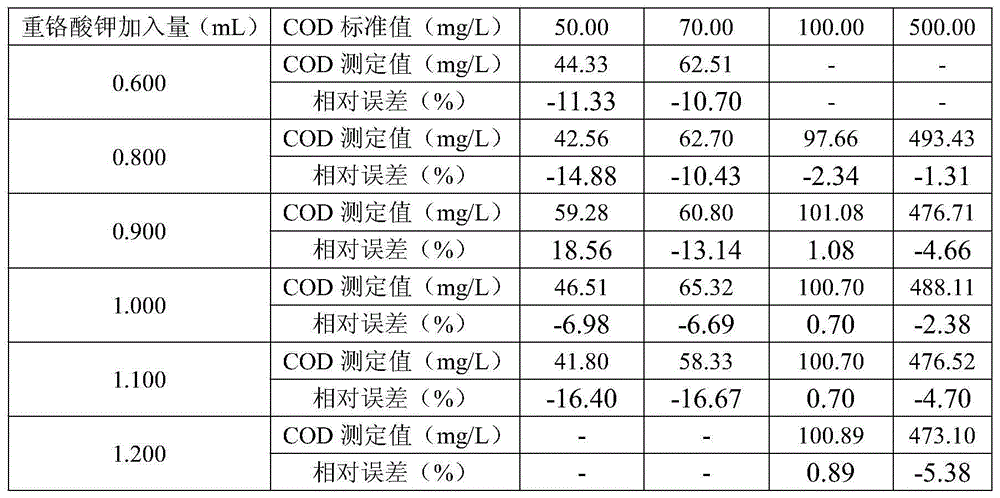

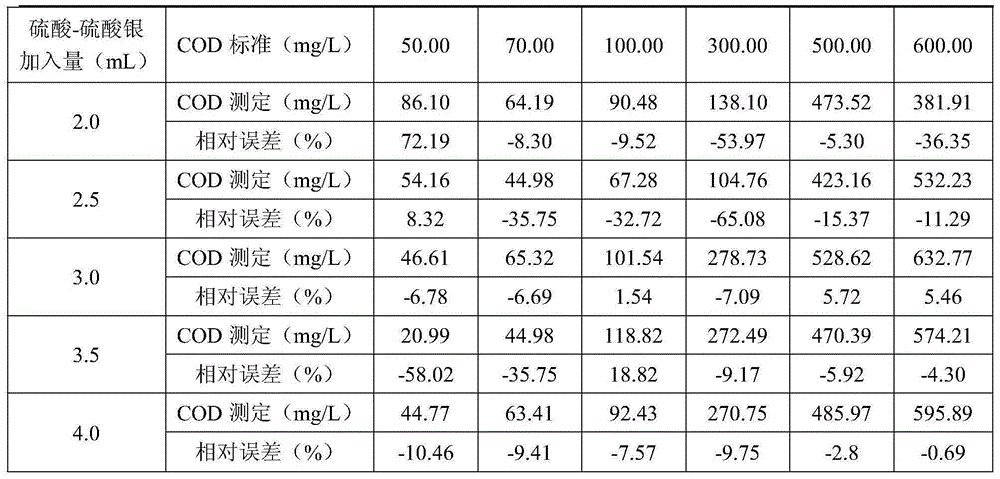

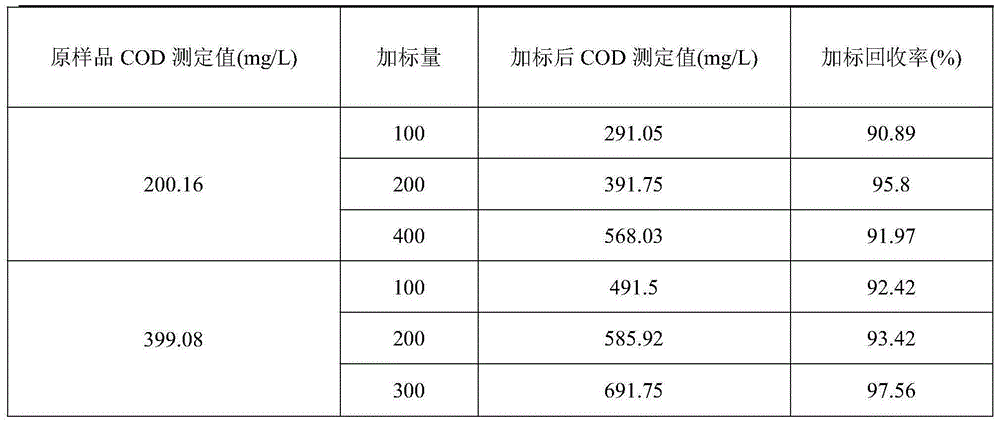

Accurate, energy-saving and consumption-reduction method for measuring COD (chemical oxygen demand)

InactiveCN104655790AEliminate the effects ofAccurate methodAnalysis using chemical indicatorsChemical analysis using titrationEnvironmental resistanceDigestion

The invention relates to an accurate, energy-saving and consumption-reduction method for measuring COD (chemical oxygen demand). The method comprises the following steps: preparing potassium dichromate standard solution with the concentration of 0.25mol / L; preparing ferroin indicator solution; preparing ammonium ferrous sulfate solution; preparing sulfuric acid-silver sulfate solution; calibrating the ammonium ferrous sulfate solution, namely, drawing 1mL of potassium dichromate standard solution, adding with water for dilution until reaching 20mL, adding with 3mL of concentrated sulfuric acid, adding with one drop of ferroin indicator solution, placing the ammonium ferrous sulfate solution into a seat type micro burette for titration; weighing 0.04g of mercury sulfate, adding into a HACH transparent threaded pipe, adding with 2mL of water sample, adding with 1mL of potassium dichromate standard solution and 3mL of sulfuric acid-silver sulfate solution simultaneously and placing into a HACH digestion apparatus; performing titration experiment, namely, cooling the solution in the HACH transparent threaded pipe to be at room temperature, transferring the solution into a 50mL conical flask and diluting to reach 20mL with deionized water, adding with one drop of ferroin indicator solution, and titrating with the seat type micro burette, therefore, the COD measurement can be finished. The method is accurate, convenient, safe and environmentally friendly.

Owner:CHINA CONSTR THIRD ENG BUREAU INSTALLATION ENG CO LTD

Method for synthesizing 2,3,4,4'-tetrahydroxybenzophenone

InactiveCN101817735AObvious beneficial effectIncrease relative volatilityOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by condensationBoron trifluorideGallic acid

The invention relates to a method for synthesizing 2,3,4,4'-tetrahydroxybenzophenone. In the method, methanol solution of boron trifluoride is used as a catalyst, pyrogallic acid and p-hydroxybenzoic acid are used as the raw materials to synthesize the 2,3,4,4'-tetrahydroxybenzophenone. The method is characterized in that: the methanol solution of boron trifluoride is used as a catalyst; and the pyrogallic acid and the p-hydroxybenzoic acid undergo an acylation reaction at a certain temperature to form the 2,3,4,4'-tetrahydroxybenzophenone.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

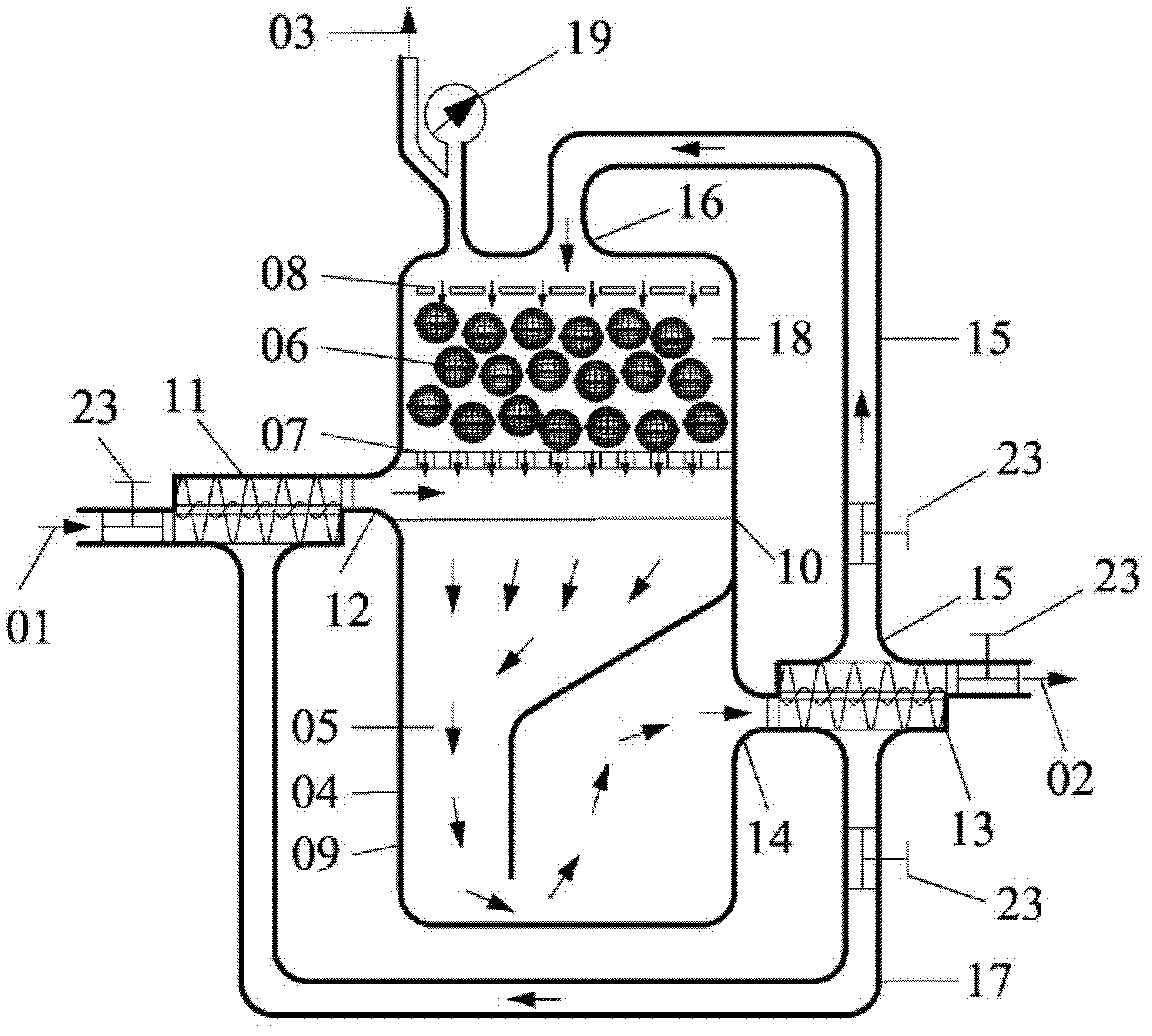

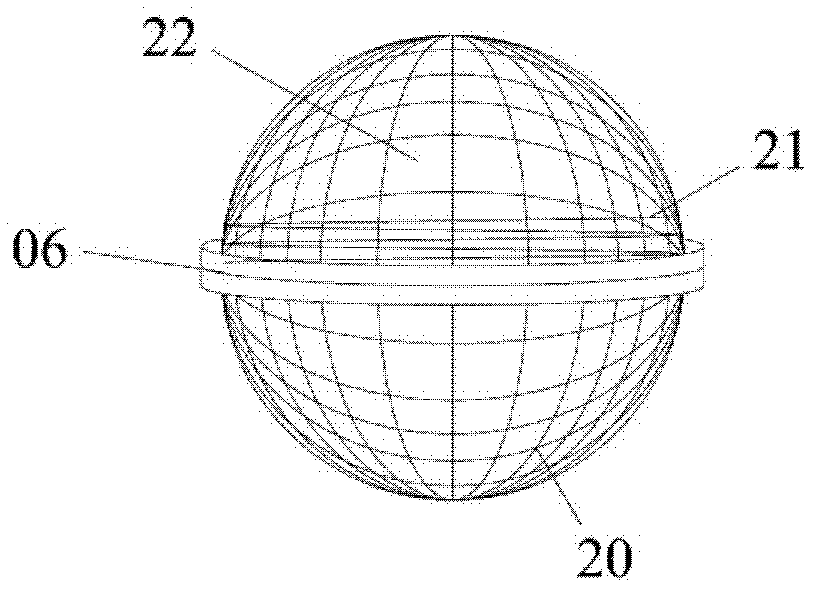

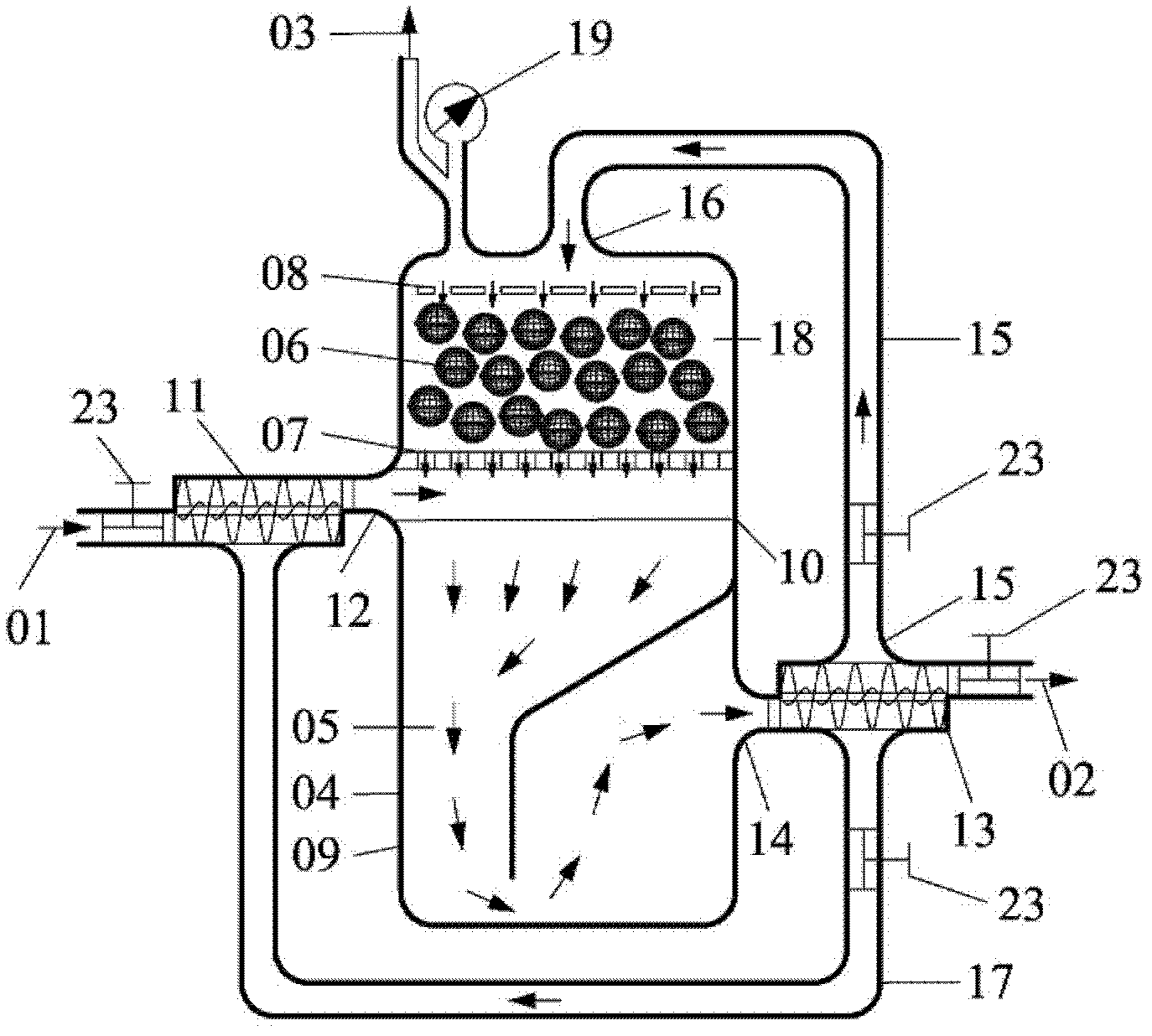

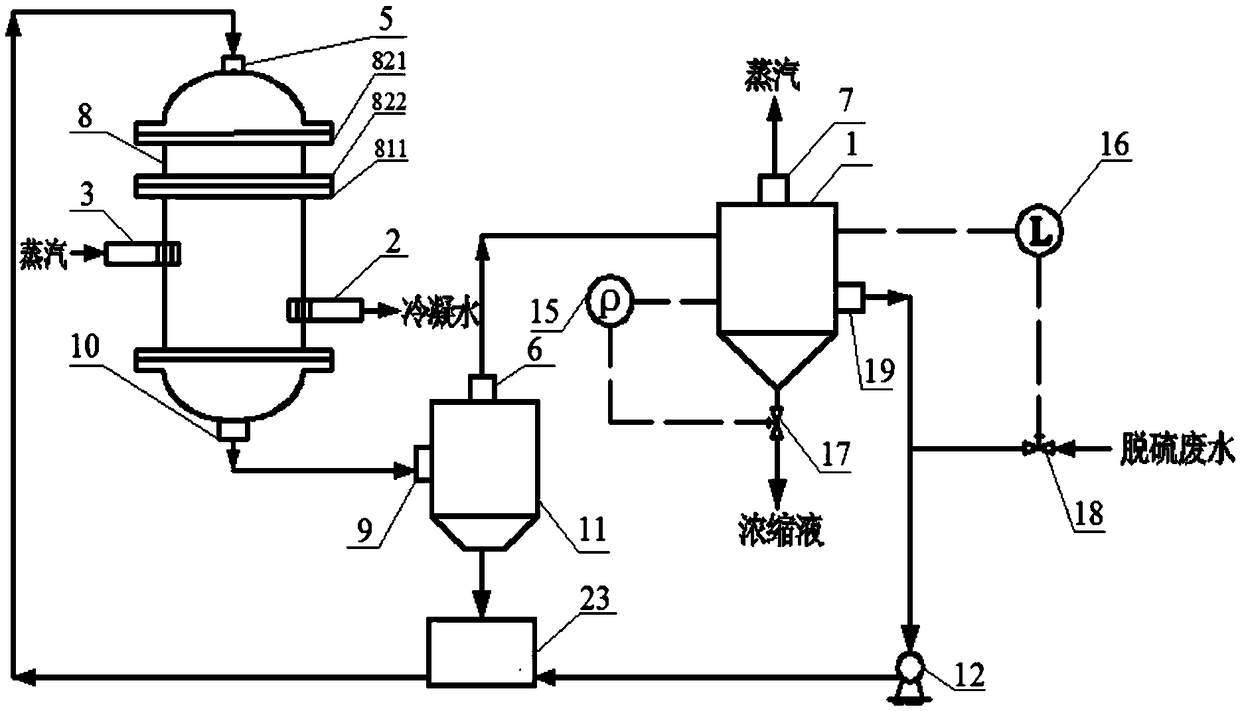

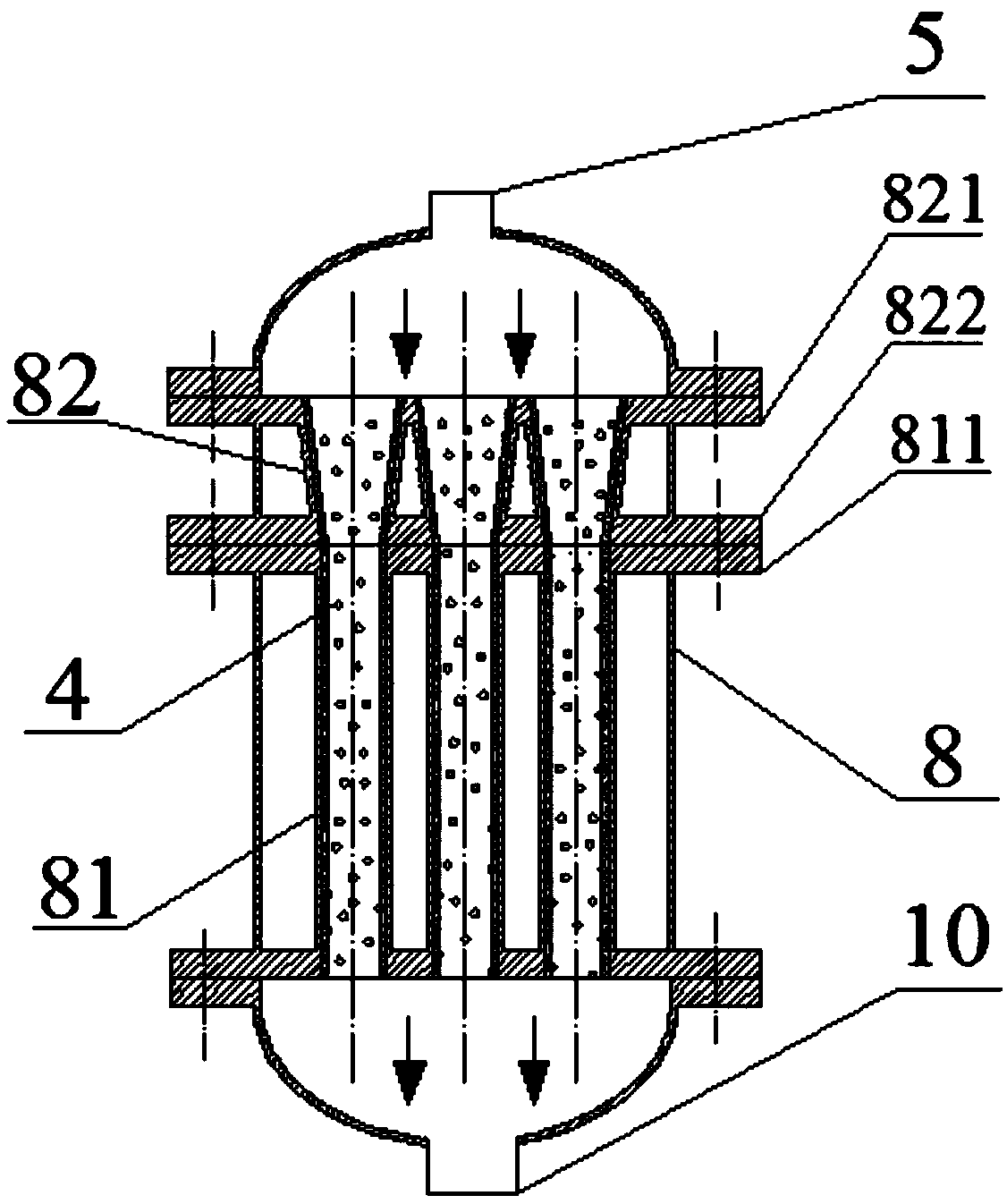

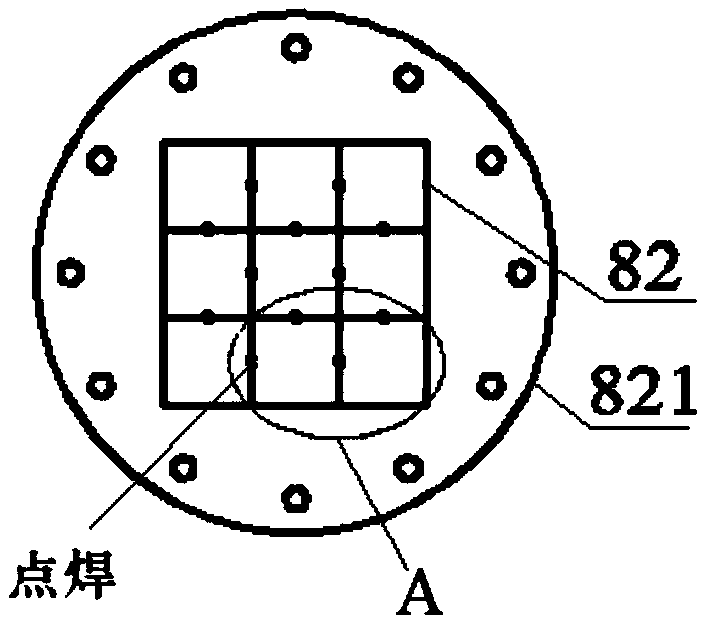

Desulfurization waste water evaporator with inert carrier circling and method

InactiveCN109354090AReduce wearExtend your lifeWaste water treatment from gaseous effluentsWater/sewage treatment by heatingVapor–liquid separatorWastewater

The invention discloses a desulfurization waste water evaporator with inert carrier circling and method. A heater, a solid-liquid mixing device connected with the upper portion of the heater, a solid-liquid separator connected with a discharging port formed in the lower portion of the heater, a gas-liquid separator connected with an upper liquid outlet port of the solid-liquid separator and a circulation pump connecting the gas-liquid separator and the solid-liquid separator, a density gauge is connected with the side face of the gas-liquid separator to regulate the discharging of concentratedliquid, a liquid level gauge is arranged on the side face of the gas-liquid separator to regulate the inlet of desulfurizing waste water, a concentration liquid outlet port is formed in the lower portion, a circulation water outlet is formed in the side face to be connected with the circulation pump, the gathering with inert carriers is achieved through the solid-liquid mixing device, and waste water and the inert carriers enter the heating device together. According to the evaporator, the inert carriers enter the solid-liquid mixing device from the lower end, waste water continuously entersthe gas-liquid separator, and evaporated gas is discharged from a gas discharging hole. The problem of inner scale forming of the evaporator is thoroughly solved, the investment cost is low, the operation is stable, and there exists no environmental secondary pollution.

Owner:SOUTHEAST UNIV +1

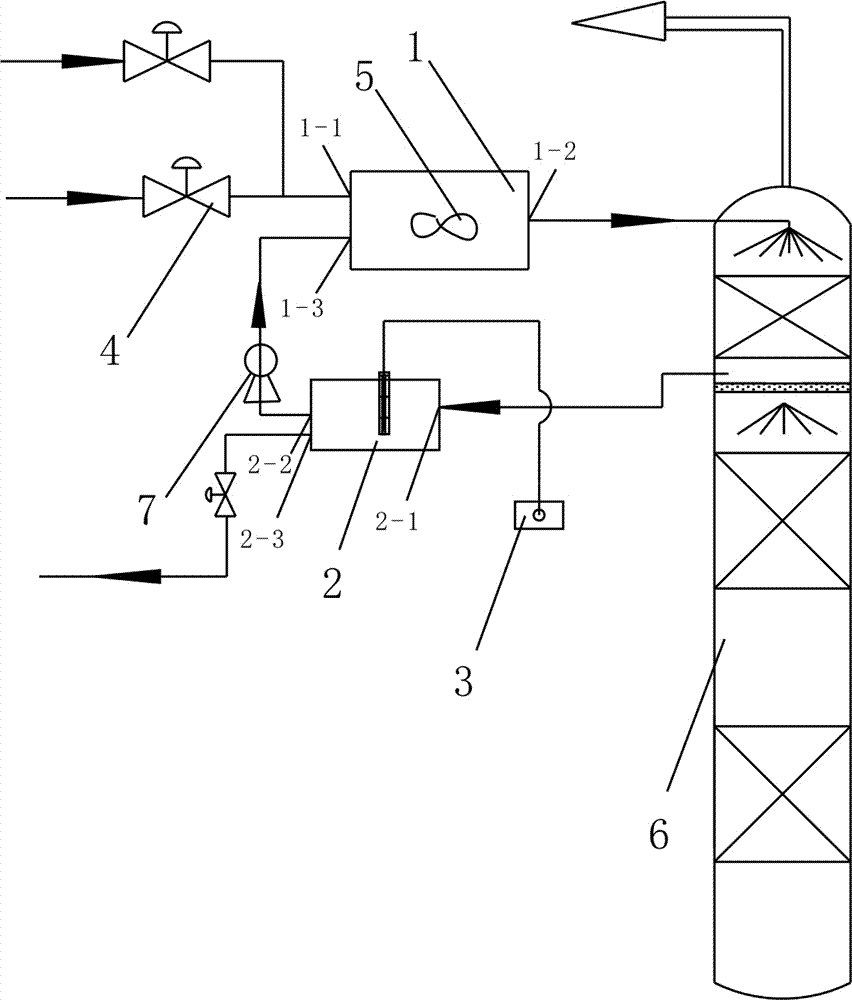

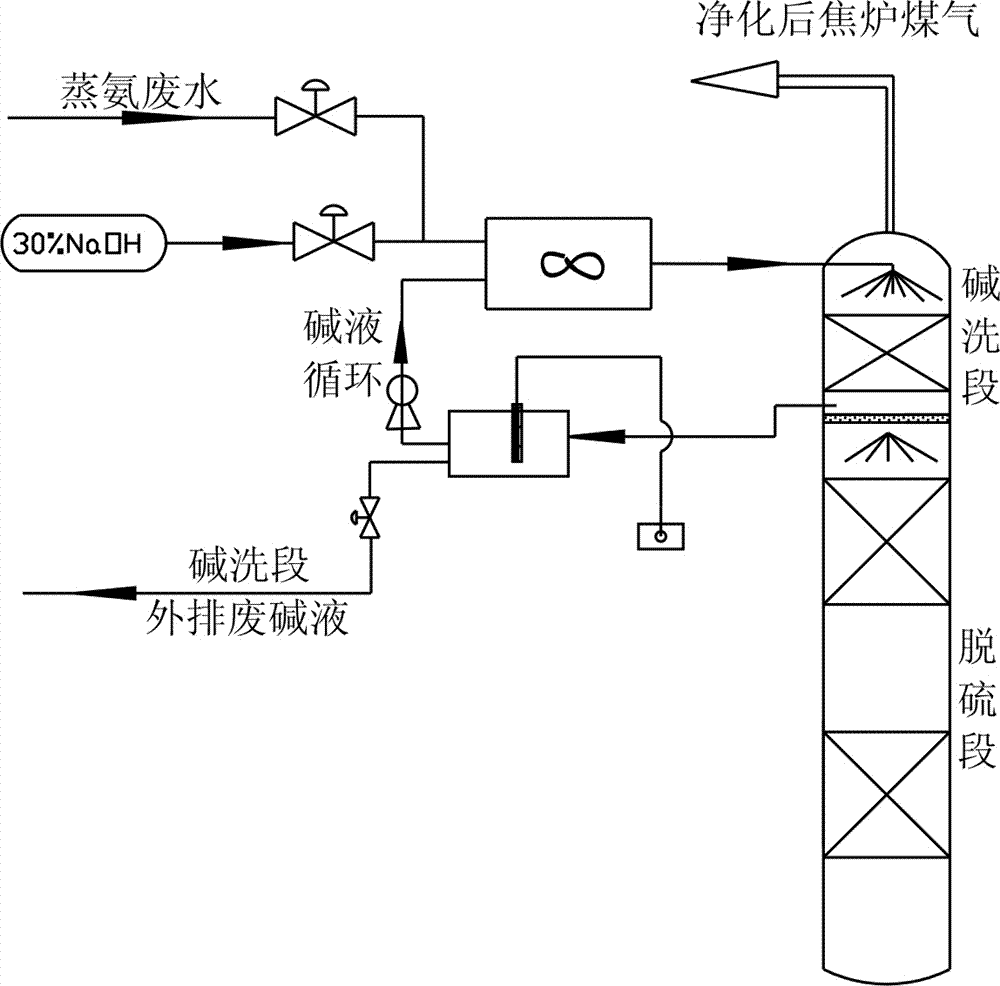

Method and device for improving utilization rate of alkali liquor at alkaline cleaning section of vacuum potassium carbonate desulfurization technique

ActiveCN103691276AImprove efficiencyGuaranteed desulfurization effectDispersed particle separationProcess engineeringEnvironmental engineering

The invention relates to method and device for improving utilization rate of alkali liquor at an alkaline cleaning section of vacuum potassium carbonate desulfurization technique. The method comprises the following steps: diluting NaOH solution by replacing industrial new water with ammonia still waste water in a chemical workshop, and storing the diluted NaOH solution in a NaOH alkali liquor tank; conveying NaOH alkali liquor in the NaOH alkali liquor tank to the NaOH alkaline cleaning section at the upper part of a desulfurizing tower for carrying out alkaline cleaning, enabling the alkaline cleaning water to flow back into a waste alkaline tank, then evenly mixing the alkaline cleaning water in the waste alkaline tank with NaOH alkali liquor in the NaOH alkali liquor tank, conveying back to the alkaline cleaning section at the upper part of the desulfurizing tower for recycling, and stopping recycling until the pH value of waste liquor in the waste alkaline tank is lower than 10; conveying the waste liquor in the waste alkaline tank into an ammonia still tower to be used as alkaline instead of NaOH. According to the method and the device, the alkaline liquor at the alkaline cleaning section can be recycled, and the usage efficiency of the alkali liquor can be improved on the premise of guaranteeing the desulfurization effect of the desulfurizing tower.

Owner:武汉钢铁有限公司

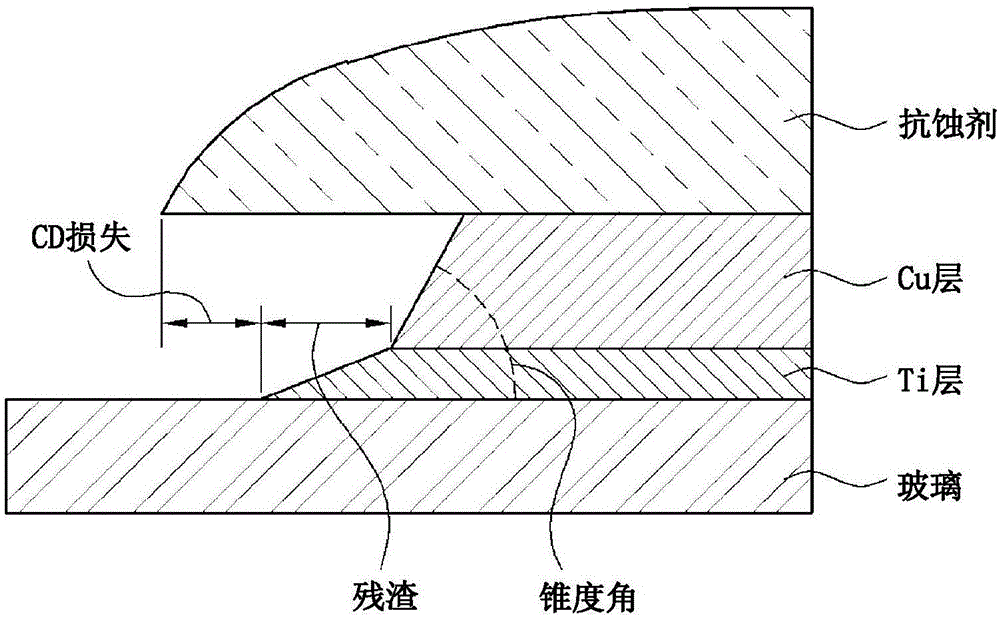

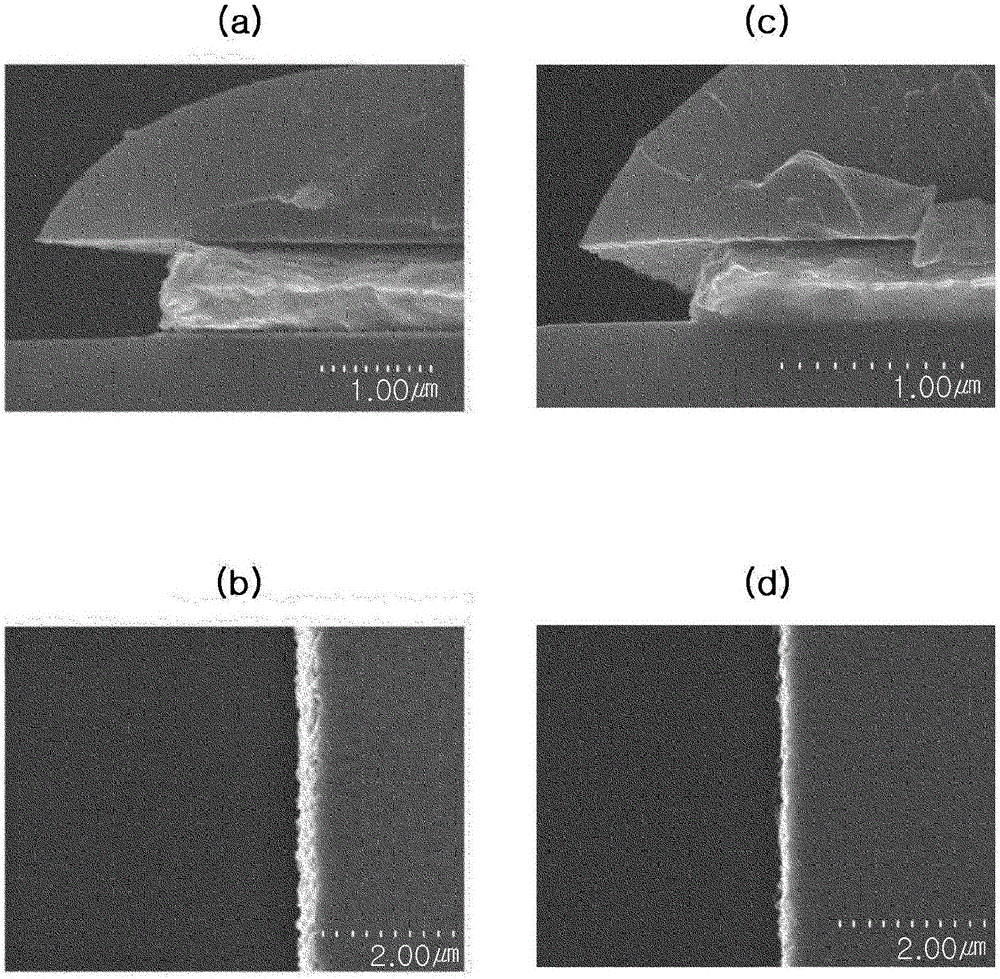

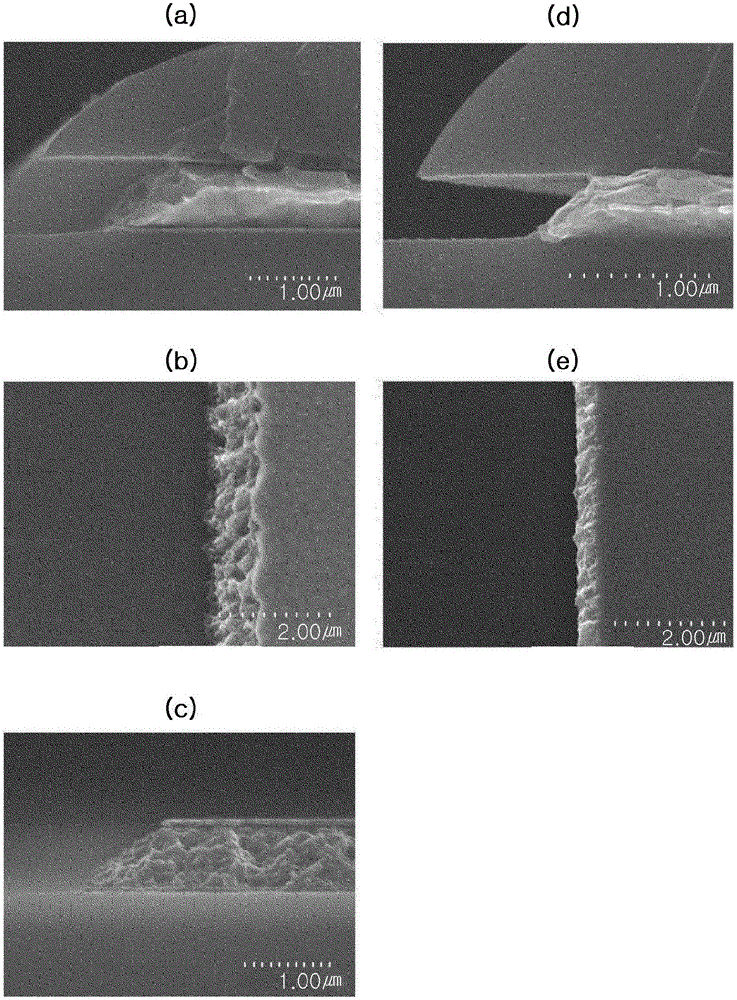

Etchant composition, method for etching multilayered film, and method for preparing display device

ActiveCN106795633APrevent or heatExtended replacement cycleSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidDisplay device

Disclosed are: an etchant composition comprising (A) a copper ion source, (B) a source of an organic acid ion having one or more carboxyl groups in a molecule, (C) a fluoride ion source, (D) an etching controller, a surface oxidizing power enhancer or a combination thereof as a first additive, and (E) a surfactant as a second additive; a method for etching a multilayered film; and a method for preparing a display device.

Owner:SAMYOUNG PURE CHEM +2

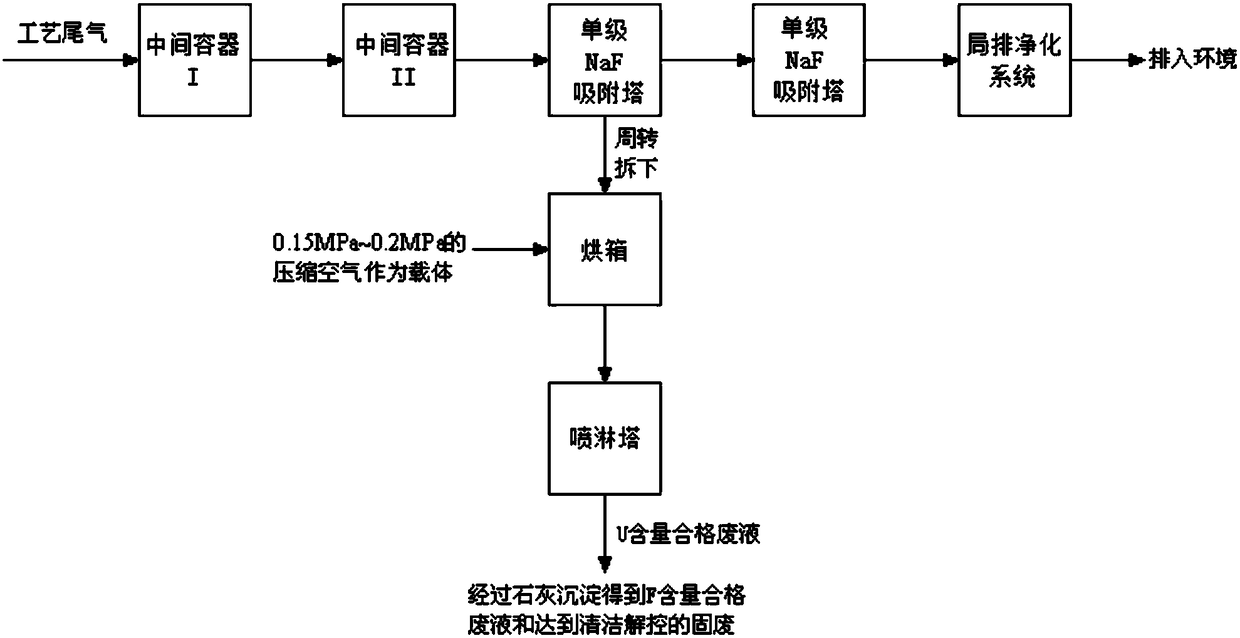

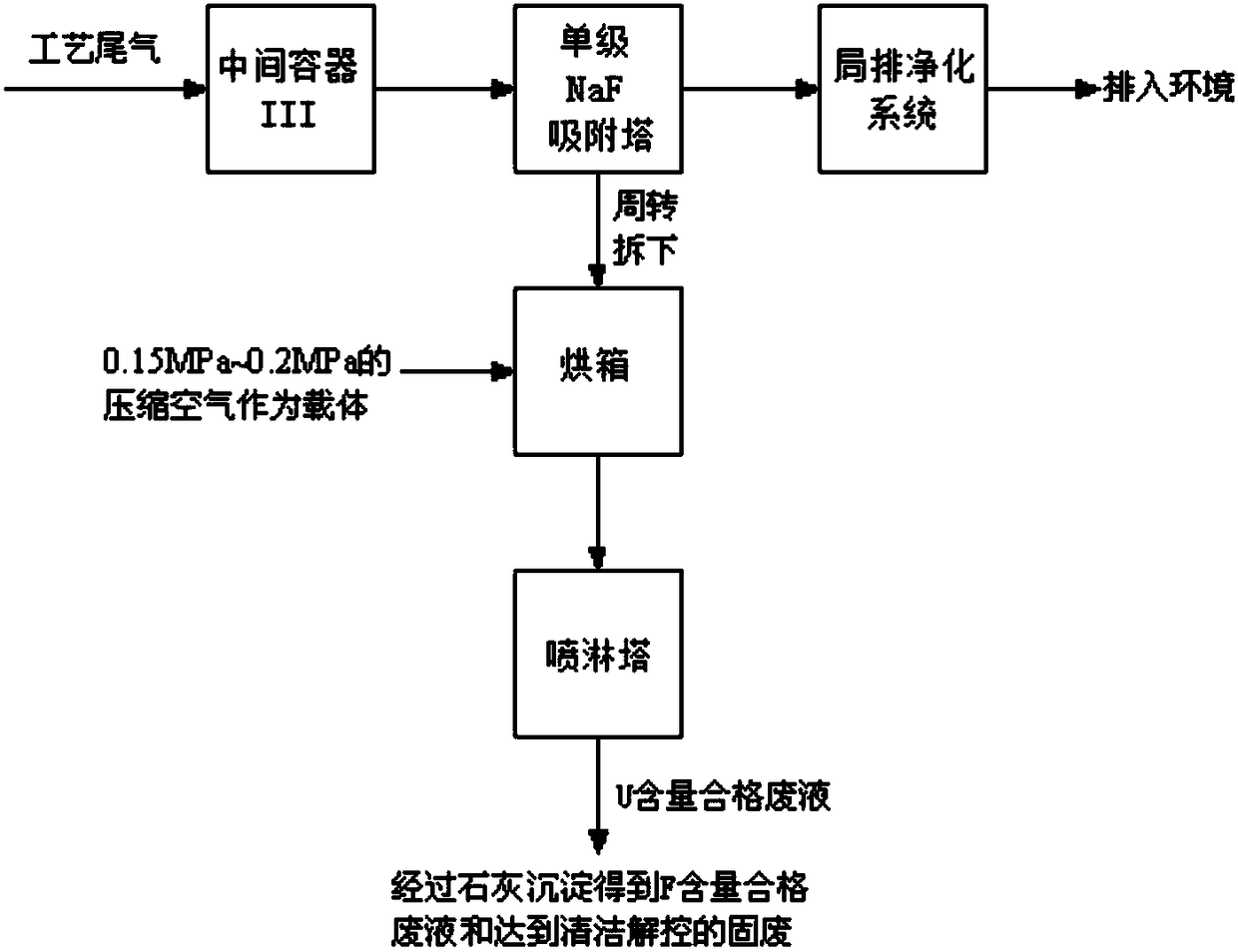

Uranium enrichment plant tail gas HF treatment process

ActiveCN108246062ASimple processReduce production labor intensityGas treatmentUranium fluoridesExhaust gasEnvironmental resistance

Belonging to the technical field of uranium enrichment technology, the invention in particular relates to a uranium enrichment plant tail gas HF treatment process. The uranium enrichment plant tail gas HF treatment process includes: employing refrigeration cabinet refrigerated intermediate containers, NaF adsorption towers and a local discharge purification system for purification treatment on tail gas HF, and discharging the tail gas into the environment when the tail gas is detected to be qualified; and conducting desorption treatment on the adsorption towers reaching an adsorbing capacity limit, and reacting the desorption treatment generated neutralizing waste liquid with lime to obtain waste liquid meeting the discharge standard and solid waste reaching the clearance level. The process provided by the invention solves the technical problems of complex procedure, high comprehensive cost and adverseness to safety and environmental protection, gets rid of the dependence of HF collection on liquid nitrogen, simplifies the process flow, reduces the comprehensive cost, and greatly improves the safety and environmental protection of the tail gas HF treatment process.

Owner:CHINA NAT NUCLEAR URANIUM ENRICHMENT

Automobile asphalt cleaning agent

InactiveCN106190632AGood dissolving effectPrevent toluene volatilizationCationic surface-active compoundsOrganic detergent compounding agentsAutomotive engineeringAsphalt

The invention discloses an automobile asphalt cleaning agent. The automobile asphalt cleaning agent is prepared from, by weight, 2-8 parts of silicone quaternary ammonium salt, 2-5 parts of a penetrating agent, 1-3 parts of a leveling agent, 0.01-0.1 part of preservatives, 3-5 parts of a surface activity dispersant, 0.2-0.6 part of an anticoagulant, 12-15 parts of methylbenzene and 15-30 parts of alcohol-water mixture. The automobile asphalt cleaning agent is free of automobile paint damages, effective in cleaning and low in cost.

Owner:ZHEJIANG AGRI BUSINESS COLLEGE

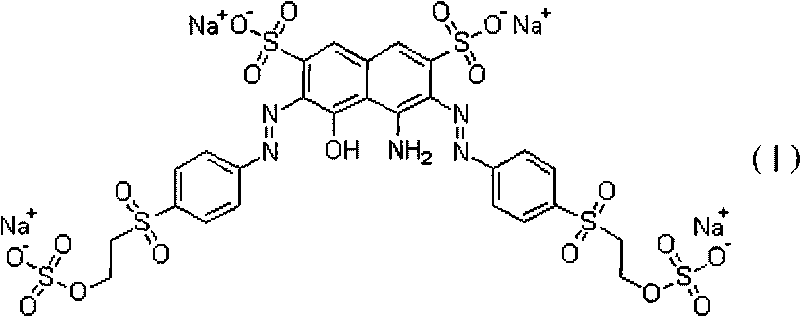

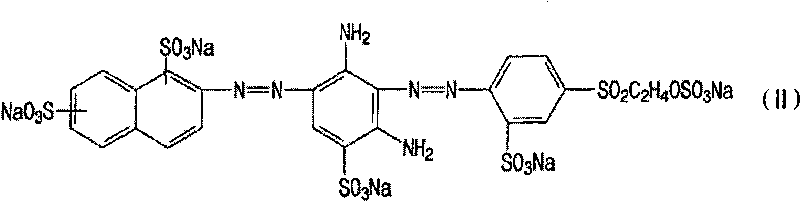

Black dye composition

InactiveCN101735662AGood water solubilityTake advantage ofOrganic dyesDyeing processSolubilitySolution treatment

The invention relates to a black dye composition, which comprises reactive black 5 and reactive orange 142, wherein the weight ratio of the reactive black 5 to the reactive orange 142 is 5-95:95-5. The reactive dye composition has good water solubility and can reach 200g / L at 25 DEG C; the dye solution is uniform; and a problem of tailing of ending in the printing process is solved. The dye solution can be fully utilized so as to reduce waste liquor, dye solution treatment cost and environmental pollution.

Owner:TIANJIN DEK CHEM

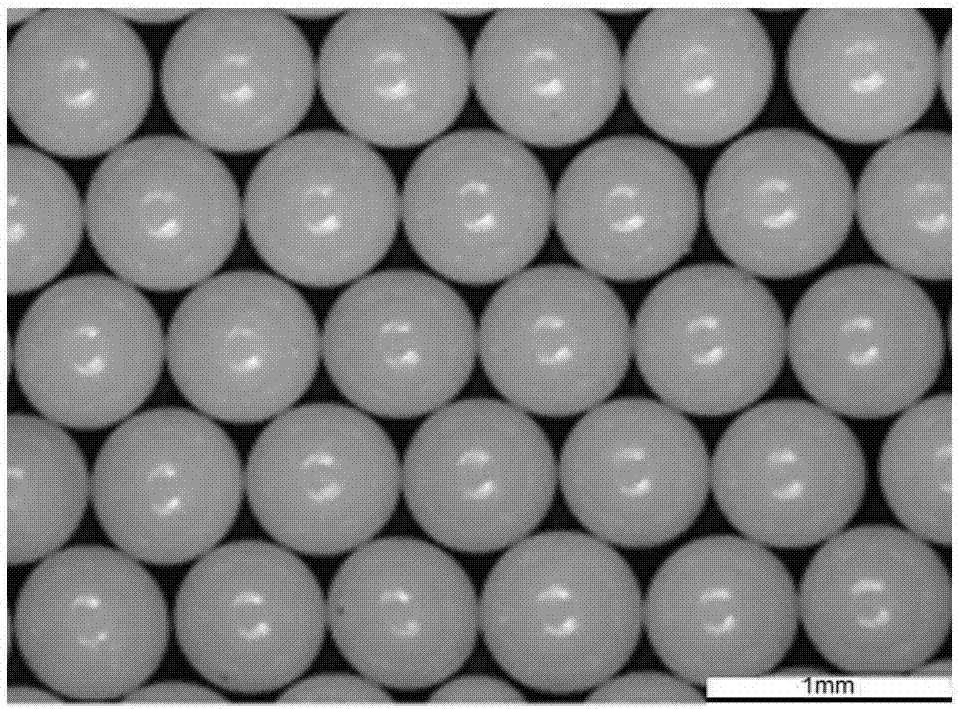

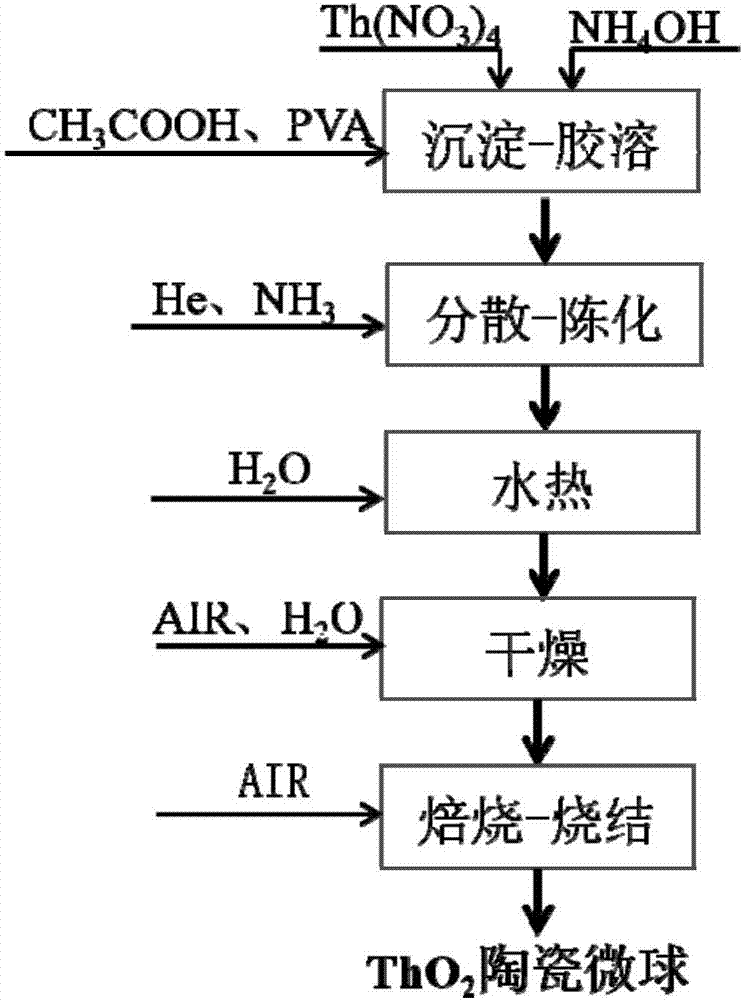

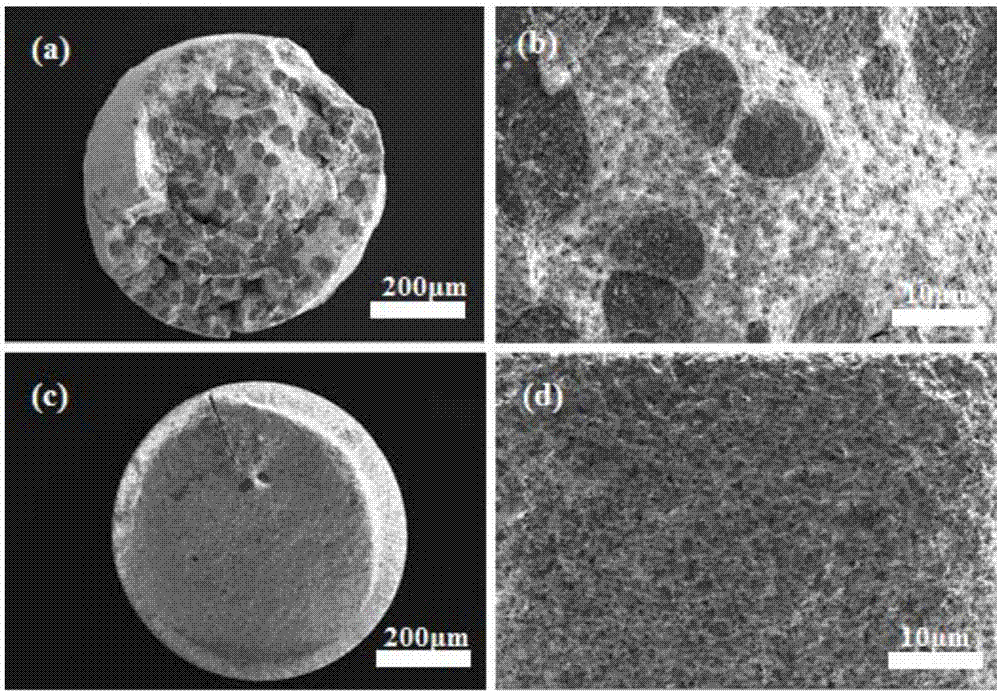

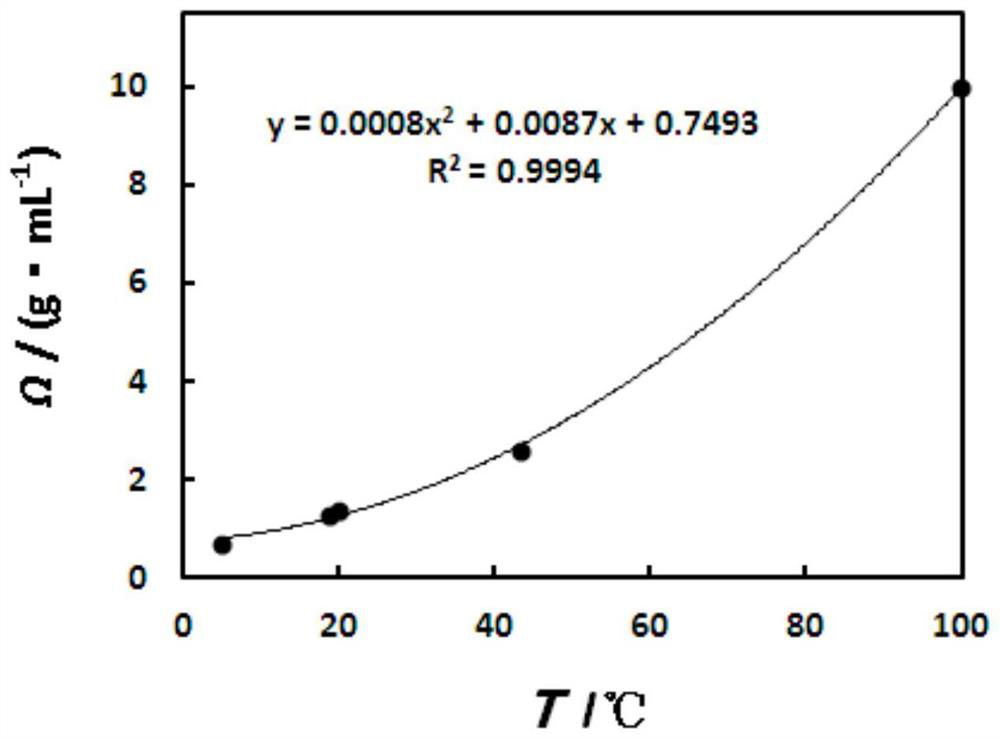

Method for preparing ceramic micro-spheres of thorium oxide

ActiveCN107010955AReduce the probability of ruptureAvoid breakingNuclear energy generationReactors manufacturePolyvinyl alcoholThorium oxide

The invention relates to a method for preparing ceramic micro-spheres of thorium oxide. The method includes dropwise adding ammonia water into thorium nitrate solution to form hydrolysis solution, dropwise adding glacial acetic acid into the hydrolysis solution to regulate the pH (potential of hydrogen) of the hydrolysis solution, and adding polyvinyl alcohol into the hydrolysis solution under stirring conditions to form thorium oxide colloidal solution; dispersing the thorium oxide colloidal solution to obtain liquid drop and allowing the liquid drop to sequentially flow through helium zones, ammonia gas zones and ammonia water zones; arranging dispersed gel particles in strong ammonia water and aging the dispersed gel particles; adding the aged gel particles and deionized water into a hydrothermal reaction kettle and carrying out temperature reaction; placing gel particles into a drying furnace after hydrothermal reaction is carried out on the gel particles, and heating and drying the gel particles under humidity control to form dried gel particles; placing the dried gel particles in a calcination furnace, filling the calcination furnace with air and heating and calcining the gel particles to obtain calcined gel particles; placing the calcined gel particles in a sintering furnace, filling the sintering furnace with air and heating and sintering the calcined gel particles to obtain the ceramic micro-spheres. The method has the advantage that the ceramic micro-spheres of the thorium oxide can be prepared by the aid of simple technologies.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

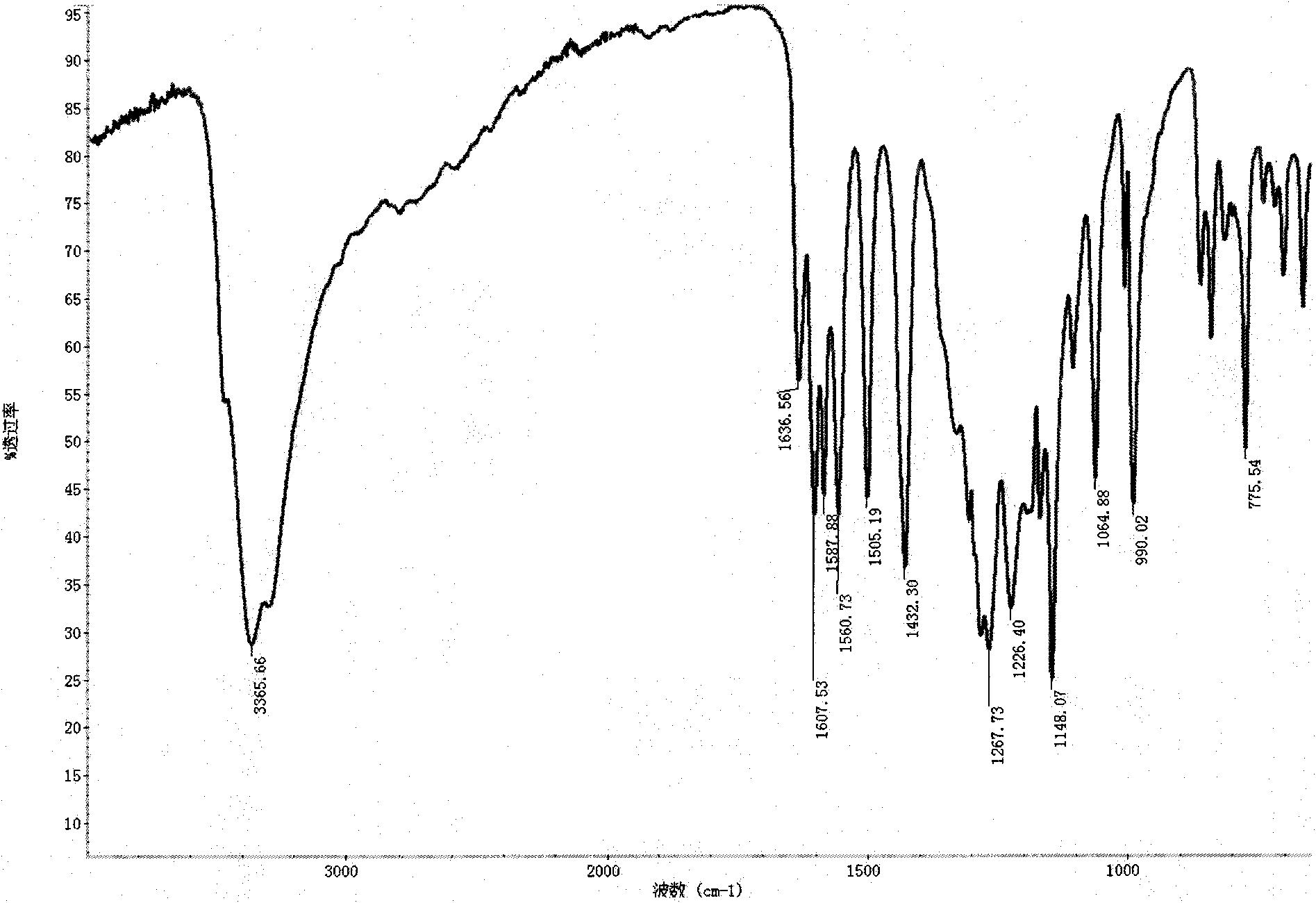

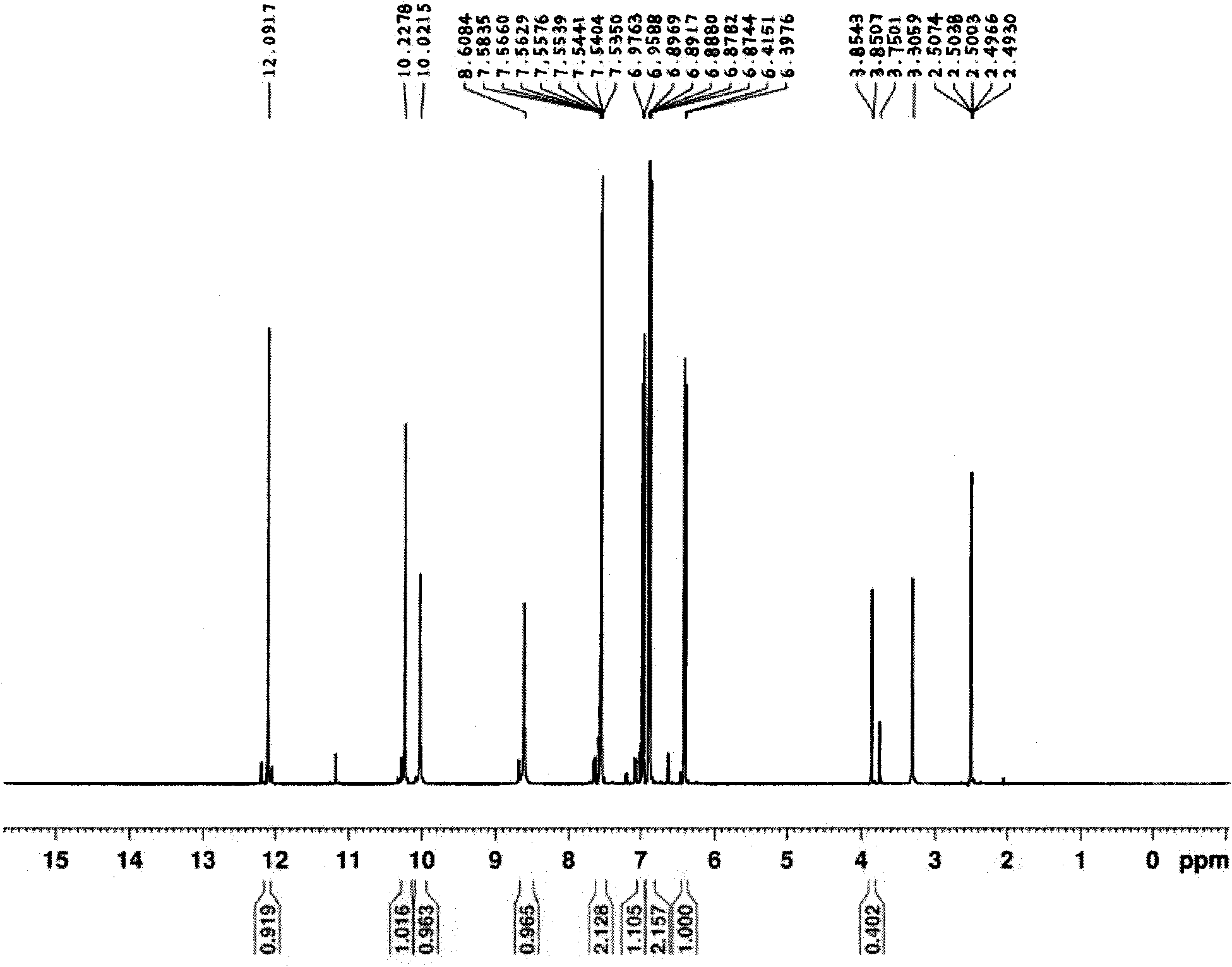

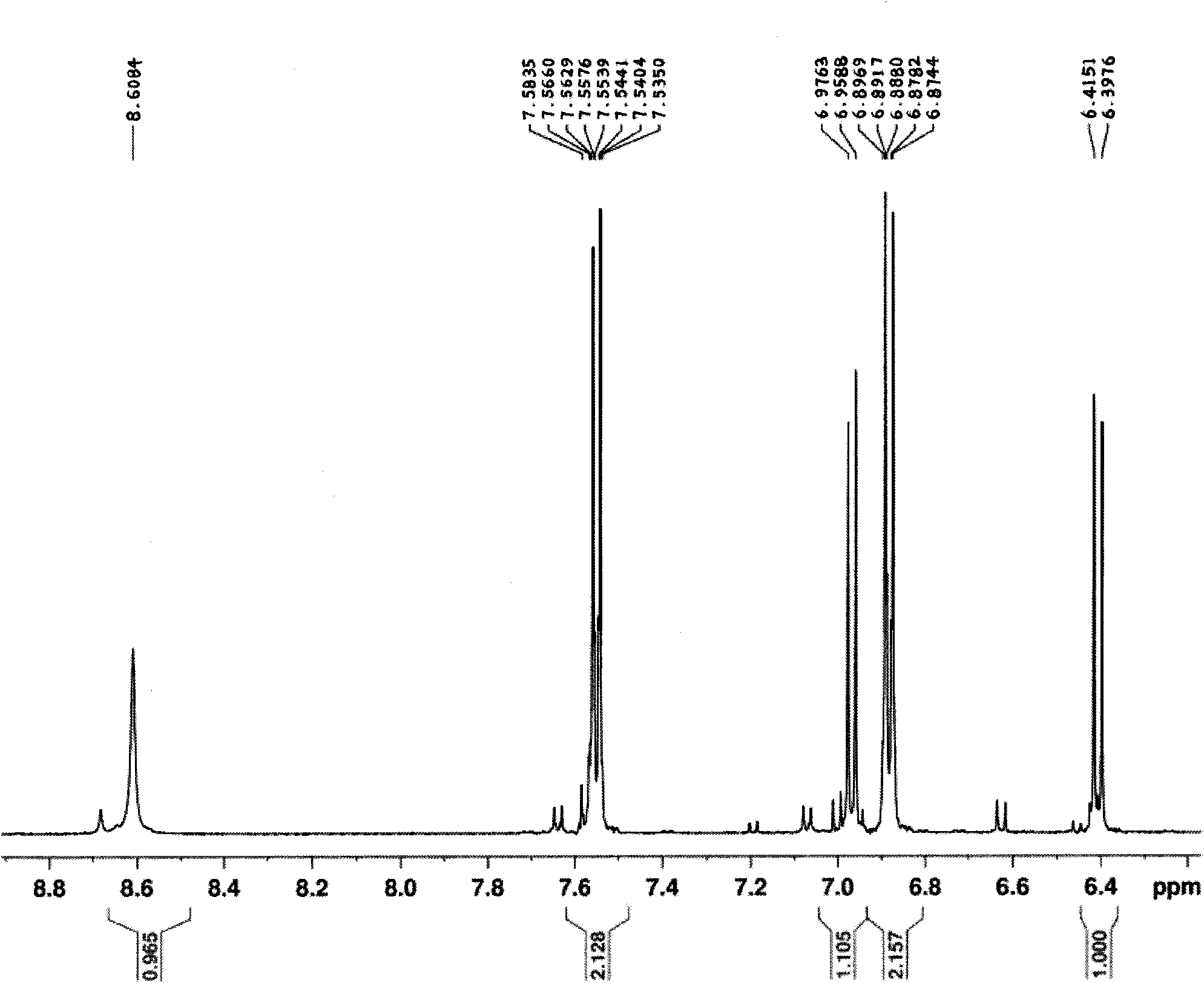

Preparation method and application of solid phase extraction membrane comprising amphipathicity functional group

InactiveCN103091429ARapid responseReaction energy consumption is lowIon-exchange process apparatusComponent separationSolid phase extractionPolypropylene

The invention relates to a solid phase extraction membrane comprising an amphipathicity functional group and applications of the solid phase extraction membrane in enrichment and extraction of trace phenols in an environment water body. A macromolecular non-woven cloth solid phase extraction membrane material with the amphipathicity functional group is prepared by taking a polypropylene and polyethylene copolymerization melt-blown non-woven cloth material as a base material and uniformly and respectively bonding a lipophilic unsaturated fattyacid alkyl ester monomer and hydrophilic ethoxyethanol unsaturated fattyacid alkyl ester to the surface of the non-woven cloth material. The non-woven cloth prepared by the invention contains a crylic acid alkyl ester lipophilic group and a hydroxyl alkyl ester hydrophilic group, so that in the process of extracting a phenol type polar compound, the non-woven cloth synchronously develops nonpolar intermolecular force and hydrogen-bond interaction and has relatively high extraction performance. The non-woven cloth material is used for preparing a solid-phase disk membrane; and in a water sample enrichment process, the mass transfer speed is high; and a large size of environment water samples can be quickly enriched and extracted.

Owner:TIANJIN POLYTECHNIC UNIV

Process for preparing phloroglucinol

InactiveCN1205158CHigh purityShort reaction timeOrganic chemistryOrganic compound preparationActivated carbonAfter treatment

The invention relates to a preparation method of phloroglucinol. The post-treatment of the hydrolysis reaction in the existing method forms a large amount of waste residue and waste liquid, which increases the workload of the post-treatment, and the final product has poor color and low purity. In addition, the reaction conditions are harsh and the operation is inconvenient. The feature of the present invention is that in the complexing and hydrolysis reaction, the complexing agent anhydrous aluminum trichloride and 1,3,5-trimethoxybenzene are used for the complexation reaction, and then the hydrolysis reaction is carried out in concentrated hydrochloric acid , The hydrolyzed solution is cooled and crystallized to obtain crude phloroglucinol; the crude product of phloroglucinol is first decolorized with activated carbon, and then recrystallized in water. Without affecting the total yield, the invention can make the phloroglucinol have good color and high purity, shorten the reaction time, reduce the amount of waste liquid produced by the hydrolysis reaction, simplify the operation conditions and improve the stability of the reaction.

Owner:ZHEJIANG NHU CO LTD

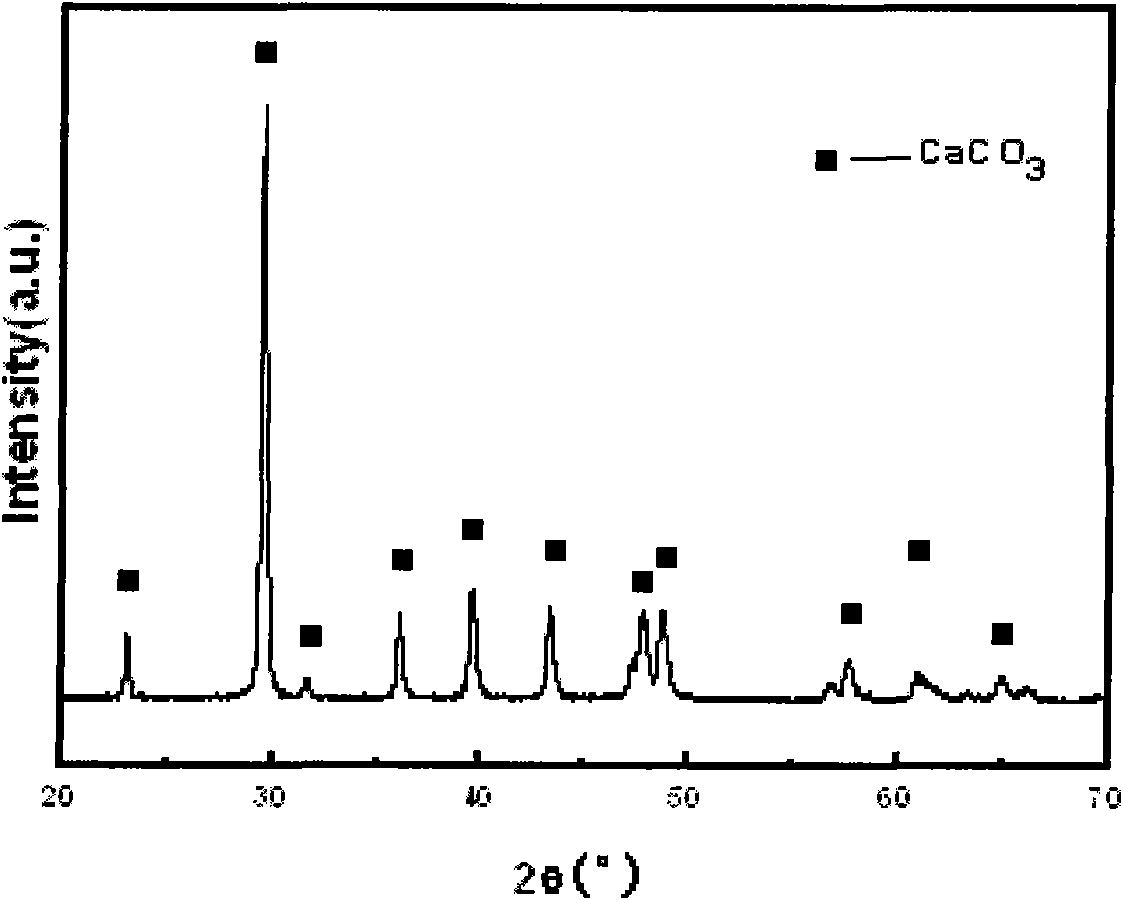

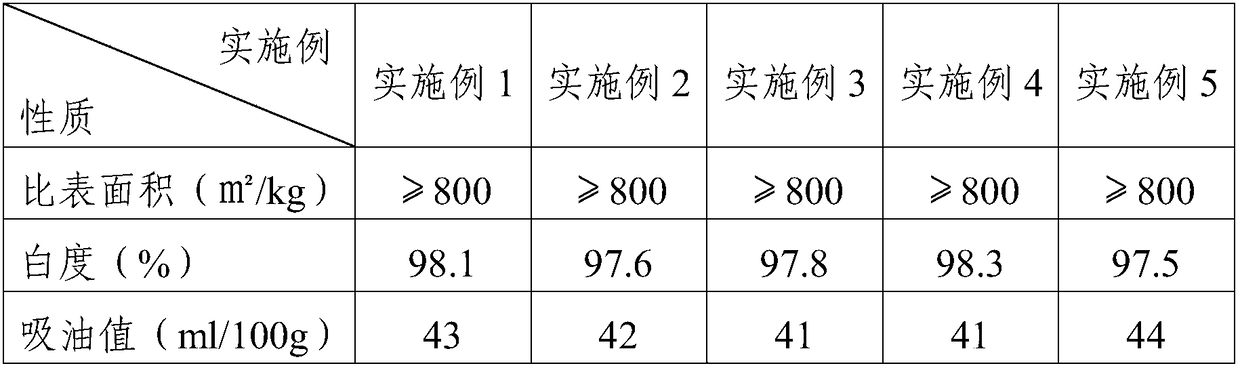

Process for preparing ultrafine calcium carbonate in wet-method grinding way

InactiveCN108557857AAvoid reunionSimple production processCalcium/strontium/barium carbonatesIron removalDiethylene glycol

The invention provides a process for preparing ultrafine calcium carbonate in a wet-method grinding way, which relates to the technical field of fine chemical industry. The process comprises the following steps: (1) transporting calcite to a jaw crusher by virtue of a transporting machine, roughly crushing the calcite, enabling the crushed calcite to enter a raymond mill to be finely crushed, filtering the finely crushed calcite, removing iron by virtue of an iron removal device, and obtaining dry powder; (2) adding water, diethylene glycol and front-stage dispersant, controlling the rotationspeed at 100 to 300 r / min, mixing for 10 to 20 min, adding the dry powder, increasing the rotation speed to 1000 to 1200 r / min, mixing for 20 to 40 min, transferring the mixed slurry into a grinding machine, wherein a ball-material ratio is 3:1, a grinding medium is grinding zirconium balls, after beginning the grinding, supplementing the front end dispersant one time every 30 minutes, grinding for 2 hours, then adding a rear dispersant and a PH adjusting agent, wherein the addition amount of the rear-stage dispersant is 0.4 to 0.5 percent of the weight of the calcite, and continuously grinding for 100 to 120 min; and (3) discharging, washing, drying, thus obtaining a finished product. By adopting the process, the agglomeration phenomenon in the production process of the ultrafine calciumcarbonate can be effectively solved, and the production scale can be increased.

Owner:立达超微工业(苏州)有限公司

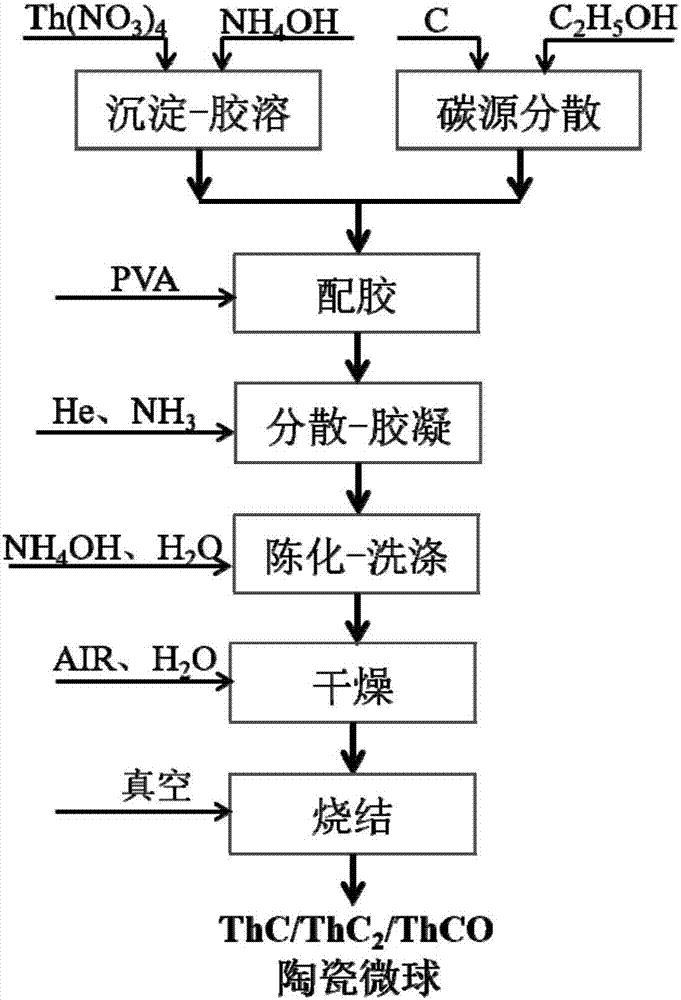

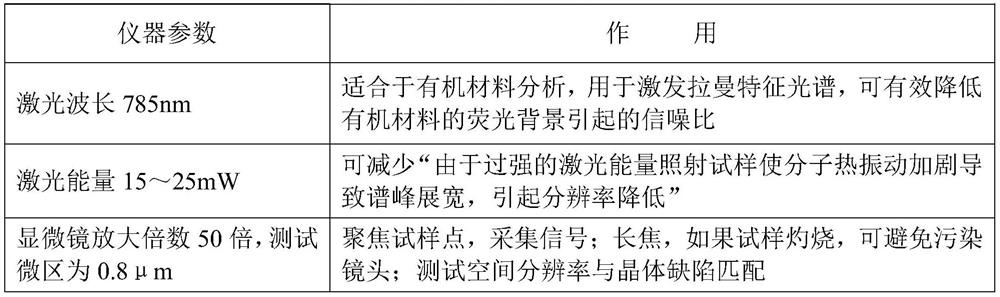

Method for preparing ceramic microspheres of thorium-based carbides and/or thorium-based oxycarbides

ActiveCN107134299AReduce the probability of ruptureNo crackNuclear energy generationReactor fuel susbtancesMicrosphereHydrolysis

The invention relates to a method for preparing ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides. The method comprises the following steps: dripping a thorium nitrate solution into ammonium hydroxide so as to form a hydrolysis solution; adding polyvinyl alcohol while stirring the hydrolysis solution so as to form sol; dispersing carbon powder by utilizing an organic reagent which is mutually soluble with water so as to form pre-dispersed carbon powder; adding the sol into the pre-dispersed carbon powder so as to form a carbon-containing colloidal solution; dispersing the carbon-containing colloidal solution into liquid drops, and enabling the liquid drops to sequentially pass through a helium area, an ammonia gas area and an ammonium hydroxide area so as to form gel particles; ageing the gel particles in stronger ammonia water, washing with deionized water, adding the washed gel particles into a drying furnace, controlling the humidity, heating and drying so as to form the dried gel particles; and adding the dried gel particles into a sintering furnace, heating and sintering under vacuum conditions, thereby obtaining the ceramic microspheres. According to the preparation method disclosed by the invention, the ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides are prepared through a simple process.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Manufacturing method of NTO-based PBX explosive molding powder

ActiveCN111875455ASolve the problem of incomplete wrappingImprove securityProductsReagentsExplosive AgentsSodium hydrogencarbonate

The invention discloses a manufacturing method of NTO-based PBX explosive molding powder. The method includes following steps: dissolving the NTO crude product in hot water, dropwise adding a sodium bicarbonate aqueous solution to neutralize residual acid, rapidly cooling and stirring the mixture at a high speed to separate out NTO solid, and filtering and drying the mixture to obtain an NTO recrystallized product; adding the NTO recrystallized products reaching the particle size requirement into the adhesive solution to form suspension liquid, and carrying out supercritical coating process toprepare the explosive molding crude powder; And carrying out programmed heat preservation at the temperature of 70 DEG C to 120 DEG C to 70 DEG C to obtain the NTO-based PBX explosive molding powder.The purity of the NTO recrystallized product is 99.4%, the residual acid content is 0.03%, and the water content is 0.05%. The manufactured PBX explosive molding powder is completely coated, so thatthe safety of a subsequent press-fitting process and the tensile strength and compressive strength of a press-fitting grain can be ensured.

Owner:XIAN MODERN CHEM RES INST

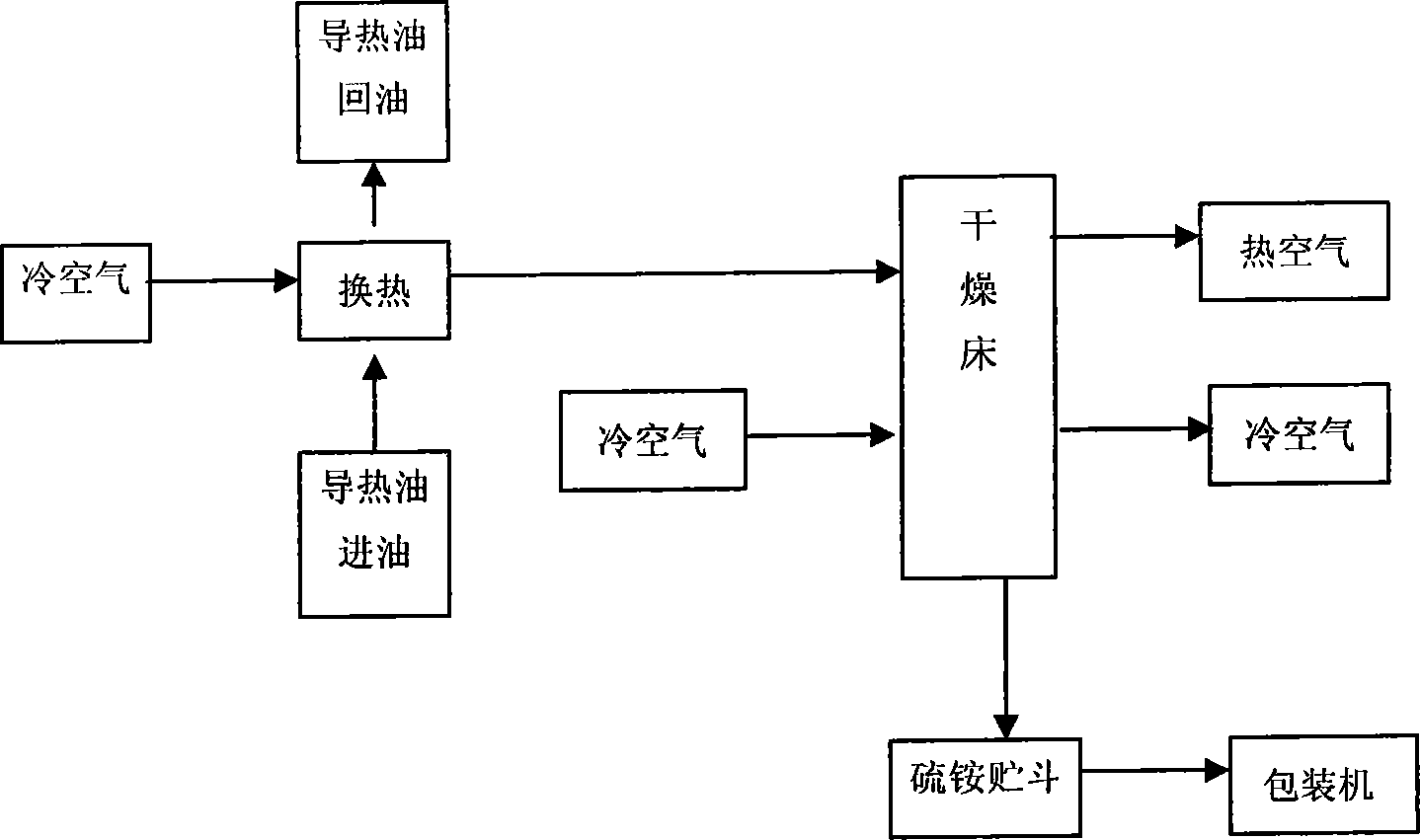

Ammonium sulfate heat conductive oil drying method

InactiveCN101050915AReduce manufacturing costProtect the environmentDrying solid materials with heatDrying gas arrangementsLiquid wasteFluidized bed drying

A method of utilizing heat conduction oil to dry thiamine includes heat exchanging heat conduction oil with air and then leading heated air into fluidized bed to dry thiamine.

Owner:SHANDONG IRON & STEEL CO LTD

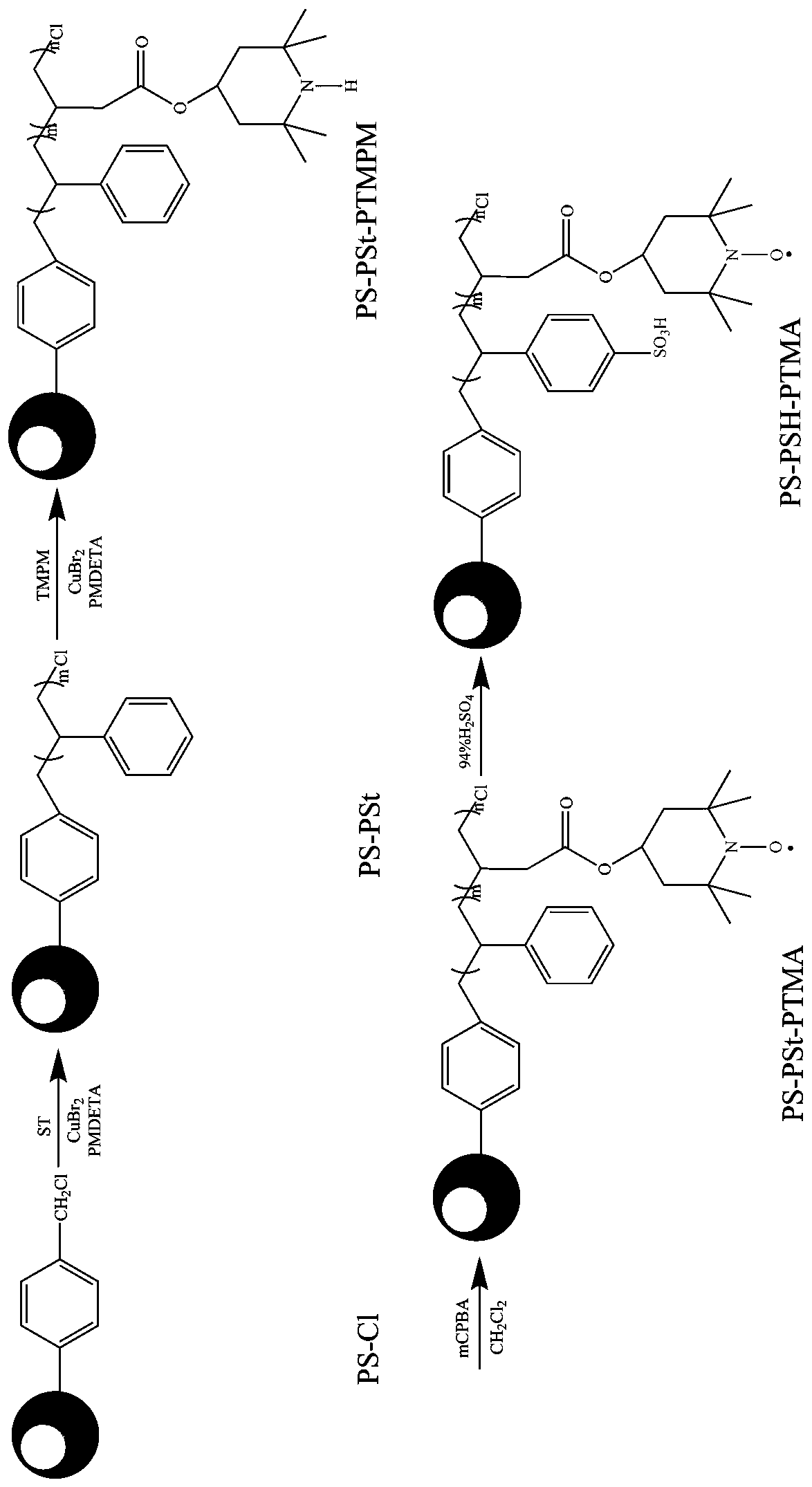

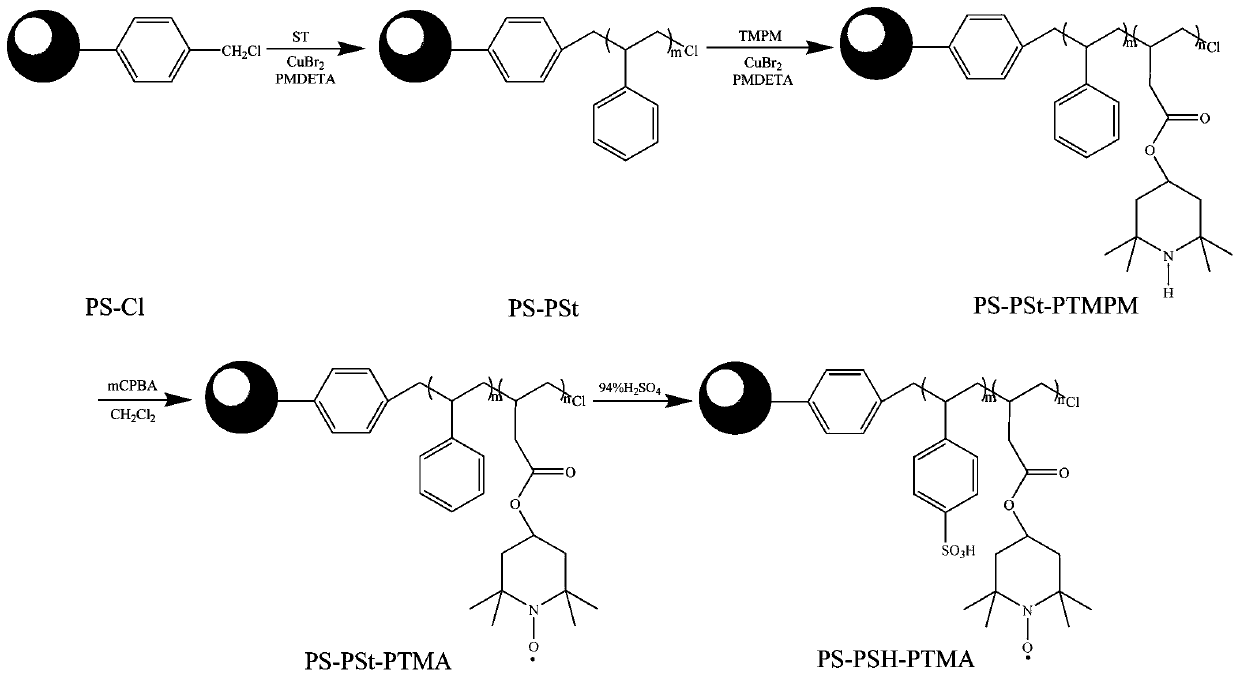

Production method and application of micron-sized supported difunctional polymer brush with nitroxide free radicals and sulfonic groups

The invention relates to a micron-sized supported difunctional polymer brush with nitroxide free radicals and sulfonic groups. A production method comprises the steps of using 2,2,6,6-tetramethyl-4-piperidyl methacrylate TMPM and styrene St as monomer, using chloromethylated cross-linked polystyrene micro-spheres with particle size of 74-149 [mu]m and a Cl content of 1.12 mmol / g as a macroinitiator, adopting ARGETATRP for synthesizing a TMPM and St block polymer brush, using m-chloroperbenzoic acid mCPBA for oxidizing piperidyl of the TMPM into the nitroxide free radicals, and using sulfur forsulfonating the St to obtain the difunctional polymer brush. Application of the difunctional polymer brush in synthesis of polycarboxylate water reducer reactive macromonomer is further provided. Theproduced difunctional polymer brush can achieve recovery and recycle of a polymerization inhibitor and an acid catalyst at the same time, the production cost is reduced, and the reaction rate is improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

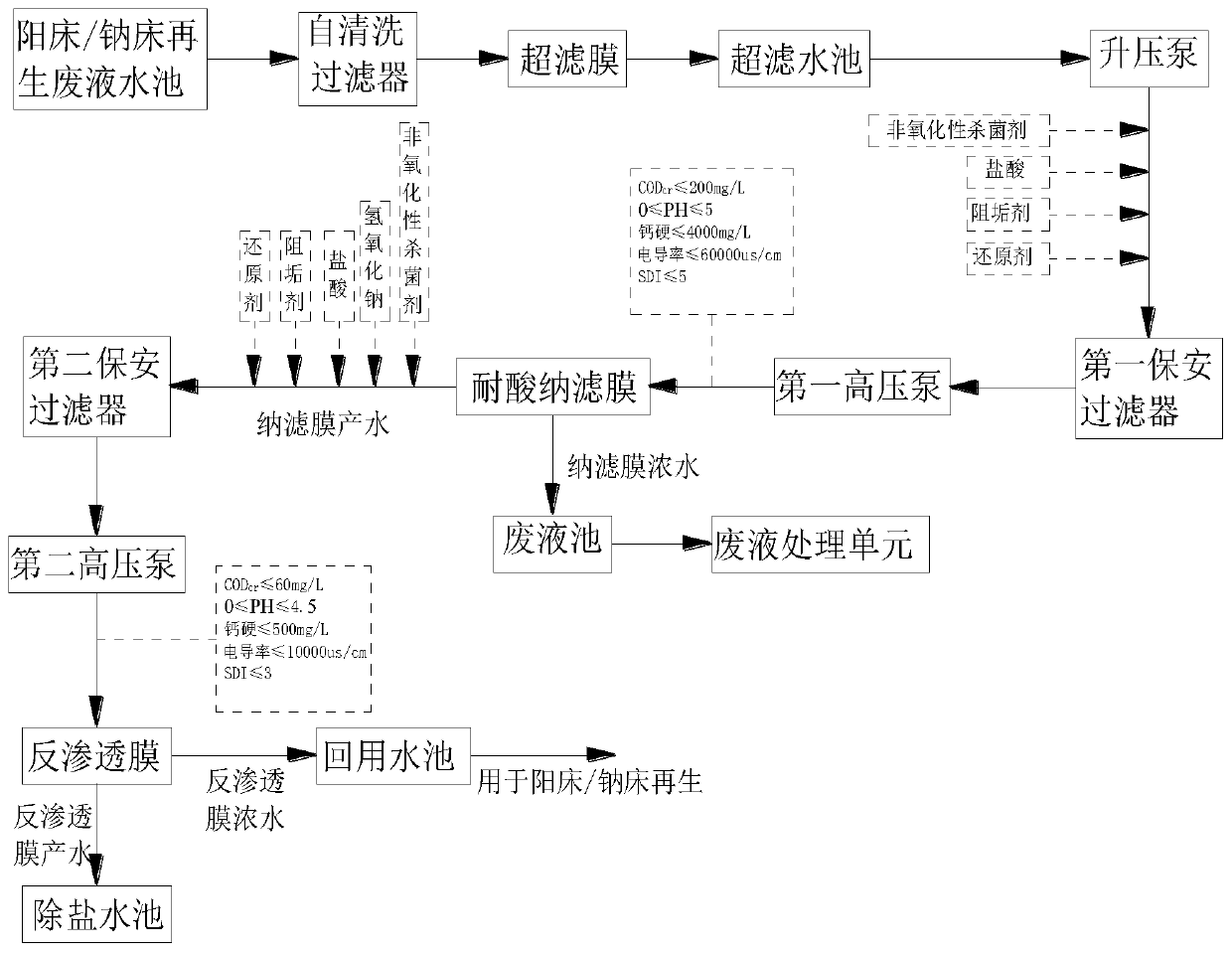

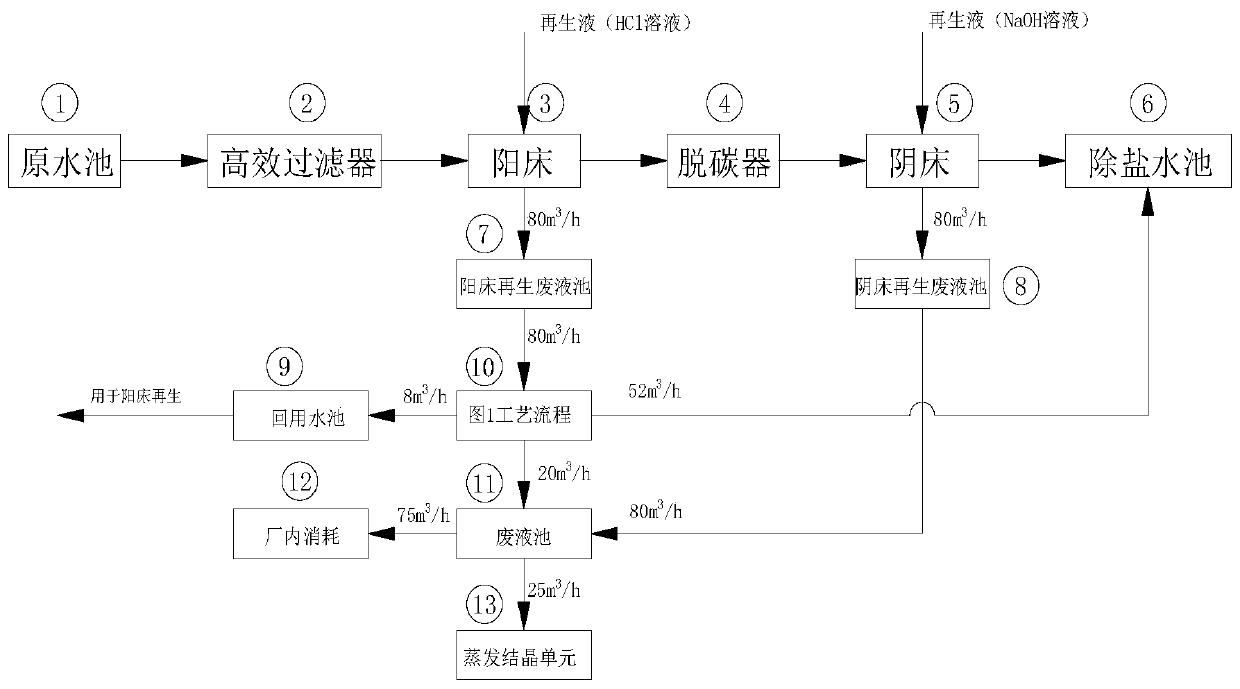

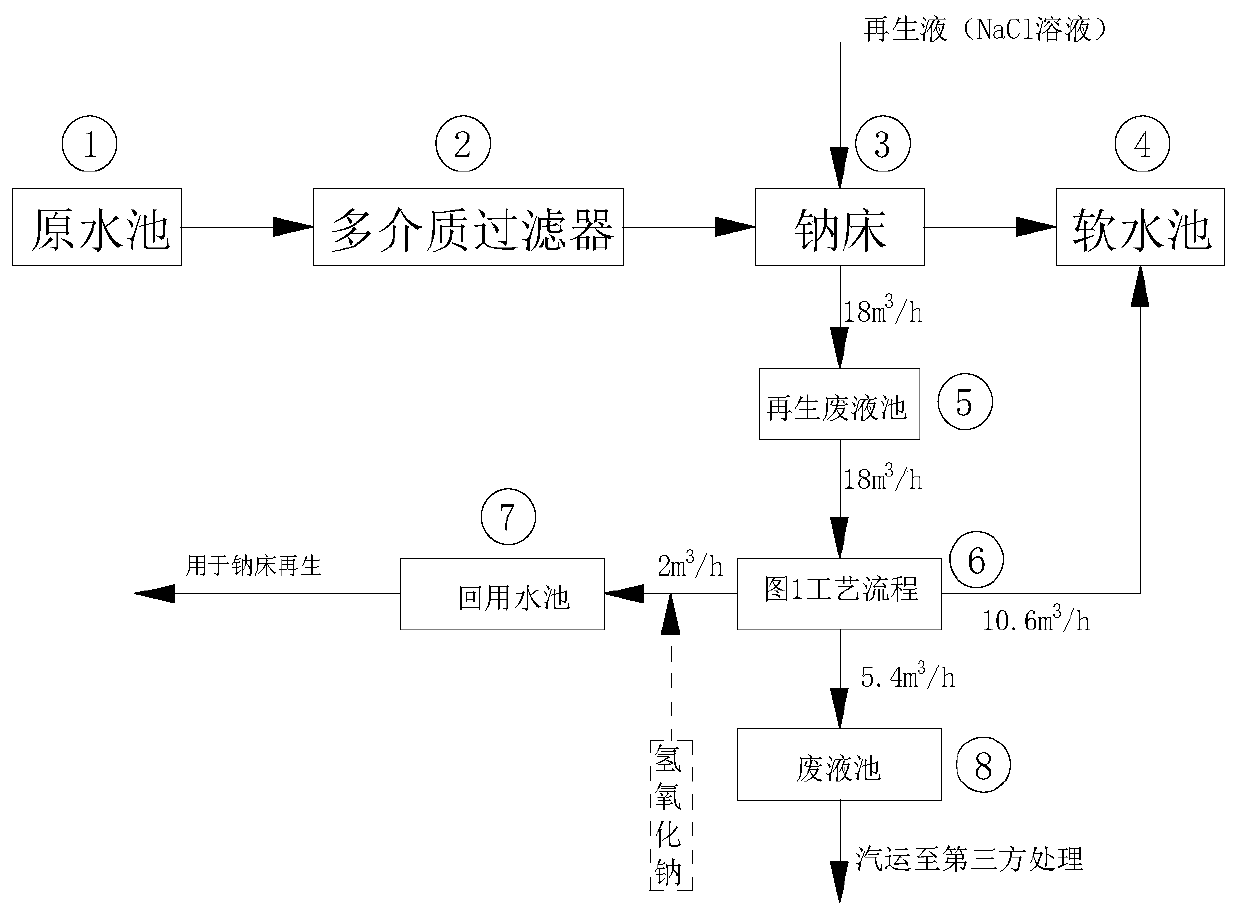

Recycling process for regeneration waste liquid

InactiveCN110316873ALow costFully regeneratedScale removal and water softeningTreatment involving filtrationLiquid wasteUltrafiltration

The invention relates to a recycling process for regeneration waste liquid. The waste liquid generated by a cation bed or a sodium bed is stored in a regeneration waste liquid pool and conveyed to a self-cleaning filter through a pump and then directly enters an ultrafiltration membrane, produced water of the ultrafiltration membrane enters an ultrafiltration pool, sequentially passes through a booster pump, a first security filter and a first high-pressure pump and then enters an acid-resistant nanofiltration membrane, the acid-resistant nanofiltration membrane separates monovalent and divalent ions in the regeneration waste liquid, divalent and multivalent ions enter a waste liquid pool along with concentrated brine of the acid-resistant nanofiltration membrane and then enter a wastewater treatment unit, monovalent cations directly enter a second security filter along with produced water of the acid-resistant nanofiltration membrane, the produced water is pressurized by a second high-pressure pump and then enters a reverse osmosis membrane for concentration treatment, produced water of the reverse osmosis membrane enters a desalting pool and then enters a recycling pool through the concentrated water side of the reverse osmosis membrane, and water in the recycling pool is used for the regeneration of the cation bed or the sodium bed. By means of the recycling process, the amount of the waste liquid is reduced to a great degree, and a lot of cost is reduced for the the subsequent treatment of the concentrated brine.

Owner:TANGSHAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com