Substrate processing appts.

A substrate processing device and substrate technology, which are applied in the fields of optics, instruments, electrical components, etc., can solve the problems of reduced utilization rate of developer, pollution of non-dissolved substances, and inability to process substrates, etc., to achieve reduced waste liquid volume, high utilization efficiency, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

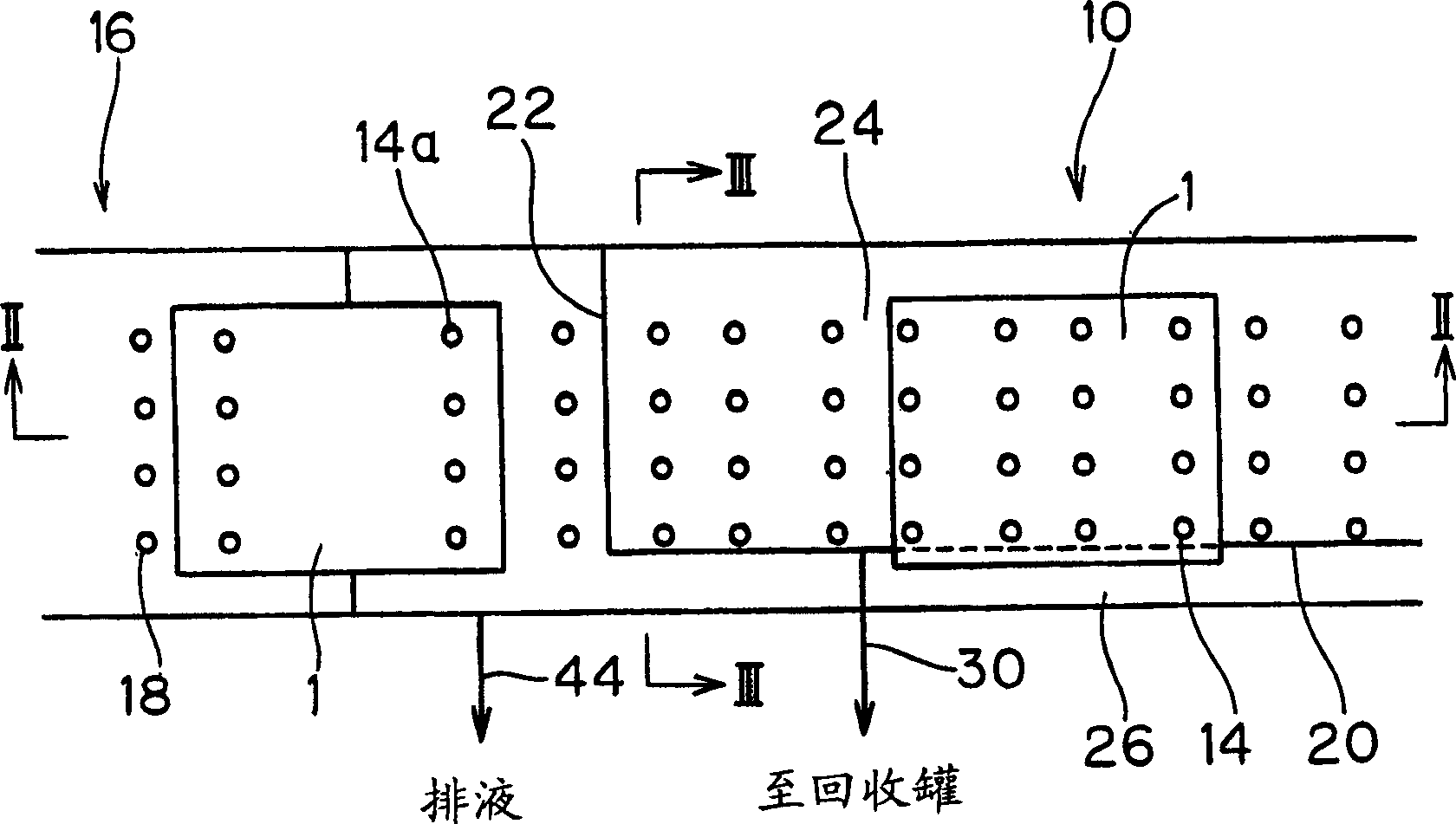

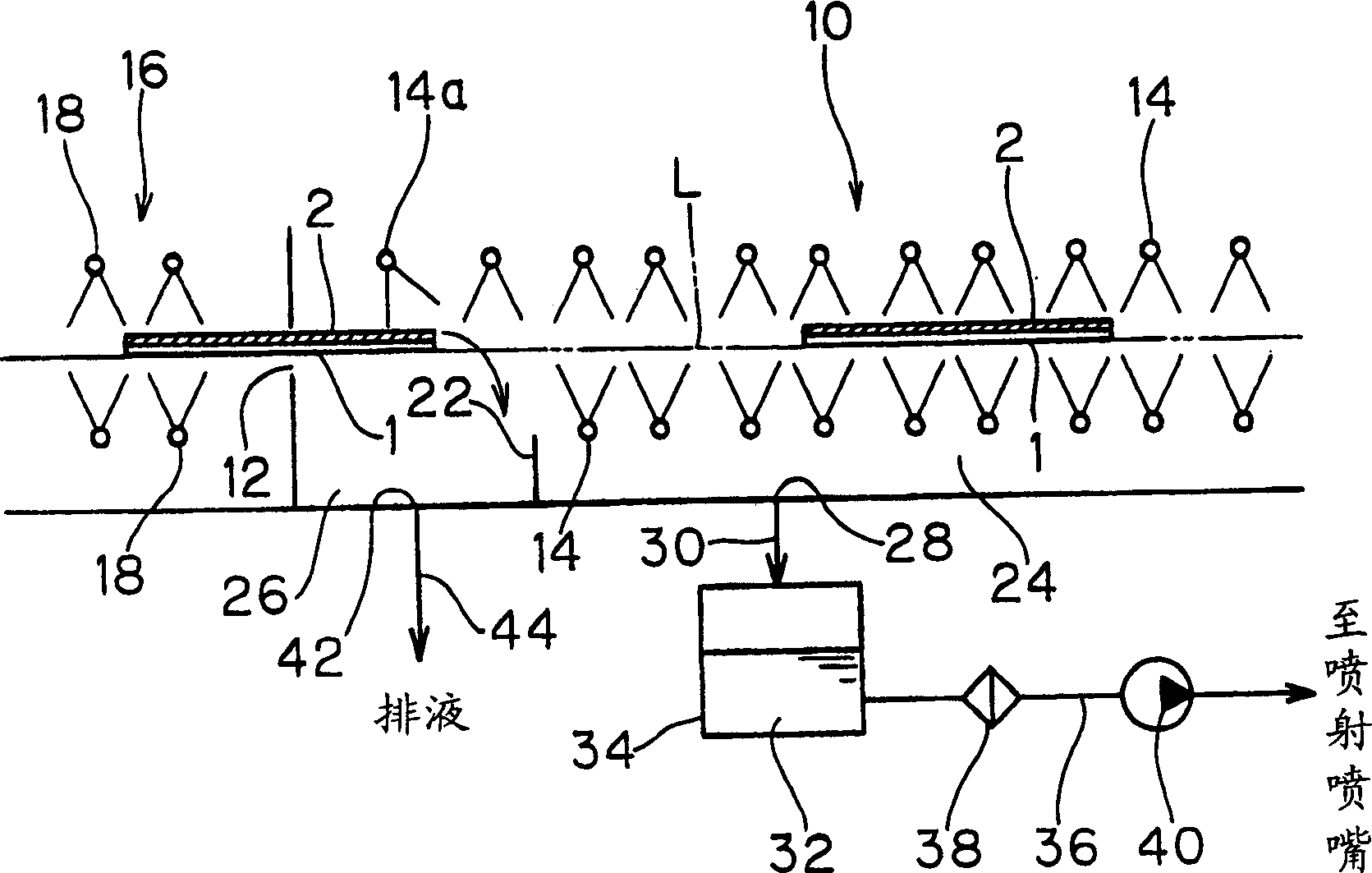

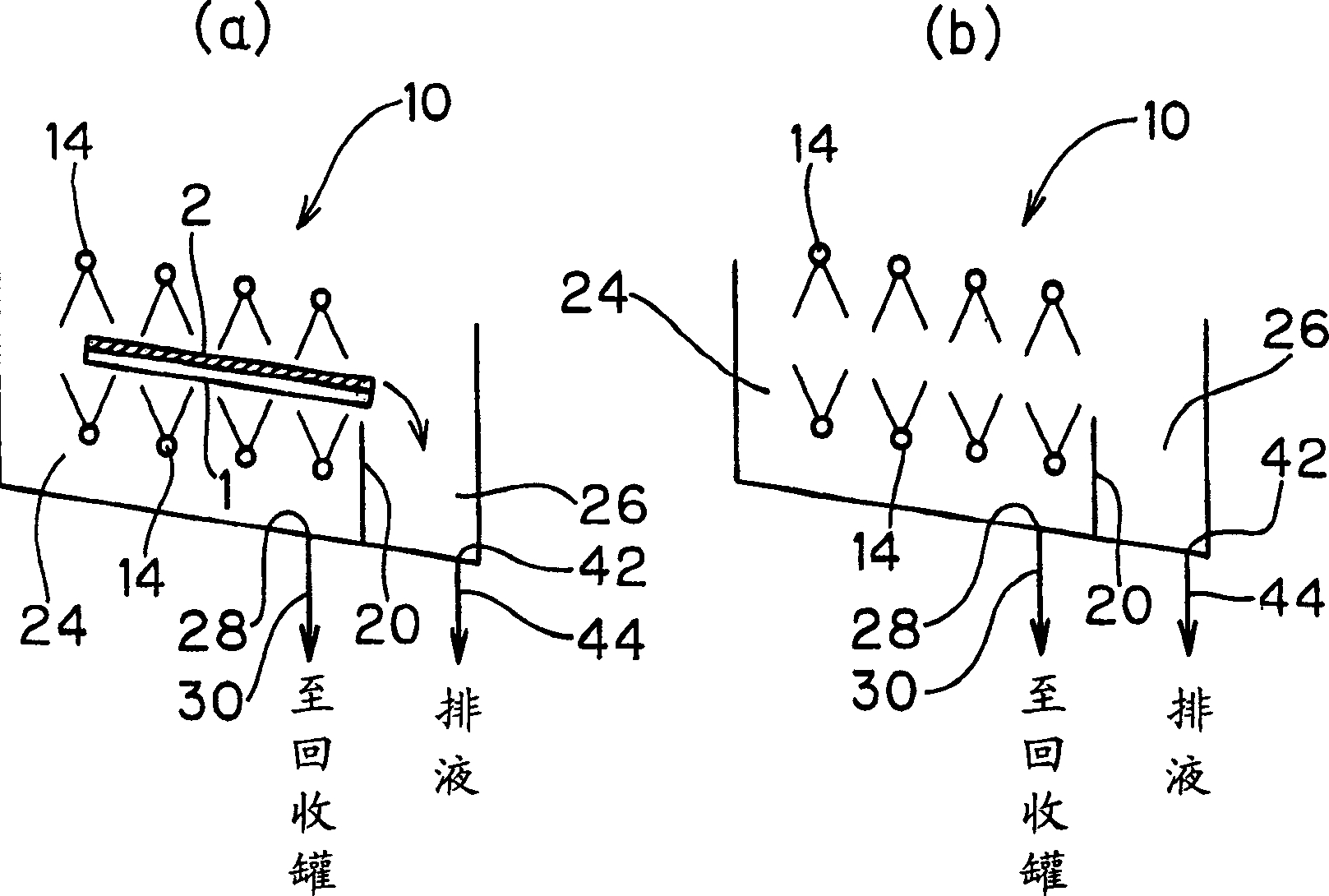

[0127] Below, refer to the attached Figures 14 to 18 A second embodiment of the present invention will be described.

[0128] Figure 14 An example of the second embodiment of the present invention is shown, and it is a side view schematically showing a schematic configuration of a development processing apparatus which is one of substrate processing apparatuses. In such a development processing device, due to the structure and operation of the main part that performs the development processing and the corresponding Figure 20 It is the same as the existing device for explanation, so in Figure 14 Mark the same part with and Figure 20 The same reference numerals as used in , and their repeated descriptions are omitted.

[0129] In such a development processing apparatus, the inside of the development processing tank 110 is partitioned off below the developer spraying nozzle 116, and a recovery tank portion 122 is provided. In addition, instead of providing the recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com