Patents

Literature

61results about How to "Fully regenerated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

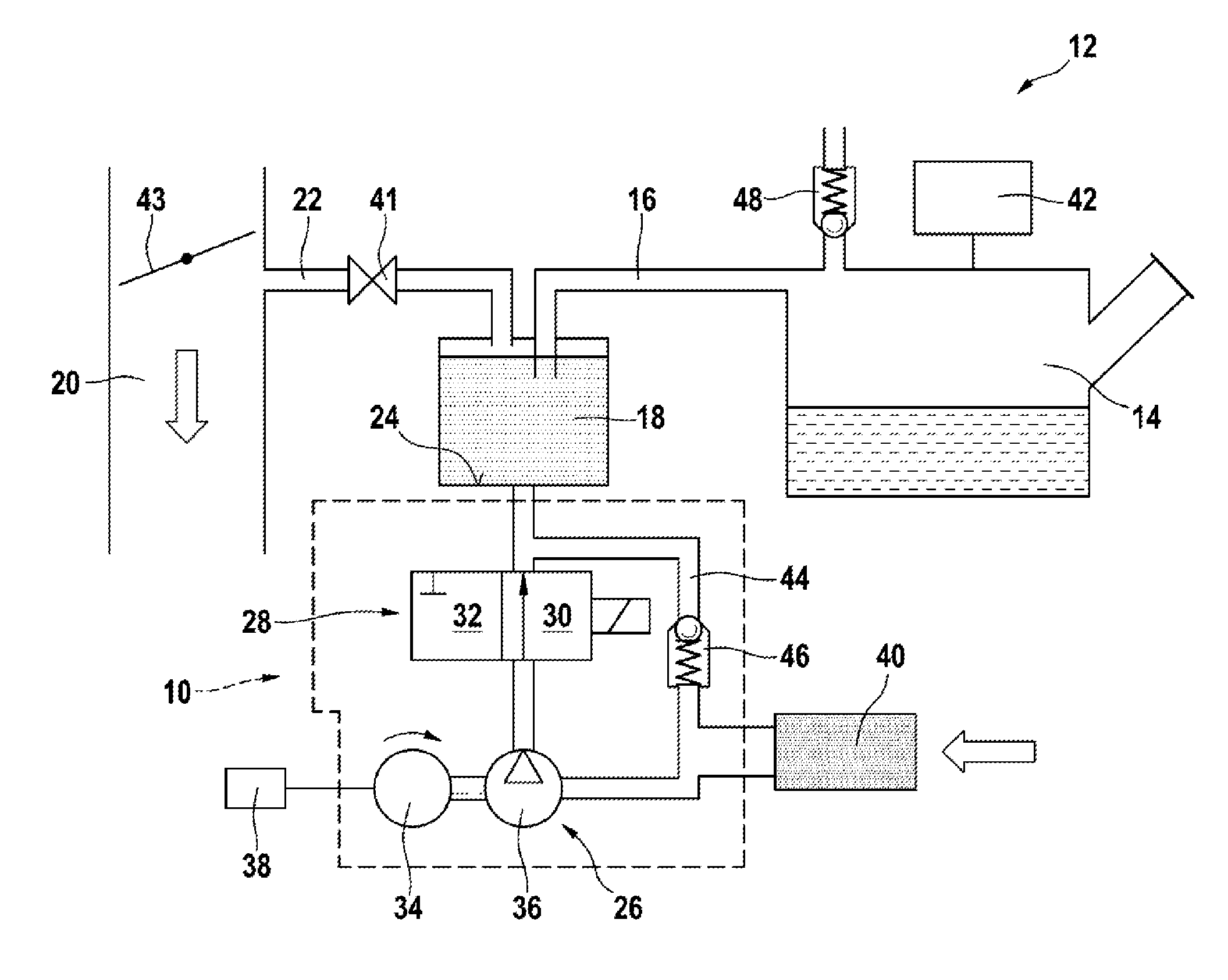

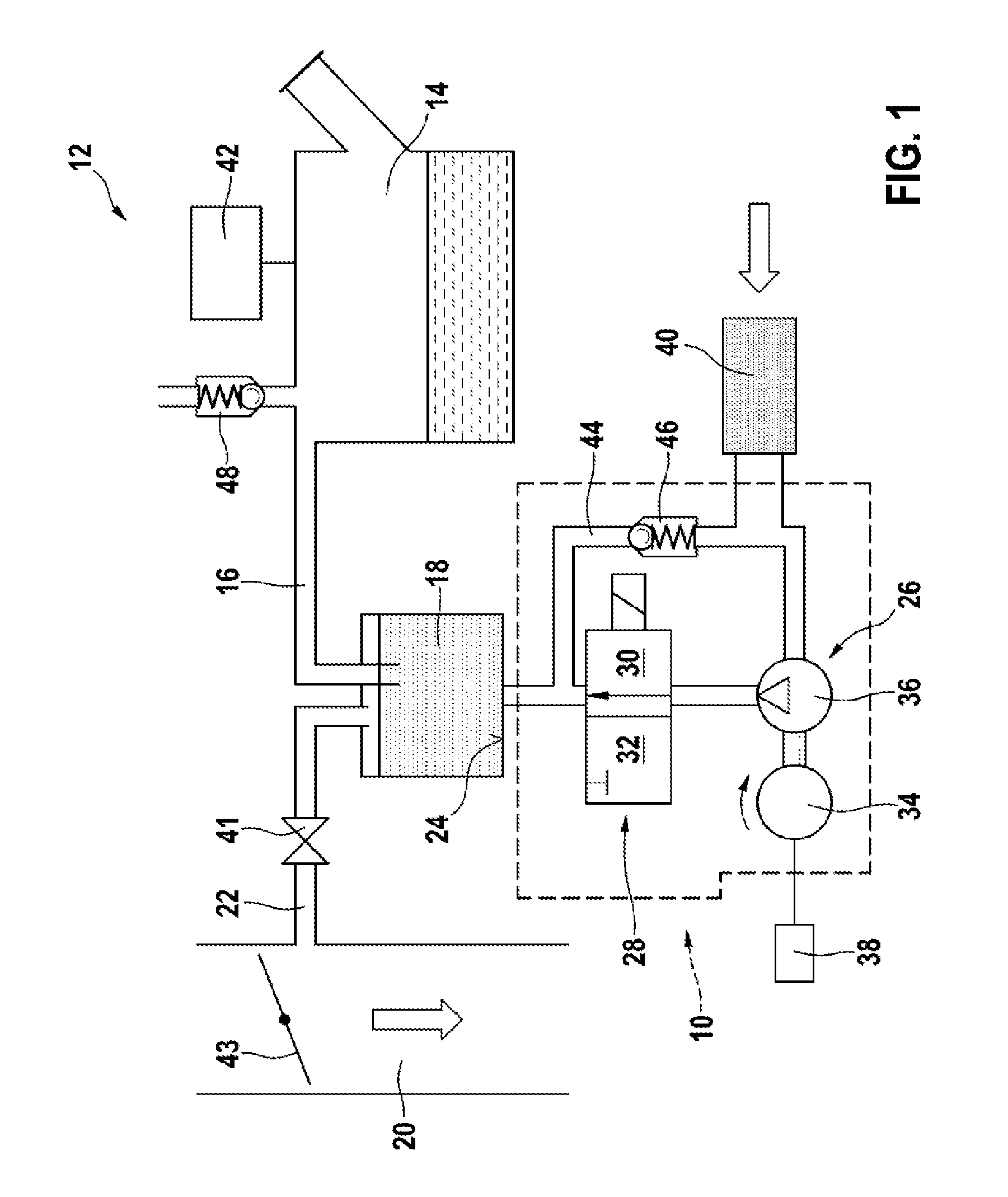

Device for selectively regenerating or performing tank leakage diagnosis of a tank ventilation system

ActiveUS20140013944A1Performed easily and cost-effectivelyReliable diagnosisNon-fuel substance addition to fuelIsotope separationFuel tankSorption

A device for selectively regenerating and performing tank leakage diagnosis of a tank ventilation system has a sorption filter and a pump. The sorption filter is configured to temporarily store fuel evaporating from a fuel tank. The pump is arranged at a fresh-air side of the sorption filter and is connected in fluid-conducting fashion to the sorption filter. The pump is configured to generate a fluid flow to regenerate the sorption filter.

Owner:ROBERT BOSCH GMBH

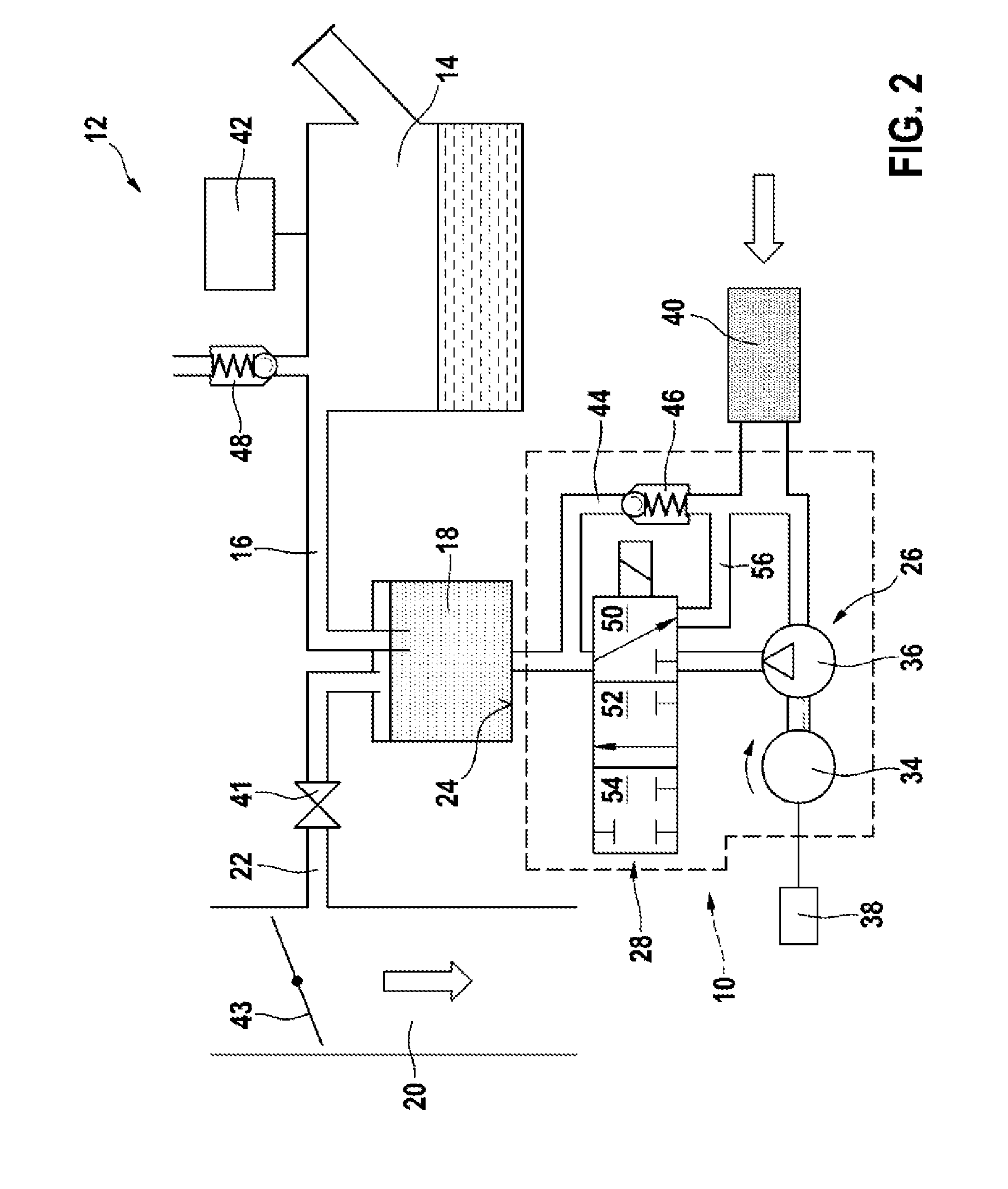

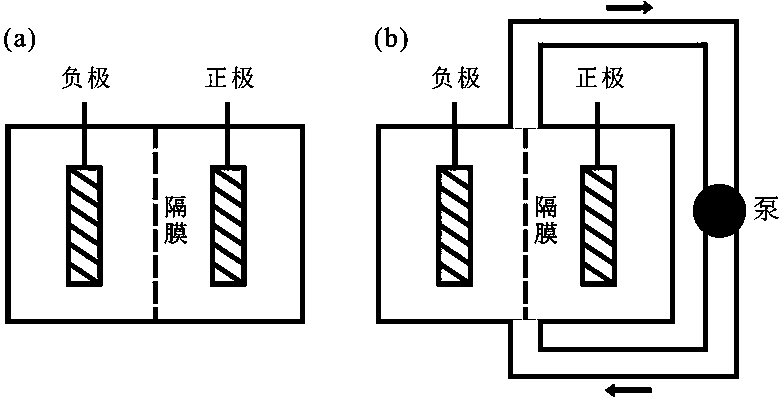

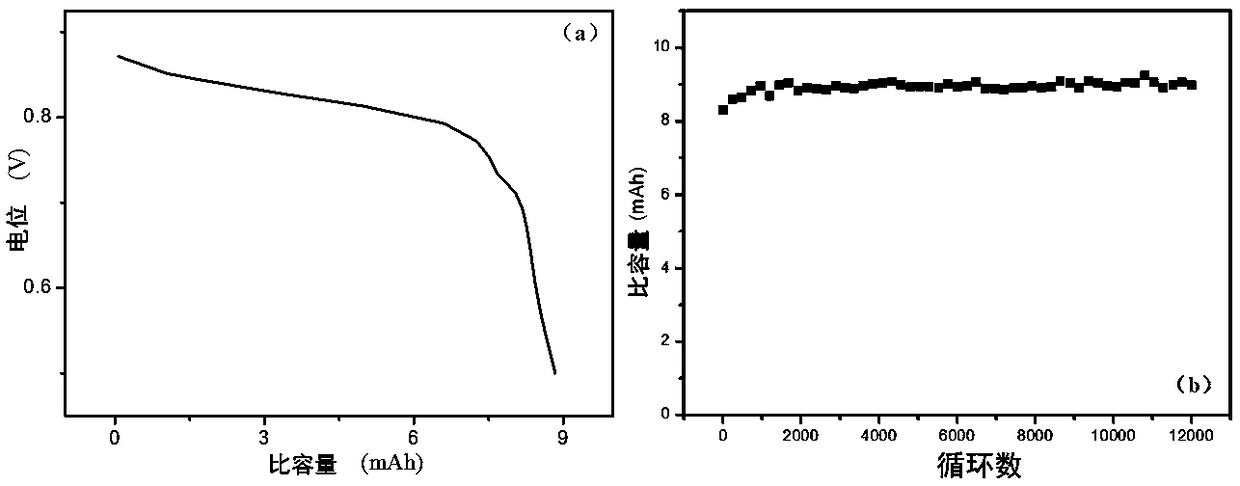

Copper-manganese aqueous secondary battery based on deposition/dissolution reaction on positive and negative poles

ActiveCN108428926AImprove cycle lifeImprove power densitySecondary cellsManganeseAqueous electrolyte

The invention belongs to the technical field of electrochemistry and particularly provides a copper-manganese aqueous secondary battery based on deposition / dissolution reaction on positive and negative poles. The battery system specifically comprises a negative current collector, a positive current collector, an aqueous electrolyte containing bivalent copper ions and bivalent manganese ions as well as a porous separator for separating the positive and negative poles. When the battery is charged, the bivalent manganese ions in a positive pole area lose electrons and are oxidized into solid manganese dioxide, solid manganese dioxide is deposited on the positive current collector, and the copper ions in a negative pole area gain electrons and are reduced into metal copper, and metal copper isdeposited on the negative current collector; during discharging, manganese dioxide on the positive pole gain the electrons and is reduced into bivalent manganese ions, the bivalent manganese ions aredissolved in the electrolyte, meanwhile, copper on the negative pole releases electrons and is oxidized into bivalent copper ions, and the bivalent copper ions are dissolved in the electrolyte. The battery has the advantages of ultrahigh power density, ultra-long cycle life, high safety and low toxicity, and can be widely applied to the fields of large energy storage and the like.

Owner:FUDAN UNIV

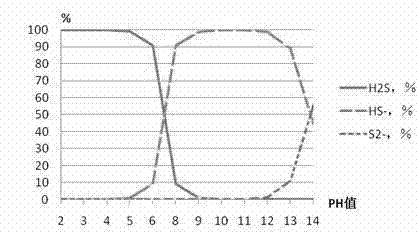

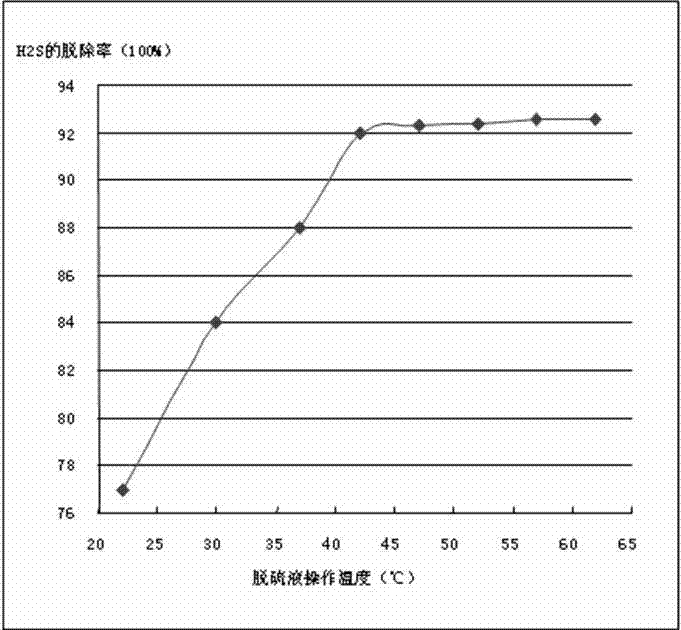

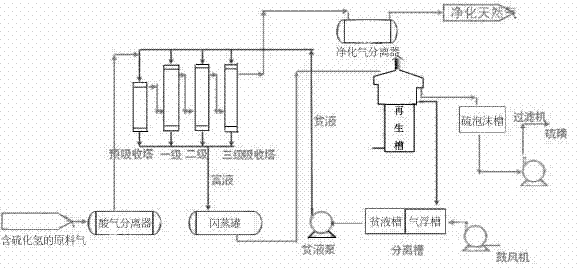

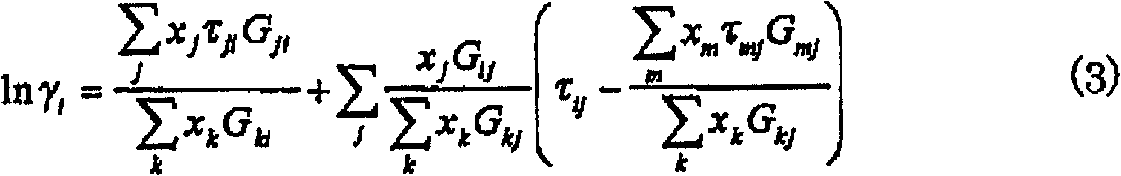

Method for production regulation of chelated iron desulfurization process

ActiveCN103691274AReduce equipment lossReduce power consumptionDispersed particle separationGaseous fuelsSolid phasesChemistry

The present invention relates to a gas treatment method, specifically to a method for production regulation of a chelated iron desulfurization process. According to the method, solid phase impurities and liquid phase impurities are removed from hydrogen sulfide-containing raw material gas through an acid-gas separator, the obtained material sequentially passes through a pre-absorption tower and an absorption tower, and reacts with the chelated iron barren solution so as to remove the hydrogen sulfide gas, and the purified nature gas enters a purified gas separator to remove water, is subjected to measurement detection, and then is directly and externally output. With the method, normal use can be achieved even when the hydrogen sulfide content in the raw material gas is changed, and production requirements can be met through adaptable regulation of other parameters according to the method so as to avoid regulation of the production process. In addition, according to the actual situation requirements of the production, the optimal desulfurization solution circulation amount is selected so as to reduce equipment loss, reduce pump power consumption and avoid waste of energy sources.

Owner:CHINA PETROLEUM & CHEM CORP +1

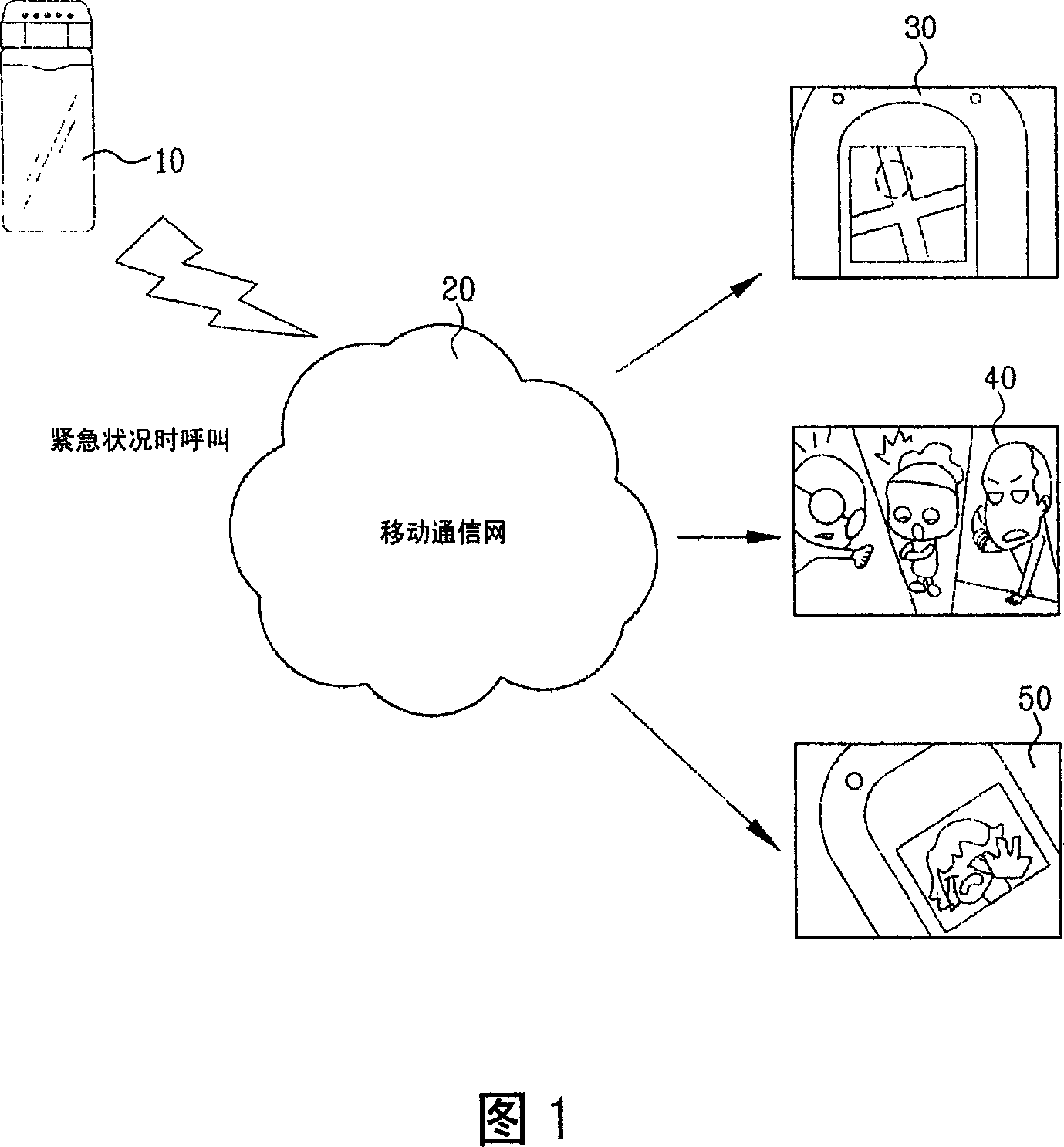

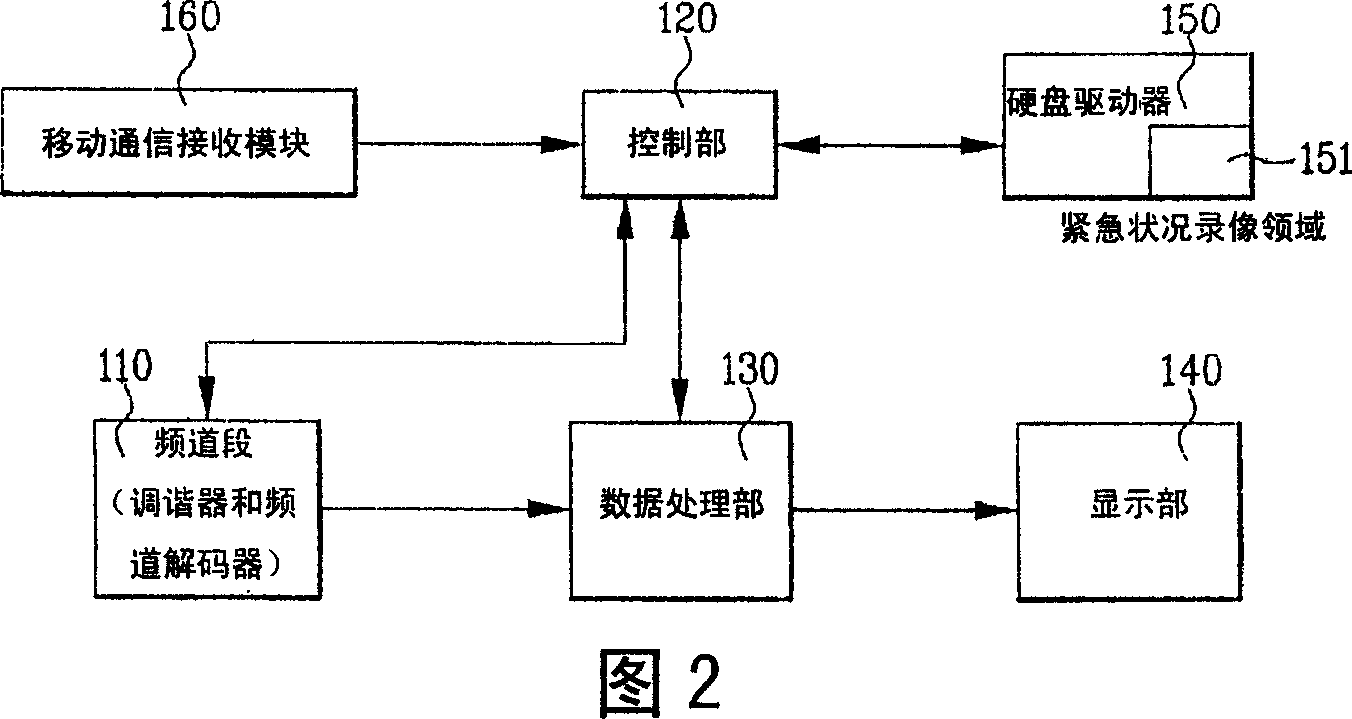

Recording TV receiver with the data recording function of the mobile phone and its data recording method of the mobile phone

InactiveCN101035214AImprove stabilityReal time monitoringTelevision system detailsColor television detailsTelevision receiversData recording

This invention relates to a method of storage the data from the phone in an emergency situation to protect and to show the data that the cell phone data with video-enabled television receivers and video phones data. Video phone data with the video television receiver functions include the following structure: a channel which for the user to select and decoders for channels; A Data Processing Department, it will be decoded in order to allow data to renewable and storage, coding and / or decoding; The Department has revealed that to show the data processing to be addressed in the Department's data; with mobile communications receiver module, which will be receive mobile phone communications network to send data and change to another identification number ; with storage devices, used to store the data processing to be addressed in the Department's data and mobile communications received from the module receiving data; Control Division, which will include data-processing controls, the Department of the entire television receiver.

Owner:LEIJIN ELECTRONIC SHENYANG CO LTD

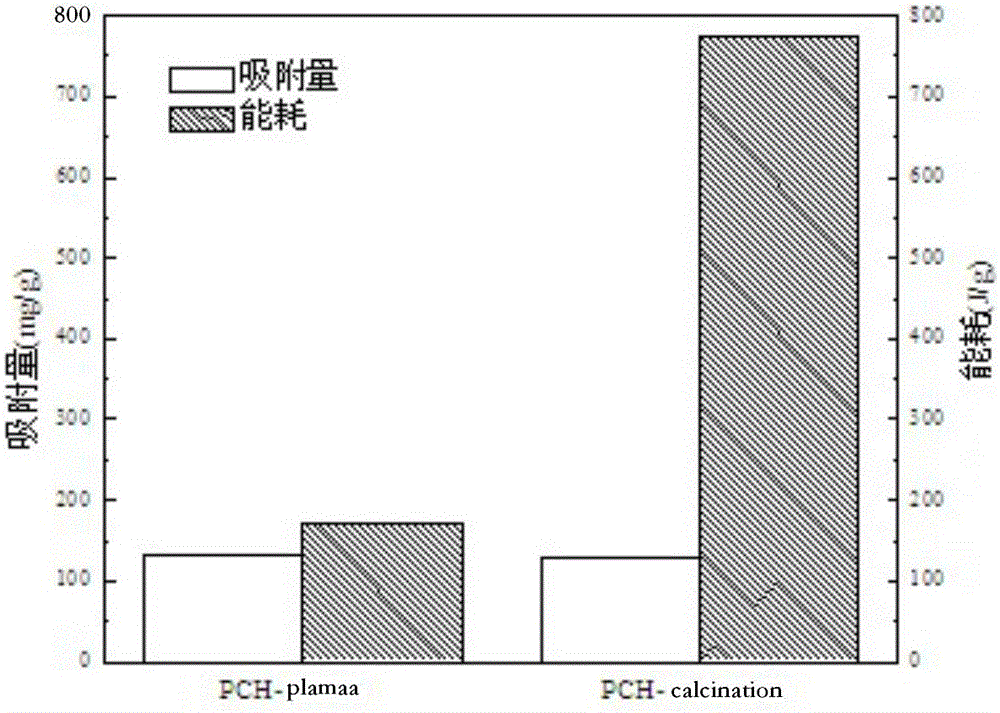

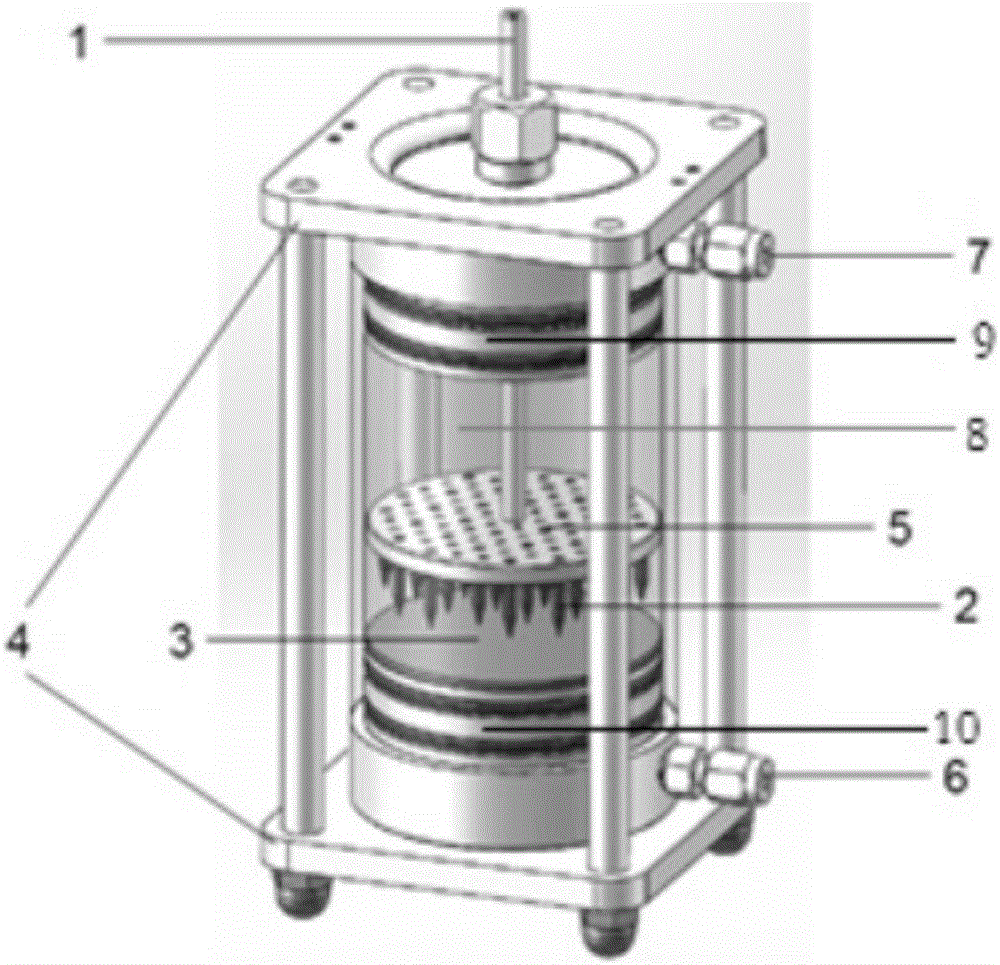

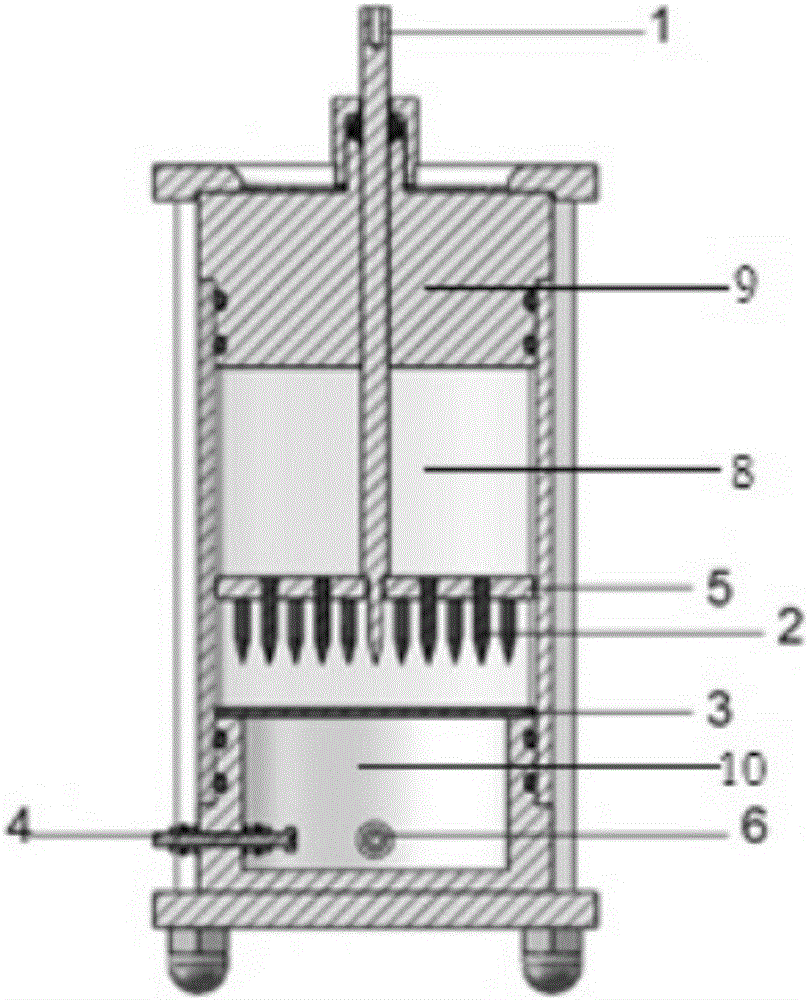

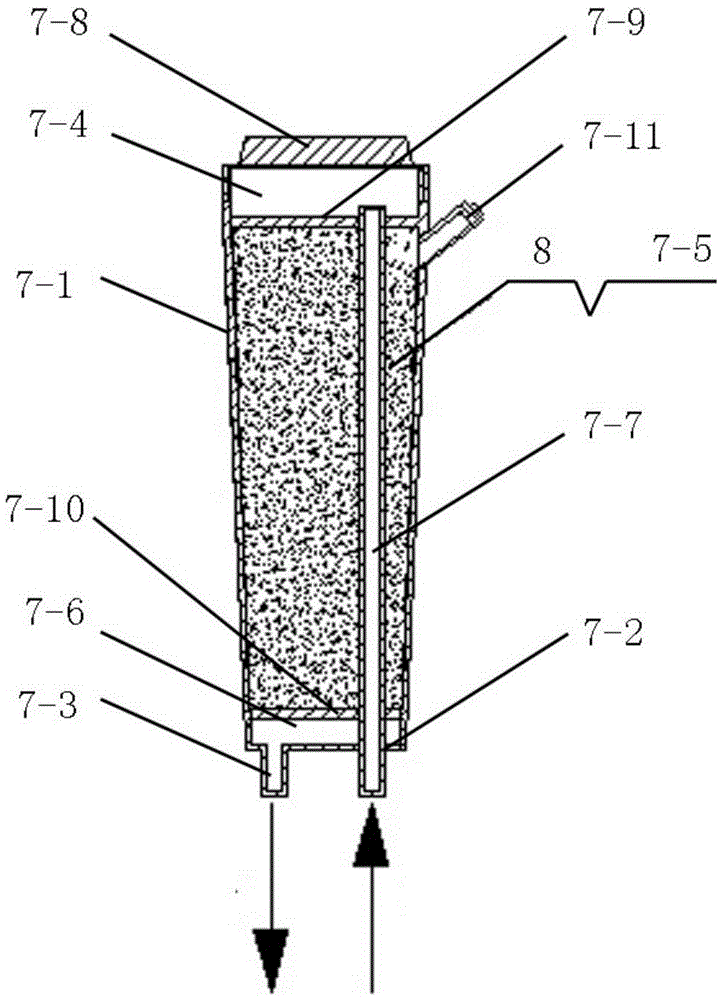

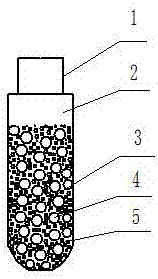

Plasma electro-discharge reactor for non-carbon absorbent regeneration and plasma electro-discharge reacting method

InactiveCN105056917AFacilitates chemisorptionGood regeneration effectCombustible gas purificationFilter regenerationPolytetrafluoroethyleneEngineering

The invention discloses a plasma electro-discharge reactor for non-carbon absorbent regeneration. The plasma electro-discharge reactor comprises a bracket, wherein a reaction sleeve in which a cavity is arranged is arranged in the bracket; an upper electrode and a lower electrode are respectively arranged on the upper side and the lower side of the cavity of the reaction sleeve; an upper air inlet and a lower air outlet are respectively formed in the upper end and the lower end of the reaction sleeve, and penetrate through the side walls of the reaction sleeve to be communicated with the cavity of the reaction sleeve; a high voltage terminal interface is formed in the upper end of the bracket, and is connected with the upper electrode; an earthing terminal interface is formed in the lower end of the bracket and is connected with the lower electrode. The bracket is the stainless-steel bracket made of stainless-steel material; the reaction sleeve is the quartz glass sleeve which is unsealed at the upper end and the lower end and is made of quartz glass material; a seal cover and a base which are made of polytetrafluoroethylene material are respectively arranged at the upper end and the lower end of the quartz glass sleeve for sealing; a fluoro rubber seal ring is arranged between the quartz glass sleeve and the seal cover as well as between the quartz glass sleeve and the base for sealing; the upper air inlet and the lower air outlet penetrate through the seal cover and the base respectively, and then are communicated with a sealed space formed by the quartz glass sleeve, the seal cover and the base.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

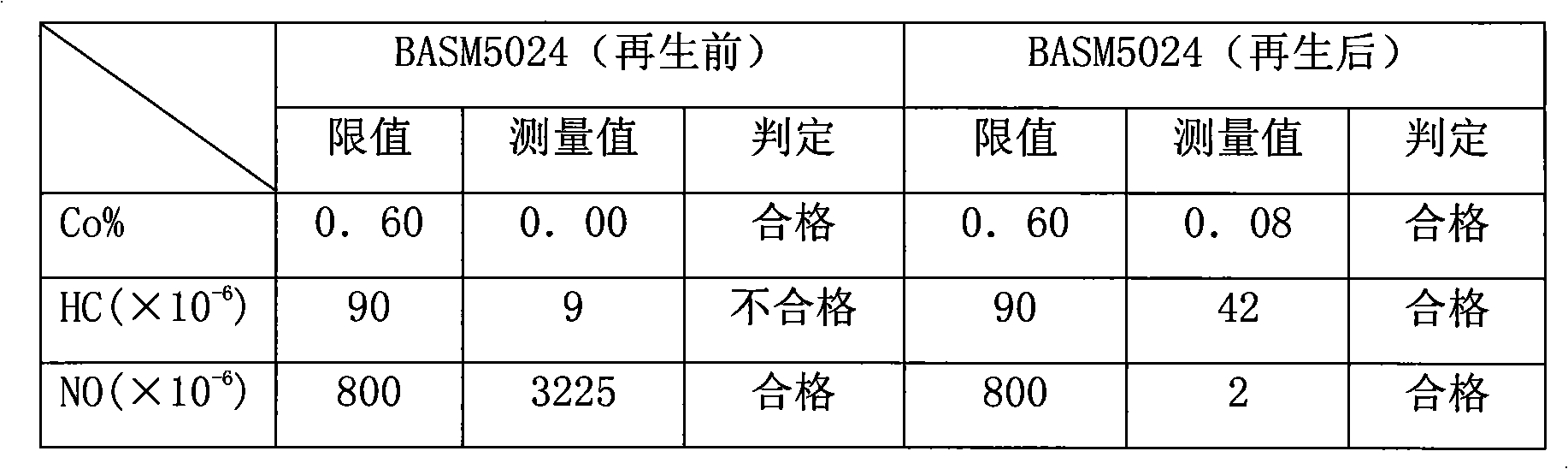

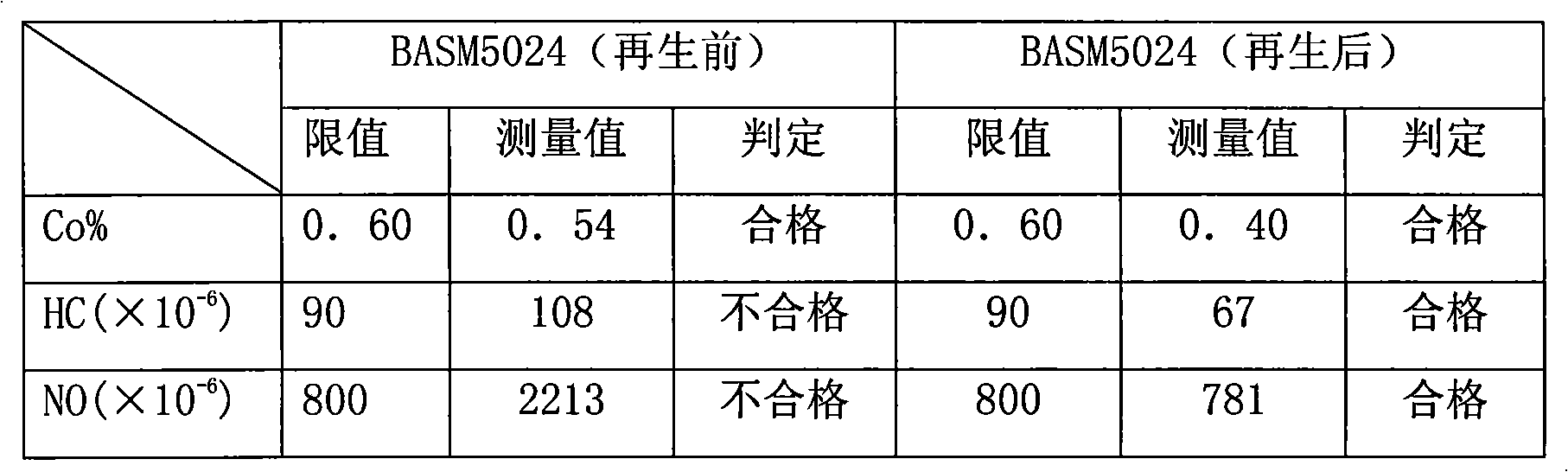

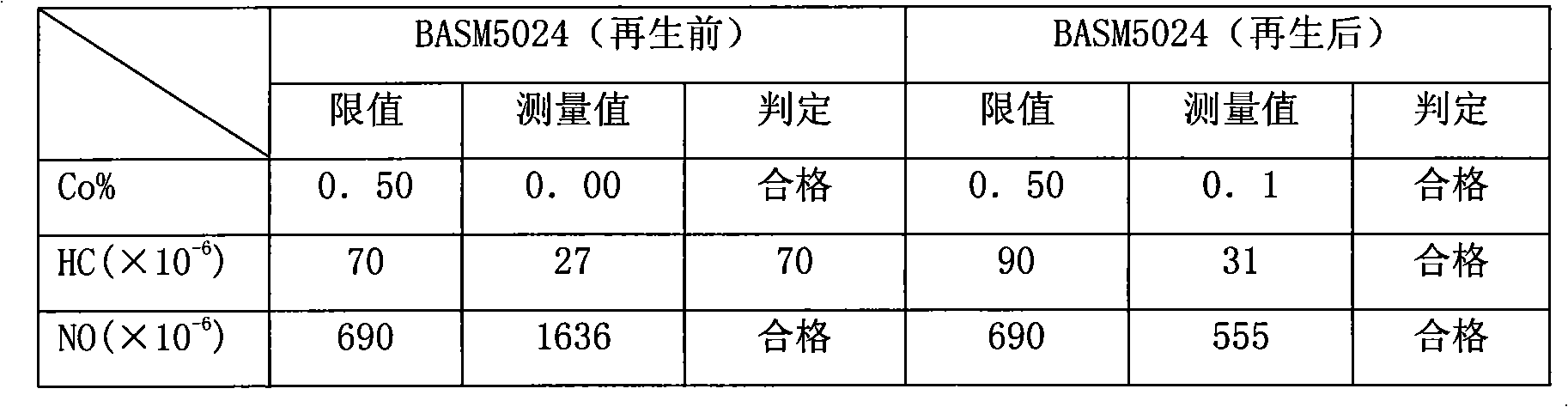

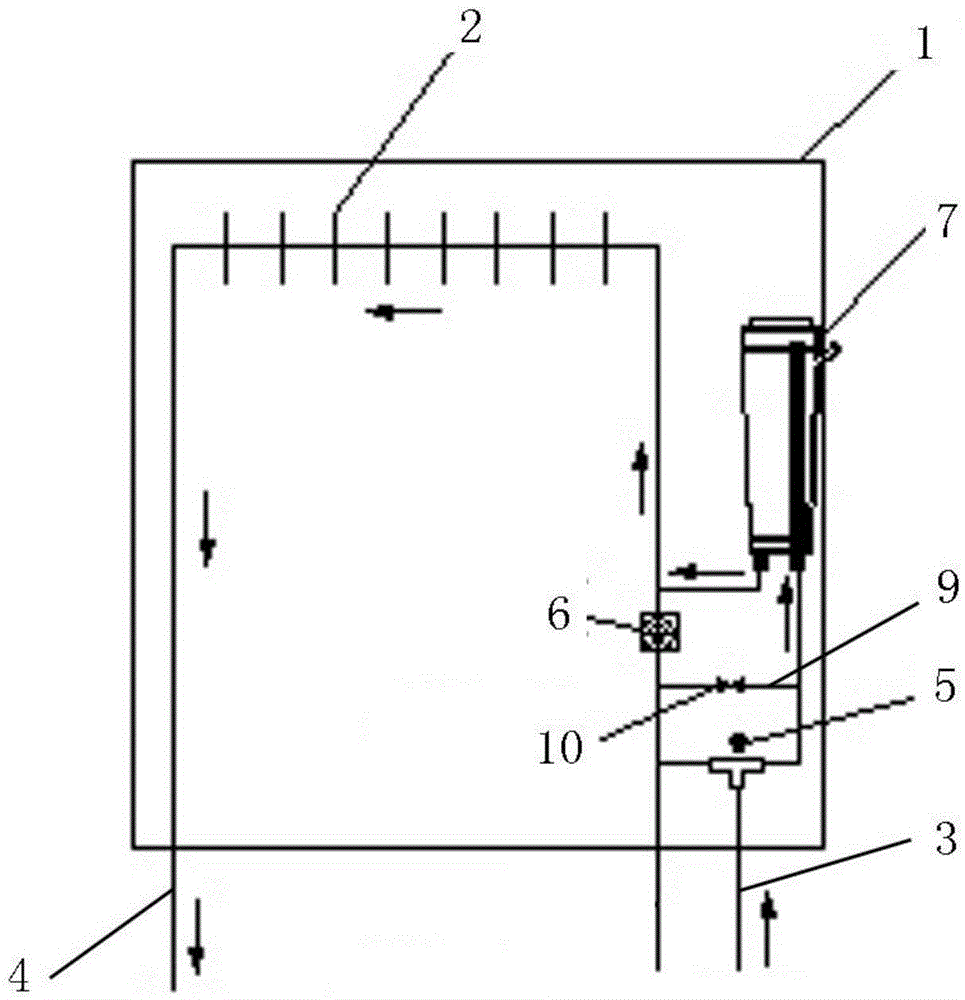

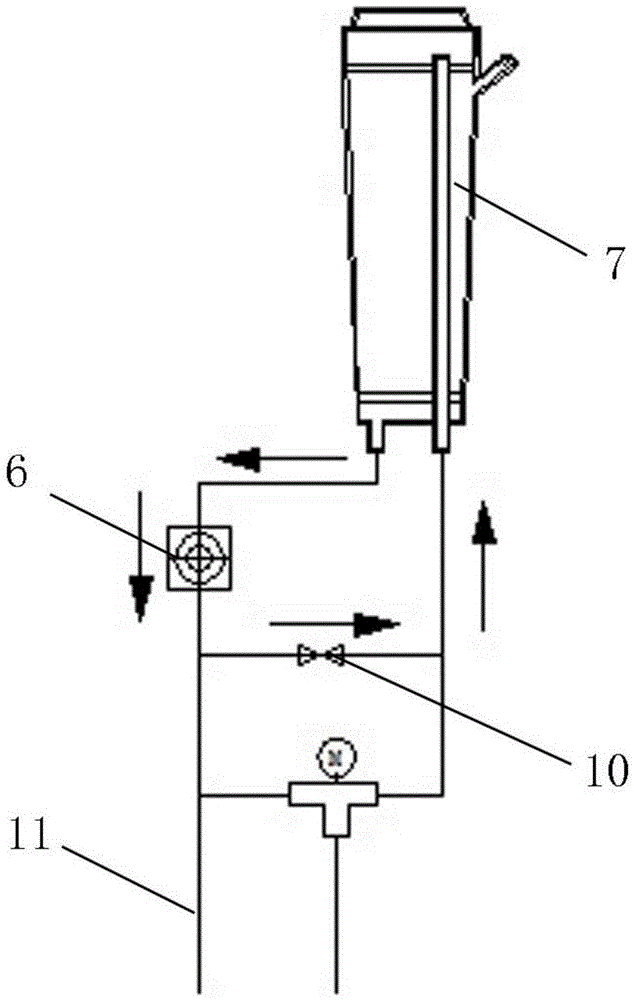

Regenerant and processing method of three-way catalytic converter of gasoline automobile

InactiveCN101884940AReduce pollutionRestore exhaust gas purification functionInternal combustion piston enginesExhaust apparatusCombustion chamberSolvent

The invention discloses a regenerant and a processing method of a three-way catalytic converter of a gasoline automobile. The regenerant comprises the following raw materials in mass percent: 0.006-0.03% of chlorine-containing solvent, 0.01-0.04% of hydrogen peroxide and 99.96-99.954% of methanol. The chlorine-containing solvent and the hydrogen peroxide in the raw materials are added into the methanol to be mixed to obtain the regenerant of the three-way catalytic converter of the gasoline automobile. The regenerant can be input into a burning chamber of an automobile engine for fully burning, then a high-temperature oxidation environment containing chlorine ions can be established in an exhaust system, the high-temperature oxidation environment can be used for removing deposited carbon and sulfur-phosphorus chemical complexes covering on the three-way catalyst in the three-way catalytic converter, and simultaneously, chlorine is replenished for the three-way catalyst which is deactivated caused by chlorine loss and grain accumulation to enable the grown grains accumulated on the surface thereof to be dispersed again, thereby realizing the regeneration of the three-way catalyst in the three-way catalytic converter.

Owner:倪初宁

Multifunctional gas water heater

InactiveCN105485918ASuppress generationAvoid cloggingFluid heatersWater/sewage treatment by ion-exchangeActivated carbonWater quality

The invention discloses a multifunctional gas water heater. The gas water heater comprises a water heater body, a heat exchanger mounted on the water heater body as well as a water inlet pipe and a water outlet pipe which are connected with the heat exchanger. The gas water heater is characterized in that a three-way valve is connected onto the water inlet pipe and divides the water inlet pipe into two branches, a water pump is arranged on one branch of the water inlet pipe, a water purifying and softening device is arranged on the other branch of the water inlet pipe, and ion exchange resin and activated carbon are arranged in the water purifying and softening device. Compared with the prior art, the gas water heater has the advantages that the water purifying and softening device is arranged, water scale production is effectively inhibited, and pipe blockage, especially blockage of a shower head, is avoided; meanwhile, the ion exchange resin and the activated carbon are arranged in the water purifying and softening device, hard water becomes soft water after passing through the ion exchange resin, the soft water contains little calcium magnesium salt and is smooth, and the bathing effect is better; the activated carbon purifies the water effectively, removes impurities and dirt, inhibits bacterium breeding and creates a safe, healthy and comfortable bathing environment.

Owner:GUANGDONG MACRO GAS APPLIANCE

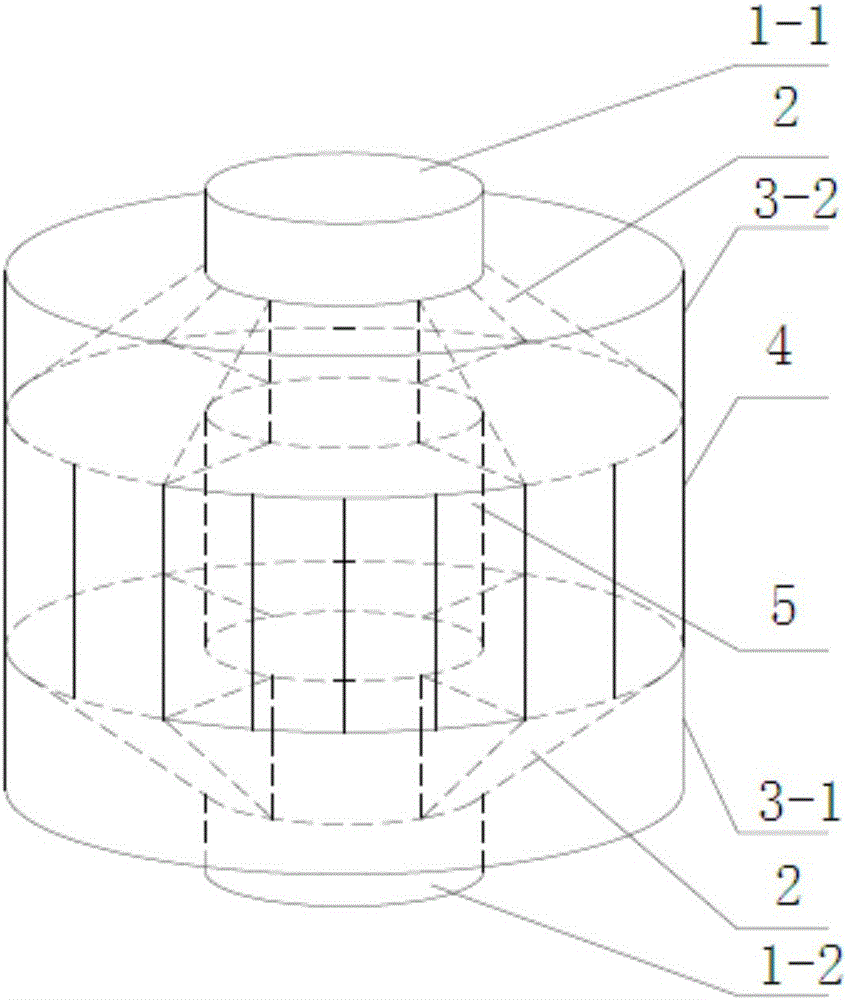

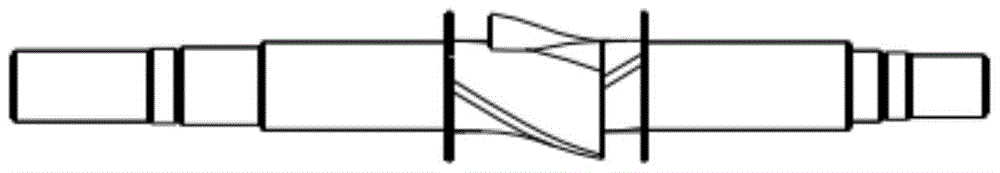

Wind cover type partition denitrification reactor

ActiveCN106731823AReduce usageAvoid clogging downstream equipmentGas treatmentDispersed particle separationInlet channelEngineering

The invention discloses a wind cover type partition rotary denitrification reactor, comprising a reactor body; the reactor body has a ring-shaped structure, and a ring-shaped area of the ring-shaped structure is divided into a plurality of fan-shaped reaction zones along the circumferential direction of the reactor body; each fan-shaped reaction zone is internally filled with a catalyst used for a reaction of smoke and reducing gas; an upper wind cover and a lower wind cover are respectively arranged at the upper part and the lower part of the reactor body; the center of the upper wind cover is connected with the center of the lower wind cover by a rotating shaft passing through the center of the reactor body; the center of the upper wind cover is connected with a reducing gas inlet channel, and the center of the lower wind cover is connected with a reducing gas outlet channel; the reducing gas inlet channel, the reducing gas outlet channel, the upper wind cover and the lower wind cover are driven to rotate along the central axis of the reactor body by the rotating shaft; the upper wind cover and the lower wind cover block part of the reaction zones of the reactor body; the upper parts of the reaction zones, which are not blocked by the upper wind cover and the lower wind cover, are connected with a smoke inlet reaction channel, and the lower parts of the reaction zones, which are not blocked by the upper wind cover and the lower wind cover, are connected with a smoke outlet reaction channel.

Owner:SHANDONG UNIV

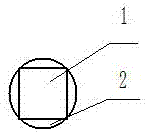

Tooth implant

ActiveCN107280789AEasy to fixLow elastic modulusDental implantsTissue regenerationBone tissueNeck parts

The invention provides an artificial tooth implant. The artificial tooth implant is composed of a body part, a neck part and an abutment, wherein the body part is a porous metal material; the porous metal material is a multi-grade-pore metal material; the multi-grade-pore metal material is composed of all grades of pore cavities which are graded according to the pore diameter size of the material and all grades of cavity walls for forming the pore cavities through surrounding; all grades of the pore cavities are mutually communicated respectively and all grades of the pore cavities are also mutually communicated respectively; the number of grades is two at least. Compared with the fusion time of a traditional artificial tooth implant with a body part which is a porous metal material with single pores, the fusion time between the artificial tooth implant and an adjacent bone tissue is remarkably shortened; the artificial tooth implant is firmly fixed on a gum so that the problems that an interface is not stable and loose are overcome.

Owner:CHONGQING RUNZE PHARM CO LTD

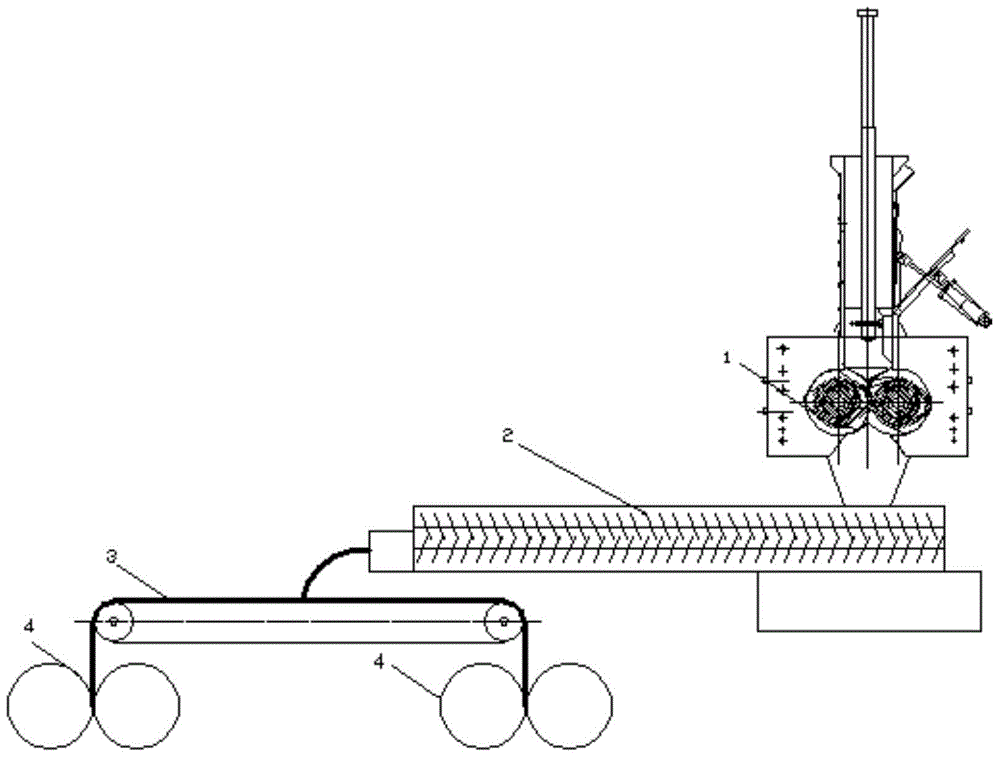

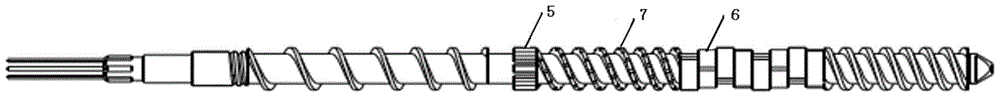

A low-temperature continuous regeneration device and process method for waste rubber

Owner:QINGDAO UNIV OF SCI & TECH

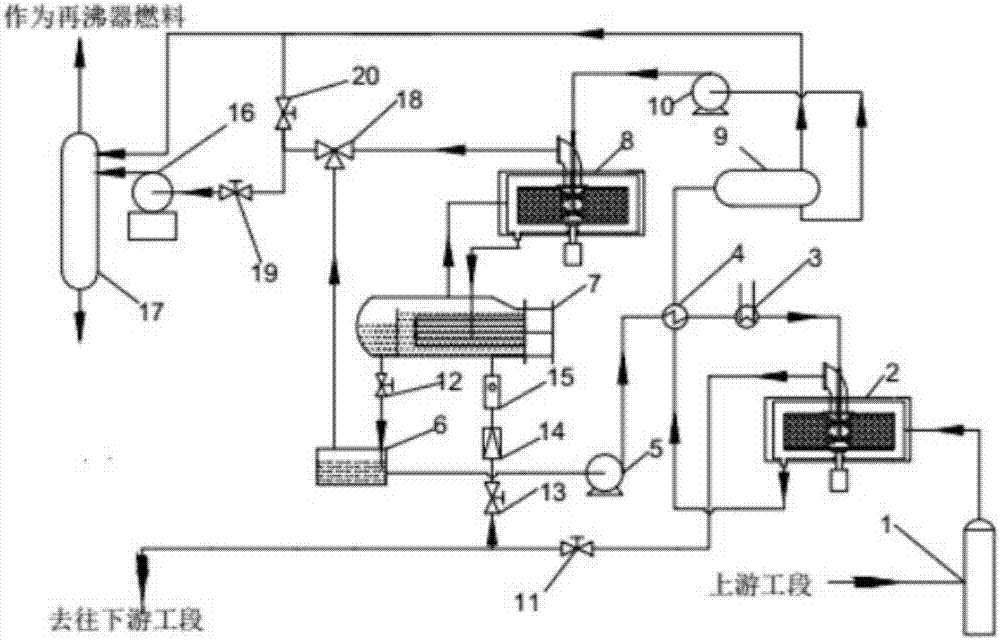

Deep dehydrating system device for natural gas and dehydrating method

InactiveCN107460015AHigh dehydration depthWide range of applicationsGas treatmentDispersed particle separationReboilerProcess engineering

The invention discloses a deep dehydrating system device for natural gas. The device is characterized by comprising a filter separator, a first super-gravity machine, a condenser, a poor / rich liquor heat exchanger, a pressurizing pump, a buffer tank, a reboiler, a second super-gravity machine, a flash tank, a conveying pump, a first stop valve, a second stop valve, a third stop valve, a fourth stop valve, a fifth stop valve, a reducing valve, a flowmeter, a vacuum pump, a gas-liquid separator and a three-way valve. The invention discloses a dehydrating method. According to the device, the purity of regenerated triethylene glycol poor liquor can be improved to 99.99wt%. By using the triethylene glycol poor liquor as an absorbent, the water dew-point at the natural gas outlet after water absorption in an absorption system is reduced to be below 35 DEG C below zero, preferably 45 DEG C below zero. The problem that the dehydrating depth of natural gas in the absorption system is low as triethylene glycol is not high in purity is solved, and the dehydrating treatment demand on low water dew point natural gas is met.

Owner:BEIJING UNIV OF CHEM TECH

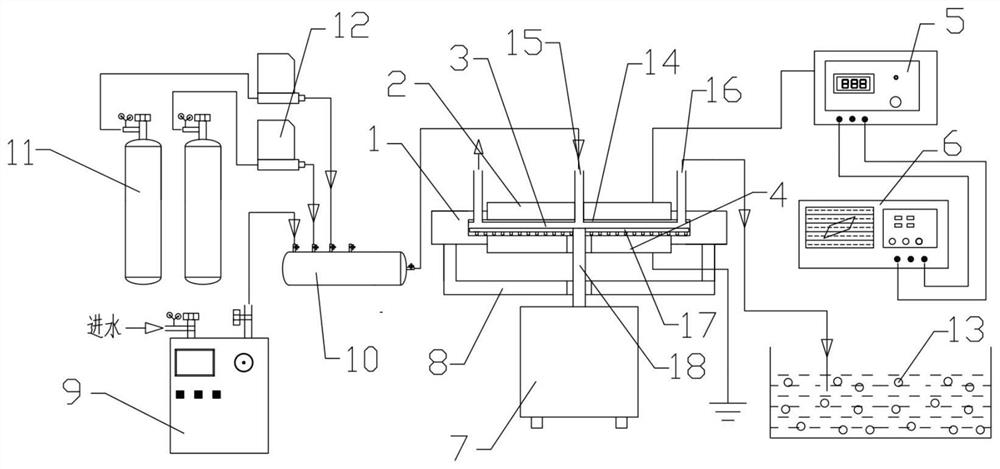

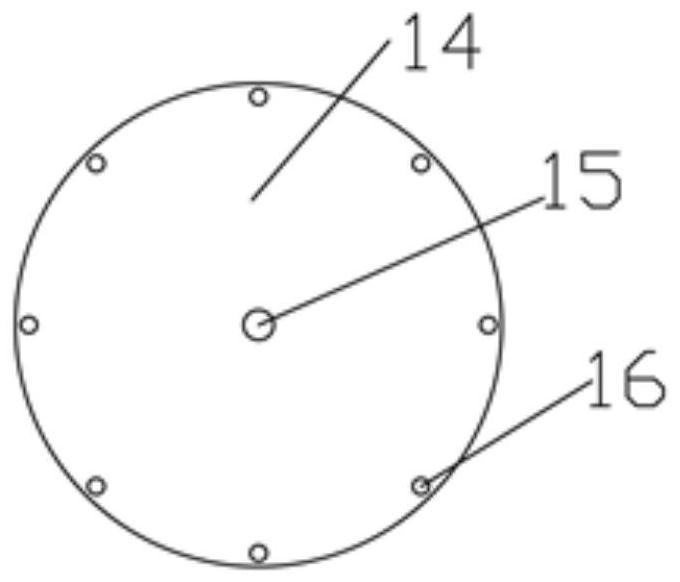

Low-temperature plasma regeneration system and method for inactivated activated carbon

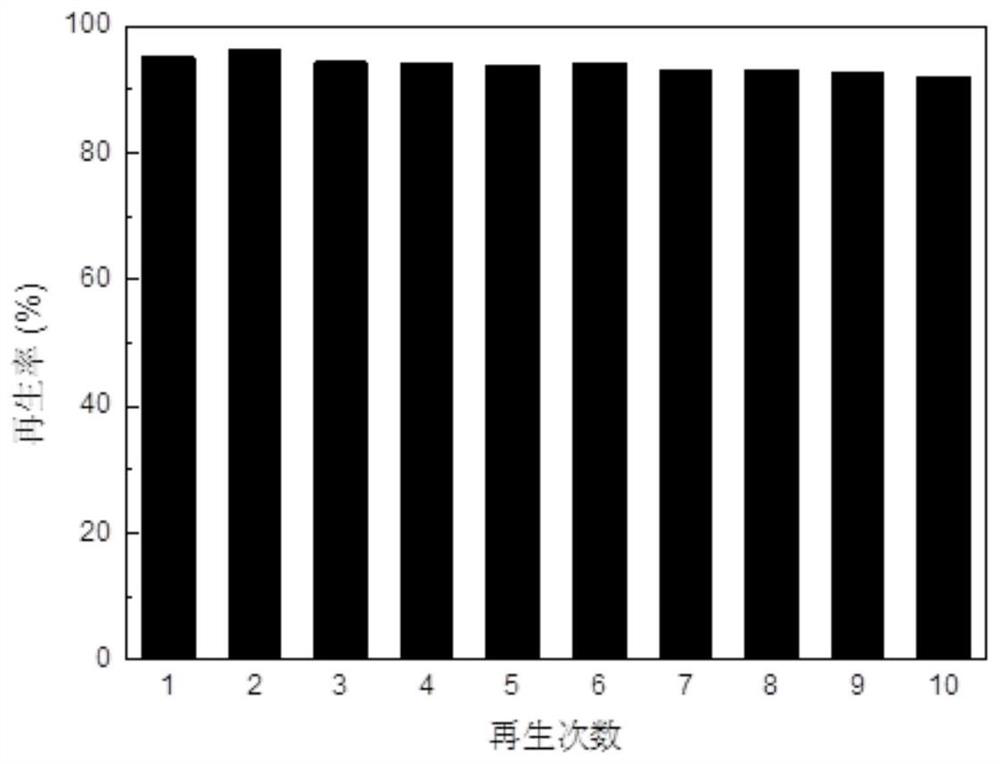

ActiveCN111790361AFully regeneratedIncrease profitGas treatmentOther chemical processesActivated carbonWater vapor

The invention discloses a low-temperature plasma regeneration system and method for inactivated activated carbon. The system comprises a gas supply system for providing gas and water vapor, a plasma reaction device and a tail gas treatment device, wherein the plasma reaction device comprises an upper electrode, a grounded lower electrode, a regeneration reactor arranged between the electrodes anda high-voltage alternating-current power supply connected with the upper electrode; a kick-out device is arranged in the regeneration reactor, an air inlet is formed in the center of the top of the reactor, and air outlets are formed in the periphery of the reactor. The device is simple and compact in structure and convenient to operate, reaction and premixing are integrated, and a large amount oflabor cost is saved; the energy consumption required by regeneration is low, pollutants are not generated, and more energy is saved and the environment is protected; the method is stronger in oxidation effect, higher in regeneration efficiency and better in effect; the total area of plasma direct irradiation is larger in a limited space, the energy utilization rate is increased, and activated carbon is fully regenerated.

Owner:SOUTHEAST UNIV

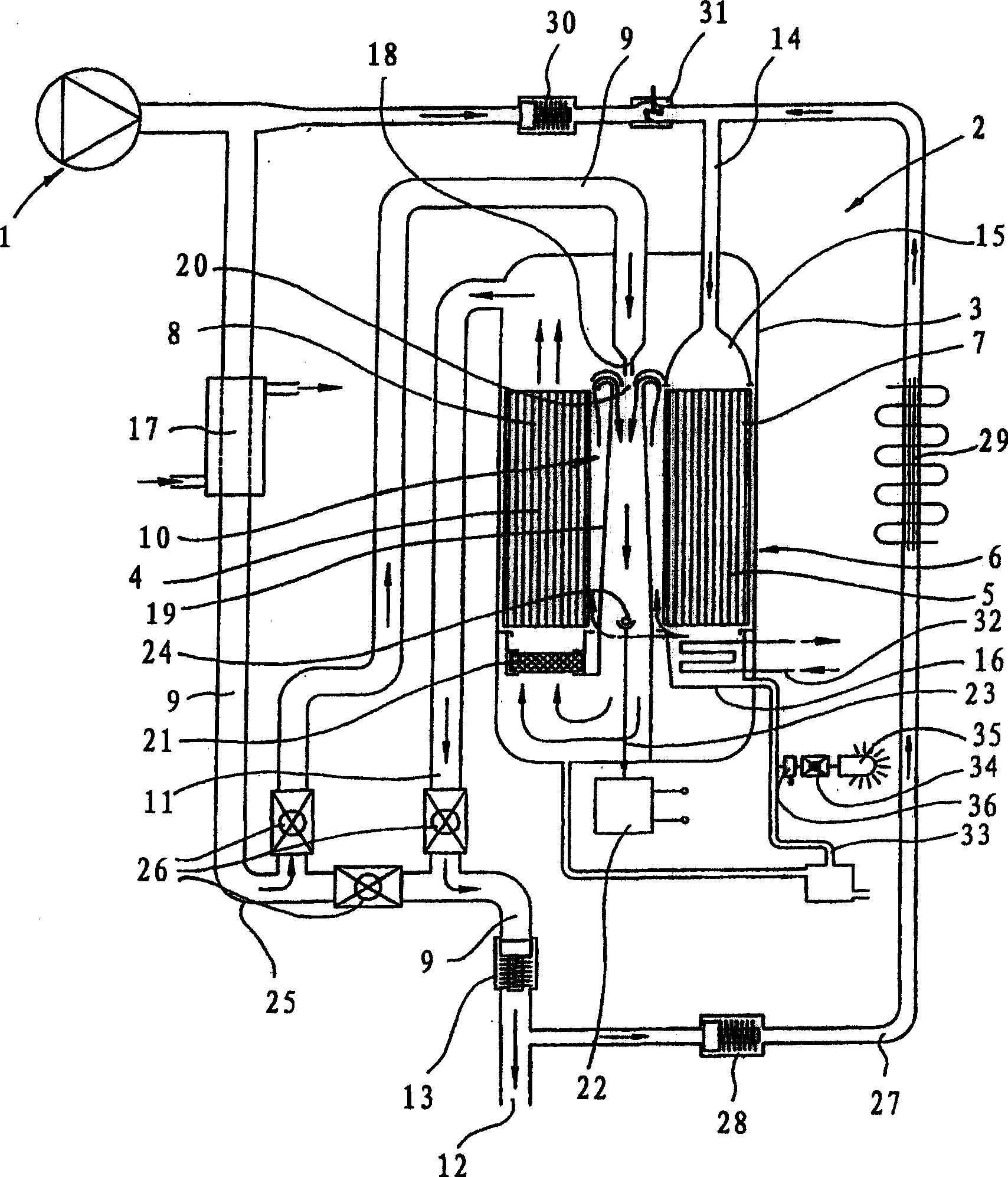

Dual-mode solution humidifying fresh air conditioning unit and air humidity regulation and control method

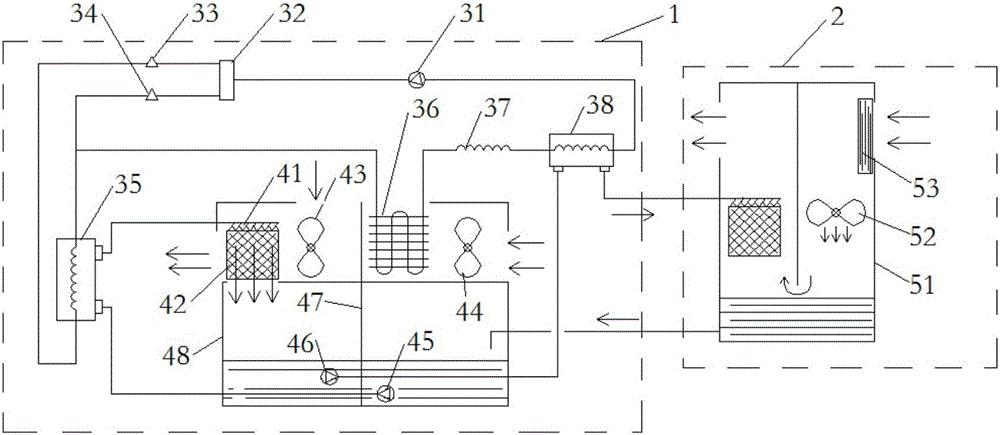

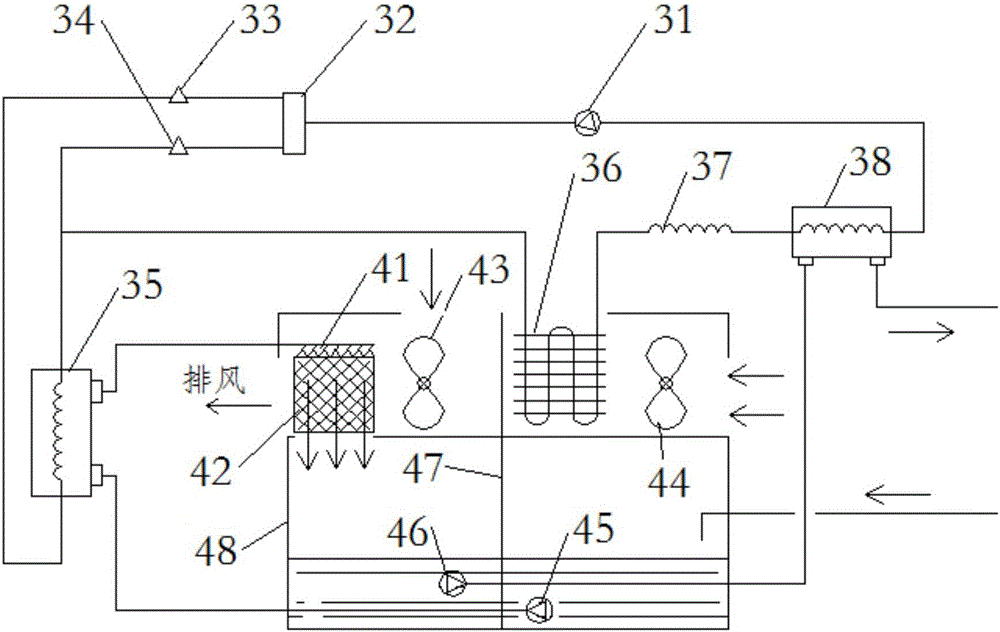

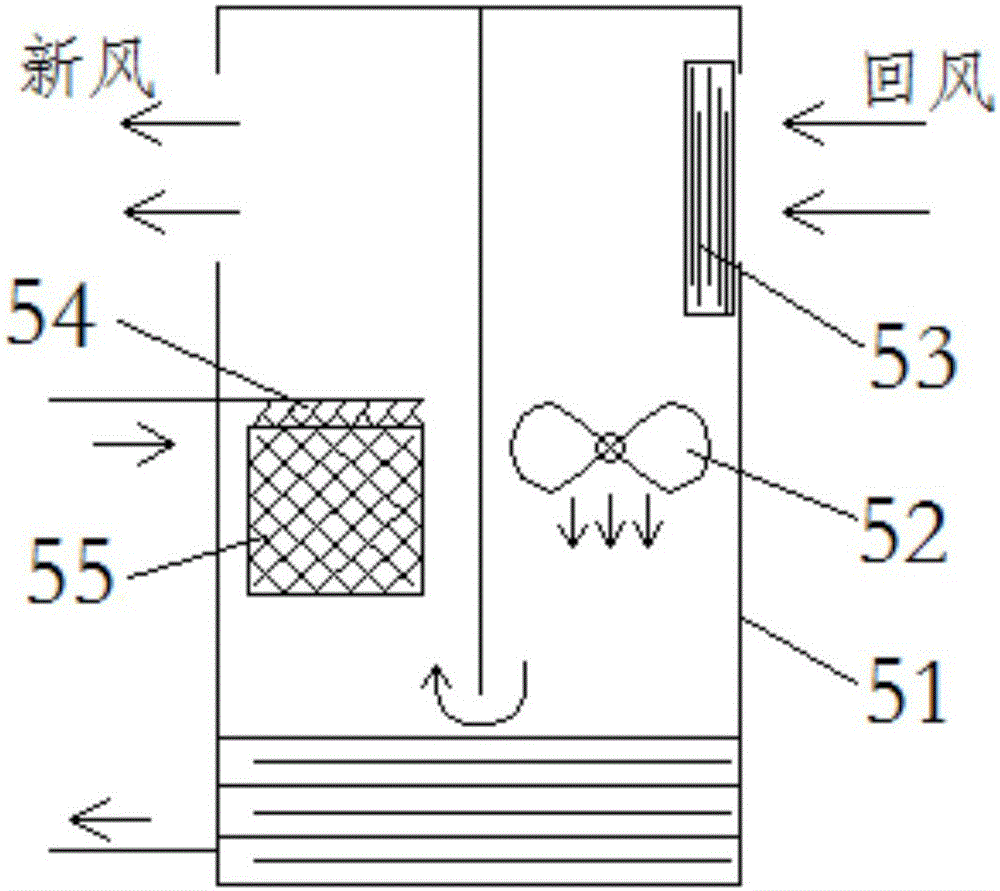

ActiveCN106369722AAvoid evaporative dryingImprove water absorptionMechanical apparatusSpace heating and ventilation safety systemsDual modeFresh air

The invention discloses a dual-mode solution humidifying fresh air conditioning unit and an air humidity regulation and control method, and belongs to the field of air-conditioner dehumidification. The dual-mode solution humidifying fresh air conditioning unit comprises a heat exchange unit, a solution regeneration unit and a fresh air humidifying unit. The heat exchange unit comprises a first heat exchange loop which is composed of a compressor, a first heat exchanger, a condenser and a second heat exchanger. The solution regeneration module further comprises a second heat exchange loop which is composed of the compressor, the condenser and the second heat exchanger. The first heat exchange loop and the second heat exchange loop can be switched through an electromagnetic valve. A solution in the solution regeneration unit flows through the first heat exchanger and then performs solution regeneration through a first spraying device, and the regenerated solution is supplied to the fresh air humidifying unit through the second heat exchanger. The air conditioning unit is simple in structure and can work in different modes according to the air humidity, so that the purposes of cooling and air humidity adjustment are achieved, and the overall utilization rate of an air-conditioner is increased.

Owner:马鞍山汉德绿色建筑环境科技有限公司

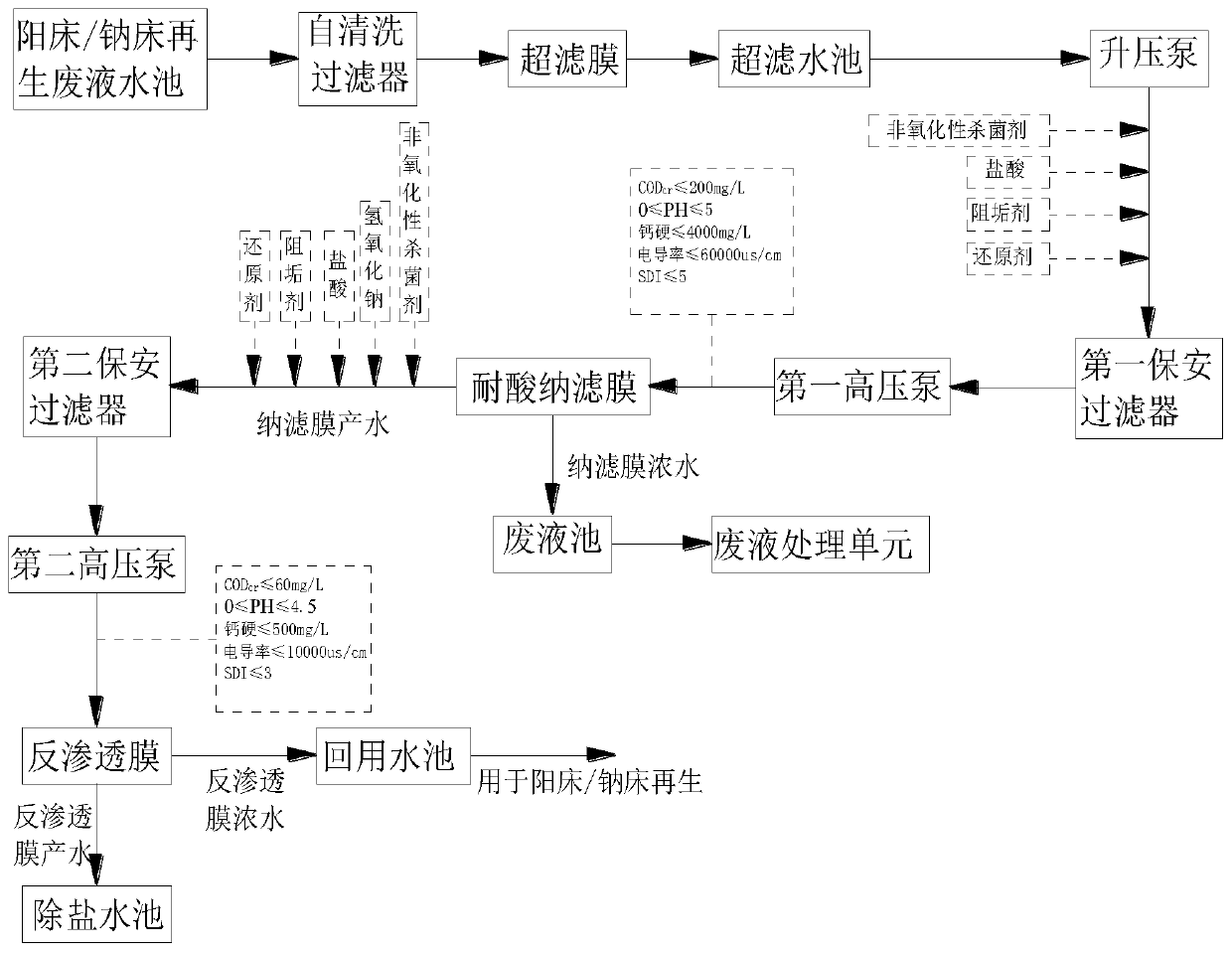

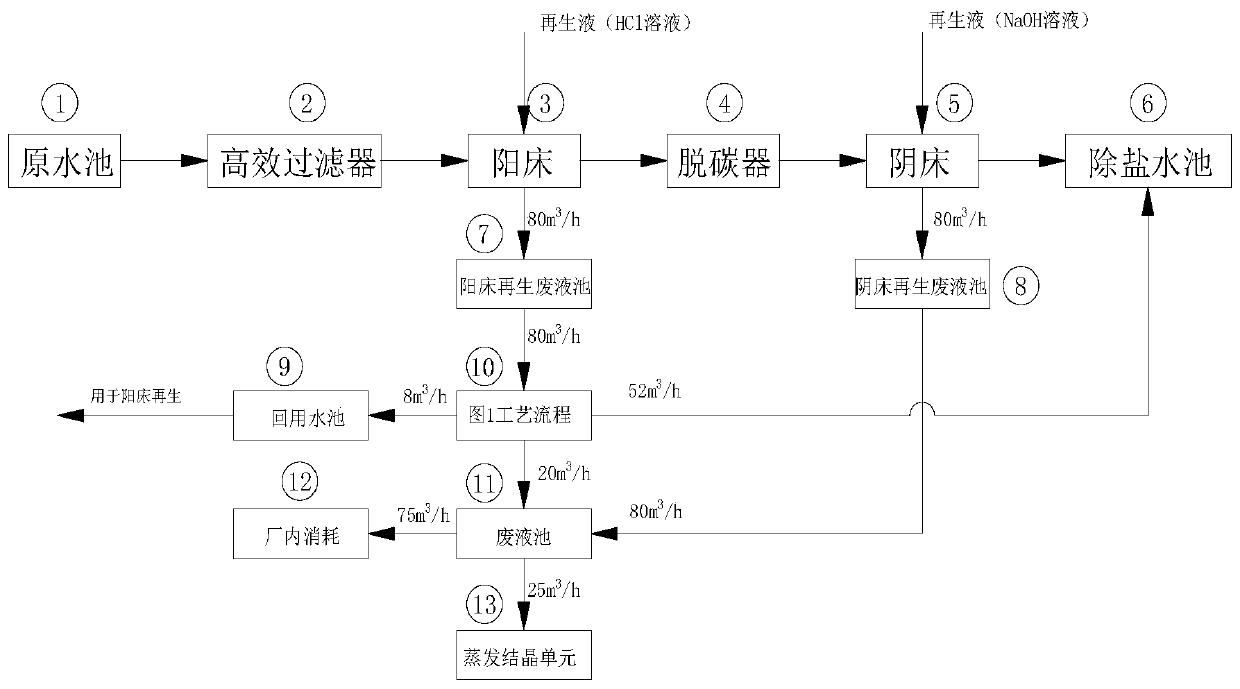

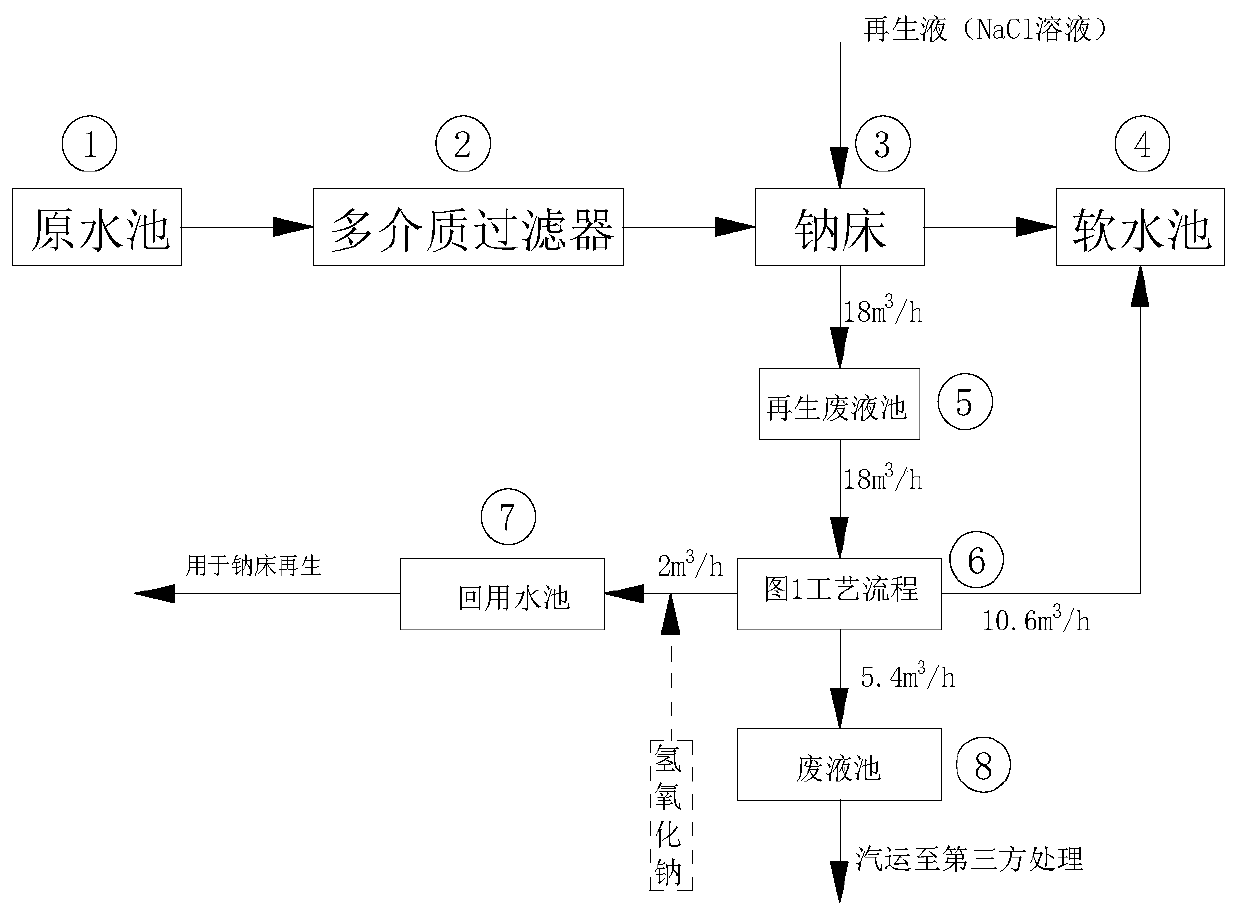

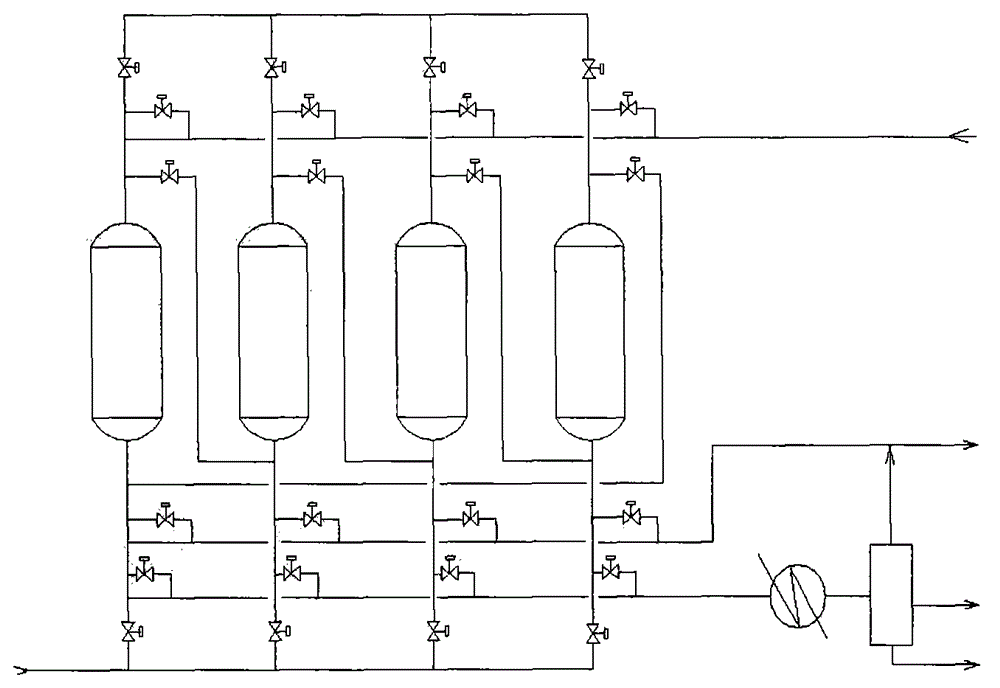

Recycling process for regeneration waste liquid

InactiveCN110316873ALow costFully regeneratedScale removal and water softeningTreatment involving filtrationLiquid wasteUltrafiltration

The invention relates to a recycling process for regeneration waste liquid. The waste liquid generated by a cation bed or a sodium bed is stored in a regeneration waste liquid pool and conveyed to a self-cleaning filter through a pump and then directly enters an ultrafiltration membrane, produced water of the ultrafiltration membrane enters an ultrafiltration pool, sequentially passes through a booster pump, a first security filter and a first high-pressure pump and then enters an acid-resistant nanofiltration membrane, the acid-resistant nanofiltration membrane separates monovalent and divalent ions in the regeneration waste liquid, divalent and multivalent ions enter a waste liquid pool along with concentrated brine of the acid-resistant nanofiltration membrane and then enter a wastewater treatment unit, monovalent cations directly enter a second security filter along with produced water of the acid-resistant nanofiltration membrane, the produced water is pressurized by a second high-pressure pump and then enters a reverse osmosis membrane for concentration treatment, produced water of the reverse osmosis membrane enters a desalting pool and then enters a recycling pool through the concentrated water side of the reverse osmosis membrane, and water in the recycling pool is used for the regeneration of the cation bed or the sodium bed. By means of the recycling process, the amount of the waste liquid is reduced to a great degree, and a lot of cost is reduced for the the subsequent treatment of the concentrated brine.

Owner:TANGSHAN IRON & STEEL GROUP +1

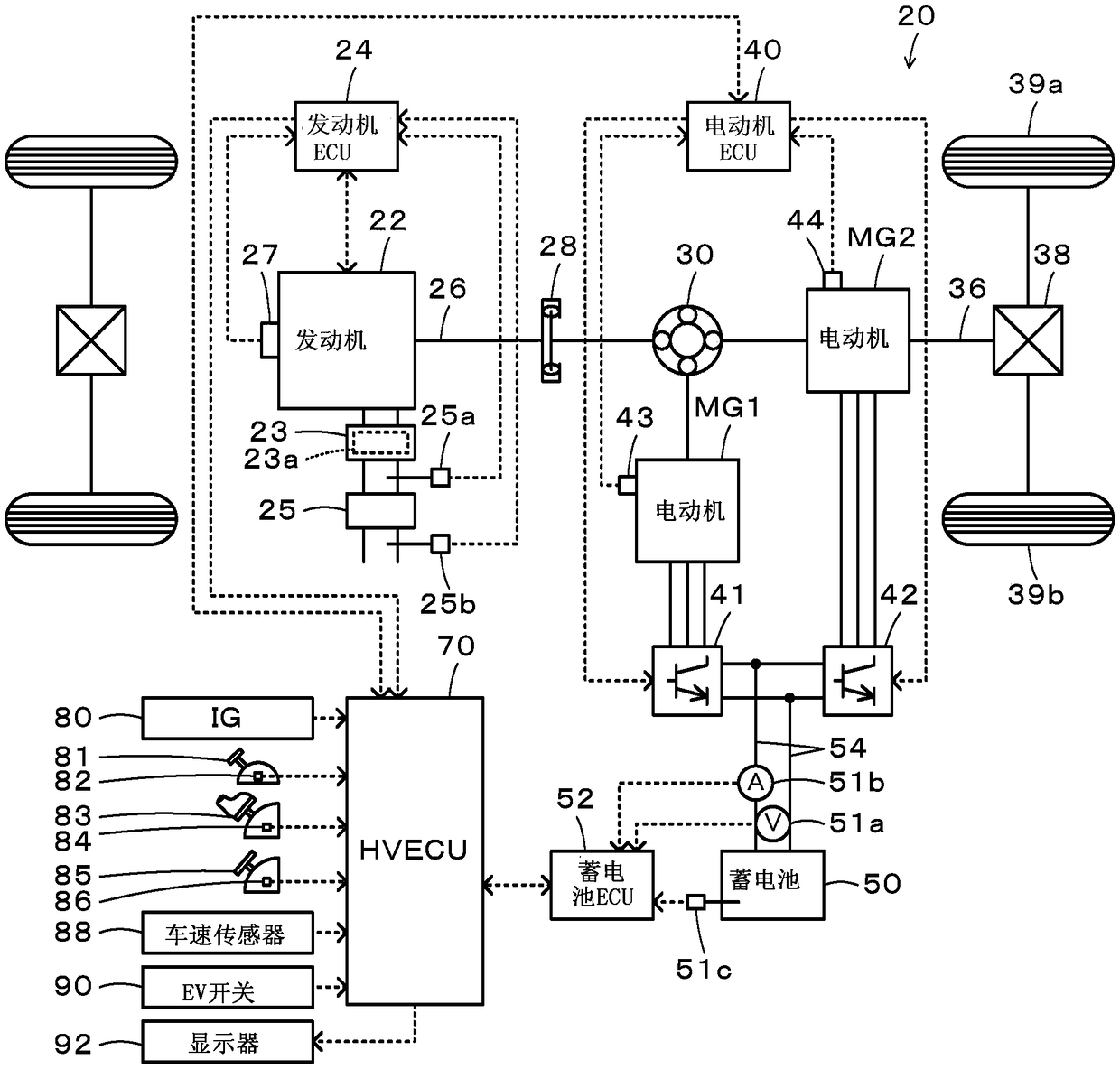

Hybrid vehicle

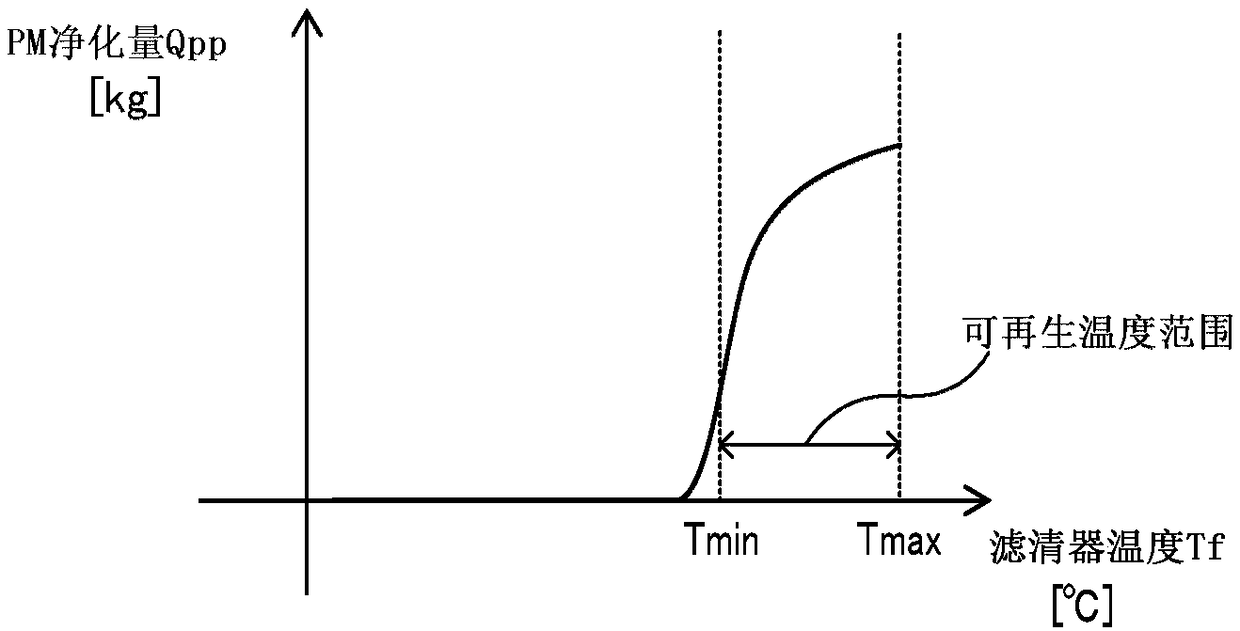

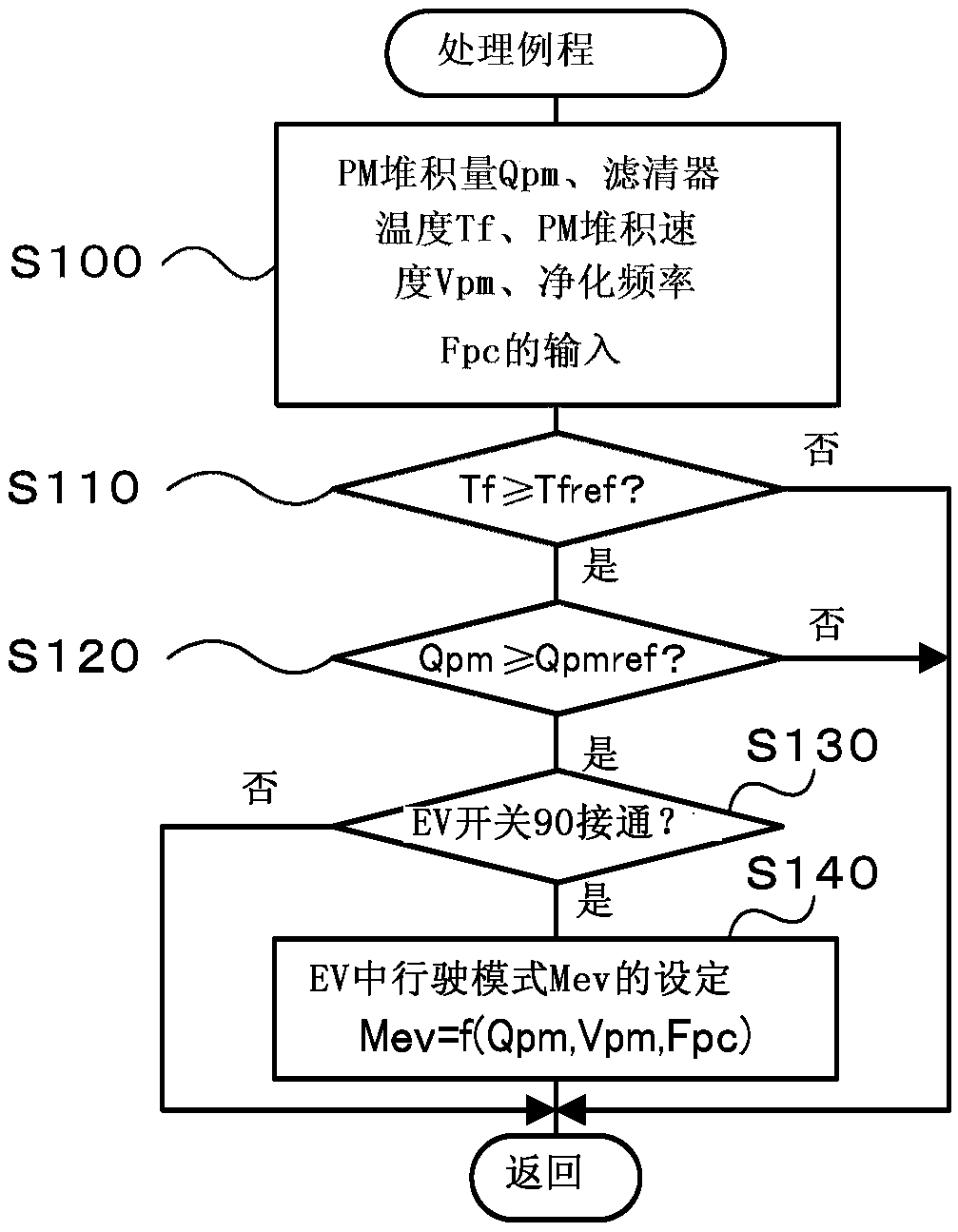

ActiveCN109263630AGuaranteed regenerationFully regeneratedHybrid vehiclesElectrical controlMode selectionDriving mode

There is provided a hybrid vehicle comprising a mode selection device configured to select one drive mode among a plurality of drive modes according to a user's operation. The plurality of drive modesinclude a first drive mode in which the hybrid vehicle is driven with power from a motor with stopping rotation of an engine and a second drive mode in which the hybrid vehicle is driven with rotation of the engine. On satisfaction of filter regeneration conditions that an accumulated amount of particulate matter accumulated on a filter is equal to or greater than a predetermined accumulated amount and that a temperature of the filter is equal to or higher than a predetermined temperature, the hybrid vehicle is driven in the second drive mode even when the first drive mode is selected by themode selection device.

Owner:TOYOTA JIDOSHA KK

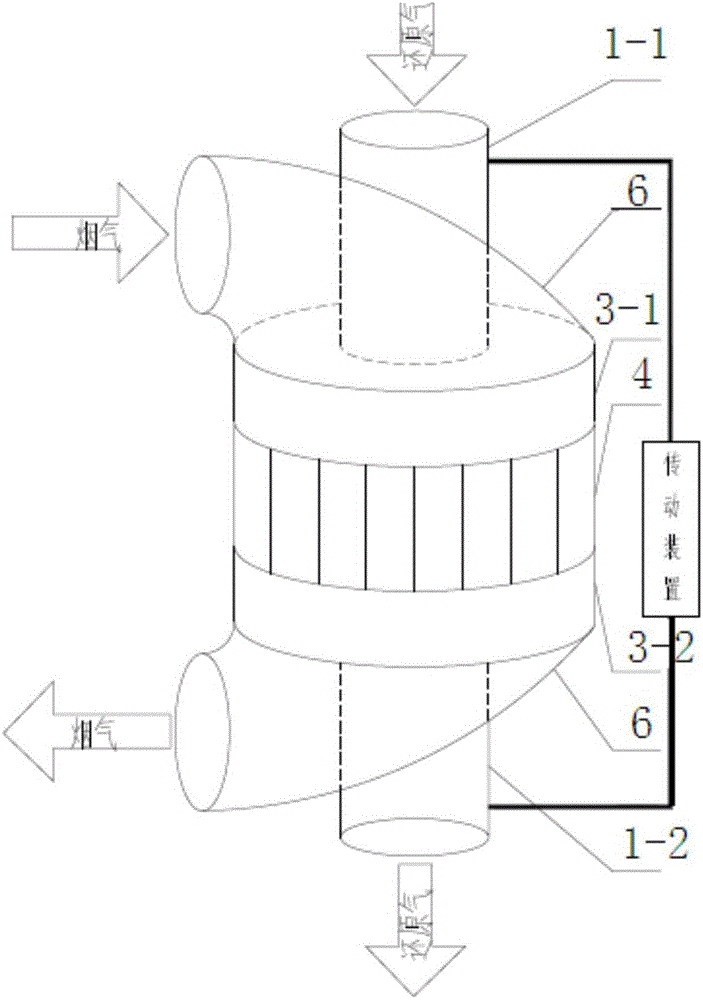

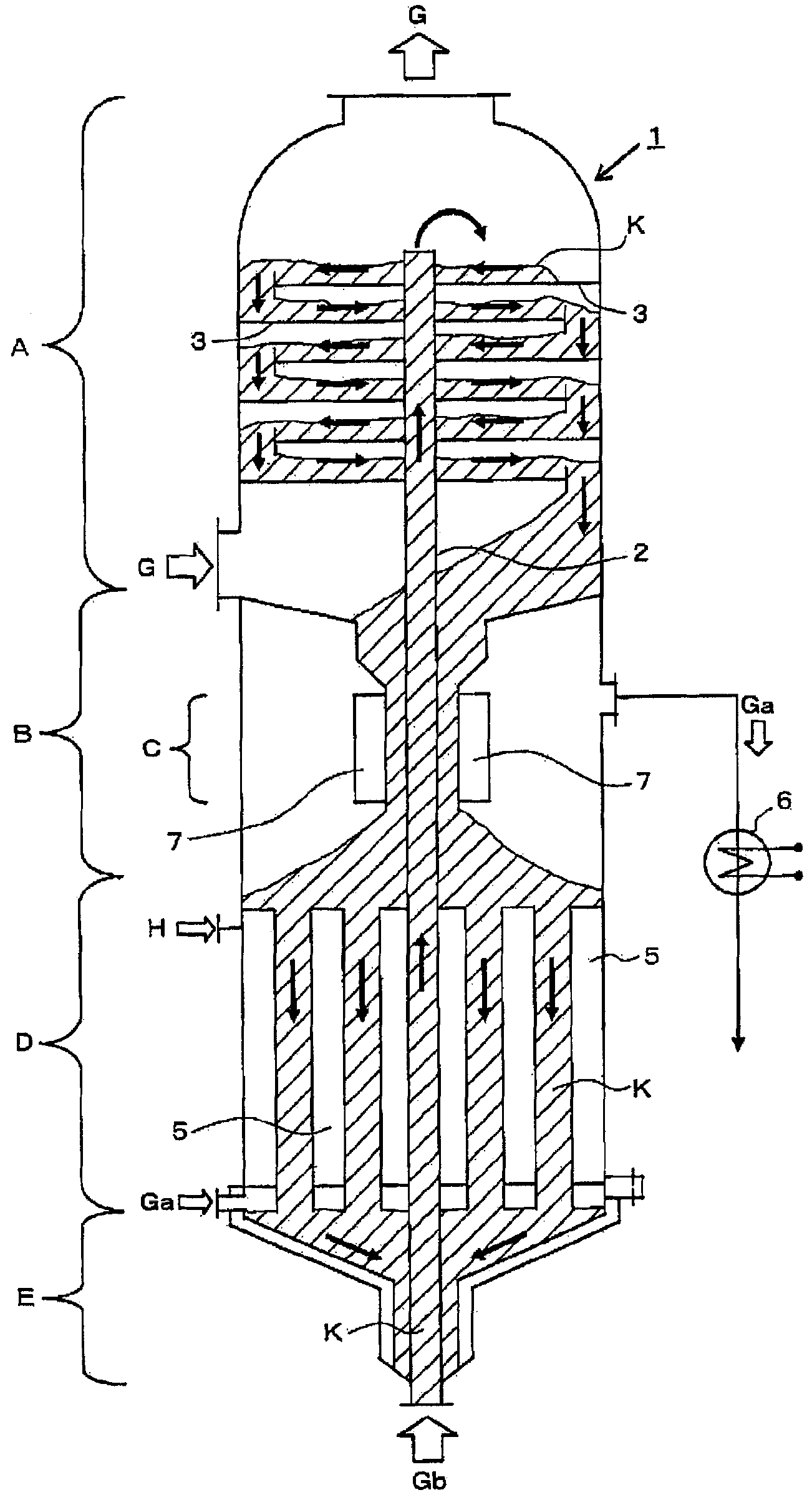

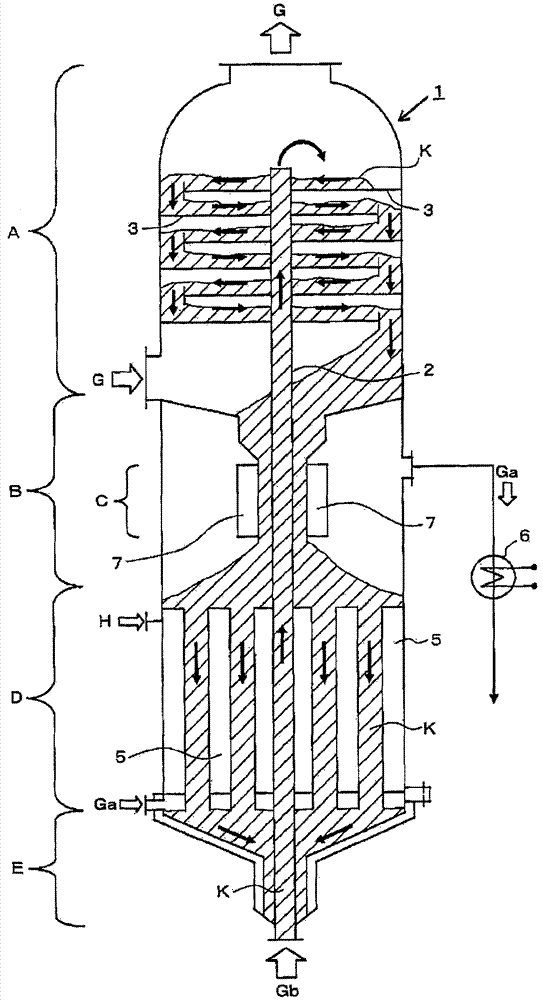

Device and method for purifying gas

ActiveCN102170956APrevent coagulationFully regeneratedGas treatmentDispersed particle separationTemperature controlPurification methods

A device and method for purifying a gas are provided in which a chemical substance is inhibited from condensing on the surface of an adsorbent falling gravitationally, whereby the flow of the adsorbent is stabilized and the adsorbent is satisfactorily regenerated. Also provided are the gas purifier and gas purification method in which a chemical substance, e.g., ethyl acetate, is inhibited from decomposing and the chemical substance having a high purity can be recovered. The gas purifier (1) has: an adsorption part (A) in which a gas (G) containing a chemical substance is brought into contact with an adsorbent (K) to adsorb the chemical substance onto the adsorbent (K); and a desorption part (D) in which a non-condensable gas (Ga) is brought into countercurrent contact with the adsorbent (K) which is descending via the adsorption part (A) while forming a moving layer, whereby the chemical substance is desorbed from the adsorbent (K). The gas purifier (1) further has an adsorbent-temperature control part (C) disposed between the adsorption part (A) and the desorption part (D) and for keeping the descending adsorbent (K) at a temperature between the dew point of the chemical-substance-containing non-condensable gas (Ga) which has passed through the desorption part (D) and [(the dew point) + 50 DEG C].

Owner:KUREHA ECOLOGY MANAGEMENT

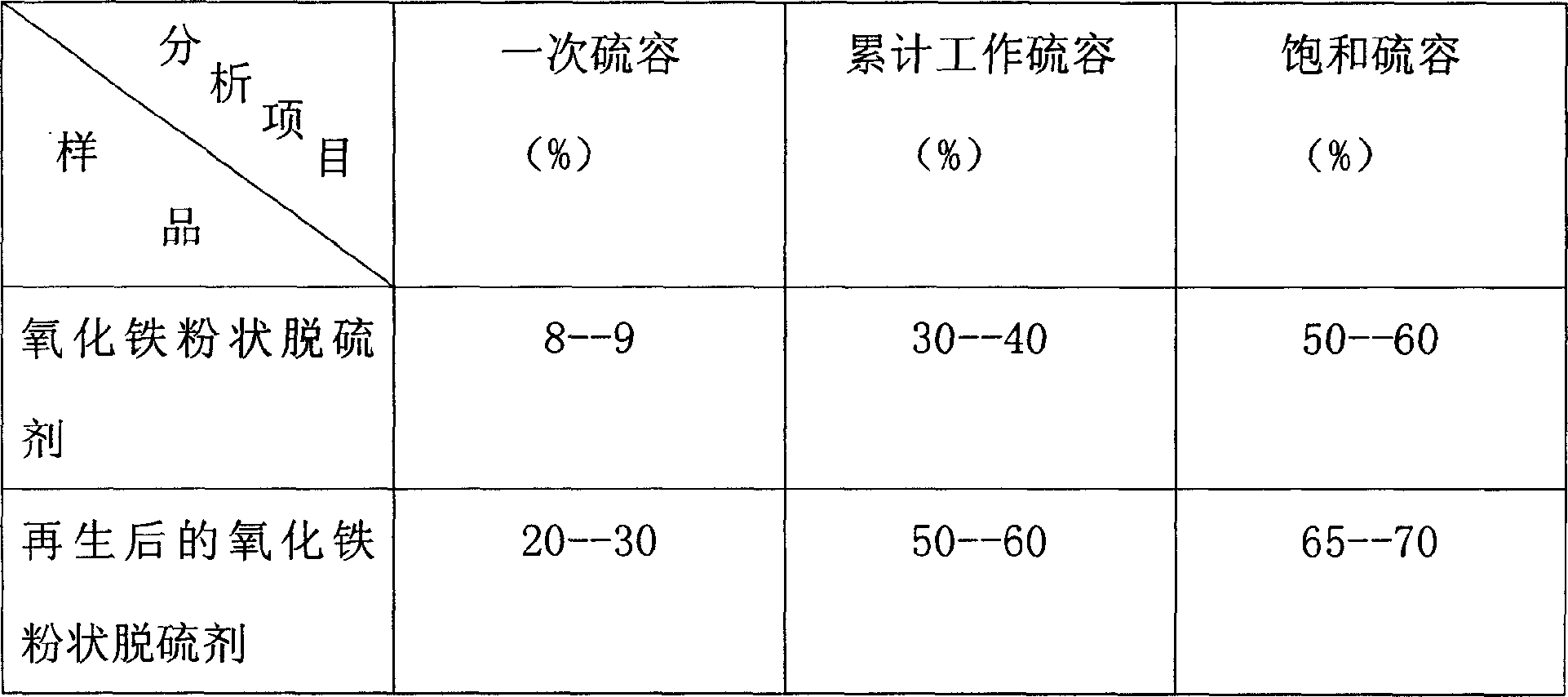

Double regeneration and utilization method for waste iron oxide desulfurizer powder

InactiveCN1593732AFully regeneratedExtend the life cycleDispersed particle separationSulfurPotassium hydroxide

The invention relates to a kind of quadratic regeneration method for waste oxidate desulfurization agent in polyiron form. It contains the steps as follows: (1) put waste oxidate polyiron desulfurization agent rejected into kneading machine and mix; (2) then put in basic salt and mix it; (3) again put in the strong alkali such as sodium hydroxide or potassium hydroxide, and then mix it; (4) then put r-FeOOH that is hydrated iron with artificially synthesis into kneading machine, then mix it, and then still standing by 72-120 hours; finally the regeneration of waste oxidate desulfurization agent in polyiron form can be acquired. Compared with the existing technology, the oxidate desulfurization agent in polyiron form that be regenerated according to the regeneration method of the invention can be made the full use. Because it adds r-FeOOH that is the hydrated iron with artificially synthesis, which can make the absorbability of sulfur increased greatly, make the primary sulfur capacity improved triple, and make the accumulated working sulfur capacity improved 18%. And moreover, it prolongs life cycle of oxidate polyiron desulfurization agent, declines changing frequency of it, and alleviates pressure that it gives to environmental protection.

Owner:于纵海

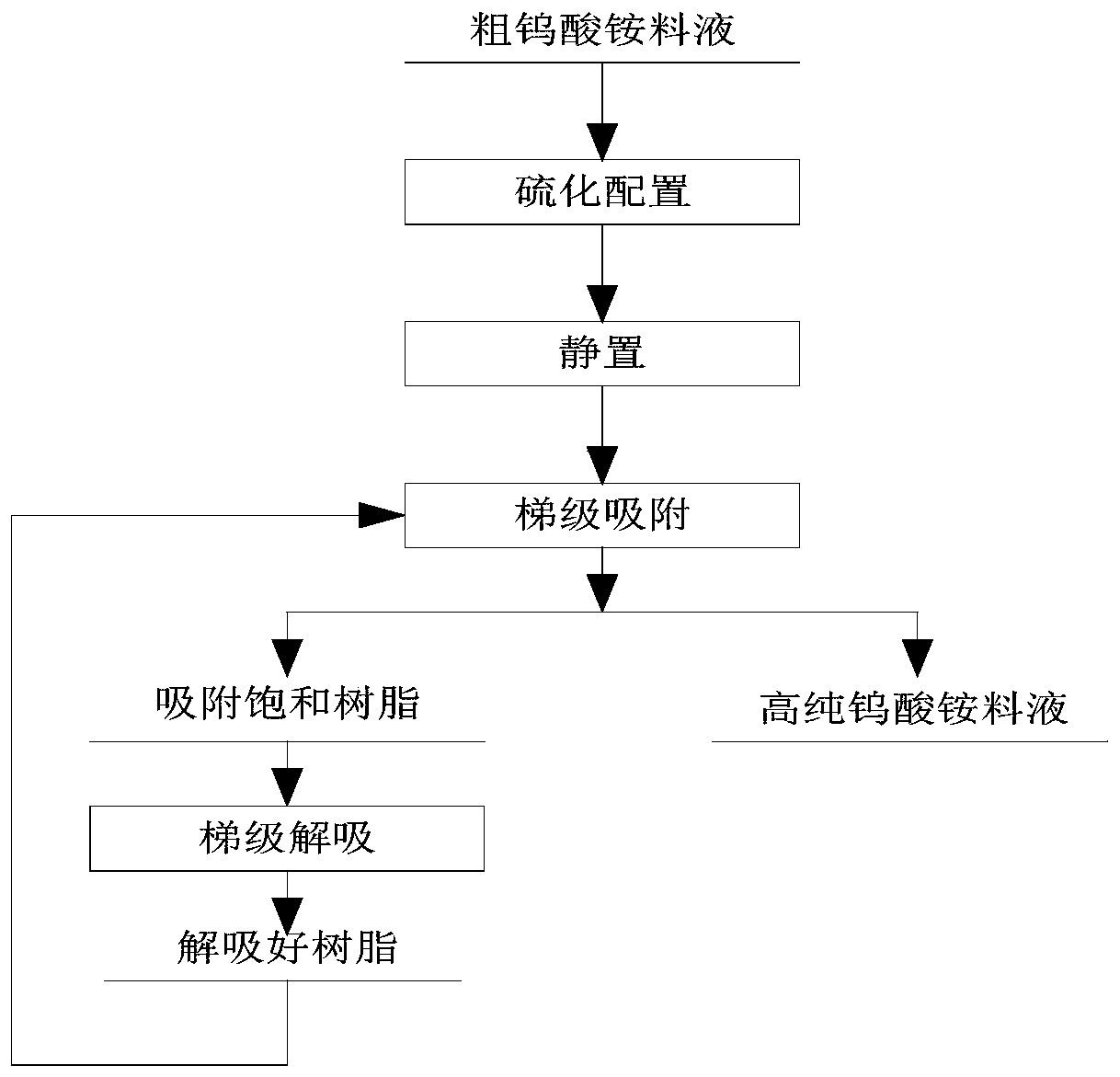

Molybdenum removal method of ammonium tungstate feed liquid

ActiveCN110104688AImprove adsorption capacityAvoid the disadvantage of poor absorption effectTungsten compounds preparationTungstateAdsorption effect

The invention provides a molybdenum removal method of ammonium tungstate feed liquid. The method comprises the steps of a sulfurizing step, wherein a sulfurizing agent is added in the ammonium tungstate feed liquid, and sulfurizing feed liquid is obtained; a stepped adsorption step, wherein the sulfurizing feed liquid is subjected to primary adsorption through WDA918 resin until achieving saturation, primary post-adsorption liquid is obtained and subjected to secondary adsorption through 201*7 resin until achieving saturation, and the molybdenum-removed ammonium tungstate feed liquid is obtained. Two kinds of resin are combined for use, the two kinds of the resin can achieve high adsorption capacity, and the good adsorption effect is achieved.

Owner:JIANGXI UNIV OF SCI & TECH

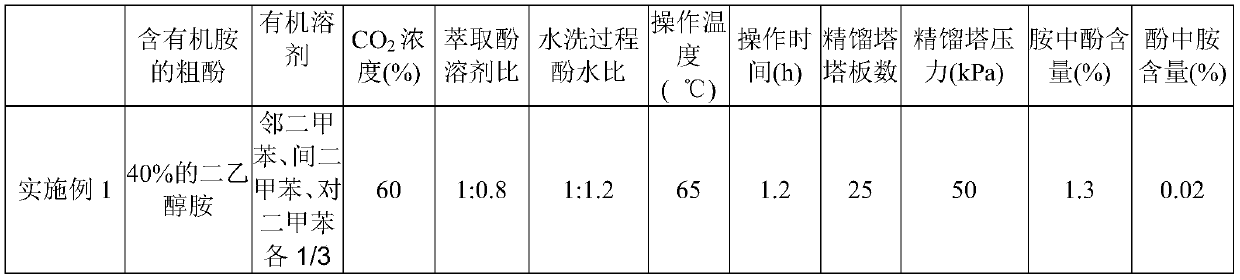

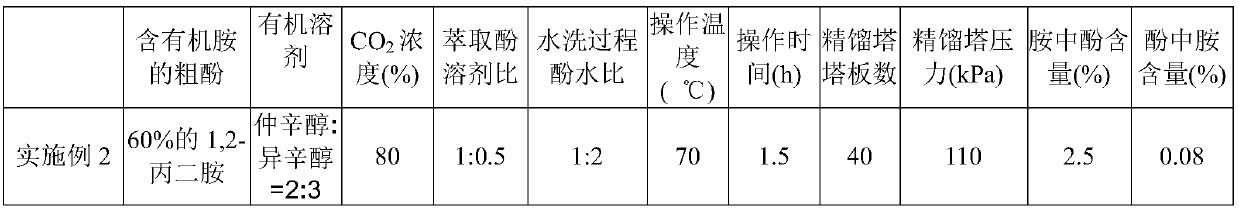

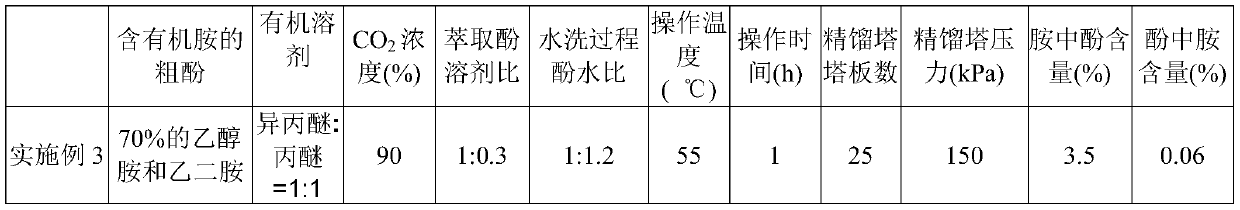

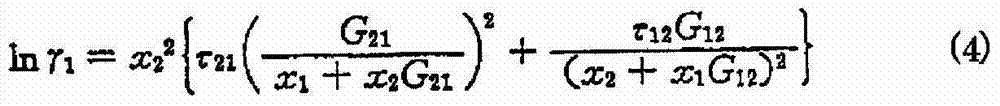

Method for separating mixture of crude phenol and organic amine

PendingCN111574330ASolve the need for repeated washingSolve excessive water consumptionOrganic compounds purification/separation/stabilisationAmino compound purification/separationOrganosolvAqueous solution

The invention discloses a method for separating a mixture of crude phenol and organic amine, which comprises the following steps: adding water and an organic solvent in the process of separating crudephenol containing organic amine by adopting an acidified water washing method, thereby obtaining a phenol phase containing the organic solvent and a water phase containing an organic amine acidifiedwater solution; rectifying the phenol phase containing the organic solvent to obtain crude phenol; and rectifying the aqueous phase containing the organic amine acidified aqueous solution to obtain the organic amine. According to the method, crude phenol and organic amine can be quickly and thoroughly separated, and the method has the advantages of simple separation process, continuous or intermittent separation, easiness in amplification, easiness in industrial implementation, low production cost and the like.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

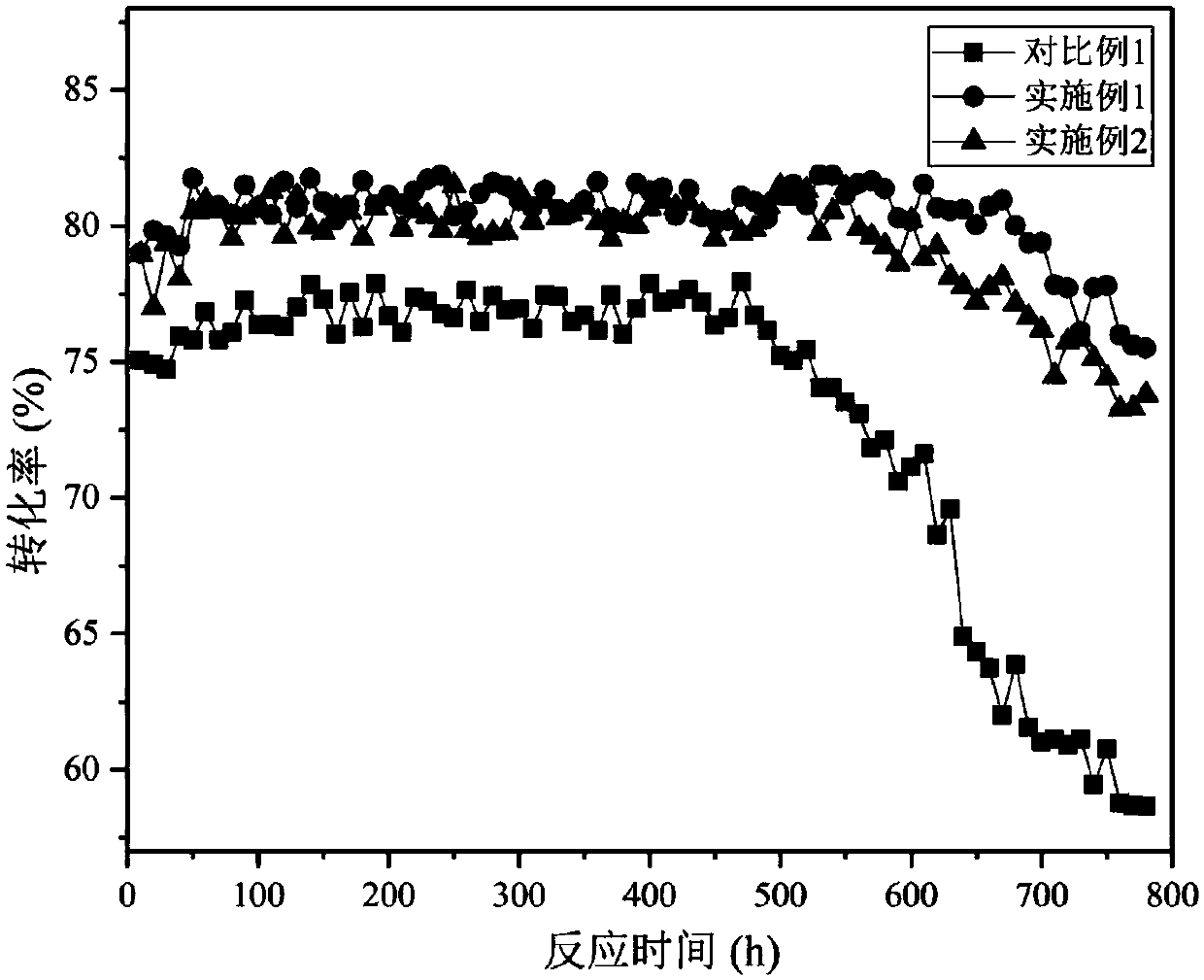

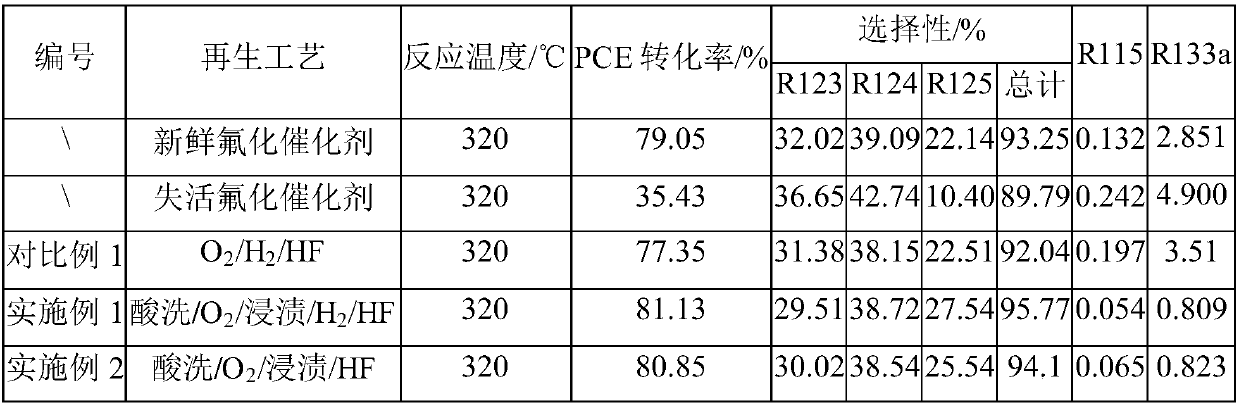

Method for regenerating fluorination catalyst

ActiveCN107899585AFully activatedEfficient removalPreparation by halogen replacementCatalyst regeneration/reactivationHydrogen fluorideHydrogen

The invention relates to a method for regenerating a fluorination catalyst. The method comprises the following steps: pickling an inactivated fluorination catalyst in an acid solution; calcining the pickled inactivated fluorination catalyst in an oxidizing gas; impregnating the calcined inactivated fluorination catalyst in an active supplementing solution; and regenerating the impregnated fluorination catalyst in a hydrogen fluoride-containing atmosphere, or regenerating the impregnated fluorination catalyst in a hydrogen-containing atmosphere and regenerating the impregnated fluorination catalyst in the hydrogen fluoride-containing atmosphere. The regeneration method has the following advantages: pickling can effectively remove metal impurities on the surface of the fluorination catalystand easily removes carbon deposited on the surface of the fluorination catalyst, so the fluorination catalyst is fully activated; and the calcined fluorination catalyst is impregnated in the active supplementing solution to make the fluorination catalyst fully obtain full new active sites in the regeneration process, so the catalytic activity of the regenerated fluorination catalyst is greatly improved. The regenerated fluorination catalyst has a good control effect on a byproduct R115 when applied to catalytic preparation of R125.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

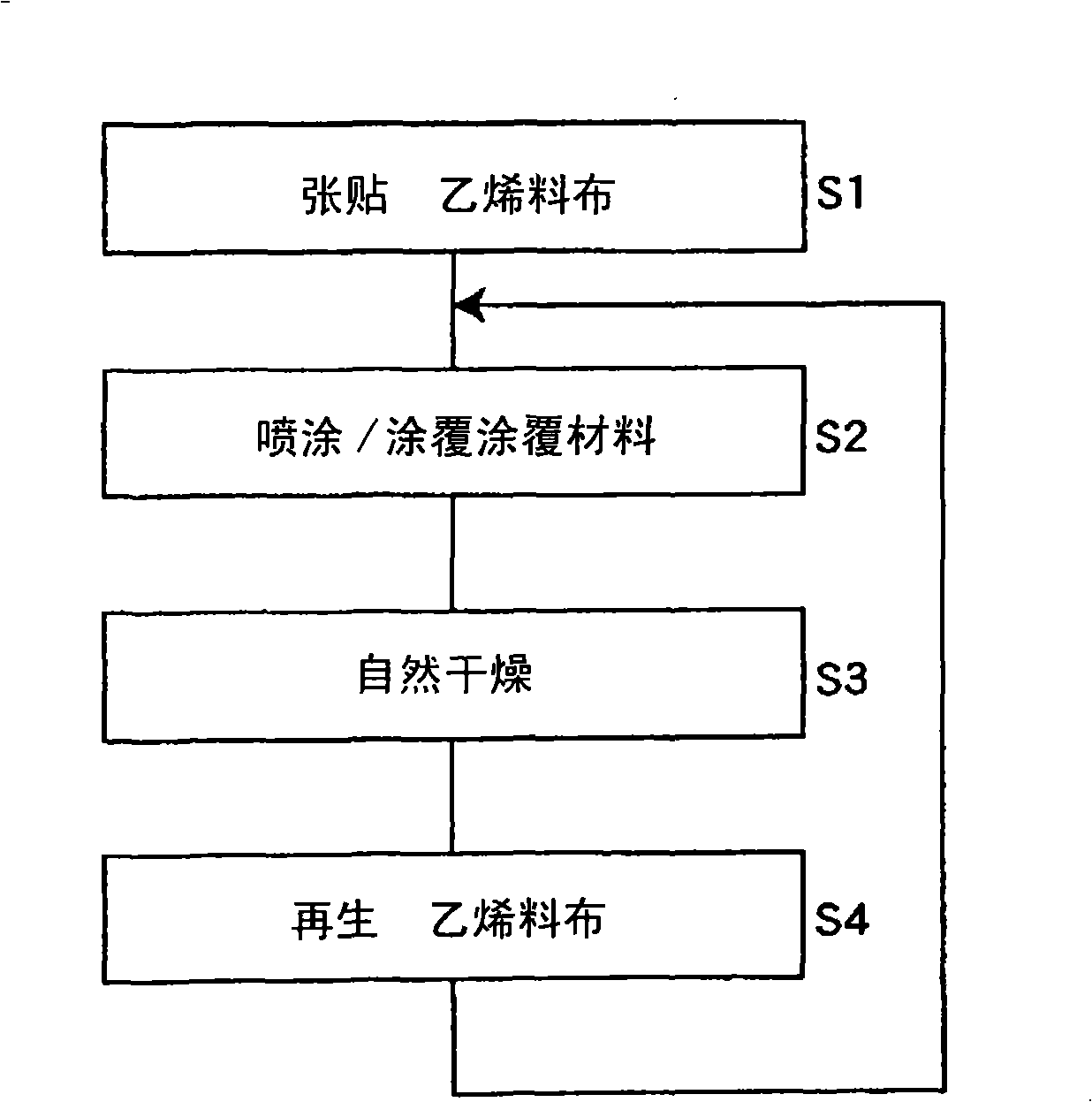

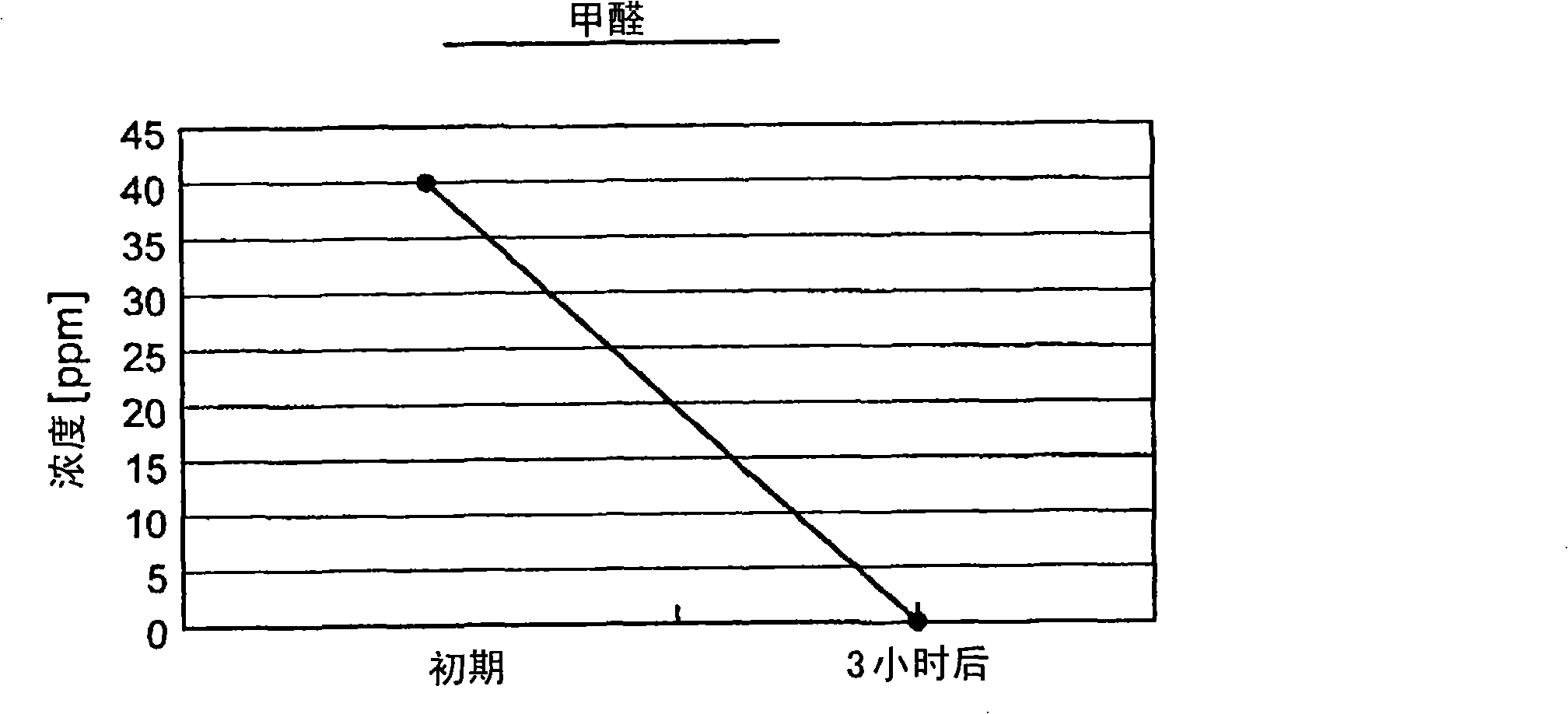

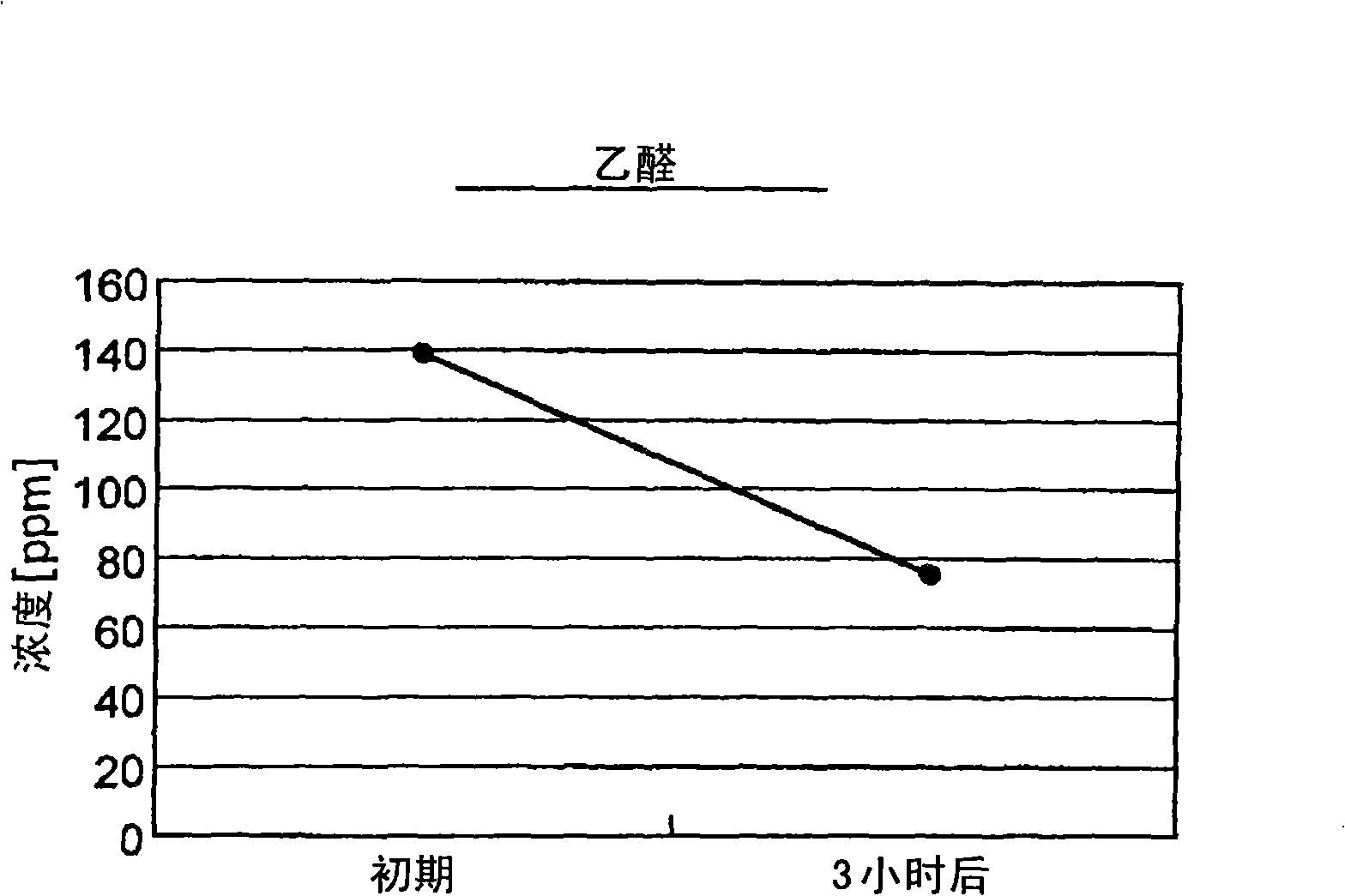

Material for indoor decoration, coating method and material thereof

InactiveCN101341304APromote regenerationFully regeneratedLiquid surface applicatorsCovering/liningsSlurry coatingCopper

After newly pasting of an interior finishing vinyl cloth onto the wall, floor or ceiling of a building, or after completion of washing / regeneration of the vinyl cloth, a liquid or slurry coating material containing titanium oxide, a sheet silicate mineral and silver ions and / or copper ions, is applied to the surface of the vinyl cloth by spray or coating. Thereafter, the coating material is naturally dried to thereby form a thin transparent coating layer. At the time of vinyl cloth regeneration, the coating layer is removed by water washing or water wiping to thereby attain complete removal of any various soils. Any one not limited to a skilled person can easily regenerate interior finishing materials, such as vinyl cloth, completely at low cost.

Owner:藤原 三洲男

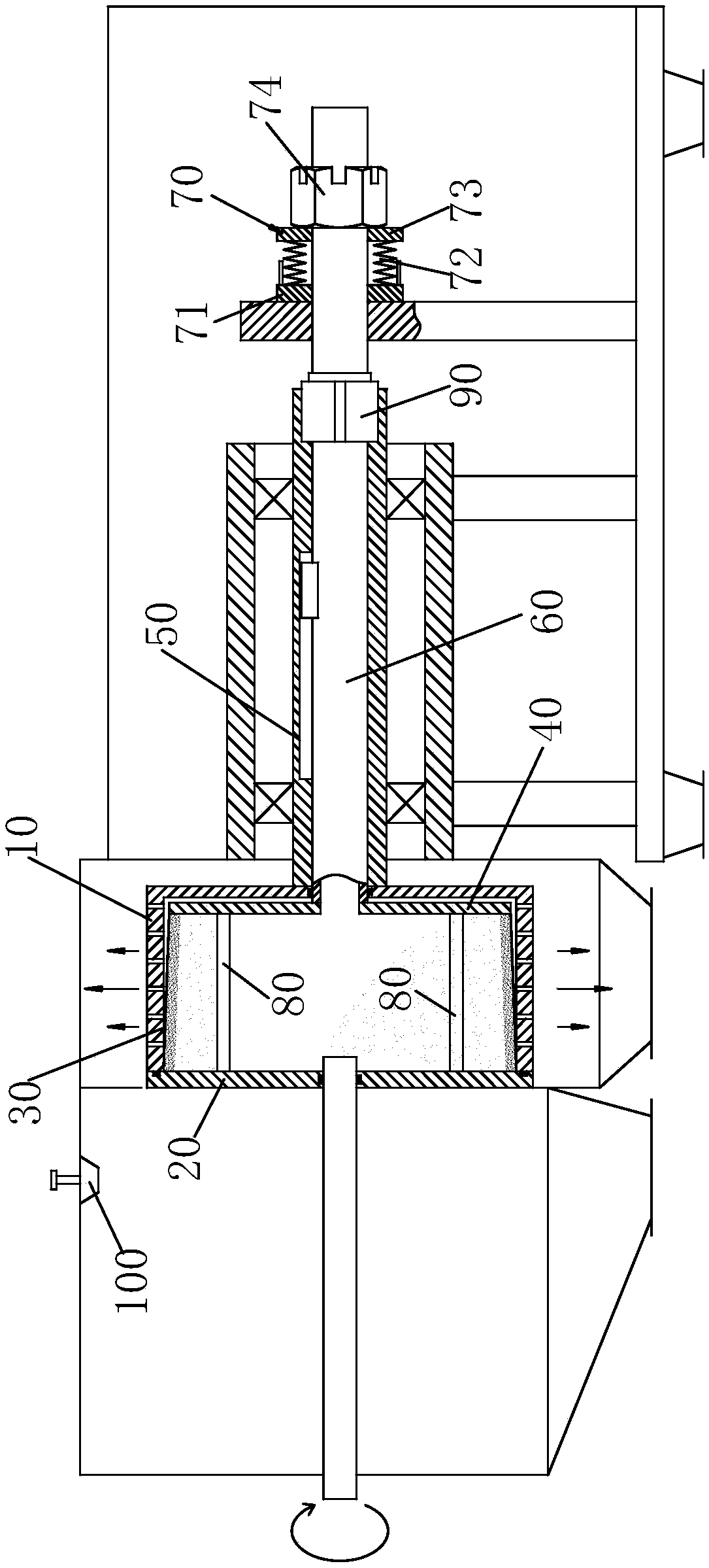

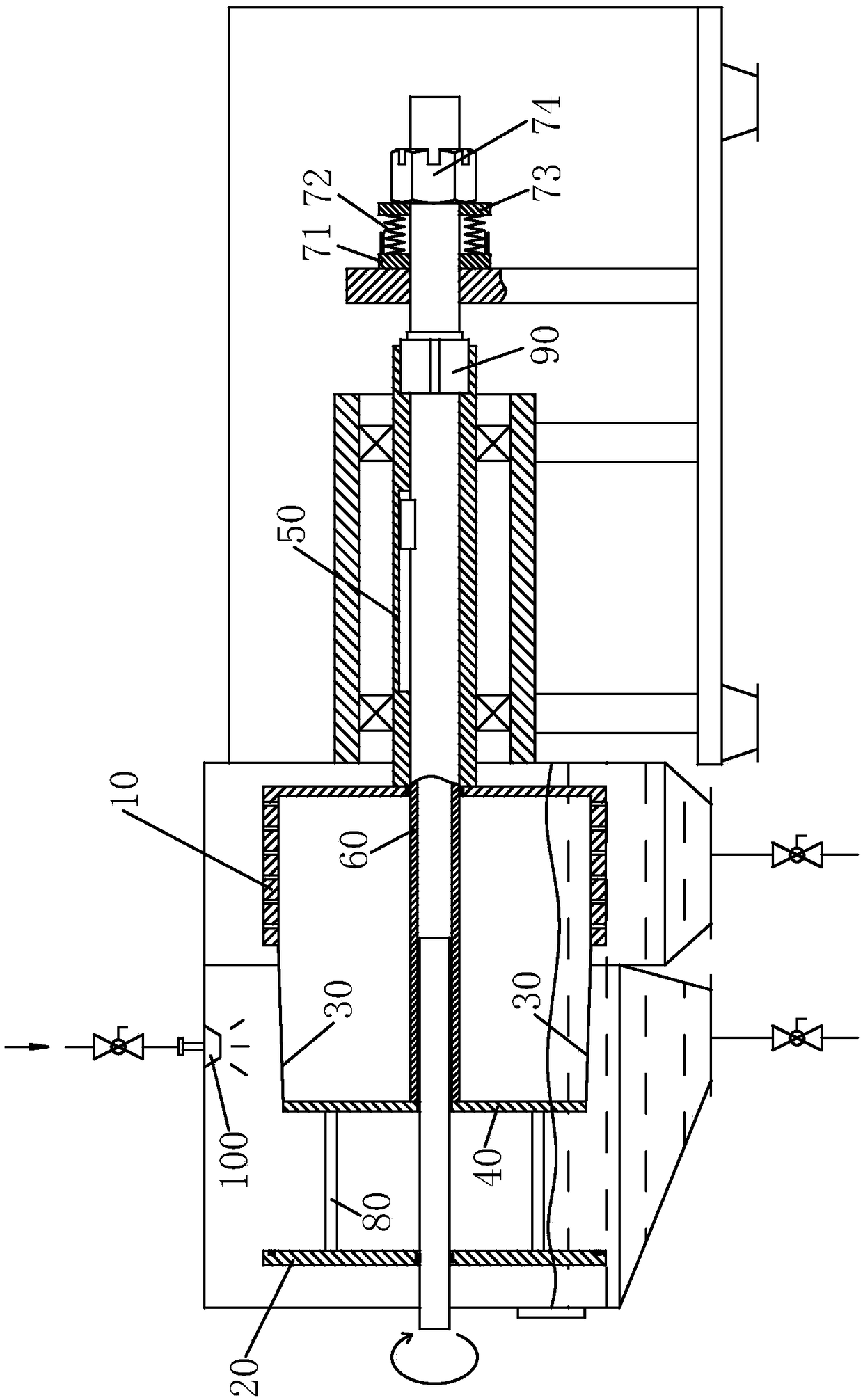

Bag turning centrifugal machine, and dehydration and filter cloth regeneration method thereof

PendingCN108273669AEasy to operateCompact structureRotary centrifugesEngineeringMechanical engineering

The invention belongs to the technical field of centrifugal filtration type solid-liquid separation and particularly relates to a bag turning centrifugal machine, and a dehydration and filter cloth regeneration method thereof. The bag turning centrifugal machine comprises a rotating drum rotatably arranged in a case and fixedly connected with a hollow spindle, and the open end of the rotating drumis provided with a front push disc. The rotating drum is further internally provided with a rear push disc fixedly connected with the front push disc, and the hollow spindle is internally provided with a moving shaft capable of axially moving relative to the hollow spindle. The moving shaft is fixedly connected with the rear push disc, and the bag turning centrifugal machine further comprises a locking device which is fixedly arranged on the side, away from the rotating drum, of the moving shaft. Through the elasticity effect, the locking device enables the front end face of the rotating drumand the front push disc to be in a sealed state when the front end face of the rotating drum and the front push disc are attached. The locking device, used for locking and sealing the front end faceof the rotating drum and the front push disc, in the bag turning centrifugal machine is simple and compact in structure, convenient to operate and maintain and capable of effectively reducing and eveneradicating the phenomena of leakage and venting.

Owner:HEFEI GENERAL MACHINERY RES INST

Catalyst used for automobile exhaust particle catalytic filter and preparation method for catalyst

ActiveCN105195174AImprove oxidation activityLower regeneration equilibrium point temperatureMetal/metal-oxides/metal-hydroxide catalystsMass ratioCerium

The invention discloses a catalyst used for an automobile exhaust particle catalytic filter. The catalyst comprises the following active components: a noble metal element, cerium, zirconium and a transition metal element, wherein the mass ratio of all the components (noble metal: cerium oxide: zirconium oxide: transition metal oxide) is (1 to 10):(20 to 40):(10 to 20):30 by oxide, and the ratio of the cerium to the zirconium is 1:(0.5 to 2). The regeneration balance point temperature of the catalyst used for a particle trap, disclosed by the invention, can be reduced, therefore exhaust gas heat is fully utilized, a heat control system is simplified, and energy consumption is reduced.

Owner:浙江通源环保科技有限公司

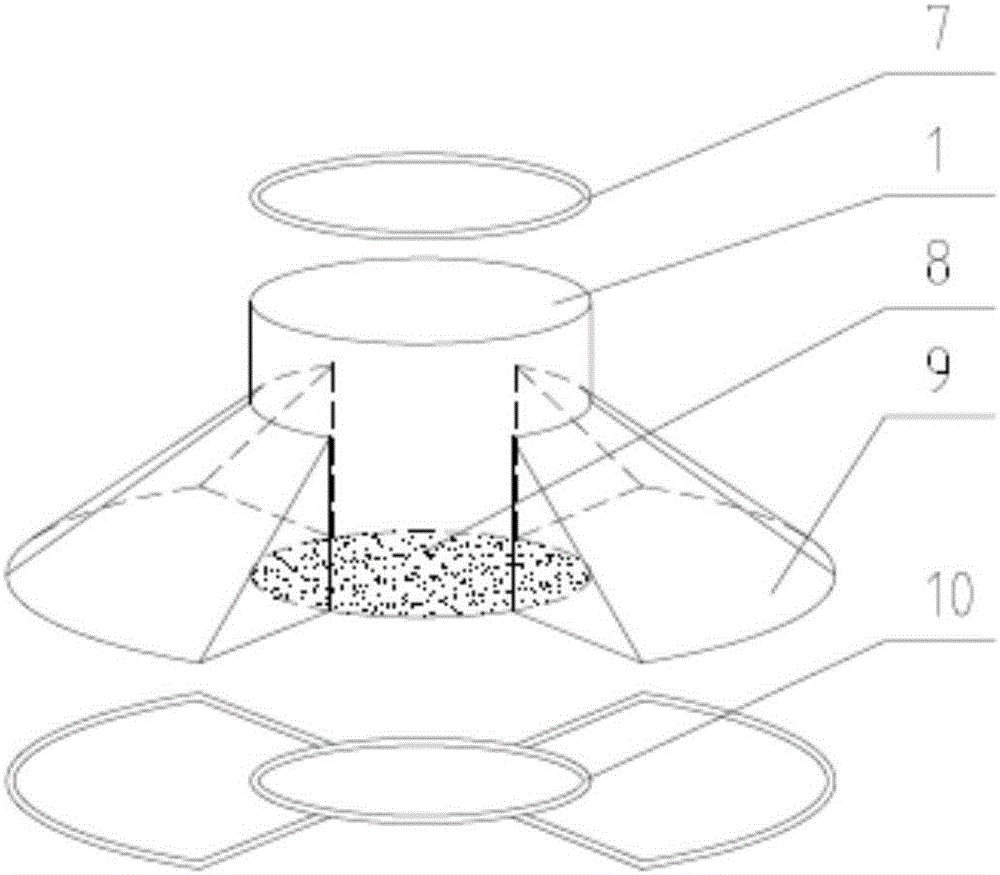

A method for drying gases and a device applied thereby

ActiveCN100464821CFully regeneratedDew point remains constantPositive displacement pump componentsDispersed particle separationLow loadEngineering

Method for drying a gas from a compressor (1) by means of a drier (2) of the type which consists of a pressure tank (3) with a drying zone (4) and a regeneration zone (5), with a rotor (6) which is composed of a drying element (7) in which has been provided an adsorption and / or absorption medium (8) which is alternately put through the drying zone (4) and the regeneration zone (5), characterised in that at a low load or zero load, the inlet of the regeneration zone (5) is connected to the user network (12) via a regeneration pipe (27), and in that the outlet of the regeneration zone (5) is connected to the atmosphere.

Owner:ATLAS COPCO AIRPOWER NV

Gas purification device and method

ActiveCN102170956BPrevent coagulationSpeed up the flowGas treatmentDispersed particle separationTemperature controlPurification methods

Owner:KUREHA ECOLOGY MANAGEMENT

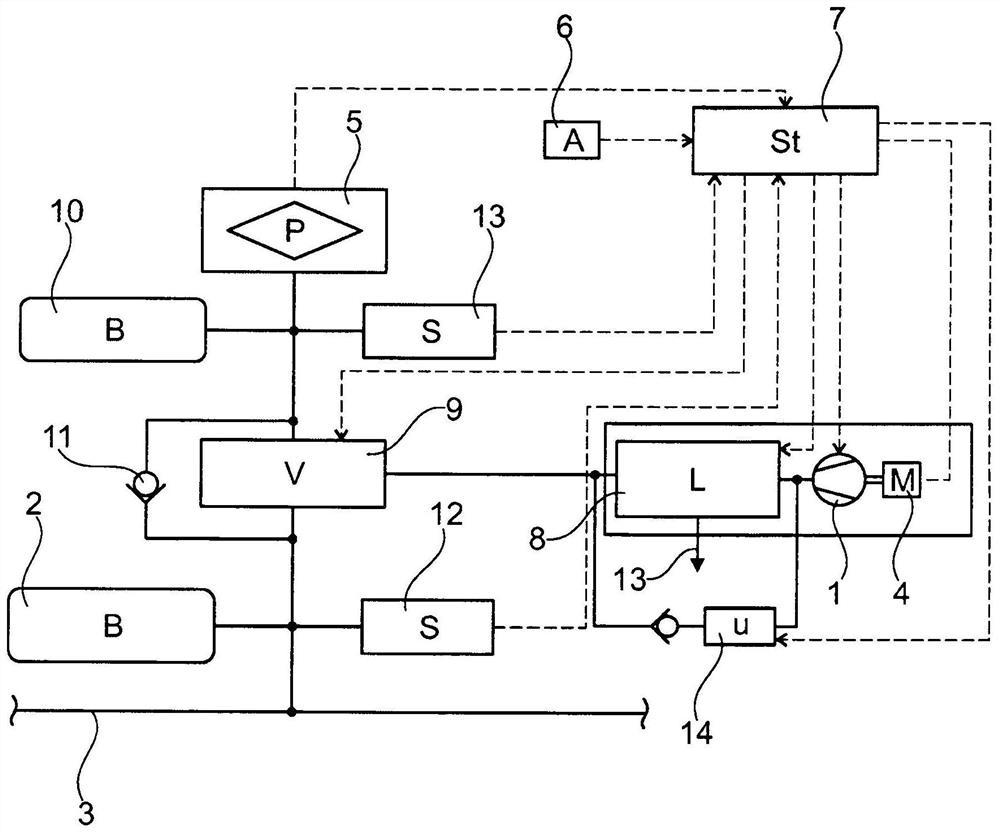

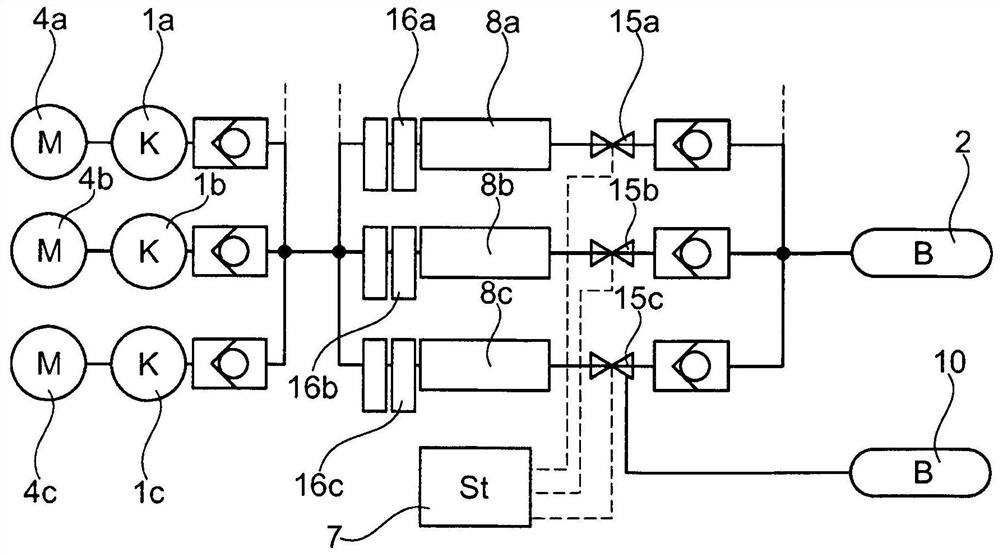

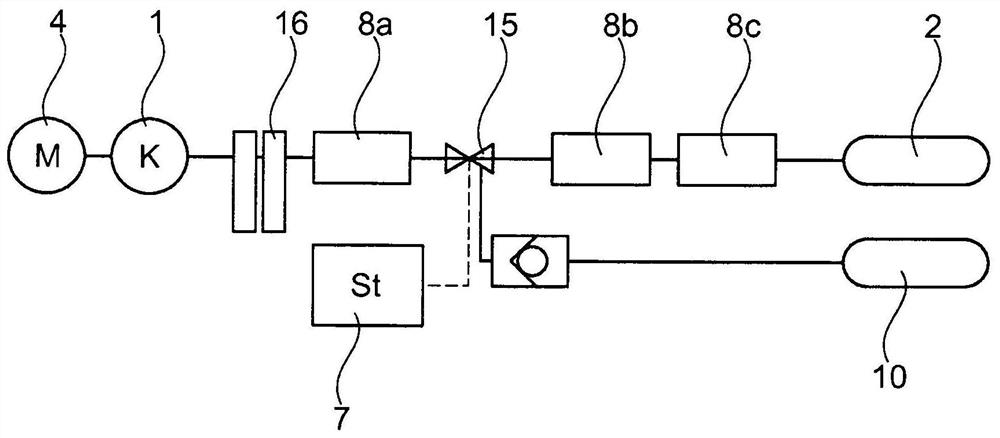

Method and device for controlling an air drying unit of an air supply system for the primary and secondary air supply of a vehicle, in particular a rail vehicle

ActiveCN108137028BLower regenerationReduce setup timeGas treatmentDispersed particle separationDesiccantEngineering

The invention relates to a method and a device for controlling at least one air drying unit (8; 8a-8c) of an air supply system for a vehicle's primary and secondary air supply, wherein at least one air drying unit (8; 8a-8c) is controlled via an electric motor ( 4; 4a‑4c) driven compressor (1; 1a‑1c) implements both the main air supply to the main air storage tank (2) and the auxiliary air supply to the auxiliary air storage tank (10), the compressor The compressed air produced by (1; 1a-1c) is led through said at least one air drying unit (8; 8a-8c) connected downstream, with which the compressor (1; 1a-8c) is supplied by the compressor (1; 1a- 1c) Drying of the generated compressed air, i.e. regeneration of the desiccant of the air drying unit (8; 8a-8c) with the dried compressed air; wherein during the supply of auxiliary air the use for drying at least one air The unit (8; 8a-8c) regenerates the air flow so that in the auxiliary air supply compared to the main air supply, there is a higher volume flow or the volume flow provided by the compressor (1; 1a-1c) can be used for Fill the auxiliary air reservoir (10).

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

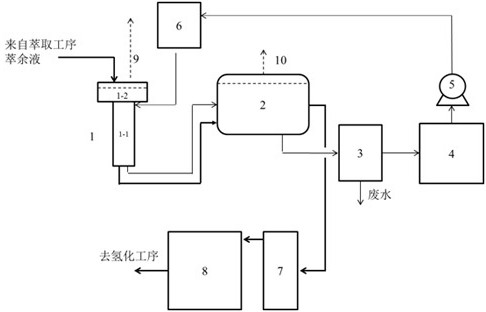

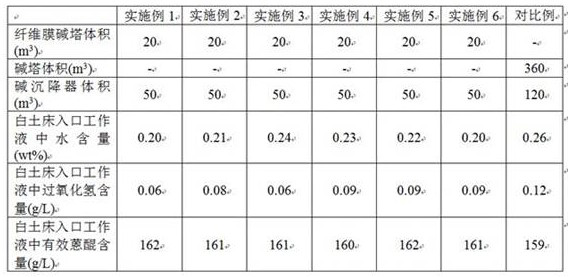

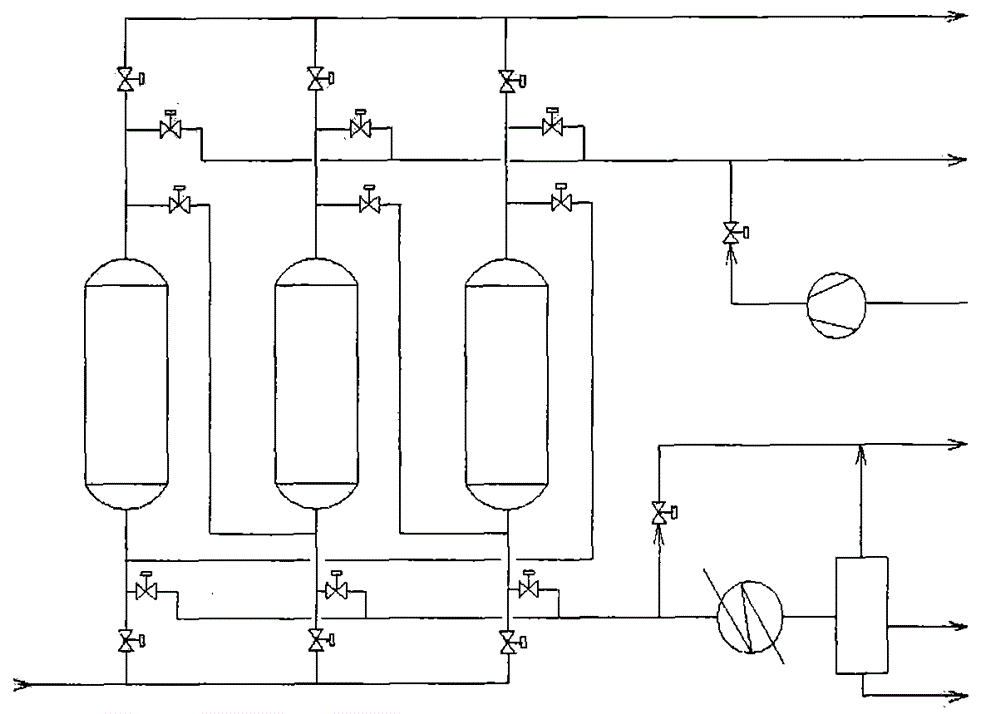

New post-treatment process of working solution for producing hydrogen peroxide by anthraquinone method

PendingCN114180773AEnhanced mass transferFully regeneratedFatty/oily/floating substances removal devicesWater contaminantsAnthraquinonesFiber

The invention relates to a novel post-treatment process of a working solution for producing hydrogen peroxide by an anthraquinone method, which comprises a fibrous membrane alkali tower, an alkali settler, an alkali evaporator, a concentrated alkali liquor storage tank, a carclazyte bed and a working solution storage tank, and is characterized in that the working solution from an extraction procedure and the concentrated alkali liquor from the concentrated alkali storage tank jointly pass through the fibrous membrane alkali tower and fully react in the fibrous membrane alkali tower; the reacted working solution and dilute alkali liquor are discharged from the fiber membrane alkali tower and enter an alkali settler; the dilute alkali liquor flows to the alkali evaporator from the alkali settler, and forms concentrated alkali liquor again after water is removed in the alkali evaporator, and the concentrated alkali liquor flows to the concentrated alkali liquor storage tank and then enters the fiber membrane alkali tower to continue to be in contact reaction with the working solution; and the working solution flows to the carclazyte bed from the alkali settler, flows into the working solution storage tank after being treated by the carclazyte bed, and then enters the hydrogenation process. The mass transfer efficiency of the working solution and the alkali liquor is remarkably improved, and the liquid holdup of an existing alkali treatment unit is reduced.

Owner:LIMING RES INST OF CHEM IND

Method for recovering gasoline from mixed gas containing gasoline

ActiveCN103386246BImprove the efficiency of gasoline recoveryFully regeneratedOther chemical processesDispersed particle separationSorbentEmission standard

Owner:BEIJING JIELINUO ENVIRONMENT SCI & TECHCO

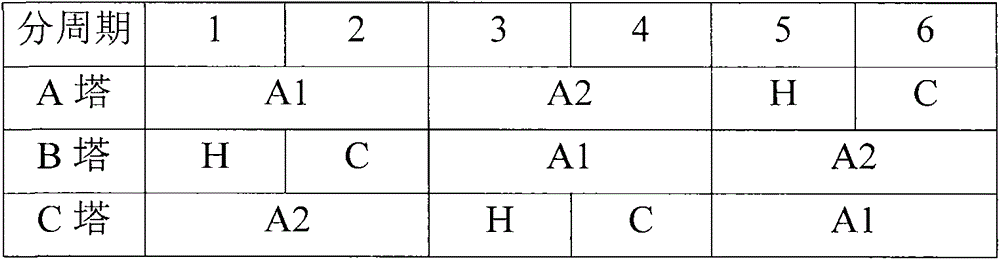

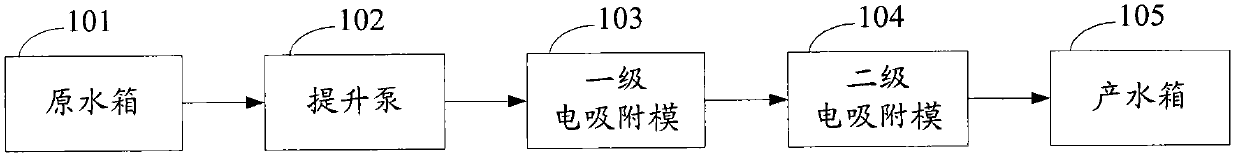

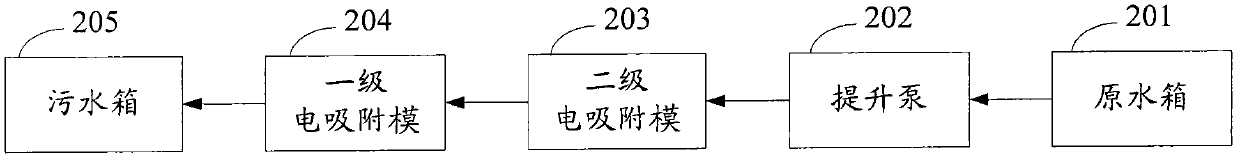

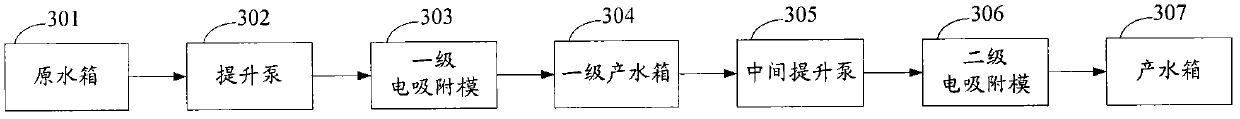

Electro-adsorption desalting system, regeneration system and corresponding method

ActiveCN102701340BReduce pressure requirementsFully regeneratedDispersed particle separationElectricitySewage

The invention discloses an electro-adsorption desalting system, a regeneration system and a corresponding method and relates to the field of water treatment, in order to solve the problems of the present technology that the treating efficiency is lower and an electro-adsorption module is required to tolerate higher water pressure. The electro-adsorption desalting system comprises a raw water tank, a lifting pump, at least two-level serial electro-adsorption modules and a water generating tank which are serially connected in turn, wherein a middle water generating tank and a middle lifting pump in serial connection are also arranged between the at least two-level serial electro-adsorption modules. The regeneration system for the electro-adsorption modules comprises a raw water tank, a lifting pump, at least two-level serial electro-adsorption modules and a sewage tank in serial connection, wherein a middle water tank and a middle lifting pump in serial connection are arranged between the at least two-level serial electro-adsorption modules. In an electro-adsorption desalting technology, the demand on the pressure resistance of the electro-adsorption modules is not increased and the use ratio of the electro-adsorption modules is increased. In an electro-adsorption module regeneration technology, the demand on the pressure resistance of the electro-adsorption modules is not increased and the water yield is higher.

Owner:EST WATER & TECH

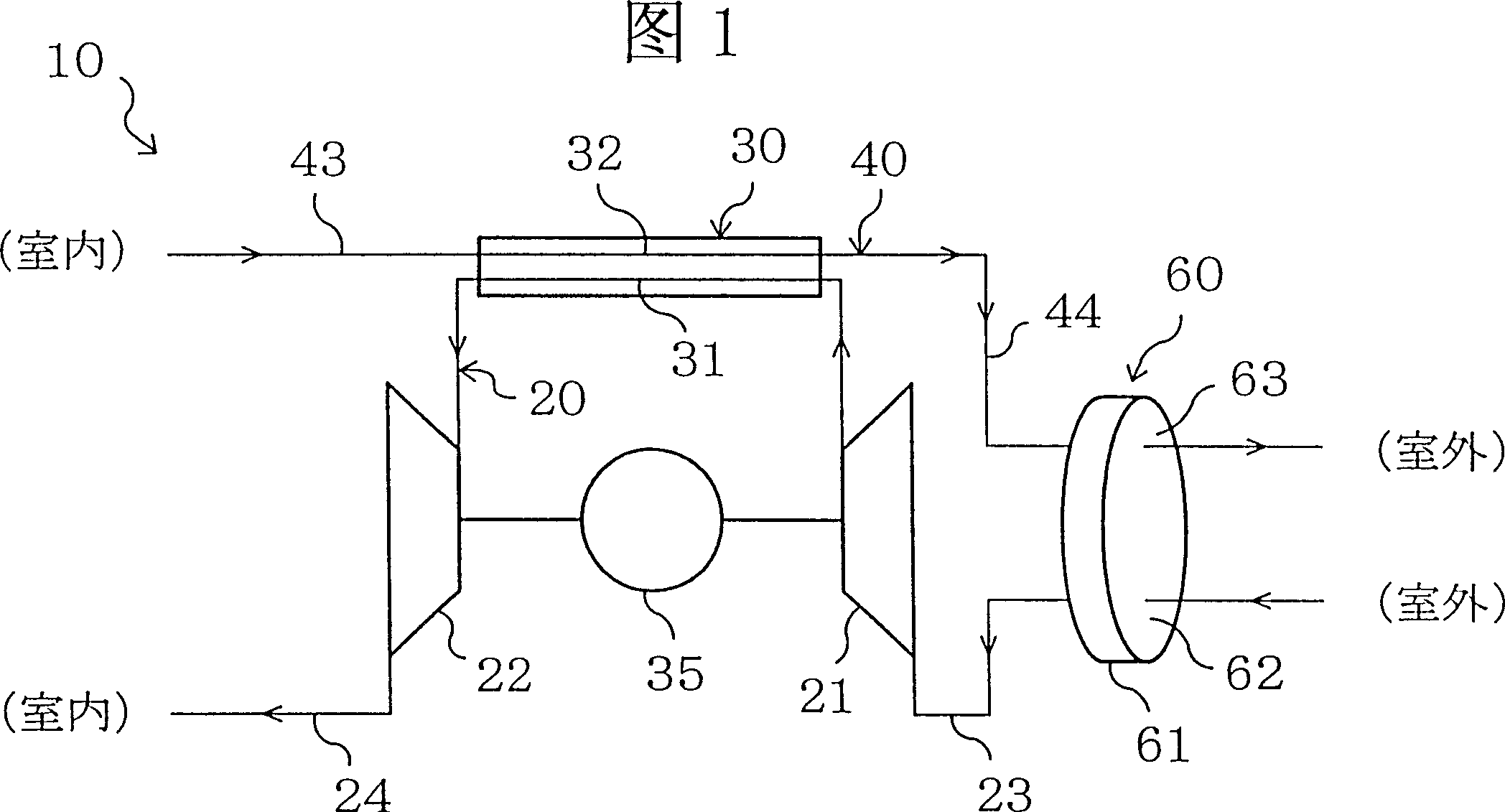

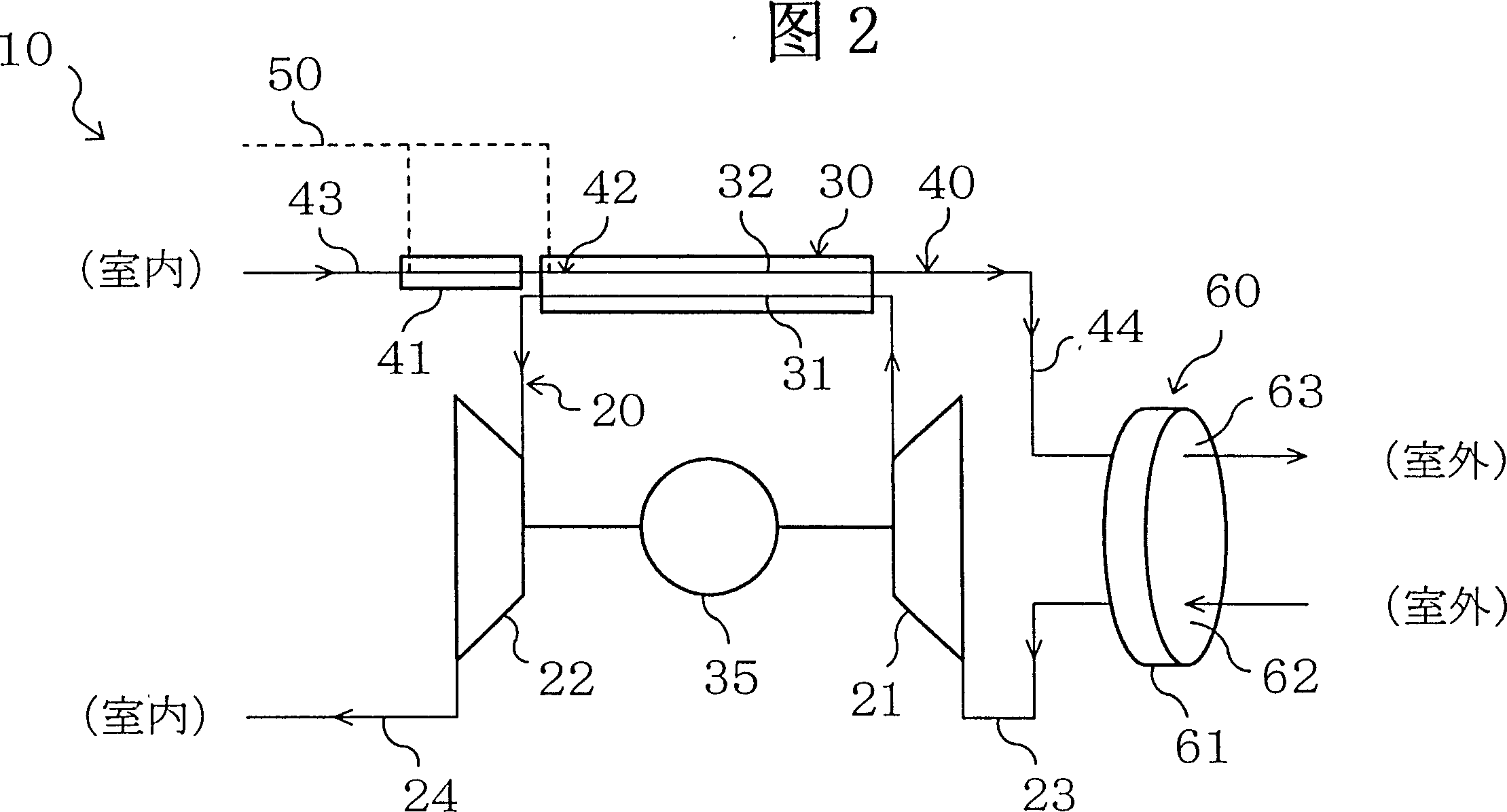

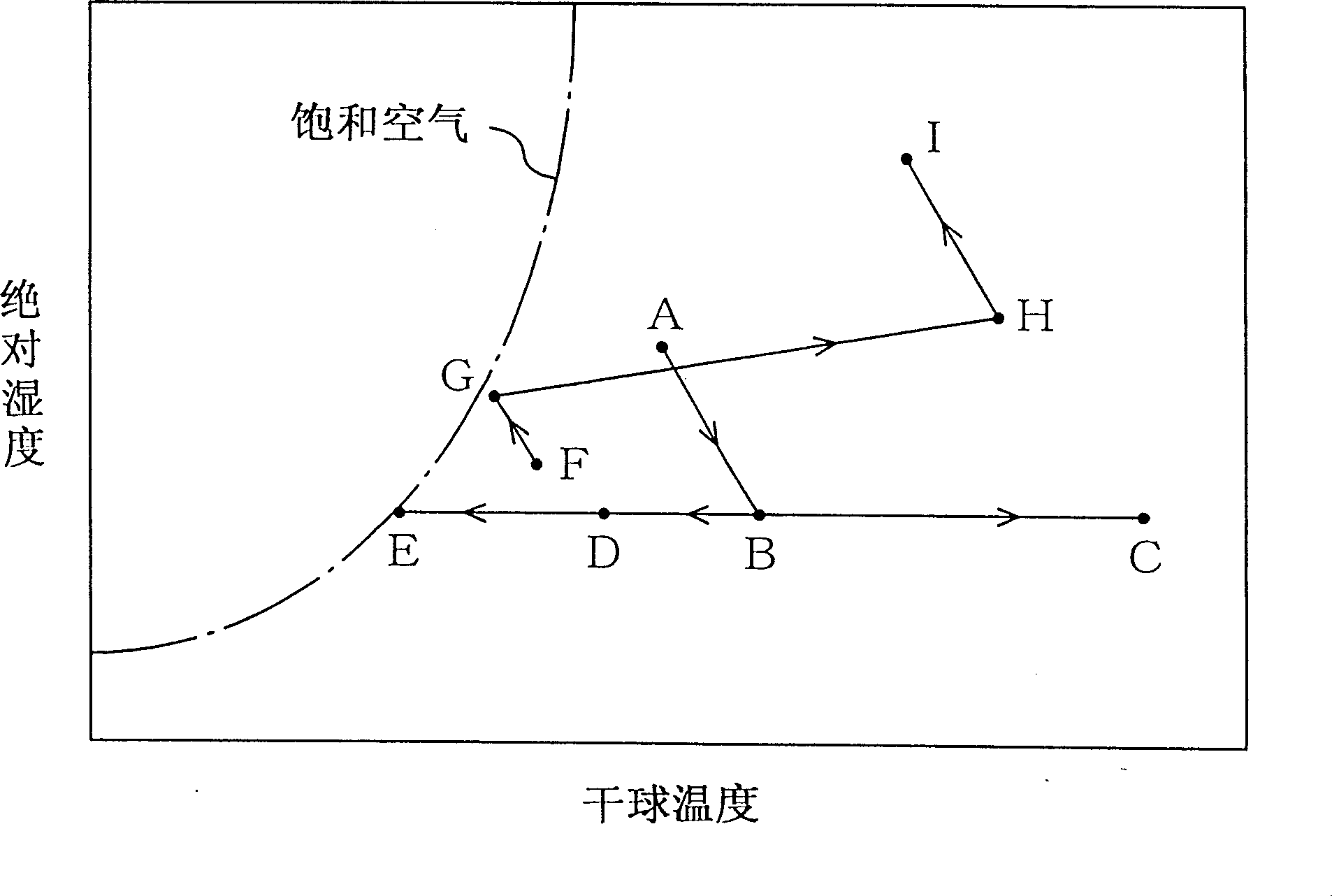

Air conditioner

InactiveCN1224816CNo direct loss of input powerPrevent leakageAir treatment detailsAir-treatment apparatus arrangementsEngineeringAir conditioning

An air conditioner using air cycling characterized in that, is formed by sequentially connecting a compressor, a heat exchanger and an expander. In the first channel, an outside air is taken through a first inlet duct and supplied to a room through a first outlet duct. A second channel is formed by connecting both ends of the heat exchanger to ducts. In the second channel, a room air is taken through the second inlet duct and discharged to outdoors through the second outlet duct. A moisture absorbing section of a dehumidifying mechanism is provided in the first inlet duct, while a moisture releasing section thereof is provided in the second inlet duct. A rotor member including a solid adsorbent rotatively moves between the moisture absorbing section and the moisture releasing section. Air dehumidified in the moisture absorbing section is supplied to the compressor.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com