Low-temperature plasma regeneration system and method for inactivated activated carbon

A low-temperature plasma and regeneration system technology, applied in the field of ion regeneration systems, can solve problems such as low plasma regeneration efficiency and chemical reagent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

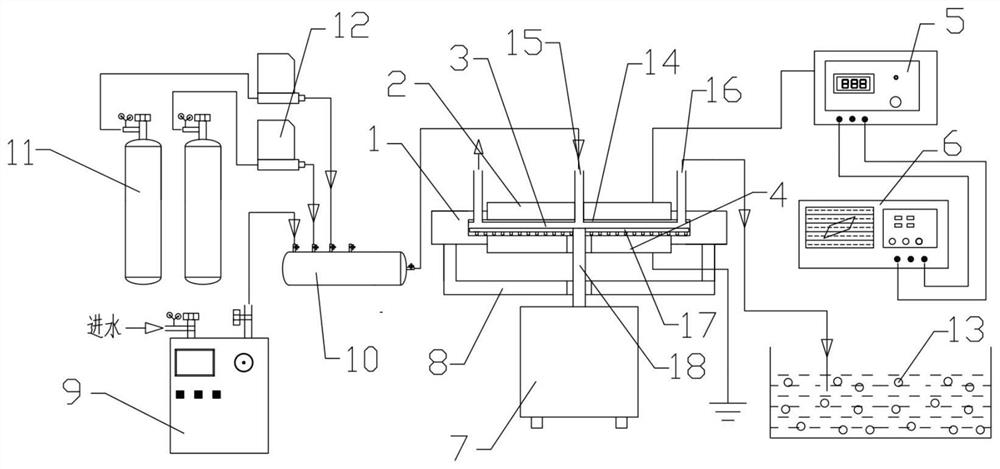

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 1 g of deactivated activated carbon and evenly spread it on the bottom plate of the quartz reactor, with a material thickness of about 3 mm.

[0035] (2) Introduce helium gas with a flow rate of 50ml / min, turn on the high-voltage AC power supply to control the discharge voltage to 30kv, discharge frequency to 10kHz, and the reaction lasts for 1min to complete the surface activation of activated carbon.

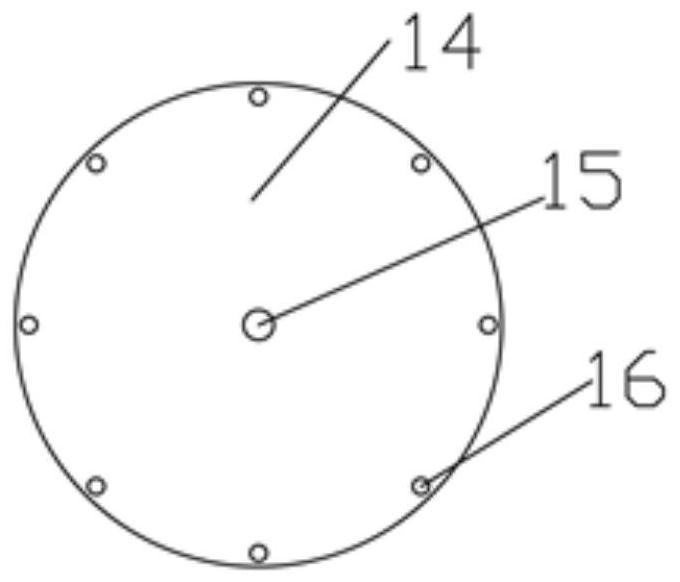

[0036] (3) Turn on the water steam generator to generate steam, water consumption / activated carbon = 0.1, oxygen and helium are introduced according to 3:7, the flow rate of mixed gas is 100ml / min, the discharge voltage is controlled by high-voltage AC power supply to 40kv, the discharge frequency is 10kHz, and the data is stored , using the Lissajous figure to calculate the power is 70W.

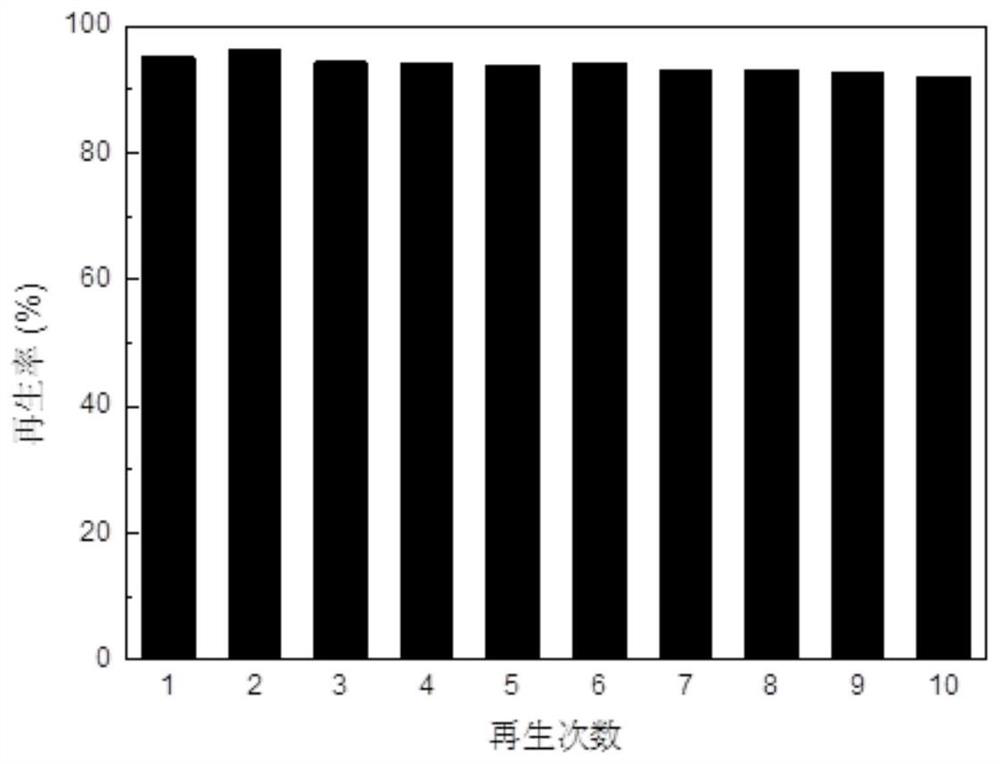

[0037](4) After 30 minutes of reaction, turn off the power to suspend the reaction, turn on the power motor to drive the rake-type feeder to rotate, mix the materials for 30...

Embodiment 2

[0041] The difference between this embodiment and embodiment 1 is that the mixed gas flow rate in step (3) is 50ml / min, the discharge voltage is 50kv, the treatment time is 20min, the input power is 98W, and the calculated regeneration rate is 88.2%.

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is that in step (3), the discharge voltage is 50kv, the input power is 98W, and the treatment time is 20min once, and the regeneration rate is calculated to be 95.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com