Patents

Literature

62 results about "Electrochemical regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The electrochemical regeneration of activated carbon based adsorbents involves the removal of molecules adsorbed onto the surface of the adsorbent with the use of an electric current in an electrochemical cell restoring the carbon’s adsorptive capacity. Electrochemical regeneration represents an alternative to thermal regeneration commonly used in waste water treatment applications. Common adsorbents include powdered activated carbon (PAC), granular activated carbon (GAC) and activated carbon fibre.

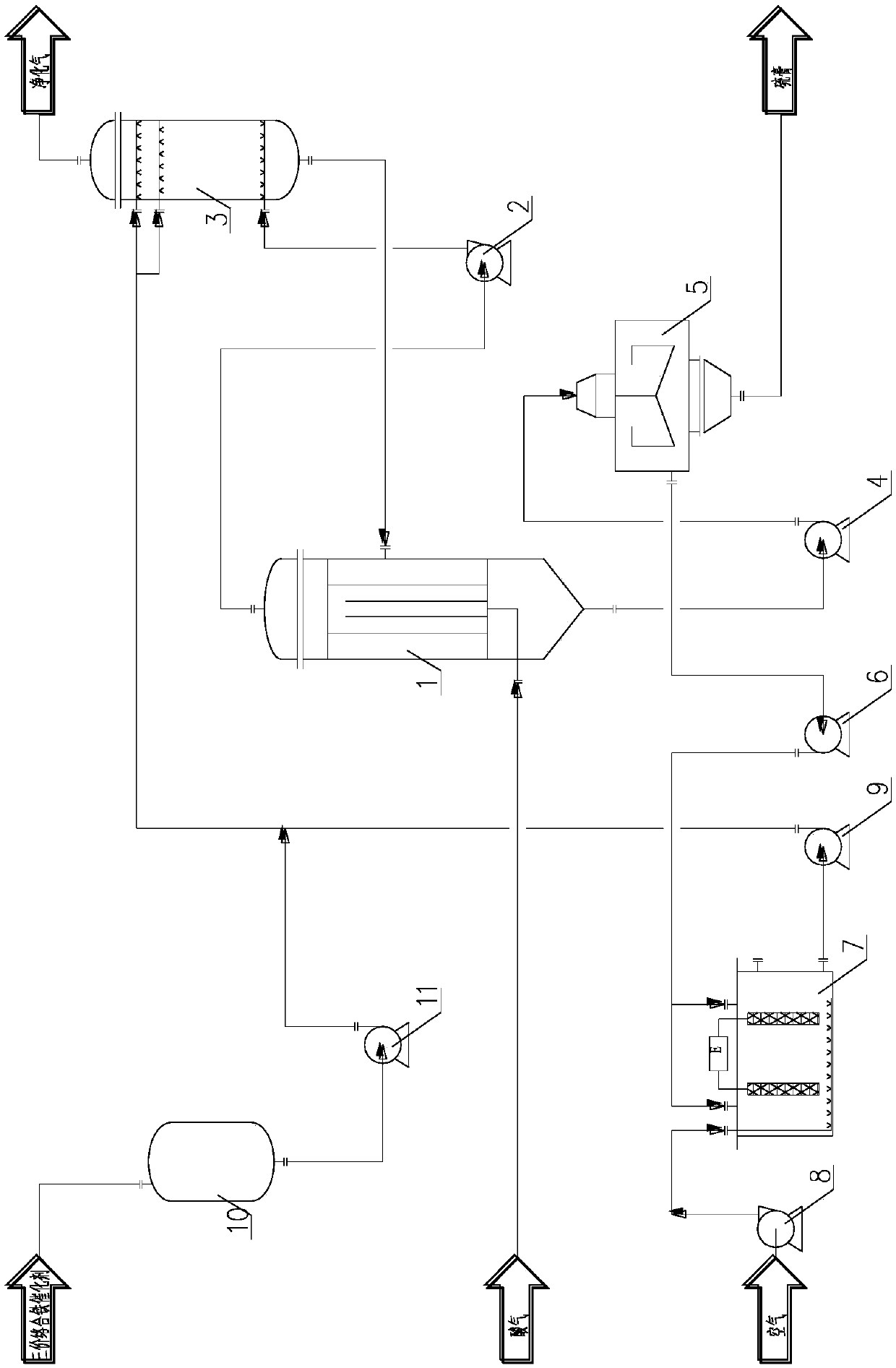

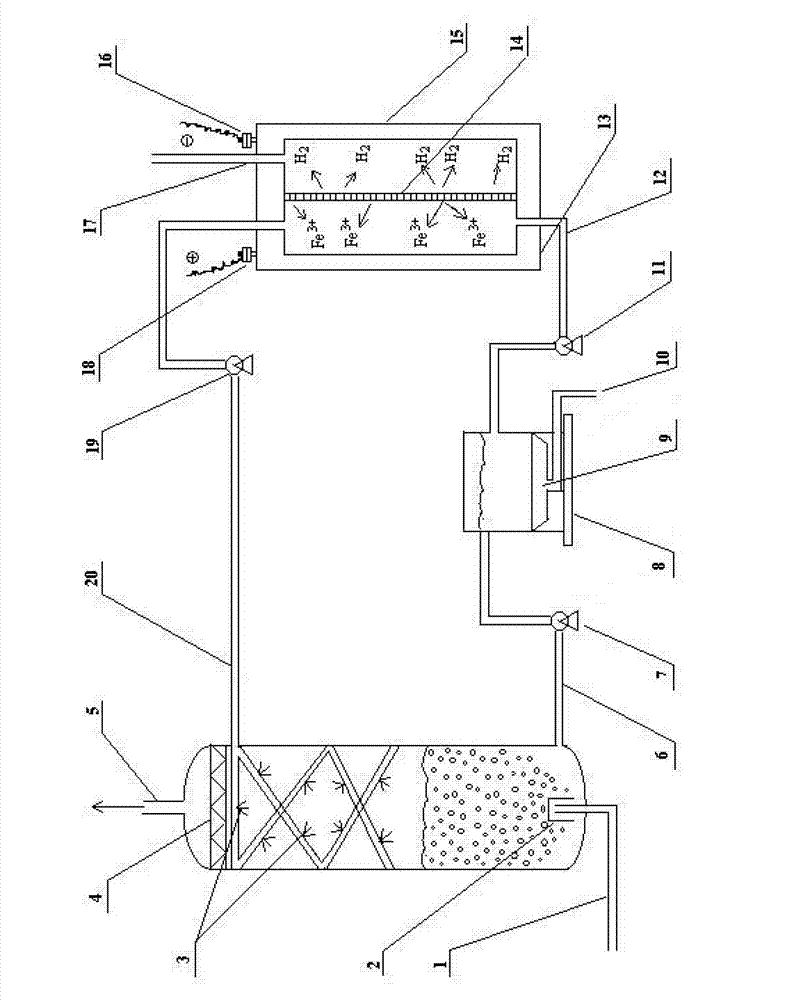

Natural gas desulfurization process suitable for offshore floating platform

InactiveCN108034466AFast regenerationImprove oxidation regeneration efficiencyGaseous fuelsChemical industryChemical reaction

The invention relates to the field of natural gas chemical industry, in particular to a natural gas desulfurization process suitable for an offshore floating platform. The natural gas desulfurizationprocess comprises a reactor, a re-reactor and a centrifugal machine; acid gas coming from a boundary region is directly introduced into the reactor, a trivalent complex iron catalyst enters the re-reactor, the trivalent complex iron catalyst at the bottom of the re-reactor enters the reactor under the control of a valve and a pipeline, a chemical reaction is then carried out, divalent complex ironobtained by means of the reaction is centrifuged, the divalent complex iron is conveyed to an electrochemical regeneration device by means of a regenerative feed pump so as to complete the regeneration, and the regenerated trivalent complex iron catalyst is returned to the re-reactor by means of a circulation pump. The natural gas desulfurization process is simple in technological process, smallin equipment size and compact in structure, and adapts to the condition limit of limited production space of offshore floating liquefied natural gas (FLNG).

Owner:SICHUAN HENGRI GAS ENG CO LTD

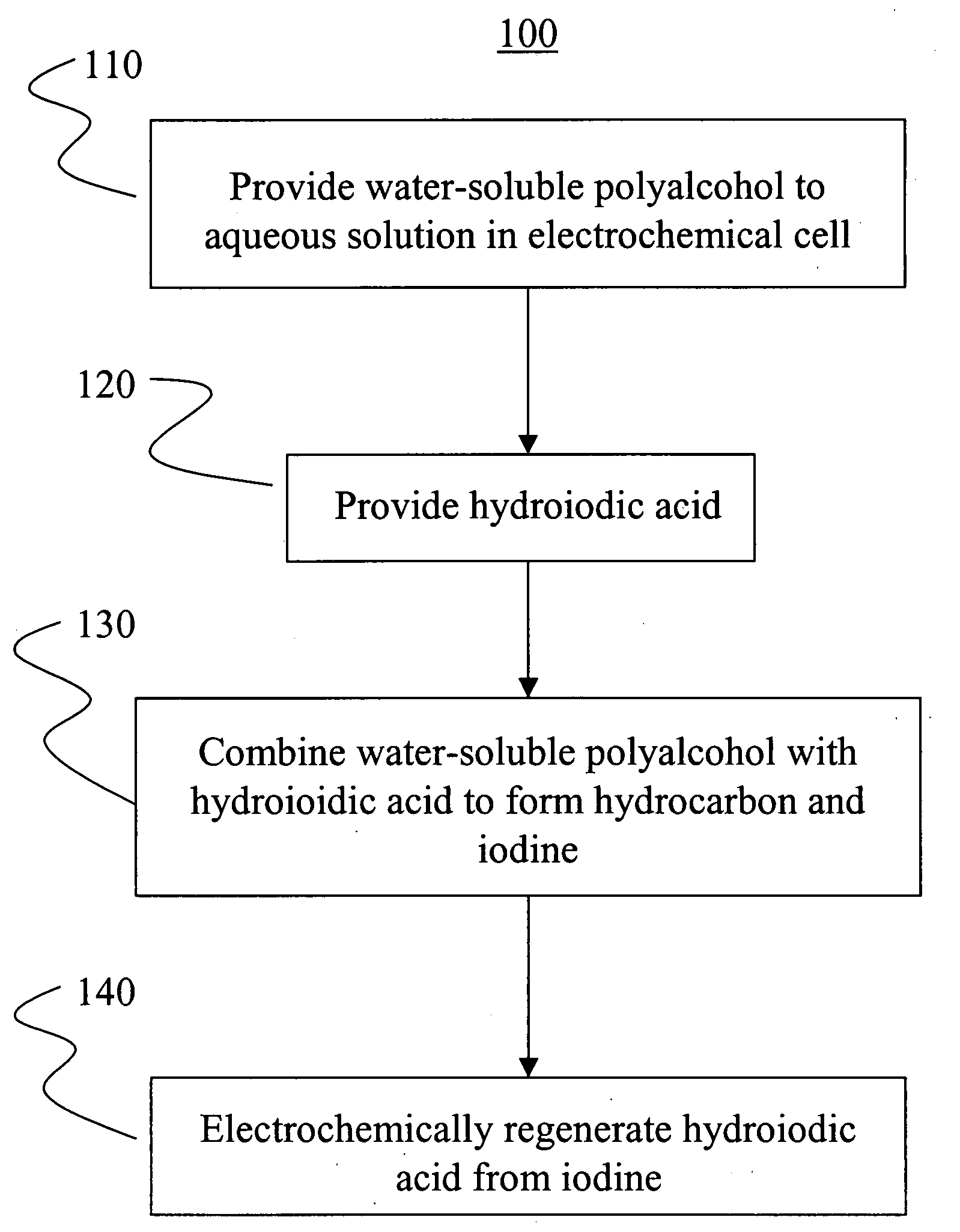

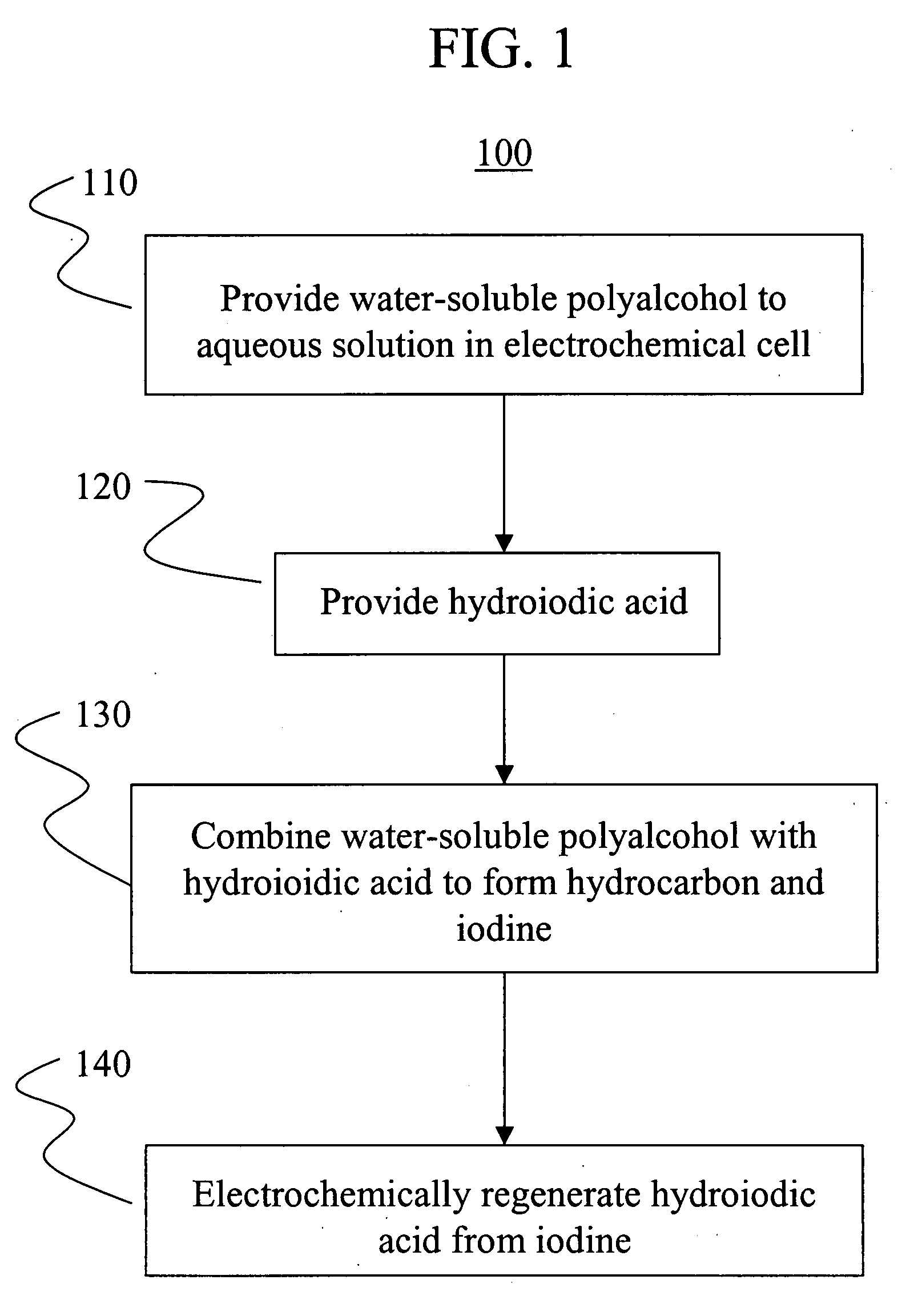

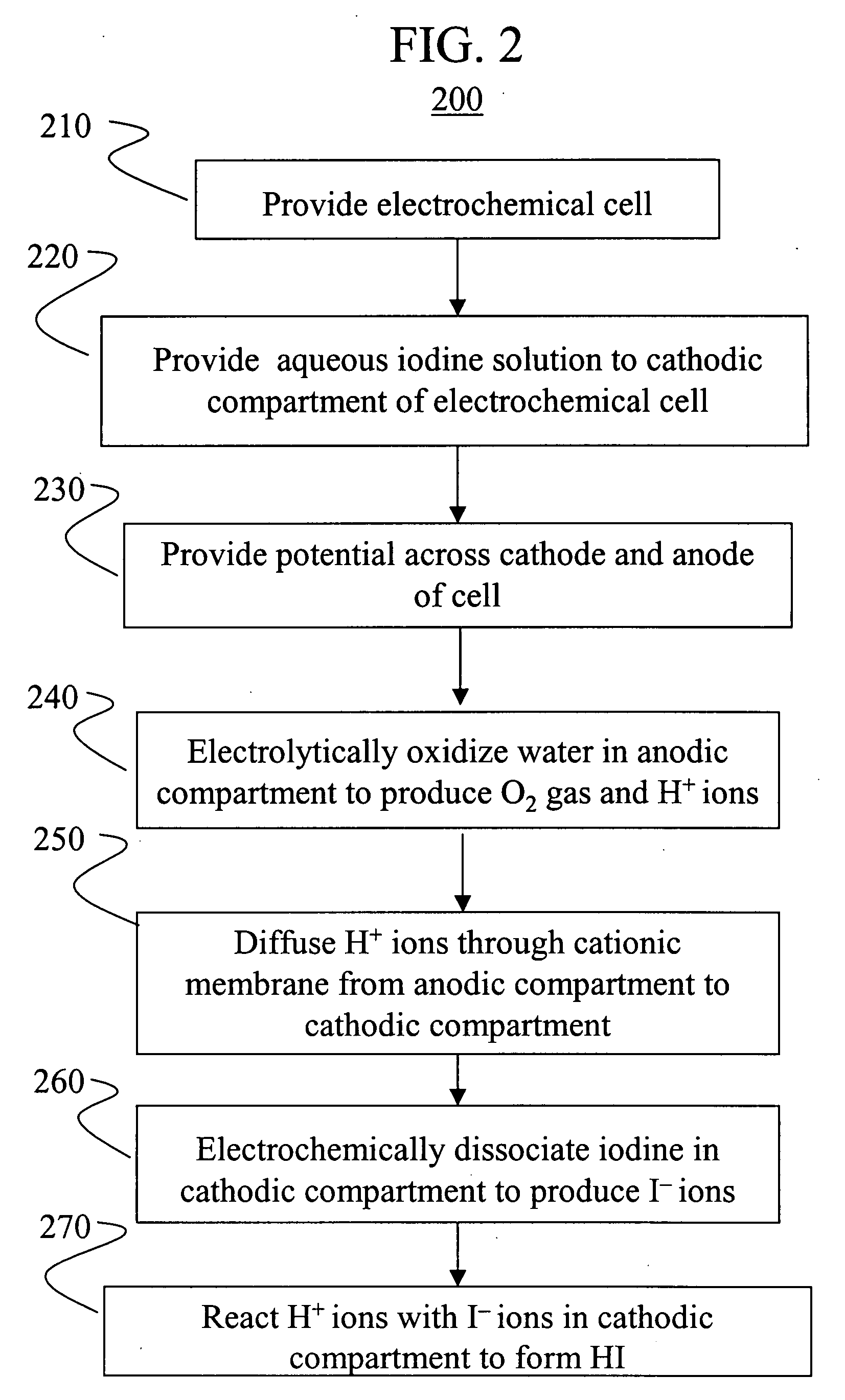

Electrochemical conversion of polyalcohols to hydrocarbons

A method of making hydrocarbons from polyalcohols, such as carbohydrates. The polyalcohols and carbohydrates may be provided from biomass, including paper, cardboard or urban generated paper product waste; wood and wood products, including forest slash and deadfall; agricultural waste; and the like. The polyalcohols and carbohydrates are combined with hydroiodic acid in aqueous solution to form the hydrocarbon and elemental iodine. Hydroiodic acid is then electrochemically regenerated by reducing the elemental iodine in a parallel reaction. A method of electrochemically generating hydroiodic acid from elemental iodine in aqueous solution is also described.

Owner:RGT UNIV OF CALIFORNIA

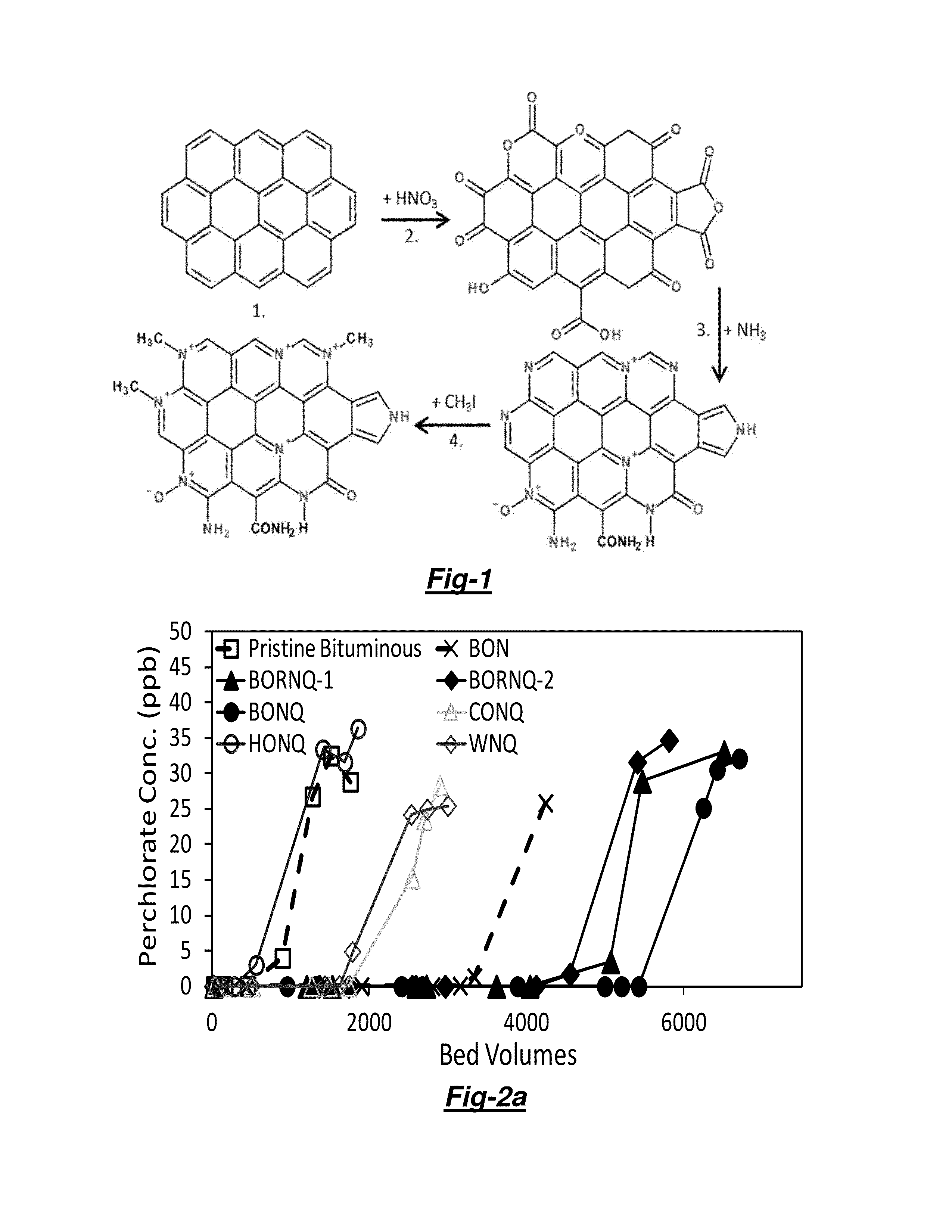

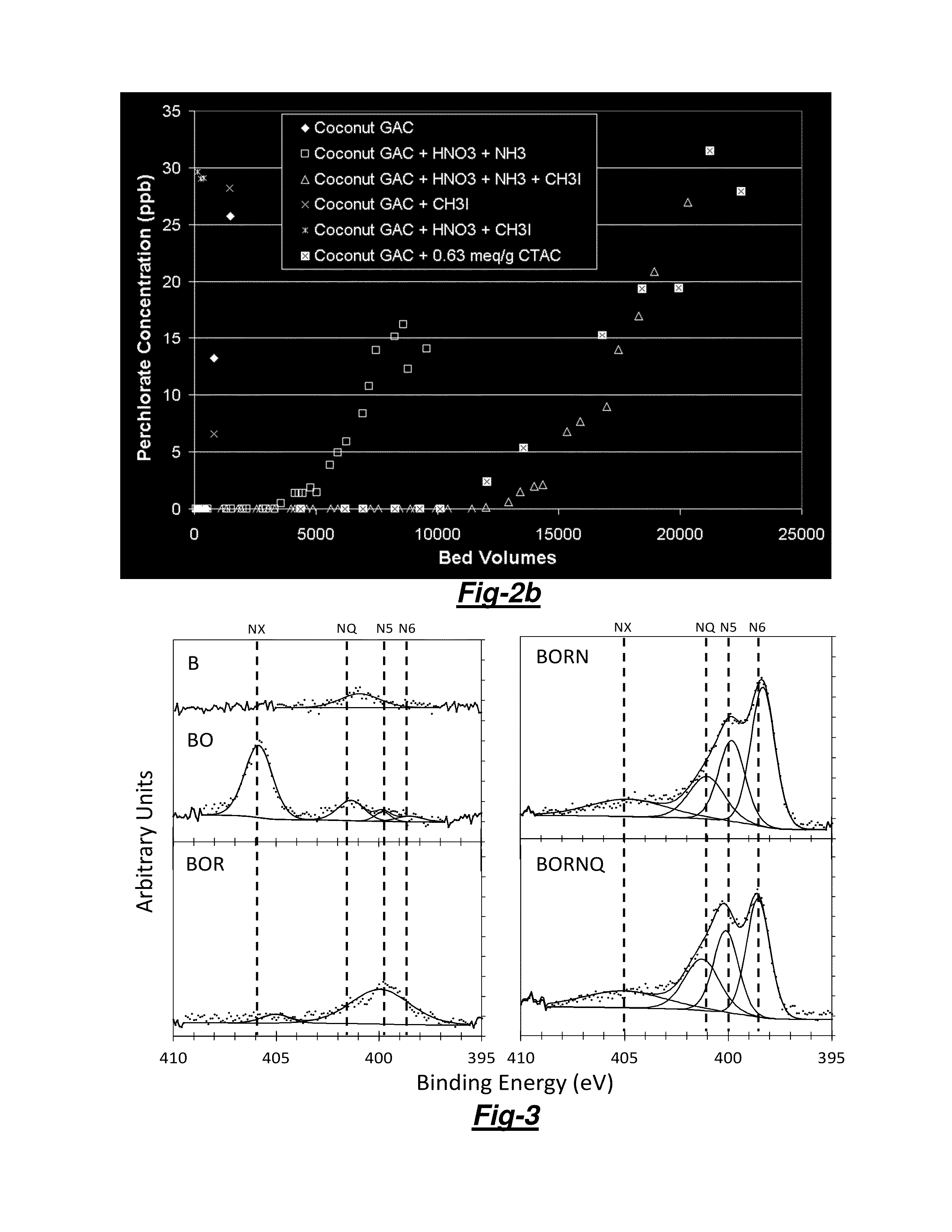

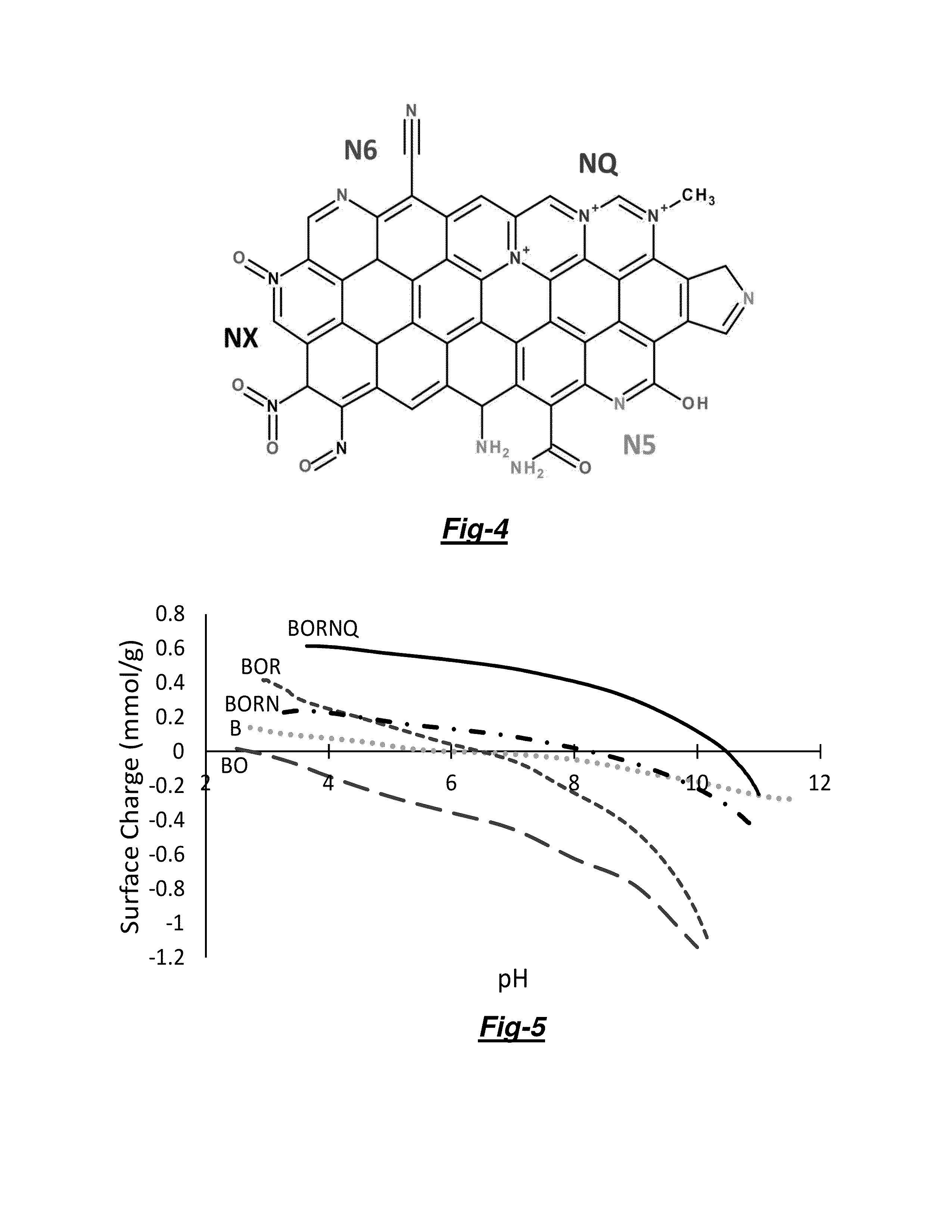

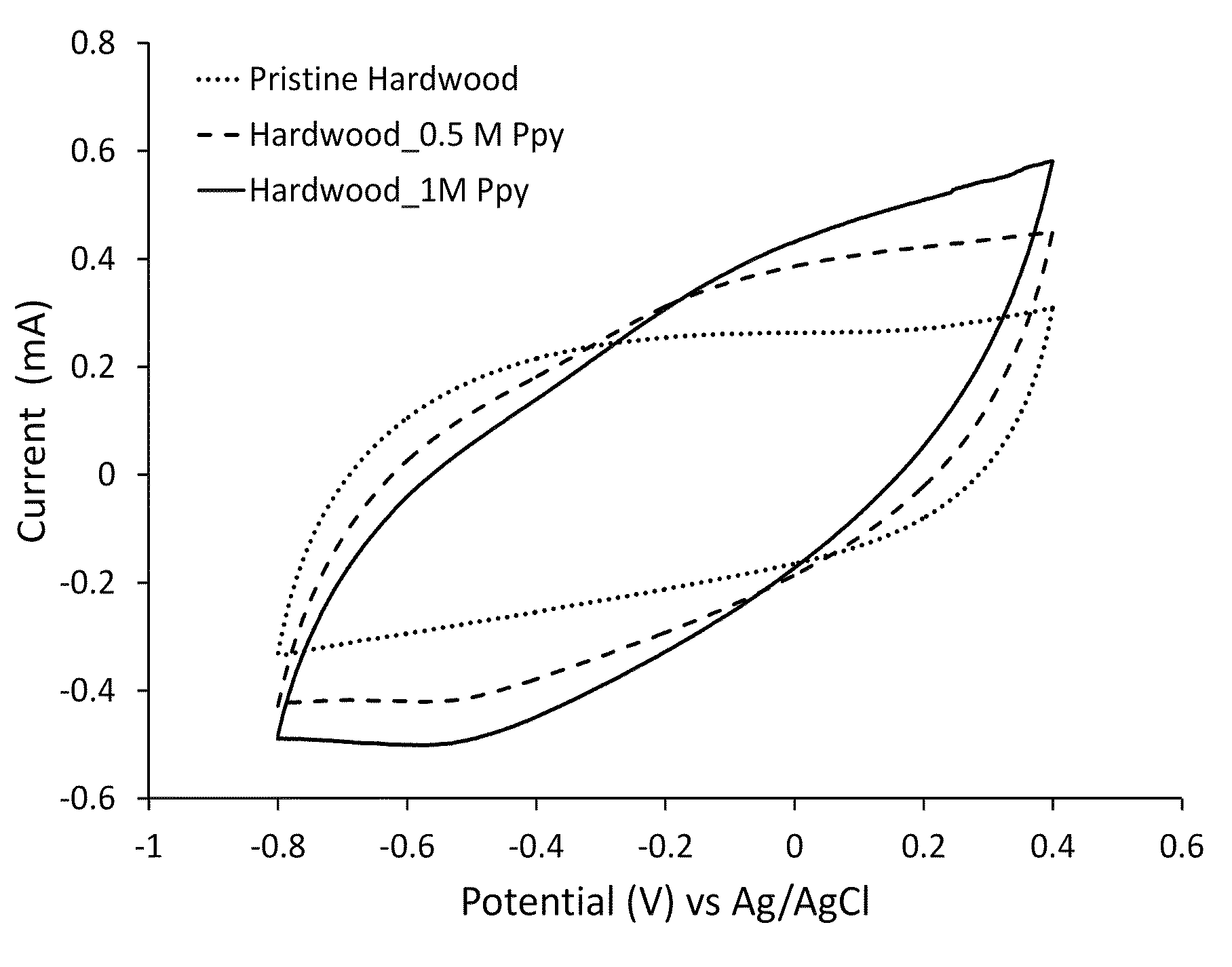

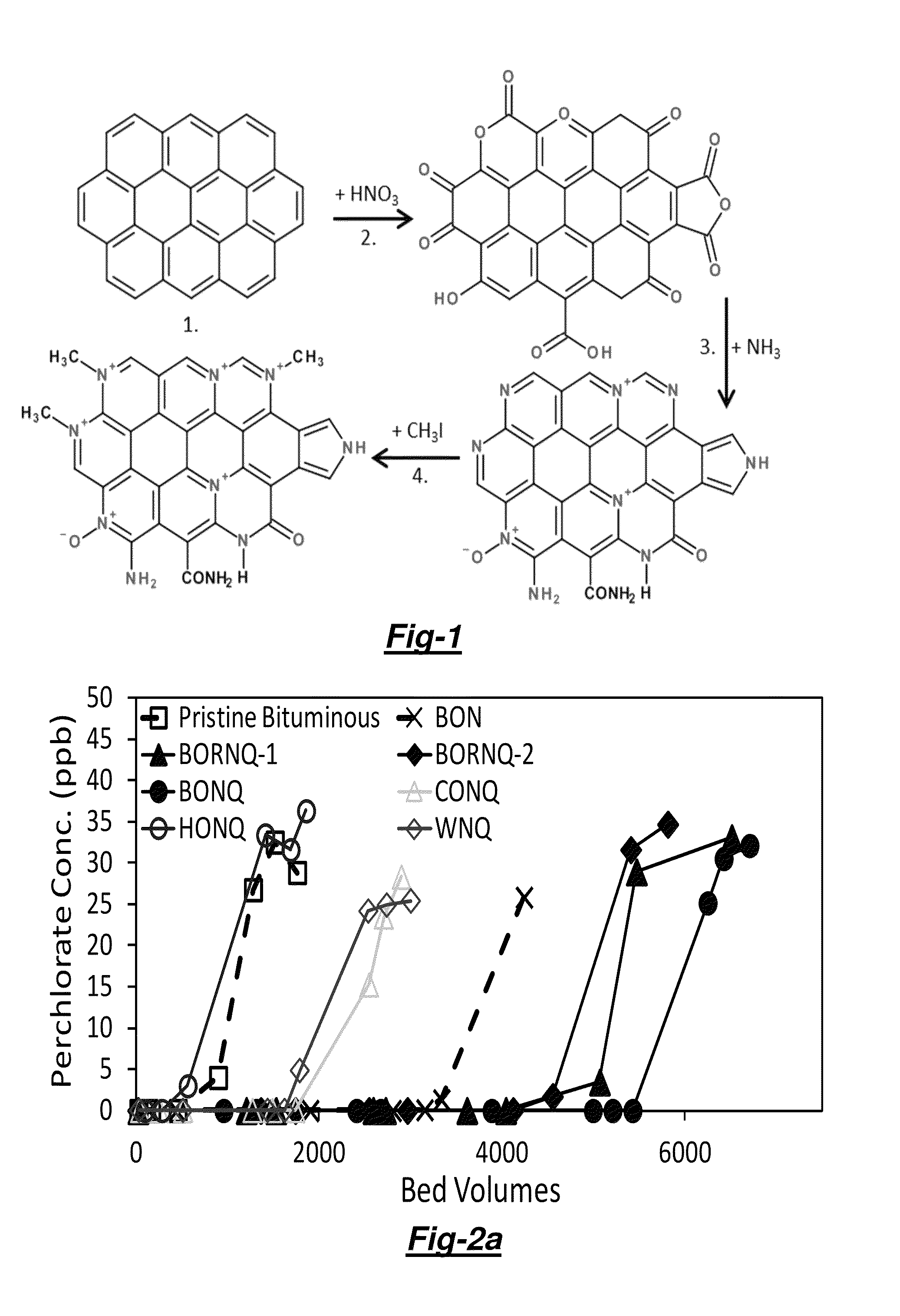

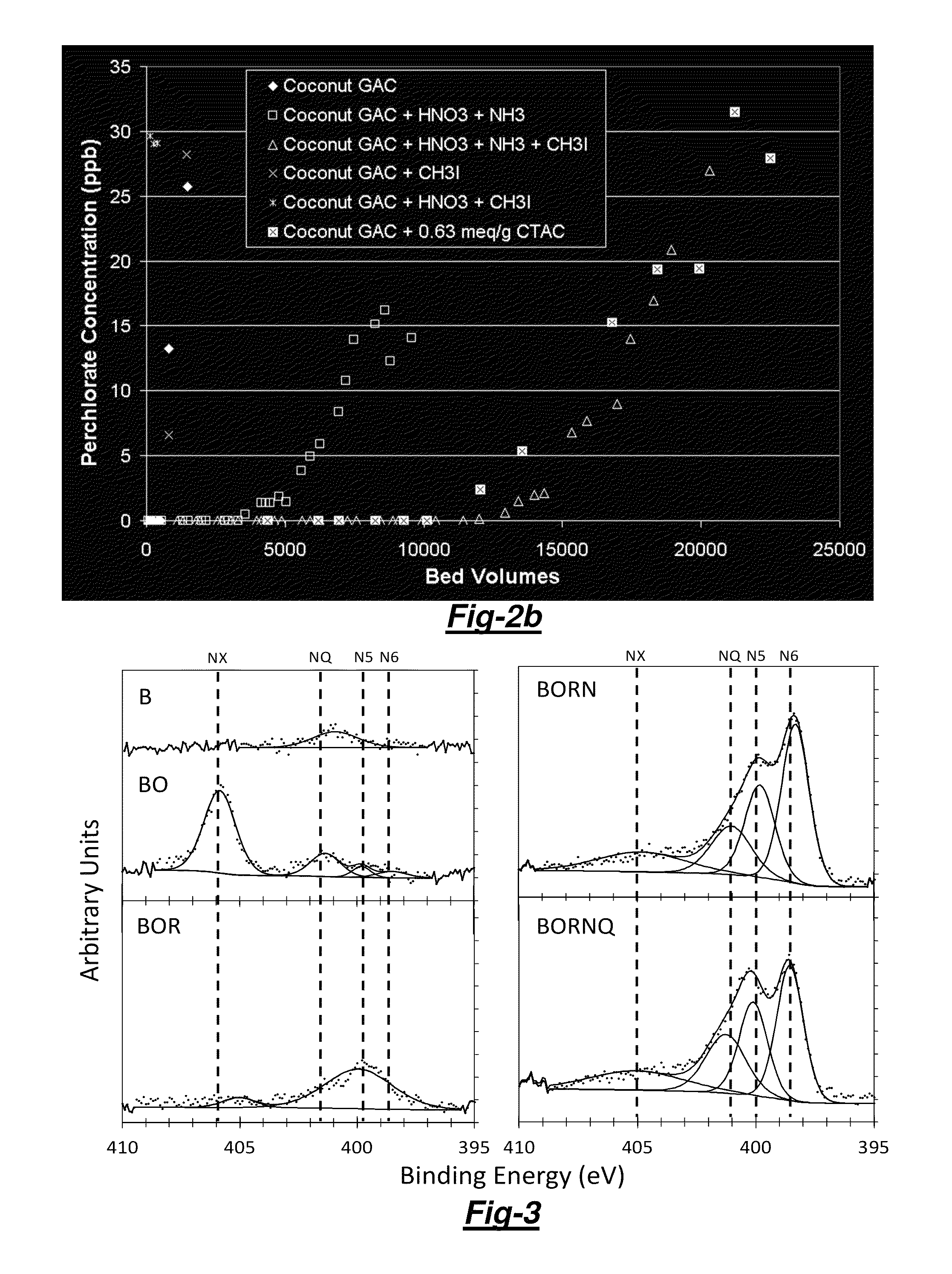

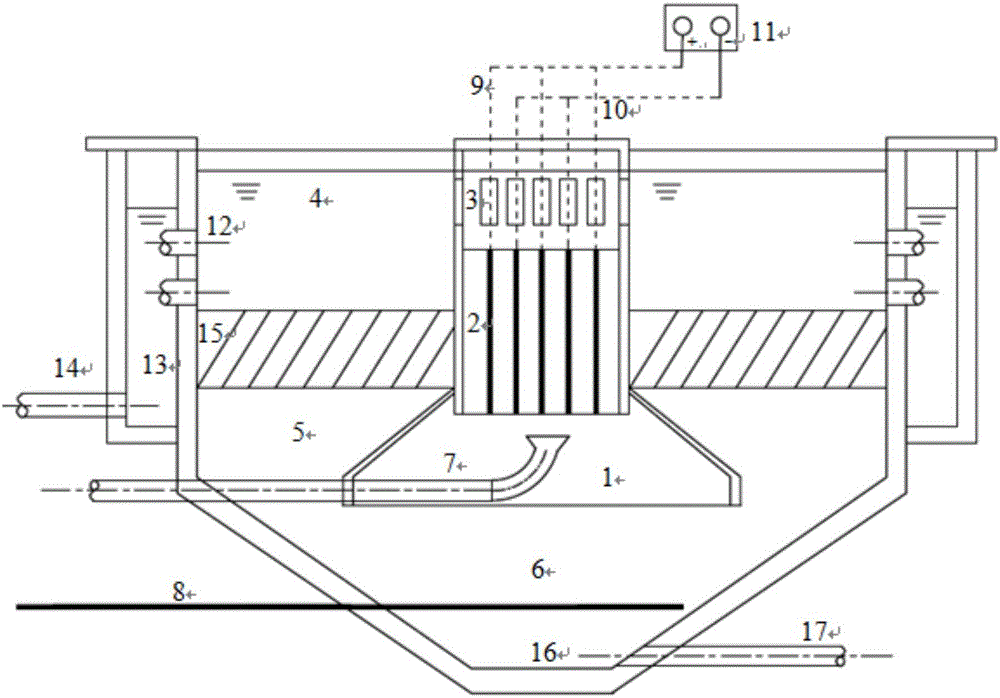

Nitrogen-containing activated carbon material

An activated carbon material for removing a contaminant from a liquid. The activated carbon material can be a plurality carbon grains that have a pore volume of approximately 0.1 milliliters per gram (mL / g) in the range of less than about 15 angstroms in width. The carbon grains can also have or contain a nitrogen-containing species having a concentration of more than 2 atomic percent nitrogen. A plurality of the carbon grains can be used to make a contactor that is operable to remove or reduce perchlorate having a concentration of 20 parts per billion (ppb) to less than 4 ppb from 4,500 bed volumes of water with the nitrogen-containing species leaching off of the carbon grains less than 0.1 mg / L. The activated carbon material can also be electrochemically regenerated.

Owner:PENN STATE RES FOUND

Electrochemical regeneration method of flue gas demercury adsorbing material

InactiveCN1559668AAvoid damageImprove featuresOther chemical processesDispersed particle separationResource recoveryFlue gas

An electrochemical process for regenerating the used adsorbent generated by demercurating fume includes such steps as treating it by oxidizing-reducing agent and complexing agent to form complexed Hg ions, applying an electric field to reduce the oxidized Hg to Hg, and modifying its surface by penetrating S, P and N.

Owner:SHANGHAI JIAO TONG UNIV

Process technique for pharmacy wastewater

InactiveCN101108762APlay a role in disinfectionLow costWater/sewage treatment by irradiationGeneral water supply conservationFiltrationActivated carbon filtration

The invention provides a process technology of the pharmaceutical wastewater, which has the steps as follows in turns: preprocess system, ozone disinfection, softening, cartridge filtration, one-pass RO, two-pass RO, ozone disinfection, 254nm ultraviolet disinfection, EDI, active carbon filtration, 185nm ultraviolet disinfection and terminal filter. The invention adopts the disinfecting method combining the ozone and the ultraviolet radiation. The 254nm ultraviolet disinfection can not only function as disinfection but also can remove the remnant ozone and save the ozone removing equipments. The invention adopts EDI instead of the mixed bed resin to realize regeneration while exchanging and produce pharmaceutical water with high quality continuously, and the amount of the ion exchange resin only equals to 5 per cent of the traditional process. Compared with the mixed bed resin, the EDI can realize the continuous effluent, save the regeneration time of the resin and increase the utilization rate of the equipments. The invention combines the EDI and the RO, which effectively reduces the raw water hardness and is beneficial for the EDI membrane stack to operate stably for a long period; at the same time, the invention is beneficial for the fresh chamber water to dissociate and produce enough H+ and OH+, thereby realizing the electrochemical regeneration of the ion exchange resin.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

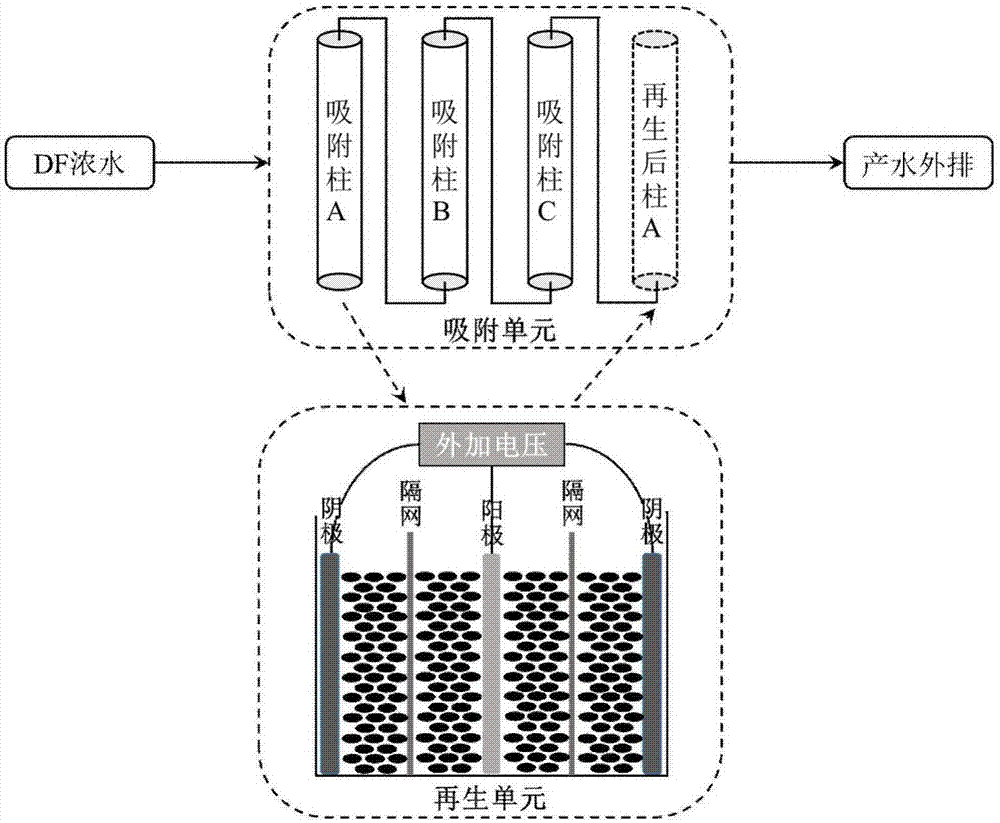

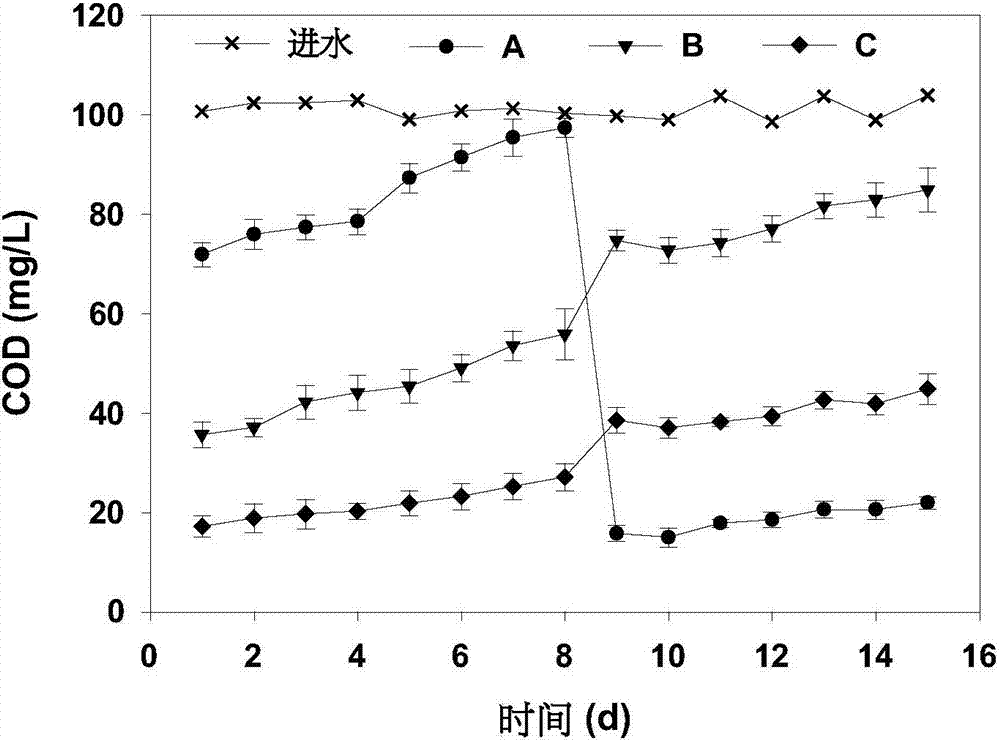

Activated carbon adsorption-electrochemical regenerating method for treating non-degradable organic wastewater

InactiveCN107055670AAdvantages of three-dimensional electrode electrolysis regeneration methodHigh yieldSpecific water treatment objectivesCombustible gas purificationActivated carbonWastewater

The invention discloses an activated carbon adsorption-electrochemical regenerating method for treating non-degradable organic wastewater. The method comprises the following steps: serially connecting an adsorption column A, an adsorption column B and an adsorption column C; filling the adsorption columns with activated carbon loading Fe and Mn catalysts, adsorbing organics in concentrated water and directly discharging generated water which reaches level A emission standard; monitoring the COD of discharged water of each column; after the first adsorption column A is penetrated through, namely, the discharged water COD of the first adsorption column A is equivalent to the entering water COD, regenerating activated carbon in the first adsorption column A with the second adsorption column B as the first adsorption column, the third adsorption column C as the second adsorption column and the adsorption column A filled with regenerated activated carbon as the third adsorption column, and continuously adsorbing organics in the concentrated water.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

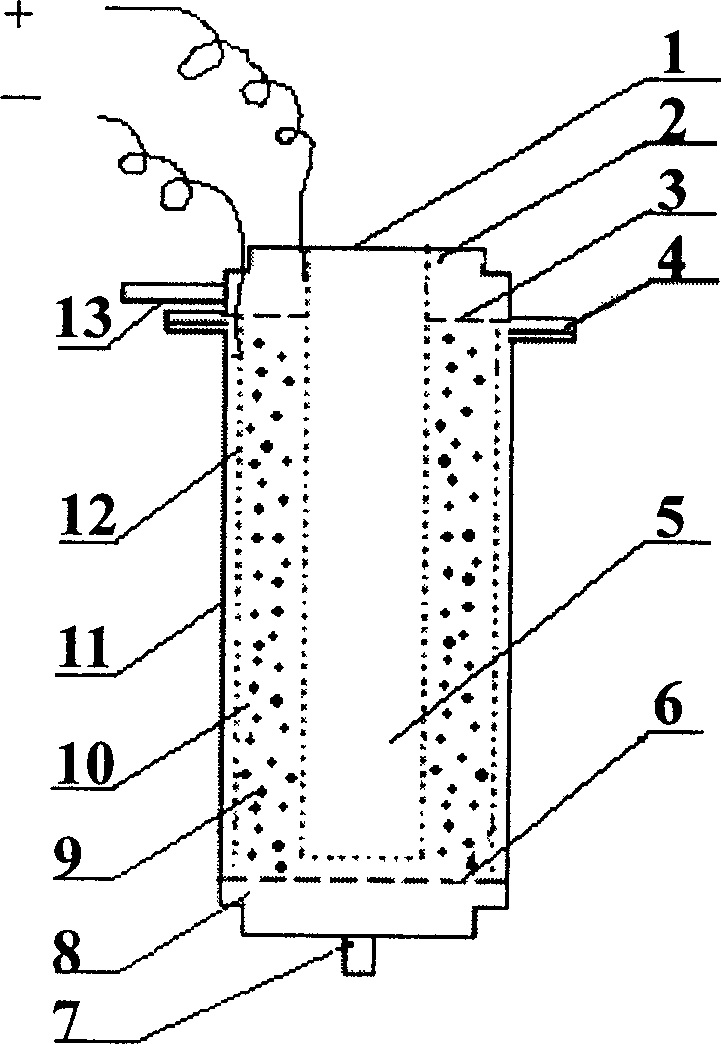

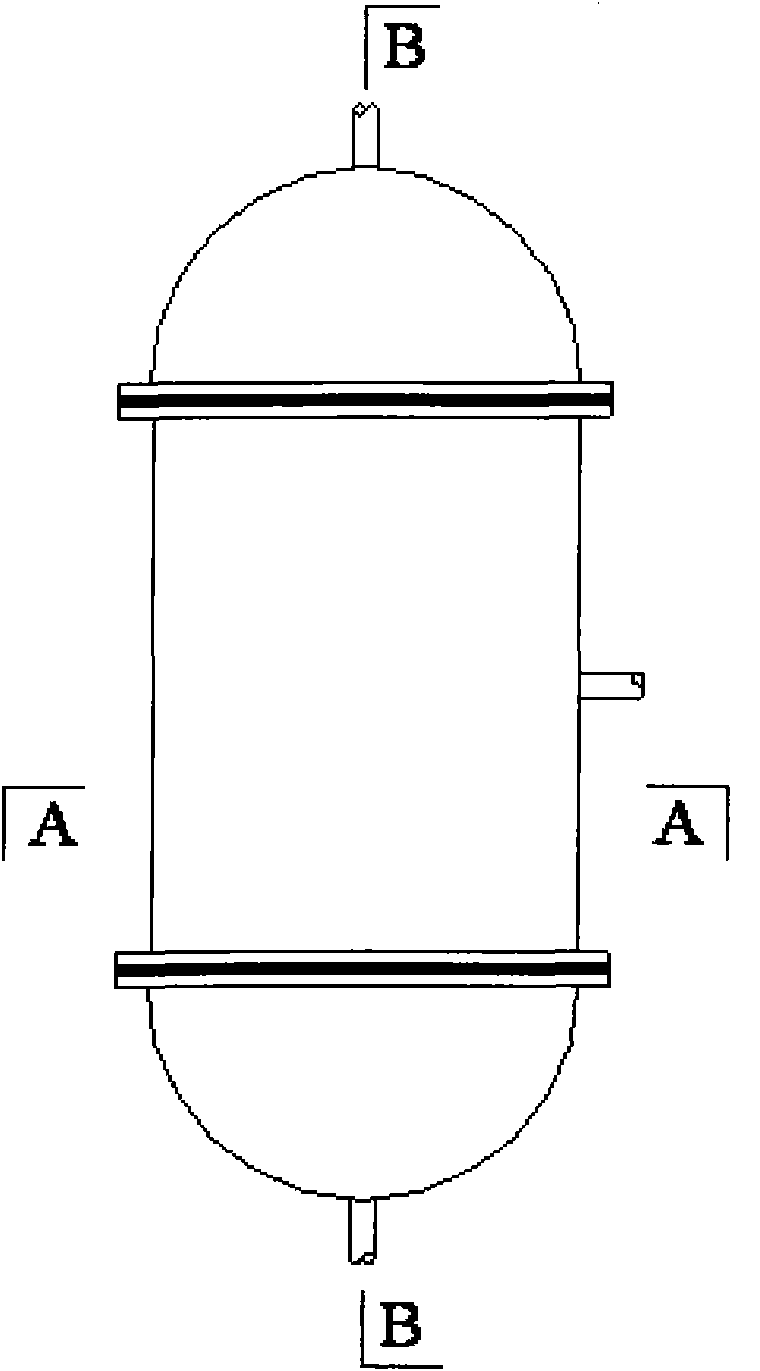

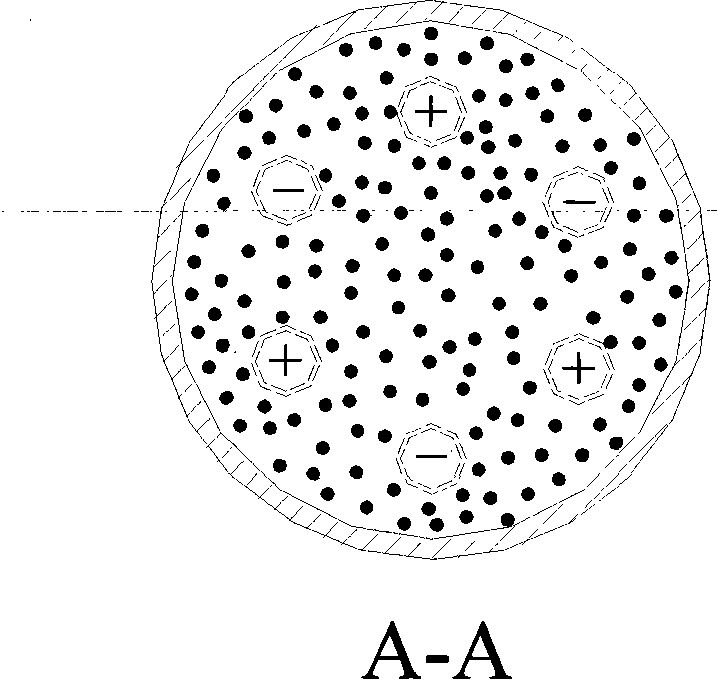

Electrochemical regenerator and regenerating method for activated carbon

InactiveCN1613552AAchieve regenerationEfficient degradationOther chemical processesCombustible gas purificationElectrochemical responseElectricity

An electrochemical device for regenerating activated carbon is composed of a casing, the first and the second hydraulic distribution plates for dividing the internal space of casing into water outlet chamber, electrochemical reaction chamber and water inlet chamber, the cathode on the inner surface of said electrochemical reaction chamber, and the central anode. Its regenerating method includes such steps as filling the activated carbon to be regenerated in the space between said anode and cathode, pumping the electrolyzing liquid into water inlet chamber to force it to flow from bottom to top for degradating the organic pollutant on the surface of activated carbon by the strong oxidizing substance generated by electric catalyzing.

Owner:ZHEJIANG UNIV

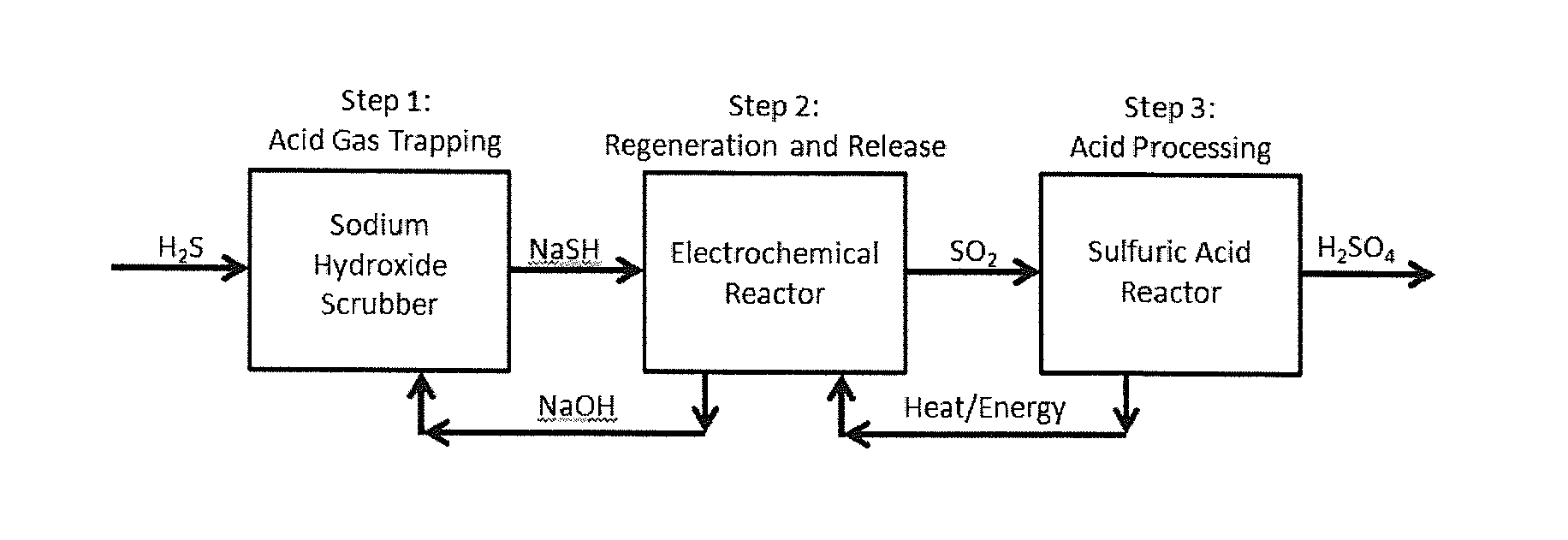

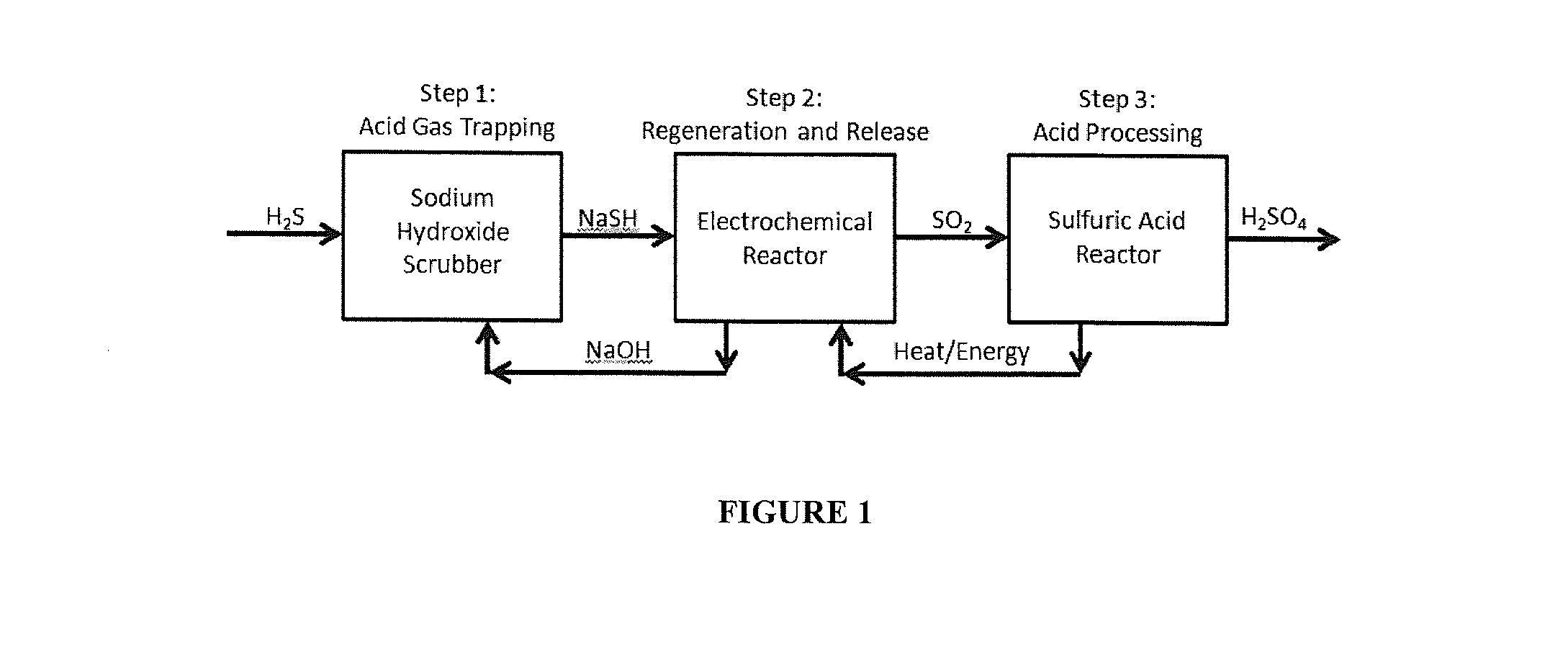

Treatment of hydrogen sulfide

ActiveUS20150322580A1Low costWeaken energyGas treatmentPhotography auxillary processesSodium hydrosulfidePolysulfide

A chemical process captures and convert hydrogen sulfide (H2S) gas into elemental sulfur, polysulfide, sulfur dioxide and / or sulfuric acid while regenerating sodium hydroxide capture agent for further use in an initial H2S capture step. Processing may include initial sodium hydroxide scrubbing of gas streams containing H2S, electrochemical regeneration of the sodium hydroxide from sodium hydrosulfide or sodium sulfide, recovery of sulfur and / or sulfur dioxide from the electrochemical processing, and production of sulfuric acid from such sulfur and / or sulfur dioxide.

Owner:SULFURCYCLE INTPROP HLDG CO LLC

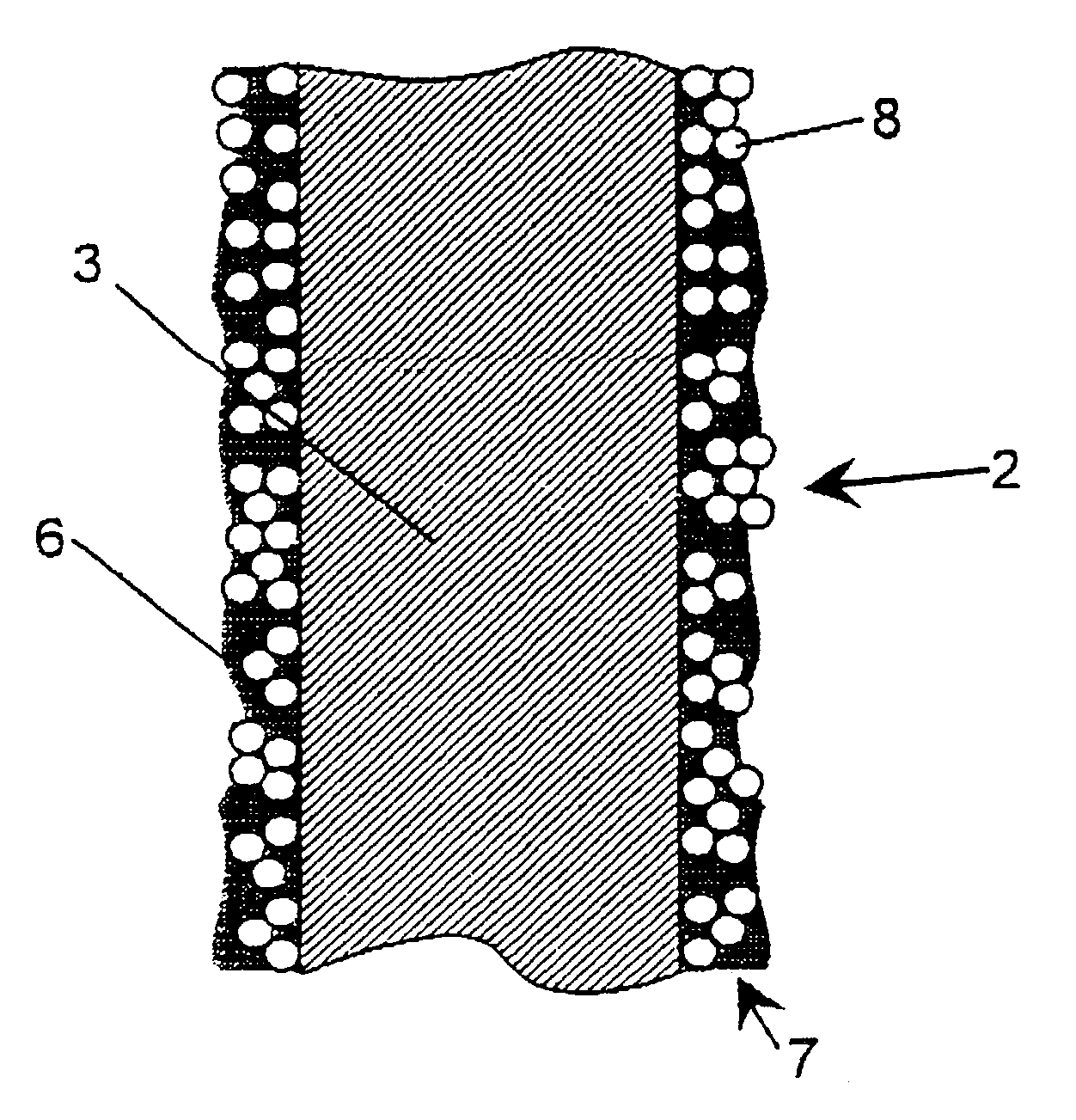

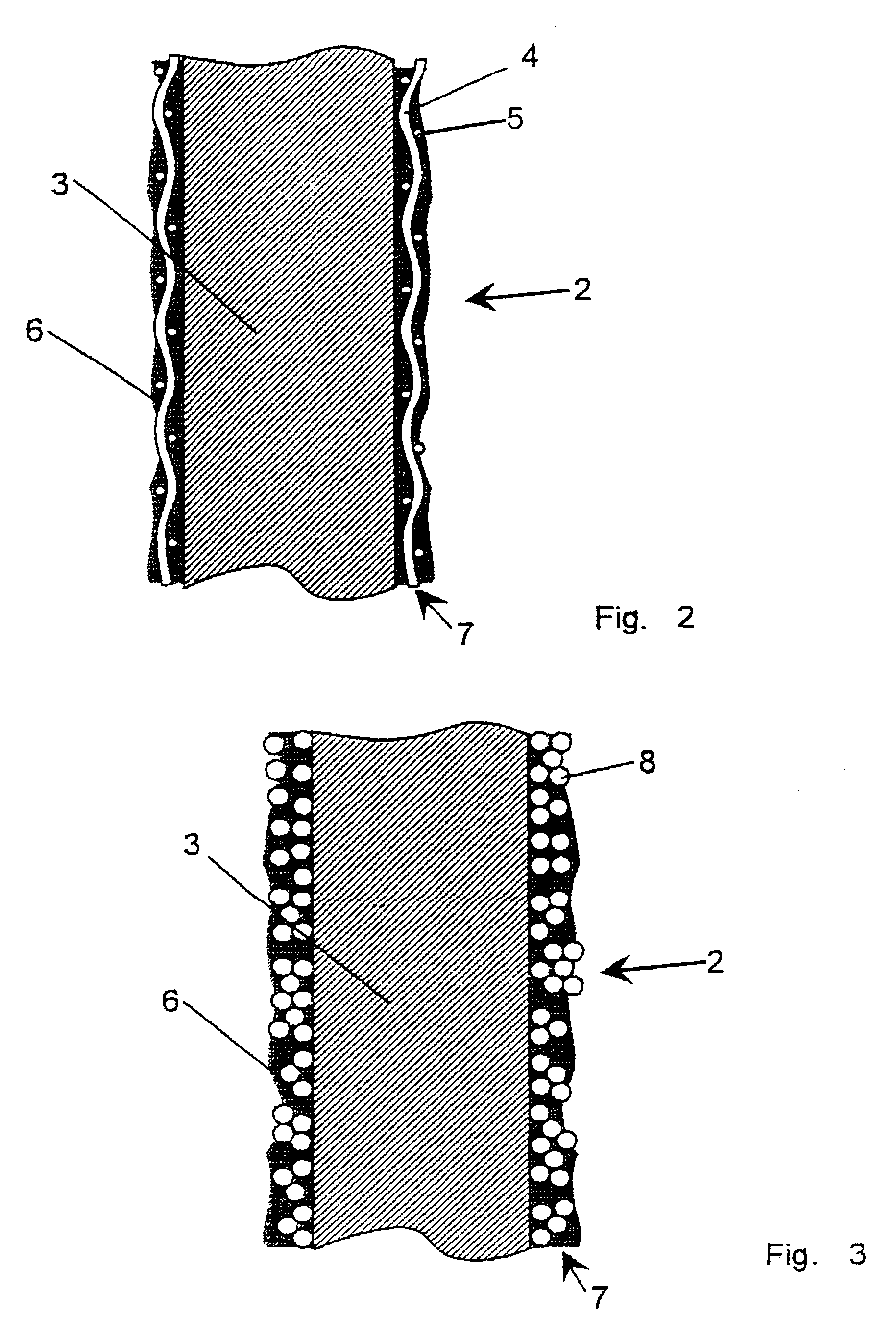

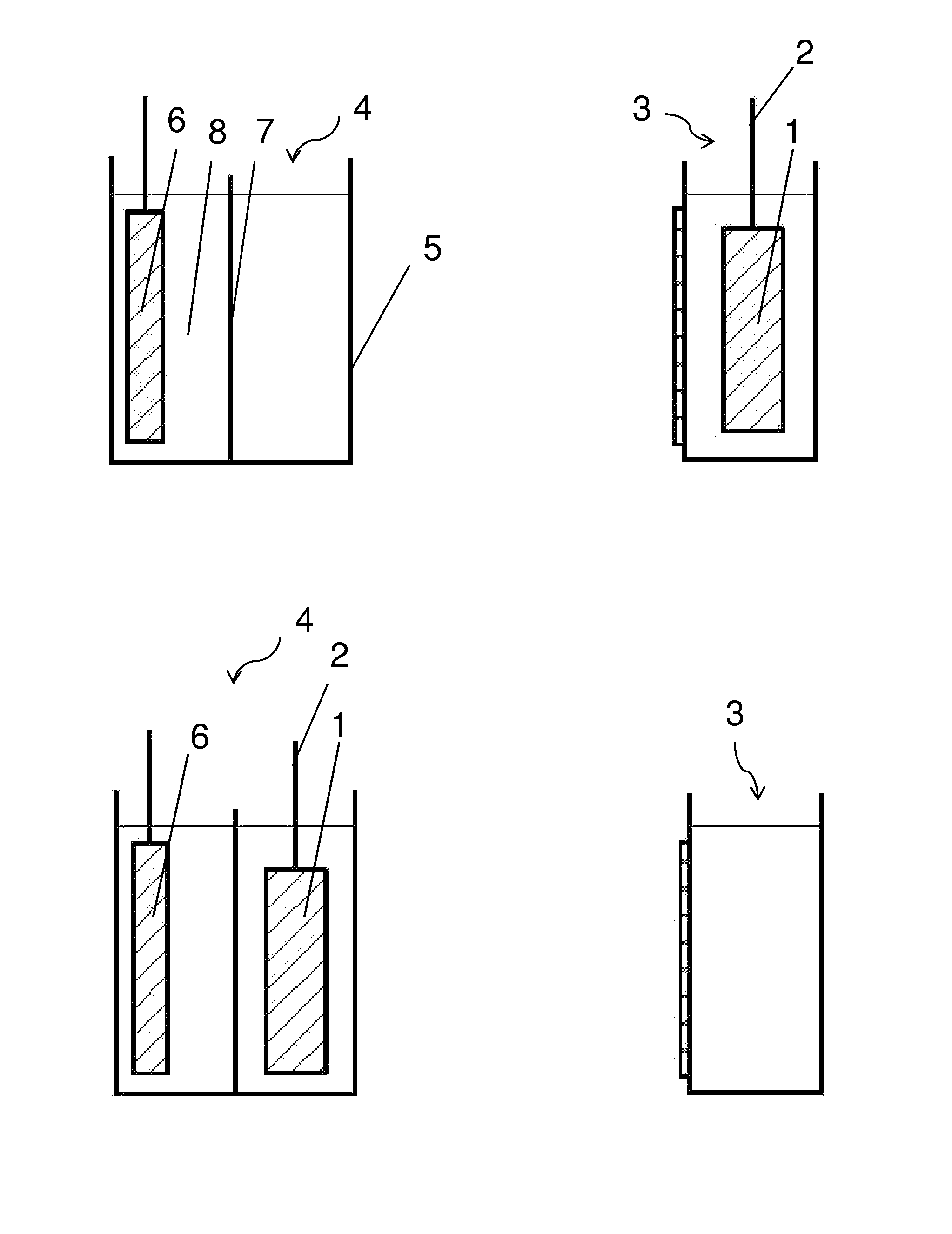

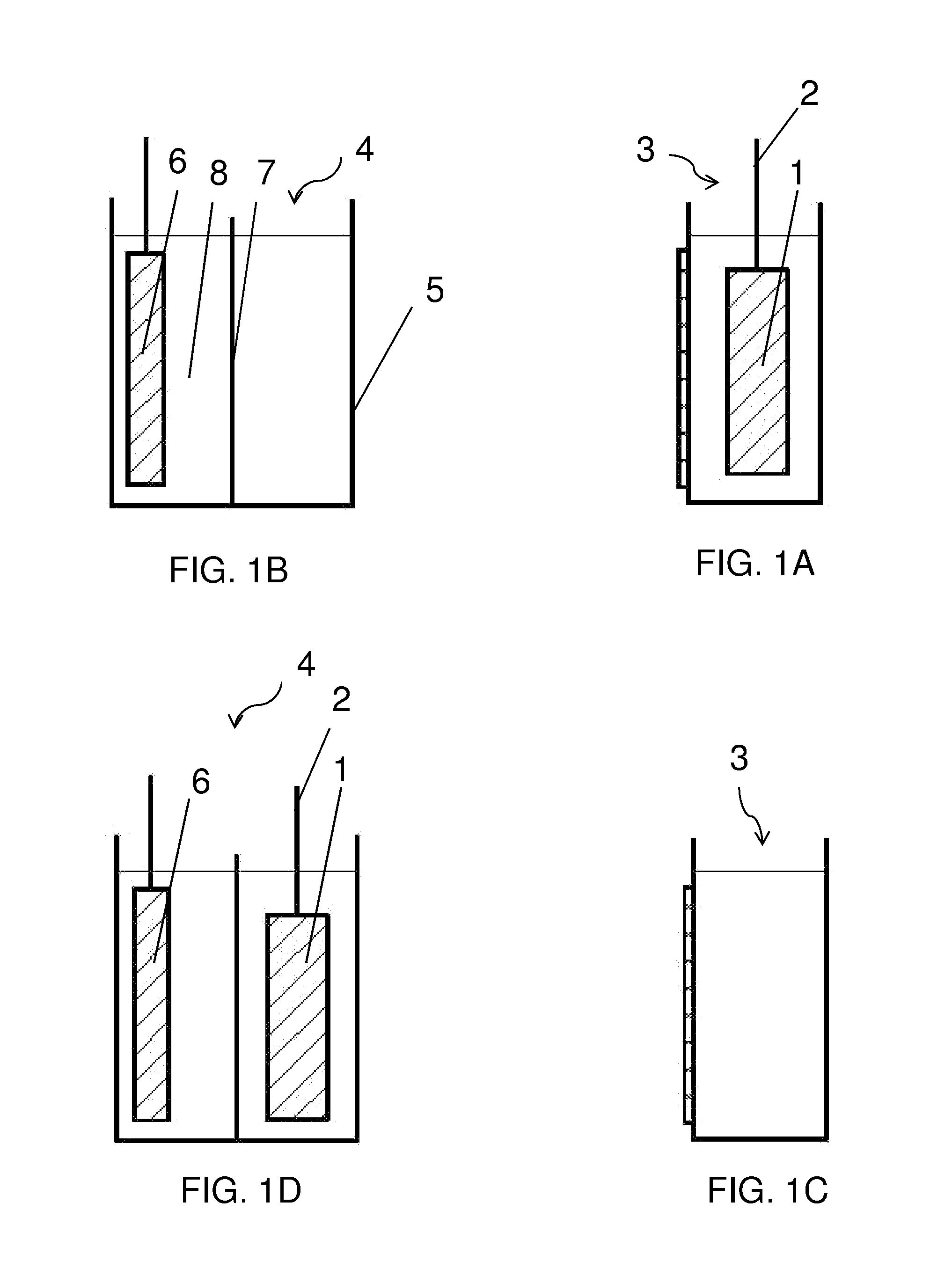

Cathode for electrochemical regeneration of permanganate etching solutions

InactiveUS7056424B2Good effectImprove regeneration efficiencyCellsMachining electrodesElectrolysisEtching

In order to regenerate permanganate solutions being utilized for the etching and roughening of plastics surfaces electrolytic methods are known. Though relatively small quantaties of by-products are produced with these methods as compared to chemical regeneration methods, large quantaties of manganese dioxide are produced when printed circuit boards are treated. In order to avoid formation of manganese dioxide during the regeneration method a novel cathode 2 has been found which is provided with a porous, electrically nonconducting layer 7 on the cathode body 3. The layer 7 preferably consists of a plastics material being resistant to acid and / or alkali.

Owner:ATOTECH DEUT GMBH

Integrated treatment device for active carbon adsorption and electrochemical regeneration and use method thereof

InactiveCN101891331ALong life cycleEmission reductionWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentFiltrationColloidal particle

The invention discloses an integrated treatment device for active carbon adsorption and electrochemical regeneration and a use method thereof, which is characterized in that the device is equipped with an adsorption column filled with granular active carbon and an equivalent microporous titanium filter element electrode array fixed on a flange of the adsorption column, and the device is multifunctional water treatment equipment integrating adsorption filtration with electrochemical treatment together. When fluid flows, adsorption and filtration are carried out, and impurities such as organic matters, suspended matters, colloidal particles and the like are removed by purification; and an electric field parallel to a flow field is applied, thus impurities such as organic pollutants, inorganic particles and the like adsorbed on the surface of the active carbon and in a pore path can be decomposed and removed simultaneously under the coupling action of an electric field force and a water flow drag force to inhibit scale generation, maintain purification effect and prolong life cycle of the active carbon. The invention solves the bottleneck problem of continuous utilization and lowers cost of continuous utilization and carbon emission.

Owner:DALIAN JIAOTONG UNIVERSITY

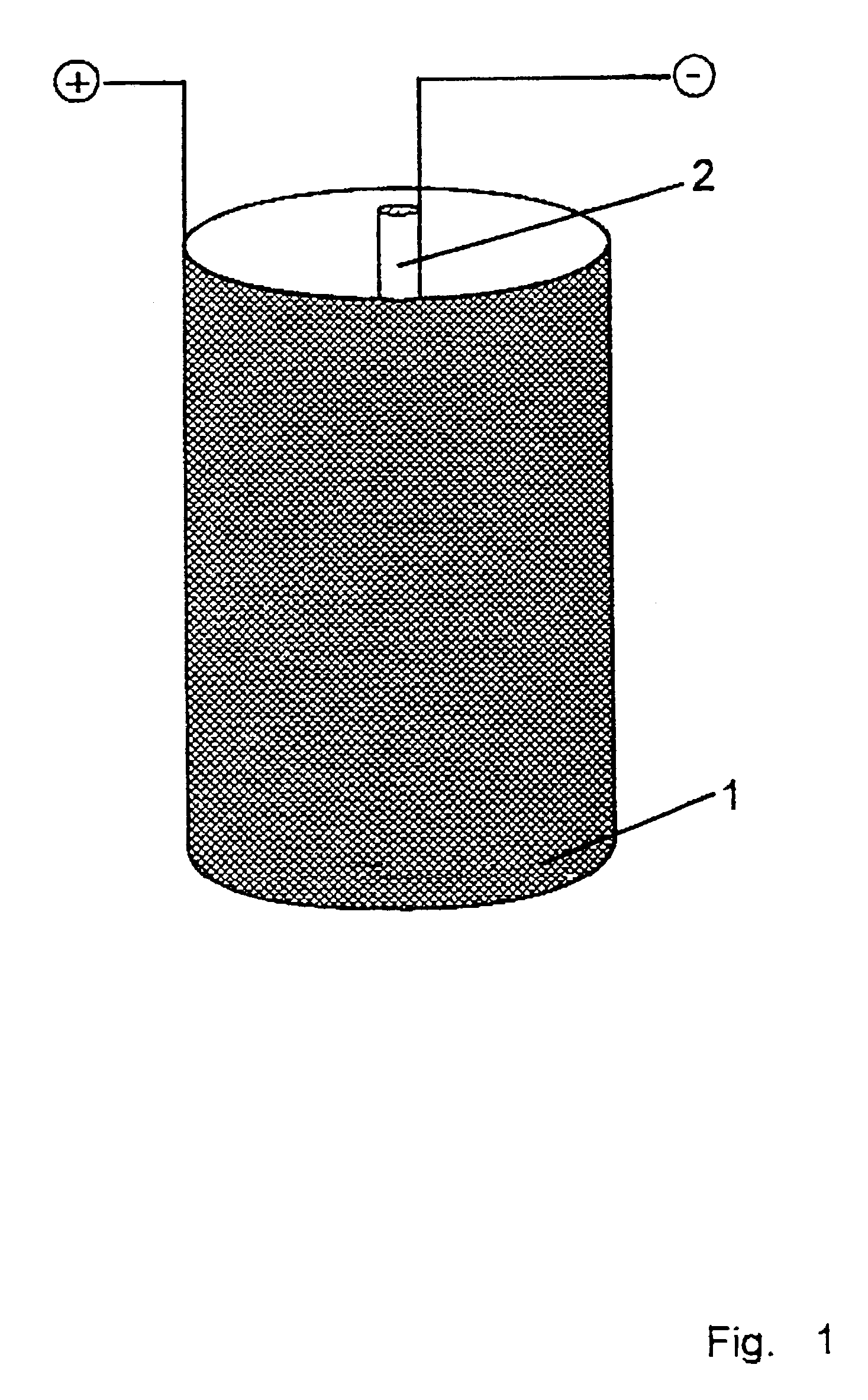

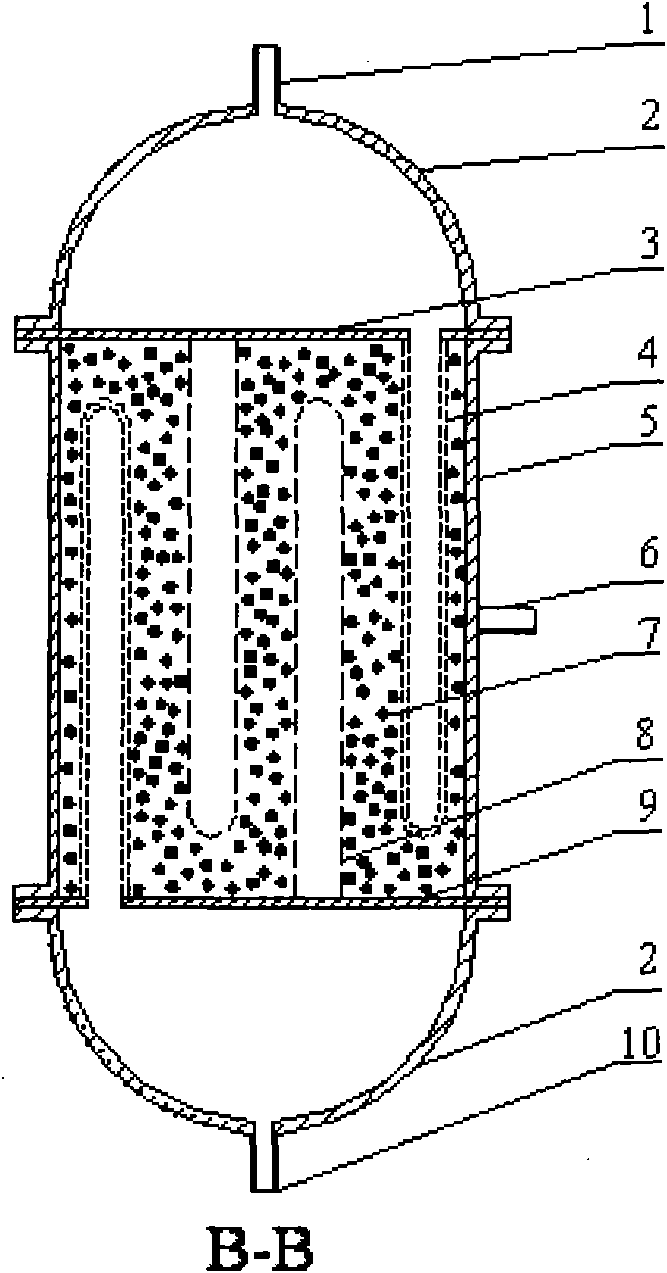

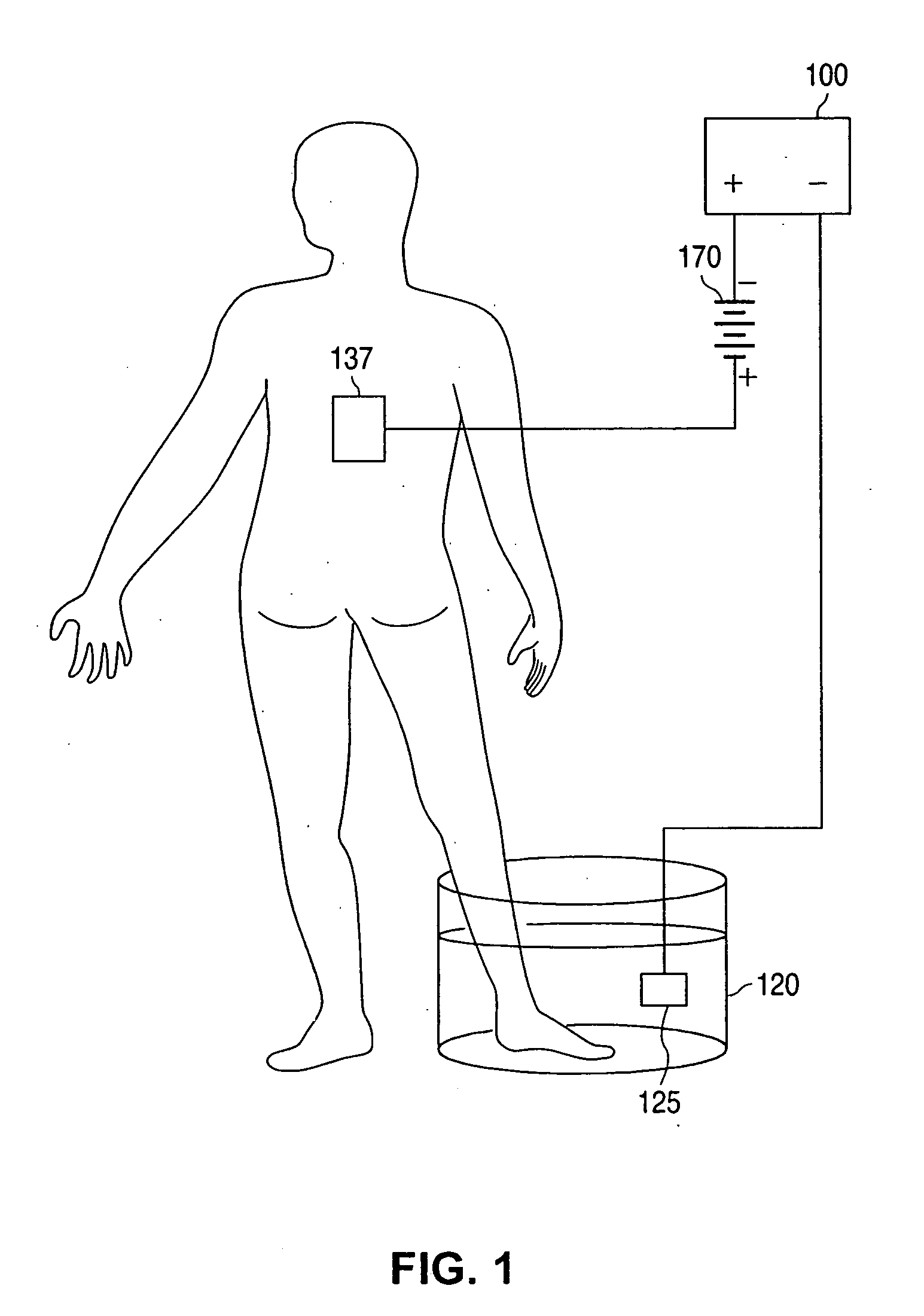

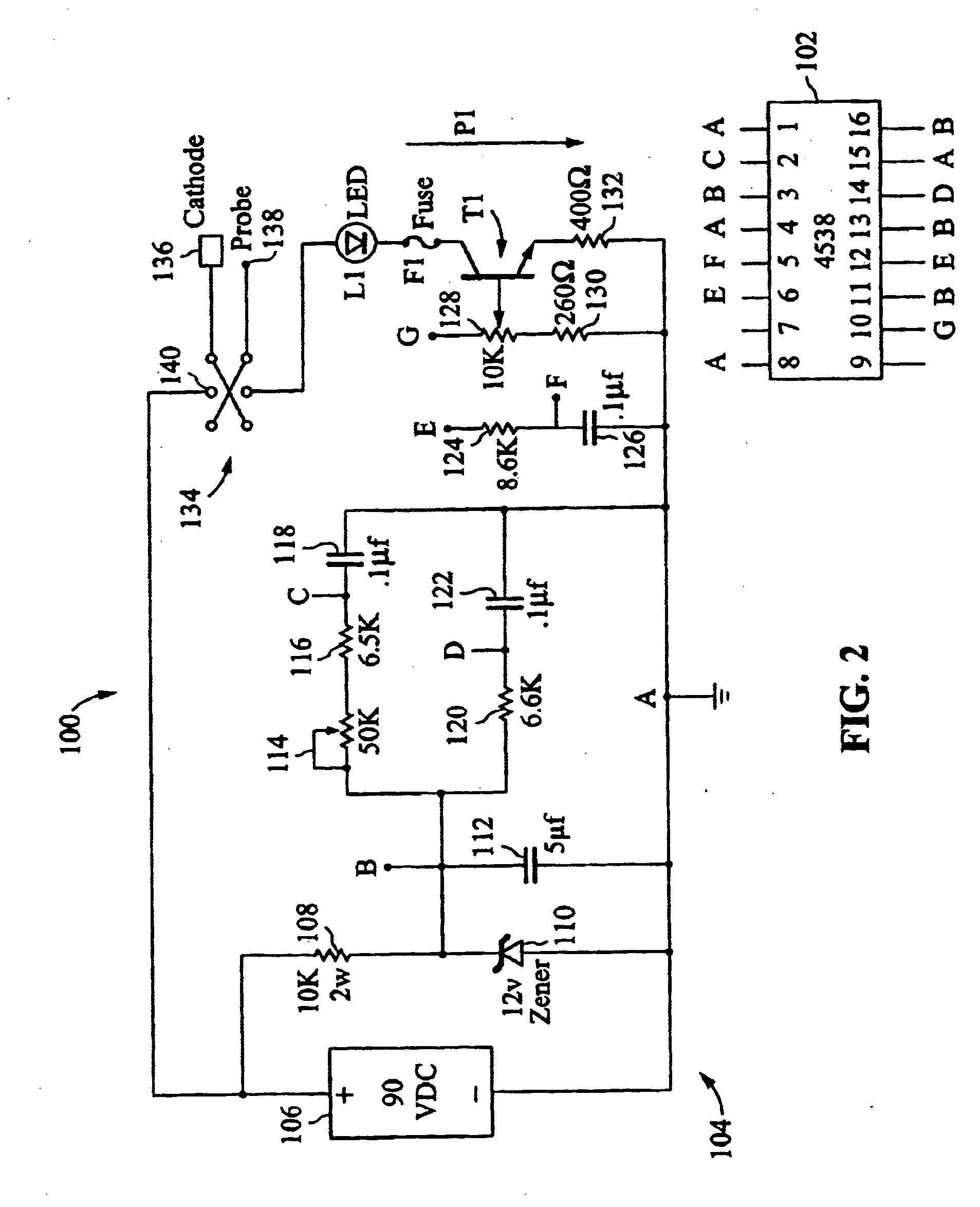

Method and device for electrochemical rejuvenation of skin and underlying tissue, and muscle building

InactiveUS20060253165A1Reduce corrosionOxidative corrosion of the battery reducesElectrotherapyEngineeringCurrent amplitude

A method and device are disclosed for using electrochemistry to rejuvenate skin and underlying tissue and to build and strengthen muscles by applying pulses of DC electrical charge, at a duration in the range of about 0.2 to about 1 millisecond and a variable frequency in the range of about 400 to about 1200 Hertz, to the skin immersed into an container of an electrolyte by means of an anode immersed in or connected to the container to cause the muscle to twitch or only slightly contract with each pulse. The DC is applied at variable current amplitude of from about 1 to about 50 milliamperes, and a voltage in the range of about 50 to about 120 volts.

Owner:OKELLY GREGORY

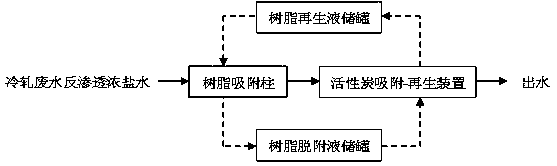

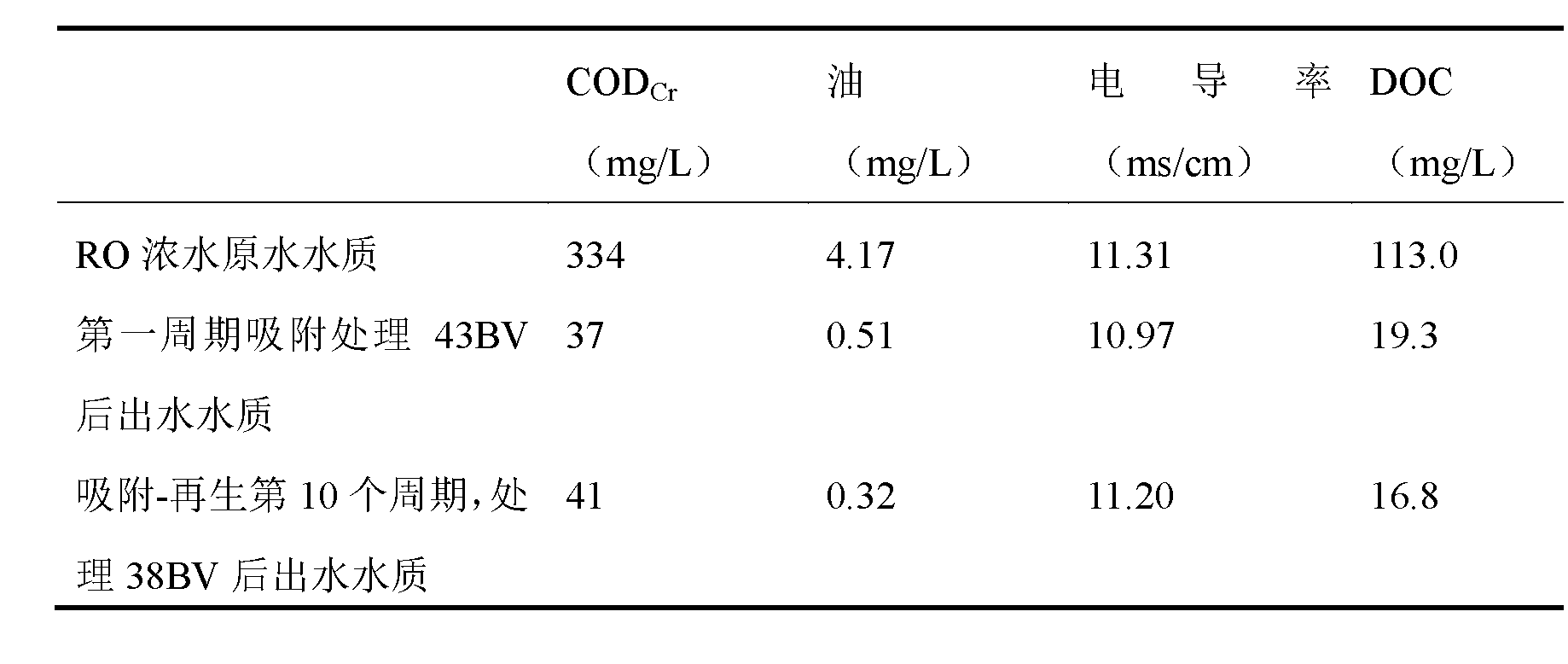

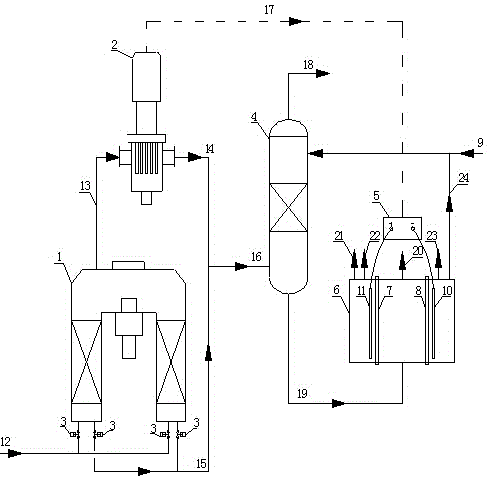

Reverse-osmosis strong brine treatment device and method for cold rolling wastewater

ActiveCN108439540AAchieve reuseOther chemical processesWater contaminantsChemical oxygen demandDesorption

The invention discloses a reverse-osmosis strong brine treatment device and method for cold rolling wastewater. The device comprises a resin adsorption column, an activated carbon adsorption-regeneration device, a resin regeneration liquid storage tank and a resin desorption liquid storage tank. According to the reverse-osmosis strong brine treatment device and method, selective ion exchange resinis used for adsorbing to remove nitrate in wastewater; granular coconut shell activated carbon is used for adsorbing to remove organic matters in the wastewater. Desorption liquid generated by regenerating nitrate adsorption resin is used as an electrolyte solution for electrochemical regeneration of the activated carbon, and the nitrate in the desorption liquid is removed in an electrochemical regeneration process of the activated carbon; the desorption liquid can be used as resin regeneration liquid to be repeatedly utilized. According to the device and method, disclosed by the invention, COD (Chemical Oxygen Demand) and total nitrogen of output water can meet the requirements of emission standards and are not influenced by factors including high salt content, high hardness and the likein strong brine.

Owner:上海东振环保工程技术有限公司

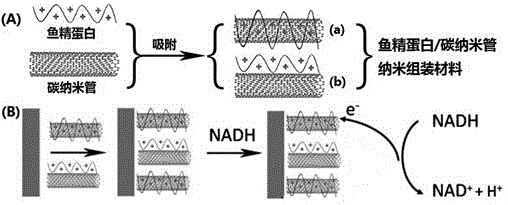

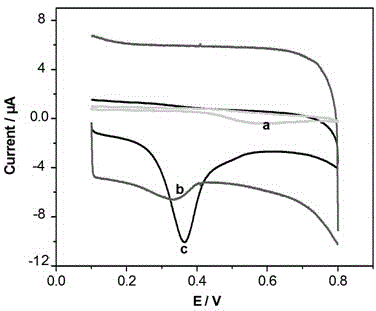

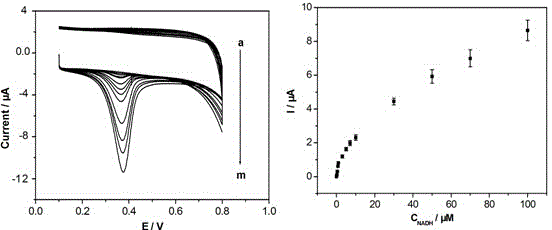

Dehydrogenase electrode and preparation method thereof

ActiveCN104132982ALittle loss of enzyme activityWide detection concentration rangeMaterial analysis by electric/magnetic meansCarbon nanomaterialsBiological macromolecule

The invention provides a dehydrogenase electrode and a preparation method thereof. The dehydrogenase electrode comprises a base electrode, an electron conduction layer coating the base electrode and a dehydrogenase layer coating the electron conduction layer. The electron conduction layer comprises a bionic nanocomposite material. The dehydrogenase layer comprises a bionic nanocomposite material / dehydrogenase compound. The preparation method comprises the following steps of a, coating the base electrode with an ultrasonically dispersed suspending liquid of a carbon nano-material and a biomacromolecule so that the electron conduction layer is obtained, and b, adding dehydrogenase into the suspending liquid, carrying out ultrasonic treatment to obtain a cured dehydrogenase system, and dropwisely coating the electron conduction layer with the cured dehydrogenase system so that the dehydrogenase layer is obtained. The dehydrogenase electrode can realize coenzyme electrochemical regeneration at low potential and has the advantages of operation simpleness, high detection sensitivity, good electrode stability and reappearance and small enzyme activity loss.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

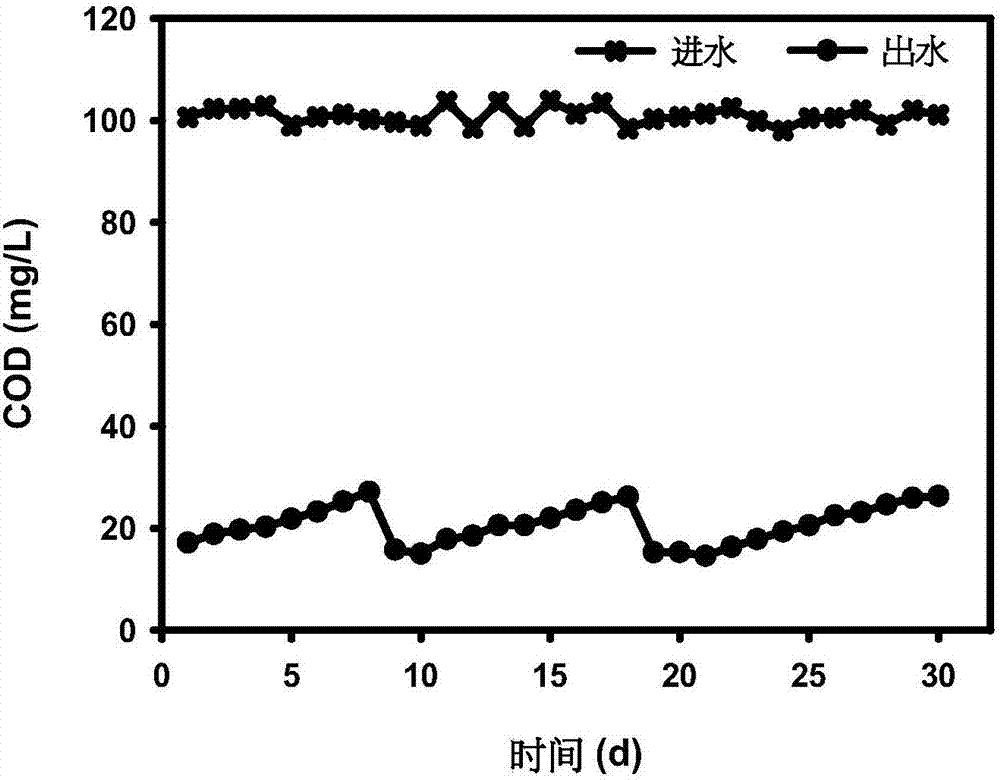

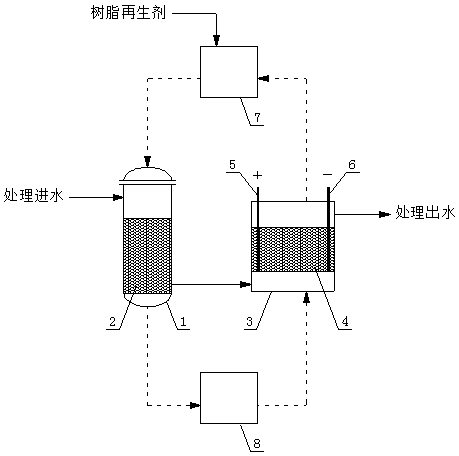

Method for reverse osmosis concentrated water by adsorption-regeneration circular treatment

ActiveCN103214056ARealize automatic controlLess investmentWater/sewage treatment by sorptionAfter treatmentChemical oxygen demand

The invention discloses a method for reverse osmosis concentrated water by adsorption-regeneration circular treatment, belonging to the field of advanced wastewater treatment. An adsorption-regeneration combination treatment process is adopted, the advanced treatment problem of reverse osmosis concentrated water is solved, the COD (Chemical Oxygen Demand) of inlet water is 150-300mg / L, the COD of the outlet water is less than or equal to 50mg / L after treatment. According to the combination process, adsorption treatment is adopted as the main, an electrochemistry regeneration manner is adopted to recover the adsorption capacity on a saturation adsorption material, the adsorption-regeneration combination treatment process is realized, and the treatment cost of the reverse osmosis concentrated water is greatly reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for electrochemically regenerating zeolite subjected to anerobic biochemical treatment and ammonia nitrogen adsorption

InactiveCN102190399AEasy loadingEasy to pourMultistage water/sewage treatmentCombustible gas purificationEnvironmental resistanceAmmoniacal nitrogen

The invention belongs to the technical field of environmental protection, and relates to a method for electrochemically regenerating zeolite subjected to anerobic biochemical treatment and ammonia nitrogen adsorption. The method comprises the following steps of: contacting pretreated town sewage with high-activity anaerobic sludge in a reactor, degrading organic pollutants in the sewage into final products such as CH4, CO2, H2O and the like by using various microbes in the anaerobic sludge, and performing electrochemical regeneration. By the method, the zeolite regeneration time is short; moreover, the ammonia nitrogen is oxidized into nitrogen and other substances in the electrochemical process, so the difficulty in treating used regenerated liquid is overcome to realize ammonia-nitrogen-free emission. Compared with bio-regeneration method and the like, the method has the advantages of small occupied area, simple operation and larger development space, and can fulfill the aims of recycling energy and saving energy.

Owner:FUDAN UNIV

Aerating and electrochemical regenerating method for activated carbon fiber

InactiveCN104043439AEasy to operateSolve the problem of large external diffusion and mass transfer resistanceCombustible gas purificationFilter regenerationFiberActivated carbon

The invention discloses an aerating and electrochemical regenerating method for an activated carbon fiber and relates to an electrochemical regenerating technology for an activated carbon adsorption material. The gas film diffusion resistance caused by the fact that an adsorbing agent adsorbs a gas product is greatly reduced by virtue of an aerating pipe and a distributor, and the regenerating effect and the COD (chemical oxygen demand) removal rate are improved. In the regenerating process, the activated carbon fiber adsorbing phenol to be saturated is arranged in an anode area or is dispersed in an electrolyte, the adsorbing agent is taken out after the activated carbon fiber is treated, the activated carbon fiber is washed and dried, and the subsequent adsorbing-regenerating cyclic operation can be carried out. Compared with other regenerating processes, the aerating and electrochemical regenerating method has the advantages that equipment is simple; the conditions are mild; the operation is convenient; large loss caused by the activated carbon fiber in the regenerating process can be effectively avoided; by additionally arranging an aerating device, the problem of large diffusion medium transfer resistance can be solved in a targeted mode, and the regenerating efficiency is improved.

Owner:扬州市形易得光电科技有限公司

Electrochemical regeneration treatment method for waste lubricating oil

ActiveCN105505551AQuality improvementTo achieve the separation effectLubricant compositionParticulatesAfter treatment

The invention relates to an electrochemical regeneration treatment method for waste lubricating oil and belongs to the technical field of waste oil regeneration. The invention aims at providing an electrochemical regeneration treatment method for waste lubricating oil with simple technology, high quality, excellent performance and high yield. The electrochemical regeneration treatment method for the waste lubricating oil comprises the following steps: adding the waste lubricating oil and tetrahydrofurfuryl carbinol into a reactor, externally applying voltage for carrying out electrochemical treatment, so that impurity particles are clustered at the periphery of an electrode and form floccules, and then directly separating out a liquid oil phase; and carrying out phase separation on the obtained liquid oil phase, and then carrying out after treatment, so that the regenerated lubricating oil is obtained. The electrochemical regeneration treatment method for the waste lubricating oil has the advantages that particulate matters in the waste lubricating oil can be well clustered and enlarged, so that a separating effect is realized; and total metal content can be controlled to be less than 180ppm, total ash removal rate can be controlled to be more than 90%, and phosphorus removal rate can be controlled to be more than 95%.

Owner:TAIZHOU UNIV

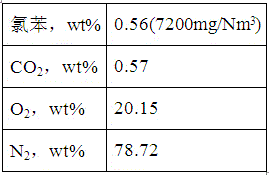

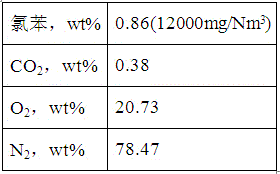

Comprehensive treatment method and comprehensive treatment apparatus for high-concentration chlorine-containing organic waste gas

ActiveCN106731562AReduce dosageReduce secondary pollutionGas treatmentDispersed particle separationHigh concentrationFlue gas

The invention discloses a comprehensive treatment method for high-concentration chlorine-containing organic waste gas. The comprehensive treatment method comprises: (1) introducing waste gas into a heat storage oxidation reactor, oxidizing, and controlling the temperature of the flue gas outlet of an oxidation bed layer at less than 100 DEG C; (2) leading out the obtained high temperature flue gas excluding the high temperature flue gas for maintaining heat storage reaction energy balance from the middle portion high temperature zone of the reactor, entering a Stirling generator, and controlling the temperature of the flue gas outlet after the electricity generation at less than 100 DEG C; (3) mixing the flue gases discharged in the step (1) and the step (2), conveying the mixed flue gas into an alkali liquid absorption tower, completely absorbing the acid gas in the flue gas, decreasing the flue gas temperature to less than 60 DEG C, and discharging the purified gas meeting the standard; and (4) conveying the absorption waste liquid into an electrochemical regeneration device, wherein the regenerated alkali liquid returns to an alkali washing absorption tower so as to be recycled. According to the present invention, the purified gas after the treatment can achieve the discharging standard, the waste of a lot of energy cannot be caused, the subsequent treatment does not require the arrangement of the cooling device, a large amount of absorption waste liquid cannot be produced, and the economy is improved remarkably.

Owner:CHINA PETROLEUM & CHEM CORP +1

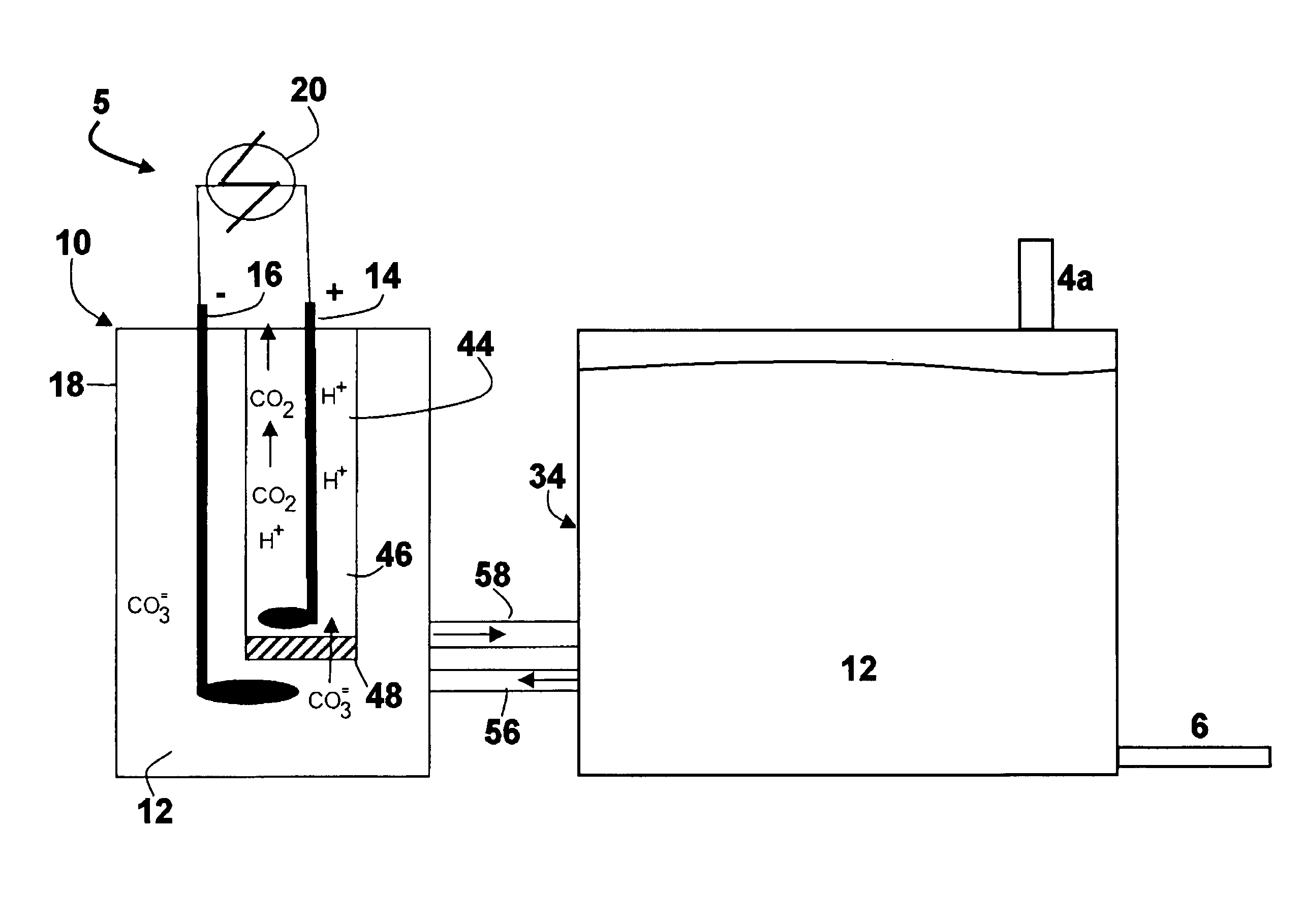

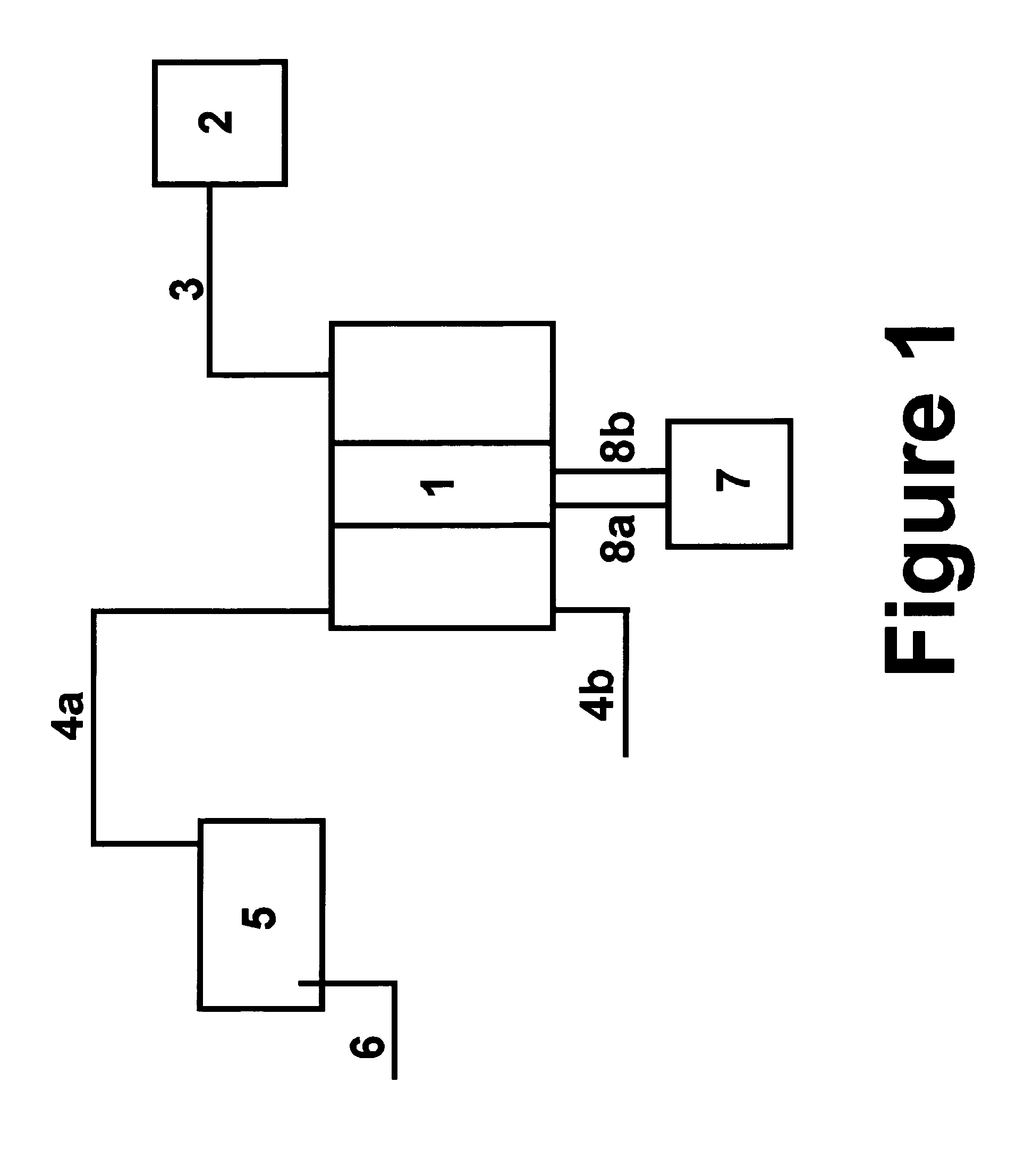

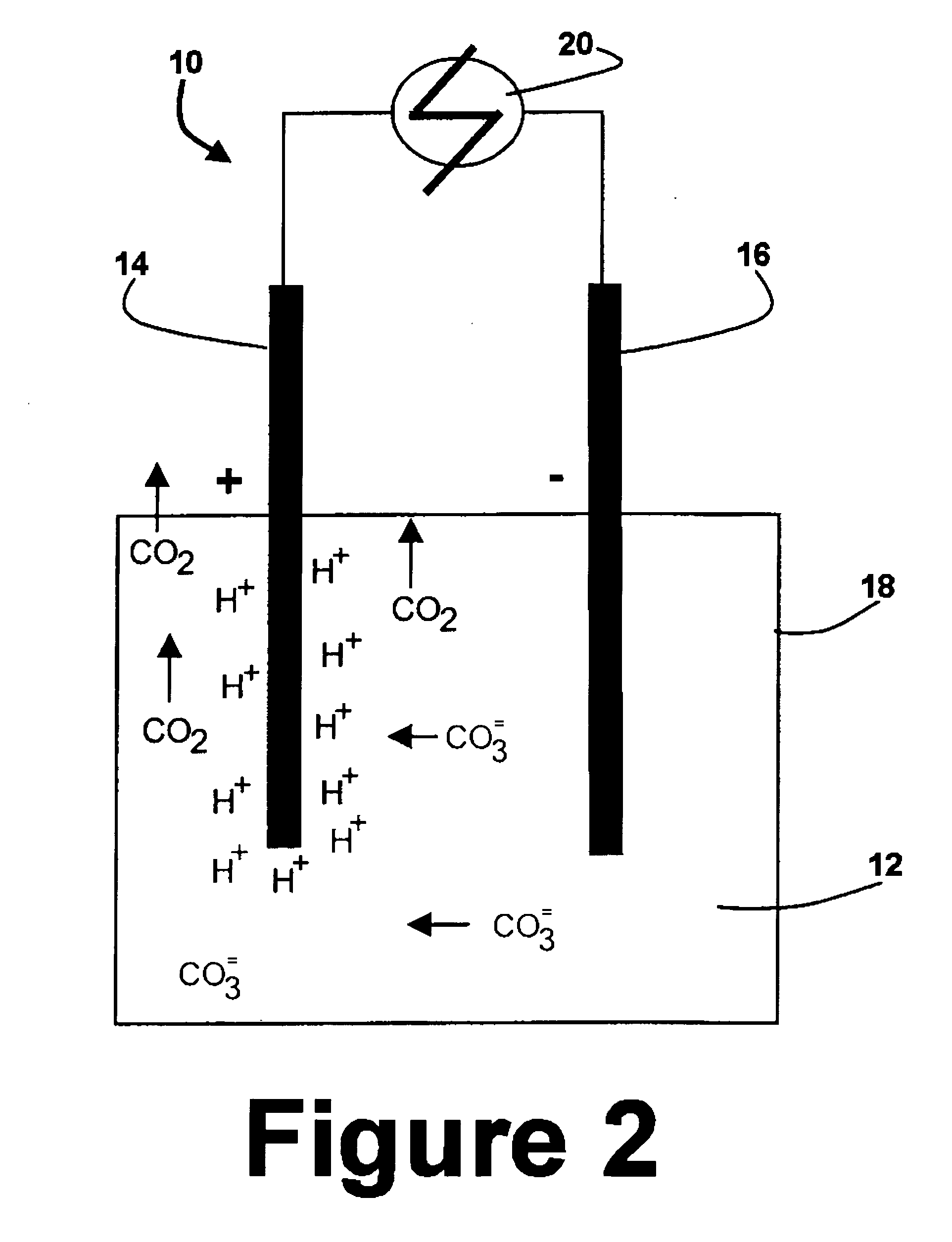

Remote emergency power unit having electrochemically regenerated carbon dioxide scrubber

An emergency power system is provided in accordance with an exemplary embodiment of the present invention. The emergency power system includes a fuel cell and an electrochemically regenerated air scrubber which removes carbon dioxide from air.

Owner:ENERGY CONVERSION DEVICES INC

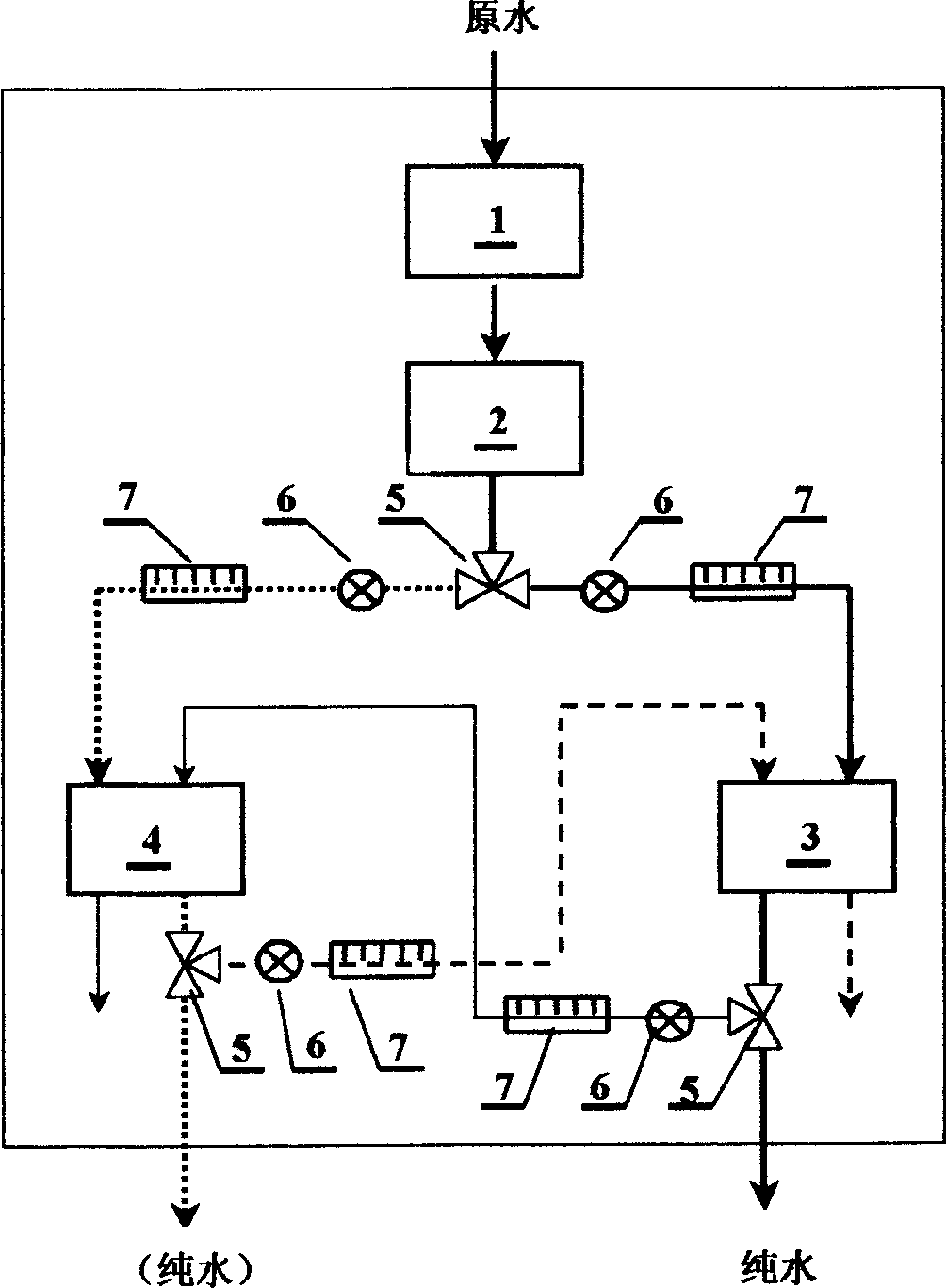

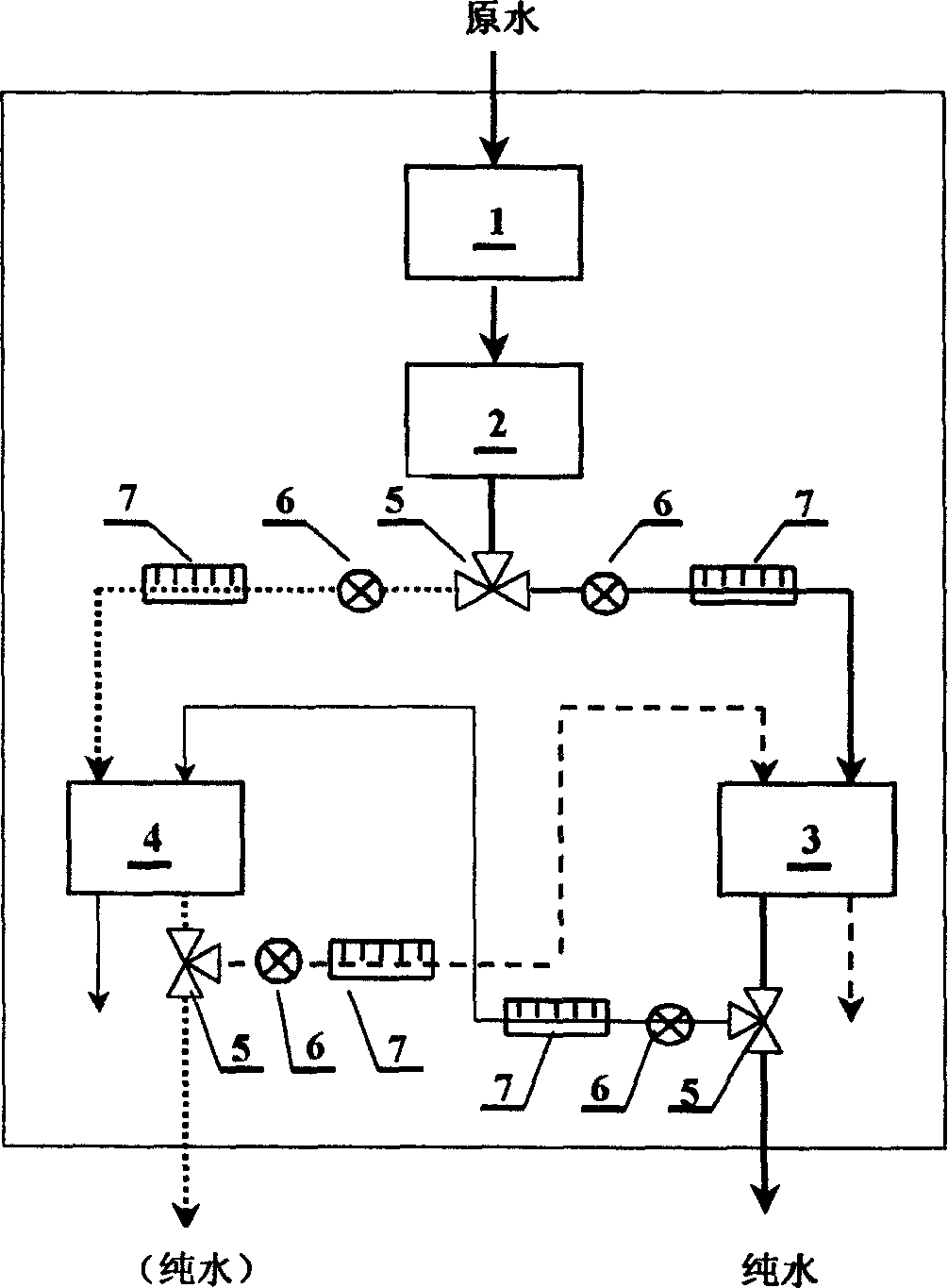

Method and apparatus for preparing pure water by continuous electricity deionizing

InactiveCN1504428AReduce manufacturing costContinuous and stable productionMultistage water/sewage treatmentElectricityIon-exchange membranes

Owner:彭昌盛 +2

Nitrogen-containing activated carbon material

An activated carbon material for removing a contaminant from a liquid. The activated carbon material can be a plurality carbon grains that have a pore volume of approximately 0.1 milliliters per gram (mL / g) in the range of less than about 15 angstroms in width. The carbon grains can also have or contain a nitrogen-containing species having a concentration of more than 2 atomic percent nitrogen. A plurality of the carbon grains can be used to make a contactor that is operable to remove or reduce perchlorate having a concentration of 20 parts per billion (ppb) to less than 4 ppb from 4,500 bed volumes of water with the nitrogen-containing species leaching off of the carbon grains less than 0.1 mg / L. The activated carbon material can also be electrochemically regenerated.

Owner:PENN STATE RES FOUND

Electrochemical regeneration method of polyoxometallate water solution after desulfuration

ActiveCN106669420AEasy to prepareGood oxidation and stabilityElectrolysis componentsDispersed particle separationElectrolysisElectron

The invention discloses an electrochemical regeneration method of a polyoxometallate water solution after desulfuration. The method comprises the steps as follows: gas containing hydrogen sulfide is introduced from the bottom of the polyoxometallate solution, and is exported from the upper end of a desulfuration reactor after being absorbed by the polyoxometallate solution; the polyoxometallate solution becomes deep blue from faint yellow after reaction for a period of time; ventilation is stopped after the numerical value of a hydrogen sulfide analyzer exceeds a constant value; the desulfurated polyoxometallate solution is electrolyzed for a period of time, anions of polyoxometallate lose electrons at an anode to be regenerated and hydrogen ions in the solution obtain electrons at a cathode to generate hydrogen; after the polyoxometallate solution becomes faint yellow from deep blue, the regeneration is completed. Regeneration of a polyoxometallate desulfurization solution is achieved by using an electrolysis method, the regeneration efficiency is high, the stability is good, the hydrogen can be generated simultaneously when the regeneration is achieved, and the electrochemical regeneration method has certain economic benefits and is beneficial to industrialized popularization.

Owner:SHANDONG UNIV

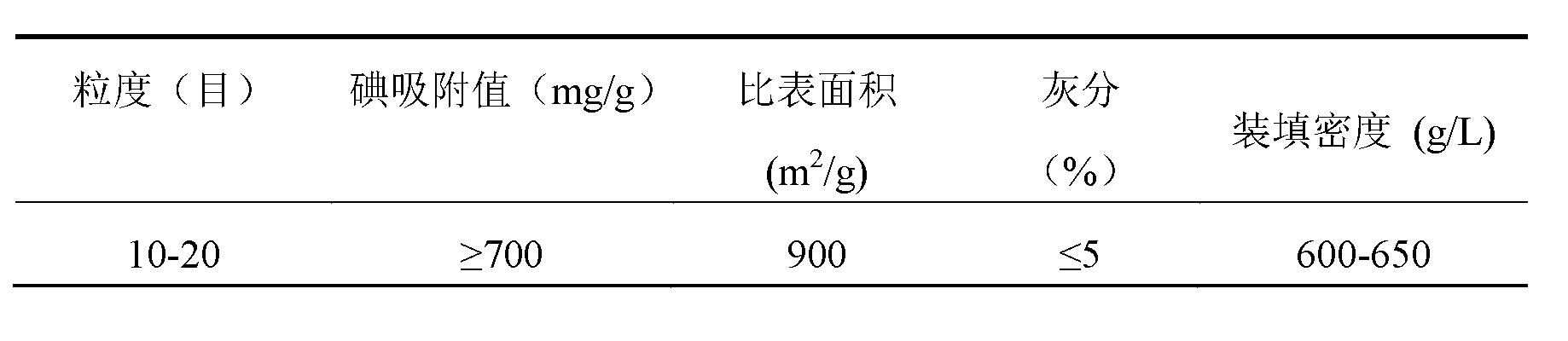

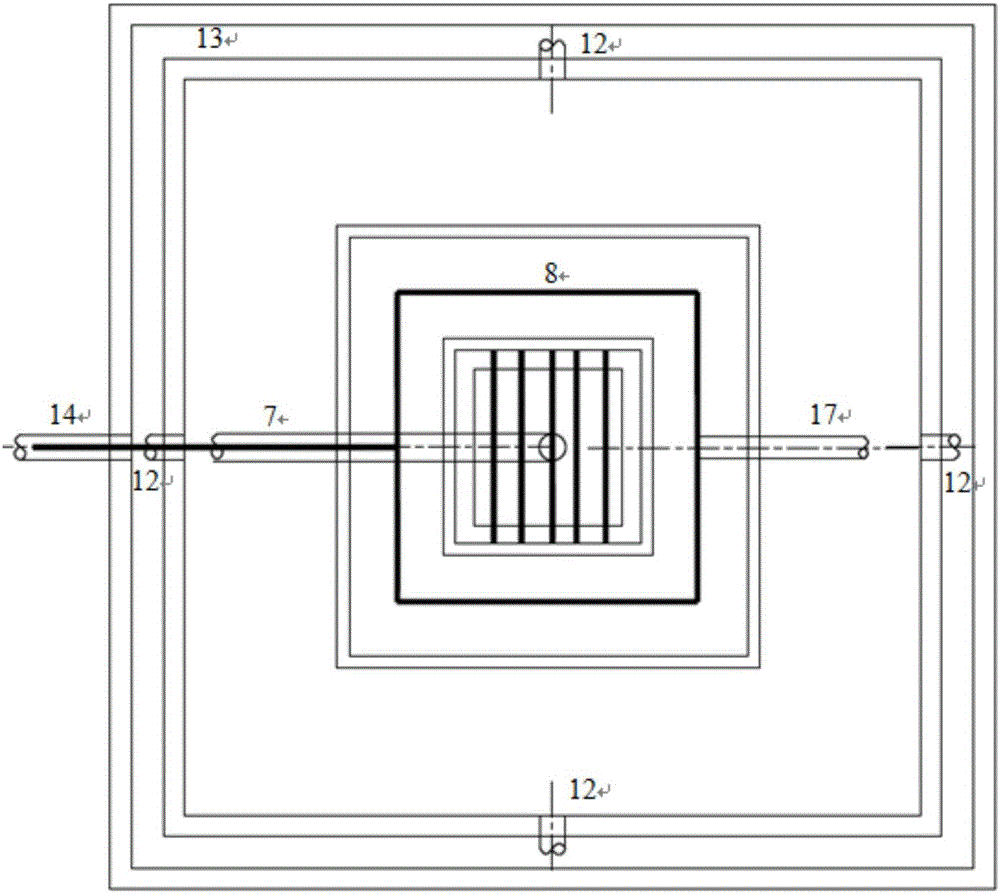

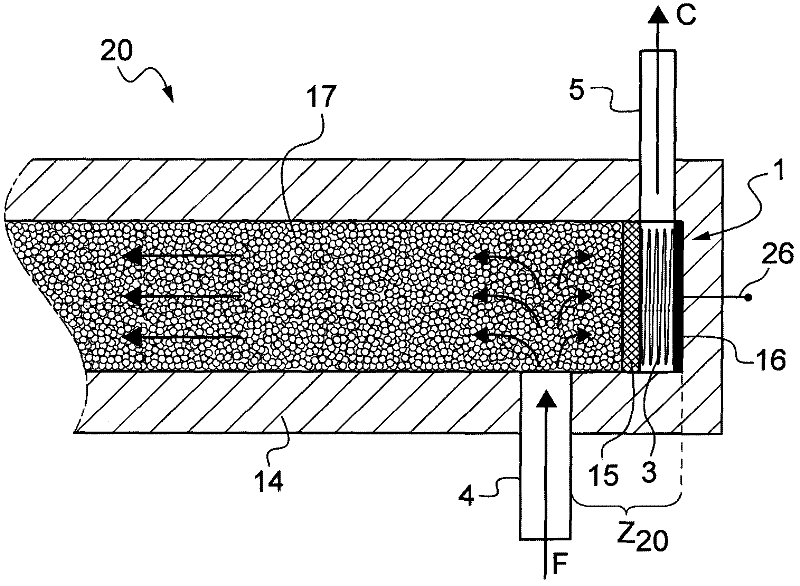

Device for regenerating powdered activated carbon

ActiveCN105771893AAchieve regenerationIncrease profitOther chemical processesCombustible gas purificationActivated carbonProduced water

The invention discloses a device for regenerating powdered activated carbon. The device has a square plane shape, and is provided with a water inlet area, an electrochemical regeneration area, a flow guiding area, a water outlet area, a precipitation separation area and a storage area from the center to the periphery, a water and carbon inlet pipe is arranged below the water inlet area, and electrolyte and saturated powdered activated carbon to be processed enter the water inlet area through the water and carbon inlet pipe and pass through the electrochemical regeneration area, the flow guiding area, the water outlet area, the precipitation separation area and the storage area sequentially; after the regeneration process is finished, produced water is discharged through a main water drain pipe, and regenerated powdered activated carbon is discharged through a regenerated carbon discharge pipe; a boron doped diamond positive pole and a stainless steel negative pole are arranged in the electrochemical regeneration area; a perforated aerator pipe, a mud bucket and the regenerated carbon discharge pipe are arranged in the storage area. According to the device, the regeneration and the precipitation separation of powdered activated carbon are integrated, and the regeneration of powdered activated carbon is realized by intermittent operation, and the utilization ration of activated carbon is improved.

Owner:BEIJING SCINOR WATER TECH CO LTD

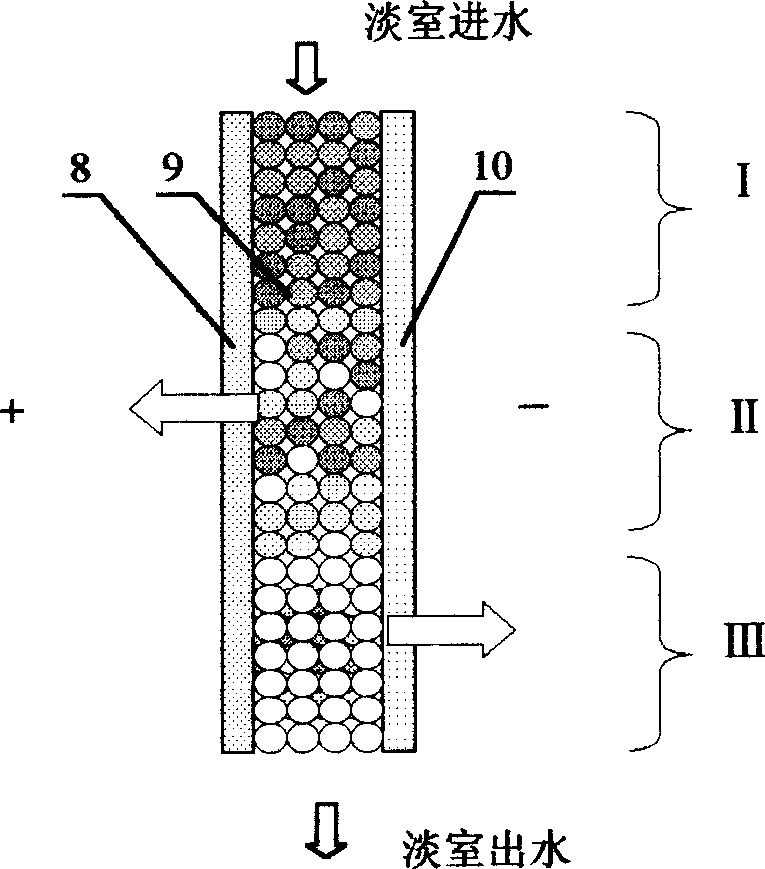

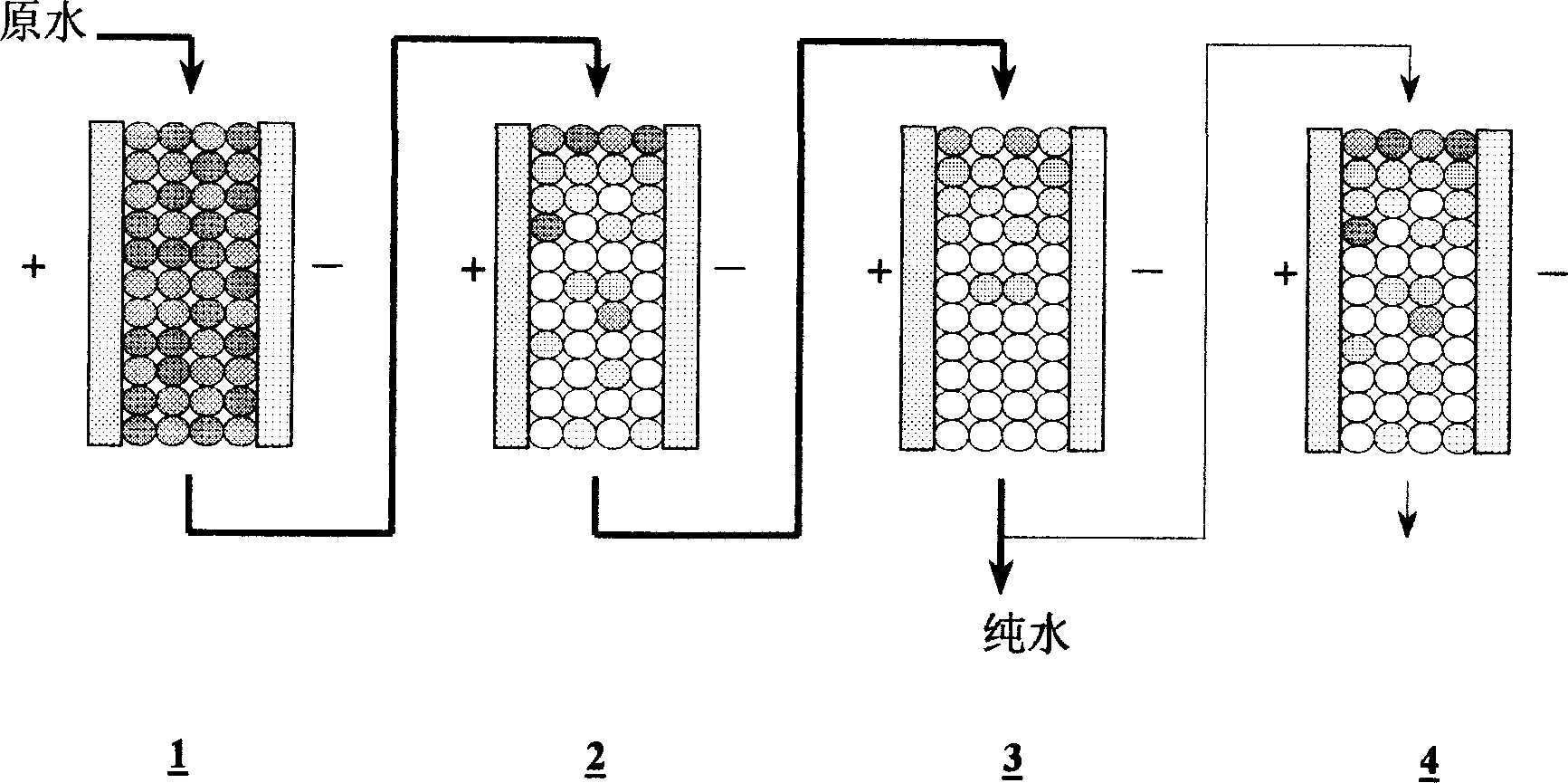

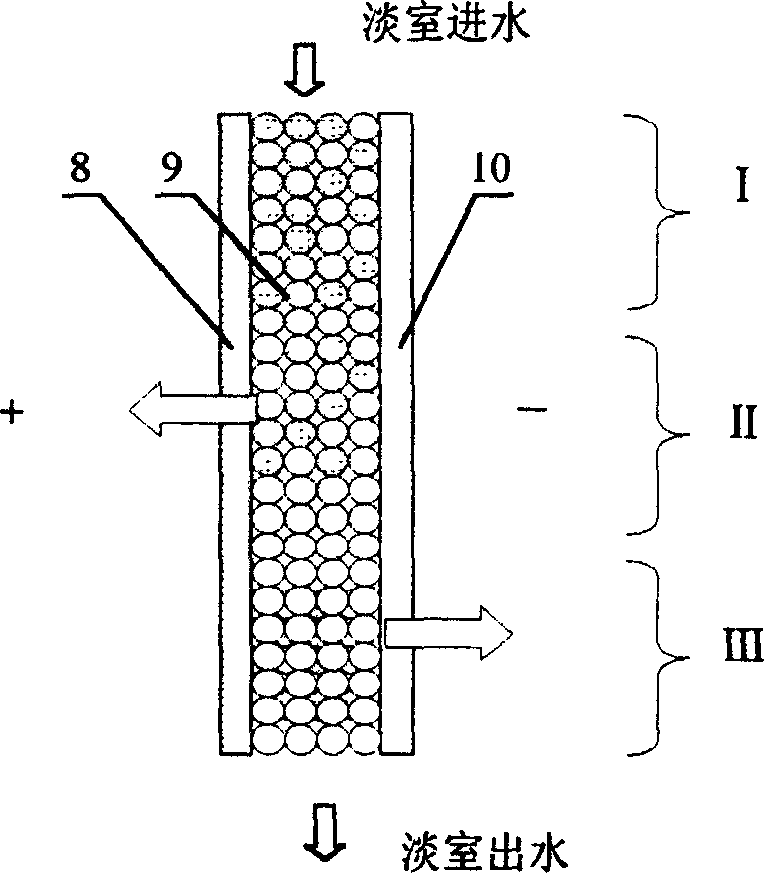

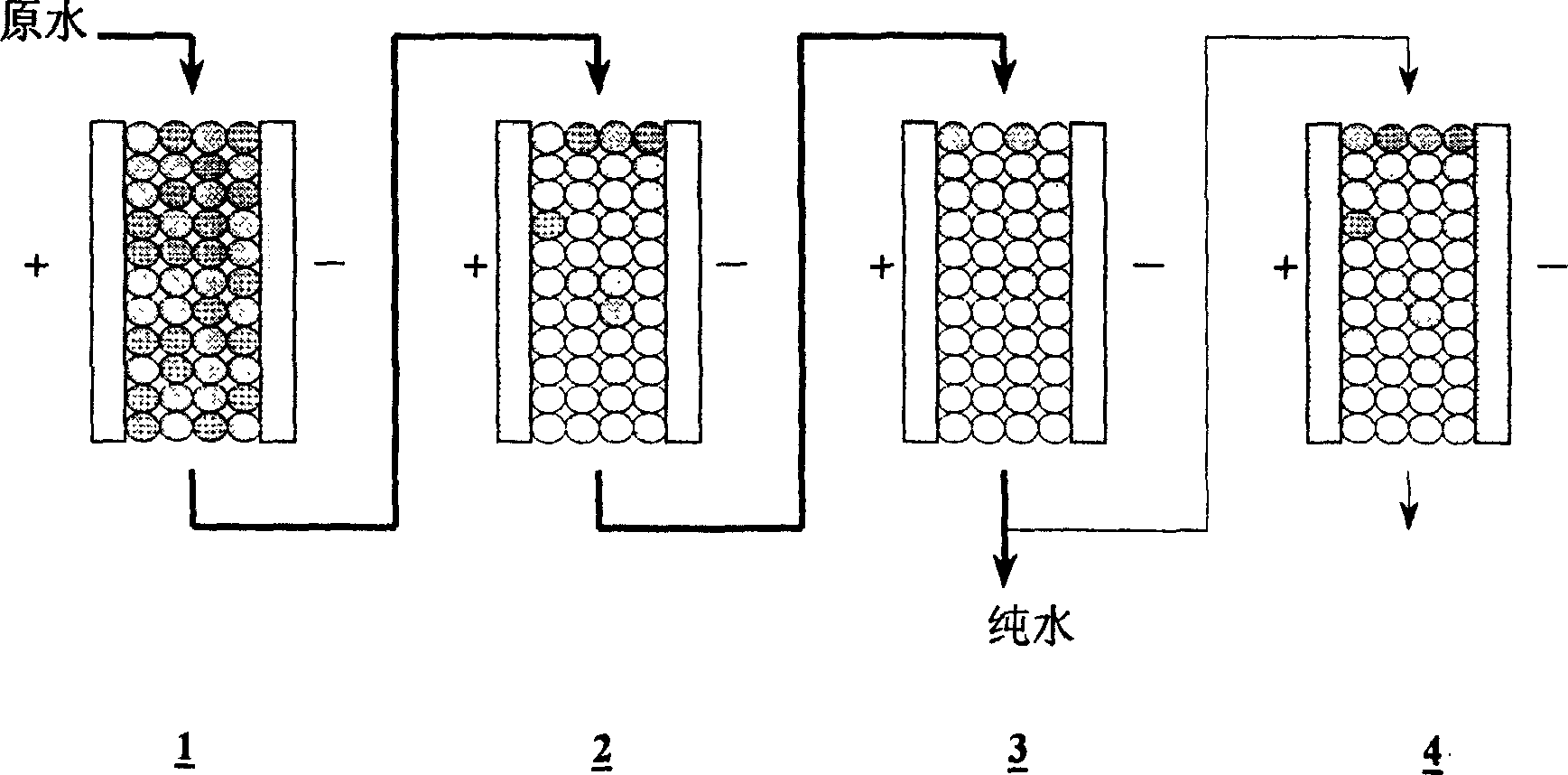

Method and apparatus for preparing pure water by continuous electricity deionizing

InactiveCN1267364CReduce manufacturing costContinuous and stable productionDispersed particle separationWater/sewage treatment by ion-exchangeElectricityIon exchange

The invention relates to a process and apparatus for making pure water by consecution electrical deionizing, wherein four same EDI devices are employed, wherein three of them are in series connection for making pure water, the other EDI apparatus is used as the regeneration device of ion exchange agent. According to the invention, the three procedures of ion exchange adsorption, ion directional transfer and electrochemical regeneration are arranged in different EDI devices, thus making them work under optimum status. The EDI devices in the invention can lower the EDI manufacturing cost substantially.

Owner:彭昌盛 +2

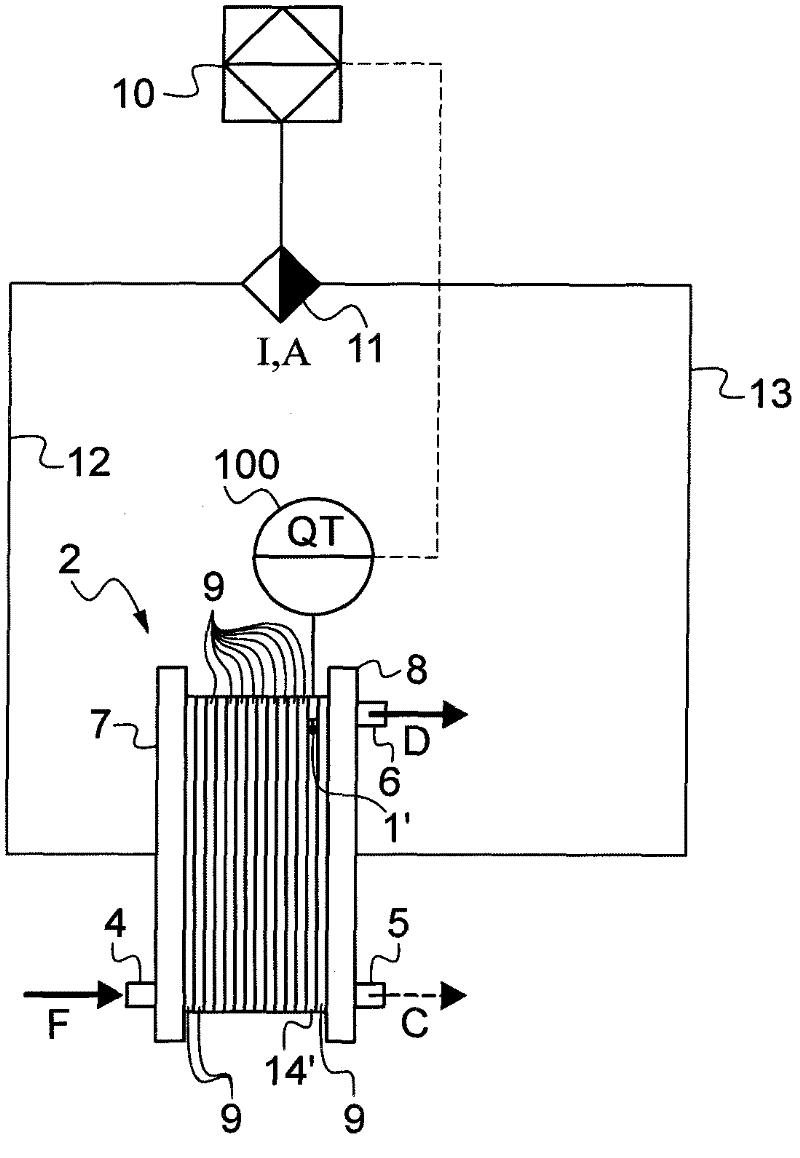

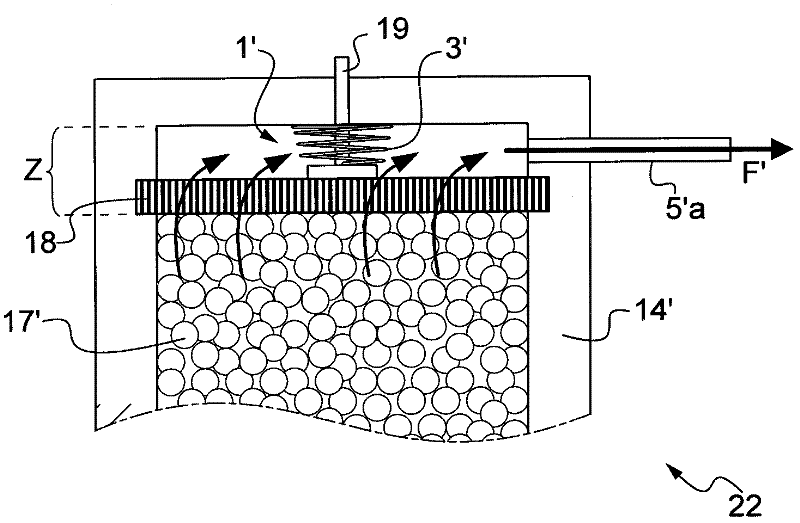

Electrodeionization device and method comprising control of the electric current by measurement of ion-exchange material expansion

ActiveCN102372346AImprove energy consumptionCheap solutionWater treatment parameter controlIon-exchange column/bed processesPower flowElectrical polarity

Device (2) for the removal of ions from a polar liquid (F), e.g. water, comprising at least one compartment (14') which comprises at least one inlet for an entering polar liquid flow and at least one outlet for an outgoing deionized liquid flow (D), in which said compartment (14') an electrochemically regenerable ion-exchange material fills a zone through which zone a liquid flow is able to pass, the device (2) being characterized in that it comprises one sensor (1) of at least one dimensional change of the ion-exchange material. The sensor can comprise a photo-sensor or a sensor of mechanical stress. Preferably an apparatus (100, 10, 11) connected to the sensor is able to analyze this dimensional change and to control the electric current. Method of using said device (2), whereby the electrical current applied to the device (2) is controlled according to the expansion of the resin.

Owner:MILLIPORE CORP

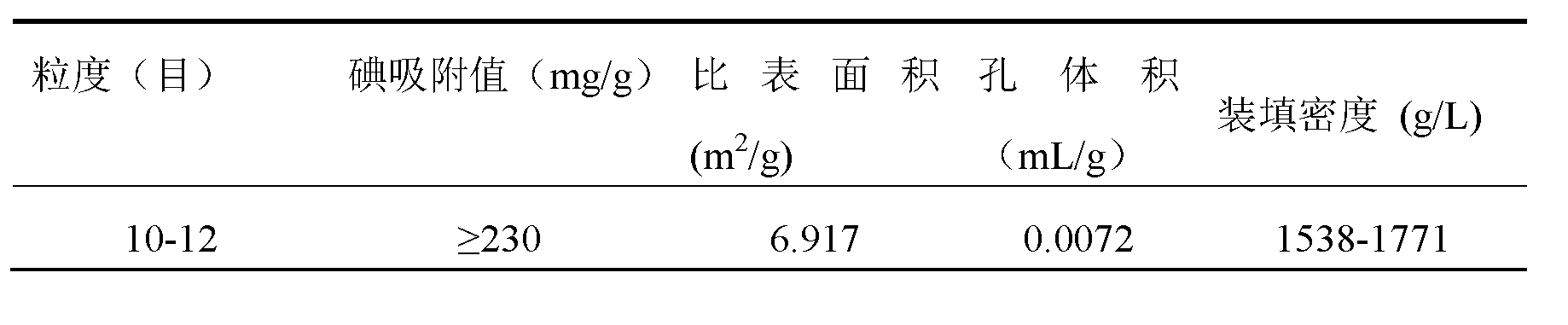

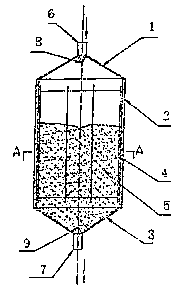

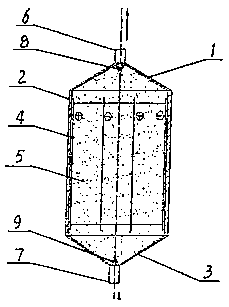

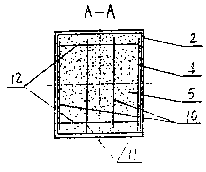

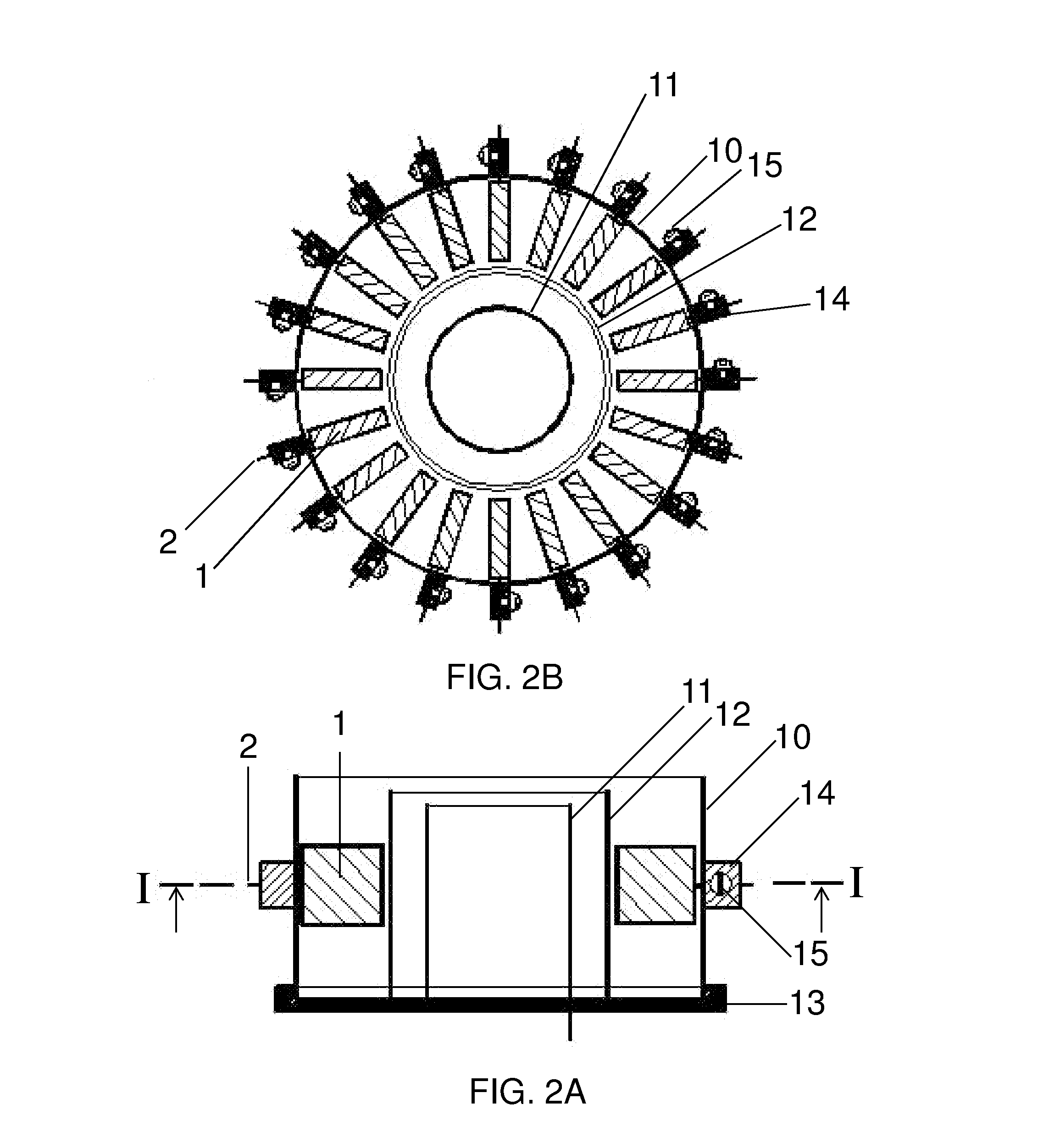

Carbon filter for electrochemical regeneration of active carbon

InactiveCN103386219AWill not cause a short circuit in the connectionFunction increaseLoose filtering material filtersGravity filtersActivated carbonFiltration

The invention discloses a carbon filter for electrochemical regeneration of active carbon. The carbon filter is characterized in that an electrode assembly (4) is arranged in a rectangular straight cylindrical shell (2); active carbon (5) is filled in the rectangular straight cylindrical shell (2); an upper head (1) is installed on the rectangular straight cylindrical shell (2); a lower head (3) is installed on the bottom of the rectangular straight cylindrical shell (2); the upper head (1) and the lower head (3) are provided with an upper water inlet / outlet (6) and a lower water inlet / outlet (7); in the upper head (1) , the upper water inlet / outlet (6) is connected to an upper hydraulic distributor (8); in the lower head (3), the lower water inlet / outlet (7) is connected to a lower hydraulic distributor (9); The volume of the active carbon (5) filled in the rectangular straight cylindrical shell (2) is 1 / 2-2 / 3 of the volume of the rectangular straight cylindrical shell (2); in filtration by the carbon filter, water flows into the carbon filter from top and flows out of the carbon filter from bottom, and in electrochemical regeneration carried out after the active carbon is in an adsorption saturation state, the water flows into the carbon filter from bottom and flows out of the carbon filter from top; under the action of the water flows, the active carbon suspend between the water and flows between anode pieces and cathode pieces of the electrode assembly (4) and simultaneously, power is supplied to the anode pieces and the cathode pieces so that electrochemical oxidation regeneration of the active carbon is realized; and in the rectangular straight cylindrical shell (2), the anode pieces (10) and the cathode pieces (11) are arranged alternately in the electrode assembly (4) and are fixed by electrode piece fixing rods (12).

Owner:GUIZHOU PROVINCIAL PRODUCT QUALITY SUPERVISION AND INSPECTION INSTITUTE

Process for desulphurizing methane through Fe-Cl mixed solution

The invention discloses the technical field of methane purification, in particular a process for removing H2S in large and medium-sized methane projects through a Fe-Cl mixed solution absorption and electrochemical regeneration method. According to the process, an Fe-Cl mixed solution is adopted as absorption liquid, and an atomizing nozzle and a methane inlet valve are opened after the volume of the absorption liquid in a desulfurizing tower reaches to a certain volume in the desulfurizing tower, so that the absorption liquid and methane form countercurrent contact; the methane passing through the desulfurizing tower flows out through an outlet of a demister; the absorption liquid which absorbs sulphur-containing substances in the methane is precipitated, solid contents are removed, and the liquid is electrolyzed in an anode chamber of an electrolytic cell; and the electrolyzed liquid is returned to the desulfurizing tower so as to be used as the absorption liquid. The process has the advantages that the design is reasonable, the process is feasible, the operation is simple and convenient, the absorption effect is high, the absorption liquid is renewable, a by-product hydrogen can be used as energy, the chemical absorption liquid can be recycled, and the absorption speed is faster.

Owner:杭州坚膜新材料有限公司

Regeneration System for Metal Electrodes

InactiveUS20140183047A1Low costReduce energy lossCellsFuel and primary cellsOligomerElectrical battery

The electrochemical regeneration of a replaceable metal electrode of a metal-air battery takes place in a supplementary electrochemical cell with a chemical agent oxidized on the counter electrode. The decrease of the regeneration voltage at the supplementary electrochemical cell results in the growth of the regeneration efficiency. The creation of a commercial product during chemical agent oxidation on the counter electrode decreases the overall cost of the regeneration. Possible chemical agents for regeneration include salts, metal complexes, monomers, conjugated organic molecules, oligomers or polymers.

Owner:PANISOLAR

Method of regenerating lead battery cells and regenerative agent for performing of this method

InactiveUS20060145664A1Slow effectImprove regenerative abilityBatteries circuit arrangementsLead-acid accumulatorsDicarbonateEngineering

The electrochemical regeneration of lead and alkaline battery cells during which, after the treatment of the battery by some of the regeneration additives on the basis of an aqueous solution of hydrogen peroxide and after the basic charging, they are alternately or internnittently charged and discharged. Above the limit located above the level of the full charge it is charged with a current of 1.1%-4% and discharged with a current of 0%-5% related to the nominal value of the capacity of the cell or storage battery, or else the charging is carried out in two phases or by a constant current. Under the limit located below the level of the permitted discharging it is discharged with a current of 1% to 4% and subsequently charged with a current of 3%-10% related to the value of the capacity of the battery to a decrease in the voltage to 1.6 V of the cell or any of the battery's cells. Then the battery supplies 10%-15% of its nominal capacity and this entire procedure is repeated 2-5 times. The regenerative agent contains, for each liter of aqueous solution 40% of hydrogen peroxide, 1 ml to 70 ml of sulfuric acid with a density of 1 to 1.32 g·cm−3, 0.1 g to 10 30 g of saccharides in solids and / or aldehydes or their derivatives, 0.1 g to 10 g of sodium and / or potassium bicarbonate and / or at least one hydroxide from the group of alkali metal hydroxides in solids, or else a mixture containing 0.1 g to 10 g of peroxoborate or tetraborate or sodium pyrophosphate in solids and also containing 0.1 g to 20 g, with an advantage 0.5 g to 2 g, of bisodium dinaphtylmethane disulfonic acid salt.

Owner:AKUROS

Method of regenerating lead battery cells and regenerative agent for performing of this method

InactiveUS20090140695A1Increase battery capacityReduce the amount requiredBatteries circuit arrangementsLead-acid accumulatorsPyrophosphateEngineering

The electrochemical regeneration of lead battery cells during which, after the treatment of the battery by some of the regeneration additives on the basis of an aqueous solution of hydrogen peroxide and after the basic charging, they are alternately or intermittently charged and discharged. Above the limit located above the level of the full charge it is charged with a current of 1.1%-4% and discharged with a current of 0%-5% related to the nominal value of the capacity of the cell or storage battery, or else the charging is carried out in two phases or by a constant current. Under the limit located below the level of the permitted discharging it is discharged with a current of 1% to 4% and subsequently charged with a current of 3%-10% related to the value of the capacity of the battery to a decrease in the voltage to 1.6 V of the cell or any of the battery's cells. Then the battery supplies 10%-15% of its nominal capacity and this entire procedure is repeated 2-5 times. The regenerative agent contains, for each liter of aqueous solution 40% of hydrogen peroxide, 1 ml to 70 ml of sulfuric acid with a density of 1 to 1.32 g.cm−3, 0.1 g to 10 g of saccharides in solids and / or aldehydes or their derivatives, 0.1 g to 10 g of sodium and / or potassium bicarbonate and / or at least one hydroxide from the group of alkali metal hydroxides in solids and 0.1 g to 20 g, with an advantage 0.5 g to 2 g, of bisodium dinaphtylmethane disulfonic acid salt. Regenerative agent can contain also 0.1 g to 10 g of peroxoborate an / or tetraborate and / or sodium pyrophosphate in solids.

Owner:AKUROS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com